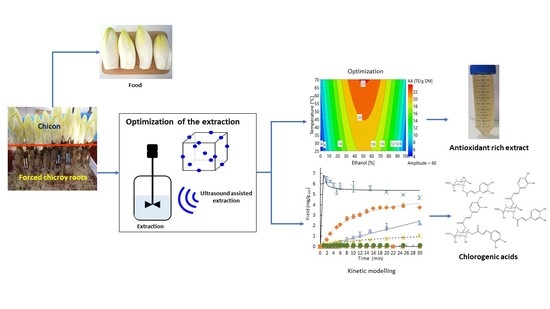

Optimization of Extraction Conditions to Improve Chlorogenic Acid Content and Antioxidant Activity of Extracts from Forced Witloof Chicory Roots

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Plant Material

2.3. Maximization of Chlorogenic Acid Content

2.3.1. Study of the Effect of the Solvent Composition and the Solid–Liquid Ratio

2.3.2. Kinetic Study of the Extraction of Chlorogenic Acids

2.3.3. Determination of Chlorogenic Acid Content by UHPLC

2.4. Optimization of the Antioxidant Activity of Extracts by Response Surface Methodology

2.4.1. Extraction Equipment and Procedure

2.4.2. Experimental Design

2.5. Measurement of Antioxidant Activity by DPPH Assay

2.6. Statistical Analysis

3. Results and Discussion

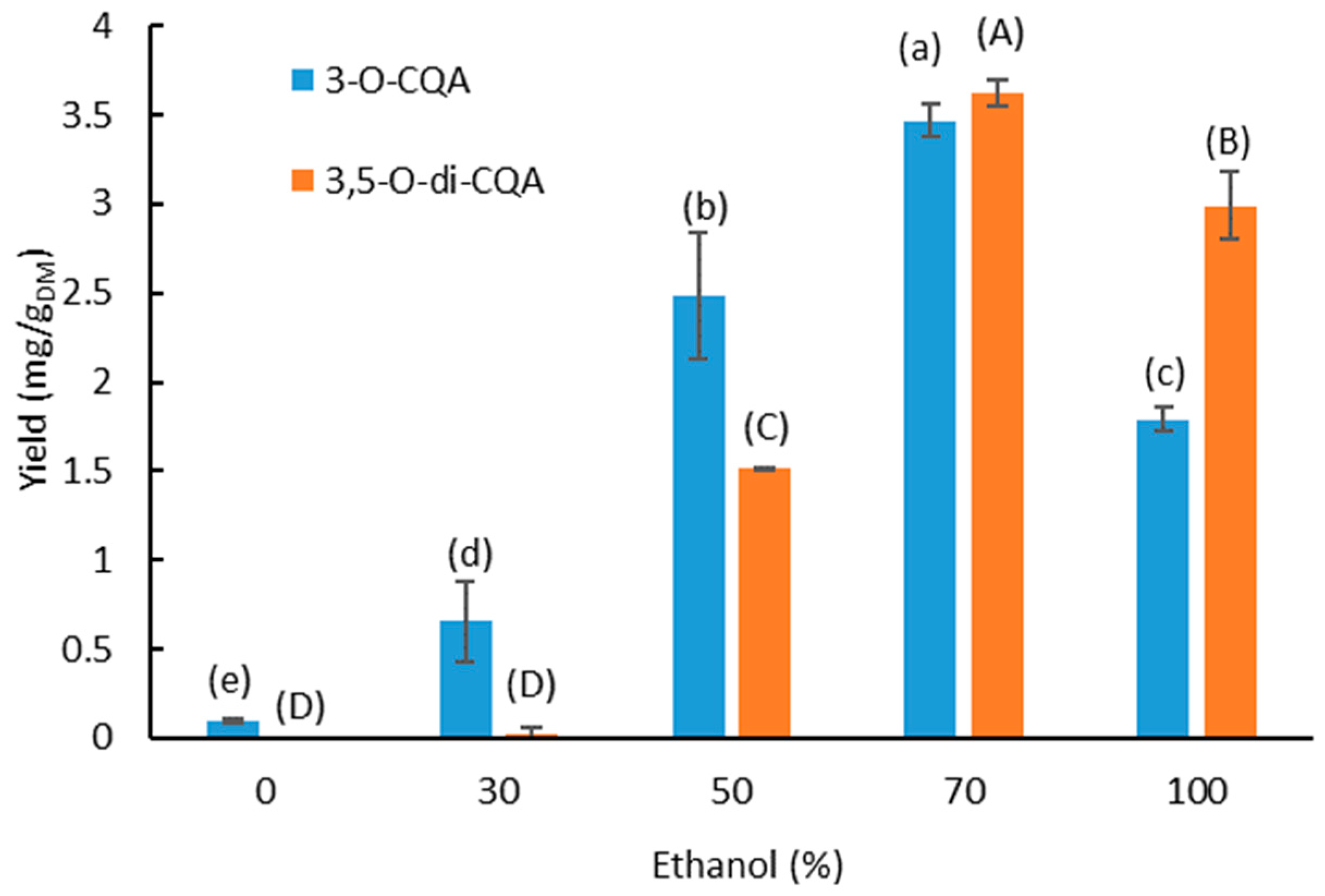

3.1. Effect of the Solvent Composition

3.2. Effect of the Solid–Liquid Ratio

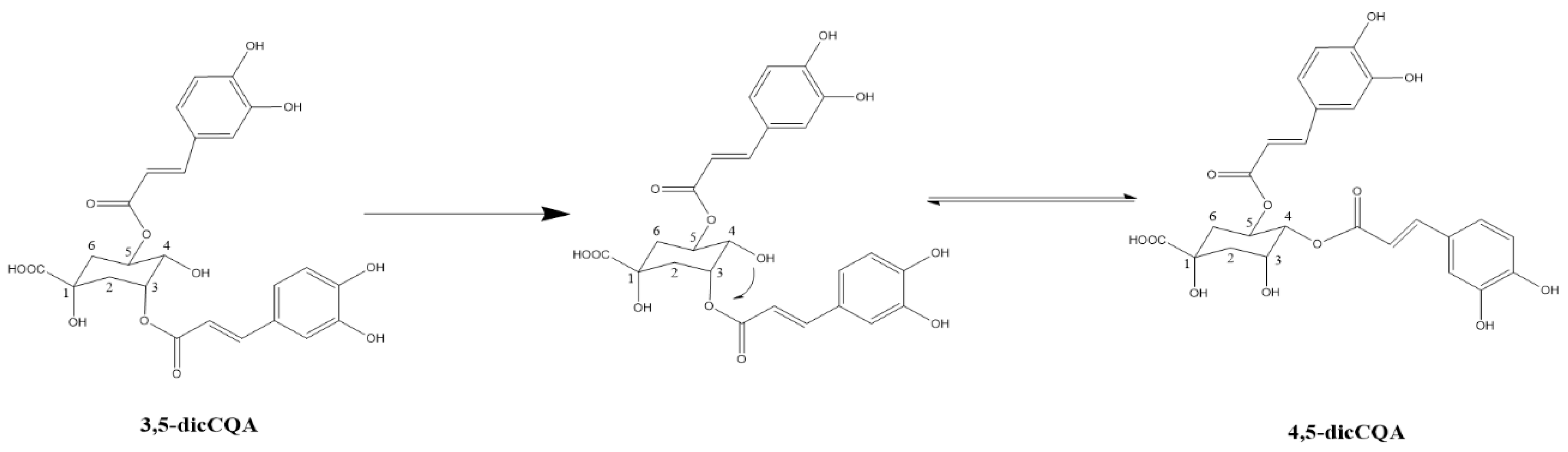

3.3. Kinetic Study According to the Extraction Temperature

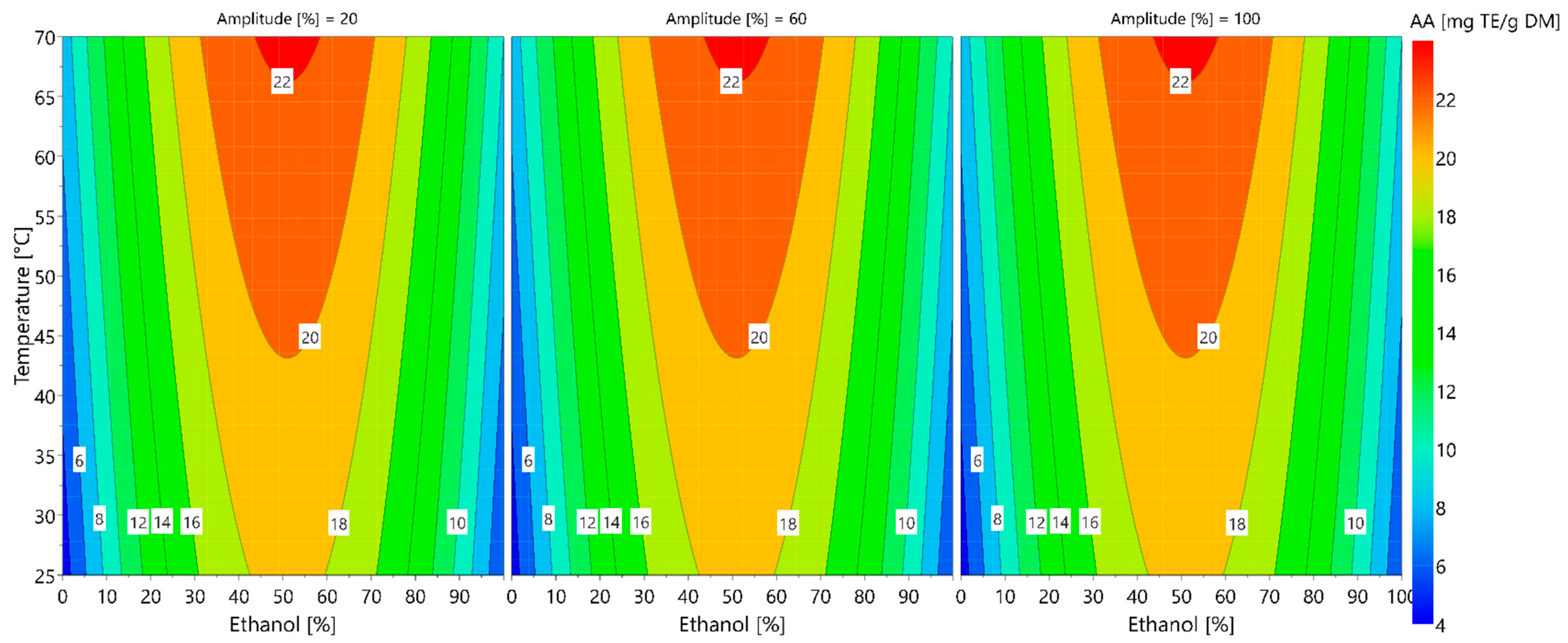

3.4. Optimization of the Antioxidant Activity of Extracts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bisht, A.; Dickens, M.; Rutherfurd-Markwick, K.; Thota, R.; Mutukumira, A.N.; Singh, H. Chlorogenic Acid Potentiates the Anti-Inflammatory Activity of Curcumin in LPS-Stimulated THP-1 Cells. Nutrients 2020, 12, 2706. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Wang, M.; Pan, Y.; Xie, Y.; Han, J.; Zhang, X.; Niayale, R.; He, H.; Li, Q.; Zhao, T.; et al. Anti-Inflammatory Effect of Astragalin and Chlorogenic Acid on Escherichia coli-Induced Inflammation of Sheep Endometrial Epithelium Cells. Front. Vet. Sci. 2020, 7, 201. [Google Scholar] [CrossRef] [PubMed]

- Liang, N.; Kitts, D. Chlorogenic Acid (CGA) Isomers Alleviate Interleukin 8 (IL-8) Production in Caco-2 Cells by Decreasing Phosphorylation of P38 and Increasing Cell Integrity. Int. J. Mol. Sci. 2018, 19, 3873. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Tian, L.; Lv, H.; Pang, Z.; Li, D.; Yao, Z.; Wang, S. Chlorogenic Acid Prevents Acute Myocardial Infarction in Rats by Reducing Inflammatory Damage and Oxidative Stress. Biomed. Pharmacother. 2020, 132, 110773. [Google Scholar] [CrossRef]

- Clifford, M.N. Chlorogenic Acids and Other Cinnamates—Nature, Occurrence, Dietary Burden, Absorption and Metabolism. J. Sci. Food Agric. 2000, 80, 1033–1043. [Google Scholar] [CrossRef]

- Cova, C.M.; Boffa, L.; Pistocchi, M.; Giorgini, S.; Luque, R.; Cravotto, G. Technology and Process Design for Phenols Recovery from Industrial Chicory (Chicorium intybus) Leftovers. Molecules 2019, 24, 2681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Didier, F.; Catherine, F.; Odile, T.; Jean-Louis, L. Caffeoyl Derivatives: Major Antioxidant Compounds of Some Wild Herbs of the Asteraceae Family. Food Nutr. Sci. 2011, 2011, 4889. [Google Scholar] [CrossRef] [Green Version]

- Milala, J.; Grzelak, K.; Krol, B.; Juskiewicz, J.; Zdunczyk, Z. Composition and Properties of Chicory Extracts Rich in Fructans and Polyphenols. Pol. J. Food Nutr. Sci. 2009, 59, 35–43. [Google Scholar]

- Stalmach, A.; Mullen, W.; Nagai, C.; Crozier, A. On-Line HPLC Analysis of the Antioxidant Activity of Phenolic Compounds in Brewed, Paper-Filtered Coffee. Braz. J. Plant Physiol. 2006, 18, 253–262. [Google Scholar] [CrossRef] [Green Version]

- Janda, K.; Gutowska, I.; Geszke-Moritz, M.; Jakubczyk, K. The Common Cichory (Cichorium intybus L.) as a Source of Extracts with Health-Promoting Properties-A Review. Molcules 2021, 26, 1814. [Google Scholar] [CrossRef]

- Nwafor, I.C.; Shale, K.; Achilonu, M.C. Chemical Composition and Nutritive Benefits of Chicory (Cichorium intybus) as an Ideal Complementary and/or Alternative Livestock Feed Supplement. Sci. World J. 2017, 2017, e7343928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stökle, K.; Kruse, A. Extraction of Sugars from Forced Chicory Roots. Biomass Convers. Biorefin. 2019, 9, 699–708. [Google Scholar] [CrossRef]

- Chadni, M.; Flourat, A.L.; Reungoat, V.; Mouterde, L.M.M.; Allais, F.; Ioannou, I. Selective Extraction of Sinapic Acid Derivatives from Mustard Seed Meal by Acting on PH: Toward a High Antioxidant Activity Rich Extract. Molecules 2021, 26, 212. [Google Scholar] [CrossRef]

- Reungoat, V.; Gaudin, M.; Flourat, A.L.; Isidore, E.; Mouterde, L.M.M.; Allais, F.; Ducatel, H.; Ioannou, I. Optimization of an Ethanol/Water-Based Sinapine Extraction from Mustard Bran Using Response Surface Methodology. Food Bioprod. Process. 2020, 122, 322–331. [Google Scholar] [CrossRef]

- Bouras, M.; Chadni, M.; Barba, F.J.; Grimi, N.; Bals, O.; Vorobiev, E. Optimization of Microwave-Assisted Extraction of Polyphenols from Quercus Bark. Ind. Crops Prod. 2015, 77, 590–601. [Google Scholar] [CrossRef]

- Boussetta, N.; Lanoisellé, J.-L.; Bedel-Cloutour, C.; Vorobiev, E. Extraction of Soluble Matter from Grape Pomace by High Voltage Electrical Discharges for Polyphenol Recovery: Effect of Sulphur Dioxide and Thermal Treatments. J. Food Eng. 2009, 95, 192–198. [Google Scholar] [CrossRef]

- Macias-Garbett, R.; Serna-Hernández, S.O.; Sosa-Hernández, J.E.; Parra-Saldívar, R. Phenolic Compounds from Brewer’s Spent Grains: Toward Green Recovery Methods and Applications in the Cosmetic Industry. Front. Sustain. Food Syst. 2021, 5, 196. [Google Scholar] [CrossRef]

- Pazo-Cepeda, V.; Benito-Román, Ó.; Navarrete, A.; Alonso, E. Valorization of Wheat Bran: Ferulic Acid Recovery Using Pressurized Aqueous Ethanol Solutions. Waste Biomass Valorization 2020, 11, 4701–4710. [Google Scholar] [CrossRef]

- Pingret, D.; Fabiano-Tixier, A.-S.; Bourvellec, C.L.; Renard, C.M.G.C.; Chemat, F. Lab and Pilot-Scale Ultrasound-Assisted Water Extraction of Polyphenols from Apple Pomace. J. Food Eng. 2012, 111, 73–81. [Google Scholar] [CrossRef]

- Chebaibi, S.; Leriche Grandchamp, M.; Burgé, G.; Clément, T.; Allais, F.; Laziri, F. Improvement of Protein Content and Decrease of Anti-Nutritional Factors in Olive Cake by Solid-State Fermentation: A Way to Valorize This Industrial by-Product in Animal Feed. J. Biosci. Bioeng. 2019, 128, 384–390. [Google Scholar] [CrossRef]

- Virot, M.; Tomao, V.; Le Bourvellec, C.; Renard, C.M.C.G.; Chemat, F. Towards the Industrial Production of Antioxidants from Food Processing By-Products with Ultrasound-Assisted Extraction. Ultrason. Sonochem. 2010, 17, 1066–1074. [Google Scholar] [CrossRef] [PubMed]

- Jurgonski, A.; Milala, J.; Juśkiewicz, J.; Zdunczyk, Z.; Król, B. Composition of Chicory Root, Peel, Seed and Leaf Ethanol Extracts and Biological Properties of Their Non-Inulin Fractions. Food Technol. Biotechnol. 2011, 49, 40–47. [Google Scholar]

- Sinkovič, L.; Hribar, J.; Znidarcic, D.; Treutter, D.; Vidrih, R. Comparison of the Phenolics Profiles of Forced and Unforced Chicory (Cichorium intybus L.) Cultivars. Agric. Conspec. Sci. 2014, 79, 133–137. [Google Scholar]

- Willeman, H.; Hance, P.; Fertin, A.; Voedts, N.; Duhal, N.; Goossens, J.-F.; Hilbert, J.-L. A Method for the Simultaneous Determination of Chlorogenic Acid and Sesquiterpene Lactone Content in Industrial Chicory Root Foodstuffs. Sci. World J. 2014, 2014, e583180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wijekoon, M.M.J.O.; Bhat, R.; Karim, A.A. Effect of Extraction Solvents on the Phenolic Compounds and Antioxidant Activities of Bunga Kantan (Etlingera elatior Jack.) Inflorescence. J. Food Compos. Anal. 2011, 24, 615–619. [Google Scholar] [CrossRef]

- Pradal, D. Eco-Procédés d’Extraction de Polyphénols Antioxydants à Partir d’un Co-Produit Agro-Alimentaire. Ph.D. Thesis, Université Lille 1, Villeneuve-d’Ascq, France, 2016. [Google Scholar]

- Benzie, I.F.F.; Strain, J.J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Thaipong, K.; Boonprakob, U.; Crosby, K.; Cisneros-Zevallos, L.; Hawkins Byrne, D. Comparison of ABTS, DPPH, FRAP, and ORAC Assays for Estimating Antioxidant Activity from Guava Fruit Extracts. J. Food Compos. Anal. 2006, 19, 669–675. [Google Scholar] [CrossRef]

- Shoaib, M.; Shah, I.; Ali, N.; Adhikari, A.; Tahir, M.N.; Shah, S.W.A.; Ishtiaq, S.; Khan, J.; Khan, S.; Umer, M.N. Sesquiterpene Lactone! A Promising Antioxidant, Anticancer and Moderate Antinociceptive Agent from Artemisia Macrocephala Jacquem. BMC Complement. Altern. Med. 2017, 17, 27. [Google Scholar] [CrossRef] [Green Version]

- Peters, A.M.; Van Amerongen, A. Sesquiterpene Lactones in Chicory (Cichorium Intybus L.): Distribution in Chicons and Effect of Storage. Food Res. Int. 1996, 29, 439–444. [Google Scholar] [CrossRef]

- Poli, F.; Sacchetti, G.; Tosi, B.; Fogagnolo, M.; Chillemi, G.; Lazzarin, R.; Bruni, A. Variation in the Content of the Main Guaianolides and Sugars in Cichorium Intybus Var. “Rosso Di Chioggia” Selections during Cultivation. Food Chem. 2002, 76, 139–147. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications. A Review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Chemat, S.; Lagha, A.; AitAmar, H.; Bartels, P.V.; Chemat, F. Comparison of Conventional and Ultrasound-Assisted Extraction of Carvone and Limonene from Caraway Seeds. Flavour Fragr. J. 2004, 19, 188–195. [Google Scholar] [CrossRef]

- Peleg, M. An empirical model for the description of moisture sorption curves. J. Food Sci. 1988, 53, 1216–1219. [Google Scholar] [CrossRef]

- Jurinjak Tušek, A.; Benković, M.; Belščak Cvitanović, A.; Valinger, D.; Jurina, T.; Gajdoš Kljusurić, J. Kinetics and Thermodynamics of the Solid-Liquid Extraction Process of Total Polyphenols, Antioxidants and Extraction Yield from Asteraceae Plants. Ind. Crops Prod. 2016, 91, 205–214. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Azabou, S.; Sebii, H.; Taheur, F.B.; Abid, Y.; Jridi, M.; Nasri, M. Phytochemical Profile and Antioxidant Properties of Tomato By-Products as Affected by Extraction Solvents and Potential Application in Refined Olive Oils. Food Biosci. 2020, 36, 100664. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Q.; Liu, Y.; Chen, G.; Cui, J. Antimicrobial and Antioxidant Activities of Cichorium intybus Root Extract Using Orthogonal Matrix Design. J. Food Sci. 2013, 78, M258–M263. [Google Scholar] [CrossRef]

- Hemwimon, S.; Pavasant, P.; Shotipruk, A. Microwave-Assisted Extraction of Antioxidative Anthraquinones from Roots of Morinda citrifolia. Sep. Purif. Technol. 2007, 54, 44–50. [Google Scholar] [CrossRef]

- Cacace, J.E.; Mazza, G. Mass Transfer Process during Extraction of Phenolic Compounds from Milled Berries. J. Food Eng. 2003, 59, 379–389. [Google Scholar] [CrossRef]

- Dawidowicz, A.L.; Typek, R. The Influence of PH on the Thermal Stability of 5-O-Caffeoylquinic Acids in Aqueous Solutions. Eur. Food Res. Technol. 2011, 233, 223–232. [Google Scholar] [CrossRef] [Green Version]

- Xue, M.; Shi, H.; Zhang, J.; Liu, Q.-Q.; Guan, J.; Zhang, J.-Y.; Ma, Q. Stability and Degradation of Caffeoylquinic Acids under Different Storage Conditions Studied by High-Performance Liquid Chromatography with Photo Diode Array Detection and High-Performance Liquid Chromatography with Electrospray Ionization Collision-Induced Dissociation Tandem Mass Spectrometry. Molecules 2016, 21, 948. [Google Scholar] [CrossRef]

- Li, Y.-J.; Zhang, C.-F.; Ding, G.; Huang, W.-Z.; Wang, Z.-Z.; Bi, Y.-A.; Xiao, W. Investigating the Thermal Stability of Six Caffeoylquinic Acids Employing Rapid-Resolution Liquid Chromatography with Quadrupole Time-of-Flight Tandem Mass Spectrometry. Eur. Food Res. Technol. 2015, 240, 1225–1234. [Google Scholar] [CrossRef]

- Clifford, M.N.; Knight, S.; Kuhnert, N. Discriminating between the Six Isomers of Dicaffeoylquinic Acid by LC-MSn. J. Agric. Food Chem. 2005, 53, 3821–3832. [Google Scholar] [CrossRef] [PubMed]

- Lavelli, V. Antioxidant Activity of Minimally Processed Red Chicory (Cichorium intybus L.) Evaluated in Xanthine Oxidase-, Myeloperoxidase-, and Diaphorase-Catalyzed Reactions. J. Agric. Food Chem. 2008, 56, 7194–7200. [Google Scholar] [CrossRef] [PubMed]

- Zardo, I.; de Espíndola Sobczyk, A.; Marczak, L.D.F.; Sarkis, J. Optimization of Ultrasound Assisted Extraction of Phenolic Compounds from Sunflower Seed Cake Using Response Surface Methodology. Waste Biomass Valorization 2019, 10, 33–44. [Google Scholar] [CrossRef]

| Factors Level (Code) | Response | |||

|---|---|---|---|---|

| Run Order | Amplitude | Ethanol | Temperature | mg Trolox/gDM |

| 7 | 20 (−1) | 0 (−1) | 47.5 (0) | 4.52 |

| 6 | 100 (+1) | 0 (−1) | 47.5 (0) | 4.18 |

| 14 | 20 (−1) | 100 (+1) | 47.5 (0) | 6.54 |

| 9 | 100 (+1) | 100 (+1) | 47.5 (0) | 7.35 |

| 8 | 20 (−1) | 50 (0) | 25 (−1) | 17.53 |

| 2 | 100 (+1) | 50 (0) | 25 (−1) | 17.24 |

| 1 | 20 (−1) | 50 (0) | 70 (+1) | 24.78 |

| 4 | 100 (+1) | 50 (0) | 70 (+1) | 21.98 |

| 15 | 60 (0) | 0 (−1) | 25 (−1) | 5.62 |

| 3 | 60 (0) | 100 (+1) | 25 (−1) | 3.25 |

| 10 | 60 (0) | 0 (−1) | 70 (+1) | 5.30 |

| 11 | 60 (0) | 100 (+1) | 70 (+1) | 7.19 |

| 13 | 60 (0) | 50 (0) | 47.5 (0) | 20.79 |

| 12 | 60 (0) | 50 (0) | 47.5 (0) | 19.11 |

| 5 | 60 (0) | 50 (0) | 47.5 (0) | 21.18 |

| Chlorogenic Acid | Solvent | Temperature °C | K1 (min gDM/mg) | K2 (gDM/mg) | R2 | RMSE |

|---|---|---|---|---|---|---|

| 3-O-CQA | 70% Ethanol | 70 | NV | NV | NV | NV |

| 60 | 0.0049 ± 0.0003 | 0.2043 ± 0.0032 | 0.9984 | 0.0763 | ||

| 50 | 0.0194 ± 0.0007 | 0.2061 ± 0.0044 | 0.9982 | 0.0786 | ||

| 40 | 0.0834 ± 0.0051 | 0.2105 ± 0.0078 | 0.9933 | 0.1642 | ||

| 25 | 0.0622 ± 0.0020 | 0.2194 ± 0.0008 | 0.9979 | 0.0787 | ||

| Water | 90 | 0.0051 ± 0.0009 | 0.1677 ± 0.0013 | 0.9936 | 0.1724 | |

| 70 | 1.3101 ± 0.1833 | 0.1875 ± 0.0366 | 0.9869 | 0.3218 | ||

| 60 | 5.7985 ± 0.0001 | 0.0947 ± 0.0002 | 0.9782 | 0.2538 | ||

| 50 | 0.9648 ± 0.4278 | 1.0397 ± 0.3028 | 0.8466 | 0.1471 | ||

| 40 | NV | NV | NV | NV | ||

| 25 | NV | NV | NV | NV | ||

| 3,5-O-di-CQA | 70% Ethanol | 70 | NV | NV | NV | NV |

| 60 | 0.0129 ± 0.0166 | 0.1662 ± 0.0043 | 0.9973 | 0.1214 | ||

| 50 | 0.0202 ± 0.0002 | 0.1701 ± 0.0045 | 0.9983 | 0.0934 | ||

| 40 | 0.0405 ± 0.0021 | 0.1722 ± 0.0984 | 0.9908 | 0.2383 | ||

| 25 | 0.0473 ± 0.0045 | 0.1908± 0.0845 | 0.9977 | 0.0944 | ||

| Water | 90 | NV | NV | NV | NV | |

| 70 | 1.7362 ± 0.2126 | 0.1832 ± 0.0008 | 0.9903 | 0.2038 | ||

| 60 | 11.6290 ± 0.0480 | NV | 0.9703 | 0.2230 | ||

| 50 | 11.8233 ± 0.4521 | 0.6735 ± 0.0766 | 0.9694 | 0.0680 | ||

| 40 | NV | NV | NV | NV | ||

| 25 | NV | NV | NV | NV |

| Coefficient | p-Value | |

|---|---|---|

| Constant | 20.354 | <0.001 |

| Amplitude (Amp) | −0.250 | 0.632 NS |

| Ethanol (Eth) | 0.445 | 0.286 NS |

| Temperature (Temp) | 1.475 | 0.003 |

| Amp × Amp | 0.095 | 0.868 NS |

| Eth × Eth | −8.502 | <0.001 |

| Temp × Temp | −0.081 | 0.888 NS |

| Amp × Eth | 0.166 | 0.764 NS |

| Amp × Temp | −0.362 | 0.520 NS |

| Eth × Temp | 0.614 | 0.292 NS |

| ANOVA: | ||

| R2 = 0.973 | ||

| R2 adj. = 0.965 |

| Response Variable | Optimum Extraction Conditions | Maximum Values (mg TE/gDM) | |||

|---|---|---|---|---|---|

| Ethanol (%) | Temperature (°C) | Amplitude (%) | Predicted | Experimental | |

| Antioxidant activity of extracts (mg TE/gDM) | 50 | 70 | 0 | 21.80 ± 1.09 | 25.88 ± 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chadni, M.; Isidore, E.; Diemer, E.; Ouguir, O.; Brunois, F.; Catteau, R.; Cassan, L.; Ioannou, I. Optimization of Extraction Conditions to Improve Chlorogenic Acid Content and Antioxidant Activity of Extracts from Forced Witloof Chicory Roots. Foods 2022, 11, 1217. https://doi.org/10.3390/foods11091217

Chadni M, Isidore E, Diemer E, Ouguir O, Brunois F, Catteau R, Cassan L, Ioannou I. Optimization of Extraction Conditions to Improve Chlorogenic Acid Content and Antioxidant Activity of Extracts from Forced Witloof Chicory Roots. Foods. 2022; 11(9):1217. https://doi.org/10.3390/foods11091217

Chicago/Turabian StyleChadni, Morad, Emilie Isidore, Etienne Diemer, Otmane Ouguir, Fanny Brunois, Régis Catteau, Laurent Cassan, and Irina Ioannou. 2022. "Optimization of Extraction Conditions to Improve Chlorogenic Acid Content and Antioxidant Activity of Extracts from Forced Witloof Chicory Roots" Foods 11, no. 9: 1217. https://doi.org/10.3390/foods11091217