Application of CO2 Gas Hydrates as Leavening Agents in Black-and-White Cookies

Abstract

1. Introduction

2. Materials and Methods

2.1. Production of GH

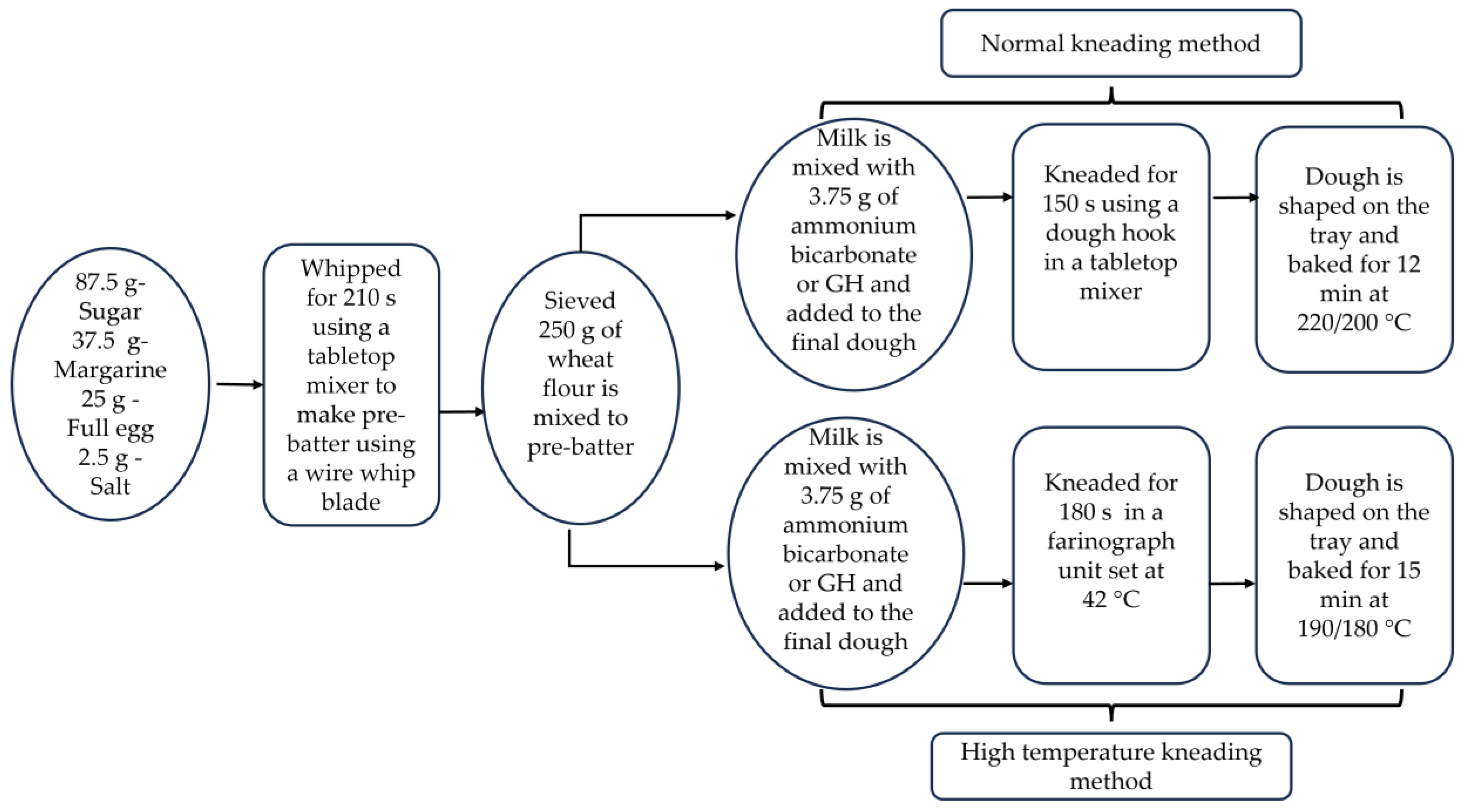

2.2. Production of Black-and-White Cookies

2.3. Analysis of Black-and-White Cookies

2.3.1. Moisture Analysis

2.3.2. Volume Analysis

2.3.3. Texture Profile Analysis

2.3.4. Pore Size Analysis

2.3.5. Color Measurements

2.3.6. Analysis of the Acrylamide Content

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physical Characteristics of Black-and-White Cookies

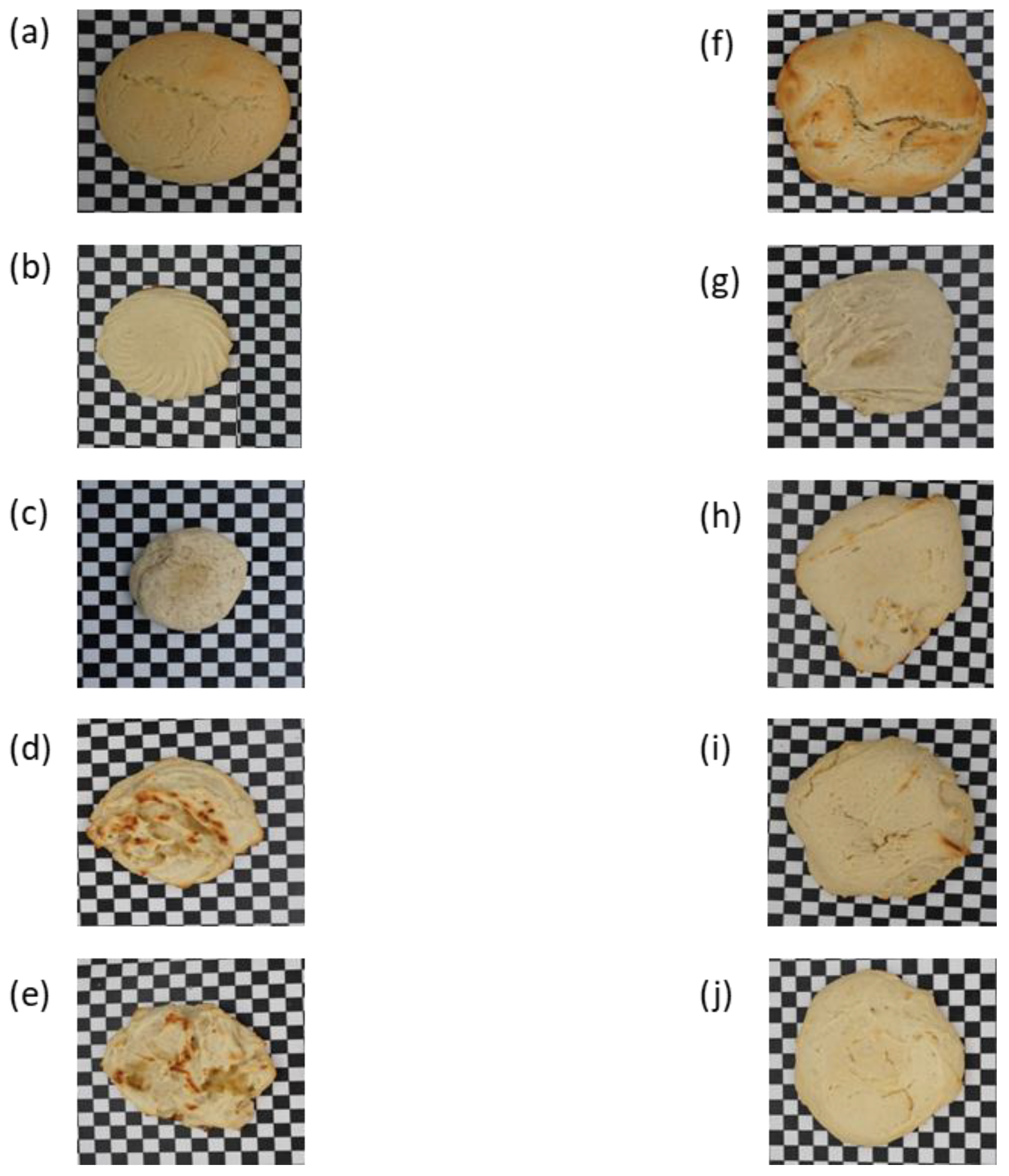

3.2. Colour and Appearance of Black-and-White Cookies

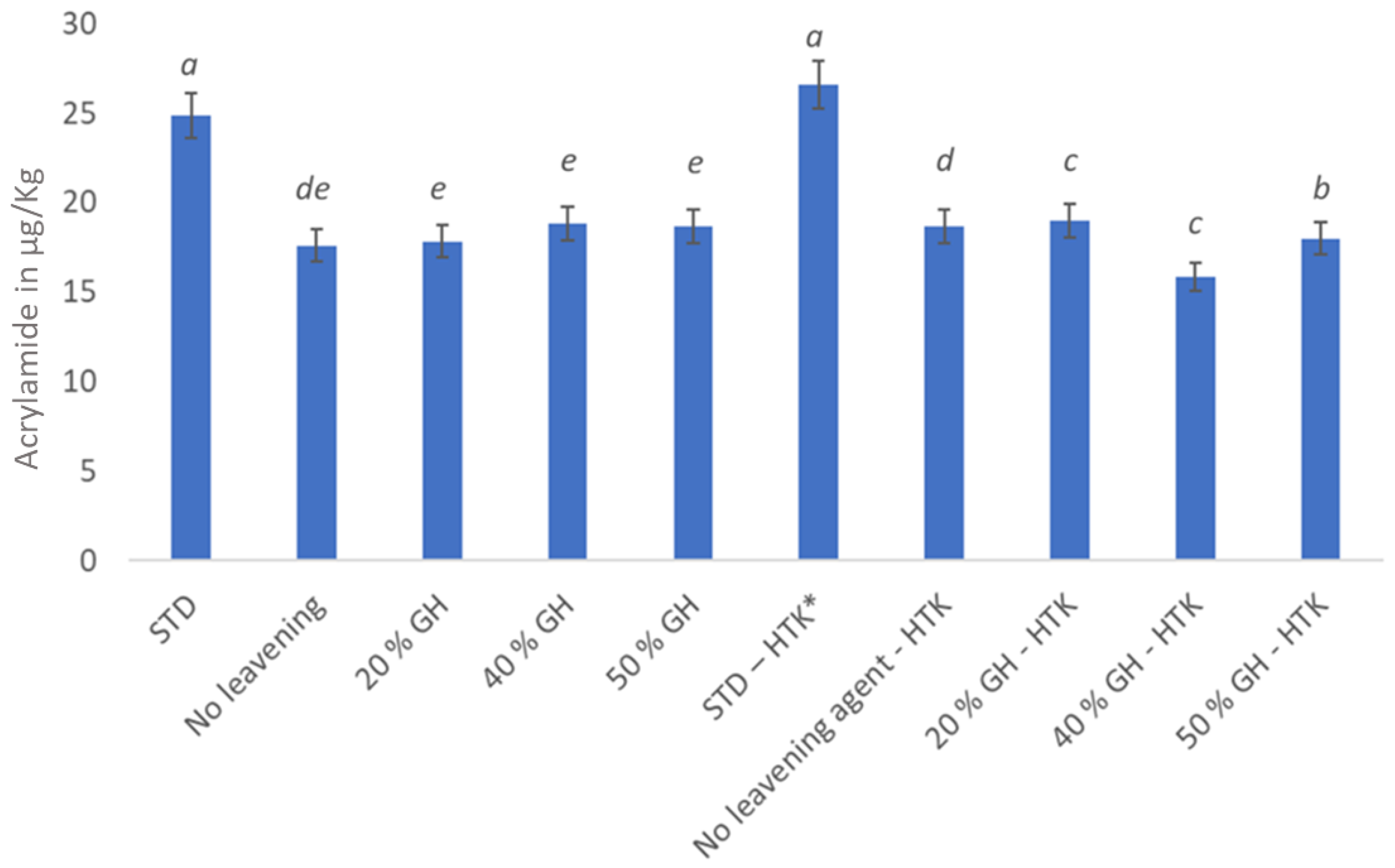

3.3. Acrylamide Content in Black-and-White Cookies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cauvain, S.P.; Young, L.S. Baked Products: Science, Technology and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Chevallier, S.; Della Valle, G.; Colonna, P.; Broyart, B.; Trystram, G. Structural and chemical modifications of short dough during baking. J. Cereal Sci. 2002, 35, 1–10. [Google Scholar] [CrossRef]

- Jukić, M.; Nakov, G.; Komlenić, D.K.; Vasileva, N.; Šumanovac, F.; Lukinac, J. Quality Assessment of cookies made from composite flours containing malted barley flour and wheat flour. Plants 2022, 11, 761. [Google Scholar] [CrossRef]

- Hesso, N.; Loisel, C.; Chevallier, S.; Marti, A.; Le-Bail, P.; Le-Bail, A.; Seetharaman, K. The role of ingredients on thermal and rheological properties of cake batters and the impact on microcake texture. LWT-Food Sci. Technol. 2015, 63, 1171–1178. [Google Scholar] [CrossRef]

- Wilderjans, E.; Luyts, A.; Brijs, K.; Delcour, J.A. Ingredient functionality in batter type cake making. Trends Food Sci. Technol. 2013, 30, 6–15. [Google Scholar] [CrossRef]

- Yazici, G.N.; Ozer, M.S. A review of egg replacement in cake production: Effects on batter and cake properties. Trends Food Sci. Technol. 2021, 111, 346–359. [Google Scholar] [CrossRef]

- Abeyrathne, E.N.S.; Lee, H.Y.; Ahn, D.U. Egg white proteins and their potential use in food processing or as nutraceutical and pharmaceutical agents—A review. Poult. Sci. 2013, 92, 3292–3299. [Google Scholar] [CrossRef]

- Zhao, Q.; Ding, L.; Xia, M.; Huang, X.; Isobe, K.; Handa, A.; Cai, Z. Role of lysozyme on liquid egg white foaming properties: Interface behavior, physicochemical characteristics and protein structure. Food Hydrocoll. 2021, 120, 106876. [Google Scholar] [CrossRef]

- Colla, K.; Costanzo, A.; Gamlath, S. Fat replacers in baked food products. Foods 2018, 7, 192. [Google Scholar] [CrossRef]

- Anese, M.; Quarta, B.; Foschia, M.; Bortolomeazzi, R. Effect of low-temperature long-time pre-treatment of wheat on acrylamide concentration in short dough biscuits. Mol. Nutr. Food Res. 2009, 53, 1526–1531. [Google Scholar] [CrossRef] [PubMed]

- Marconi, O.; Bravi, E.; Perretti, G.; Martini, R.; Montanari, L.; Fantozzi, P. Acrylamide risk in food products: The shortbread case study. Anal. Methods 2010, 2, 1686–1691. [Google Scholar] [CrossRef]

- Weisshaar, R. Acrylamide in bakery products-Results from model experiments. Dtsch. Lebensm.-Rundsch. 2004, 100, 92. [Google Scholar]

- Lyon, F. IARC monographs on the evaluation of carcinogenic risks to humans. Some Ind. Chem. 1994, 60, 389–433. [Google Scholar]

- Manley, D. Biscuit Cracker and Cookie Recipes for the Food Industry; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Caballero, B.; Trugo, L.C.; Finglas, P.M. Encyclopedia of Food Sciences and Nutrition; Academic Press: San Diego, CA, USA, 2003. [Google Scholar]

- Canali, G.; Balestra, F.; Glicerina, V.; Pasini, F.; Caboni, M.F.; Romani, S. Influence of different baking powders on physico-chemical, sensory and volatile compounds in biscuits and their impact on textural modifications during soaking. J. Food Sci. Technol. 2020, 57, 3864–3873. [Google Scholar] [CrossRef]

- Harrison, S.E. Natural Gas Hydrates; Submitted as course for Physics 240; Stanford University: Stanford, CA, USA, 2010. [Google Scholar]

- Frühling, Y.; Claßen, T.; Mobarak, M.; Bauer, M.; Zettel, V.; Gatternig, B.; Hitzmann, B.; Delgado, A. CO2 gas hydrate as an innovative leavening agent for baked goods. Future Foods 2023, 7, 100213. [Google Scholar] [CrossRef]

- Qi, R.; Qin, X.; Bian, H.; Lu, C.; Yu, L.; Ma, C. Overview of molecular dynamics simulation of natural gas hydrate at nanoscale. Geofluids 2021, 2021, 6689254. [Google Scholar] [CrossRef]

- Bhattacharjee, G.; Linga, P. Amino acids as kinetic promoters for gas hydrate applications: A mini review. Energy Fuels 2021, 35, 7553–7571. [Google Scholar] [CrossRef]

- Srivastava, S.; Hitzmann, B.; Zettel, V. A future road map for carbon dioxide (CO2) gas hydrate as an emerging technology in food research. Food Bioprocess Technol. 2021, 14, 1758–1762. [Google Scholar] [CrossRef]

- Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Claßen, T.; Gatternig, B.; Delgado, A.; Hitzmann, B. Experimental investigation of CO2 uptake in CO2 hydrates formation with amino acids as kinetic promoters and its dissociation at high temperature. Sci. Rep. 2022, 12, 8359. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Claßen, T.; Mobarak, M.; Gatternig, B.; Delgado, A.; Jekle, M.; Hitzmann, B. An Innovative Approach in the Baking of Bread with CO2 Gas Hydrates as Leavening Agents. Foods 2022, 11, 3570. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of Analysis, in Measurement of Bread Firmness by Universal Testing Machine, 11th ed.; Method 74–09.01; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Jakubczyk, E.; Niranjan, K. Transient development of whipped cream properties. J. Food Eng. 2006, 77, 79–83. [Google Scholar] [CrossRef]

- Badve, M. A novel gas inducing rotor-stator impeller for gas-liquid foam generation. Chem. Eng. Process.-Process Intensif. 2021, 159, 108216. [Google Scholar] [CrossRef]

- Jha, P.K.; Sadot, M.; Chevallier, S.; Rawson, A.; Le-Bail, A. Impact of Overhead Pressure During Mixing on the Quality of Sandwich Bread. Food Bioprocess Technol. 2022, 15, 1896–1906. [Google Scholar] [CrossRef]

- Chesterton, A.K.S.; de Abreu, D.P.; Moggridge, G.D.; Sadd, P.A.; Wilson, D.I. Evolution of cake batter bubble structure and rheology during planetary mixing. Food Bioprod. Process. 2013, 91, 192–206. [Google Scholar] [CrossRef]

- Cappelli, A.; Bettaccini, L.; Cini, E. The kneading process: A systematic review of the effects on dough rheology and resulting bread characteristics, including improvement strategies. Trends Food Sci. Technol. 2020, 104, 91–101. [Google Scholar] [CrossRef]

- Van der Sman, R.G.M.; Renzetti, S. Understanding functionality of sucrose in biscuits for reformulation purposes. Crit. Rev. Food Sci. Nutr. 2019, 59, 2225–2239. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B. Recent developments of oleogel utilizations in bakery products. Crit. Rev. Food Sci. Nutr. 2020, 60, 2460–2479. [Google Scholar] [CrossRef]

- Laguna, L.; Vallons, K.J.; Jurgens, A.; Sanz, T. Understanding the effect of sugar and sugar replacement in short dough biscuits. Food Bioprocess Technol. 2013, 6, 3143–3154. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Attabi, Z.H.; Al-Habsi, N.; Al-Khusaibi, M. Measurement of Instrumental Texture Profile Analysis (TPA) of Foods. In Techniques to Measure Food Safety and Quality: Microbial, Chemical, and Sensory; Springer: Cham, Switzerland, 2021; pp. 427–465. [Google Scholar]

- Chin, N.L.; Campbell, G.M. Dough aeration and rheology: Part 1. Effects of mixing speed and headspace pressure on mechanical development of bread dough. J. Sci. Food Agric. 2005, 85, 2184–2193. [Google Scholar] [CrossRef]

- Rathnayake, H.A.; Navaratne, S.B.; Navaratne, C.M. Porous crumb structure of leavened baked products. Int. J. Food Sci. 2018, 2018, 8187318. [Google Scholar] [CrossRef]

- Mack, S.; Hussein, M.A.; Becker, T. Investigation of heat transfer in cereal-based foam from a micro-scale perspective using the lattice Boltzmann method. J. Non-Equilib. Thermodyn. 2011, 36, 311–335. [Google Scholar] [CrossRef]

- Elgeti, D.; Jekle, M.; Becker, T. Strategies for the aeration of gluten-free bread–A review. Trends Food Sci. Technol. 2015, 46, 75–84. [Google Scholar] [CrossRef]

- Mogol, B.A.; Gökmen, V. Mitigation of acrylamide and hydroxymethylfurfural in biscuits using a combined partial conventional baking and vacuum post-baking process: Preliminary study at the lab scale. Innov. Food Sci. Emerg. Technol. 2014, 26, 265–270. [Google Scholar] [CrossRef]

- Liu, X.; Xia, B.; Hu, L.T.; Ni, Z.J.; Thakur, K.; Wei, Z.J. Maillard conjugates and their potential in food and nutritional industries: A review. Food Front. 2020, 1, 382–397. [Google Scholar] [CrossRef]

- Karseno, E.; Yanto, T.; Setyowati, R.; Haryanti, P. Effect of pH and temperature on browning intensity of coconut sugar and its antioxidant activity. Food Res. 2018, 2, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Amrein, T.M.; Schönbächler, B.; Escher, F.; Amadò, R. Acrylamide in gingerbread: Critical factors for formation and possible ways for reduction. J. Agric. Food Chem. 2004, 52, 4282–4288. [Google Scholar] [CrossRef]

- Biedermann, M.; Grob, K. Model studies on acrylamide formation in potato, wheat flour and corn starch; ways to reduce acrylamide contents in bakery ware. Mitteilungen Leb. Hyg. 2003, 94, 406–422. [Google Scholar]

- Ahrné, L.; Andersson, C.G.; Floberg, P.; Rosén, J.; Lingnert, H. Effect of crust temperature and water content on acrylamide formation during baking of white bread: Steam and falling temperature baking. LWT-Food Sci. Technol. 2007, 40, 1708–1715. [Google Scholar] [CrossRef]

| Specific Volume (mL/g) | Moisture (%) | Hardness (N) | Springiness (%) | |

|---|---|---|---|---|

| STD | 2.85 ± 0.04 a | 30.6 ± 0.3 a | 5 ± 1.08 g | 0.73 ± 0.13 a |

| No leavening | 0.74 ± 0.02 de | 30.12 ± 0.31 a | 90 ± 4.12 a | 0.52 ± 0.01 c |

| 20% GH | 0.719 ± 0.02 e | 30.67 ± 0.23 a | 45.52 ± 4.26 cd | 0.71 ± 0.03 a |

| 40% GH | 0.724 ± 0.03 e | 30.75 ± 0.19 a | 39.08 ± 1.65 d | 0.74 ± 0.03 a |

| 50% GH | 0.73 ± 0.01 e | 31.10 ± 0.62 a | 38. 76 ± 1.89 d | 0.73 ± 0.01 a |

| STD—HTK * | 2.75 ± 0.06 a | 29.58 ± 0.42 b | 8.41 ± 0.88 f | 0.76 ± 0.09 a |

| No leavening agent—HTK | 0.89 ± 0.11 d | 30.12 ± 0.18 a | 70.36 ± 2.14 b | 0.56 ± 0.08 b |

| 20% GH—HTK | 1.40 ± 0.09 c | 31.57 ± 0.76 a | 48.94 ± 4.43 c | 0.70 ± 0.07 a |

| 40% GH—HTK | 1.44 ± 0.06 c | 30.82 ± 0.58 a | 40.81 ± 3.41 cd | 0.72 ± 0.05 a |

| 50% GH—HTK | 1.80 ± 0.05 b | 30.76 ± 0.41 a | 31.25 ± 2.18 e | 0.73 ± 0.02 a |

| Very Small | Small | Medium | Big | Very Big | |

|---|---|---|---|---|---|

| STD | 36.44 ± 4.87 de | 11.7 ± 1.87 ab | 27.29 ± 2.45 a | 20.93 ± 3.56 | 3.67 ± 1.41 ab |

| No leavening | 39.01 ± 3.98 bcd | 12.71 ± 2.07 ab | 24.93 ± 2.59 ab | 19.26 ± 2.76 | 4.1 ± 1.56 ab |

| 20% GH | 43.62 ± 3.92 a | 10.75 ± 2.05 ab | 22.40 ± 2.64 ab | 19.99 ± 3.82 | 3.24 ± 1.74 b |

| 40% GH | 38.74 ± 4.68 cd | 14.83 ± 3.31 a | 19.22 ± 2.87 b | 18.65 ± 2.65 | 8.56 ± 1.63 a |

| 50% GH | 43.97 ± 5.52 a | 9.9 ± 1.54 b | 20.2 ± 2.66 b | 24.31 ± 3.69 | 1.61 ± 0.98 b |

| STD—HTK * | 41.79 ± 2.02 abc | 10.43 ± 1.25 ab | 22.31 ± 2.13 ab | 22.07 ± 3.73 | 3.39 ± 1.22 ab |

| No leavening agent—HTK | 42.80 ± 3.72 a | 9.71 ± 2.16 b | 23.03 ± 1.92 ab | 20.42 ± 2.88 | 4.06 ± 1.08 ab |

| 20% GH—HTK | 31.35 ± 3.94 f | 13.34 ± 2.77 ab | 24.91 ± 1.66 ab | 24.66 ± 3.49 | 5.73 ± 2.26 a |

| 40% GH—HTK | 32.65 ± 2.13 f | 12.59 ± 1.65 ab | 26.07 ± 0.59 a | 21.64 ± 3.01 | 7.05 ± 2.99 a |

| 50% GH—HTK | 35.71 ± 4.36 e | 10.6 ± 2.75 ab | 25.3 ± 1.94 ab | 22.37 ± 2.74 | 6.02 ± 1.15 a |

| L* | a* | b* | |

|---|---|---|---|

| STD | 76.78 ± 1.17 c | 1.70 ± 0.82 ab | 13.2 ± 2.12 b |

| No leavening | 84.08 ± 0.67 a | 0.8 ± 0.01 b | 12.04 ± 0.81 b |

| 20% GH | 81.86 ± 0.48 ab | 1.6 ± 0.93 ab | 12.21 ± 3.52 b |

| 40% GH | 83.97 ± 1.06 ab | 2.15 ± 0.31 a | 12.95 ± 0.99 b |

| 50% GH | 82.16 ± 1.65 ab | 2.37 ± 0.43 a | 14.26 ± 1.34 b |

| STD—HTK * | 76.28 ± 1.00 c | 3.54 ± 1.05 a | 20.47 ± 1.03 a |

| No leavening agent—HTK | 79.90 ± 1.53 b | 0.71 ± 0.04 b | 12.59 ± 0.59 b |

| 20% GH—HTK | 82.44 ± 0.92 ab | 0.89 ± 0.13 b | 11.81 ± 0.74 b |

| 40% GH—HTK | 77.15 ± 0.76 c | 1.24 ± 0.04 b | 15.32 ± 0.39 b |

| 50% GH—HTK | 81.58 ± 1.95 ab | 0.83 ± 0.65 b | 15.08 ± 0.61 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kollemparembil, A.M.; Srivastava, S.; Zettel, V.; Gatternig, B.; Delgado, A.; Jekle, M.; Hitzmann, B. Application of CO2 Gas Hydrates as Leavening Agents in Black-and-White Cookies. Foods 2023, 12, 2797. https://doi.org/10.3390/foods12142797

Kollemparembil AM, Srivastava S, Zettel V, Gatternig B, Delgado A, Jekle M, Hitzmann B. Application of CO2 Gas Hydrates as Leavening Agents in Black-and-White Cookies. Foods. 2023; 12(14):2797. https://doi.org/10.3390/foods12142797

Chicago/Turabian StyleKollemparembil, Ann Mary, Shubhangi Srivastava, Viktoria Zettel, Bernhard Gatternig, Antonio Delgado, Mario Jekle, and Bernd Hitzmann. 2023. "Application of CO2 Gas Hydrates as Leavening Agents in Black-and-White Cookies" Foods 12, no. 14: 2797. https://doi.org/10.3390/foods12142797

APA StyleKollemparembil, A. M., Srivastava, S., Zettel, V., Gatternig, B., Delgado, A., Jekle, M., & Hitzmann, B. (2023). Application of CO2 Gas Hydrates as Leavening Agents in Black-and-White Cookies. Foods, 12(14), 2797. https://doi.org/10.3390/foods12142797