Effect of Hopper Loading on the Formation of Alkyl Alcohols in Olive Fruits and Its Relationship with Sensory Quality Losses of Virgin Olive Oil

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiments

2.2. Sampling

2.2.1. Determination of Physicochemical Properties

2.2.2. Sample Preparation for Subsequent GC Analysis

2.2.3. Obtaining Olive Oils

2.2.4. Reference Samples

2.3. Chemicals and Reagents

2.4. Analytical Procedure

2.5. Sensory Evaluation

2.6. Statistical Analysis

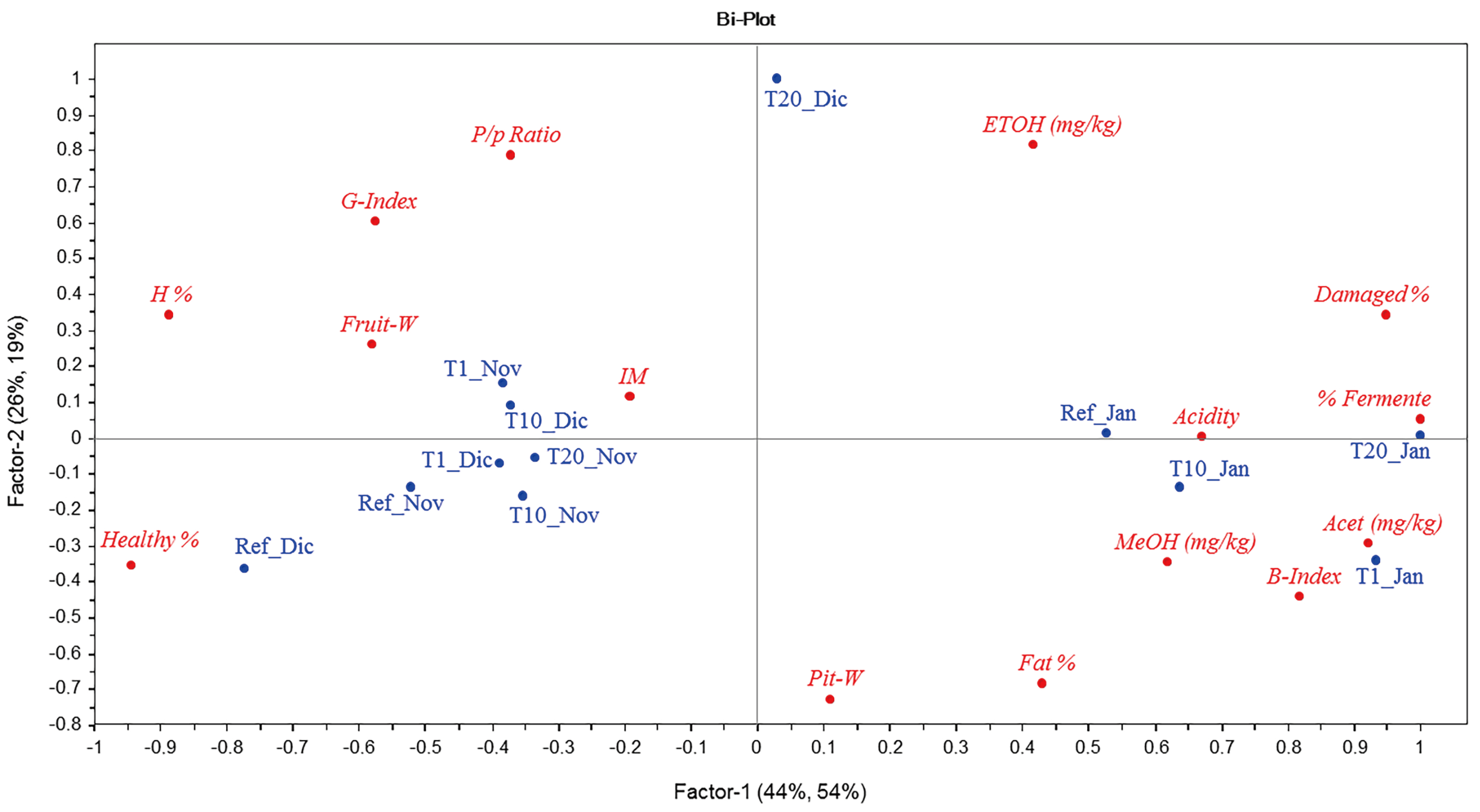

3. Results and Discussion

3.1. Fruit Characteristics

3.2. Tasting Panel Results

3.3. Content of Alcohols

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mele, M.A.; Islam, M.Z.; Kang, H.M.; Giuffré, A.M. Pre-and post-harvest factors and their impact on oil composition and quality of olive fruit. Emir. J. Food Agric. 2018, 30, 592–603. [Google Scholar] [CrossRef]

- García, J.M.; Yousfi, K. The postharvest of mill olives. Grasas Aceites 2006, 57, 16–24. [Google Scholar] [CrossRef]

- Kalua, C.M.; Bedgood, D.R.J.; Bishop, A.G.; Prenzler, P.D. Changes in virgin olive oil quality during low-temperature fruit storage. J. Agric. Food Chem. 2008, 56, 2415–2422. [Google Scholar] [CrossRef]

- Brkić, B.K.; Lukić, M.; Novoselić, A.; Krapac, M.; Lukić, I. Olive Fruit Refrigeration during Prolonged Storage Preserves the Quality of Virgin Olive Oil Extracted Therefrom. Foods 2020, 9, 1445. [Google Scholar] [CrossRef] [PubMed]

- De Toro, M.D.; Sanchez, M.T.; Montes, F. Olives. Postharvest quality. Aliment. Equipos Tecnol. 2002, 21, 75–77. [Google Scholar]

- Vichi, S.; Boynuegri, P.; Caixach, J.; Romero, A. Quality losses in virgin olive oil due to washing and short-term storage before olive milling. Eur. J. Lipid Sci. Technol. 2015, 117, 2015–2022. [Google Scholar] [CrossRef]

- Di Giovacchino, L. Analysis and properties. In Handbook of Olive Oil, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Chapter 3: Technological Aspects; Springer: Berlin/Heidelberg, Germany, 2013; pp. 57–96. [Google Scholar] [CrossRef]

- Vichi, S.; Romero, A.; Gallardo-Chacóna, J.; Tous, J.; López-Tamamesa, E.; Buxaderasa, S. Volatile phenols in virgin olive oils: Influence of olive variety on their formation during fruits storage. Food Chem. 2009, 116, 651–656. [Google Scholar] [CrossRef]

- Olías, J.M.; García, J.M. Olive. In Postharvest Physiology and Storage of Tropical and Subtropical Fruits; Mitra, S., Ed.; CAD International: Wallingfort, UK, 1997; pp. 225–239. [Google Scholar]

- García, J.M.; Gutiérrez, F.; Castellano, J.M.; Perdiguero, S.; Morilla, A.; Albi, M.A. Influence of storage temperature on fruit ripening and olive oil quality. J. Agric. Food Chem. 1996, 44, 264–267. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Muraglia, M.; Crupi, P.; Hbaieb, R.H.; De Santis, S.; Desantis, A.; Corbo, F. The Tower of Babel of Pharma-Food Study on Extra Virgin Olive Oil Polyphenols. Foods 2022, 11, 1915. [Google Scholar] [CrossRef]

- Bongartz, A.; Oberg, D.G. Sensory Evaluation of Extra Virgin Olive Oil (EVOO) Extended to Include the Quality Factor “Harmony”. J. Agric. Sci. Technol. 2011, A1, 422–443. [Google Scholar]

- Díez-Betriu, A.; Romero, A.; Ninot, A.; Tres, A.; Vichi, S.; Guardiola, F. Effect of freezing, fast freezing by liquid nitrogen or refrigeration to preserve premium extra virgin olive oil during storage. Eur. Food Res. Technol. 2022, 248, 2651–2663. [Google Scholar] [CrossRef]

- Procida, G.; Giomo, A.; Cichelli, A.; Conte, L.S. Study of volatile compounds of defective virgin olive oils and sensory evaluation: A chemometric approach. J. Sci. Food Agric. 2005, 85, 2175–2183. [Google Scholar] [CrossRef]

- Angerosa, F.; Servili, M.; Selvaggini, R.; Taticchi, A.; Esposto, S.; Montedoro, G.F. Volatile compounds in virgin olive oil: Occurrence and their relationship with the quality. J. Chromatogr. A 2004, 1054, 17–31. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.T.; Luna, G.; Aparicio, R. Comparative study of virgin olive oil sensory defects. Food Chem. 2005, 91, 293–301. [Google Scholar] [CrossRef]

- Borràs, E.; Mestres, M.; Aceña, L.; Busto, O.; Ferré, J.; Boqué, R.; Calvo, A. Identification of olive oil sensory defects by multivariate analysis of mid infrared spectra. Food Chem. 2015, 187, 197–203. [Google Scholar] [CrossRef]

- Aparicio, R.; Morales, M.T.; García-González, D.L. Towards new analyses of aroma and volatiles to understand sensory perception of olive oil. Eur. Lipid Sci. Technol. 2012, 114, 1114–1125. [Google Scholar] [CrossRef]

- Cayuela, J.A.; Gómez-Coca, R.B.; Moreda, W.; Pérez-Camino, M.C. Sensory defects of virgin olive oil from a microbiological perspective. Trends Food Sci. Technol. 2015, 43, 227–235. [Google Scholar] [CrossRef]

- Perez-Camino, M.D.C.; Cert, A.; Romero-Segura, A.; Cert-Trujillo, R.; Moreda, W. Alkyl esters of fatty acids a useful tool to detect soft deodorized olive oils. J. Agric. Food Chem. 2008, 56, 6740–6744. [Google Scholar] [CrossRef]

- COI/T.15/NC No 3/Rev 10; International Trade Standard Applying To Olive Oils and Olive-Pomace Oils. International Olive Council: Madrid, Spain, 2015; p. 10.

- Gómez-Coca, R.B.; Moreda, W.; Pérez-Camino, M. Fatty acid alkyl esters presence in olive oil vs. organoleptic assessment. Food Chem. 2012, 135, 1205–1209. [Google Scholar] [CrossRef]

- Boudebouz, A. Effect of Agronomic and Technological Factors on the Formation of Ethyl Esters in Virgin Olive Oil in Catalonia. Doctoral Thesis, Universitat Rovira i Virgili, Tarragona, Spain, 2021; p. 186. [Google Scholar]

- Jabeur, H.; Zribi, A.; Abdelhedi, R.; Bouaziz, M. Effect of olive storage conditions on Chemlali olive oil quality and the effective role of fatty acids alkyl esters in checking olive oils authenticity. Food Chem. 2015, 169, 289–296. [Google Scholar] [CrossRef]

- Uceda, M.; Frías, L. Harvest dates: Evolution of the fruits oil content, oil composition and oil quality. In Proceedings of the II Seminario Oleícola Internacional, Córdoba, Spain, 6–17 October 1975; pp. 125–128. [Google Scholar]

- UNE 55030; Determination of the Content in Total Fat of Olives. Spanish Association for Standardization and Certification: Madrid, Spain, 1961.

- Boudebouz, A.; Romero, A.; Boqué, R.; Aceña, L.; Busto, O.; Mestres, M. Quantitation of endogenous amount of ethanol, methanol, and acetaldehyde in ripe fruits of different Spanish olive varieties. J. Sci. Food Agric. 2020, 100, 3173–3181. [Google Scholar] [CrossRef]

- Romero, A.; Tous, J.; Guerrero, L. El análisis sensorial del aceite de oliva virgen. In Introducción al Análisis Sensorial de Los Alimentos; Sancho, J., Bota, E., de Castro, J., Eds.; Universitat de Barcelona: Barcelona, Spain, 1999; pp. 183–197. ISBN 8483380528. [Google Scholar]

- Guerrero, L.; Romero, A.; Tous, J. Importance of Generalized Procrustes analysis in sensory characterization of virgin olive oil. Food Qual. Prefer. 2001, 12, 515–520. [Google Scholar] [CrossRef]

- Cavallo, C.; Caracciolo, F.; Cicia, G.; Del Giudice, T. Extra-virgin olive oil: Are consumers provided with the sensory quality they want? A hedonic price model with sensory attributes. J. Sci. Food Agr. 2018, 98, 1591–1598. [Google Scholar] [CrossRef]

- Rallo, L.; Concepción, M.D.; Morales-Sillero, A.; Miho, H.; Priego-Capote, F.; Rallo, P. Quality of olives: A focus on agricultural preharvest factors. Sci. Hortic. 2018, 233, 491–509. [Google Scholar] [CrossRef]

- Rotondi, A.; Morrone, L.; Bertazza, G.; Neri, L. Effect of Duration of Olive Storage on Chemical and Sensory Quality of Extra Virgin Olive Oils. Foods 2021, 10, 2296. [Google Scholar] [CrossRef]

- Beltrán, G.; Bejaoui, M.A.; Jimenez, A.; Sanchez-Ortiz, A. Ethanol in Olive Fruit. Changes during Ripening. J. Agric. Food Chem. 2015, 63, 5309–5312. [Google Scholar] [CrossRef]

- Beltran, G.; Hueso, A.; Bejaoui, M.A.; Gila, A.M.; Costales, R.; Sánchez-Ortiz, A.; Aguilera, M.P.; Jimenez, A. How olive washing and storage affect fruit ethanol and virgin olive oil ethanol, ethyl esters and composition. J. Sci. Food Agric. 2020, 101, 3714–3722. [Google Scholar] [CrossRef]

- Frenkel, C.; Peters, J.S.; Tieman, D.M.; Tiznado, M.E.; Handa, A.K. Pectin Methylesterase Regulates Methanol and Ethanol Accumulation in Ripening Tomato (Lycopersicon esculentum) Fruit. J. Biol. Chem. 1998, 273, 4293–4295. [Google Scholar] [CrossRef]

| Sample | (1) Healthy (%) | (1) Damaged (%) | Olives T °C | (2) Maturity Index | (2) Fruit Weight (g) | (2) Flesh/Pit Ratio | (2) Moisture (%) | (2) Oil Content (%) | |

|---|---|---|---|---|---|---|---|---|---|

| 27 Nov. | Ref | 88 a | 12 a | 9 | 2.4 b ± 0.2 | 1.08 b | 4.1 b ± 0.3 | 53.1 a ± 1.2 | 21.9 a ± 1.6 |

| T1 | 82 a | 18 a | 11 | ||||||

| T10 | 82 a | 18 a | 12 | ||||||

| T20 | 80 a | 20 a | 12 | ||||||

| 12 Dec. | Ref | 94 a | 6 c | 7 | 2.5 b ± 0.2 | 1.28 a | 5.1 a ± 0.8 | 54.1 a ± 2.3 | 21.5 a ± 1.8 |

| T1 | 76 b | 24 b | 10 | ||||||

| T10 | 74 b | 26 b | 12 | ||||||

| T20 | 52 c | 48 a | 12 | ||||||

| 7 Jan. | Ref | 60 a | 40 a | 5 | 3.5 a ± 0.3 | 1.03 b | 3.4 b ± 0.4 | 49.4 b ± 1.6 | 23.7 b ± 1.1 |

| T1 | 58 a | 42 a | 6 | ||||||

| T10 | 58 a | 42 a | 7 | ||||||

| T20 | 46 a | 54 a | 10 | ||||||

| Attributes | 27 Nov. | 12 Dec. | 7 Jan. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref | T1 | T10 | T20 | Ref | T1 | T10 | T20 | Ref | T1 | T10 | T20 | ||

| negative attributes | Fusty | 0.0 a ± 0.0 | 0.0 a ± 0.8 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 b ± 0.0 | 0.0 b ± 0.0 | 0.0 b ± 0.0 | 0.7 a ± 0.6 | 0.2 a ± 0.0 | 0.2 a ± 0.0 | 0.3 a ±0.0 | 0.3 a ± 0.0 |

| Musty | 0.0 a ± 0.0 | 0.0 a ± 0.2 | 0.0 a ± 0.1 | 0.0 a ± 0.0 | 0.0 b ± 0.0 | 0.0 b ± 0.0 | 0.0 b ± 0.0 | 1.9 a ± 0.8 | 0.2 a ± 0.0 | 0.5 a ± 0.1 | 0.4 a ± 0.1 | 0.3 a ± 0.0 | |

| Winey | 0.0 a ± 0.0 | 0.0 a ± 0.3 | 0.0 a ± 0.1 | 0.0 a ± 0.0 | 0.0 b ± 0.0 | 0.1 ab ± 0.3 | 0.0 b ± 0.0 | 0.5 a ± 0.4 | 0.0 a ± 0.0 | 0.5 a ± 0.2 | 0.0 a ± 0.0 | 0.3 a ± 0.0 | |

| Frost Olive | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 1.6 a ± 1.1 | 3.8 a ± 0.7 | 2.7 a ± 0.4 | 2.8 a ± 1.4 | |

| Rancid | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | |

| Others | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.0 | 0.0 a ± 0.4 | 0.0 a ± 0.0 | 0.0 a ± 0.3 | 0.0 a ± 0.3 | 0.0 a ± 0.4 | 0.0 a ± 0.1 | 0.0 a ± 0.8 | |

| positive attributes | Fruity | 4.8 a ± 0.2 | 3.7 b ± 0.4 | 3.6 a ± 0.4 | 4.3 ab ± 0.2 | 5.1 a ± 0.2 | 4.9 a ± 0.2 | 4.8 a ± 0.2 | 3.2 b ± 0.6 | 3.1 a ± 0.6 | 2.5 a ± 0.6 | 2.9 a ± 0.6 | 2.8 a ± 0.8 |

| Bitter | 3.6 a ± 0.2 | 2.7 b ± 0.2 | 3.4 ab ± 0.4 | 3.6 a ± 0.2 | 4.2 a ± 0.3 | 4.2 a ± 0.2 | 4.3 a ± 0.3 | 2.1 b ± 0.4 | 2.1 b ± 0.4 | 3.2 a ± 0.5 | 2.7 ab ± 0.3 | 2.6 ab ± 0.5 | |

| Pungent | 4.4 a ± 0.2 | 4.2 a ± 0.3 | 4.5 a ± 0.2 | 4.5 a ± 0.2 | 4.7 a ± 0.2 | 4.8 a ± 0.2 | 4.6 a ± 0.3 | 3.7 b ± 0.2 | 3.2 a ± 0.4 | 3.6 a ± 0.3 | 3.4 a ± 0.4 | 3.5 a ± 0.4 | |

| Green | 2.7 a ± 0.4 | 2.0 a ± 0.9 | 2.3 a ± 0.2 | 2.4 a ± 0.1 | 3.7 a ± 0.1 | 3.7 a ± 0.4 | 3.2 a ± 0.3 | 1.2 b ± 0.6 | 1.2 a ± 0.5 | 1.1 a ± 0.7 | 1.1 a ± 0.7 | 1.3 a ± 0.7 | |

| Sweet | 4.3 a ± 0.1 | 4.6 a ± 0.1 | 4.0 a ± 0.3 | 4.4 a ± 0.2 | 4.3 a ± 0.2 | 4.2 a ± 0.3 | 4.1 a ± 0.6 | 4.7 a ± 0.3 | 5.1 a ± 0.2 | 4.6 a ± 0.1 | 5.1 a ± 0.1 | 4.8 a ± 0.2 | |

| Astringent | 2.2 a ± 0.1 | 1.1 b ± 0.6 | 1.8 ab ± 0.4 | 1.8 ab ± 0.3 | 2.1 a ± 0.4 | 2.1 a ± 0.4 | 1.9 a ± 0.4 | 0.2 b ± 0.2 | 0.4 a ± 0.1 | 1.1 a ± 0.8 | 0.9 a ± 0.4 | 0.6 a ± 0.4 | |

| Almond | 2.3 a ± 0.2 | 1.8 a ± 0.4 | 1.1 a ± 0.7 | 1.7 a ± 0.6 | 2.7 a ± 0.1 | 2.3 a ± 0.2 | 2.4 a ± 0.4 | 0.0 b ± 0.5 | 1.4 a ± 0.4 | 1.2 a ± 0.8 | 1.1 a ± 0.7 | 1.1 a ± 0.8 | |

| Walnut | 1.4 a ± 0.8 | 1.0 a ± 0.9 | 0.6 a ± 0.2 | 1.1 a ± 0.8 | 1.7 a ± 0.3 | 1.5 a ± 0.8 | 1.3 a ± 0.7 | 0.5 a ± 0.1 | 0.7 a ± 0.4 | 0.6 a ± 0.2 | 0.6 a ± 0.2 | 0.6 a ± 0.2 | |

| Other | 2.3 a ± 0.1 | 2.1 a ± 0.4 | 1.6 a ± 0.8 | 1.7 a ± 0.9 | 2.7 a ± 0.1 | 2.4 a ± 0.2 | 2.1 ab ± 0.2 | 1.4 b ± 0.6 | 1.6 a ± 0.5 | 1.3 a ± 0.7 | 1.7 a ± 0.6 | 1.6 a ± 0.4 | |

| Complexity (*) | 4.0 | 3.0 | 2.0 | 2.0 | 6.0 | 4.0 | 4.0 | 5.0 | 2.0 | 1.0 | 1.0 | 1.0 | |

| Global score (*) | 7.2 | 5.9 | 6.3 | 6.4 | 7.6 | 6.7 | 7.2 | 5.4 | 5.6 | 5.3 | 5.5 | 5.4 | |

| Compound | Date | Ref | T1 | T10 | T20 | Average |

|---|---|---|---|---|---|---|

| Acet. | 27 Nov. | 0.7 a ± 0.1 | 1.2 ab ± 0.4 | 1.3 b ± 0.2 | 1.9 C ± 0.2 | 1.26 A |

| 10 Dec. | 0.8 a ± 0.2 | 1.0 ab ± 0.1 | 1.2 b ± 0.2 | 1.9 C ± 0.1 | 1.01 A | |

| 7 Jan. | 3.1 a ± 0.3 | 3.3 a ± 0.3 | 3.0 a ± 0.6 | 3.0 a ± 0.4 | 3.10 B | |

| average | 1.76 A | 1.76 A | 1.78 A | 1.94 A | ||

| EtOH | 27 Nov. | 36.5 a ± 11.2 | 78.7 b ± 3.6 | 77.0 b ± 8.3 | 71.3 b ± 4.5 | 65.9 A |

| 10 Dec. | 23.7 a ± 9.5 | 83.6 b ± 6.3 | 91.8 b ± 4.5 | 201.3 c ± 19.1 | 134.3 B | |

| 7 Jan. | 138.3 a ± 11.7 | 106.6 a ± 13.5 | 118.5 a ± 34.4 | 121.4 a ± 17.9 | 122.6 B | |

| average | 71.5 A | 87.5 B | 95.8 B | 164.7 C | ||

| MeOH | 27 Nov. | 66.1 a ± 40.4 | 132.9 a ± 52.8 | 100.8 a ± 33.2 | 174.2 a ± 50.7 | 123.3 AB |

| 10 Dec. | 53.2 a ± 4.7 | 86.6 a ± 71.1 | 110.1 a ± 52.4 | 57.5 a ± 36.9 | 79.0 A | |

| 7 Jan. | 100.7 a ± 29.8 | 232.7 a ± 135.0 | 126.9 a ± 68.6 | 176.3 a ± 41.5 | 159.2 B | |

| average | 77.3 A | 150.7 B | 112.6 B | 136.0 B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boudebouz, A.; Romero, A.; Hermoso, J.-F.; Boqué, R.; Mestres, M. Effect of Hopper Loading on the Formation of Alkyl Alcohols in Olive Fruits and Its Relationship with Sensory Quality Losses of Virgin Olive Oil. Foods 2023, 12, 2633. https://doi.org/10.3390/foods12132633

Boudebouz A, Romero A, Hermoso J-F, Boqué R, Mestres M. Effect of Hopper Loading on the Formation of Alkyl Alcohols in Olive Fruits and Its Relationship with Sensory Quality Losses of Virgin Olive Oil. Foods. 2023; 12(13):2633. https://doi.org/10.3390/foods12132633

Chicago/Turabian StyleBoudebouz, Abdelaziz, Agustí Romero, Juan-F. Hermoso, Ricard Boqué, and Montserrat Mestres. 2023. "Effect of Hopper Loading on the Formation of Alkyl Alcohols in Olive Fruits and Its Relationship with Sensory Quality Losses of Virgin Olive Oil" Foods 12, no. 13: 2633. https://doi.org/10.3390/foods12132633

APA StyleBoudebouz, A., Romero, A., Hermoso, J.-F., Boqué, R., & Mestres, M. (2023). Effect of Hopper Loading on the Formation of Alkyl Alcohols in Olive Fruits and Its Relationship with Sensory Quality Losses of Virgin Olive Oil. Foods, 12(13), 2633. https://doi.org/10.3390/foods12132633