The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients

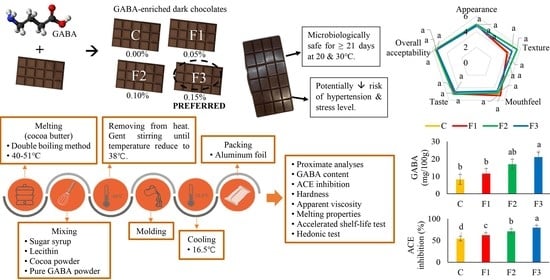

2.2. Preparation of Dark Chocolate

2.3. Proximate Composition

2.4. Quantification of GABA in Dark Chocolate Using HPLC

2.5. Angiotensin-Converting-Enzyme (ACE) Inhibitory Activity

2.6. Textural Properties: Hardness

2.7. Rheological Measurements: Apparent Viscosity

2.8. Melting Properties

2.9. Accelerated Shelf-Life Test: Microbial Analysis

2.10. Hedonic Test

2.11. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition

3.2. GABA Content

3.3. Angiotensin-Converting-Enzyme (ACE) Inhibitory Activity

3.4. Hardness

3.5. Apparent Viscosity

3.6. Melting Properties

3.7. Accelerated Shelf-Life Test: Microbial Analysis

3.8. Hedonic Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Health Organization. A Global Brief on Hypertension. 2013. Available online: https://www.WHO/DCO/WHD/2013.2 (accessed on 28 October 2022).

- Tablado, M.; Angel, M. Accuracy in the diagnosis of hypertension and CKD is key to determine their possible association. Endocrine 2022, 78, 642–643. [Google Scholar] [CrossRef] [PubMed]

- Krzemińska, J.; Wronka, M.; Młynarska, E.; Franczyk, B.; Rysz, J. Arterial Hypertension—Oxidative Stress and Inflammation. Antioxidants 2022, 11, 172. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Grosse, S.D.; Schooley, M.W. Conducting Research on the Economics of Hypertension to Improve Cardiovascular Health. Am. J. Prev. Med. 2017, 53, S115–S117. [Google Scholar] [CrossRef] [PubMed]

- Kearney, P.M.; Whelton, M.; Reynolds, K.; Muntner, P.; Whelton, P.K.; He, J. Global burden of hypertension: Analysis of worldwide data. Lancet 2005, 365, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Phan, T.T.V.; Heo, S.-Y.; Jung, W.-K.; Yi, M. Spontaneous hinge-bending motions of angiotensin i converting enzyme: Role in activation and inhibition. Molecules 2020, 25, 1288. [Google Scholar] [CrossRef] [PubMed]

- Tu, J.; Liu, G.; Jin, Y.; Tang, C.; Yao, T.; Zhuo, J.; Li, Q.; Liu, L.; Wang, J. Enrichment of γ-aminobutyric acid in mulberry leaves and the inhibitory effects of the water extract on ACE and α-glucosidase activity. Ind. Crops Prod. 2022, 177, 114485. [Google Scholar] [CrossRef]

- Guiyun, C.; Yushan, W.; Mingyue, Z.; Wanxing, M.; Xixian, X.; Ye, C. Cold atmospheric plasma treatment improves the γ-aminobutyric acid content of buckwheat seeds providing a new anti-hypertensive functional ingredient. Food Chem. 2022, 388, 133064. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhou, X.; He, J.; Xie, Z.; Xia, S.; Lu, G. The roles of GABA in ischemia-reperfusion injury in the central nervous system and peripheral organs. Oxid. Med. Cell. Longev. 2019, 2019, 1–19. [Google Scholar] [CrossRef]

- Murala, S.; Yelam, A.; Ismail, M.M.; Bollu, P.C. History of GABA. In Neurochemistry in Clinical Practice; Springer: Berlin/Heidelberg, Germany, 2022; pp. 73–89. [Google Scholar]

- Luo, H.; Liu, Z.; Xie, F.; Bilal, M.; Liu, L.; Yang, R.; Wang, Z. Microbial production of gamma-aminobutyric acid: Applications, state-of-the-art achievements, and future perspectives. Crit. Rev. Biotechnol. 2021, 41, 491–512. [Google Scholar] [CrossRef]

- Ramos-Ruiz, R.; Poirot, E.; Flores-Mosquera, M. GABA, a non-protein amino acid ubiquitous in food matrices. Cogent Food Agric. 2018, 4, 1534323. [Google Scholar] [CrossRef]

- Marenco, S.; Meyer, C.; van der Veen, J.W.; Zhang, Y.; Kelly, R.; Shen, J.; Weinberger, D.R.; Dickinson, D.; Berman, K.F. Role of gamma-amino-butyric acid in the dorsal anterior cingulate in age-associated changes in cognition. Neuropsychopharmacology 2018, 43, 2285–2291. [Google Scholar] [CrossRef] [PubMed]

- Galli, V.; Venturi, M.; Mari, E.; Guerrini, S.; Granchi, L. Gamma-aminobutyric acid (GABA) production in fermented milk by lactic acid bacteria isolated from spontaneous raw milk fermentation. Int. Dairy J. 2022, 127, 105284. [Google Scholar] [CrossRef]

- Sahab, N.R.; Subroto, E.; Balia, R.L.; Utama, G.L. γ-Aminobutyric acid found in fermented foods and beverages: Current trends. Heliyon 2020, 6, e05526. [Google Scholar] [CrossRef] [PubMed]

- Pandey, P.; Mishra, H.N. Co-microencapsulation of γ-aminobutyric acid (GABA) and probiotic bacteria in thermostable and biocompatible exopolysaccharides matrix. LWT 2021, 136, 110293. [Google Scholar] [CrossRef]

- Pu, Y.; Sinclair, A.J.; Zhong, J.; Liu, D.; Song, L. Determination of ϒ-aminobutyric acid (GABA) in jujube fruit (Ziziphus jujuba Mill.). CyTA 2019, 17, 158–162. [Google Scholar] [CrossRef]

- Statista. Size of the chocolate confectionery market worldwide from 2016 to 2027. Available online: https://www.statista.com/forecasts/983554/global-chocolate-confectionery-market-size (accessed on 28 October 2022).

- Fibrianto, K.; Azhar, L.O.M.F.; Widyotomo, S.; Harijono, H. Effect of cocoa bean origin and conching time on the physicochemical and microstructural properties of Indonesian dark chocolate. Braz. J. Food Technol. 2021, 24, e2019249. [Google Scholar] [CrossRef]

- Faccinetto-Beltrán, P.; Gómez-Fernández, A.R.; Santacruz, A.; Jacobo-Velázquez, D.A. Chocolate as Carrier to Deliver Bioactive Ingredients: Current Advances and Future Perspectives. Foods 2021, 10, 2065. [Google Scholar] [CrossRef]

- Codex Alimentarius, FAO/WHO. Standard for Chocolate and Chocolate Products; CODEX STAN 87-1981; Codex Alimentarius Commission: Rome, Italy, 2003. [Google Scholar]

- Fanton, S.; Cardozo, L.F.; Combet, E.; Shiels, P.G.; Stenvinkel, P.; Vieira, I.O.; Narciso, H.R.; Schmitz, J.; Mafra, D. The sweet side of dark chocolate for chronic kidney disease patients. Clin. Nutr. 2021, 40, 15–26. [Google Scholar] [CrossRef]

- Patel, N.; Jayswal, S.; Maitreya, B.B. Dark Chocolate: Consumption for human health. J. Pharmacogn. Phytochem. 2019, 8, 2887–2890. [Google Scholar]

- Hue, C.; Gunata, Z.; Breysse, A.; Davrieux, F.; Boulanger, R.; Sauvage, F.-X. Impact of fermentation on nitrogenous compounds of cocoa beans (Theobroma cacao L.) from various origins. Food Chem. 2016, 192, 958–964. [Google Scholar] [CrossRef]

- Dala-Paula, B.M.; Deus, V.L.; Tavano, O.L.; Gloria, M.B.A. In vitro bioaccessibility of amino acids and bioactive amines in 70% cocoa dark chocolate: What you eat and what you get. Food Chem. 2021, 343, 128397. [Google Scholar] [CrossRef] [PubMed]

- Le, P.H.; Le, T.T.; Raes, K. Effects of pH and heat treatment on the stability of γ-aminobutyric acid (GABA) in germinated soymilk. J. Food Process. Preserv. 2020, 44, e14301. [Google Scholar] [CrossRef]

- Ward, J. From South America to Willy Wonka–a brief outline of the production and composition of chocolate. Chem. N. Z. 2018, 82, 71–73. [Google Scholar]

- Chandio, Z.A.; Sidiqua, A.; Khaskheli, M.I.; Waghani, A.; Metlo, W.A. Review effect of caffeine overdose. RADS J. Biol. Res. Appl. Sci. 2020, 11, 154–158. [Google Scholar] [CrossRef]

- Gammone, M.A.; D’Orazio, N. Cocoa overconsumption and cardiac rhythm: Potential arrhythmogenic trigger or beneficial pleasure? Curr. Res. Nutr. Food Sci. 2021, 9, 40–51. [Google Scholar] [CrossRef]

- Inoue, K.; Shirai, T.; Ochiai, H.; Kasao, M.; Hayakawa, K.; Kimura, M.; Sansawa, H. Blood-pressure-lowering effect of a novel fermented milk containing gamma-aminobutyric acid (GABA) in mild hypertensives. Eur. J. Clin. Nutr. 2003, 57, 490–495. [Google Scholar] [CrossRef] [PubMed]

- Nishimura, M.; Yoshida, S.-i.; Haramoto, M.; Mizuno, H.; Fukuda, T.; Kagami-Katsuyama, H.; Tanaka, A.; Ohkawara, T.; Sato, Y.; Nishihira, J. Effects of white rice containing enriched gamma-aminobutyric acid on blood pressure. eJTCM 2016, 6, 66–71. [Google Scholar] [CrossRef]

- Zareian, M.; Oskoueian, E.; Majdinasab, M.; Forghani, B. Production of GABA-enriched idli with ACE inhibitory and antioxidant properties using Aspergillus oryzae: The antihypertensive effects in spontaneously hypertensive rats. Food Funct. 2020, 11, 4304–4313. [Google Scholar] [CrossRef]

- Kawakami, K.; Yamada, K.; Yamada, T.; Nabika, T.; Nomura, M. Antihypertensive effect of γ-aminobutyric acid-enriched brown rice on spontaneously hypertensive rats. J. Nutr. Sci. Vitaminol. 2018, 64, 56–62. [Google Scholar] [CrossRef]

- Ibrahim, S.F.; Dalek, N.E.M.; Raffie, Q.F.M.; Ain, M.F. Quantification of physicochemical and microstructure properties of dark chocolate incorporated with palm sugar and dates as alternative sweetener. Mater. Today Proc. 2020, 31, 366–371. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Chen, Y.; Liu, W.; Xue, J.; Yang, J.; Chen, X.; Shao, Y.; Kwok, L.-y.; Bilige, M.; Mang, L.; Zhang, H. Angiotensin-converting enzyme inhibitory activity of Lactobacillus helveticus strains from traditional fermented dairy foods and antihypertensive effect of fermented milk of strain H9. J. Dairy Sci. 2014, 97, 6680–6692. [Google Scholar] [CrossRef] [PubMed]

- McGill, J.; Hartel, R.W. Water relations in confections. In Water Activity in Foods: Fundamentals and Applications; Wiley: New York, NY, USA, 2020; pp. 483–500. [Google Scholar]

- Cahyani, A.; Kurniasari, J.; Nafingah, R.; Rahayoe, S.; Harmayani, E.; Saputro, A.D. Determining casson yield value, casson viscosity and thixotropy of molten chocolate using viscometer. IOP Conf. Ser. Earth Environ. Sci. 2019, 355, 012041. [Google Scholar] [CrossRef]

- Goktas, H.; Konar, N.; Sagdic, O.; Toker, O.S. Investigation effects of inulin degree of polymerization on compound chocolate quality. J. Food Process. Preserv. 2021, 45, e15766. [Google Scholar] [CrossRef]

- Phimolsiripol, Y.; Suppakul, P. Techniques in shelf-life evaluation of food products. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–8. [Google Scholar]

- Ramdany, R.; Rachmawati, Y.; Supu, L.; Mallongi, A. The effect of substitution of purple sweet potato flour and tempeh on organoleptic quality of MP-ASI biscuit. Syst. Rev. Pharm. 2020, 11, 957–961. [Google Scholar]

- Pero, M.; Borhani, B.; Parvian, S.K.; Rashidi, R.; Jafari Asl, M. Substitution of sucrose with HFCS-55 in the formulation of chocolate syrup: Effects on the physicochemical and sensorial properties. J. Food Process. Preserv. 2022, 46, e16422. [Google Scholar] [CrossRef]

- Kuswari, M.; Gifari, N.; Nuzrina, R.; Justickarin, S.; Fathiya, A.; Hutasuhut, F. Analysis of protein content on commercial protein supplement in Indonesia. JUARA J. Olahraga 2021, 6, 207–212. [Google Scholar] [CrossRef]

- Joseph, C.; Batra, R.; Selvasekaran, P.; Chidambaram, R. Low calorie cocoa-based products: A short review. JFST 2021, 59, 2931–2939. [Google Scholar] [CrossRef]

- Kim, S.M.; Woo, J.H.; Kim, H.W.; Park, H.J. Formulation and evaluation of cold-extruded chocolate ganache for three-dimensional food printing. J. Food Eng. 2022, 314, 110785. [Google Scholar] [CrossRef]

- EC (European Commission). Commission Regulation (EC) No 1924/2006 of 20 December 2006 on Nutrition and Health Claims Made on Foods. Available online: http://data.europa.eu/eli/reg/2006/1924/oj (accessed on 28 October 2022).

- Melo, C.W.B.d.; Bandeira, M.d.J.; Maciel, L.F.; Bispo, E.d.S.; Souza, C.O.d.; Soares, S.E. Chemical composition and fatty acids profile of chocolates produced with different cocoa (Theobroma cacao L.) cultivars. Food Sci.Technol. 2020, 40, 326–333. [Google Scholar] [CrossRef]

- Kruszewski, B.; Obiedziński, M.W. Multivariate analysis of essential elements in raw cocoa and processed chocolate mass materials from three different manufacturers. LWT 2018, 98, 113–123. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA). Available online: https://fdc.nal.usda.gov/fdc-app.html#/?query=dark%20chocolate (accessed on 28 October 2022).

- U.S. Code of Federal Regulations. Title 40, Parts 180. Available online: https://www.ecfr.gov/current/title-40/chapter-I/subchapter-E/part-180/subpart-D/section-180.1188 (accessed on 28 October 2022).

- JECFA (Joint FAO/WHO Expert Committee on Food Additives World Health Organization). Evaluation of Certain Food Additives and Contaminants: Sixty-First Report of the Joint FAO/WHO Expert Committee on Food Additives; World Health Organization: Geneva, Switzerland, 2004; Volume 61. [Google Scholar]

- Natural and Non-Prescription Health Products Directorate (NNHPD). Natural Health Products Ingredients Database. 4-Aminobutanoic Acid. Group 7: Ingredients with Relaxation Action. 2021. Available online: http://webprod.hc-sc.gc.ca/nhpid-bdipsn/atReq.do?atid=fonc.cognitive.func&lang=eng (accessed on 28 October 2022).

- Monthly Index of Medical Specialities (MIMS). Aminobutyric Acid. Available online: https://www.mims.com/malaysia/drug/info/aminobutyric%20acid?mtype=generic (accessed on 28 October 2022).

- Bruhns, P.; Kanzler, C.; Degenhardt, A.G.; Koch, T.J.; Kroh, L.W. Basic structure of melanoidins formed in the Maillard reaction of 3-deoxyglucosone and γ-aminobutyric acid. J. Agric. Food Chem. 2019, 67, 5197–5203. [Google Scholar] [CrossRef] [PubMed]

- Ji, D.; Ma, H.; Chen, X. Ultrasonication increases γ-aminobutyric acid accumulation in coffee leaves and affects total phenolic content and angiotensin-converting enzyme inhibitory activity. J. Food Process. Preserv. 2021, 45, e15777. [Google Scholar] [CrossRef]

- Suri, T.; Basu, S. Heat resistant chocolate development for subtropical and tropical climates: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 5603–5622. [Google Scholar] [CrossRef] [PubMed]

- Lončarević, I.; Pajin, B.; Fišteš, A.; Šaponjac, V.T.; Petrović, J.; Jovanović, P.; Vulić, J.; Zarić, D. Enrichment of white chocolate with blackberry juice encapsulate: Impact on physical properties, sensory characteristics and polyphenol content. LWT 2018, 92, 458–464. [Google Scholar] [CrossRef]

- Toker, O.S.; Konar, N.; Pirouzian, H.R.; Oba, S.; Polat, D.G.; Palabiyik, I.; Poyrazoglu, E.S.; Sagdic, O. Developing functional white chocolate by incorporating different forms of EPA and DHA-Effects on product quality. LWT 2018, 87, 177–185. [Google Scholar] [CrossRef]

- Sun, P.; Xia, B.; Ni, Z.-J.; Wang, Y.; Elam, E.; Thakur, K.; Ma, Y.-L.; Wei, Z.-J. Characterization of functional chocolate formulated using oleogels derived from β-sitosterol with γ-oryzanol/lecithin/stearic acid. Food Chem. 2021, 360, 130017. [Google Scholar] [CrossRef]

- Saglio, A.; Bourgeay, J.; Socrate, R.; Canette, A.; Cuvelier, G. Understanding the structure of ganache: Link between composition and texture. Int. J. Gastron. Food Sci. 2018, 13, 29–37. [Google Scholar] [CrossRef]

- Ozturk, B.; Elvan, M.; Ozer, M.; Harsa, S.T. Effect of different microencapsulating materials on the viability of S. thermophilus CCM4757 incorporated into dark and milk chocolates. Food Biosci. 2021, 44, 101413. [Google Scholar] [CrossRef]

- Gadhiya, D.; Shah, N.; Patel, A.; Prajapati, J. Preparation and shelf-life study of probiotic chocolate manufactured using Lactobacillus helveticus MTCC 5463. Acta Aliment. 2018, 47, 350–358. [Google Scholar] [CrossRef]

- Food and Drug Administration (FDA). Revised Guidelines for the Assessment of Microbiological Quality of Processed Foods. No. 2013-010; 2013. Available online: https://www.fda.gov.ph/wp-content/uploads/2021/03/FDA-Circular-No.-2013-010.pdf (accessed on 27 December 2022).

- International Commission on Microbiological Specifications for Foods (ICMSF). Microorganisms in Foods 5: Microbiological Specifications of Pathogens; Blackie Academic & Professional: London, UK, 1996; pp. 141–182. [Google Scholar]

- Halim, H.S.a.A.; Selamat, J.; Mirhosseini, S.H.; Hussain, N. Sensory preference and bloom stability of chocolate containing cocoa butter substitute from coconut oil. J. Saudi Soc. Agric. Sci. 2019, 18, 443–448. [Google Scholar]

- Sethupathy, P.; Priyadarshini, S.; Moses, J.A.; Anandharamakrishnan, C. Matrix-dependent oral processing, oro-sensory perception, and glycemic index of chocolate bars. J. Food Process. Preserv. 2021, 45, e16067. [Google Scholar] [CrossRef]

- Hwang, L.-D.; Lin, C.; Gharahkhani, P.; Cuellar-Partida, G.; Ong, J.-S.; An, J.; Gordon, S.D.; Zhu, G.; MacGregor, S.; Lawlor, D.A. New insight into human sweet taste: A genome-wide association study of the perception and intake of sweet substances. AJCN 2019, 109, 1724–1737. [Google Scholar] [CrossRef] [PubMed]

| Formulations | Ingredients (% w/w) | ||||

|---|---|---|---|---|---|

| Sugar Syrup | Cocoa Powder | Cocoa Butter | GABA | Lecithin | |

| C | 45.00 | 27.50 | 27.00 | 0.00 | 0.50 |

| F1 | 44.95 | 27.50 | 27.00 | 0.05 | 0.50 |

| F2 | 44.90 | 27.50 | 27.00 | 0.10 | 0.50 |

| F3 | 44.85 | 27.50 | 27.00 | 0.15 | 0.50 |

| Formulations | Nutritional Content (%) | ||||||

|---|---|---|---|---|---|---|---|

| Moisture | Protein | Fat | Fibre | Ash | Carbohydrate | Calorie (kcal) | |

| C | 15.89 ± 0.06 a | 6.37 ± 0.01 c | 29.48 ± 0.77 a | 14.73 ± 0.23 a | 2.24 ± 0.06 a | 31.29 ± 0.87 a | 415.97 ± 3.48 a |

| F1 | 15.78 ± 0.04 ab | 6.39 ± 0.01 bc | 31.10 ± 0.98 a | 14.70 ± 0.16 a | 2.31 ± 0.14 a | 29.73 ± 0.76 a | 424.34 ± 5.88 a |

| F2 | 15.61 ± 0.07 b | 6.41 ± 0.01 ab | 29.47 ± 0.74 a | 14.77 ± 0.9 a | 2.25 ± 0.13 a | 31.49 ± 0.86 a | 416.77 ± 3.34 a |

| F3 | 15.34 ± 0.10 c | 6.43 ± 0.01 a | 30.80 ± 1.05 a | 14.73 ± 0.13 a | 2.32 ± 0.09 a | 30.38 ± 1.26 a | 424.47 ± 5.32 a |

| Formulations | Concentration of GABA (mg/100 g) |

|---|---|

| C | 8.23 ± 0.14 b |

| F1 | 11.60 ± 0.51 b |

| F2 | 16.96 ± 2.11 ab |

| F3 | 21.09 ± 4.99 a |

| Formulations | ACE Inhibition (%) |

|---|---|

| C | 54.41 ± 0.90 d |

| F1 | 62.20 ± 0.89 c |

| F2 | 71.02 ± 1.14 b |

| F3 | 79.54 ± 1.53 a |

| Formulations | Hardness (g) |

|---|---|

| C | 468.10 ± 10.77 d |

| F1 | 618.57 ± 7.93 c |

| F2 | 845.36 ± 20.07 b |

| F3 | 923.41 ± 41.81 a |

| Formulations | Apparent Viscosity (104 mPa∙s) | ||||||

|---|---|---|---|---|---|---|---|

| 10 rpm | 12 rpm | 20 rpm | 30 rpm | 50 rpm | 60 rpm | 100 rpm | |

| C | 34.17 ± 2.61 a | 14.63 ± 0.79 a | 6.95 ± 0.45 a | 2.89 ± 0.18 a | 1.57 ± 0.43 a | 0.56 ± 0.06 a | 0.31 ± 0.06 a |

| F1 | 30.24 ± 0.48 a | 14.76 ± 1.27 a | 7.07 ± 0.097 a | 2.80 ± 0.20 a | 1.44 ± 0.07 a | 0.47 ± 0.01 a | 0.19 ± 0.01 a |

| F2 | 19.44 ± 4.50 a | 14.42 ± 3.14 a | 4.99 ± 11.01 a | 2.20 ± 0.73 a | 0.92 ± 0.26 a | 0.55 ± 0.17 a | 0.24 ± 0.08 a |

| F3 | 17.03 ± 0.39 a | 12.92 ± 0.71 a | 4.97 ± 0.44 a | 1.75 ± 0.19 a | 0.74 ± 0.08 a | 0.61 ± 0.02 a | 0.29 ± 0.01 a |

| Formulations | Tonset (°C) | Tpeak (°C) | Tend (°C) | ΔHmelt (J/g) |

|---|---|---|---|---|

| C | 30.65 ± 0.69 a | 33.45 ± 0.50 a | 35.70 ± 0.48 a | 22.35 ± 1.32 a |

| F1 | 31.00 ± 0.15 a | 33.47 ± 0.21 a | 35.42 ± 0.61 a | 20.48 ± 8.41 a |

| F2 | 31.03 ± 0.15 a | 33.53 ± 1.09 a | 35.82 ± 0.75 a | 30.29 ± 1.55 a |

| F3 | 31.97 ± 1.78 a | 33.61 ± 0.16 a | 35.04 ± 0.45 a | 24.33 ± 0.19 a |

| Formulations | Storage Period (Day) | |||||||||||

| 1 | 6 | 8 | 13 | 15 | 21 | |||||||

| 20 °C | 30 °C | 20 °C | 30 °C | 20 °C | 30 °C | 20 °C | 30 °C | 20 °C | 30 °C | 20 °C | 30 °C | |

| Bacteria Count (CFU/g) | ||||||||||||

| C | - | - | - | - | TNTC | - | - | 7.5×10−3 | 2.1 × 10−1 | 1.2 × 10−3 | 4.4 × 10−1 | 1.3 × 10−1 |

| F1 | - | - | TNTC | - | - | TNTC | 2.9 × 10−2 | 4.5 × 10−3 | 7.7 × 10−2 | 1.2 × 10−2 | 8.7 × 10−2 | 2.3 × 100 |

| F2 | - | - | - | - | - | - | 2.9 × 10−2 | TNTC | 1.1 × 100 | 1.2 × 10−2 | 2.0 × 100 | 2.1 × 10−1 |

| F3 | - | - | - | - | 1.4 × 10−2 | 5.8 × 10−2 | 1.7 × 10−1 | 1.6 × 10−2 | 2.3 × 10−1 | 1.2 × 100 | 2.3 × 100 | 2.7 × 100 |

| Yeast and mould count (CFU/g) | ||||||||||||

| C | - | - | TNTC | TNTC | TNTC | - | - | - | 1.7 × 100 | 6.7 × 10−3 | 2.3 × 100 | 9.5 × 10−1 |

| F1 | - | - | TNTC | - | TNTC | TNTC | 1.7 × 10−2 | 2.4 × 10−3 | 1.7 × 10−2 | 1.1 × 10−2 | 1.0 × 10−1 | 2.0 × 100 |

| F2 | - | - | TNTC | TNTC | TNTC | - | 9.5 × 10−2 | - | 1.1 × 10−1 | 1.4 × 10−2 | 2.1 × 100 | 2.0 × 100 |

| F3 | - | - | TNTC | - | 9.2 × 10−3 | - | 1.4 × 10−1 | 6.6 × 10−3 | 1.4 × 10−1 | 8.4 × 10−2 | 2.3 × 100 | 2.9 × 100 |

| Formulations | Sensory Attributes | ||||

|---|---|---|---|---|---|

| Appearance: Glossiness | Texture: Hardness | Mouthfeel: Melting Rate | Taste: Bittersweetness | Overall Acceptability | |

| C | 4.91 ± 1.25 a | 4.46 ± 1.94 a | 5.07 ± 0.24 a | 5.02 ± 0.19 a | 5.60 ± 0.19 a |

| F1 | 4.80 ± 1.41 a | 4.30 ± 0.25 a | 5.25 ± 0.21 a | 4.96 ± 0.21 a | 5.37 ± 0.15 a |

| F2 | 4.93 ± 1.46 a | 4.51 ± 0.22 a | 4.82 ± 0.21 a | 5.03 ± 0.19 a | 5.51 ± 0.17 a |

| F3 | 4.73 ± 1.46 a | 4.81 ± 0.20 a | 4.55 ± 0.19 a | 4.70 ± 0.17 a | 5.40 ± 0.18 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koh, W.Y.; Lim, X.X.; Teoh, E.S.W.; Kobun, R.; Rasti, B. The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate. Foods 2023, 12, 213. https://doi.org/10.3390/foods12010213

Koh WY, Lim XX, Teoh ESW, Kobun R, Rasti B. The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate. Foods. 2023; 12(1):213. https://doi.org/10.3390/foods12010213

Chicago/Turabian StyleKoh, Wee Yin, Xiao Xian Lim, Eva Sheue Wen Teoh, Rovina Kobun, and Babak Rasti. 2023. "The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate" Foods 12, no. 1: 213. https://doi.org/10.3390/foods12010213

APA StyleKoh, W. Y., Lim, X. X., Teoh, E. S. W., Kobun, R., & Rasti, B. (2023). The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate. Foods, 12(1), 213. https://doi.org/10.3390/foods12010213