Uncover the Flavor Code of Roasted Sesame for Sesame Flavor Baijiu: Advance on the Revelation of Aroma Compounds in Sesame Flavor Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation

Abstract

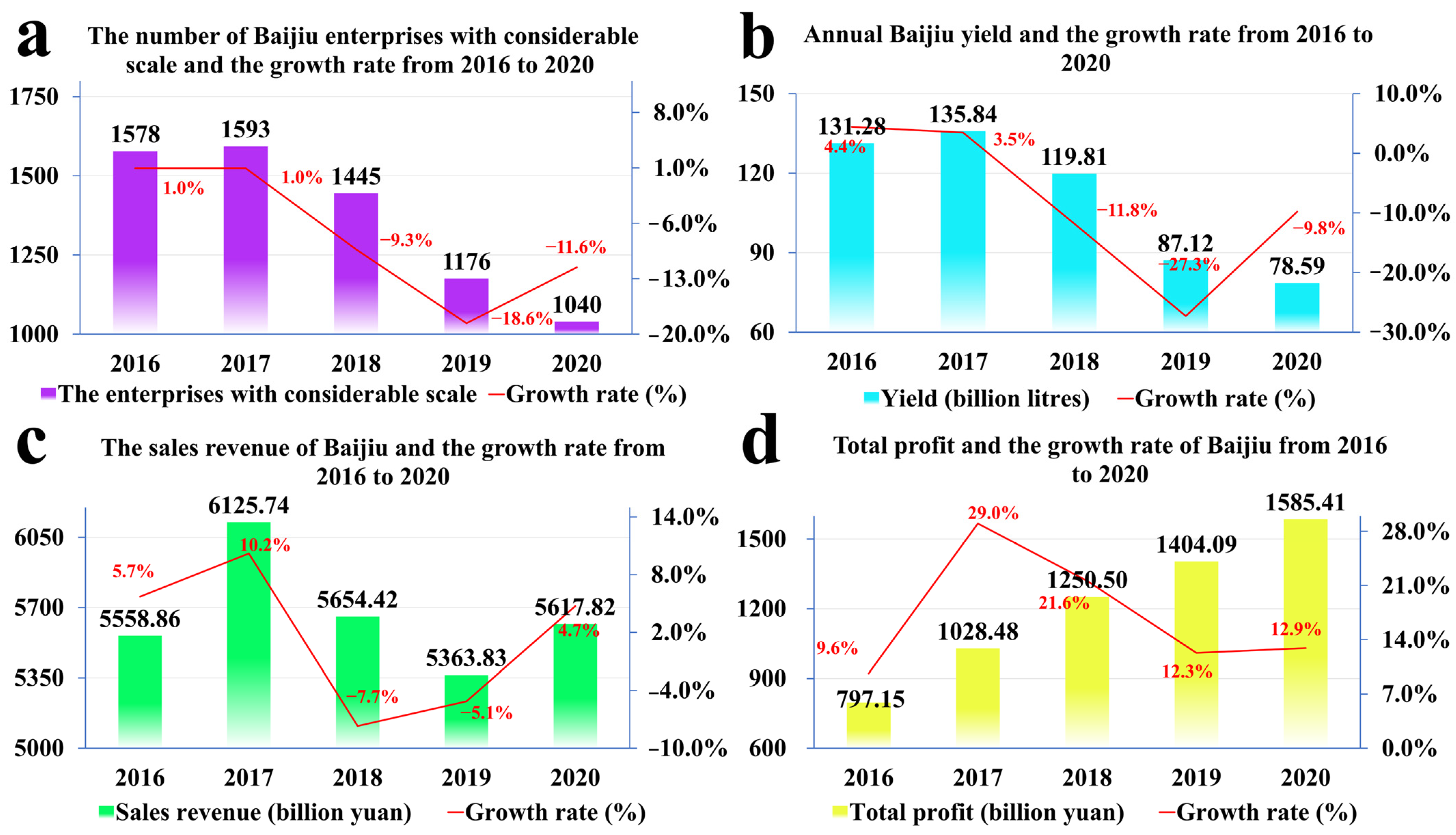

:1. Introduction

2. Introduction for the Extraction Method of Trace Components in Baijiu

2.1. Direct Injection

2.2. Liquid–Liquid Extraction

2.3. Solid Phase Microextraction

2.4. Stir Bar Sorptive Extraction

2.5. Other Methods

3. Introduction for the Detection Technique of Trace Components in Baijiu

3.1. Mass Spectrometry

3.2. Flame Ionization Detector

3.3. Sulfur Chemiluminescence Detector

3.4. Flame Photometric Detector

3.5. Nitrogen Phosphorus Detector

3.6. Gas Chromatography-Olfactometry

3.7. Time of Flight Mass Spectrometry

4. Methods for the Analysis of Trace Components in Baijiu

4.1. Qualitative Analysis of Volatile Substances in Baijiu

4.1.1. Spectral Library Retrieval

4.1.2. Standard Comparison Method

4.1.3. Retention Index Comparison

4.1.4. Aroma Characteristic Comparison

4.2. Quantitative Analysis Method

4.2.1. Semi-Quantitative Method

4.2.2. Area Normalization Method

4.2.3. External Standard Method

4.2.4. Internal Standard Method

4.2.5. Stable Isotope Dilution Method

5. Evaluation Methods for Aroma Compounds in Baijiu

5.1. Frequency Method

5.2. Time Intensity Method

5.3. Dilution Method

5.4. Odor Active Value

5.5. Sensory Evaluation Method

6. Research Progress of Aroma Compounds in Sesame Flavor Baijiu

6.1. Qualitative Analysis of Trace Components in Sesame Flavor Baijiu

6.2. Quantitative Analysis of Trace Components in Sesame Flavor Baijiu

6.3. Screening and Evaluation for the Aroma Compounds of Sesame Flavor Baijiu

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclature

References

- Sun, B. Baijiu and Huangjiu-Chinese National Alcohols, 1st ed.; Chemical Industry Press: Beijing, China, 2019; pp. 4–6. [Google Scholar]

- Fan, G.; Liu, P.; Chang, X.; Yin, H.; Cheng, L.; Teng, C.; Gone, Y.; Li, X. Isolation and Identification of a High-Yield Ethyl Caproate-Producing Yeast From Daqu and Optimization of Its Fermentation. Front. Microbiol. 2021, 12, 663744. [Google Scholar] [CrossRef]

- Wang, J.; Chen, H.; Wu, Y.; Zhao, D. Uncover the flavor code of strong-aroma baijiu: Research progress on the revelation of aroma compounds in strong-aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499. [Google Scholar] [CrossRef]

- Hong, J.; Wang, J.; Zhang, C.; Zhao, Z.; Tian, W.; Wu, Y.; Chen, H.; Zhao, D.; Sun, J. Unraveling variation on the profile aroma compounds of strong aroma type of Baijiu in different regions by molecular matrix analysis and olfactory analysis. RSC Adv. 2021, 11, 33511–33521. [Google Scholar] [CrossRef]

- Wu, Z.; Qin, D.; Duan, J.; Li, H.; Sun, J.; Huang, M.; Sun, B. Characterization of benzenemethanethiol in sesame-flavour baijiu by high-performance liquid chromatography-mass spectrometry and sensory science. Food Chem. 2021, 364, 130345. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wang, X.; Liu, X.; Li, X.; Zhang, C.; Li, W.; Sun, X.; Wang, W.; Sun, B. Discovery and development of a novel short-chain fatty acid ester synthetic biocatalyst under aqueous phase from Monascus purpureus isolated from Baijiu. Food Chem. 2021, 338, 128025. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Ma, Y.; Chen, S.; Xu, Y.; Tang, K. Exploring the Mystery of the Sweetness of Baijiu by Sensory Evaluation, Compositional Analysis and Multivariate Data Analysis. Foods 2021, 10, 2843. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Chen, S.; Nie, Y.; Xu, Y. Quantitative Analysis of Pyrazines and Their Perceptual Interactions in Soy Sauce Aroma Type Baijiu. Foods 2021, 10, 441. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Ni, W.; Ji, Z.; Liu, S.; Han, X.; Li, X.; Mao, J. Development of a Rapid Method for Determination of Main Higher Alcohols in Fermented Alcoholic Beverages Based on Dispersive Liquid-Liquid Microextraction and Gas Chromatography-Mass Spectrometry. Food Anal. Methods 2020, 13, 591–600. [Google Scholar] [CrossRef]

- Hong, J.; Tian, W.; Zhao, D. Research progress of trace components in sesame-aroma type of baijiu. Food Res. Int. 2020, 137, 109695. [Google Scholar] [CrossRef]

- Hu, G.; Lu, J.; Cai, X.; Yin, J. Analysis and study on characteristic components of Sesame flavor liquor. Liquor-Mak. Sci. Technol. 1994, 4, 75–77. (In Chinese) [Google Scholar]

- Fan, W.; Qian, M.C. Identification of aroma compounds in Chinese ‘Yanghe Daqu’ liquor by normal phase chromatography fractionation followed by gas chromatography[sol ]olfactometry. Flavour Fragr. J. 2006, 21, 333–342. [Google Scholar] [CrossRef]

- Zhu, M.; Fan, W.; Xu, Y.; Zhou, Q. 1,1-Diethoxymethane and methanethiol as age markers in Chinese roasted-sesame-like aroma and flavour type liquor. Eur. Food Res. Technol. 2016, 242, 1985–1992. [Google Scholar] [CrossRef]

- Fan, W.; Shen, H.; Xu, Y. Quantification of volatile compounds in Chinese soy sauce aroma type liquor by stir bar sorptive extraction and gas chromatography-mass spectrometry. J. Sci. Food Agric. 2011, 91, 1187–1198. [Google Scholar] [CrossRef]

- Cai, X.; Yin, J.; Hu, G. Determination of liquor flavor components by capillary column direct injection. Chromatography 1997, 5, 9–13. (In Chinese) [Google Scholar]

- Huang, Y.; Lu, J.; Li, A.; Lv, C.; Lu, W.; Huang, G. Analysis of Flavoring Substances in Gujing Gongjiu Liquor by GC/MS. Liquor-Mak. Sci. Technol. 2006, 7, 91–99. [Google Scholar]

- Zhao, D.; Shi, D.; Sun, J.; Li, H.; Zhao, M.; Sun, B. Quantification and cytoprotection by vanillin, 4-methylguaiacol and 4-ethylguaiacol against AAPH-induced abnormal oxidative stress in HepG2 cells. RSC Adv. 2018, 8, 35474–35484. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Chen, Y.; Wang, S. Analysis of Flavoring Compositions in Liquor by SBSE Absorption Techonolgy Coupled with GC× GC/TOFMS Technology. Liquor-Mak. Sci. Technol. 2012, 7, 50–55. [Google Scholar]

- Fan, W.; Xu, Y. Identification of Volatile Compounds of Fenjiu and Langjiu by Liquid-liquid Extraction Coupled with Normal Phase Liquid Chromatography (Last Part). Liquor-Mak. Sci. Technol. 2013, 2, 17–26. [Google Scholar]

- Xie, Z.; Lian, S.; Li, Y.; Ye, H. Research on Earthy-musty Substances in Liquor-making Bran. Liquor-Mak. Sci. Technol. 2016, 1, 47–49. [Google Scholar]

- Hu, G.; Lu, J.; Cai, X. Dynamic headspace sampling technique was used to analyze trace volatile components of liquor. Liquor Mak. 1992, 1, 67–71. (In Chinese) [Google Scholar]

- Wang, L.; Li, J. Research on the Extraction of Concentrated Trace Flavoring Substance in Liquor by Simultaneous Distillation Extraction. Liquor-Mak. Sci. Technol. 2010, 9, 25–27. [Google Scholar]

- Fan, W.; Xu, Y.; Yang, T.; Yubai, Z.; Zhu, G.; Zhou, X.; Chen, X. Volatile Compounds of Supple and Mellow Flavor Type in Yanghe’s Lansejidian Liquors Detected by Liquid-liquid Extraction Coupled with Fractionation. Liquor Mak. 2012, 39, 21–29. [Google Scholar]

- Zhao, D. Research on the Aroma Compounds of Gujinggong Chinese Baijiu and Evaluation of the Antioxidant and Anti-Inflammatory Effects of Phenolic Aroma Compounds; SCUT (South China University of Technology): Guangzhou, China, 2019. [Google Scholar]

- Song, X.; Zhu, L.; Jing, S.; Li, Q.; Ji, J.; Zheng, F.; Zhao, Q.; Sun, J.; Chen, F.; Zhao, M.; et al. Insights into the Role of 2-Methyl-3-furanthiol and 2-Furfurylthiol as Markers for the Differentiation of Chinese Light, Strong, and Soy Sauce Aroma Types of Baijiu. J. Agric. Food Chem. 2020, 68, 7946–7954. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Zhang, F.; Huang, M.; Liu, Y.; Sun, B. Analysis of sulfur—Containing flavor components in Sesame—Flavor liquor. Chin. J. Food Sci. 2014, 14, 218–225. [Google Scholar]

- Wang, B.; Li, H.; Zhang, F.; Xin, C.; Sun, J.; Huang, M.; Sun, B. Analysis of nitrogen compounds in Guojing sesame flavor liquor by liquid-liquid extraction combined with GC-MS and GC-NPD. Food Sci. 2014, 35, 126–131. [Google Scholar]

- Niu, Y.; Kong, J.; Xiao, Z.; Chen, F.; Ma, N.; Zhu, J. Characterization of odor-active compounds of various Chinese “Wuliangye” liquors by gas chromatography–olfactometry, gas chromatography–mass spectrometry and sensory evaluation. Int. J. Food Prop. 2017, 20 (Suppl. 1), S735–S745. [Google Scholar] [CrossRef] [Green Version]

- Yin, J. Analysis of Pyrazin Compounds in Liquor. 1991 Beijing Institute of Food Science and Technology Excellence Award Paper Selection, 1992nd ed.; Beijing Institute of Food Science and Technology: Beijing, China, 1992; pp. 77–81. [Google Scholar]

- Lu, J.; Hu, G. Analysis of volatile sulfur compounds in liquor by gas chromatography. Liquor-Mak. Sci. Technol. 1994, 1, 23–25. (In Chinese) [Google Scholar]

- Jin, P. Preliminary study on sulfur compounds in Meilan Spring wine. Liquor-Mak. Sci. Technol. 1993, 1, 65–67. (In Chinese) [Google Scholar]

- Wang, B.; Xin, C.; Han, J.; Sun, J.; Huang, M.; Sun, B. Analysis of nitrogen compounds in Sesame liquor by headspace solid phase microextraction combined with GC/NPD. Chin. J. Food Sci. 2015, 15, 247–253. [Google Scholar]

- Fan, H.; Fan, W.; Xu, Y. Characterization of key odorants in Chinese chixiang aroma-type liquor by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agric. Food Chem. 2015, 63, 3660–3668. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Lu, X.; Ji, K.; Guo, K.; Li, Y.; Wu, C.; Xu, G. Characterization of flavor compounds in Chinese liquor Moutai by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Anal. Chim. Acta 2007, 597, 340–348. [Google Scholar] [CrossRef]

- Chen, S.; Xu, Y. Characterization of volatile compounds in Chinese roasted sesame-like flavor type liquor by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Food Ferment. Ind. 2017, 43, 207–213. [Google Scholar]

- Li, A.; Xu, X.; Tang, Y.; Liu, G.; Gao, J.; Li, J. Research on Functional Ingredients of Gujing Gongjiu by Two Comprehensive Dimensional Gas Chromatography-Time of Flight Mass. Liquor-Mak. Sci. Technol. 2016, 1, 50–52. [Google Scholar]

- Zheng, Y.; Zhao, J.; Zhang, F.; Huang, M.; Sun, B.; Zheng, F.; Sun, J. Analysis of aroma components of Chuanfangjing Sesame liquor. Food Sci. 2014, 35, 60–65. [Google Scholar]

- Wang, X.; Fan, W.; Xu, Y. Characetrization of volatile aroma componentsin Chinese soy sauce aroma type Xijiu liquor by GC-O and GC-MS. Food Ferment. Ind. 2013, 39, 154–160. [Google Scholar]

- Li, X.; Chen, J.; Wang, L.; Wang, D.; Lei, L. Analysis of Organic Acids in Jiangxiang Baijiu. Liquor-Mak. Sci. Technol. 2019, 105–111. [Google Scholar]

- Zhang, M.; Li, L.; Xie, Z.; Huang, Z. Effects of Turbidity Removal by Active Carbon on the Aroma of Low-alcohol Liquor. Liquor-Mak. Sci. Technol. 2010, 12, 30–34. [Google Scholar]

- Sun, X.; Zhang, F.; Dong, W.; Zhao, D.; Sun, J.; Sun, B. Analysis of 3-Methylthiopropanol in Sesame Flavor Liquor by GC-MS/SIM. Chin. J. Food Sci. 2015, 15, 214–222. [Google Scholar]

- Zuo, H.; Du, Y.; Zuo, H.; Qiu, Y.; Zhang, L. Evaluation of the Uncertainty in the Determination of Ethyl Acetate in Baijiu by Internal Standard Gas Chromatography. Liquor-Mak. Sci. Technol. 2021, 4, 100–105. [Google Scholar]

- Su, Z.; Zhang, S.; Zhao, J.; Zhang, L.; Huang, X.; Yang, X.; Xu, Y.; Wu, W.; Yang, P.; Qin, H. Optimization of the determination of 16 phthalate acid esters in Baijiu by GC-MS/lsotope internal standard method. China Brew. 2019, 38, 173–177. [Google Scholar]

- Lian, S.; Liu, F.; Lan, S. Determination of sulfides in liquor by DNP—Tween column. Liquor-Mak. Sci. Technol. 1992, 2, 62. (In Chinese) [Google Scholar]

- Wu, J.; Huang, M.; Sun, B.; Zheng, F.; Sun, J. Analysis of Volatile Compounds in Jingzhi Baigan Liquor by Liquid-liquid Extraction(LLE) and Gas Chromatography-Mass Spectrometry(GC-MS). Food Sci. 2014, 35, 72–75. [Google Scholar]

- Liu, J. Studies on Aroma Compounds of Chinese “Kouzijiao” and “Jiannanchun” Liquors; Jiangnan University: Wuxi, China, 2008. [Google Scholar]

- Sha, S.; Chen, S.; Qian, M.; Wang, C.; Xu, Y. Characterization of the Typical Potent Odorants in Chinese Roasted Sesame-like Flavor Type Liquor by Headspace Solid Phase Microextraction-Aroma Extract Dilution Analysis, with Special Emphasis on Sulfur-Containing Odorants. J. Agric. Food Chem. 2017, 65, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Kesen, S.; Amanpour, A.; Sarhir, S.T.; Sevindik, O.; Guclu, G.; Kelebek, H.; Selli, S. Characterization of Aroma-Active Compounds in Seed Extract of Black Cumin (Nigella sativa L.) by Aroma Extract Dilution Analysis. Foods 2018, 7, 98. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y. Characterization of the Key Odorants in Chinese Zhima aroma-type Baijiu Studies; SCUT (South China University of Technology): Guangzhou, China, 2017. [Google Scholar]

- Zheng, Y.; Sun, B.; Zhao, M.; Zheng, F.; Huang, M.; Sun, J.; Sun, X.; Li, H. Characterization of the Key Odorants in Chinese Zhima Aroma-Type Baijiu by Gas Chromatography-Olfactometry, Quantitative Measurements, Aroma Recombination, and Omission Studies. J. Agric. Food Chem. 2016, 64, 5367–5374. [Google Scholar] [CrossRef]

- Wang, J.; Huang, M.; Zhang, J.; Wu, J. Flavor Chemistry in Baijiu with Sesame Flavor: A Review. In Sex, Smoke, and Spirits: The Role of Chemistry; American Chemical Society: Washington, DC, USA, 2019; pp. 177–224. [Google Scholar]

- Jin, G.; Zhu, Y.; Xu, Y. Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 2017, 63, 18–28. [Google Scholar] [CrossRef]

- Lai, A.; Zhao, D.; Cao, J. History, Status and Development Trend of Zhima-flavor Chinese Spirits. Liquor Mak. 2009, 36, 91–93. [Google Scholar]

- Wang, H.; Yu, Z. The typicality of Jingzhi Baigan Wine—Review and prospect of research on “sesame flavor”. Liquor Mak. 1992, 4, 61–70. (In Chinese) [Google Scholar]

- Gao, C. Formation and Innovation of Typical Styles of Meilanchun Sesame-flavor liquor. Liquor-Mak. Sci. Technol. 2010, 6, 101–107. [Google Scholar]

- Institute CFFIR, LTD SJWIC. Sesame-Flavor Baijiu; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardiza-tion Administration of China: Beijing, China, 2007; pp. 1–5. [Google Scholar]

- Wu, J.; Sun, Q.; Jiang, S.; Zhao, C. Analysis of & Discussion on the Compositions of Shengliyuan Sesame—Flavor Liquor. Liquor-Mak. Sci. Technol. 2009, 6, 65–69. [Google Scholar]

- Wu, T.; Zhu, S.; Sun, X.; Zhao, W.; Cui, G. Analysis of Health Factors of Meilanchun Sesame-flavor Liquor. Liquor-Mak. Sci. Technol. 2013, 8, 125–130. [Google Scholar]

- Thomas, C.; Mercier, F.; Tournayre, P.; Martin, J.L.; Berdagué, J. Identification and origin of odorous sulfur compounds in cooked ham. Food Chem. 2014, 155, 207–213. [Google Scholar] [CrossRef]

- Tressl, R.; Silwar, R. Investigation of sulfur-containing components in roasted coffee. J. Agric. Food Chem. 1981, 29, 1078–1082. [Google Scholar] [CrossRef] [PubMed]

- Capone, D.L.; Ristic, R.; Pardon, K.H.; Jeffery, D.W. Simple quantitative determination of potent thiols at ultratrace levels in wine by derivatization and high-performance liquid chromatography-tandem mass spectrometry (HPLC-MS/MS) analysis. Anal. Chem. 2015, 87, 1226–1231. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Sun, J.; Zhang, F.; Zhang, Q.; Huang, M.; Sun, B. Determination of Sulfur Compounds in Bandaojing Sesame Flavor Liquor. Chin. J. Food Sci. 2012, 12, 173–179. [Google Scholar]

- Zhao, D.; Zhang, L.; Zhang, F.; Sun, J.; Sun, X.; Huang, M.; Zheng, F.; Sun, B. Analysis of Sulfur-Containing Compounds in Sesame-flavor Chinese Liquor by Solid Phase Microextraction and Liquid-Liquid Extraction Coupled with GC-MS. Food Sci. 2016, 37, 99–106. [Google Scholar]

- Sun, X.; Zhang, F.; Dong, W.; Sun, J.; Sun, B. GC-FPD Analysis of 3-Methylthiopropanol in Sesame-Flavor Liquor. J. Food Sci. Technol. 2014, 32, 27–34. [Google Scholar]

- Zhu, S.; Gao, C.; Cui, G. Analysis of Trace Compositions of Meilanchun Sesame-flavor Liquor. Liquor-Mak. Sci. Technol. 2012, 6, 106–110. [Google Scholar]

- Sun, J.; Zhao, D.; Zhang, F.; Sun, B.; Zheng, F.; Huang, M.; Sun, X.; Li, H. Joint direct injection and GC–MS chemometric approach for chemical profile and sulfur compounds of sesame-flavor Chinese Baijiu (Chinese liquor). Eur. Food Res. Technol. 2018, 244, 145–160. [Google Scholar] [CrossRef]

- Fan, W.; Xu, Y. Determination of Order Thresholds of Volatile Aroma Compounds in Baijiu by A Forced-choice Ascending Concentration Series Method of Limits. Liquor Mak. 2011, 38, 80–84. [Google Scholar]

- Zhou, Q. Order Profile of Chinese Roasted-Sesame-Like Aroma Type Liquor; Jiangnan University: Wuxi, China, 2015. [Google Scholar]

- Sun, J.; Li, Q.; Luo, S.; Zhang, J.; Huang, M.; Chen, F.; Zheng, F.; Sun, X.; Li, H. Characterization of key aroma compounds in Meilanchun sesame flavor style baijiu by application of aroma extract dilution analysis, quantitative measurements, aroma recombination, and omission/addition experiments. RSC Adv. 2018, 8, 23757–23767. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Li, Q.; Huang, M.; Wu, J.; Li, H.; Sun, J.; Sun, X.; Zheng, F.; Sun, B. Analysis of Odor-Active Compounds in 2 Sesame-Flavor Chinese Baijius. Food Sci. 2019, 40, 214–222. [Google Scholar]

- Li, H.; Qin, D.; Wu, Z.; Sun, B.; Sun, X.; Huang, M.; Sun, J.; Zheng, F. Characterization of key aroma compounds in Chinese Guojing sesame-flavor Baijiu by means of molecular sensory science. Food Chem. 2019, 284, 100–107. [Google Scholar] [CrossRef] [PubMed]

| No. | Aroma Compounds | CAS Number | Aroma Descriptors | FD Factor | OAV | Ref. 1 (Year) |

|---|---|---|---|---|---|---|

| 1 | ethyl hexanoate | 123-66-0 | fruity | 4096 | 2691 | [50] (2016) |

| 2 | 3-methylbutanal | 590-86-3 | malty | 8 | 2403 | [50] (2016) |

| 3 | ethyl acrylate | 140-88-5 | plastic | 512 | 2225 | [50] (2016) |

| 4 | 2-furfurylthiol | 98-02-2 | roasted sesame seeds | 400 | 1182 | [47] (2017) |

| 5 | ethyl pentanoate | 539-82-2 | fruity | 2048 | 1019 | [50] (2016) |

| 6 | ethyl octanoate | 106-32-1 | fruity | 25 | 782 | [50] (2016) |

| 7 | ethyl 2-methylpropanoate | 97-62-1 | fruity, sweet | 100 | 600 | [47] (2017) |

| 8 | 3-methylbutyl acetate | 123-92-2 | fruity | 495 | [47] (2017) | |

| 9 | ethyl butanoate | 105-54-4 | fruity | 2048 | 447 | [50] (2016) |

| 10 | dimethyl trisulfide | 3658-80-8 | onion | 128 | 388 | [41] (2016) |

| 11 | benzyl mercaptan | 100-53-8 | roasted | 19,683 | 286 | [64] (2019) |

| 12 | 2-methylpropanoic acid | 79-31-2 | rancid | 4 | 226 | [47] (2017) |

| 13 | ethyl 2-methylbutanoate | 7452-79-1 | fruity | 400 | 215 | [50] (2016) |

| 14 | β-damascenone | 23696-85-7 | tea flavor | 116 | [47] (2017) | |

| 15 | 3-methylbutanoic acid | 503-74-2 | sweaty | 2048 | 89 | [50] (2016) |

| 16 | butanoic acid | 107-92-6 | sweaty, rancid | 1024 | 57 | [50] (2016) |

| 17 | ethyl acetate | 141-78-6 | pineapple | 100 | 56 | [47] (2017) |

| 18 | ethyl decanoate | 110-38-3 | fruity | 16 | 46 | [50] (2016) |

| 19 | pentanoic acid | 109-52-4 | sweaty | 256 | 46 | [50] (2016) |

| 20 | hexanoic acid | 142-62-1 | sweaty | 2048 | 35 | [50] (2016) |

| 21 | geosmin | 104873-46-3 | 22 | [47] (2017) | ||

| 22 | methional | 3268-49-3 | cooked potato | 25 | 99 | [50] (2016) |

| 23 | ethyl lactate | 97-64-3 | fruity | 16 | 15 | [50] (2016) |

| 24 | dimethyl sulfide | 75-18-3 | cooked onion | 5 | 14 | [47] (2017) |

| 25 | s-methyl thioacetate | 1534-08-3 | rotten cabbage | 100 | 13 | [47] (2017) |

| 26 | 2-phenylethyl acetate | 103-45-7 | floral | 32 | 7 | [50] (2016) |

| 27 | 1-propanol | 71-23-8 | fruity | 100 | 6 | [47] (2017) |

| 28 | 2-methyl-1-propanol | 78-83-1 | fruity | 8 | 4 | [50] (2016) |

| 29 | ethyl 3-phenylpropanoate | 2021-28-5 | floral | 16 | 3 | [50] (2016) |

| 30 | phenylacetic acid | 103-82-2 | sweet, honey | 2 | 3 | [50] (2016) |

| 31 | ethyl phenylacetate | 101-97-3 | fruity, sweet | 64 | 3 | [50] (2016) |

| 32 | 4-ethyl-2-methoxyphenol | 2785-89-9 | smoky | 4 | 2 | [50] (2016) |

| 33 | 3-methyl-1-butanol | 123-51-3 | malty | 1024 | 2 | [50] (2016) |

| 34 | 2-furfural | 98-01-1 | sweet | 64 | 2 | [50] (2016) |

| 35 | furfuryl alcohol | 98-00-0 | caramel | 16 | 1 | [50] (2016) |

| 36 | ethyl benzoate | 93-89-0 | fruity | 32 | <1 | [50] (2016) |

| 37 | acetic acid | 64-19-7 | vinegar | 5 | <1 | [50] (2016) |

| 38 | 5-methyl furfural | 620-02-0 | baked | 25 | <1 | [50] (2016) |

| 39 | 3-methylthio-1-propanol | 505-10-2 | cooked vegetable | 100 | <1 | [47] (2017) |

| 40 | trimethyl pyrazine | 14667-55-1 | nutty | 4 | <1 | [50] (2016) |

| 41 | octanoic acid | 124-07-2 | sweaty | 32 | <1 | [50] (2016) |

| 42 | diethyl butanedioate | 123-25-1 | sweet | 25 | <1 | [50] (2016) |

| 43 | 2-acetyl furan | 1192-62-7 | sweet | 25 | <1 | [50] (2016) |

| 44 | heptanoic acid | 111-14-8 | sweaty | 32 | <1 | [50] (2016) |

| 45 | diethyl acetal | 105-57-7 | fruity | 512 | <1 | [50] (2016) |

| 46 | ethyl propanoate | 105-37-3 | fruity | 100 | <1 | [50] (2016) |

| 47 | benzyl alcohol | 100-51-6 | sweet | 16 | <1 | [50] (2016) |

| 48 | propanoic acid | 79-09-4 | sour | 128 | <1 | [50] (2016) |

| 49 | 2-phenylethanol | 60-12-8 | rose-like | 256 | <1 | [50] (2016) |

| 50 | ethyl 3-methylthio propionate | 13327-56-5 | fruity | <1 | [67] (2016) | |

| 51 | terpineol | 8000-41-7 | floral | 200 | [47] (2017) | |

| 52 | hexyl hexanoate | 6378-65-0 | apple, peach | 10 | [47] (2017) | |

| 53 | propyl hexanoate | 626-77-7 | fruity | 200 | [47] (2017) | |

| 54 | ethyl 2-mercaptoacetate | 623-51-8 | cooked vegetable | 100 | [47] (2017) | |

| 55 | 1-octen-3-one | 4312-99-6 | mushroom | 5 | [47] (2017) | |

| 56 | ethyl benzoate | 32874-26-3 | fruity | 10 | [50] (2016) | |

| 57 | 3-methylbutyl hexanoate | 2198-61-0 | fruity | 100 | [47] (2017) | |

| 58 | naphthalene | 16728-99-7 | musty | 5 | [70] (2019) [47] (2017) | |

| 59 | benzaldehyde | 100-52-7 | fruity | 5 | [70] (2019) [50] (2017) | |

| 60 | ethyl 3-(methylthio) propanoate | 13532-18-8 | sulfur, rotten cabbage | 5 | [70] (2019) [47] (2017) | |

| 61 | 2,5-dimethyl-3-ethylpyrazine | 13360-65-1 | baked | 100 | [70] (2019) [47] (2017) | |

| 62 | 2-acetyl-5-methyl furan | 1193-79-9 | baked | 5 | [69] (2018) | |

| 63 | 1-hexanol | 111-27-3 | floral | 25 | [47] (2017) | |

| 64 | 2,6-dimethylpyrazine | 108-50-9 | nutty | 100 | [69] (2018) [47] (2017) | |

| 65 | methyl hexanoate | 106-70-7 | floral | 25 | [69] (2018) | |

| 66 | benzoic acid | 65-85-0 | balsam | 2 | [50] (2016) | |

| 67 | ethyl hexadecanoate | 628-97-7 | waxy | 1 | [50] (2016) | |

| 68 | ethyl 2-hydroxybutanoate | 52089-54-0 | fruity | 4 | [50] (2016) | |

| 69 | ethyl 4-methylpentanoate | 25415-67-2 | fruity | 16 | [50] (2016) | |

| 70 | 2-furaldehyde diethyl acetal | 13529-27-6 | sweet | 4 | [50] (2016) | |

| 71 | phenol | 108-95-2 | phenolic | 4 | [50] (2016) | |

| 72 | ethyl 3-methylbutanoate | 108-64-5 | berry | 512 | [50] (2016) | |

| 73 | 2-ethyl-6-methyl-pyrazine | 13925-03-6 | nutty | 32 | [50] (2016) | |

| 74 | difurfuryldisulfide | 224-649-6 | nutty, coffee | 4 | [50] (2016) | |

| 75 | 2-acetyl-pyrrole | 214-016-2 | nutty | 3 | [50] (2018) | |

| 76 | dimethyl disulfide | 624-92-0 | onion, cabbage, meat, corn. | 3 | [50] (2018) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Wu, Y.; Wang, J.; Hong, J.; Tian, W.; Zhao, D.; Sun, J.; Huang, M.; Li, H.; Zheng, F.; et al. Uncover the Flavor Code of Roasted Sesame for Sesame Flavor Baijiu: Advance on the Revelation of Aroma Compounds in Sesame Flavor Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation. Foods 2022, 11, 998. https://doi.org/10.3390/foods11070998

Chen H, Wu Y, Wang J, Hong J, Tian W, Zhao D, Sun J, Huang M, Li H, Zheng F, et al. Uncover the Flavor Code of Roasted Sesame for Sesame Flavor Baijiu: Advance on the Revelation of Aroma Compounds in Sesame Flavor Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation. Foods. 2022; 11(7):998. https://doi.org/10.3390/foods11070998

Chicago/Turabian StyleChen, Hao, Yashuai Wu, Junshan Wang, Jiaxin Hong, Wenjing Tian, Dongrui Zhao, Jinyuan Sun, Mingquan Huang, Hehe Li, Fuping Zheng, and et al. 2022. "Uncover the Flavor Code of Roasted Sesame for Sesame Flavor Baijiu: Advance on the Revelation of Aroma Compounds in Sesame Flavor Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation" Foods 11, no. 7: 998. https://doi.org/10.3390/foods11070998

APA StyleChen, H., Wu, Y., Wang, J., Hong, J., Tian, W., Zhao, D., Sun, J., Huang, M., Li, H., Zheng, F., & Sun, B. (2022). Uncover the Flavor Code of Roasted Sesame for Sesame Flavor Baijiu: Advance on the Revelation of Aroma Compounds in Sesame Flavor Baijiu by Means of Modern Separation Technology and Molecular Sensory Evaluation. Foods, 11(7), 998. https://doi.org/10.3390/foods11070998