Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Isolation of gums

2.2. Preparation of wheat flour and gum blends

2.3. Rapid Visco analyzer measurements (RVA)

2.4. Gel Texture

2.5. Dough Mixing Properties Assessed using DoughLab

2.6. Bread Baking Procedure

2.7. Cake Baking Procedure

2.8. Bread and Cake Firmness after Storage

2.9. Crumb Color of Bread and Cakes

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

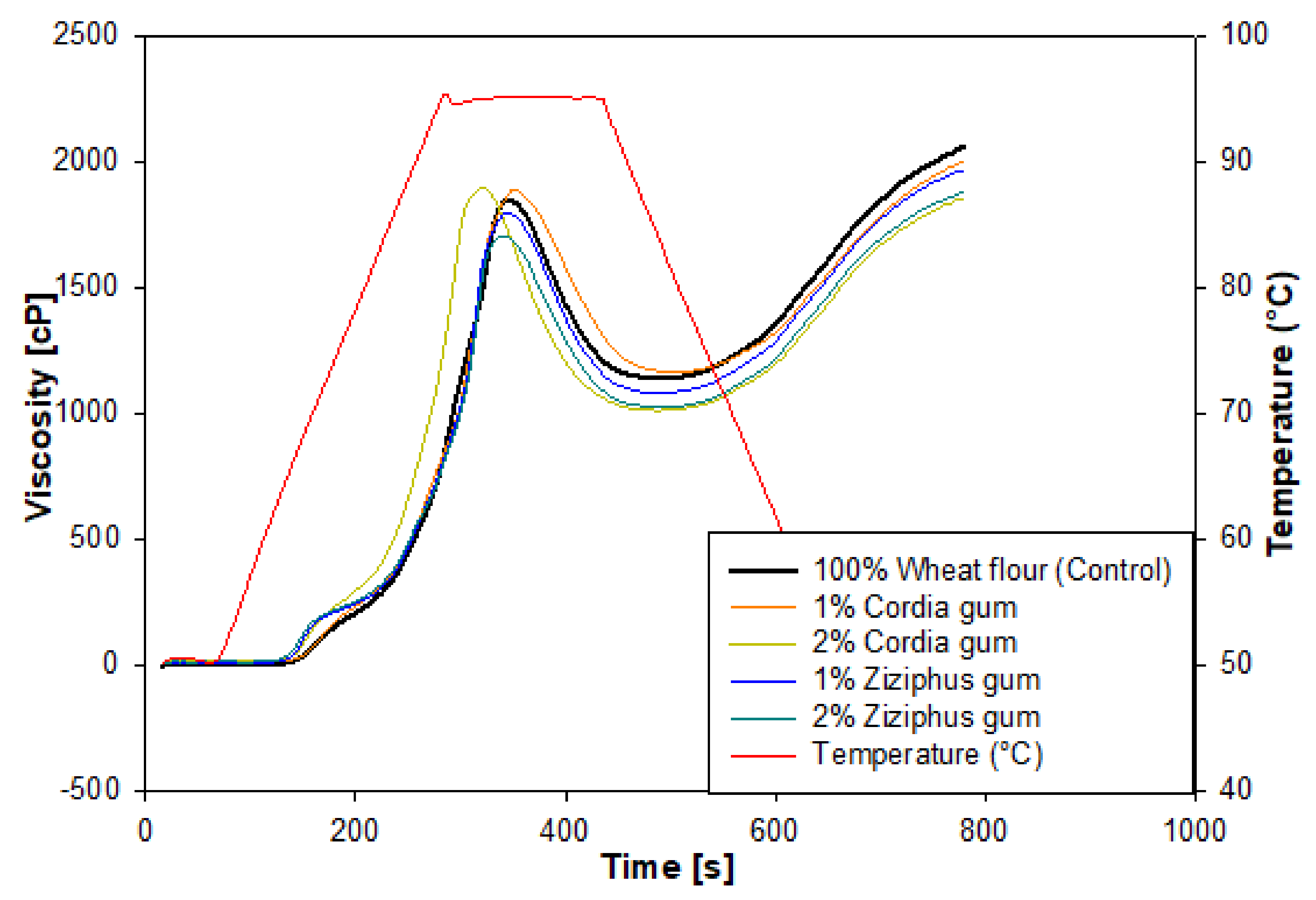

3.1. Pasting Properties of Flour Blends (RVA)

3.2. Textural Properties of Flour Blends

3.3. Dough Mixing Properties

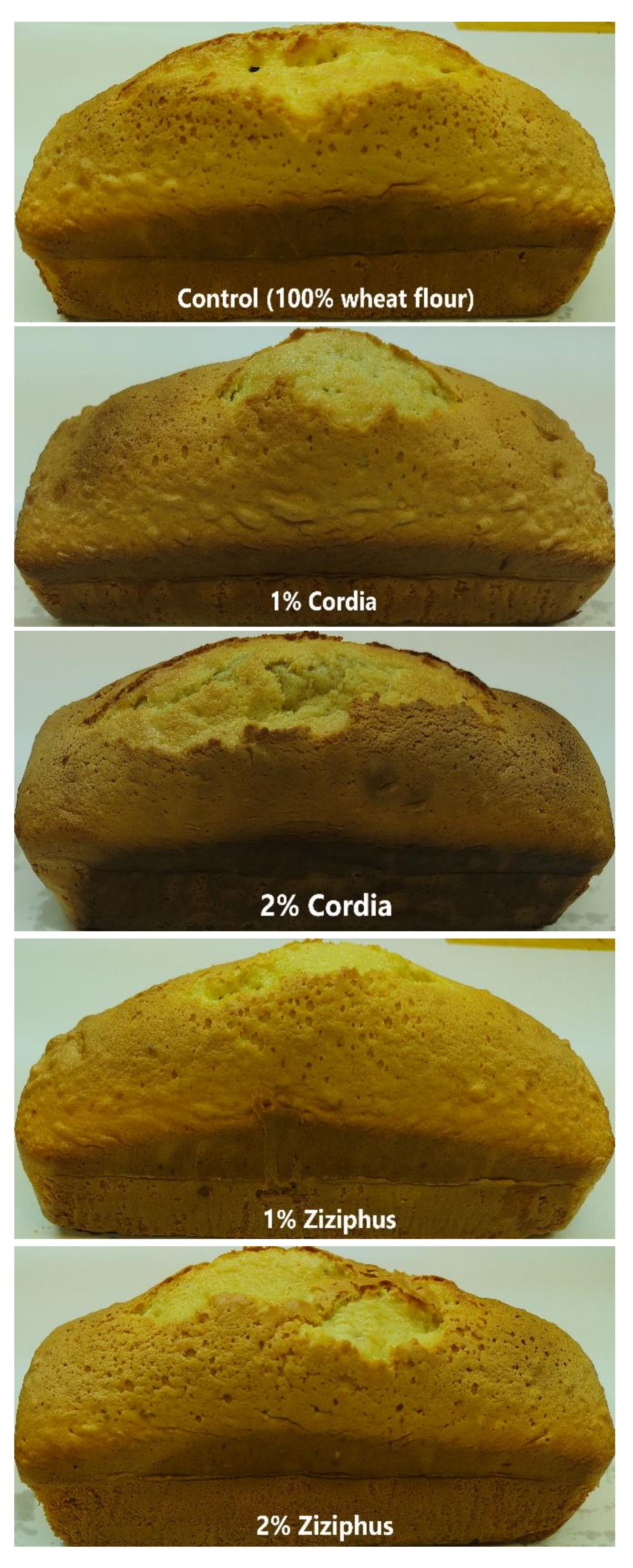

3.4. Bread and Cake Quality Evaluation

3.5. Crumb Color of Bread and Cakes

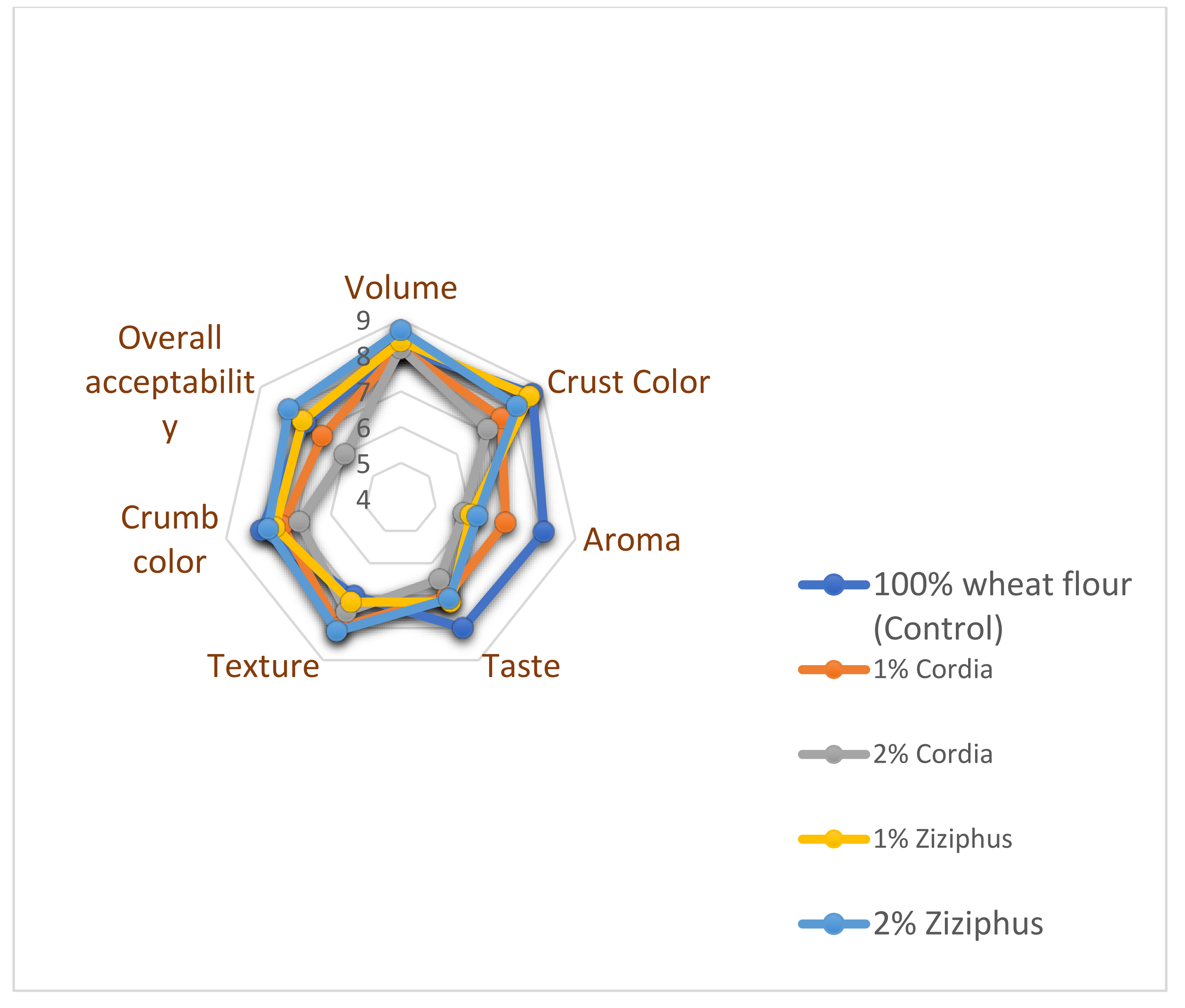

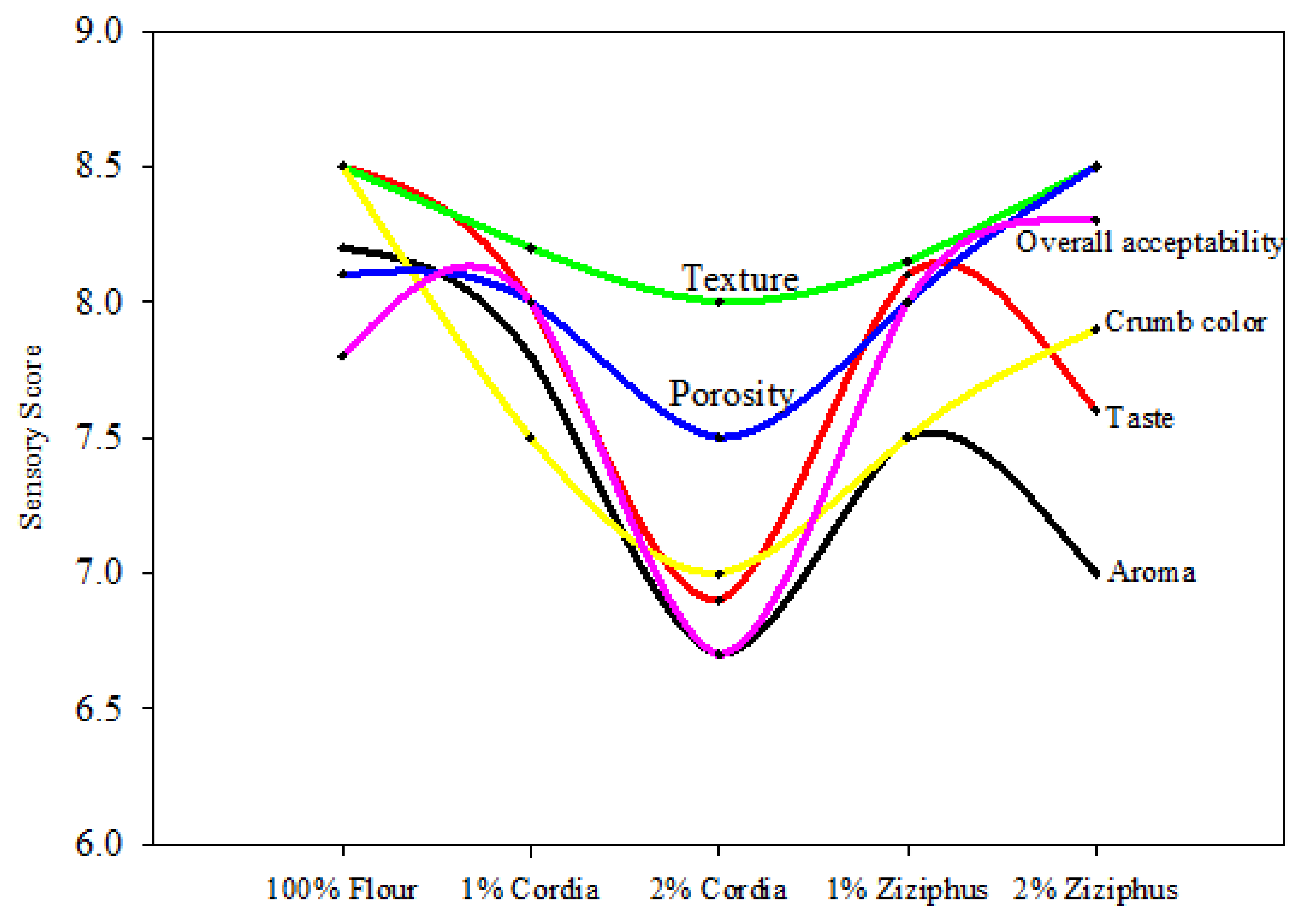

3.6. Sensory Evolution of Bread and Cake

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Armero, E.; Collar, C. Antistaling additives, flour type and sourdough process effects on functionality of wheat doughs. J. Food Sci. 1996, 61, 299–303. [Google Scholar] [CrossRef]

- Stauffer, C. Emulsifiers and dough strengtheners. In Functional Additives for Bakery Foods; Springer: Delaware, NY, USA, 1990; pp. 69–124. [Google Scholar]

- Dziezak, J.D. A focus on gums. Food Technol.Chic. 1991, 45, 116–132. [Google Scholar]

- Selomulyo, V.O.; Zhou, W. Frozen bread dough: Effects of freezing storage and dough improvers. J. Cereal Sci. 2007, 45, 1–17. [Google Scholar] [CrossRef]

- Sidhu, J.P.S.; Bawa, A. Dough characteristics and baking studies of wheat flour fortified with xanthan gum. Int. J. Food Prop. 2002, 5, 1–11. [Google Scholar] [CrossRef]

- Collar, C.; Andreu, P.; Martınez, J.; Armero, E. Optimization of hydrocolloid addition to improve wheat bread dough functionality: A response surface methodology study. Food Hydrocoll. 1999, 13, 467–475. [Google Scholar] [CrossRef]

- Fiszman, S.; Salvador, A. Recent developments in coating batters. Trends Food Sci. Technol. 2003, 14, 399–407. [Google Scholar] [CrossRef]

- Guarda, A.; Rosell, C.M.; Benedito, C.; Galotto, M.J. Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll. 2004, 18, 241–247. [Google Scholar] [CrossRef]

- Bárcenas, M.E.; Rosell, C.M. Different approaches for increasing the shelf life of partially baked bread: Low temperatures and hydrocolloid addition. Food Chem. 2007, 100, 1594–1601. [Google Scholar] [CrossRef]

- Davidou, S.; Le Meste, M.; Debever, E.; Bekaert, D. A contribution to the study of staling of white bread: Effect of water and hydrocolloid. Food Hydrocoll. 1996, 10, 375–383. [Google Scholar] [CrossRef]

- Rojas, J.A.; Rosell, C.M.; De Barber, C.B. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Rosell, C.M.; Rojas, J.A.; De Barber, C.B. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocoll. 2001, 15, 75–81. [Google Scholar] [CrossRef]

- Shittu, T.A.; Aminu, R.A.; Abulude, E.O. Functional effects of xanthan gum on composite cassava-wheat dough and bread. Food Hydrocoll. 2009, 23, 2254–2260. [Google Scholar] [CrossRef]

- Shi, X.; BeMiller, J.N. Effects of food gums on viscosities of starch suspensions during pasting. Carbohydr. Polym. 2002, 50, 7–18. [Google Scholar] [CrossRef]

- Sahi, S.S.; Alava, J.M. Functionality of emulsifiers in sponge cake production. J. Sci. Food Agric. 2003, 83, 1419–1429. [Google Scholar] [CrossRef]

- Kalinga, D.; Mishra, V.K. Rheological and physical properties of low fat cakes produced by addition of cereal β-glucan concentrates. J. Food Processing Preserv. 2009, 33, 384–400. [Google Scholar] [CrossRef]

- Lee, S.; Inglett, G.; Carriere, C. Effect of nutrim oat bran and flaxseed on rheological properties of cakes. Cereal Chem. 2004, 81, 637–642. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Kim, S.; Inglett, G.E. Effect of shortening replacement with oatrim on the physical and rheological properties of cakes. Cereal Chem. 2005, 82, 120–124. [Google Scholar] [CrossRef]

- Haq, M.A.; Hasnain, A. Antioxidant containing gum cordia coatings for control of peanut oxidation. J. Food Process. Preserv. 2014, 38, 896–904. [Google Scholar] [CrossRef]

- Hasani, M.; Yazdanpanah, S. The Effects of Gum Cordia on the Physicochemical, Textural, Rheological, Microstructural, and Sensorial Properties of Apple Jelly. J. Food Qual. 2020, 2020, 8818960. [Google Scholar] [CrossRef]

- Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Shahzad, S.A.; Ababtain, I.A. Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods 2020, 9, 909. [Google Scholar] [CrossRef]

- Lu, R.; Van Beers, R.; Saeys, W.; Li, C.; Cen, H. Measurement of optical properties of fruits and vegetables: A review. Postharvest Biol. Technol. 2020, 159, 111003. [Google Scholar] [CrossRef]

- Haq, M.A.; Alam, M.J.; Hasnain, A. Gum Cordia: A novel edible coating to increase the shelf life of Chilgoza (Pinus gerardiana). LWT Food Sci. Technol. 2013, 50, 306–311. [Google Scholar] [CrossRef]

- Delfanian, M.; Esmaeilzadeh Kenari, R.; Sahari, M.A. Utilization of Jujube fruit (Ziziphus mauritiana Lam.) extracts as natural antioxidants in stability of frying oil. Int. J. Food Prop. 2016, 19, 789–801. [Google Scholar] [CrossRef] [Green Version]

- Obeed, R.; Harhash, M.; Abdel-Mawgood, A. Fruit properties and genetic diversity of five ber (Ziziphus mauritiana Lamk.) cultivars. Pak. J. Biol. Sci. 2008, 11, 888–893. [Google Scholar] [CrossRef] [PubMed]

- Muchuweti, M.; Zenda, G.; Ndhlala, A.R.; Kasiyamhuru, A. Sugars, organic acid and phenolic compounds of Ziziphus mauritiana fruit. Eur. Food Res. Technol. 2005, 221, 570–574. [Google Scholar] [CrossRef]

- Ray, P.; Chatterjee, S.; Saha, P. Screening of polysaccharides from fruit pulp of Ziziphus mauritiana L. and Artocarpus heterophyllus L. as natural mucoadhesives. Future J. Pharm. Sci. 2021, 7, 1–10. [Google Scholar] [CrossRef]

- Lee, H.B.; Kim, S.Y. Studies on the changes of chemical components of dried jujube (Zizyphus jujuba Miller) during storage. Korean J. Agric. Sci. 1988, 15, 95–113. [Google Scholar]

- Mohamed, A.; Hussain, S.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Ababtain, I.A. Physicochemical Properties of Starch Binary Mixtures with Cordia and Ziziphus Gums. Processes 2022, 10, 180. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. Effects of alkaline-soluble okra gum on rheological and thermal properties of systems with wheat or corn starch. Food Hydrocoll. 2013, 30, 541–551. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Singh, N. Some properties of corn starches II: Physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem. 2007, 101, 1499–1507. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists; American Association of Cereal Chemists: Ann Arbor, MI, USA, 2000; Volume 1. [Google Scholar]

- Alamri, M.S. Okra-gum fortified bread: Formulation and quality. J. Food Sci. Technol. 2014, 51, 2370–2381. [Google Scholar] [CrossRef] [Green Version]

- Christianson, D.; Hodge, J.; Osborne, D.; Detroy, R.W. Gelatinization of wheat starch as modified by xanthan gum, guar gum, and cellulose gum. Cereal Chem 1981, 6, 513–517. [Google Scholar]

- Vedantam, S.K.; Sagili, J.L.; Dikkala, P.K.; Sridhar, K. Functional, thermal, pasting, and rheological properties of gluten-free maize composite flour: Effect of moth bean flour and hydrocolloid addition. J. Food Processing Preserv. 2021, 45, e16104. [Google Scholar] [CrossRef]

- Sudhakar, V.; Singhal, R.S.; Kulkarni, P.R. Studies on starch-hydrocolloid interactions: Effect of salts. Food Chem. 1995, 53, 405–408. [Google Scholar] [CrossRef]

- Alloncle, M.; Lefebvre, J.; Llamas, G.; Doublier, J. A rheological characterization of cereal starch-galactomannan mixtures. Cereal Chem. 1989, 66, 90–93. [Google Scholar]

- Hammed, A.M.; Ozsisli, B.; Simsek, S. Utilization of microvisco-amylograph to study flour, dough, and bread qualities of hydrocolloid/flour blends. Int. J. Food Prop. 2016, 19, 591–604. [Google Scholar] [CrossRef]

- Alam, F.; Siddiqui, A.; Lutfi, Z.; Hasnain, A. Effect of different hydrocolloids on gelatinization behaviour of hard wheat flour. Trakia J. Sci. 2009, 7, 1–6. [Google Scholar]

- Funami, T.; Kataoka, Y.; Omoto, T.; Goto, Y.; Asai, I.; Nishinari, K. Effects of non-ionic polysaccharides on the gelatinization and retrogradation behavior of wheat starch. Food Hydrocoll. 2005, 19, 1–13. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Huang, S.; Wang, N.; Zhang, Y.; Zhang, F.; Zheng, J. Physical, thermal and structural properties of rice starch as affected by the addition of bamboo shoot shell fibres. Int. J. Food Sci. Technol. 2020, 55, 3658–3669. [Google Scholar] [CrossRef]

- Yildiz, Ö.; Yurt, B.; Baştürk, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S.; Dağlıoğlu, O. Pasting properties, texture profile and stress–relaxation behavior of wheat starch/dietary fiber systems. Food Res. Int. 2013, 53, 278–290. [Google Scholar] [CrossRef]

- Linlaud, N.; Puppo, M.; Ferrero, C. Effect of hydrocolloids on water absorption of wheat flour and farinograph and textural characteristics of dough. Cereal Chem. 2009, 86, 376–382. [Google Scholar] [CrossRef]

- Simsek, S. Application of xanthan gum for reducing syruping in refrigerated doughs. Food Hydrocoll. 2009, 23, 2354–2358. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, C.; Bai, J.; Liang, J. Mixing, tensile and pasting properties of wheat flour mixed with raw and enzyme treated rice bran. J. Food Sci. Technol. 2015, 52, 3014–3021. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, H.; Morgenstern, M.; Campanella, O.; Larsen, N. Rheological properties of dough during mechanical dough development. J. Cereal Sci. 2000, 32, 293–306. [Google Scholar] [CrossRef]

- Raczyk, M.; Kruszewski, B.; Michałowska, D. Effect of Coconut and Chestnut Flour Supplementations on Texture, Nutritional and Sensory Properties of Baked Wheat Based Bread. Molecules 2021, 26, 4641. [Google Scholar] [CrossRef]

- Maleki, G.; MilaNi, J.M. Effect of guar gum, xanthan gum, CMC and HPMC on dough rhealogy and physical properties of Barbari bread. Food Sci. Technol. Res. 2013, 19, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Bell, D.A. Methylcellulose as a structure enhancer in bread baking. Cereal Foods World 1990, 35, 1001–1006. [Google Scholar]

- Filipčev, B.; Lević, L.; Bodroža-Solarov, M.; Mišljenović, N.; Koprivica, G. Quality characteristics and antioxidant properties of breads supplemented with sugar beet molasses-based ingredients. Int. J. Food Prop. 2010, 13, 1035–1053. [Google Scholar] [CrossRef] [Green Version]

- Schiraldi, A.; Piazza, L.; Riva, M. Bread staling: A calorimetric approach. Cereal Chem. 1996, 73, 32–39. [Google Scholar]

- Gomez, M.; Ronda, F.; Caballero, P.A.; Blanco, C.A.; Rosell, C.M. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007, 21, 167–173. [Google Scholar] [CrossRef]

- Paraskevopoulou, A.; Kiosseoglou, V. Texture profile analysis of heat-formed gels and cakes prepared with low cholesterol egg yolk concentrates. J. Food Sci. 1997, 62, 208–211. [Google Scholar] [CrossRef]

- Esteller, M.S.; Amaral, R.L.; Lannes, S.C.D.S. Effect of sugar and fat replacers on the texture of baked goods. J. Texture Stud. 2004, 35, 383–393. [Google Scholar] [CrossRef]

- Della Valle, G.; Chiron, H.; Jury, V.; Raitière, M.; Réguerre, A.-L. Kinetics of crust formation during conventional French bread baking. J. Cereal Sci. 2012, 56, 440–444. [Google Scholar] [CrossRef]

| 2PV (cP) | 3BD (cP) | 4FV (cP) | 5SB 6(cP) | 7PT (°C) | |

|---|---|---|---|---|---|

| Control (100% WF1) | 1886 ± 35.26 b | 736 ± 21.39 bc | 2056 ± 1.70 a | 905 ± 12.36 a | 69.40 ± 0.04 a |

| 1% Cordia gum | 1885 ± 2.87 b | 763 ± 32.32 b | 1968 ± 21.67 b | 813 ± 49.71 c | 66.93 ± 0.61 b |

| 2% Cordia gum | 1951 ± 41.67 a | 918 ± 23.72 a | 1869 ± 12.28 c | 834 ± 5.89 bc | 67.37 ± 0.33 b |

| 1% Ziziphus gum | 1776 ± 18.80 c | 709 ± 8.65 cd | 1950 ± 11.84 b | 883 ± 1.70 ab | 66.13 ± 0.02 c |

| 2% Ziziphus gum | 1712 ± 7.93 d | 674 ± 3.68 d | 1893 ± 14.82 c | 849 ± 2.62 bc | 65.65 ± 0.35 c |

| Hardness (N) | Gumminess (N) | Chewiness (N.mm) | Springiness (mm) | Cohesiveness | Adhesiveness (mJ) | |

|---|---|---|---|---|---|---|

| Control 1 | 0.60 ± 0.01 a | 0.29 ± 0.01 b | 2.93 ± 0.01 b | 10.00 ± 0.08 a | 0.49 ± 0.01 d | 0.83 ± 0.05 a |

| 1% Cordia | 0.56 ± 0.01 bc | 0.29 ± 0.01 b | 2.90 ± 0.06 b | 9.85 ± 0.09 b | 0.52 ± 0.01 c | 0.27 ± 0.04 c |

| 2% Cordia | 0.52 ± 0.00 d | 0.29 ± 0.01 b | 2.81 ± 0.01 c | 9.73 ± 0.05 c | 0.55 ± 0.01 b | 0.37 ± 0.05 c |

| 1% Ziziphus | 0.54 ± 0.01 c | 0.32 ± 0.00 a | 3.12 ± 0.04 a | 9.87 ± 0.04 b | 0.58 ± 0.00 a | 0.33 ± 0.09 c |

| 2% Ziziphus | 0.57 ± 0.01 b | 0.30 ± 0.01 b | 2.90 ± 0.04 b | 9.73 ± 0.05 c | 0.53 ± 0.01 c | 0.67 ± 0.05 b |

| 2WA (%) | 3DDT (min) | Stability (min) | Softening 4(FU) | 5MTI (FU) | 6FQN (mm) | |

|---|---|---|---|---|---|---|

| Control1 | 55.27 ± 0.09a | 1.60 ± 0.08b | 5.70 ± 0.22a | 91.67 ± 2.36d | 35.67 ± 4.19c | 61.23 ± 0.95a |

| 1% Cordia | 54.33 ± 0.12b | 1.40 ± 0.16c | 3.53 ± 0.78b | 75.00 ± 4.08e | 42.00 ± 5.89c | 59.47 ± 1.08a |

| 2% Cordia | 54.03 ± 0.09c | 1.13 ± 0.21c | 2.20 ± 0.22c | 100 ± 4.08c | 70 ± 0.00b | 52.30 ± 0.78b |

| 1% Ziziphus | 55.25 ± 0.04a | 3.53 ± 0.12a | 4.03 ± 0.29b | 112.30 ± 2.58b | 85.33 ± 4.11a | 48.07 ± 041c |

| 2% Ziziphus | 55.20 ± 0.08a | 3.43 ± 0.05a | 3.50 ± 0.08b | 126.30 ± 2.58a | 89.00 ± 1.41a | 46.20 ± 0.57d |

| Loaf Volume (cm3) | Loaf Weight (g) | Specific Volume (cm3/g) | Firmness (g) 24 Hours | Springiness (%) 24 Hours | Firmness (g) 96 Hours | Springiness (%) 96 Hours | |

|---|---|---|---|---|---|---|---|

| Pan bread | |||||||

| Control (100% WF) | 791.67 ± 8.50 e | 310.00 ± 0.82 c | 2.55 ± 0.03 e | 865.84 ± 23.81 a | 1- | 2333.05 ± 92.65 a | 1- |

| 1% Cordia gum | 900.00 ± 8.16 d | 325.17 ± 1.03 a | 2.77 ± 0.03 d | 251.35 ± 9.89 d | - | 645.41 ± 32.05 bc | - |

| 2% Cordia gum | 968.33 ± 6.24 b | 323.00 ± 0.14 a | 2.99 ± 0.02 c | 361.55 ± 16.22 b | - | 762.54 ± 65.44 b | - |

| 1% Ziziphus gum | 953.33 ± 4.71 c | 311.33 ± 0.47 c | 3.07 ± 0.01 b | 301.07 ± 8.69 c | - | 623.99 ± 28.33 c | - |

| 2% Ziziphus gum | 985.00 ± 4.08 a | 313.67 ± 0.47 b | 3.14 ± 0.01 a | 238.86 ± 10.93 d | - | 519.99 ± 27.49 c | - |

| Sponge cake | |||||||

| Control (100% WF) | 740 ± 10.21 c | 261 ± 0.89 d | 2.84 ± 0.02 a | 221.60 ± 10.48 b | 52.54 ± 0.04 c | 402.81 ± 12.80 a | 49.65 ± 0.23 c |

| 1% Cordia gum | 718 ± 5.36 d | 272 ± 1.23 c | 2.64 ± 0.01 e | 265.13 ± 07.48 a | 53.69 ± 0.23 b | 384.79 ± 06.07 ab | 50.91 ± 0.08 b |

| 2% Cordia gum | 711 ± 7.36 d | 258 ± 0.80 d | 2.75 ± 0.05 b | 191.07 ± 13.92 c | 55.44 ± 0.44 a | 262.02 ± 16.79 c | 51.65 ± 0.26 a |

| 1% Ziziphus gum | 820 ± 4.20 a | 300 ± 1.23 a | 2.73 ± 0.02 c | 225.88 ± 08.12 b | 54.53 ± 0.96 a | 361.90 ± 18.53 b | 51.36 ± 0.79 a |

| 2% Ziziphus gum | 784 ± 6.32 b | 288 ± 2.10 b | 2.71 ± 0.03 d | 203.45 ± 09.20 c | 52.71 ± 0.60 c | 385.53 ± 19.00 ab | 48.58 ± 0.99 d |

| 2L* | 3a* | 4b* | |

|---|---|---|---|

| Pan bread | |||

| 1Control | 79.43 ± 0.39 a | −7.39 ± 0.06 d | 21.11 ± 0.16 a |

| 1% Cordia gum | 73.14 ± 1.02 cd | −6.68 ± 0.09 c | 19.54 ± 0.36 b |

| 2% Cordia gum | 72.79 ± 0.37 d | −6.31 ± 0.11b | 19.94 ± 0.39 b |

| 1% Ziziphus gum | 74.59 ± 0.98 c | −6.79 ± 0.05 c | 18.50 ± 0.08 c |

| 2% Ziziphus gum | 76.41 ± 0.81 b | −6.08 ± 0.02 a | 18.25 ± 0.10 c |

| Sponge cake | |||

| Control1 | 81.53 ± 0.20 a | −9.16 ± 0.07 e | 26.79 ± 0.12 a |

| 1% Cordia gum | 75.78 ± 0.61d | −7.34 ± 0.13 b | 24.69 ± 0.14 b |

| 2% Cordia gum | 72.72 ± 0.52 e | −6.12 ± 0.08 a | 23.59 ± 0.12 c |

| 1% Ziziphus gum | 79.65 ± 0.27 c | −8.49 ± 0.21d | 24.82 ± 0.05 b |

| 2% Ziziphus gum | 80.44 ± 0.38 b | −8.18 ± 0.12 c | 23.56 ± 0.18 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alamri, M.S.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Hakeem, M.J.; Ababtain, I.A. Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes. Foods 2022, 11, 460. https://doi.org/10.3390/foods11030460

Alamri MS, Mohamed AA, Hussain S, Ibraheem MA, Qasem AAA, Shamlan G, Hakeem MJ, Ababtain IA. Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes. Foods. 2022; 11(3):460. https://doi.org/10.3390/foods11030460

Chicago/Turabian StyleAlamri, Mohamed Saleh, Abdellatif A. Mohamed, Shahzad Hussain, Mohamed A. Ibraheem, Akram A. Abdo Qasem, Ghalia Shamlan, Mohammed Jamal Hakeem, and Ibrahim A. Ababtain. 2022. "Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes" Foods 11, no. 3: 460. https://doi.org/10.3390/foods11030460

APA StyleAlamri, M. S., Mohamed, A. A., Hussain, S., Ibraheem, M. A., Qasem, A. A. A., Shamlan, G., Hakeem, M. J., & Ababtain, I. A. (2022). Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes. Foods, 11(3), 460. https://doi.org/10.3390/foods11030460