Spray Drying Encapsulation of Pediococcus acidilactici at Different Inlet Air Temperatures and Wall Material Ratios

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Culture

2.2. Culture Preparation for Spray Drying

2.3. Viable Cell Counting

2.4. Spray Drying

2.5. Viability Loss

2.6. Gastrointestinal Simulation

2.7. Storage Test

2.8. Physicochemical Analysis

2.9. Data Analysis

3. Results and Discussion

3.1. Survivability of Spray-Dried P. acidilactici

3.2. Production Yield, Moisture Content, and Water Activity of Spray-Dried P. acidilactici

3.3. Survival of P. acidilactici in Simulated GIT

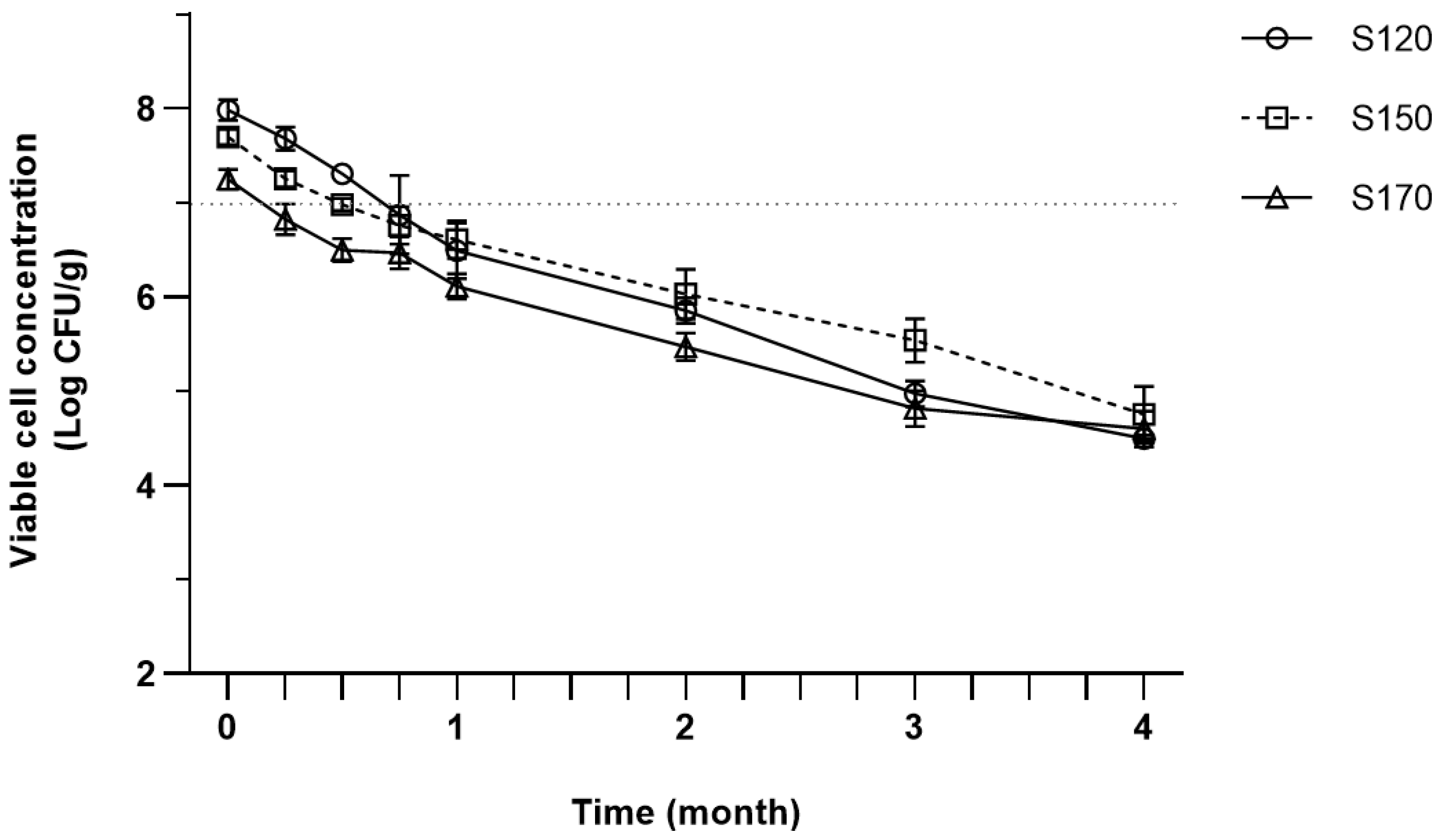

3.4. Survival of Spray-Dried P. acidilactici during Storage

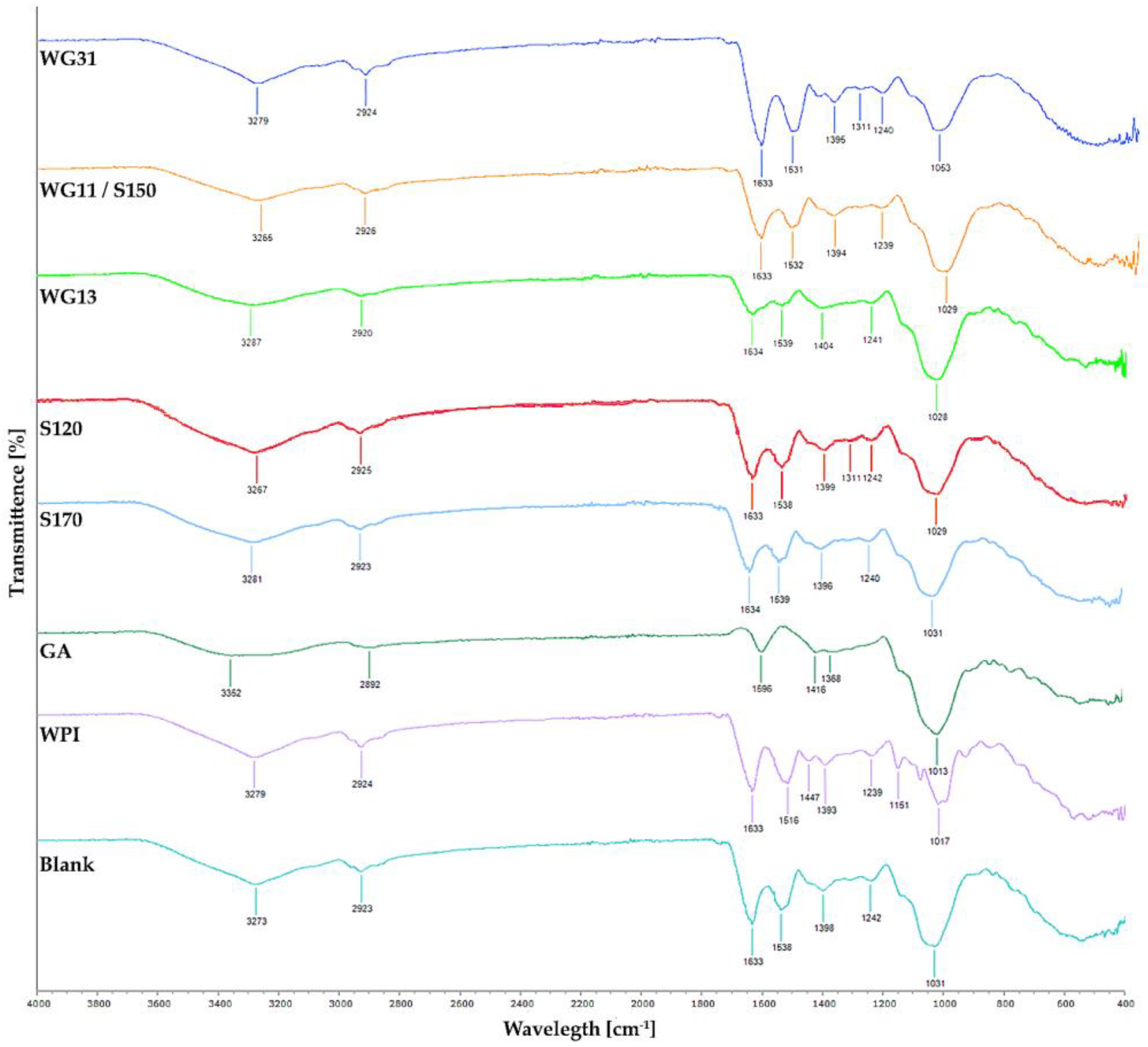

3.5. FT-IR Analysis of Spray-Dried P. acidilactici

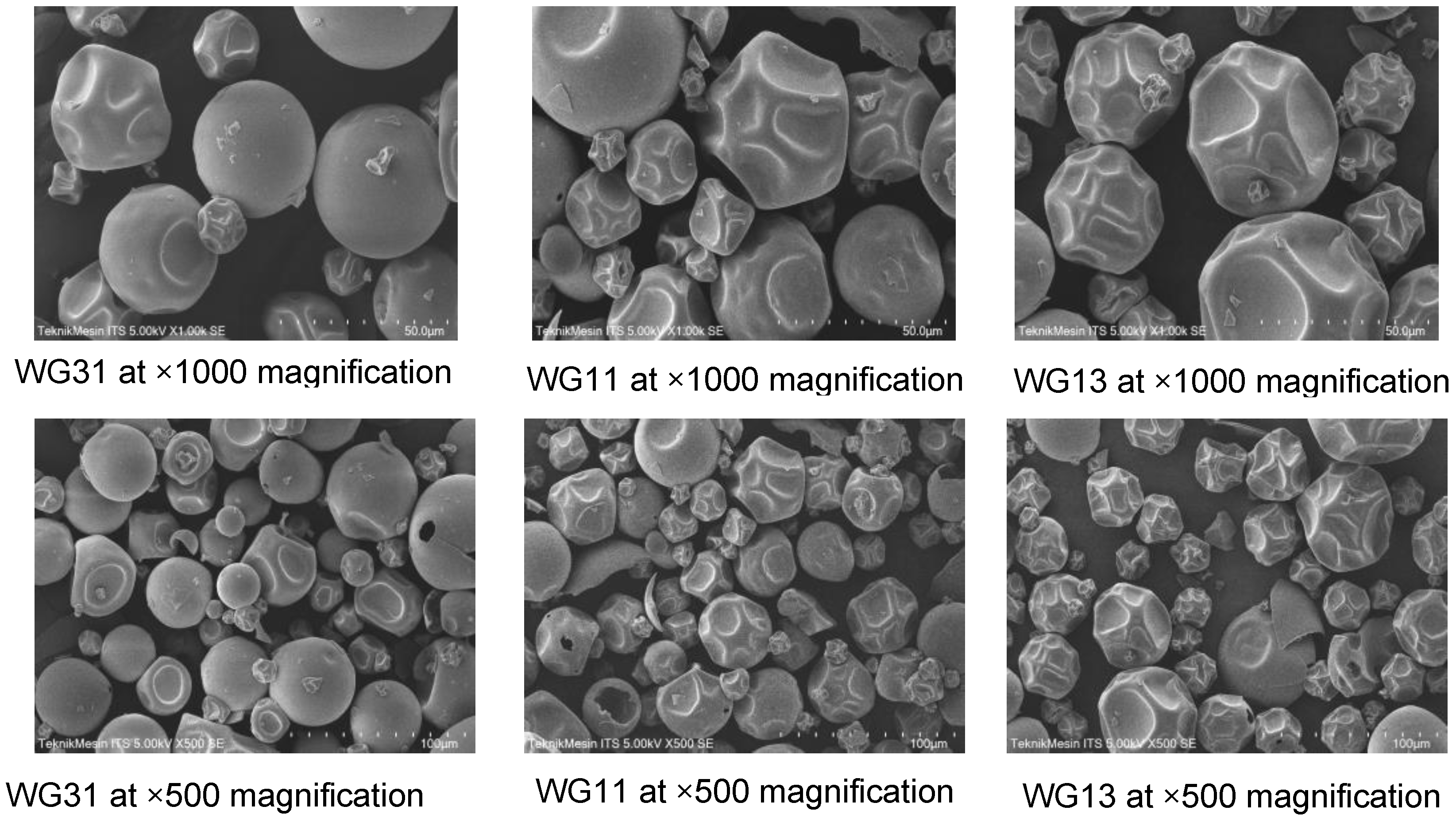

3.6. SEM Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kechagia, M.; Basoulis, D.; Konstantopoulou, S.; Dimitriadi, D.; Gyftopoulou, K.; Skarmoutsou, N.; Fakiri, E.M. Health Benefits of Probiotics: A Review. ISRN Nutr. 2013, 2013, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Huq, T.; Vu, K.D.; Riedl, B.; Bouchard, J.; Han, J.; Lacroix, M. Development of Probiotic Tablet Using Alginate, Pectin, and Cellulose Nanocrystals as Excipients. Cellulose 2016, 23, 1967–1978. [Google Scholar] [CrossRef]

- Lourens-Hattingh, A.; Viljoen, B.C. Yogurt as Probiotic Carrier Food. Int. Dairy J. 2001, 11, 1–17. [Google Scholar] [CrossRef]

- Rolim, F.R.L.; Freitas Neto, O.C.; Oliveira, M.E.G.; Oliveira, C.J.B.; Queiroga, R.C.R.E. Cheeses as Food Matrixes for Probiotics: In Vitro and in Vivo Tests. Trends Food Sci. Technol. 2020, 100, 138–154. [Google Scholar] [CrossRef]

- Ogunremi, O.R.; Agrawal, R.; Sanni, A.I. Development of Cereal-based Functional Food Using Cereal-mix Substrate Fermented with Probiotic Strain—Pichia Kudriavzevii OG32. Food Sci. Nutr. 2015, 3, 486–494. [Google Scholar] [CrossRef]

- Mirković, M.; Seratlić, S.; Kilcawley, K.; Mannion, D.; Mirković, N.; Radulović, Z. The Sensory Quality and Volatile Profile of Dark Chocolate Enriched with Encapsulated Probiotic Lactobacillus Plantarum Bacteria. Sensors 2018, 18, 2570. [Google Scholar] [CrossRef]

- Dias, C.O.; dos Santos Opuski de Almeida, J.; Pinto, S.S.; de Oliveira Santana, F.C.; Verruck, S.; Müller, C.M.O.; Prudêncio, E.S.; de Mello Castanho Amboni, R.D. Development and Physico-Chemical Characterization of Microencapsulated Bifidobacteria in Passion Fruit Juice: A Functional Non-Dairy Product for Probiotic Delivery. Food Biosci. 2018, 24, 26–36. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Giri, S.K. Probiotic Functional Foods: Survival of Probiotics during Processing and Storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Corona-Hernandez, R.I.; Álvarez-Parrilla, E.; Lizardi-Mendoza, J.; Islas-Rubio, A.R.; de la Rosa, L.A.; Wall-Medrano, A. Structural Stability and Viability of Microencapsulated Probiotic Bacteria: A Review. Compr. Rev. Food Sci. Food Safety 2013, 12, 614–628. [Google Scholar] [CrossRef]

- Chean, S.X.; Hoh, P.Y.; How, Y.H.; Nyam, K.L.; Pui, L.P. Microencapsulation of Lactiplantibacillus Plantarum with Inulin and Evaluation of Survival in Simulated Gastrointestinal Conditions and Roselle Juice. Braz. J. Food Technol. 2021, 24. [Google Scholar] [CrossRef]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. The International Scientific Association for Probiotics and Prebiotics Consensus Statement on the Scope and Appropriate Use of the Term Probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef]

- Villamil, L.; Figueras, A.; Planas, M.; Novoa, B. Pediococcus Acidilactici in the Culture of Turbot (Psetta Maxima) Larvae: Administration Pathways. Aquaculture 2010, 307, 83–88. [Google Scholar] [CrossRef]

- Yavorov-Dayliev, D.; Milagro, F.I.; Ayo, J.; Oneca, M.; Aranaz, P. Pediococcus Acidilactici CECT9879 (PA1c) Counteracts the Effect of a High-Glucose Exposure in C. Elegans by Affecting the Insulin Signaling Pathway (IIS). Int. J. Mol. Sci. 2022, 23, 2689. [Google Scholar] [CrossRef]

- Abbasiliasi, S.; Tan, J.S.; Bashokouh, F.; Ibrahim, T.A.T.; Mustafa, S.; Vakhshiteh, F.; Sivasamboo, S.; Ariff, A.B. In Vitro Assessment of Pediococcus Acidilactici Kp10 for Its Potential Use in the Food Industry. BMC Microbiol. 2017, 17, 121. [Google Scholar] [CrossRef]

- Hasan, M.T.; Je Jang, W.; Lee, J.M.; Lee, B.-J.; Hur, S.W.; Gu Lim, S.; Kim, K.W.; Han, H.-S.; Kong, I.-S. Effects of Immunostimulants, Prebiotics, Probiotics, Synbiotics, and Potentially Immunoreactive Feed Additives on Olive Flounder (Paralichthys Olivaceus): A Review. Rev. Fish. Sci. Aquac. 2019, 27, 417–437. [Google Scholar] [CrossRef]

- Porto, M.C.W.; Kuniyoshi, T.M.; Azevedo, P.O.S.; Vitolo, M.; Oliveira, R.P.S. Pediococcus Spp.: An Important Genus of Lactic Acid Bacteria and Pediocin Producers. Biotechnol. Adv. 2017, 35, 361–374. [Google Scholar] [CrossRef]

- Marlida, Y.; Wizna, W.; Jamsari, J.; Mirzah, M.; Anggraini, L. Optimization of Nutrient Medium for Pediococcus Acidilactici DS15 to Produce GABA. J. Worlds Poult Res. 2019, 9, 139–146. [Google Scholar] [CrossRef]

- Merrifield, D.L.; Bradley, G.; Harper, G.M.; Baker, R.T.M.; Munn, C.B.; Davies, S.J. Assessment of the Effects of Vegetative and Lyophilized Pediococcus Acidilactici on Growth, Feed Utilization, Intestinal Colonization and Health Parameters of Rainbow Trout (Oncorhynchus Mykiss Walbaum). Aquac. Nutr. 2011, 17, 73–79. [Google Scholar] [CrossRef]

- Standen, B.T.; Rawling, M.D.; Davies, S.J.; Castex, M.; Foey, A.; Gioacchini, G.; Carnevali, O.; Merrifield, D.L. Probiotic Pediococcus Acidilactici Modulates Both Localised Intestinal- and Peripheral-Immunity in Tilapia (Oreochromis Niloticus). Fish Shellfi. Immunol. 2013, 35, 1097–1104. [Google Scholar] [CrossRef]

- Ruiz-Moyano, S.; Martín, A.; Benito, M.J.; Hernández, A.; Casquete, R.; de Guia Córdoba, M. Application of Lactobacillus Fermentum HL57 and Pediococcus Acidilactici SP979 as Potential Probiotics in the Manufacture of Traditional Iberian Dry-Fermented Sausages. Food Microbiol. 2011, 28, 839–847. [Google Scholar] [CrossRef]

- Barbosa, J.; Borges, S.; Amorim, M.; Pereira, M.J.; Oliveira, A.; Pintado, M.E.; Teixeira, P. Comparison of Spray Drying, Freeze Drying and Convective Hot Air Drying for the Production of a Probiotic Orange Powder. J. Funct. Foods 2015, 17, 340–351. [Google Scholar] [CrossRef]

- Cristiny de Oliveira Vieira, K.; da Silva Ferreira, C.; Toso Bueno, E.B.; de Moraes, Y.A.; Campagnolo Gonçalves Toledo, A.C.; Nakagaki, W.R.; Pereira, V.C.; Winkelstroter, L.K. Development and Viability of Probiotic Orange Juice Supplemented by Pediococcus Acidilactici CE51. LWT 2020, 130, 109637. [Google Scholar] [CrossRef]

- İncili, G.K.; Karatepe, P.; İlhak, O.İ. Effect of Chitosan and Pediococcus Acidilactici on E. Coli O157:H7, Salmonella Typhimurium and Listeria Monocytogenes in Meatballs. LWT 2020, 117, 108706. [Google Scholar] [CrossRef]

- Sangami, R.; Radhai Sri, S. Emerging Trends in Improving Viability, Advanced Stability Techniques and Health Claims of Healthy Microbiome—The Probiotics. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 194–200. [Google Scholar] [CrossRef][Green Version]

- Fiocco, D.; Longo, A.; Arena, M.P.; Russo, P.; Spano, G.; Capozzi, V. How Probiotics Face Food Stress: They Get by with a Little Help. Crit. Rev. Food Sci. Nutr. 2020, 60, 1552–1580. [Google Scholar] [CrossRef]

- Fernandez, B.; Hammami, R.; Savard, P.; Jean, J.; Fliss, I. Pediococcus Acidilactici UL5 and Lactococcus Lactis ATCC 11454 Are Able to Survive and Express Their Bacteriocin Genes under Simulated Gastrointestinal Conditions. J. Appl. Microbiol. 2014, 116, 677–688. [Google Scholar] [CrossRef]

- Ranadheera, C.S.; Evans, C.A.; Baines, S.K.; Balthazar, C.F.; Cruz, A.G.; Esmerino, E.A.; Freitas, M.Q.; Pimentel, T.C.; Wittwer, A.E.; Naumovski, N.; et al. Probiotics in Goat Milk Products: Delivery Capacity and Ability to Improve Sensory Attributes. Compr. Rev. Food Sci. Food Saf. 2019, 18, 867–882. [Google Scholar] [CrossRef]

- Fu, N.; Huang, S.; Xiao, J.; Chen, X.D. Producing Powders Containing Active Dry Probiotics With the Aid of Spray Drying. Adv. Food Nutr. Res. 2018, 85, 211–262. [Google Scholar]

- Lipan, L.; Rusu, B.; Sendra, E.; Hernández, F.; Vázquez-Araújo, L.; Vodnar, D.C.; Carbonell-Barrachina, Á.A. Spray Drying and Storage of Probiotic-enriched Almond Milk: Probiotic Survival and Physicochemical Properties. J. Sci. Food Agric. 2020, 100, 3697–3708. [Google Scholar] [CrossRef]

- Santos Monteiro, S.; Albertina Silva Beserra, Y.; Miguel Lisboa Oliveira, H.; Pasquali, M. Production of Probiotic Passion Fruit (Passiflora Edulis Sims f. Flavicarpa Deg.) Drink Using Lactobacillus Reuteri and Microencapsulation via Spray Drying. Foods 2020, 9, 335. [Google Scholar] [CrossRef]

- Huang, S.; Vignolles, M.-L.; Chen, X.D.; le Loir, Y.; Jan, G.; Schuck, P.; Jeantet, R. Spray Drying of Probiotics and Other Food-Grade Bacteria: A Review. Trends Food Sci. Technol. 2017, 63, 1–17. [Google Scholar] [CrossRef]

- Tao, T.; Ding, Z.; Hou, D.; Prakash, S.; Zhao, Y.; Fan, Z.; Zhang, D.; Wang, Z.; Liu, M.; Han, J. Influence of Polysaccharide as Co-Encapsulant on Powder Characteristics, Survival and Viability of Microencapsulated Lactobacillus Paracasei Lpc-37 by Spray Drying. J. Food Eng. 2019, 252, 10–17. [Google Scholar] [CrossRef]

- Santos, D.; Mauricio, A.C.; Sencadas, V.; Santos, J.D.; Fernandes, M.H.; Gomes, P.S. Spray Drying: An Overview. Biomaterials-Physics and Chemistry-New Edition; Pignatello, R., Musumeci, T., Eds.; IntechOpen: London, UK, 2018; pp. 9–35. [Google Scholar]

- Selvamuthukumaran, M. Handbook on Spray Drying Applications for Food Industries, 1st ed.; Selvamuthukumaran, M., Ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9780429055133. [Google Scholar]

- Makinen, K.; Berger, B.; Bel-Rhlid, R.; Ananta, E. Science and Technology for the Mastership of Probiotic Applications in Food Products. J. Biotechnol. 2012, 162, 356–365. [Google Scholar] [CrossRef]

- Rajam, R.; Anandharamakrishnan, C. Microencapsulation of Lactobacillus Plantarum (MTCC 5422) with Fructooligosaccharide as Wall Material by Spray Drying. LWT Food Sci. Technol. 2015, 60, 773–780. [Google Scholar] [CrossRef]

- Fazilah, N.F.; Hamidon, N.H.; Ariff, A.B.; Khayat, M.E.; Wasoh, H.; Halim, M. Microencapsulation of Lactococcus Lactis Gh1 with Gum Arabic and Synsepalum Dulcificum via Spray Drying for Potential Inclusion in Functional Yogurt. Molecules 2019, 24, 1422. [Google Scholar] [CrossRef]

- Kandansamy, K.; Somasundaram, P.D. Microencapsulation of Colors by Spray Drying—A Review. Int. J. Food Eng. 2012, 8. [Google Scholar] [CrossRef]

- Flores-Belmont, I.A.; Palou, E.; López-Malo, A.; Jiménez-Munguía, M.T. Simple and Double Microencapsulation of Lactobacillus Acidophilus with Chitosan Using Spray Drying. Int. J. Food Stud. 2015, 4. [Google Scholar] [CrossRef]

- Ortega, R.; Vandeker, V. Comparative Viability of Spray Dried Lactobacilli Affected by Different Protective Agents and Storage Conditions. Master Thesis, Louisiana State University and Agricultural & Mechanical College, Baton Rouge, LA, USA, 2017. [Google Scholar]

- Chew, S.-C.; Tan, C.-H.; Pui, L.-P.; Chong, P.N.; Gunasekaran, B.; Lin, N.K. Encapsulation Technologies: A Tool for Functional Foods Development. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 154–162. [Google Scholar]

- Perdana, J.; Bereschenko, L.; Fox, M.B.; Kuperus, J.H.; Kleerebezem, M.; Boom, R.M.; Schutyser, M.A.I. Dehydration and Thermal Inactivation of Lactobacillus Plantarum WCFS1: Comparing Single Droplet Drying to Spray and Freeze Drying. Food Res. Int. 2013, 54, 1351–1359. [Google Scholar] [CrossRef]

- Chandralekha, A.; Rani, A.; Tavanandi, H.A.; Amrutha, N.; Hebbar, U.; Raghavarao, K.S.M.S. Role of Carrier Material in Encapsulation of Yeast (Saccharomyces cerevisiae) by Spray Drying. Dry. Technol. 2017, 35, 1029–1042. [Google Scholar] [CrossRef]

- Leylak, C.; Özdemir, K.S.; Gurakan, G.C.; Ogel, Z.B. Optimisation of Spray Drying Parameters for Lactobacillus Acidophilus Encapsulation in Whey and Gum Arabic: Its Application in Yoghurt. Int. Dairy J. 2021, 112, 104865. [Google Scholar] [CrossRef]

- Krunić, T.Ž.; Obradović, N.S.; Rakin, M.B. Application of Whey Protein and Whey Protein Hydrolysate as Protein Based Carrier for Probiotic Starter Culture. Food Chem. 2019, 293, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Klein, M.; Aserin, A.; Ben Ishai, P.; Garti, N. Interactions between Whey Protein Isolate and Gum Arabic. Colloids Surf. B Biointerfaces 2010, 79, 377–383. [Google Scholar] [CrossRef]

- Arslan, S.; Erbas, M.; Tontul, I.; Topuz, A. Microencapsulation of Probiotic Saccharomyces Cerevisiae Var. Boulardii with Different Wall Materials by Spray Drying. LWT Food Sci. Technol. 2015, 63, 685–690. [Google Scholar] [CrossRef]

- Miles, A.A.; Misra, S.S.; Irwin, J.O. The Estimation of the Bactericidal Power of the Blood. Epidemiol. Infect. 1938, 38, 732–749. [Google Scholar] [CrossRef] [PubMed]

- Eckert, C.; Serpa, V.G.; Felipe dos Santos, A.C.; Marinês da Costa, S.; Dalpubel, V.; Lehn, D.N.; Volken de Souza, C.F. Microencapsulation of Lactobacillus Plantarum ATCC 8014 through Spray Drying and Using Dairy Whey as Wall Materials. LWT Food Sci. Technol. 2017, 82, 176–183. [Google Scholar] [CrossRef]

- Aponte, M.; Troianiello, G.D.; di Capua, M.; Romano, R.; Blaiotta, G. Impact of Different Spray-Drying Conditions on the Viability of Wine Saccharomyces Cerevisiae Strains. World J. Microbiol. Biotechnol. 2016, 32, 13. [Google Scholar] [CrossRef][Green Version]

- Kulkarni, S.; Haq, S.F.; Samant, S.; Sukumaran, S. Adaptation of Lactobacillus Acidophilus to Thermal Stress Yields a Thermotolerant Variant Which Also Exhibits Improved Survival at PH 2. Probiotics Antimicrob. Proteins 2018, 10, 717–727. [Google Scholar] [CrossRef]

- Femat-Castañeda, C.; Chávez-Rodríguez, A.; Chávez-Rodríguez, A.M.; Flores-Martínez, H.; Farías-Cervantes, V.S.; Andrade-González, I. Effect of Agave Fructans and Maltodextrin on Zn 2+ Chlorophyll Microencapsulation by Spray Drying. J. Food Qual. 2019, 2019, 6312584. [Google Scholar] [CrossRef]

- Gallagher, E.; Kenny, S.; Arendt, E.K. Impact of Dairy Protein Powders on Biscuit Quality. Eur. Food Res. Technol. 2005, 221, 237–243. [Google Scholar] [CrossRef]

- Foerst, P.; Kulozik, U.; Schmitt, M.; Bauer, S.; Santivarangkna, C. Storage Stability of Vacuum-Dried Probiotic Bacterium Lactobacillus Paracasei F19. Food Bioprod. Process. 2012, 90, 295–300. [Google Scholar] [CrossRef]

- Lapsiri, W.; Bhandari, B.; Wanchaitanawong, P. Viability of Lactobacillus Plantarum TISTR 2075 in Different Protectants during Spray Drying and Storage. Dry. Technol. 2012, 30, 1407–1412. [Google Scholar] [CrossRef]

- Arslan-Tontul, S.; Erbas, M. Single and Double Layered Microencapsulation of Probiotics by Spray Drying and Spray Chilling. LWT Food Sci. Technol. 2017, 81, 160–169. [Google Scholar] [CrossRef]

- Behboudi-Jobbehdar, S.; Soukoulis, C.; Yonekura, L.; Fisk, I. Optimization of Spray-Drying Process Conditions for the Production of Maximally Viable Microencapsulated L. Acidophilus NCIMB 701748. Dry. Technol. 2013, 31, 1274–1283. [Google Scholar] [CrossRef]

- Rishabh, D.; Athira, A.; Preetha, R.; Nagamaniammai, G. Freeze Dried Probiotic Carrot Juice Powder for Better Storage Stability of Probiotic. J. Food Sci. Technol. 2021, 58, 1–9. [Google Scholar] [CrossRef]

- Sharifi, S.; Rezazad-Bari, M.; Alizadeh, M.; Almasi, H.; Amiri, S. Use of Whey Protein Isolate and Gum Arabic for the Co-Encapsulation of Probiotic Lactobacillus Plantarum and Phytosterols by Complex Coacervation: Enhanced Viability of Probiotic in Iranian White Cheese. Food Hydrocoll. 2021, 113, 106496. [Google Scholar] [CrossRef]

- Eratte, D.; McKnight, S.; Gengenbach, T.R.; Dowling, K.; Barrow, C.J.; Adhikari, B.P. Co-Encapsulation and Characterisation of Omega-3 Fatty Acids and Probiotic Bacteria in Whey Protein Isolate–Gum Arabic Complex Coacervates. J. Funct. Foods 2015, 19, 882–892. [Google Scholar] [CrossRef]

- Khem, S.; Bansal, V.; Small, D.M.; May, B.K. Comparative Influence of PH and Heat on Whey Protein Isolate in Protecting Lactobacillus Plantarum A17 during Spray Drying. Food Hydrocoll. 2016, 54, 162–169. [Google Scholar] [CrossRef]

- Bhagwat, A.; Bhushette, P.; Annapure, U.S. Spray Drying Studies of Probiotic Enterococcus Strains Encapsulated with Whey Protein and Maltodextrin. Beni-Suef Univ. J. Basic Appl. Sci. 2020, 9, 33. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Spray Drying of Tomato Pulp in Dehumidified Air: II. The Effect on Powder Properties. J. Food Eng. 2005, 66, 35–42. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of Process Conditions on the Physicochemical Properties of Açai (Euterpe Oleraceae Mart.) Powder Produced by Spray Drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-Drying of Fruit and Vegetable Juices: Effect of Drying Conditions on the Product Yield and Physical Properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of Spray Drying Conditions and Feed Composition on the Physical Properties of Black Mulberry Juice Powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Fazaeli, M.; Emam-Djomeh, Z.; Yarmand, M.S. Influence of Black Mulberry Juice Addition and Spray Drying Conditions on Some Physical Properties of Ice Cream Powder. Int. J. Food Eng. 2016, 12, 277–285. [Google Scholar] [CrossRef]

- Willaert, R.; Nedovic, V.A. Primary Beer Fermentation by Immobilised Yeast—A Review on Flavour Formation and Control Strategies. J. Chem. Technol. Biotechnol. 2006, 81, 1353–1367. [Google Scholar] [CrossRef]

- Vesterlund, S.; Salminen, K.; Salminen, S. Water Activity in Dry Foods Containing Live Probiotic Bacteria Should Be Carefully Considered: A Case Study with Lactobacillus Rhamnosus GG in Flaxseed. Int. J. Food Microbiol. 2012, 157, 319–321. [Google Scholar] [CrossRef]

- Poddar, D.; Das, S.; Jones, G.; Palmer, J.; Jameson, G.B.; Haverkamp, R.G.; Singh, H. Stability of Probiotic Lactobacillus Paracasei during Storage as Affected by the Drying Method. Int. Dairy J. 2014, 39, 1–7. [Google Scholar] [CrossRef]

- Jouppila, K.; Roos, Y.H. Glass Transitions and Crystallization in Milk Powders. J. Dairy Sci. 1994, 77, 2907–2915. [Google Scholar] [CrossRef]

- Heidebach, T.; Först, P.; Kulozik, U. Influence of Casein-Based Microencapsulation on Freeze-Drying and Storage of Probiotic Cells. J. Food Eng. 2010, 98, 309–316. [Google Scholar] [CrossRef]

- Shokri, Z.; Fazeli, M.R.; Ardjmand, M.; Mousavi, S.M.; Gilani, K. Factors Affecting Viability of Bifidobacterium Bifidum during Spray Drying. DARU J. Pharm. Sci. 2015, 23, 7. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Fontana, A.J.J.R.; Schmidt, S.J.; Labuza, T.P. (Eds.) Water Activity in Foods; Wiley: Hoboken, NJ, USA, 2020; ISBN 9781118768310. [Google Scholar]

- Arepally, D.; Goswami, T.K. Effect of Inlet Air Temperature and Gum Arabic Concentration on Encapsulation of Probiotics by Spray Drying. LWT 2019, 99, 583–593. [Google Scholar] [CrossRef]

- Liu, H.; Gong, J.; Chabot, D.; Miller, S.S.; Cui, S.W.; Ma, J.; Zhong, F.; Wang, Q. Incorporation of Polysaccharides into Sodium Caseinate-Low Melting Point Fat Microparticles Improves Probiotic Bacterial Survival during Simulated Gastrointestinal Digestion and Storage. Food Hydrocoll. 2016, 54, 328–337. [Google Scholar] [CrossRef]

- Ng, S.; Wong, P.; Tan, C.; Long, K.; Nyam, K. Influence of the Inlet Air Temperature on the Microencapsulation of Kenaf (Hibiscus cannabinus L.) Seed Oil. Eur. J. Lipid Sci. Technol. 2013, 115, 1309–1318. [Google Scholar] [CrossRef]

- Suez, J.; Zmora, N.; Zilberman-Schapira, G.; Mor, U.; Dori-Bachash, M.; Bashiardes, S.; Zur, M.; Regev-Lehavi, D.; Ben-Zeev Brik, R.; Federici, S.; et al. Post-Antibiotic Gut Mucosal Microbiome Reconstitution Is Impaired by Probiotics and Improved by Autologous FMT. Cell 2018, 174, 1406–1423.e16. [Google Scholar] [CrossRef] [PubMed]

- Doherty, S.B.; Gee, V.L.; Ross, R.P.; Stanton, C.; Fitzgerald, G.F.; Brodkorb, A. Development and Characterisation of Whey Protein Micro-Beads as Potential Matrices for Probiotic Protection. Food Hydrocoll. 2011, 25, 1604–1617. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, H.; Hu, X.; Bao, S.; Huang, H. Synthesis and Release Studies of Microalgal Oil-Containing Microcapsules Prepared by Complex Coacervation. Colloids Surf. B Biointerfaces 2012, 89, 61–66. [Google Scholar] [CrossRef]

- Vasisht, N. Factors and Mechanisms in Microencapsulation. In Microencapsulation in the Food Industry; Elsevier: Amsterdam, The Netherlands, 2014; pp. 15–24. [Google Scholar]

- Taranto, M.P.; Fernandez Murga, M.L.; Lorca, G.; Valdez, G.F. Bile Salts and Cholesterol Induce Changes in the Lipid Cell Membrane of Lactobacillus Reuteri. J. Appl. Microbiol. 2003, 95, 86–91. [Google Scholar] [CrossRef]

- Ilango, S.; Pandey, R.; Antony, U. Functional Characterization and Microencapsulation of Probiotic Bacteria from Koozh. J. Food Sci. Technol. 2016, 53, 977–989. [Google Scholar] [CrossRef]

- Wendel, U. Assessing Viability and Stress Tolerance of Probiotics—A Review. Front. Microbiol. 2022, 12, 818468. [Google Scholar] [CrossRef]

- Golowczyc, M.A.; Silva, J.; Abraham, A.G.; de Antoni, G.L.; Teixeira, P. Preservation of Probiotic Strains Isolated from Kefir by Spray Drying. Lett. Appl. Microbiol. 2010, 50, 7–12. [Google Scholar] [CrossRef]

- Abe, F.; Miyauchi, H.; Uchijima, A.; Yaeshima, T.; Iwatsuki, K. Effects of Storage Temperature and Water Activity on the Survival of Bifidobacteria in Powder Form. Int. J. Dairy Technol. 2009, 62, 234–239. [Google Scholar] [CrossRef]

- Teixeira, P.; Castro, H.; Kirby, R. Evidence of Membrane Lipid Oxidation of Spray-Dried Lactobacillus Bulgaricus during Storage. Lett. Appl. Microbiol. 1996, 22, 34–38. [Google Scholar] [CrossRef]

- Santos, M.G.; Bozza, F.T.; Thomazini, M.; Favaro-Trindade, C.S. Microencapsulation of Xylitol by Double Emulsion Followed by Complex Coacervation. Food Chem. 2015, 171, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Daoub, R.M.A.; Elmubarak, A.H.; Misran, M.; Hassan, E.A.; Osman, M.E. Characterization and Functional Properties of Some Natural Acacia Gums. J. Saudi Soc. Agric. Sci. 2018, 17, 241–249. [Google Scholar] [CrossRef]

- Mahdi, A.A.; Mohammed, J.K.; Al-Ansi, W.; Ghaleb, A.D.S.; Al-Maqtari, Q.A.; Ma, M.; Ahmed, M.I.; Wang, H. Microencapsulation of Fingered Citron Extract with Gum Arabic, Modified Starch, Whey Protein, and Maltodextrin Using Spray Drying. Int. J. Biol. Macromol. 2020, 152, 1125–1134. [Google Scholar] [CrossRef]

- Kim, E.H.-J.; Chen, X.D.; Pearce, D. Surface Composition of Industrial Spray-Dried Milk Powders. 2. Effects of Spray Drying Conditions on the Surface Composition. J. Food Eng. 2009, 94, 169–181. [Google Scholar] [CrossRef]

- Nishanthi, M.; Chandrapala, J.; Vasiljevic, T. Properties of Whey Protein Concentrate Powders Obtained by Spray Drying of Sweet, Salty and Acid Whey under Varying Storage Conditions. J. Food Eng. 2017, 214, 137–146. [Google Scholar] [CrossRef]

- Rosland Abel, S.E.; Yusof, Y.A.; Chin, N.L.; Chang, L.S.; Mohd Ghazali, H.; Manaf, Y.N. Characterisation of Physicochemical Properties of Gum Arabic Powder at Various Particle Sizes. Food Res. 2020, 4, 107–115. [Google Scholar] [CrossRef]

| Sample (Inlet Temperature) | Viable Cell Concentration (Log CFU/g) | Viability Loss (Log Reduction) | |

|---|---|---|---|

| Before Spray Drying | After Spray Drying | ||

| S120 (120 °C) | 8.57 ± 0.15 aA | 7.98 ± 0.19 aB | 0.59 ± 0.32 A |

| S150 (150 °C) | 8.32 ± 0.06 aA | 7.69 ± 0.14 bA | 0.62 ± 0.09 A |

| S170 (170 °C) | 8.61 ± 0.07 aA | 7.25 ± 0.19 bB | 1.36 ± 0.24 B |

| Sample (WPI:GA) | Viable Cell Concentration (Log CFU/g) | Viability Loss (Log Reduction) | |

|---|---|---|---|

| Before Spray Drying | After Spray Drying | ||

| WG11 (1:1) | 8.32 ± 0.06 aA | 7.69 ± 0.14 bA | 0.62 ± 0.09 A |

| WG31 (3:1) | 8.36 ± 0.32 aA | 7.78 ± 0.13 bA | 0.58 ± 0.23 A |

| WG13 (1:3) | 8.60 ± 0.04 aA | 7.49 ± 0.43 bA | 1.11 ± 0.47 A |

| Sample | Inlet Air Temperature (°C) | Production Yield (%) | Moisture Content (%) | Water Activity (aw) |

|---|---|---|---|---|

| S120 | 120 | 58.97 ± 0.03 b | 6.80 ± 0.92 a | 0.29 ± 0.04 a |

| S150 | 150 | 63.12 ± 0.04 ab | 5.71 ± 0.28 b | 0.21 ± 0.02 b |

| S170 | 170 | 69.62 ± 0.02 a | 4.75 ± 0.14 c | 0.16 ± 0.02 b |

| Sample | WPI:GA Ratio | Production Yield (%) | Moisture Content (%) | Water Activity (aw) |

|---|---|---|---|---|

| WG11 | 1:1 | 63.12 ± 4.13 a | 5.71 ± 0.29 a | 0.21 ± 0.04 a |

| WG31 | 3:1 | 67.10 ± 2.00 a | 4.66 ± 0.48 b | 0.19 ± 0.02 a |

| WG13 | 1:3 | 65.97 ± 4.06 a | 5.91 ± 0.42 a | 0.17 ± 0.02 a |

| Sample | Viable Cell Concentration (Log CFU/g) | Viability Loss after GIT Simulation (Log Reduction) | ||

|---|---|---|---|---|

| Initial | After SGJ | After SIJ | ||

| Free cell | 8.00 ± 0.04 aA | 0.00 ± 0.00 bA | 0.00 ± 0.00 bA | 8.00 ± 0.04 A |

| S120 | 7.52 ± 0.14 aB | 6.49 ± 0.11 bB | 6.75 ± 0.05 cB | 0.77 ± 0.17 B |

| S150 | 6.60 ± 0.21 aC | 6.09 ± 0.21 bC | 6.10 ± 0.08 bC | 0.50 ± 0.19 B |

| S170 | 6.43 ± 0.07 aC | 5.59 ± 0.16 bD | 5.65 ± 0.07 bD | 0.78 ± 0.14 B |

| Sample | Viable Cell Concentration (Log CFU/g) | Viability Loss after GIT Simulation (Log Reduction) | ||

|---|---|---|---|---|

| Initial | After SGJ | After SIJ | ||

| Free cell | 8.00 ± 0.04 aA | 0.00 ± 0.00 bA | 0.00 ± 0.00 bA | 8.00 ± 0.04 A |

| WG11 | 6.60 ± 0.21 aB | 6.09 ± 0.21 bBC | 6.10 ± 0.08 bB | 0.50 ± 0.19 BC |

| WG31 | 6.85 ± 0.08 aBC | 6.41 ± 0.24 bBC | 6.55 ± 0.28 abC | 0.30 ± 0.21 C |

| WG13 | 5.99 ± 0.12 aD | 5.62 ± 0.11 bD | 5.24 ± 0.09 cD | 0.75 ± 0.04 B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tirta, G.D.; Martin, L.; Bani, M.D.; Kho, K.; Pramanda, I.T.; Pui, L.P.; How, Y.H.; Lim, C.S.Y.; Devanthi, P.V.P. Spray Drying Encapsulation of Pediococcus acidilactici at Different Inlet Air Temperatures and Wall Material Ratios. Foods 2023, 12, 165. https://doi.org/10.3390/foods12010165

Tirta GD, Martin L, Bani MD, Kho K, Pramanda IT, Pui LP, How YH, Lim CSY, Devanthi PVP. Spray Drying Encapsulation of Pediococcus acidilactici at Different Inlet Air Temperatures and Wall Material Ratios. Foods. 2023; 12(1):165. https://doi.org/10.3390/foods12010165

Chicago/Turabian StyleTirta, Gabriella Devina, Leon Martin, Mario Donald Bani, Katherine Kho, Ihsan Tria Pramanda, Liew Phing Pui, Yu Hsuan How, Crystale Siew Ying Lim, and Putu Virgina Partha Devanthi. 2023. "Spray Drying Encapsulation of Pediococcus acidilactici at Different Inlet Air Temperatures and Wall Material Ratios" Foods 12, no. 1: 165. https://doi.org/10.3390/foods12010165

APA StyleTirta, G. D., Martin, L., Bani, M. D., Kho, K., Pramanda, I. T., Pui, L. P., How, Y. H., Lim, C. S. Y., & Devanthi, P. V. P. (2023). Spray Drying Encapsulation of Pediococcus acidilactici at Different Inlet Air Temperatures and Wall Material Ratios. Foods, 12(1), 165. https://doi.org/10.3390/foods12010165