Physicochemical Properties and Tissue Structure of High Kernel Elongation Rice (Oryza sativa L.) Varieties as Affected by Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Source Population

2.2. Artificial Ageing Treatment

2.3. Determination of Physicochemical Properties

2.3.1. Alkali Digestion Value

2.3.2. Water Uptake Ratio (WUR)

2.3.3. Solids in Cooking Water (SCW)

2.3.4. High Kernel Elongation (HKE) Ratio

2.4. Amylose Content

2.5. Determination of Starch Chain-Length Distribution

2.6. Statistical Analysis

3. Results

3.1. Physicochemical Properties of High Kernel Elongation Rice

3.1.1. Correlation among Physicochemical Characteristics

3.1.2. Absolute Amylose Content

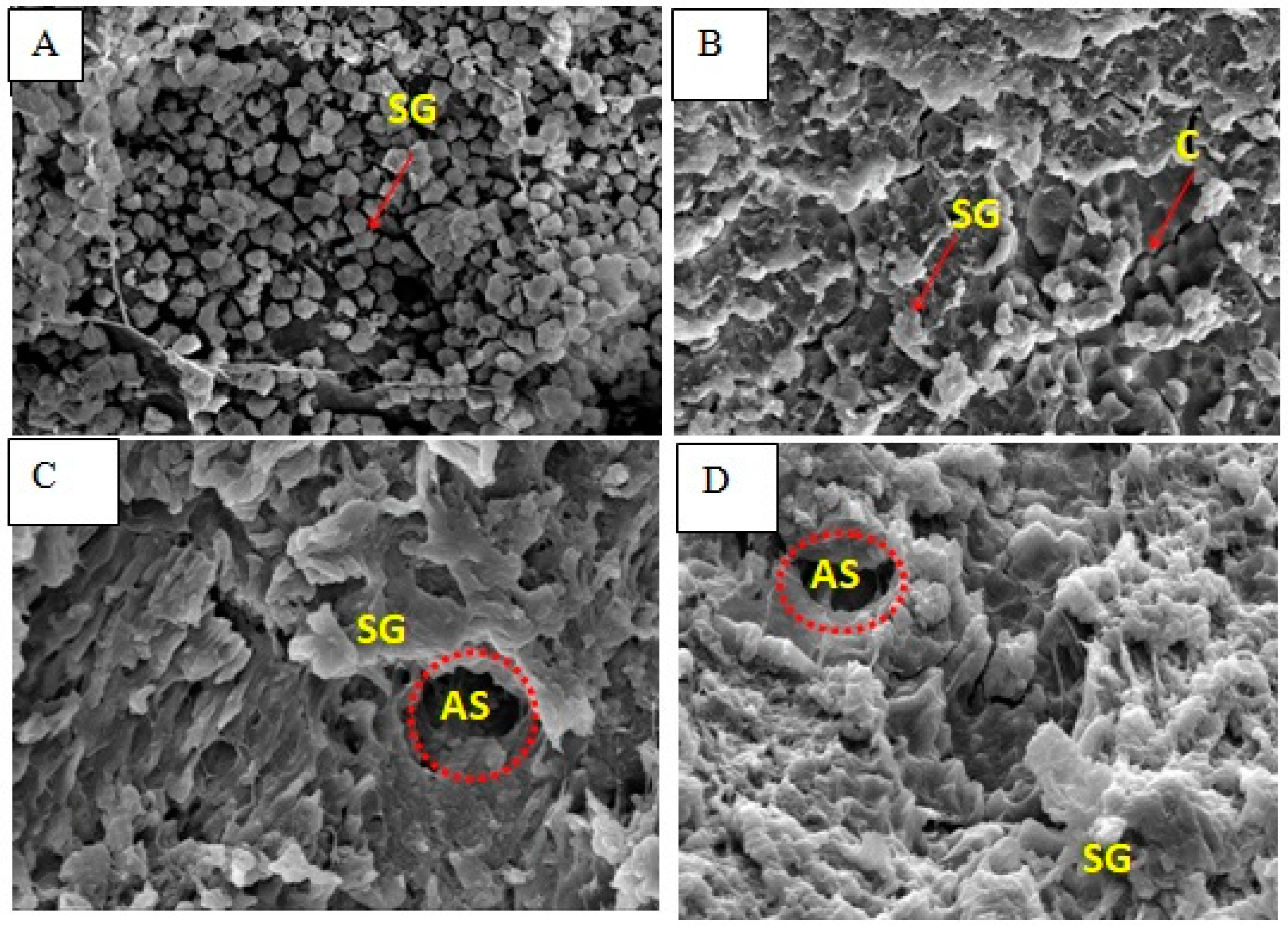

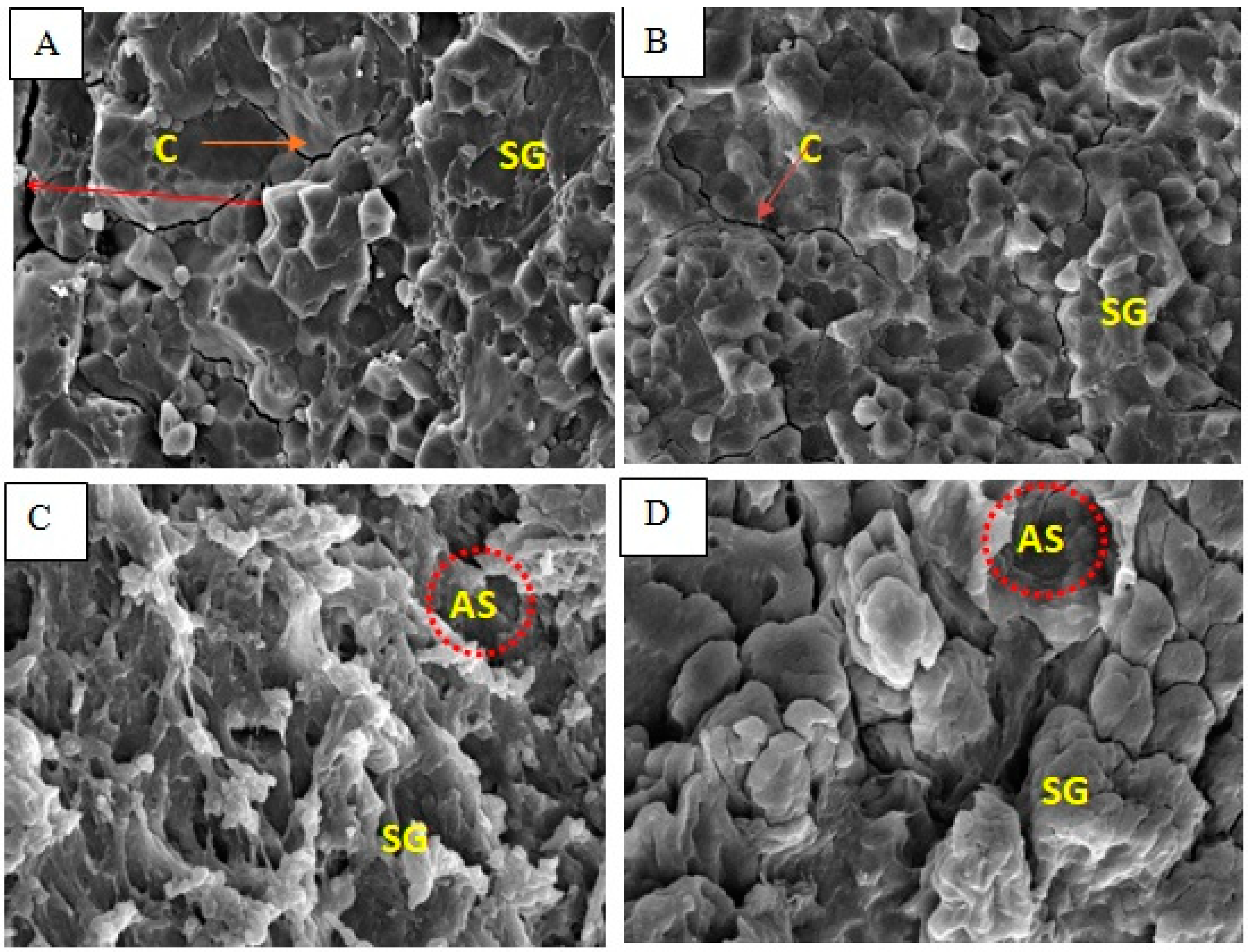

3.1.3. Examination of Kernel Structure through Electron Microscope (SEM)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Le, T.Q.; Songsermpong, S.; Rumpagaporn, P.; Suwanagul, A.; Wallapa, S. Microwave heating for accelerated aging of paddy and white rice. Aust. J. Crop Sci. 2014, 8, 1348–1358. [Google Scholar]

- Ab. Halim, A.A.; Rafii, M.Y.; Osman, M.B.; Oladosu, Y.; Chukwu, S.C. Ageing effects, generation means, and path coefficient analyses on high kernel elongation in mahsurimutan and basmati 370 rice populations. BioMed Res. Int. 2021, 2021, 8350136. [Google Scholar]

- Jaisut, D.; Prachayawarakorn, S.; Varanyanond, W.; Tungtrakul, P.; Soponronnarit, S. Accelerated aging of jasmine brown rice by high-temperature fluidization technique. Food Res. Int. 2009, 42, 674–681. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Rafii, M.Y.; Izzati, M.N.; Khalilah, A.K.; Awad, E.A.; Kaka, U.; Chukwu, S.C.; Liang, J.B.; Sazili, A.Q. Biological additives improved qualities, in vitro gas production kinetics, digestibility, and rumen fermentation characteristics of different varieties of rice straw silage. Anim. Prod. Sci. 2022. [Google Scholar] [CrossRef]

- Cruz, N.D.; Khush, G.S. Rice grain quality evaluation procedures. Aromat. Rices 2000, 3, 15–28. [Google Scholar]

- Sarif, H.M.; Rafii, M.Y.; Ramli, A.; Oladosu, Y.; Musa, H.M.; Rahim, H.A.; Zuki, Z.M.; Chukwu, S.C. Genetic diversity and variability among pigmented rice germplasm using molecular marker and morphological traits. Biotechnol. Biotechnol. Equip. 2020, 34, 747–762. [Google Scholar] [CrossRef]

- Rani, N.S.; Pandey, M.K.; Prasad, G.S.; Sudharshan, I. Historical significance, grain quality features and precision breeding for improvement of export quality basmati varieties in India. Indian J. Crop Sci. 2006, 1, 29–41. [Google Scholar]

- Chukwu, S.C.; Rafii, M.Y.; Oladosu, Y.; Okporie, E.O.; Akos, I.S.; Musa, I.; Swaray, S.; Jalloh, M.; Al-Mamun, M. Genotypic and phenotypic selection of newly improved putra rice and the correlations among quantitative traits. Diversity 2022, 14, 812. [Google Scholar] [CrossRef]

- Sujatha, S.J.; Ahmad, R.; Bhat, P.R. Physicochemical properties and cooking qualities of two varieties of raw and parboiled rice cultivated in the coastal region of Dakshina Kannada, India. Food Chem. 2004, 86, 211–216. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Magaji, U.; Abdullah, N.; Miah, G.; Chukwu, S.C.; Hussin, G.; Ramli, A.; Kareem, I. Genotypic and phenotypic relationship among yield components in rice under tropical conditions. BioMed Res. Int. 2018, 2018, 8936767. [Google Scholar] [CrossRef]

- Fitzgerald, M.A.; McCouch, S.R.; Hall, R.D. Not just a grain of rice: The quest for quality. Trends Plant Sci. 2009, 14, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Verma, D.K.; Mohan, M.; Prabhakar, P.K.; Srivastav, P.P. Physico-chemical and cooking characteristics of Azad basmati. Int. Food Res. J. 2015, 22, 1380. [Google Scholar]

- Okporie, E.O.; Chukwu, S.C.; Onyishi, G.C.; Ekwu, L.G.; Oko, G.O. Increase in protein, oil, amylose and amylopectin contents of two populations of maize (Zea mays L.) after two cycles of reciprocal recurrent selection. IOSR J. Agric. Vet Sci. 2014, 6, 17–22. [Google Scholar]

- Siddiqui, S.U.; Kumamaru, T.; Satoh, H. Pakistan rice genetic resources-I: Grain morphological diversity and its distribution. Pak. J. Bot. 2007, 39, 841–848. [Google Scholar]

- Okporie, E.O.; Chukwu, S.C.; Onyishi, G.C. Phenotypic recurrent selection for increase yield and chemical constituents of maize (Zea mays L.). World Appl. Sci. J. 2013, 21, 994–999. [Google Scholar]

- Yadav, R.B.; Khatkar, B.S.; Yadav, B.S. Morphological, physicochemical and cooking properties of some Indian rice (Oryza sativa L.) cultivars. J. Agric. Technol. 2007, 3, 203–210. [Google Scholar]

- Sabri, R.S.; Rafii, M.Y.; Ismail, M.R.; Yusuff, O.; Chukwu, S.C.; Hasan, N.A. Assessment of agro-morphologic performance, genetic parameters and clustering pattern of newly developed blast resistant rice lines tested in four environments. Agronomy 2020, 10, 1098. [Google Scholar] [CrossRef]

- Ebem, E.C.; Afuape, S.O.; Chukwu, S.C.; Ubi, B.E. Genotype× environment interaction and stability analysis for root yield in sweet potato [Ipomoea batatas (L.) lam]. Front. Agron. 2021, 3, 665564. [Google Scholar] [CrossRef]

- Salleh, S.B.; Rafii, M.Y.; Ismail, M.R.; Ramli, A.; Chukwu, S.C.; Yusuff, O.; Hasan, N.A. Genotype-by-environment interaction effects on blast disease severity and genetic diversity of advanced blast-resistant rice lines based on quantitative traits. Front. Agron. 2022, 4, 990397. [Google Scholar] [CrossRef]

- Akos, I.S.; Yusop, M.R.; Ismail, M.R.; Ramlee, S.I.; Shamsudin, N.A.; Ramli, A.B.; Haliru, B.S.; Ismai’la, M.; Chukwu, S.C. A review on gene pyramiding of agronomic, biotic and abiotic traits in rice variety development. Int. J. Appl. Biol. 2019, 3, 65–96. [Google Scholar]

- Akos, I.S.; Rafii, M.Y.; Ismail, M.R.; Ramlee, S.I.; Shamsudin, N.A.; Ramli, A.; Chukwu, S.C.; Swaray, S.; Jalloh, M. Evaluation of inherited resistance genes of bacterial leaf blight, blast and drought tolerance in improved rice lines. Rice Sci. 2021, 28, 279–288. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Chukwu, S.C.; Fatai, A.; Magaji, U.; Kareem, I.; Kamarudin, Z.S.; Muhammad, I.I.; Kolapo, K. Drought resistance in rice from conventional to molecular breeding: A review. Int. J. Mol. Sci. 2019, 20, 3519. [Google Scholar] [CrossRef]

- Chukwu, S.C.; Rafii, M.Y.; Ramlee, S.I.; Ismail, S.I.; Hasan, M.M.; Oladosu, Y.A.; Magaji, U.G.; Akos, I.; Olalekan, K.K. Bacterial leaf blight resistance in rice: A review of conventional breeding to molecular approach. Mol. Biol. Rep. 2019, 46, 1519–1532. [Google Scholar] [CrossRef]

- Chukwu, S.C.; Rafii, M.Y.; Ramlee, S.I.; Ismail, S.I.; Oladosu, Y.; Okporie, E.; Onyishi, G.; Utobo, E.; Ekwu, L.; Swaray, S.; et al. Marker-assisted selection and gene pyramiding for resistance to bacterial leaf blight disease of rice (Oryza sativa L.). Biotechnol. Biotechnol. Equip. 2019, 33, 440–455. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Arolu, F.; Chukwu, S.C.; Muhammad, I.; Kareem, I.; Salisu, M.A.; Arolu, I.W. Submergence tolerance in rice: Review of mechanism, breeding and, future prospects. Sustainability 2020, 12, 1632. [Google Scholar] [CrossRef]

- Chukwu, S.C.; Rafii, M.Y.; Ramlee, S.I.; Ismail, S.I.; Oladosu, Y.; Kolapo, K.; Musa, I.; Halidu, J.; Muhammad, I.I.; Ahmed, M. Marker-assisted introgression of multiple resistance genes confers broad spectrum resistance against bacterial leaf blight and blast diseases in Putra-1 rice variety. Agronomy 2019, 10, 42. [Google Scholar] [CrossRef]

- Chukwu, S.C.; Rafii, M.Y.; Ramlee, S.I.; Ismail, S.I.; Oladosu, Y.; Muhammad, I.I.; Musa, I.; Ahmed, M.; Jatto, M.I.; Yusuf, B.R. Recovery of recurrent parent genome in a marker-assisted backcrossing against rice blast and blight infections using functional markers and SSRs. Plants 2020, 9, 1411. [Google Scholar] [CrossRef]

- Chukwu, S.C.; Rafii, M.Y.; Ramlee, S.I.; Ismail, S.I.; Oladosu, Y.; Muhammad, I.I.; Ubi, B.E.; Nwokwu, G. Genetic analysis of microsatellites associated with resistance against bacterial leaf blight and blast diseases of rice (Oryza sativa L.). Biotechnol. Biotechnol. Equip. 2020, 34, 898–904. [Google Scholar] [CrossRef]

- Seila, S.A.; Tizzotti, M.J.; Hasjim, J.; Gilbert, R.G. Effects of rice variety and growth location in Cambodia on grain composition and starch structure. Rice Sci. 2014, 21, 47–58. [Google Scholar]

- Faruq, G.; Prodhan, Z.H.; Nezhadahmadi, A. Effects of ageing on selected cooking quality parameters of rice. Int. J. Food Prop. 2015, 18, 922–933. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Arolu, F.; Chukwu, S.C.; Salisu, M.A.; Fagbohun, I.K.; Muftaudeen, T.K.; Swaray, S.; Haliru, B.S. Superabsorbent polymer hydrogels for sustainable agriculture: A review. Horticulturae 2022, 8, 605. [Google Scholar] [CrossRef]

- Saikrishna, A.; Dutta, S.; Subramanian, V.; Moses, J.A.; Anandharamakrishnan, C. Ageing of rice: A review. J. Cereal Sci. 2018, 81, 161–170. [Google Scholar] [CrossRef]

- Normand, F.L. Process of Ageing Rice Artificially. U.S. Patent US3258342A, 28 June 1966. [Google Scholar]

- Abdullah, N.S.; Abdullah, M.Y.; Ghaffar, M.B.; Awal, A.; Aziz, N.A.; Abdullah, S. Traits Performance and Heterosis Estimation in F1 Rice Generations Crossed between Basmati 370 and Selected Malaysian Rice Varieties. Pertanika J. Trop. Agric. Sci. 2018, 41, 1033–1045. [Google Scholar]

- Faruq, G.; Mohamad, O.; Hadzim, M.; Meisner, C.A.; Perai, S. Optimization of aging time and temperature for four Malaysian rice cultivars. Pak. J. Nutr. 2003, 2, 125–1231. [Google Scholar]

- Oko, A.O.; Ubi, B.E.; Dambaba, N. Rice cooking quality and physico-chemical characteristics: A comparative analysis of selected local and newly introduced rice varieties in Ebonyi State, Nigeria. Food Public Health 2012, 2, 43–49. [Google Scholar]

- Faruq, G.; Khalid, N.; Jennifer, A.H.; Subha, B.; Zulqarnain, M.; Osman, M.; Nazia, A.M.; Mohammad, O. Evaluation of kernel elongation ratio and aroma association in global popular aromatic rice cultivars in tropical environment. Afr. J. Agric. Res. 2010, 5, 1515–1522. [Google Scholar]

- Fitzgerald, M.A.; Bergman, C.J.; Resurreccion, A.P.; Möller, J.; Jimenez, R.; Reinke, R.F.; Martin, M.; Blanco, P.; Molina, F.; Chen, M.H.; et al. Addressing the dilemmas of measuring amylose in rice. Cereal Chem. 2009, 86, 492–498. [Google Scholar] [CrossRef]

- Lim, S.T.; Kasemsuwan, T.; Jane, J. Characterization of phosphorus in starches using 31P-NMR spectroscopy. Cereal Chem. 1994, 7, 488–493. [Google Scholar]

- Jane, J.L.; Chen, J.F. Effect of amylose molecular size and amylopectin branch chain length on paste properties of starch. Cereal Chem. 1992, 69, 60–65. [Google Scholar]

- Kasemsuwan, T.; Jane, J.; Schnable, P.; Stinard, P.; Robertson, D. Characterization of the dominant mutant amylose-extender (Ae1-5180) maize starch. Cereal Chem. 1995, 72, 457–464. [Google Scholar]

- Takeda, Y.; Hizukuri, S.; Juliano, B.O. Structures of rice amylopectins with low and high affinities for iodine. Carbohydr. Res. 1987, 168, 79–88. [Google Scholar] [CrossRef]

- SAS. The SAS System for Windows; Version 9.4 (TS1M0); SAS Institute Inc.: Cary, NC, USA, 2013. [Google Scholar]

- Chukwu, S.C.; Ekwu, L.G.; Onyishi, G.C.; Okporie, E.O.; Obi, I.U. Correlation between agronomic and chemical characteristics of maize (Zea mays L.) genotypes after two years of mass selection. Int. J. Sci. Res. 2013, 4, 1708–1712. [Google Scholar]

- Hashim, N.; Rafii, M.Y.; Oladosu, Y.; Ismail, M.R.; Ramli, A.; Arolu, F.; Chukwu, S. Integrating multivariate and univariate statistical models to investigate genotype–environment interaction of advanced fragrant rice genotypes under rainfed condition. Sustainability 2021, 13, 4555. [Google Scholar] [CrossRef]

- Shamim, F.; Raza, M.A.; Akhtar, M. Grain quality attributes of new Rice Basmati lines of Pakistan. J. Appl. Agric. Biotechnol. 2017, 2, 37–47. [Google Scholar] [CrossRef]

- Prodhan, Z.H.; Faruq, G.; Taha, R.M.; Rashid, K.A. Agronomic, transcriptomic and metabolomic expression analysis of aroma gene (badh2) under different temperature regimes in rice. Int. J. Agric. Biol. 2017, 19, 569–576. [Google Scholar] [CrossRef]

- Binodh, A.K.; Kalaiyarasi, R.; Thiyagarajan, K. Genetic divergence of rice varieties and hybrids for quality traits. ORYZA-Int. J. Rice 2010, 47, 91–95. [Google Scholar]

- Tomar, J.B.; Nanda, J.S. Inheritance of cooking quality components in rice. Oryza 1982, 19, 98–103. [Google Scholar]

- Deosarkar, D.B.; Nerkar, Y.S. Correlation and path analysis for grain quality characters in indica rice. J. Maharashtra Agric. Univ. 1994, 19, 175–177. [Google Scholar]

- Wu, L.; Zhang, W.; Ding, Y.; Zhang, J.; Cambula, E.D.; Weng, F.; Liu, Z.; Ding, C.; Tang, S.; Chen, L.; et al. Shading contributes to the reduction of stem mechanical strength by decreasing cell wall synthesis in japonica rice (Oryza sativa L.). Front. Plant Sci. 2017, 8, 881. [Google Scholar] [CrossRef]

- Hanashiro, I.; Abe, J.I.; Hizukuri, S. A periodic distribution of the chain length of amylopectin as revealed by high-performance anion-exchange chromatography. Carbohydr. Res. 1996, 283, 151–159. [Google Scholar] [CrossRef]

- Cameron, R.E.; Donald, A.M. A small-angle X-ray scattering study of the annealing and gelatinization of starch. Polymer 1992, 33, 2628–2635. [Google Scholar] [CrossRef]

- Jane, J.L.; Chen, Y.Y.; Lee, L.F.; McPherson, A.E.; Wong, K.S.; Radosavljevic, M.; Kasemsuwan, T. Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem. 1999, 76, 629–637. [Google Scholar] [CrossRef]

- Keawpeng, I.; Venkatachalam, K. Effect of aging on changes in rice physical qualities. Int. Food Res. J. 2015, 22, 2180–2187. [Google Scholar]

- Golam, F.; Prodhan, Z.H. Kernel elongation in rice. J. Sci. Food Agric. 2012, 1, 2231–2245. [Google Scholar] [CrossRef] [PubMed]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT-Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Kanlayakrit, W.; Maweang, M. Postharvest of paddy and milled rice affected physicochemical properties using different storage conditions. Int. Food Res. J. 2013, 20, 1359–1366. [Google Scholar]

- Tamura, M.; Nagai, T.; Hidaka, Y.; Noda, T.; Yokoe, M.; Ogawa, Y. Changes in histological tissue structure and textural characteristics of rice grain during cooking process. Food Struct. 2014, 1, 164–170. [Google Scholar] [CrossRef]

- Rewthong, O.; Soponronnarit, S.; Taechapairoj, C.; Tungtrakul, P.; Prachayawarakorn, S. Effects of cooking, drying and pretreatment methods on texture and starch digestibility of instant rice. J. Food Eng. 2011, 103, 258–264. [Google Scholar] [CrossRef]

- Yang, L.; Sun, Y.H.; Liu, Y.; Mao, Q.; You, L.X.; Hou, J.M.; Ashraf, M.A. Effects of leached amylose and amylopectin in rice cooking liquidon texture and structure of cooked rice. Braz. Arch. Biol. Technol. 2016, 59, e16160504. [Google Scholar] [CrossRef]

- Chandi, G.K.; Sogi, D.S. Characterization of traditional (Basmati 370) and developed (Pusa Basmati 1) basmati rice. Int. J. Food Prop. 2008, 11, 910–918. [Google Scholar] [CrossRef]

| Factor | SC (Leached) (g) | HKE | ASV | AC (mg/L) | WUR |

|---|---|---|---|---|---|

| Rice varieties (RV) | |||||

| MR219 | 0.07 b | 1.44 c | 4.35 b | 24.63 a | 9.35 b |

| Mahsuri Mutant | 0.08 b | 2.15 b | 5.10 a | 24.03 b | 7.45 c |

| B370 | 0.17 a | 2.71 a | 3.30 c | 20.03 c | 10.7 a |

| LSD Value | 0.0046 | 0.1065 | 0.07 | 0.5928 | 0.0719 |

| Ageing treatment (AT) | |||||

| Ageing | 0.153 a | 2.425 a | 4.575 a | 24.26 a | 8.46 a |

| Non-Aging | 0.116 b | 2.131 b | 3.83 b | 22.74 b | 9.29 b |

| LSD value | 0.0038 | 0.087 | 0.0572 | 0.484 | 0.0587 |

| RV | 0.021 ** | 3.266 ** | 6.540 ** | 50.148 ** | 21.311 ns |

| AT | 0.007 ** | 0.481 ** | 2.006 ** | 13.009 ** | 27.468 ns |

| RV × AT | ** | ns | ** | ns | ** |

| Factor | SC (Leached) (g) | ASV | WUR | |||

|---|---|---|---|---|---|---|

| Rice Varieties (RV) | A | NA | A | NA | A | NA |

| MR219 | 0.069 e | 0.0825 c | 4.45 c | 4.25 e | 11.242 e | 7.4600 b |

| Mahsuri Mutant | 0.138 b | 0.02175 d | 5.4 a | 4.8 b | 8.603 d | 6.3000 f |

| B370 | 0.1675 a | 0.16675 a | 4.35 d | 2.25 f | 12.163 a | 9.2398 c |

| Physiochemical Characteristics | WUR | SC | HKE | ASV | AC |

|---|---|---|---|---|---|

| WUR | 1.00 | 0.107 ns | 0.019 * | −0.153 ns | −0.427 ** |

| SC | 1.00 | 0.829 ** | −0.353 * | 0.026 ns | |

| HKE | 1.00 | −0.264 ns | −0.206 ns | ||

| ASV | 1.00 | 0.626 ** | |||

| AC | 1.00 |

| Iodine Affinity | Percent Amylose Content | ||||

|---|---|---|---|---|---|

| Rice Variety/Source | Starch | Amylopectin | Apparent (A) | Absolute (B) | D = A − B |

| A-type starch | |||||

| MR219 | 5.44 ± 0.16 | 1.34 ± 0.02 | 27.6 | 24.63 | 2.97 |

| Mahsuri mutant | 5.66 ± 0.13 | 0.65 ± 0.06 | 25.2 | 24.03 | 1.17 |

| Basmati 370 | 5.10 ± 0.01 | 1.12 ± 0.01 | 24.98 | 20.03 | 4.95 |

| Source | Iodine Affinity | Apparent Amylose Content (%) |

|---|---|---|

| A-type starch | ||

| Waxy starch | 0.001 ± 0.0 | 0.0 |

| Very low | 0.43 ± 0.02 | 1.4 |

| Low | 0.01 ± 0.01 | 2.0 |

| Intermediate | 0.42 ± 0.02 | 2.3 |

| High | 0.76 ± 0.02 | 3.5 |

| Peak dp | Average | Distribution (%) | Maximum Detectable dp | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Rice Type/Source | I | II | CL | dp 6–9 | dp 6–12 | dp 13–24 | dp 25–36 | dp > 37 | |

| A-type starch | |||||||||

| MR219 | 12 | 47 | 23.6 | 4.22 | 20.5 | 53.4 | 13.4 | 17.6 | 81 |

| Mahsuri mutant | 12 | 46 | 22.5 | 8.69 | 24.6 | 49.65 | 14.6 | 15 | 79 |

| Basmati 370 | 12 | 42 | 19.8 | 9.66 | 28.5 | 54.33 | 13.6 | 7.7 | 67 |

| Ageing rice | 13 | 48 | 24.2 | 3.87 | 17.8 | 46.8 | 14.7 | 18.9 | 82 |

| Non-ageing rice | 12 | 43 | 22.3 | 4.9 | 20.6 | 47.8 | 16.9 | 13.2 | 77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Halim, A.A.B.A.; Rafii, M.Y.; Osman, M.B.; Chukwu, S.C.; Oladosu, Y. Physicochemical Properties and Tissue Structure of High Kernel Elongation Rice (Oryza sativa L.) Varieties as Affected by Heat Treatment. Foods 2023, 12, 2207. https://doi.org/10.3390/foods12112207

Halim AABA, Rafii MY, Osman MB, Chukwu SC, Oladosu Y. Physicochemical Properties and Tissue Structure of High Kernel Elongation Rice (Oryza sativa L.) Varieties as Affected by Heat Treatment. Foods. 2023; 12(11):2207. https://doi.org/10.3390/foods12112207

Chicago/Turabian StyleHalim, Anna Arina Bt Ab., Mohd Y. Rafii, Mohamad B. Osman, Samuel C. Chukwu, and Yusuff Oladosu. 2023. "Physicochemical Properties and Tissue Structure of High Kernel Elongation Rice (Oryza sativa L.) Varieties as Affected by Heat Treatment" Foods 12, no. 11: 2207. https://doi.org/10.3390/foods12112207

APA StyleHalim, A. A. B. A., Rafii, M. Y., Osman, M. B., Chukwu, S. C., & Oladosu, Y. (2023). Physicochemical Properties and Tissue Structure of High Kernel Elongation Rice (Oryza sativa L.) Varieties as Affected by Heat Treatment. Foods, 12(11), 2207. https://doi.org/10.3390/foods12112207