Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

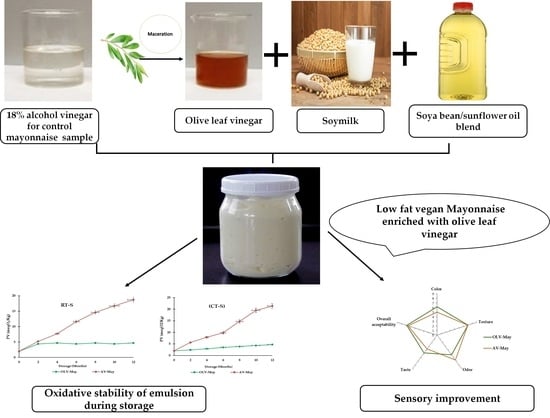

2.2. Preparation and Storage of Mayonnaise

2.3. Chemical Determination

2.4. Antioxidant Activity by the DPPH Method

2.5. Sensory Evaluation

2.6. Statistical Analyses

3. Results and Discussion

3.1. Main Characteristics of Mayonnaise Ingredients

3.2. Main Characteristics of Formulated Mayonnaise

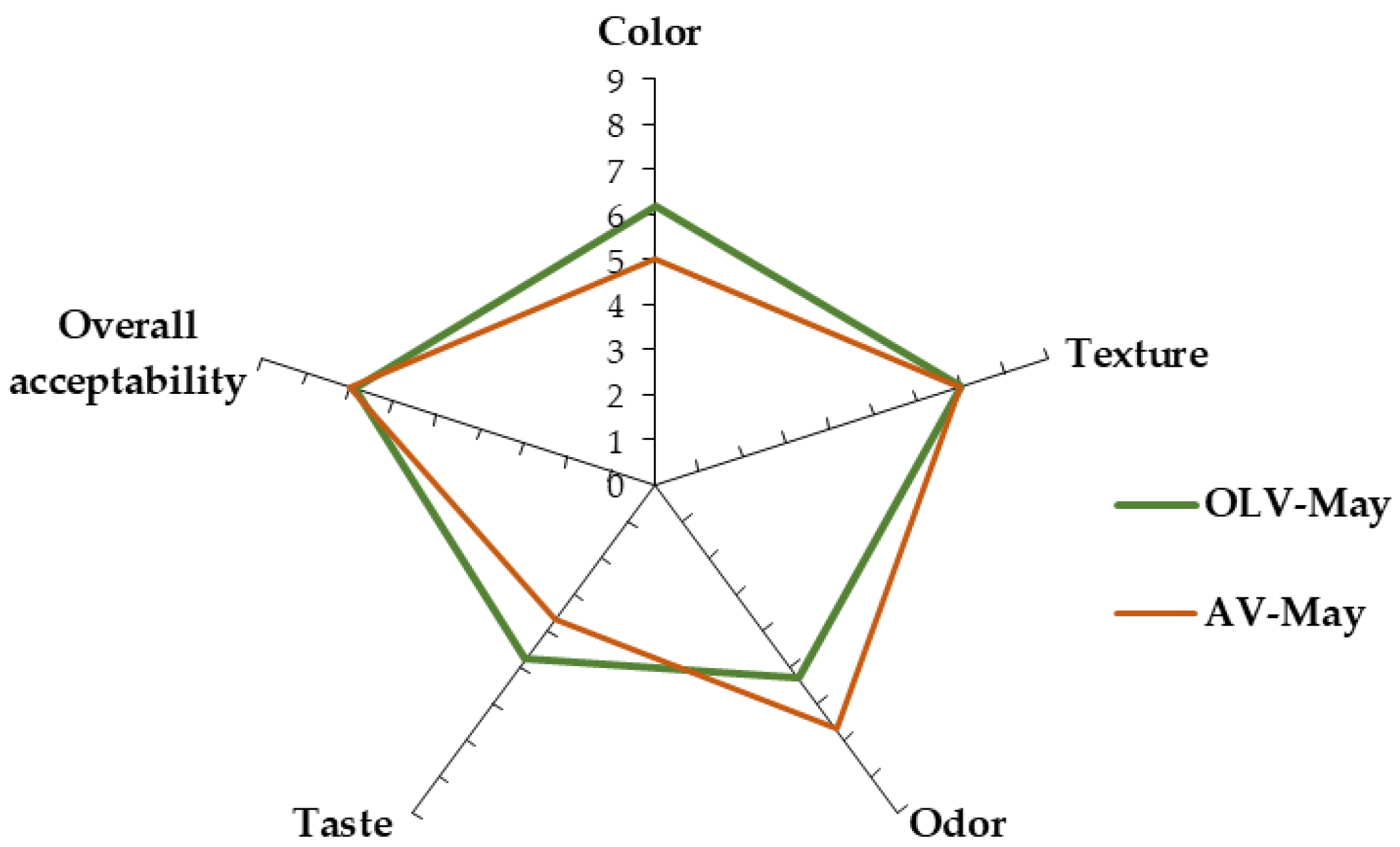

3.3. Mayonnaise Sensory Analysis

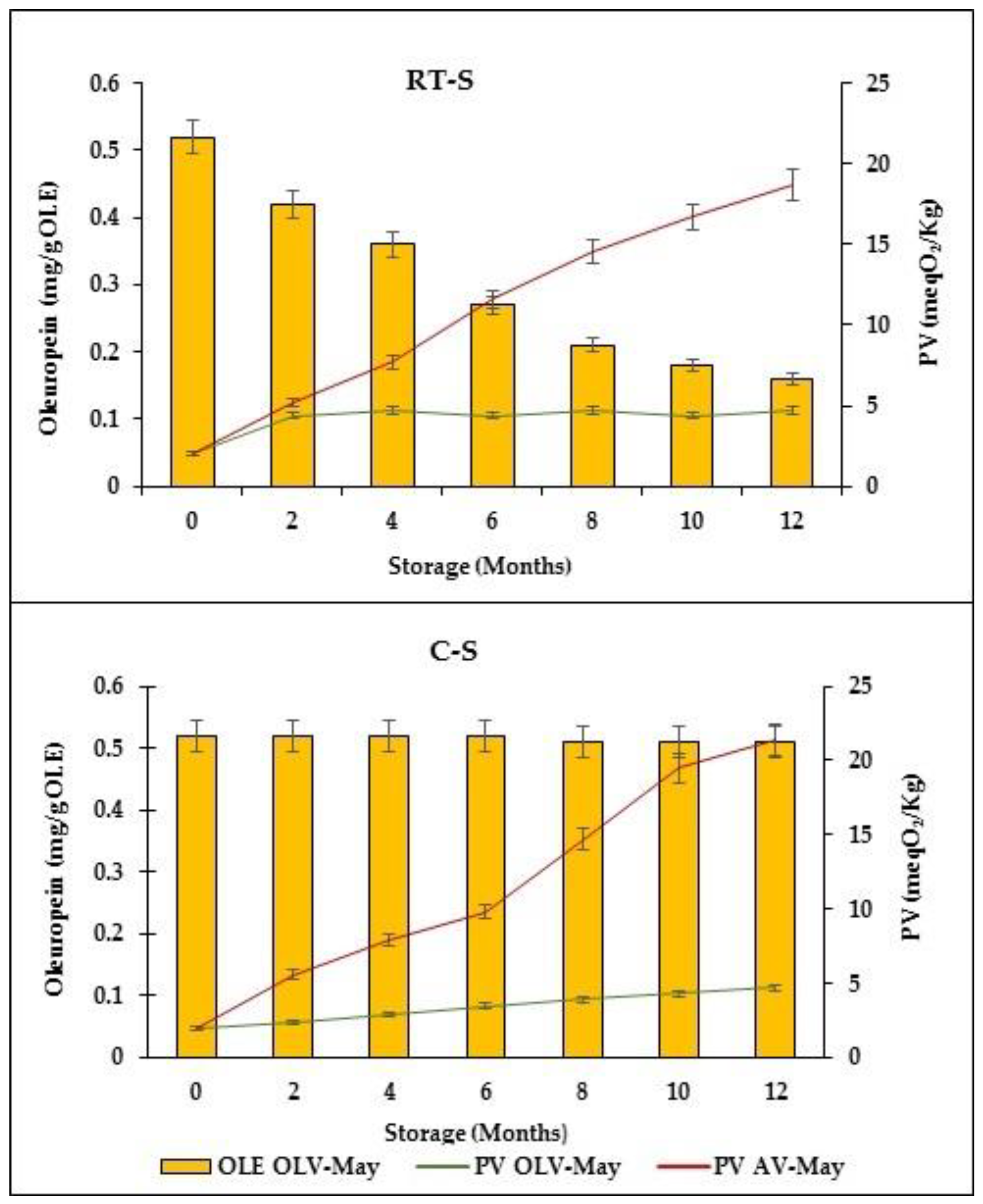

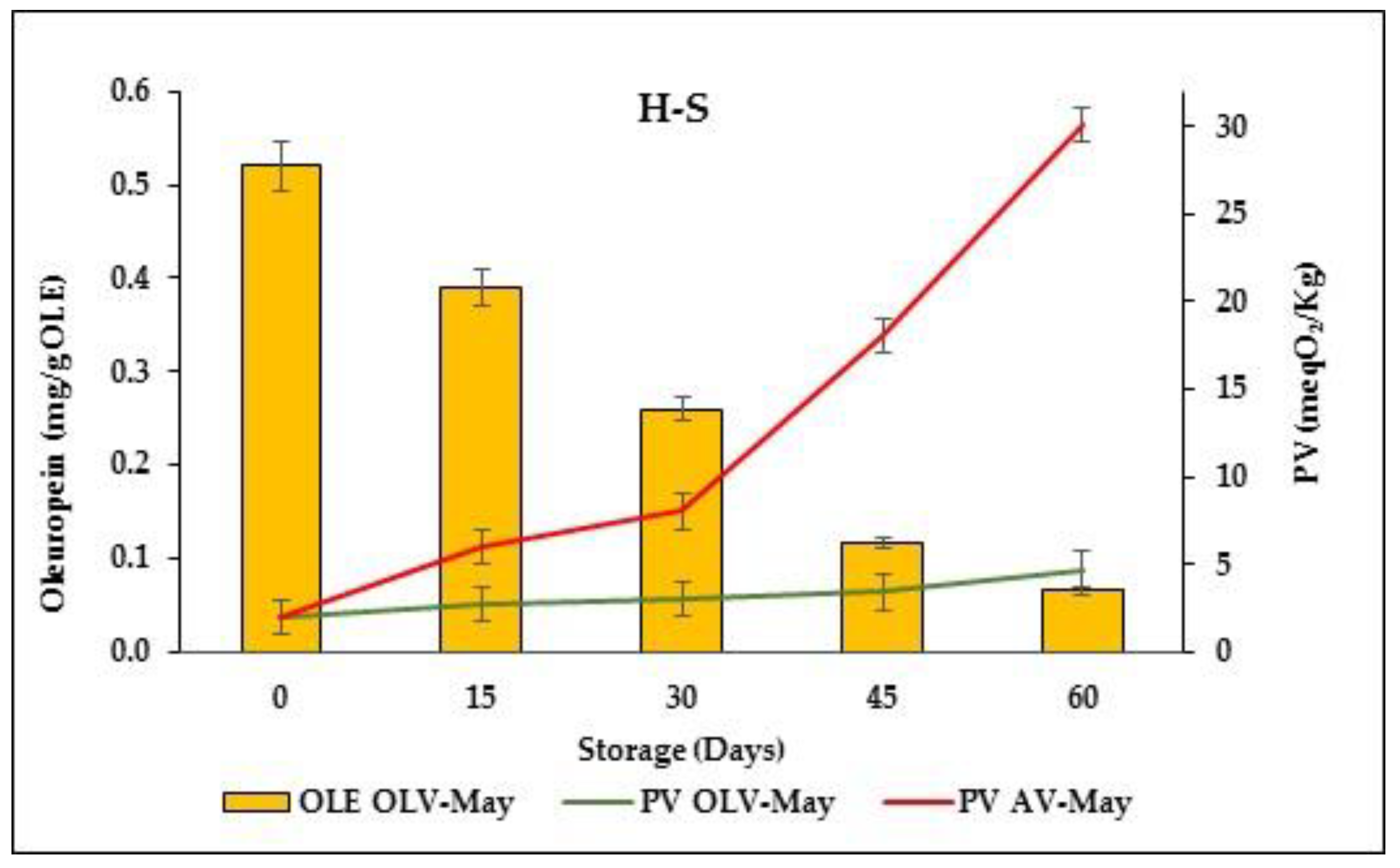

3.4. Mayonnaise Oxidative Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AV | 18% alcoholic vinegar |

| AV-May | Alcoholic vinegar mayonnaise |

| C-S | Cold storage |

| H-S | Heat storage |

| MS | Median score |

| OB | Oil blend |

| OLE | Oleuropein |

| OLV | Olive leaf vinegar |

| OLV-May | Olive leaf vinegar mayonnaise |

| PV | Peroxide value |

| RT-S | Room temperature storage |

| TP | Total phenols |

References

- Harrison, L.J.; Cunningham, F.E. Factors influencing the quality of mayonnaise: A review. J. Food Qual. 1985, 8, 1–20. [Google Scholar] [CrossRef]

- Mayonnaise Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027. Available online: https://www.imarcgroup.com/top-mayonnaise-companies-world (accessed on 10 November 2022).

- Mosca, M.; Diantom, A.; Lopez, F.; Ambrosone, L.; Ceglie, A. Impact of antioxidants dispersions on the stability and oxidation of water-in-olive-oil emulsions. Eur. Food Res. Technol. 2013, 236, 319–328. [Google Scholar] [CrossRef]

- Pal, R. Metering of two-phase liquid-liquid emulsions: A state-of-the-art review. Ind. Eng. Chem. Res. 1994, 33, 1413–1435. [Google Scholar] [CrossRef]

- Lopez, F.; Cinelli, G.; Colella, M.; De Leonardis, A.; Palazzo, G.; Ambrosone, L. The role of microemulsions in lipase-catalyzed hydrolysis reactions. Biotechnol. Prog. 2014, 30, 360–366. [Google Scholar] [CrossRef] [PubMed]

- Lauridsen, J.B. Food emulsifiers: Surface activity, edibility, manufacture, composition, and application. J. Am. Oil. Chem. Soc. 1976, 53, 400–407. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F. Potential applications of multiple emulsions in the development of healthy and functional foods. Food Res. Int. 2013, 52, 64–74. [Google Scholar] [CrossRef]

- De Leonardis, A.; Macciola, V.; Iacovino, S. Delivery systems for hydroxytyrosol supplementation: State of the art. J. Colloid Interface Sci. 2020, 4, 25. [Google Scholar] [CrossRef]

- Cuomo, F.; Iacovino, S.; Sacco, P.; De Leonardis, A.; Ceglie, A.; Lopez, F. Progress in colloid delivery systems for protection and delivery of phenolic bioactive compounds: Two study cases-hydroxytyrosol and curcumin. Molecules 2022, 27, 921. [Google Scholar] [CrossRef]

- Guilmineau, F.; Kulozik, U. Influence of a thermal treatment on the functionality of hen’s egg yolk in mayonnaise. J. Food Eng. 2007, 78, 648–654. [Google Scholar] [CrossRef]

- Gorji, S.G.; Smyth, H.E.; Sharma, M.; Fitzgerald, M. Lipid oxidation in mayonnaise and the role of natural antioxidants: A review. Trends Food Sci. Technol. 2016, 56, 88–102. [Google Scholar] [CrossRef]

- Mirzanajafi-Zanjani, M.; Yousefi, M.; Ehsani, A. Challenges and approaches for production of a healthy and functional mayonnaise sauce. Food Sci. Nutr. 2019, 7, 2471–2484. [Google Scholar] [CrossRef]

- Wang, W.; Hu, C.; Sun, H.; Zhao, J.; Xu, C.; Ma, Y.; Jiang, Z. Low-cholesterol-low-fat mayonnaise prepared from soybean oil body as a substitute for egg yolk: The effect of substitution ratio on physicochemical properties and sensory evaluation. LWT-Food Sci. Technol. 2022, 167, 113867. [Google Scholar] [CrossRef]

- Depree, J.A.; Savage, G.P. Physical and flavour stability of mayonnaise. Trends Food Sci. Technol. 2001, 12, 157–163. [Google Scholar] [CrossRef]

- Di Mattia, C.; Balestra, F.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and structural properties of extra-virgin olive oil-based mayonnaise. LWT-Food Sci. Technol. 2014, 62, 764–770. [Google Scholar] [CrossRef]

- Khalid, M.U.; Shabbir, M.A.; Mustafa, S.; Hina, S.; Quddoos, M.Y.; Mahmood, S.; Rafique, A. Effect of apple peel as an antioxidant on the quality characteristics and oxidative stability of mayonnaise. Appl. Food Res. 2021, 1, 100023. [Google Scholar] [CrossRef]

- Şahin, S.; Bilgin, M. Olive tree (Olea europaea L.) leaf as a waste by-product of table olive and olive oil industry: A review. J. Sci. Food Agric. 2018, 98, 1271–1279. [Google Scholar] [CrossRef] [PubMed]

- Palmeri, R.; Siracusa, L.; Carrubba, M.; Parafati, L.; Proetto, I.; Pesce, F.; Fallico, B. Olive leaves, a promising byproduct of olive oil industry: Assessment of metabolic profiles and antioxidant capacity as a function of cultivar and seasonal change. Agronomy 2022, 12, 2007. [Google Scholar] [CrossRef]

- Özcan, M.M.; Matthäus, B. A review: Benefit and bioactive properties of olive (Olea europaea L.) leaves. Eur. Food Res. Technol. 2016, 243, 89–99. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Crupi, P.; Annunziato, A.; Corbo, F. Innovative extraction technologies for development of functional ingredients based on polyphenols from olive leaves. Foods 2021, 11, 103. [Google Scholar] [CrossRef] [PubMed]

- Difonzo, G.; Squeo, G.; Pasqualone, A.; Summo, C.; Paradiso, V.M.; Caponio, F. The challenge of exploiting polyphenols from olive leaves: Addition to foods to improve their shelf-life and nutritional value. J. Sci. Food Agric. 2021, 101, 3099–3116. [Google Scholar] [CrossRef]

- Famiglietti, M.; Savastano, A.; Gaglione, R.; Arciello, A.; Naviglio, D.; Mariniello, L. Edible films made of dried olive leaf extract and chitosan: Characterization and applications. Foods 2022, 11, 2078. [Google Scholar] [CrossRef] [PubMed]

- De Leonardis, A.; Macciola, V.; Iftikhar, A.; Lopez, F. Antioxidant effect of traditional and new vinegars on functional oil/vinegar dressing-based formulations. Eur. Food Res. Technol. 2022, 248, 1573–1582. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Official Method of Analysis, 12th ed.; Association of Official Analytical Chemists (AOAC): Washington, DC, USA, 1984. [Google Scholar]

- Pradhananga, M.; Adhikari, B. Sensory and quality evaluation of mayonnaise and its effect on storage stability. Sunsari. Tech. Coll. J. 2015, 2, 48–53. [Google Scholar] [CrossRef]

- De Leonardis, A.; Macciola, V. Innovative sunflower edible oils with modified composition. In Sunflowers: Cultivation, Nutrition, and Biodiesel Uses; Hughes, V.C., Ed.; Chapter 7; Nova Science Publisher Inc.: Hauppauge, NY, USA, 2011; pp. 183–200. ISBN 978-1-61761-309-8. [Google Scholar]

- Sales-Campos, H.; Reis de Souza, P.; Crema Peghini, B.; Santana da Silva, J.; Ribeiro Cardoso, C. An overview of the modulatory effects of oleic acid in health and disease. Mini-Rev. Med. Chem. 2013, 13, 201–210. [Google Scholar] [CrossRef] [PubMed]

- Ang, H.G.; Kwik, W.L.; Theng, C.Y. Development of soymilk: A review. Food Chem. 1985, 17, 235–250. [Google Scholar] [CrossRef]

- Perumpuli, P.A.B.N.; Dilrukshi, D.M.N. Vinegar: A functional ingredient for human health. Int. Food Res. J. 2022, 29, 959–974. [Google Scholar] [CrossRef]

- Ho, C.W.; Lazim, A.M.; Fazry, S.; Zaki, U.K.H.H.; Lim, S.J. Varieties, production, composition, and health benefits of vinegars: A review. Food Chem. 2017, 221, 1621–1630. [Google Scholar] [CrossRef]

- De Leonardis, A.; Macciola, V.; Iorizzo, M.; Lombardi, S.J.; Lopez, F.; Marconi, E. Effective assay for olive vinegar production from olive oil mill wastewaters. Food Chem. 2018, 240, 437–440. [Google Scholar] [CrossRef]

- Nikzade, V.; Tehrani, M.M.; Tarzjan, S.M. Optimization of low-cholesterol-low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2012, 28, 344–352. [Google Scholar] [CrossRef]

- Riscardo, M.A.; Franco, J.M.; Gallegos, C. Influence of composition of emulsifier blends on the rheological properties of salad dressing-type emulsion. Food Sci. Technol. Int. 2003, 9, 53–63. [Google Scholar] [CrossRef]

- Abu Ghoush, M.; Samhouri, M.; Al-Holy, M.; Herald, T. Formulation and fuzzy modeling of emulsion stability and viscosity of a gum protein emulsifier in a model mayonnaise system. J. Food Eng. 2008, 84, 348–357. [Google Scholar] [CrossRef]

- Marquez, A.L.; Wagner, J.R. Rheology of double (W/O/W) emulsions prepared with soybean milk and fortified with calcium. J. Texture Stud. 2010, 41, 651–671. [Google Scholar] [CrossRef]

- Park, J.J.; Olawuyi, I.F.; Lee, W.Y. Characteristics of low-fat mayonnaise using different modified arrowroot starches as fat replacer. Int. J. Biol. Macromol. 2020, 153, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Su, H.P.; Lien, C.P.; Lee, T.A.; Ho, J.H. Development of low-fat mayonnaise containing polysaccharide gums as functional ingredients. J. Sci. Food Agric. 2010, 90, 806–812. [Google Scholar] [CrossRef]

- Palma, A.; Aziz, M.; Chawdhury, M.; Uddin, B.; Alam, M. Effect of edible oils on quality and shelf life of low-fat mayonnaise. Pak. J. Nutr. 2004, 3, 340–343. [Google Scholar] [CrossRef][Green Version]

- Muhammad, S.I.; Ghulam, R.; Sarfraz, H.; Zafar, A. Effect of corn oil on the quality characteristics of mayonnaise. Pak. J. Nutr. 2013, 12, 860–864. [Google Scholar] [CrossRef][Green Version]

- Sánchez De Medina, V.; Priego-Capote, F.; Jiménez-Ot, C.; Luque De Castro, M.D. Quality and stability of edible oils enriched with hydrophilic antioxidants from the olive tree: The role of enrichment extracts and lipid composition. J. Agric. Food Chem. 2011, 59, 11432–11441. [Google Scholar] [CrossRef]

- Wang, W.; Hu, C.; Sun, H.; Zhao, J.; Xu, C.; Ma, Y.; Hou, J. Physicochemical properties, stability, and texture of soybean-oil-body-substituted low-fat mayonnaise: Effects of thickeners and storage temperatures. Foods 2022, 11, 2201. [Google Scholar] [CrossRef]

- Jadhav, H.B.; Gogate, P.; Annapure, U. Studies on chemical and physical stability of mayonnaise prepared from enzymatically interesterified corn oil-based designer lipids. ACS Food Sci. Technol. 2022, 2, 359–367. [Google Scholar] [CrossRef]

- Vissers, M.N.; Zock, P.L.; Katan, M.B. Bioavailability and antioxidant effects of olive oil phenols in humans: A review. Eur. J. Clin. Nutr. 2004, 58, 955–965. [Google Scholar] [CrossRef]

- Giacintucci, V.; Di Mattia, C.; Sacchetti, G.; Neri, L.; Pittia, P. Role of olive oil phenolics in physical properties and stability of mayonnaise-like emulsions. Food Chem. 2016, 213, 369–377. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Regulation (EU) No 432/2012 of 16 May 2012 Establishing a List of Permitted Health Claims Made on Foods, Other than Those Referring to the Reduction of Disease Risk and to Children’s Development and Health. Off. J. Eur. Union 2012, L136, 1–40. [Google Scholar]

- European Union. Regulation (EC), No. 1924/2006 of the European Parliament and the Council of 20 December 2006 on nutrition and health claims made on foods. Off J. Eur. Union 2006, L 404, L12/13–L12/17. [Google Scholar]

- De Bruno, A.; Romeo, R.; Gattuso, A.; Piscopo, A.; e Poiana, M. Functionalization of a vegan mayonnaise with high value ingredient derived from the agro-industrial sector. Foods 2021, 10, 2684. [Google Scholar] [CrossRef] [PubMed]

- Chukwu, O.; Sadiq, Y. Storage stability of groundnut oil and soya oil-based mayonnaise. J. Food Technol. 2008, 6, 217–220. [Google Scholar]

- Duh, P.D. Antioxidant activity of water extract of four Harng Jyur (Chrysanthemum morifolium Ramat) varieties in soybean oil emulsion. Food Chem. 1999, 66, 471–476. [Google Scholar] [CrossRef]

- Raikos, V.; McDonagh, A.; Ranawana, V.; Duthie, G. Processed beetroot (Beta vulgaris L.) as a natural antioxidant in mayonnaise: Effects on physical stability, texture and sensory attributes. Food Sci. Hum. Well. 2016, 5, 191–198. [Google Scholar] [CrossRef]

- Paradiso, V.M.; Flamminii, F.; Pittia, P.; Caponio, F.; Di Mattia, C. Radical scavenging activity of olive oil phenolic antioxidants in oil or water phase during the oxidation of o/w emulsions: An oxidomics approach. Antioxidants 2020, 9, 996. [Google Scholar] [CrossRef]

- De Leonardis, A.; Macciola, V.; Spadanuda, P.; Cuomo, F. Effects of bag-in-box packaging on long-term shelf life of extra virgin olive oil. Eur. Food Res. Technol. 2021, 247, 839–850. [Google Scholar] [CrossRef]

| Determinations | Oil Blend (OB) | Soymilk | Olive Leaf Vinegar (OLV) | Alcoholic Vinegar (AV) |

|---|---|---|---|---|

| pH | 2.16 ± 0.06 | 2.15 ± 0.08 | ||

| Total phenols (mg/mL GAE) | 7.2 ± 0.8 | – | ||

| Oleuropein (mg/mL OLE) | 6.0 ± 0.5 | – | ||

| Free acidity (% oleic acid) | 0.2 ± 0.0 | |||

| Peroxide value (meq O2/kg) | 3.5 ± 0.1 | |||

| Fatty acids (%) | ||||

| C14:0 | 0.15 ± 0.0 | 0.6 ± 0.0 | ||

| C16:0 | 4.6 ± 0.2 | 12.3 ± 0.6 | ||

| C16:1 | 0.1 ± 0.0 | 0.9 ± 0.0 | ||

| C17:0 | 0.1 ± 0.0 | 0.1 ± 0.0 | ||

| C17:1 | trace | 0.1 ± 0.2 | ||

| C18:0 | 3.1 ± 0.1 | 4.0 ± 2.2 | ||

| C18:1 | 74.6 ± 3.7 | 43.7 ± 1.6 | ||

| C18:2 | 14.7 ± 0.73 | 32.1 ± 0.3 | ||

| C18:3 | 0.9 ± 0.0 | 5.0 ± 0.1 | ||

| C20:0 | 0.3 ± 0.0 | 0.6 ± 0.1 | ||

| C20:1 | 0.3 ± 0.0 | 0.6 ± 0.1 | ||

| C22:0 | 0.9 ± 0.0 | – | ||

| C24:0 | 0.3 ± 0.0 | – |

| Determinations | AV-May | OLV-May |

|---|---|---|

| Water (%) | 31.6 ± 1.9 a | 31.0 ± 1.7 a |

| Fat (%) | 58.2 ± 2.6 a | 57.0 ± 2.4 a |

| Saturated fatty acids (%) | 11.4 ± 0.5 a | 11.1 ± 0.6 a |

| Monounsaturated fatty acids (%) | 21.8 ± 1.1 a | 21.3 ± 1.0 a |

| Polyunsaturated fatty acids (%) | 23.5 ± 1.0 a | 23.0 ± 0.9 a |

| Linolenic acid (ω-3) (%) | 1.7 ± 0.1 a | 1.7 ± 0.1 a |

| pH | 2.16 ± 0.45 a | 2.15 ± 0.38 a |

| Total phenols (mg/g GAE) | 0.13 ± 0.1 a | 0.68 ± 0.1 b |

| Oleuropein (mg/g OLE) | – | 0.52 ± 0.1 |

| Peroxide value (meqO2/kg) | 2.0 ± 0.1 a | 1.9 ± 0.1 a |

| Antioxidant activity (IC50 DPPH, mg/g) | – | 0.10 ± 0.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Leonardis, A.; Macciola, V.; Iftikhar, A.; Lopez, F. Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient. Foods 2022, 11, 4006. https://doi.org/10.3390/foods11244006

De Leonardis A, Macciola V, Iftikhar A, Lopez F. Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient. Foods. 2022; 11(24):4006. https://doi.org/10.3390/foods11244006

Chicago/Turabian StyleDe Leonardis, Antonella, Vincenzo Macciola, Ayesha Iftikhar, and Francesco Lopez. 2022. "Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient" Foods 11, no. 24: 4006. https://doi.org/10.3390/foods11244006

APA StyleDe Leonardis, A., Macciola, V., Iftikhar, A., & Lopez, F. (2022). Characterization, Sensory and Oxidative Stability Analysis of Vegetable Mayonnaise Formulated with Olive Leaf Vinegar as an Active Ingredient. Foods, 11(24), 4006. https://doi.org/10.3390/foods11244006