Physicochemical Properties of Soft and Hard-type Rice Flour According to Moisture Content and High Hydrostatic Pressure Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Rice Flour Samples

2.2. High Hydrostatic Pressure (HHP) Treatment

2.3. Heat Treatment

2.4. Water Absorption Index (WAI)

2.5. Solubility and Swelling Power

2.6. Scanning Electron Microscopy (SEM)

2.7. X-ray Diffraction

2.8. α-Amylase hydrolysis

2.9. Rapid Viscosity Analysis (RVA)

2.10. Statistical Analysis

3. Results and Discussion

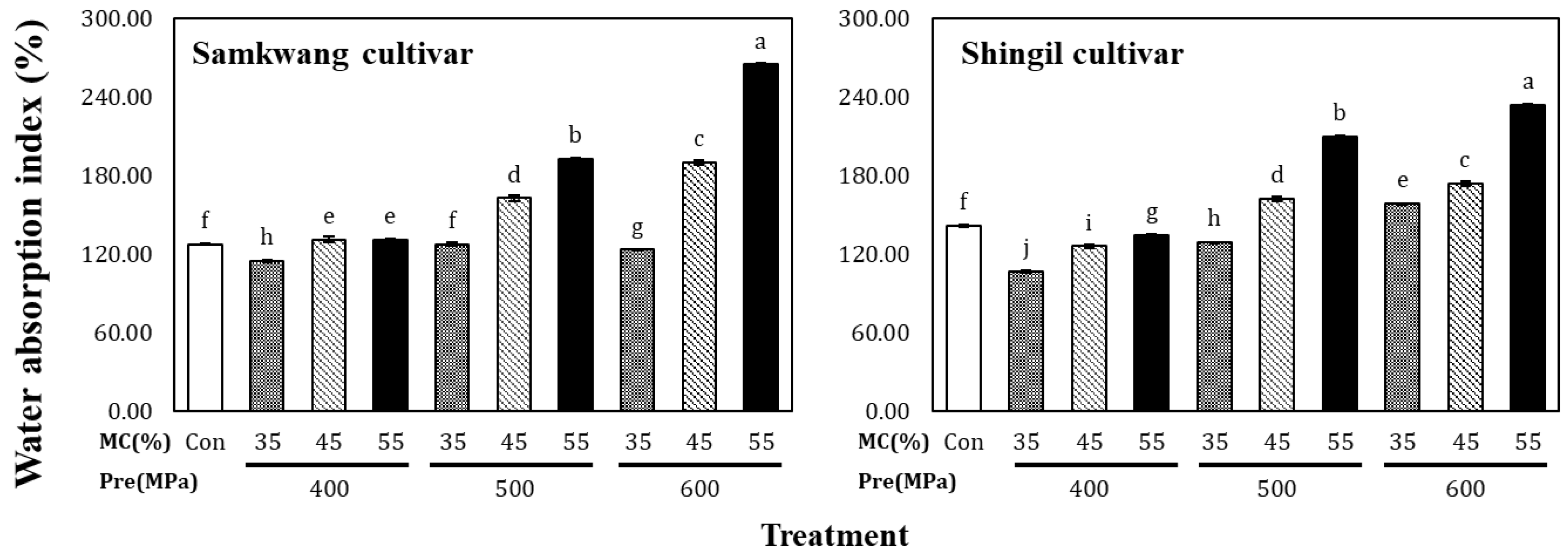

3.1. Water Absorption Index

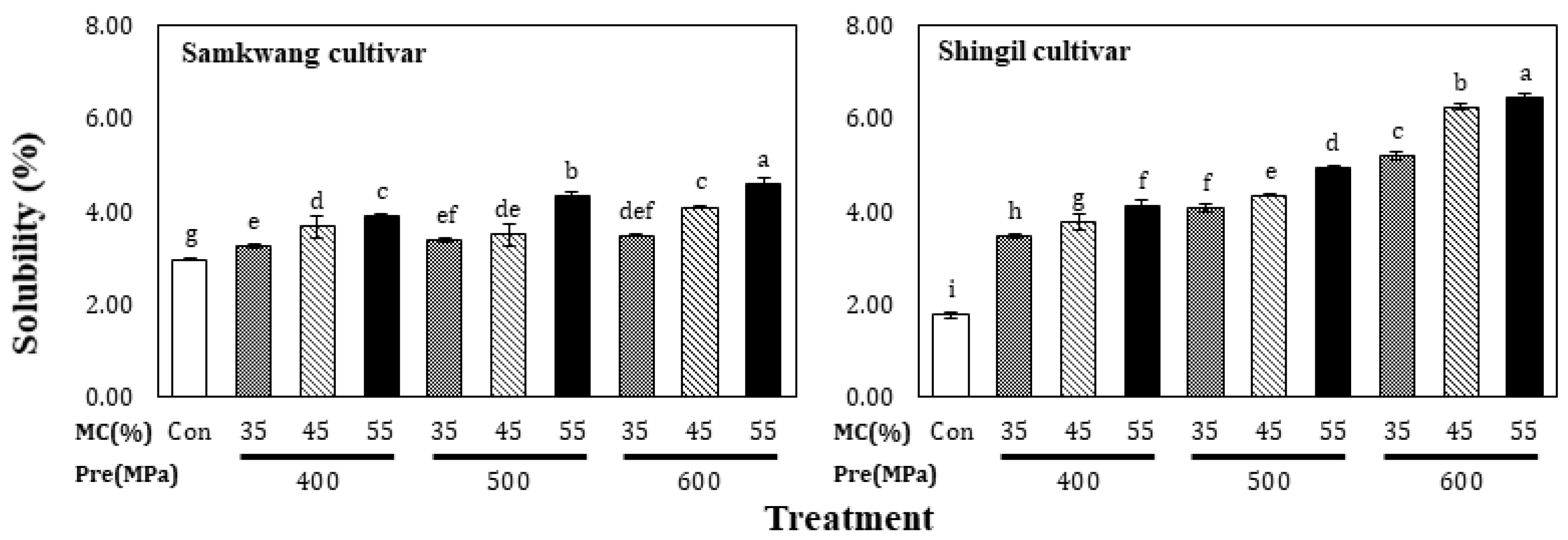

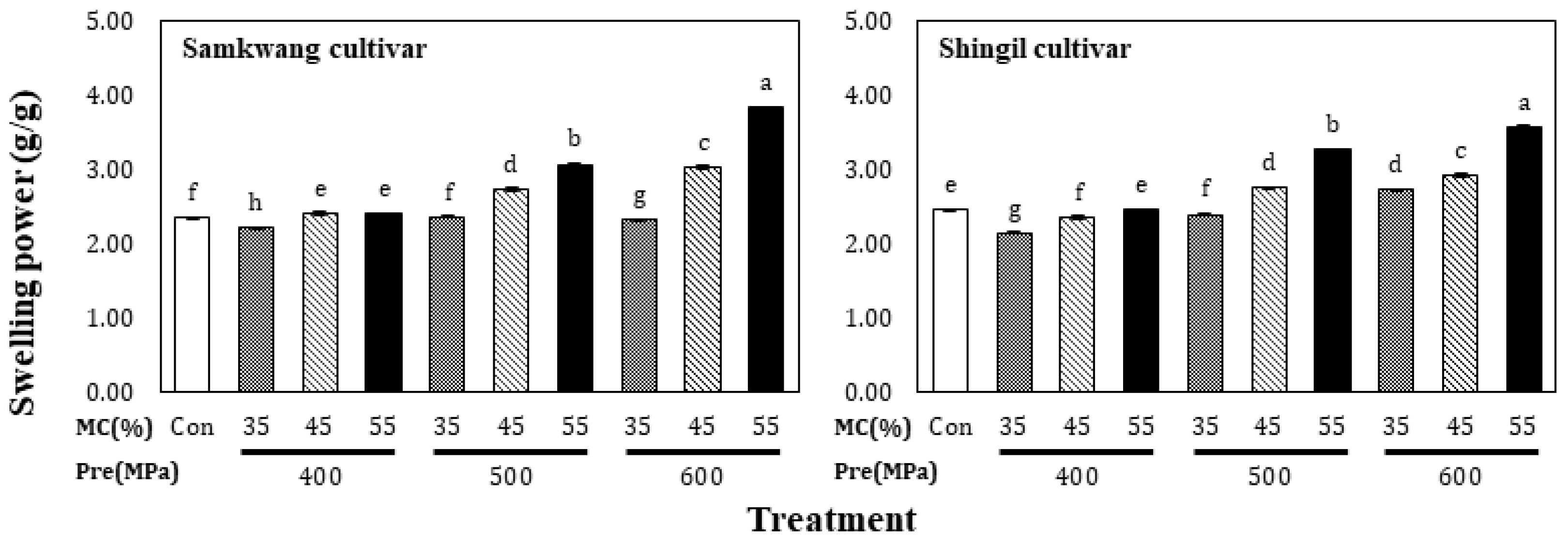

3.2. Solubility and Swelling Power

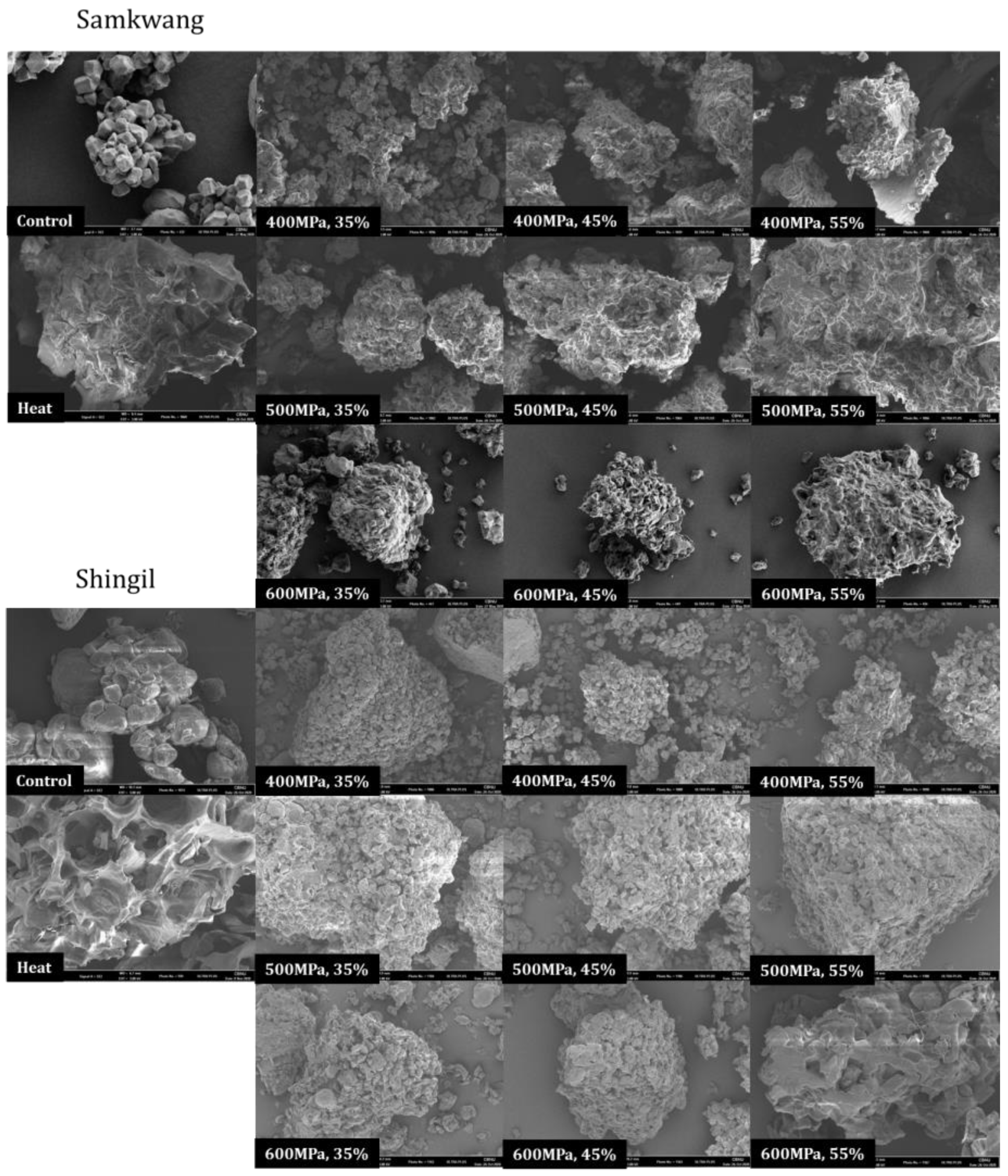

3.3. Scanning Electron Microscopy (SEM)

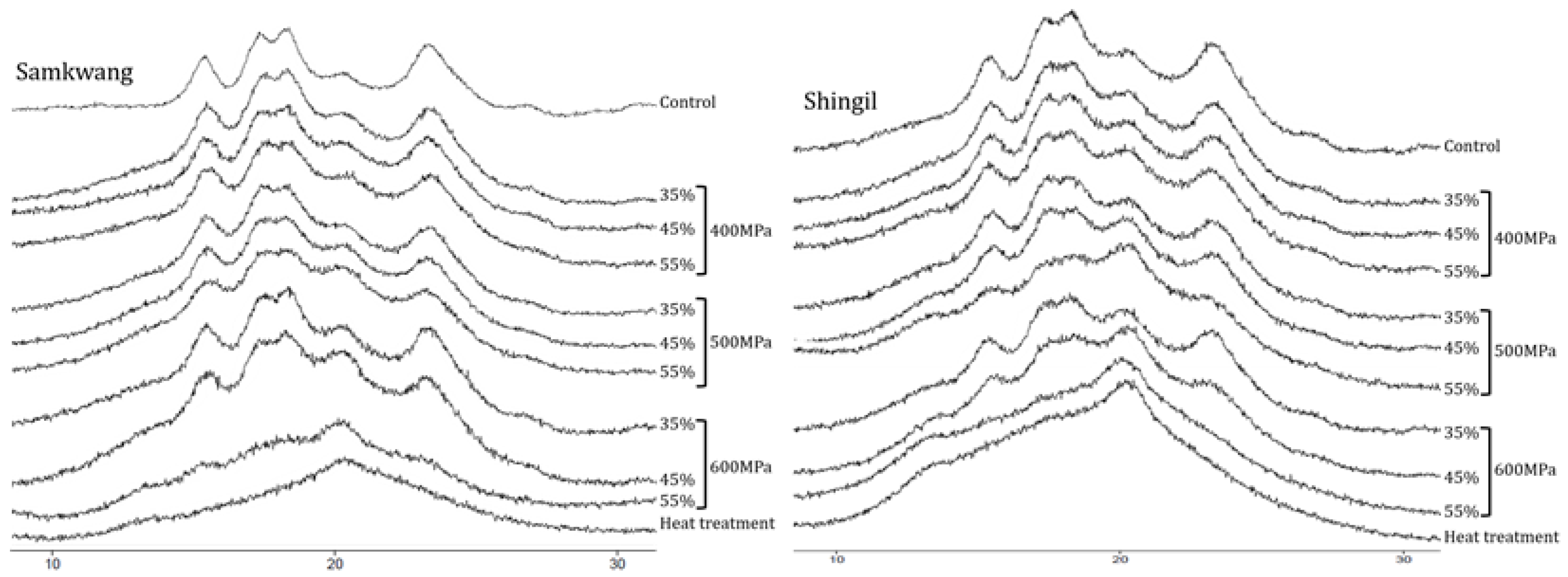

3.4. X-ray Diffraction

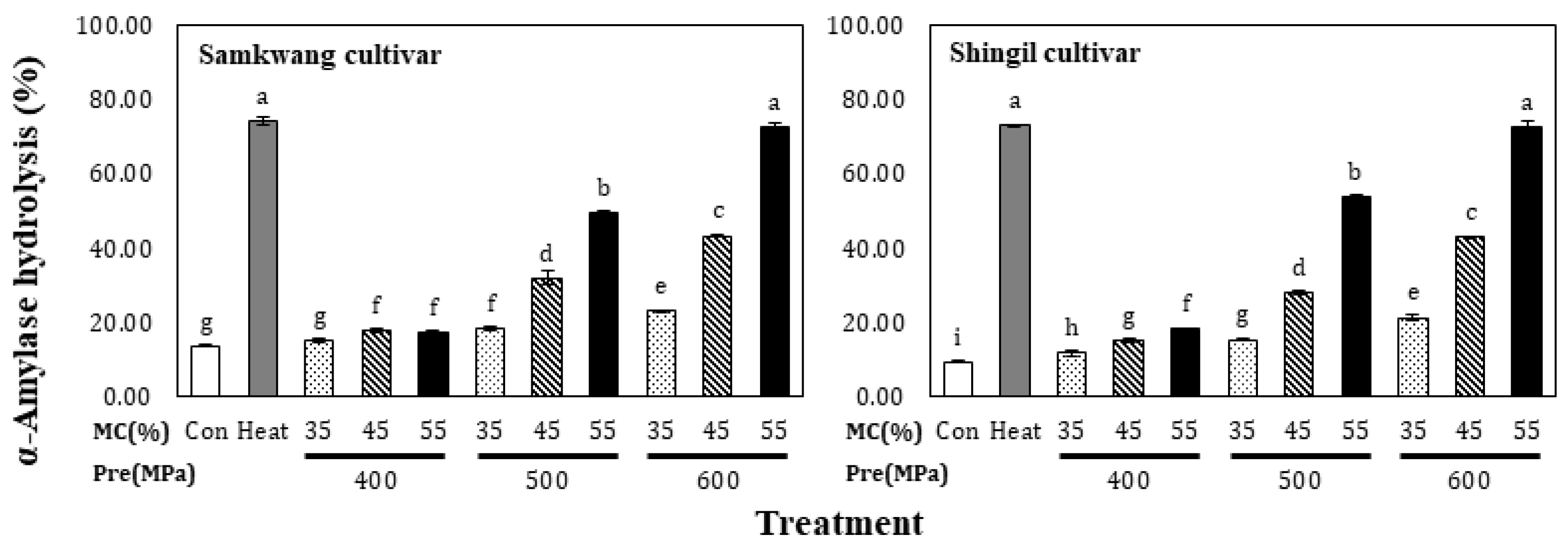

3.5. α-Amylase Hydrolysis

3.6. Rapid Viscosity Analysis (RVA)

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Toepfl, S.; Mathys, A.; Heinz, V.; Knorr, D. Potential of high hydrostatic pressure and pulsed electric fields for energy efficient and environmentally friendly food processing. Food Rev. Int. 2006, 22, 405–423. [Google Scholar] [CrossRef]

- Hayashi, R. Utilization of pressure in addition to temperature in food science and technology. In High Pressure Biotechnology; John Libbey Eurotext: Montrouge, France, 1992; pp. 185–193. [Google Scholar]

- Ratnayake, W.S.; Hoover, R.; Warkentin, T. Pea starch: Composition, structure and properties—A review. Starch-Stärke 2002, 54, 217–234. [Google Scholar] [CrossRef]

- Kim, S.L.; Son, Y.K.; Son, J.R.; Hur, H.S. Effect of germination condition and drying methods on physicochemical properties of sprouted brown rice. Korean J. Crop. Sci. 2001, 46, 221–228. [Google Scholar]

- Lee, N.Y. Starch and pasting characteristics of various rice flour collected from markets. Korean J. Food Preserv. 2012, 19, 257–262. [Google Scholar] [CrossRef][Green Version]

- Oh, S.K. Development of Rice Varieties for Processing and Trend of Food Industry. Food Ind. Nutr. 2016, 21, 8–14. [Google Scholar]

- Medcalf, D.G. Wheat starches I. Comparison of physicochemical properties. Cereal Chem. 1965, 42, 558–568. [Google Scholar]

- Jin, S. Starch Structure, Gelatinization and Retrogradation Properties of Different Rice Varietys. Master’s Thesis, Chung Nam University, Deajeon, Republic of Korea, 2008. [Google Scholar]

- Lee, S.; Lee, E.J.; Chung, H.J. Structural and physicochemical cha-racterization of starch from Korean rice varietys for special uses. Kroean J. Food Sci.Technol. 2017, 49, 1–7. [Google Scholar] [CrossRef][Green Version]

- Xue, Q.; Newman, R.K.; Newman, C.W. Effects of heat treatment of barley starches on in vitro digestibility and glucose responses in rats. Cereal Chem. 1996, 73, 588–592. [Google Scholar]

- AACC. Approved Methods of the AACC, 9th ed.; American Association of Cereal Chemists, Method61–02: St. Paul, MN, USA, 1995. [Google Scholar]

- Park, J.Y.; Lee, S.K.; Park, H.Y.; Choi, H.S.; Cho, D.H.; Lee, K.H.; Han, S.I.; Cho, J.H.; Oh, S.K. Physicochemical properties of rice flour of different cultivars using wet and dry milling process. Korean J. Crop. Sci. 2017, 62, 184–192. [Google Scholar]

- Pei-Ling, L.; Xiao-Song, H.; Qun, S. Effect of high hydrostatic pressure on starches: A review. Starch-Stärke 2010, 62, 615–628. [Google Scholar] [CrossRef]

- Oh, H.E.; Hemar, Y.; Anema, S.G.; Wong, M.; Pinder, D.N. Effect of high-pressure treatment on normal rice and waxy rice starch inwater suspensions. CarbohydratePolymers 2008, 73, 332–343. [Google Scholar]

- Li, W.; Bai, Y.; Mousaa, S.A.; Zhang, Q.; Shen, Q. Effect of high hydrostatic pressure on physicochemical and structural properties of rice starch. Food Bioprocess. Technol. 2012, 5, 2233–2241. [Google Scholar] [CrossRef]

- Buckow, R.; Jankowiak, L.; Knorr, D.; Versteeg, C. ressure temperature phase diagrams of maize starches with different amylose content-s. J. Agric. Food Chem. 2009, 57, 11510–11516. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Kaur, L. Morphological, thermal, rheological and retrogradation properties of potato starch fractions varying in granule size. J. Sci. Food Agric. 2004, 84, 1241–1252. [Google Scholar] [CrossRef]

- Chiotelli, E.; Le Meste, M. Effect of small and large wheat star-ch granules on thermomechanical behavior of starch. Cereal Chem. 2002, 79, 286–293. [Google Scholar] [CrossRef]

- Liu, H.; Yu, L.; Dean, K.; Simon, G.; Petinakis, E.; Chen, L. S-tarch gelatinization under pressure studied by high pressure DSC. Carboh-Ydratepolymers 2009, 75, 395–400. [Google Scholar] [CrossRef]

- Kim, S.K.; Park, H.H.; Chung, H.M.; Kim, K. Degree of ge-latinization during cooking of rice by X-ray diffractometry. Appl. Biol. Chem. 1983, 26, 266–268. [Google Scholar]

- Kim, D.H. Food Chemistry; Tamgudang: Seoul, Republic of Korea, 2007; pp. 255–300. [Google Scholar]

- South, J.B.; Morrison, W.R.; Nelson, O.E. A relationship between the amylose and lipid contents of starches from various mutants for amylose content in maize. J. Cereal Sci. 1991, 14, 267–278. [Google Scholar] [CrossRef]

- Leloup, V.M.; Colonna, P.; Ring, S.G.; Roberts, K.; Wells, B. Microstructure of amylose gels. Carbohydr. Polym. 1992, 18, 189–197. [Google Scholar] [CrossRef]

| Variety | Pressure (MPa) | Moisture Content (%) | RVU | Peak Time (min) | Pasting Temperature (°C) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Peak Viscosity | Trough | Final Viscosity | Breakdown | Setback | |||||

| Sam kwang | Control | 237.83 ± 0.33 a | 147.13 ± 0.21 a b | 257.08 ± 0.42 a | 90.71 ± 0.54 a | 19.25 ± 0.75 f g | 6.37 ± 0.03 a b | 69.98 ± 0.43 a | |

| Heat treatment | 156.33 ± 1.00 i | 107.35 ± 0.90 h | 199.39 ± 0.53 i | 48.98 ± 0.10 f | 43.05 ± 0.47 a | 6.27 ± 0.00 b | 63.90 ± 0.75 d | ||

| 400 | 35 | 236.46 ± 1.38 a | 148.79 ± 0.96 a | 255.66 ± 1.51 b | 87.46 ± 0.29 b | 19.20 ± 0.13 f g | 6.33 ± 0.00 a b | 69.65 ± 0.00 a b | |

| 45 | 234.17 ± 0.75 b | 145.13 ± 0.21 b c | 253.42 ± 0.50 c | 89.04 ± 0.96 a b | 19.25 ± 0.25 f g | 6.30 ± 0.03 a b | 69.70 ± 0.05 a | ||

| 55 | 232.58 ± 0.58 c | 143.29 ± 1.63 c | 253.42 ± 0.33 c | 89.29 ± 1.04 a b | 20.83 ± 0.25 e | 6.33 ± 0.00 a b | 69.28 ± 0.32 a b | ||

| 500 | 35 | 237.17 ± 0.08 a | 146.25 ± 0.33 b | 255.92 ± 0.00 b | 90.92 ± 0.25 a | 18.75 ± 0.08 g | 6.30 ± 0.03 a b | 69.30 ± 0.35 a b | |

| 45 | 222.63 ± 1.20 e | 138.23 ± 0.10 e | 242.96 ± 0.54 e | 84.40 ± 1.10 c | 20.33 ± 0.67 e f | 6.46 ± 0.01 a | 68.43 ± 0.33 c | ||

| 55 | 215.08 ± 0.25 f | 131.17 ± 0.75 f | 237.83 ± 0.75 g | 83.92 ± 1.00 c | 22.75 ± 0.50 d | 6.37 ± 0.03 a b | 69.28 ± 0.43 a b | ||

| 600 | 35 | 228.50 ± 0.42 d | 140.92 ± 0.00 d | 248.67 ± 0.25 d | 87.58 ± 0.42 b | 20.17 ± 0.17 e f | 6.37 ± 0.03 a b | 68.80 ± 0.05 b c | |

| 45 | 209.84 ± 1.01 g | 129.71 ± 1.71 f g | 240.36 ± 0.55 f | 80.13 ± 0.70 d | 30.53 ± 1.56 c | 6.33 ± 0.27 a b | 69.15 ± 0.50 a b c | ||

| 55 | 193.43 ± 0.35 h | 127.68 ± 2.84 g | 228.20 ± 0.71 h | 65.75 ± 2.50 e | 34.77 ± 1.06 b | 6.37 ± 0.03 a b | 69.55 ± 0.85 a b | ||

| Shingil | Control | 94.54 ± 0.38 c | 60.04 ± 0.04 c | 136.67 ± 0.17 a | 34.50 ± 0.42 a | 42.12 ± 0.21 c | 6.13 ± 0.03 a | 87.45 ± 0.35 c | |

| Heat treatment | 58.67 ± 0.15 h | 42.71 ± 0.10 g | 110.53 ± 0.05 i | 15.95 ± 0.25 f | 51.86 ± 0.20 a | 5.83 ± 0.10 b | 88.38 ± 0.17 b | ||

| 400 | 35 | 94.89 ± 0.19 b c | 60.58 ± 0.33 b | 135.81 ± 0.21 c | 34.31 ± 0.53 a | 40.92 ± 0.40 d e | 6.14 ± 0.04 a | 88.45 ± 0.05 b | |

| 45 | 95.58 ± 0.26 a | 60.83 ± 0.00 b | 135.98 ± 0.07 b c | 34.74 ± 0.26 a | 40.41 ± 0.32 e | 6.15 ± 0.02 a | 88.75 ± 0.65 a b | ||

| 55 | 95.03 ± 0.49 b | 60.56 ± 0.28 b | 136.13 ± 0.15 b | 34.47 ± 0.21 a | 41.10 ± 0.63 d | 6.15 ± 0.02 a | 87.93 ± 0.98 b c | ||

| 500 | 35 | 95.47 ± 0.25 a | 60.83 ± 0.00 b | 135.78 ± 0.20 c | 34.63 ± 0.25 a | 40.32 ± 0.45 e | 6.14 ± 0.01 a | 88.55 ± 0.00 b | |

| 45 | 90.35 ± 0.20 d | 62.25 ± 0.25 a | 132.27 ± 0.19 d | 28.10 ± 0.05 c | 41.93 ± 0.39 c | 6.13 ± 0.00 a | 89.03 ± 0.27 a | ||

| 55 | 89.12 ± 0.10 e | 62.25 ± 0.25 a | 131.41 ± 0.24 e | 26.87 ± 0.15 d | 42.29 ± 0.34 c | 6.17 ± 0.00 a | 88.28 ± 0.48 b | ||

| 600 | 35 | 90.22 ± 0.00 d | 58.69 ± 0.15 d | 130.73 ± 0.18 f | 31.53 ± 0.15 b | 40.52 ± 0.18 d e | 6.16 ± 0.01 a | 88.13 ± 0.28 b c | |

| 45 | 83.27 ± 0.25 f | 55.26 ± 0.15 e | 125.79 ± 0.21 g | 28.00 ± 0.10 c | 42.53 ± 0.46 c | 6.13 ± 0.03 a | 88.63 ± 0.03 b | ||

| 55 | 72.46 ± 0.04 g | 50.43 ± 0.07 f | 116.21 ± 0.21 h | 22.03 ± 0.03 e | 43.75 ± 0.17 b | 6.16 ± 0.01 a | 88.48 ± 0.07 b | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, J.-H.; Jo, Y.-J.; Lee, Y.-R.; Lee, J.; Jeong, H.-S. Physicochemical Properties of Soft and Hard-type Rice Flour According to Moisture Content and High Hydrostatic Pressure Treatment. Foods 2023, 12, 227. https://doi.org/10.3390/foods12010227

Seo J-H, Jo Y-J, Lee Y-R, Lee J, Jeong H-S. Physicochemical Properties of Soft and Hard-type Rice Flour According to Moisture Content and High Hydrostatic Pressure Treatment. Foods. 2023; 12(1):227. https://doi.org/10.3390/foods12010227

Chicago/Turabian StyleSeo, Jeong-Hyun, Yeon-Jae Jo, Youn-Ri Lee, Junsoo Lee, and Heon-Sang Jeong. 2023. "Physicochemical Properties of Soft and Hard-type Rice Flour According to Moisture Content and High Hydrostatic Pressure Treatment" Foods 12, no. 1: 227. https://doi.org/10.3390/foods12010227

APA StyleSeo, J.-H., Jo, Y.-J., Lee, Y.-R., Lee, J., & Jeong, H.-S. (2023). Physicochemical Properties of Soft and Hard-type Rice Flour According to Moisture Content and High Hydrostatic Pressure Treatment. Foods, 12(1), 227. https://doi.org/10.3390/foods12010227