Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement

Abstract

1. Introduction

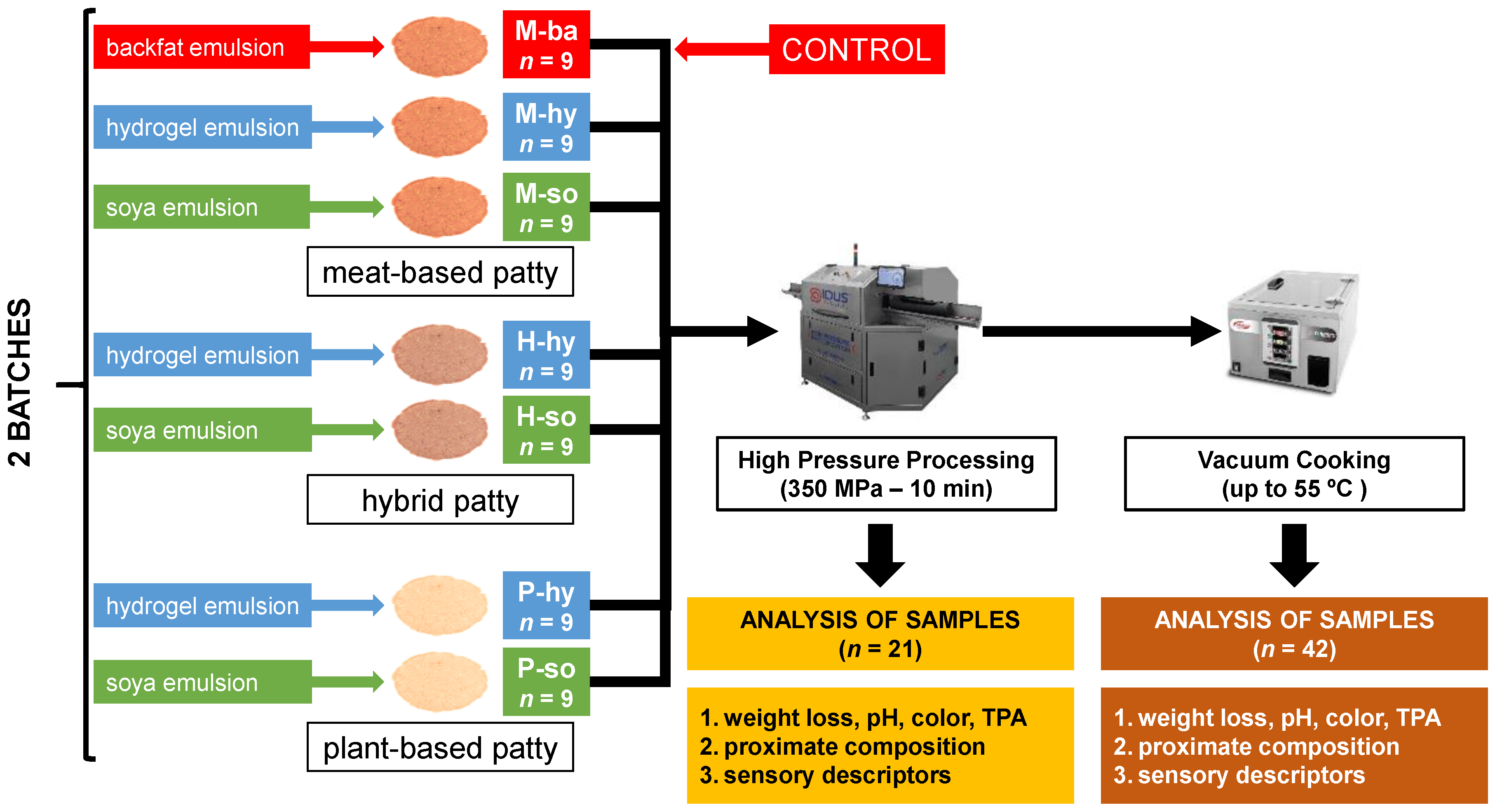

2. Materials and Methods

2.1. Emulsion and Sample Preparation

2.2. Experimental Design

2.3. Treatments

2.4. Physical Characterization of the Emulsions

2.5. Proximate Analysis of Samples

2.6. Weight Loss of Samples

2.7. pH of Samples

2.8. Instrumental Color of Samples

2.9. Instrumental Texture of Samples

2.10. Sensory Analysis of Samples

2.11. Data Analysis and Modeling

3. Results and Discussions

3.1. Characterization of the Emulsions

3.2. Proximate Analysis of Samples

3.3. Physical Parameters of HPP Treated Patties

3.3.1. Weight Loss and pH

3.3.2. Instrumental Color

3.3.3. Instrumental Texture

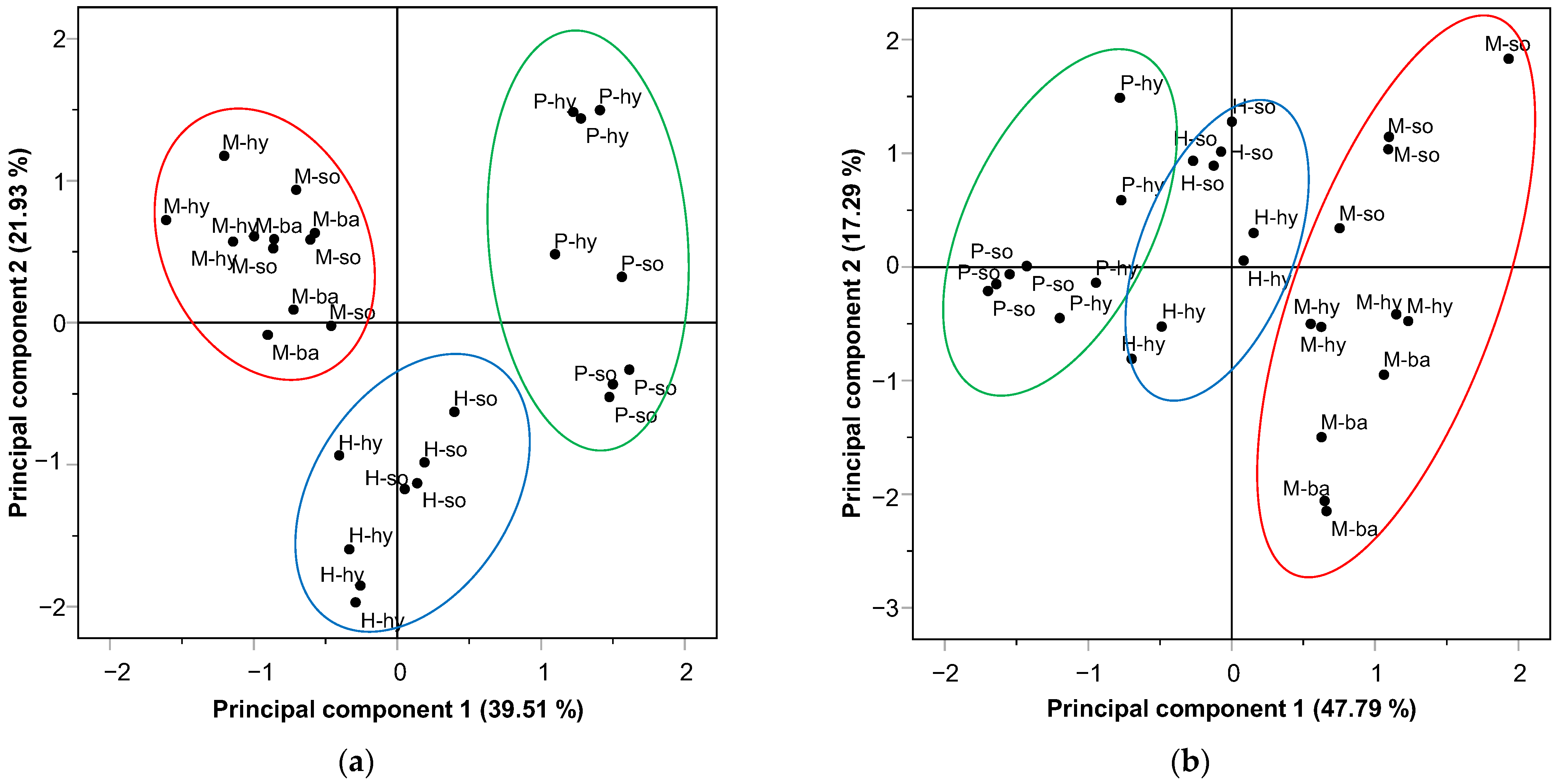

3.3.4. Principal Component Analysis

3.4. Physical Parameters HPP + SVCOOK Treated Patties

3.4.1. Weight Loss and pH

3.4.2. Instrumental Color

3.4.3. Instrumental Texture

3.4.4. Principal Component Analysis

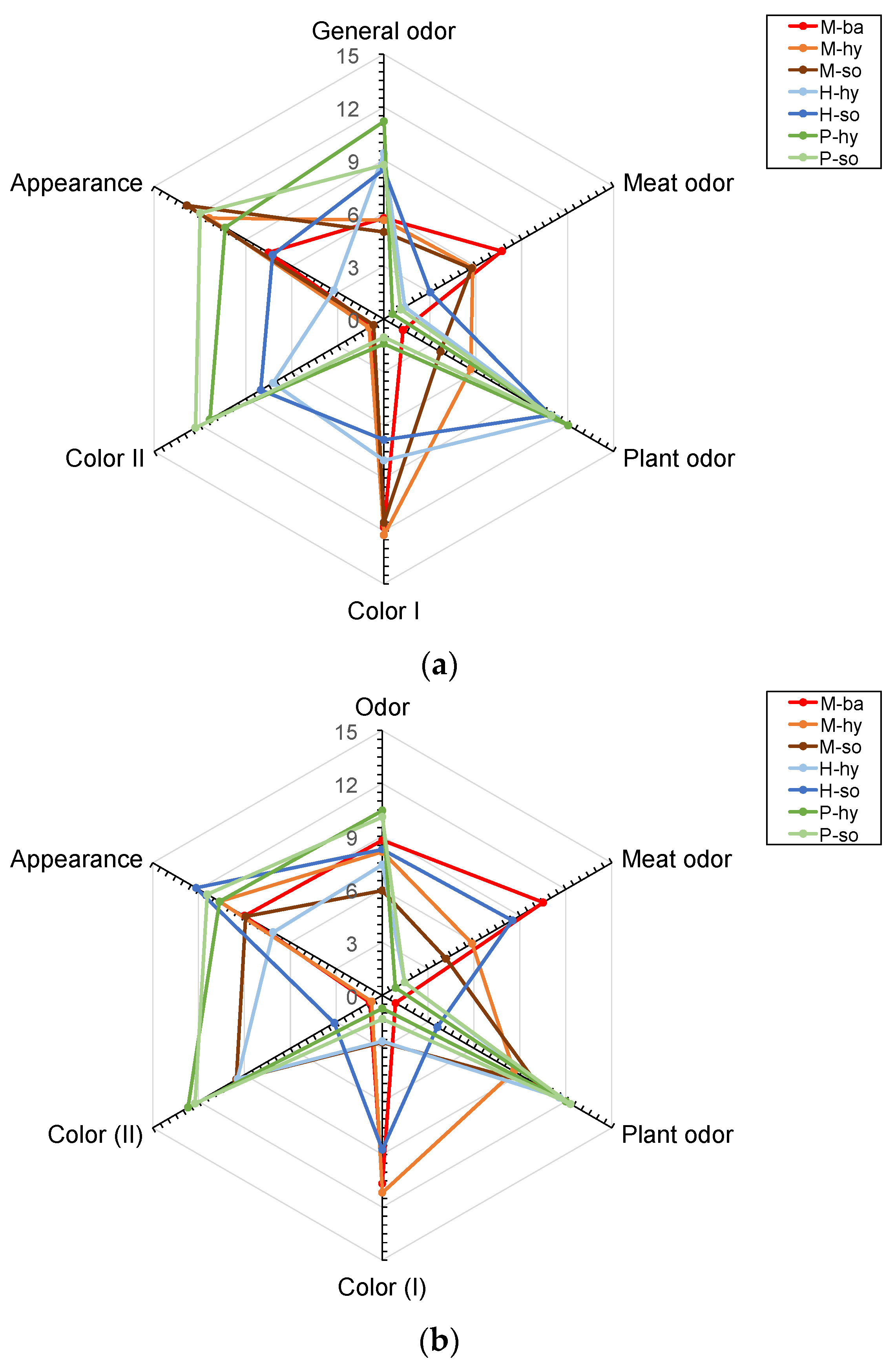

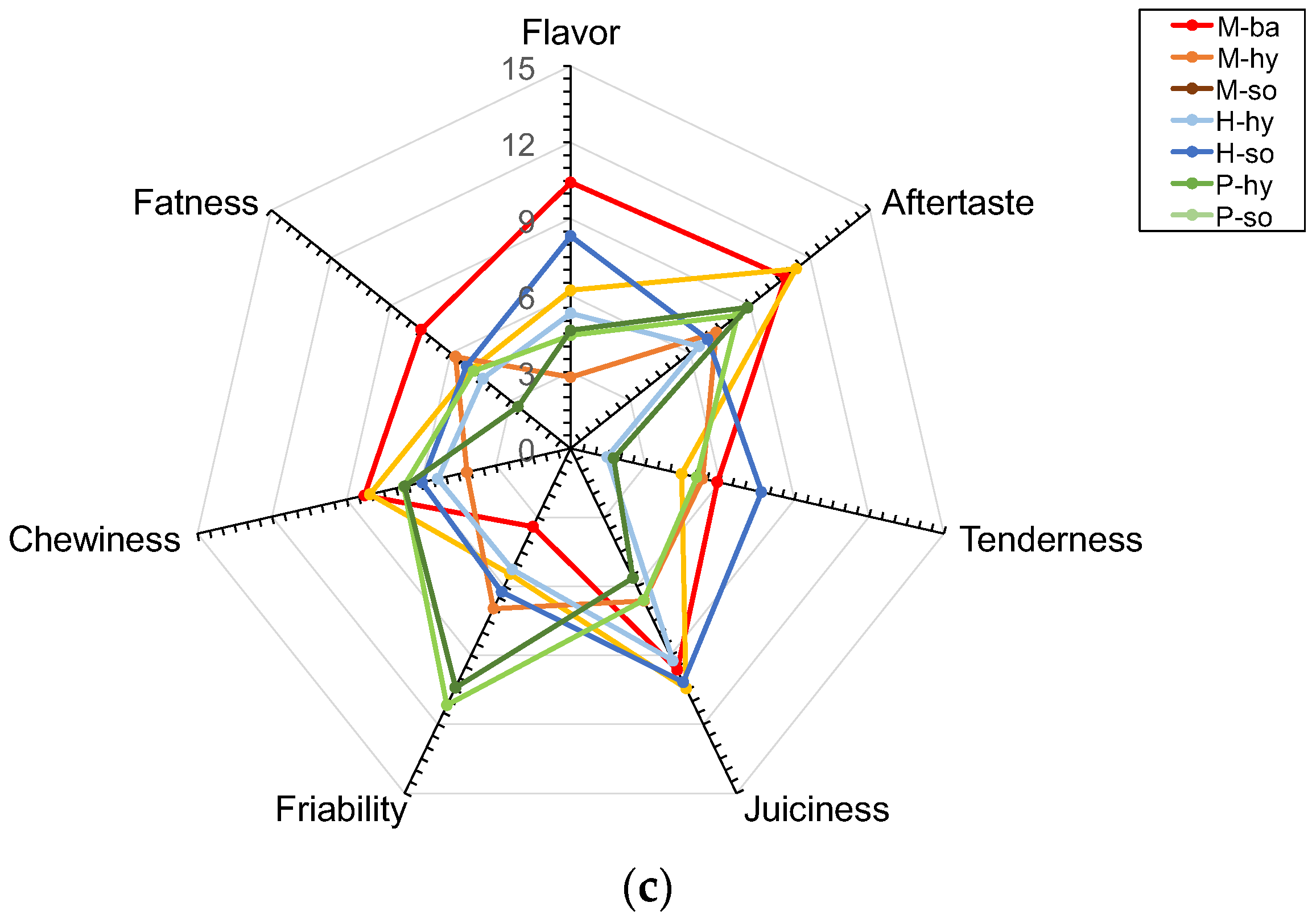

3.5. Sensory Analysis

3.5.1. HPP Patties

3.5.2. HPP + SVCOOK Patties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agarwal, S.; Fulgoni, V.L. Contribution of beef to key nutrient intakes in American adults: An updated analysis with NHANES 2011–2018. Nutr. Res. 2022, 105, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Cocking, C.; Walton, J.; Kehoe, L.; Cashman, K.D.; Flynn, A. The role of meat in the European diet: Current state of knowledge on dietary recommendations, intakes and contribution to energy and nutrient intakes and status. Nutr. Res. Rev. 2020, 33, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Boer, J.; Aiking, H. Climate change and species decline: Distinct sources of European consumer concern supporting more sustainable diets. Ecol. Econ. 2021, 188, 107141. [Google Scholar] [CrossRef]

- Tilman, D.; Clark, M. Global diets link environmental sustainability and human health. Nature 2014, 515, 518–522. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-based meat alternatives: Compositional analysis, current development and challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Heywood, A.A.; Myers, D.J.; Bailey, T.B.; Johnson, L.A. Effect of value-enhanced texturized soy protein on the sensory and cooking properties of beef patties. J. Am. Oil Chem. Soc. 2002, 79, 703–707. [Google Scholar] [CrossRef]

- Zhou, H.; Vu, G.; Gong, X.; McClements, D.J. Comparison of the cooking behaviors of meat and plant-based meat analogues: Appearance, texture, and fluid holding properties. ACS Food Sci. Technol. 2022, 2, 844–851. [Google Scholar] [CrossRef]

- Asgar, M.A.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A.A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef]

- Verbeke, W. Profiling consumers who are ready to adopt insects as a meat substitute in a Western society. Food Qual. Prefer. 2015, 39, 147–155. [Google Scholar] [CrossRef]

- Profeta, A.; Baune, M.-C.; Smetana, S.; Broucke, K.; Royen, G.; Weiss, J.; Hieke, S.; Heinz, V.; Terjung, N. Consumer preferences for meat blended with plant proteins. Empir. Find. Belgium. Future Foods 2021, 4, 100088. [Google Scholar] [CrossRef]

- Gómez, I.; Sarriés, M.V.; Ibañez, F.C.; Beriain, M.J. Quality characteristics of a low-fat beef patty enriched by polyunsaturated fatty acids and vitamin D3. J. Food Sci. 2018, 83, 454–463. [Google Scholar] [CrossRef]

- Heck, R.T.; Saldaña, E.; Lorenzo, J.M.; Correa, L.P.; Fagundes, M.B.; Cichoski, A.J.; Menezes, C.R.; Wagner, R.; Campagnol, P.C.B. Hydrogelled emulsion from chia and linseed oils: A promising strategy to produce low-fat burgers with a healthier lipid profile. Meat Sci. 2019, 156, 174–182. [Google Scholar] [CrossRef]

- Rodríguez-Carpena, J.G.; Morcuende, D.; Estévez, M. Avocado, sunflower and olive oils as replacers of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and quality traits. Meat Sci. 2012, 90, 106–115. [Google Scholar] [CrossRef]

- Afshari, R.; Hosseini, H.; Mousavi Khaneghah, A.; Khaksar, R. Physico-chemical properties of functional low-fat beef burgers: Fatty acid profile modification. LWT-Food Sci. Technol. 2017, 78, 325–331. [Google Scholar] [CrossRef]

- Domínguez, R.; Munekata, P.E.; Pateiro, M.; López-Fernández, O.; Lorenzo, J.M. Immobilization of oils using hydrogels as strategy to replace animal fats and improve the healthiness of meat products. Curr. Opin. Food Sci. 2021, 37, 135–144. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Ruiz-Capillas, C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, PUFA-enriched, dry fermented sausages. LWT-Food Sci. Technol. 2013, 51, 158–163. [Google Scholar] [CrossRef]

- Selani, M.M.; Shirado, G.A.N.; Margiotta, G.B.; Saldaña, E.; Spada, F.P.; Piedade, S.M.S.; Contreras-Castillo, C.J.; Canniatti-Brazaca, S.G. Effects of pineapple byproduct and canola oil as fat replacers on physicochemical and sensory qualities of low-fat beef burger. Meat Sci. 2016, 112, 69–76. [Google Scholar] [CrossRef]

- Ciriano, M.G.-I.; Rehecho, S.; Calvo, M.I.; Cavero, R.Y.; Navarro, Í.; Astiasarán, I.; Ansorena, D. Effect of lyophilized water extracts of Melissa officinalis on the stability of algae and linseed oil-in-water emulsion to be used as a functional ingredient in meat products. Meat Sci. 2010, 85, 373–377. [Google Scholar] [CrossRef]

- Herrero, A.M.; Carmona, P.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Polysaccharide gels as oil bulking agents: Technological and structural properties. Food Hydrocoll. 2014, 36, 374–381. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Carmona, P.; Jiménez-Colmenero, F.; Herrero, A.M. Oil bulking agents based on polysaccharide gels in meat batters: A Raman spectroscopic study. Food Chem. 2013, 141, 3688–3694. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Storage stability of low-fat sodium reduced fresh merguez sausage prepared with olive oil in konjac gel matrix. Meat Sci. 2013, 94, 438–446. [Google Scholar] [CrossRef]

- Utrilla, M.C.; García Ruiz, A.; Soriano, A. Effect of partial replacement of pork meat with an olive oil organogel on the physicochemical and sensory quality of dry-ripened venison sausages. Meat Sci. 2014, 97, 575–582. [Google Scholar] [CrossRef]

- Poyato, C.; Astiasarán, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT-Food Sci. Technol. 2015, 62, 1069–1075. [Google Scholar] [CrossRef]

- Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The effects of processing and preservation technologies on meat quality: Sensory and nutritional aspects. Foods 2020, 10, 1416. [Google Scholar] [CrossRef]

- Huang, H.W.; Lung, H.M.; Yang, B.B.; Wang, C.Y. Responses of microorganisms to high hydrostatic pressure processing. Food Control 2014, 40, 250–259. [Google Scholar] [CrossRef]

- Jia, G.; Orlien, V.; Liu, H.; Sun, A. Effect of high pressure processing of pork (Longissimus dorsi) on changes of protein structure and water loss during frozen storage. LWT-Food Sci. Technol. 2021, 135, 110084. [Google Scholar] [CrossRef]

- Truong, B.Q.; Buckow, R.; Nguyen, M.H.; Stathopoulos, C.E. High pressure processing of barramundi (Lates calcarifer) muscle before freezing: The effects on selected physicochemical properties during frozen storage. J. Food Eng. 2016, 169, 72–78. [Google Scholar] [CrossRef]

- Hall, A.E.; Moraru, C.I. Structure and function of pea, lentil and faba bean proteins treated by high pressure processing and heat treatment. LWT-Food Sci. Technol. 2021, 152, 112349. [Google Scholar] [CrossRef]

- Leite, T.S.; Jesus, A.L.T.; Schmiele, M.; Tribst, A.A.L.; Cristianini, M. High pressure processing (HPP) of pea starch: Effect on the gelatinization properties. LWT-Food Sci. Technol. 2017, 76, 361–369. [Google Scholar] [CrossRef]

- Janardhanan, R.; Virseda, P.; Huerta-Leidenz, N.; Beriain, M.J. Effect of high–hydrostatic pressure processing and sous-vide cooking on physicochemical traits of Biceps femoris veal patties. Meat Sci. 2022, 188, 108772. [Google Scholar] [CrossRef]

- European Union. Council Regulation (EC) No 1099/2009 on protection of animals at the time of killing. Off. J. Eur. Union 2009, L303, 1–30. [Google Scholar]

- Poyato, C.; Ansorena, D.; Berasategi, I.; Navarro-Blasco, Í.; Astiasarán, I. Optimization of a gelled emulsion intended to supply ω-3 fatty acids into meat products by means of response surface methodology. Meat Sci. 2014, 98, 615–621. [Google Scholar] [CrossRef] [PubMed]

- I.S.O. Meat and Meat Products—Determination of Moisture Content (Reference Method); International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- I.S.O. Meat and Meat Products—Determination of Nitrogen Content (Reference Method); International Organization for Standardization: Geneva, Switzerland, 1978. [Google Scholar]

- I.S.O. Meat and meat products—Determination of Total Fat Content; International Organization for Standardization: Geneva, Switzerland, 1973. [Google Scholar]

- I.S.O. Meat and Meat Products—Determination of Total Ash; International Organization for Standardization: Geneva, Switzerland, 1998. [Google Scholar]

- Murphy, E.W.; Criner, P.E.; Gray, B.C. Comparisons of methods for calculating retention of nutrients in cooked foods. J. Agric. Food Chem. 1975, 23, 1153–1157. [Google Scholar] [CrossRef] [PubMed]

- I.S.O. Meat and Meat Products—Measurement of PH; International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

- Mittal, G.S.; Nadulski, R.; Barbut, S.; Negi, S.C. Textural profile analysis test conditions for meat products. Food Res. Int. 1992, 25, 411–417. [Google Scholar] [CrossRef]

- del Estado, J. Ley Orgánica 3/2018, de 5 de Diciembre, de Protección de Datos Personales y Garantía de Los Derechos Digitales; Independently Published: Thousand Oaks, CA, USA, 2018; Volume BOE-A-2018-16673, pp. 119788–119857. [Google Scholar]

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- European Union. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, L404, 9–25. [Google Scholar]

- Botella-Martinez, C.; Lucas-González, R.; Lorenzo, J.M.; Santos, E.M.; Rosmini, M.; Sepúlveda, N.; Teixeira, A.; Sayas-Barberá, E.; Pérez-Alvarez, J.A.; Fernandez-Lopez, J.; et al. Cocoa coproducts-based and walnut oil gelled emulsion as animal fat replacer and healthy bioactive source in beef burgers. Foods 2021, 10, 2706. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, G.M.; Souza, X.R.; Costa, D.P.B.; Faria, P.B.; Vicente, J. Partial substitution of pork fat with canola oil in Toscana sausage. Innov. Food Sci. Emerg. Technol. 2017, 44, 2–8. [Google Scholar] [CrossRef]

- Cittadini, A.; Munekata, P.E.S.; Pateiro, M.; Sarriés, M.V.; Domínguez, R.; Lorenzo, J.M. Physicochemical composition and nutritional properties of foal burgers enhanced with healthy oil emulsion hydrogels. Int. J. Food Sci. Technol. 2021, 56, 6182–6191. [Google Scholar] [CrossRef]

- Foggiaro, D.; Domínguez, R.; Pateiro, M.; Cittadini, A.; Munekata, P.E.S.; Campagnol, P.C.B.; Fraqueza, M.J.; Palo, P.; Lorenzo, J.M. Use of healthy emulsion hydrogels to improve the quality of pork burgers. Foods 2022, 11, 596. [Google Scholar] [CrossRef]

- Jung, S.; Ghoul, M.; Lamballerie-Anton, M. Influence of high pressure on the color and microbial quality of beef meat. LWT-Food Sci. Technol. 2003, 36, 625–631. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; Carvalho, F.A.L.; Domínguez, R.; Trindade, M.A.; Pateiro, M.; Lorenzo, J.M. Healthy beef burgers: Effect of animal fat replacement by algal and wheat germ oil emulsions. Meat Sci. 2021, 173, 108396. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; Carvalho, F.A.L.; Pateiro, M.; Barba, F.J.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Use of tiger nut (Cyperus esculentus L.) oil emulsion as animal fat replacement in beef burgers. Foods 2020, 9, 44. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P.E.S.; Pateiro, M.; Franco, D.; Campagnol, P.C.B.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Physicochemical composition and nutritional properties of deer burger enhanced with healthier oils. Foods 2020, 9, 571. [Google Scholar] [CrossRef] [PubMed]

- Hanula, M.; Szpicer, A.; Górska-Horczyczak, E.; Khachatryan, G.; Pogorzelska-Nowicka, E.; Poltorak, A. Quality of beef burgers formulated with fat substitute in a form of freeze-dried hydrogel enriched with açai oil. Molecules 2022, 27, 3700. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Sample | Weight Loss (g/100 g) | pH | Moisture (g/100 g) | Fat (g/100 g) | Protein (g/100 g) | Ash (g/100 g) |

|---|---|---|---|---|---|---|---|

| HPP | M-ba | 1.07 (0.08) b | 5.70 (0.06) cd | 58.4 (0.3) c | 22.2 (0.7) a | 17.3 (0.2) c | 2.3 (0.2) a |

| M-hy | 2.98 (0.59) a | 5.67 (0.02) d | 69.0 (1.1) a | 10.6 (0.4) b | 17.0 (0.4) c | 3.3 (1.0) ab | |

| M-so | 1.96 (1.04) ab | 5.76 (0.04) c | 69.1 (0.1) a | 9.7 (0.4) c | 19.6 (1.1) ab | 2.5 (0.1) bc | |

| H-hy | 2.08 (0.50) ab | 6.02 (0.02) b | 62.2 (0.6) b | 10.3 (0.2) bc | 17.6 (0.1) c | 3.0 (0.1) abc | |

| H-so | 0.90 (0.45) b | 6.01 (0.04) b | 62.6 (0.4) b | 7.9 (0.4) d | 19.6 (0.2) ab | 3.0 (0.1) abc | |

| P-hy | 2.09 (0.47) ab | 6.20 (0.02) a | 55.7 (0.2) d | 8.3 (0.4) d | 18.8 (0.6) d | 3.7 (0.1) a | |

| P-so | 1.23 (0.31) b | 6.21 (0.06) a | 56.6 (0.1) d | 6.0 (0.2) e | 20.1 (0.2) a | 3.6 (0.1) a | |

| HPP + SVCOOK | M-ba | 8.25 (1.33) b | 5.68 (0.03) e | 57.6 (0.9) cd | 22.8 (2.1) a | 17.6 (0.8) c | 2.3 (0.1) ab |

| M-hy | 16.34 (3.20) a | 5.71 (0.01) e | 68.1 (1.6) a | 9.6 (1.2) b | 18.4 (0.2) bc | 3.3 (0.7) a | |

| M-so | 13.84 (2.11) a | 5.80 (0.04) d | 67.8 (0.7) a | 9.1 (0.6) b | 20.3 (0.4) a | 1.6 (1.5) b | |

| H-hy | 3.71 (0.72) c | 5.96 (0.05) c | 61.9 (0.8) b | 10.0 (0.4) b | 17.6 (0.4) c | 3.1 (0.0) ab | |

| H-so | 2.00 (0.50) c | 6.02 (0.01) b | 63.0 (0.1) b | 7.8 (0.2) bc | 19.7 (0.3) ab | 3.1 (0.0) ab | |

| P-hy | 2.56 (1.89) c | 6.14 (0.03) a | 55.6 (1.2) d | 8.5 (1.3) b | 18.7 (1.5) abc | 3.7 (0.0) a | |

| P-so | 0.86 (0.05) c | 6.19 (0.02) a | 58.0 (1.4) c | 5.3 (1.0) c | 19.5 (0.4) ab | 3.6 (0.2) a |

| Treatment | Sample | L* | a* | b* |

|---|---|---|---|---|

| HPP | M-ba | 51.78 (4.18) bc | 8.83 (1.59) b | 13.66 (4.38) d |

| M-hy | 47.60 (3.12) c | 9.10 (2.51) b | 12.26 (4.78) d | |

| M-so | 50.07 (5.41) bc | 10.84 (1.91) b | 14.71 (5.45) cd | |

| H-hy | 52.88 (4.64) bc | 13.37 (2.39) a | 19.97 (5.49) bc | |

| H-so | 53.32 (6.54) b | 13.97 (2.59) a | 20.88 (5.66) b | |

| P-hy | 61.92 (4.31) a | 10.38 (0.93) b | 27.83 (2.89) a | |

| P-so | 63.77 (3.62) a | 9.90 (0.73) b | 26.97 (3.79) a | |

| HPP + SVCOOK | M-ba | 50.53 (4.50) cd | 8.73 (0.64) d | 12.55 (5.08) c |

| M-hy | 48.81 (4.89) d | 8.81 (1.11) d | 12.60 (5.28) c | |

| M-so | 50.71 (4.46) cd | 9.68 (0.82) cd | 13.97 (5.49) bc | |

| H-hy | 53.94 (4.87) cd | 11.75 (1.71) a | 19.82 (7.09) b | |

| H-so | 55.90 (4.25) bc | 11.36 (1.06) ab | 19.82 (5.77) b | |

| P-hy | 60.80 (5.81) ab | 10.27 (0.49) bc | 29.17 (4.01) a | |

| P-so | 62.50 (4.79) a | 9.67 (0.59) cd | 26.78 (3.34) a |

| Treatment | Sample | Hardness (N) | Springiness | Cohesiveness | Chewiness (N) |

|---|---|---|---|---|---|

| HPP | M-ba | 8.15 (1.79) b | 0.52 (0.06) bc | 0.39 (0.06) bc | 1.61 (0.28) bc |

| M-hy | 5.95 (2.26) bc | 0.67 (0.05) a | 0.46 (0.02) a | 1.84 (0.70) ab | |

| M-so | 7.06 (1.02) b | 0.66 (0.05) a | 0.41 (0.03) ab | 1.92 (0.31) ab | |

| H-hy | 4.46 (0.94) c | 0.45 (0.06) d | 0.31 (0.03) d | 0.60 (0.14) d | |

| H-so | 6.74 (1.27) bc | 0.46 (0.05) cd | 0.33 (0.03) d | 1.03 (0.26) cd | |

| P-hy | 8.27 (2.28) b | 0.67 (0.04) a | 0.43 (0.05) ab | 2.41 (0.82) a | |

| P-so | 11.00 (3.18) a | 0.53 (0.06) b | 0.34 (0.03) cd | 1.96 (0.59) ab | |

| HPP + SVCOOK | M-ba | 29.90 (7.00) ab | 0.71 (0.06) b | 0.51 (0.05) bc | 11.05 (3.37) bc |

| M-hy | 18.81 (4.44) cd | 0.81 (0.06) a | 0.58 (0.09) ab | 8.95 (2.97) bc | |

| M-so | 34.29 (9.84) a | 0.78 (0.02) ab | 0.61 (0.03) a | 16.54 (5.18) a | |

| H-hy | 13.35 (6.38) d | 0.72 (0.06) b | 0.48 (0.07) c | 5.01 (3.30) cd | |

| H-so | 23.38 (4.61) bc | 0.76 (0.02) ab | 0.50 (0.04) bc | 9.05 (2.25) bc | |

| P-hy | 16.57 (8.10) cd | 0.73 (0.09) b | 0.50 (0.10) bc | 6.85 (4.67) cd | |

| P-so | 13.11 (3.69) d | 0.57 (0.08) c | 0.33 (0.02) d | 2.38 (0.55) d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janardhanan, R.; González-Diez, M.; Ibañez, F.C.; Beriain, M.J. Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement. Foods 2022, 11, 3678. https://doi.org/10.3390/foods11223678

Janardhanan R, González-Diez M, Ibañez FC, Beriain MJ. Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement. Foods. 2022; 11(22):3678. https://doi.org/10.3390/foods11223678

Chicago/Turabian StyleJanardhanan, Rasmi, Mikel González-Diez, Francisco C. Ibañez, and Maria Jose Beriain. 2022. "Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement" Foods 11, no. 22: 3678. https://doi.org/10.3390/foods11223678

APA StyleJanardhanan, R., González-Diez, M., Ibañez, F. C., & Beriain, M. J. (2022). Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement. Foods, 11(22), 3678. https://doi.org/10.3390/foods11223678