Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Experimental Design for Optimization

2.3. Response Parameters Analysis

2.3.1. Degree of Hydrolysis Determination

2.3.2. α-Amylase Inhibition Assay

2.3.3. α-Glucosidase Inhibition Assay

2.4. Protein Patterns by SDS-PAGE

2.5. Antioxidant Activity

2.5.1. DPPH Radical-Scavenging Activity (DPPH-RSA)

2.5.2. ABTS Radical Cation Scavenging Activity (ABTS-RSA)

2.6. Data Analysis

3. Results and Discussion

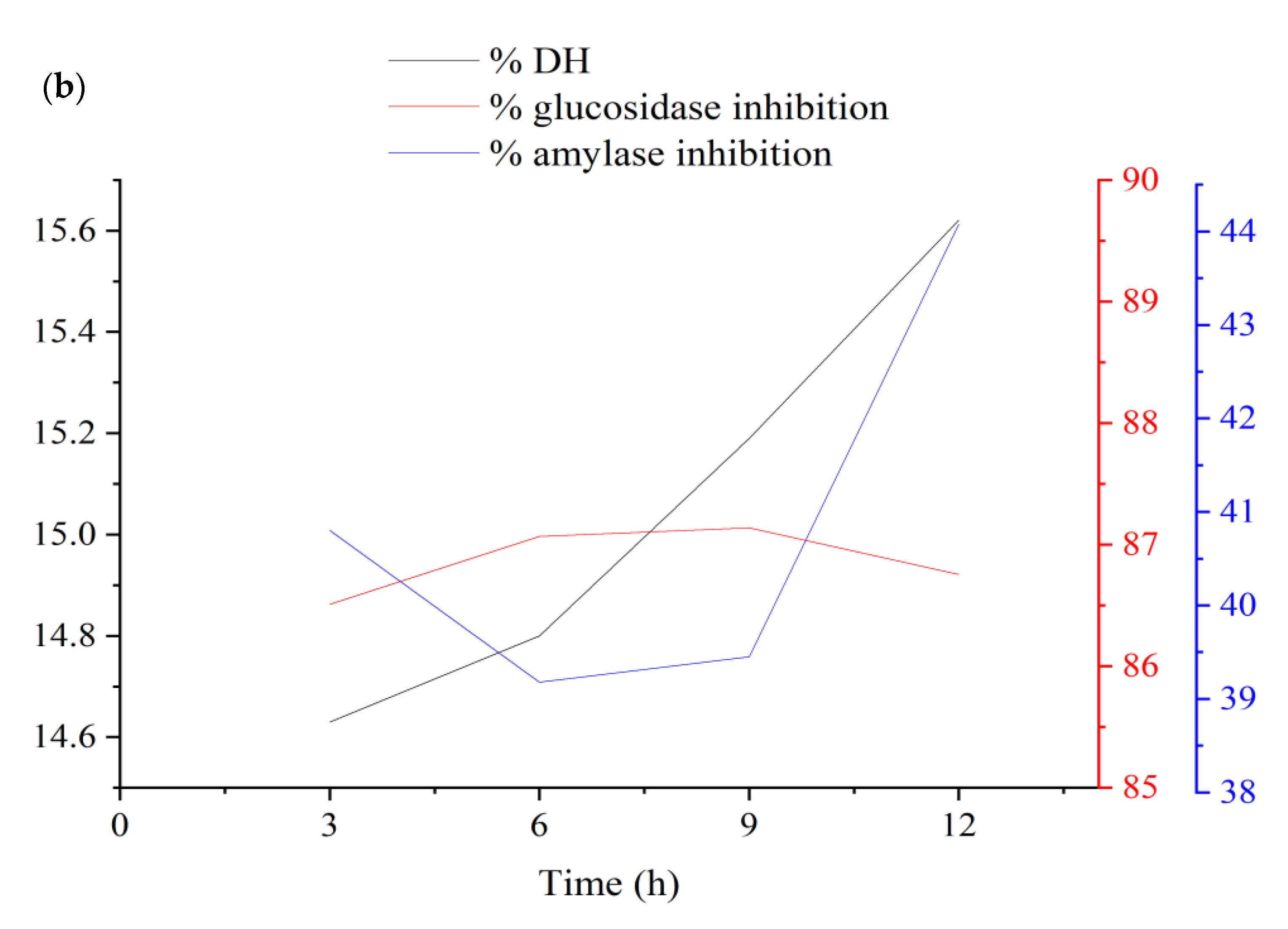

3.1. Optimization of Enzymolysis Conditions

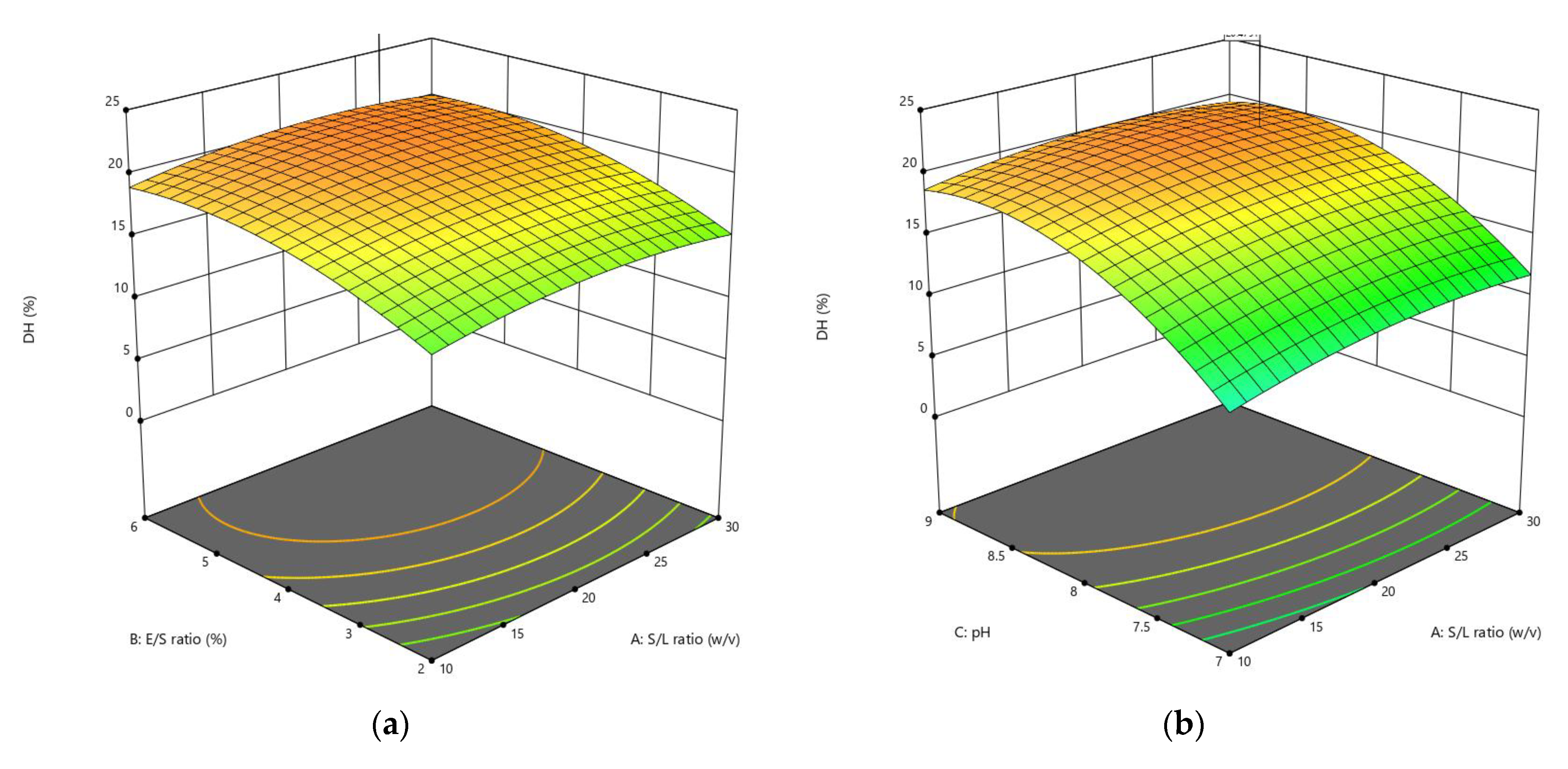

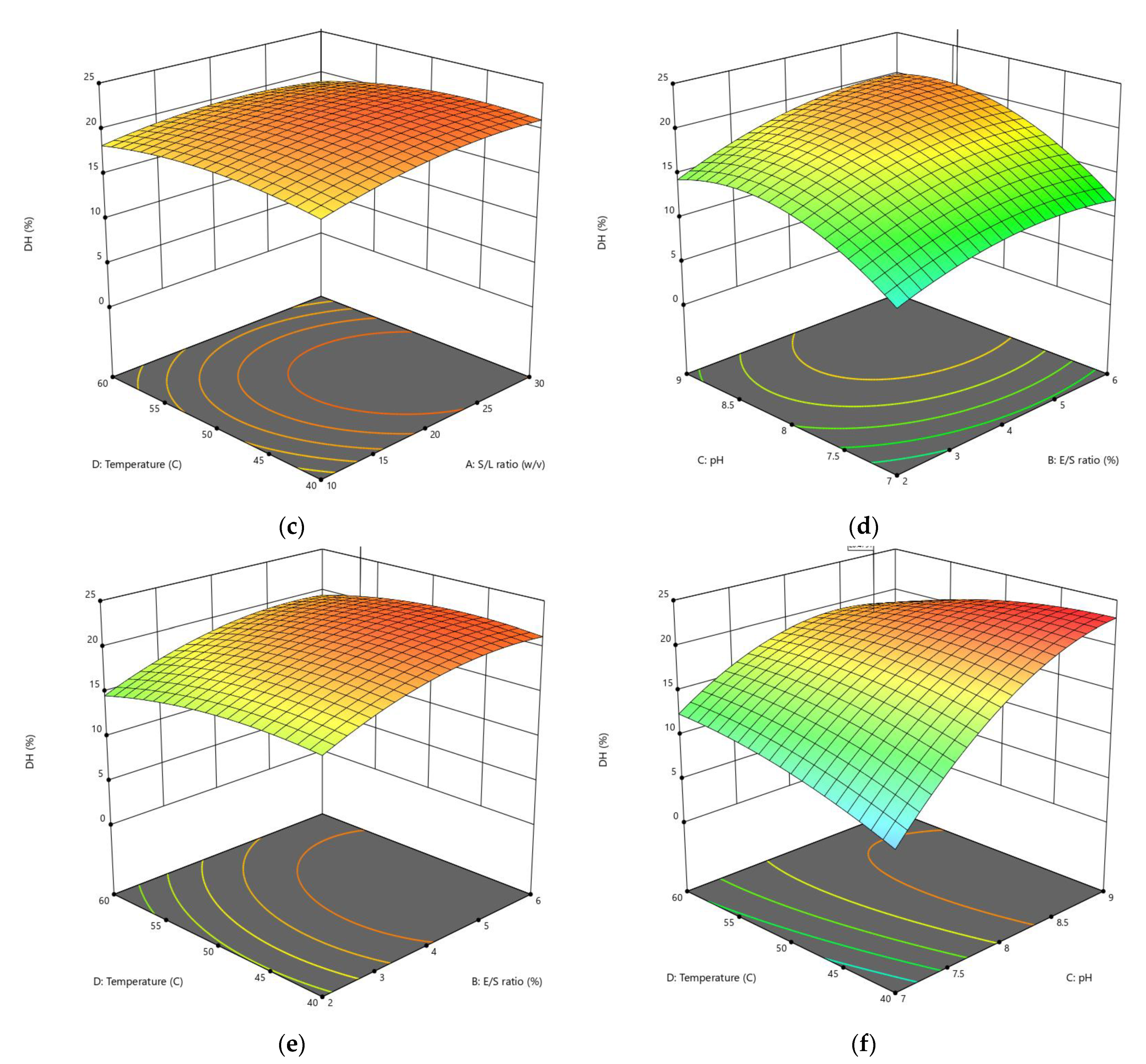

3.1.1. Influences of Parameters on the DH

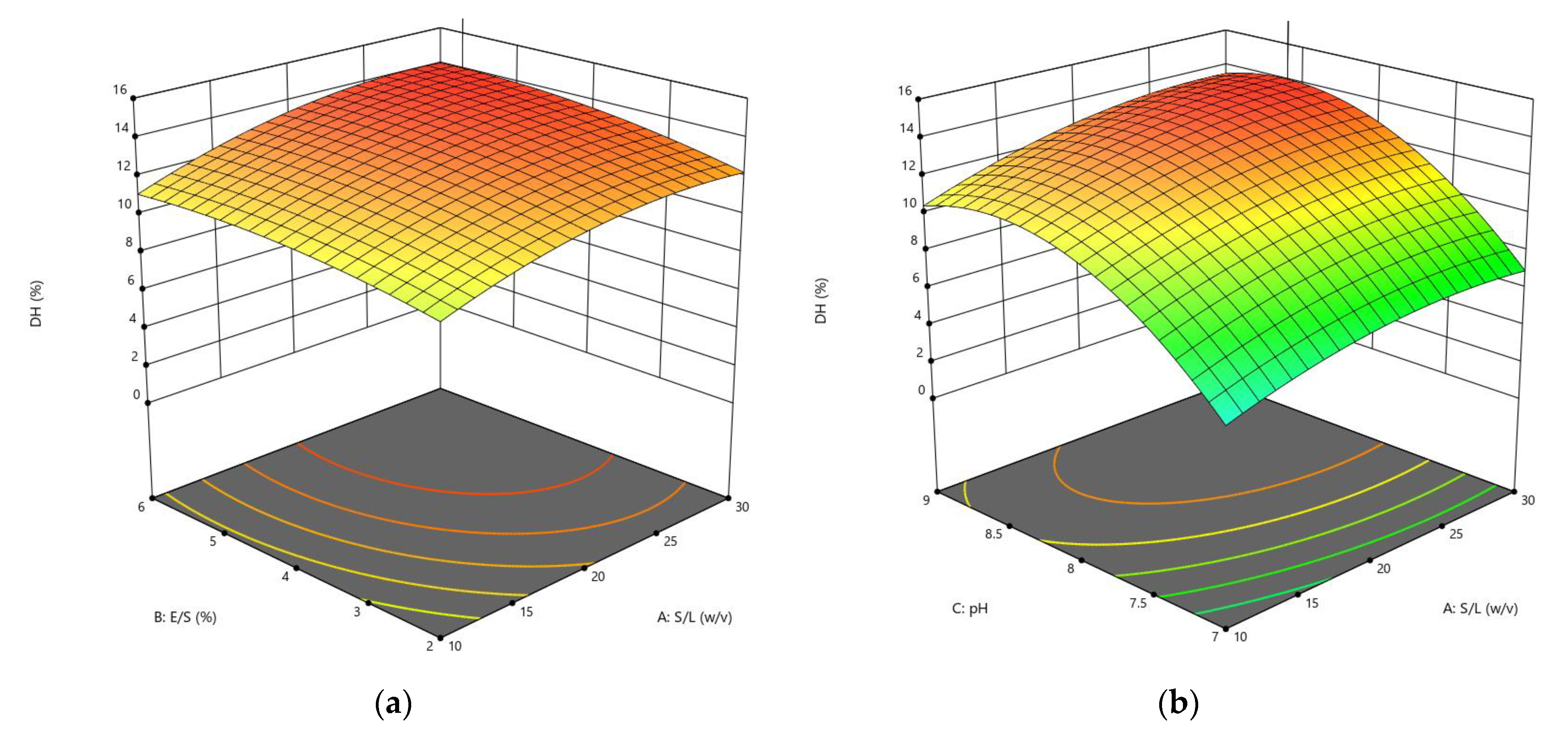

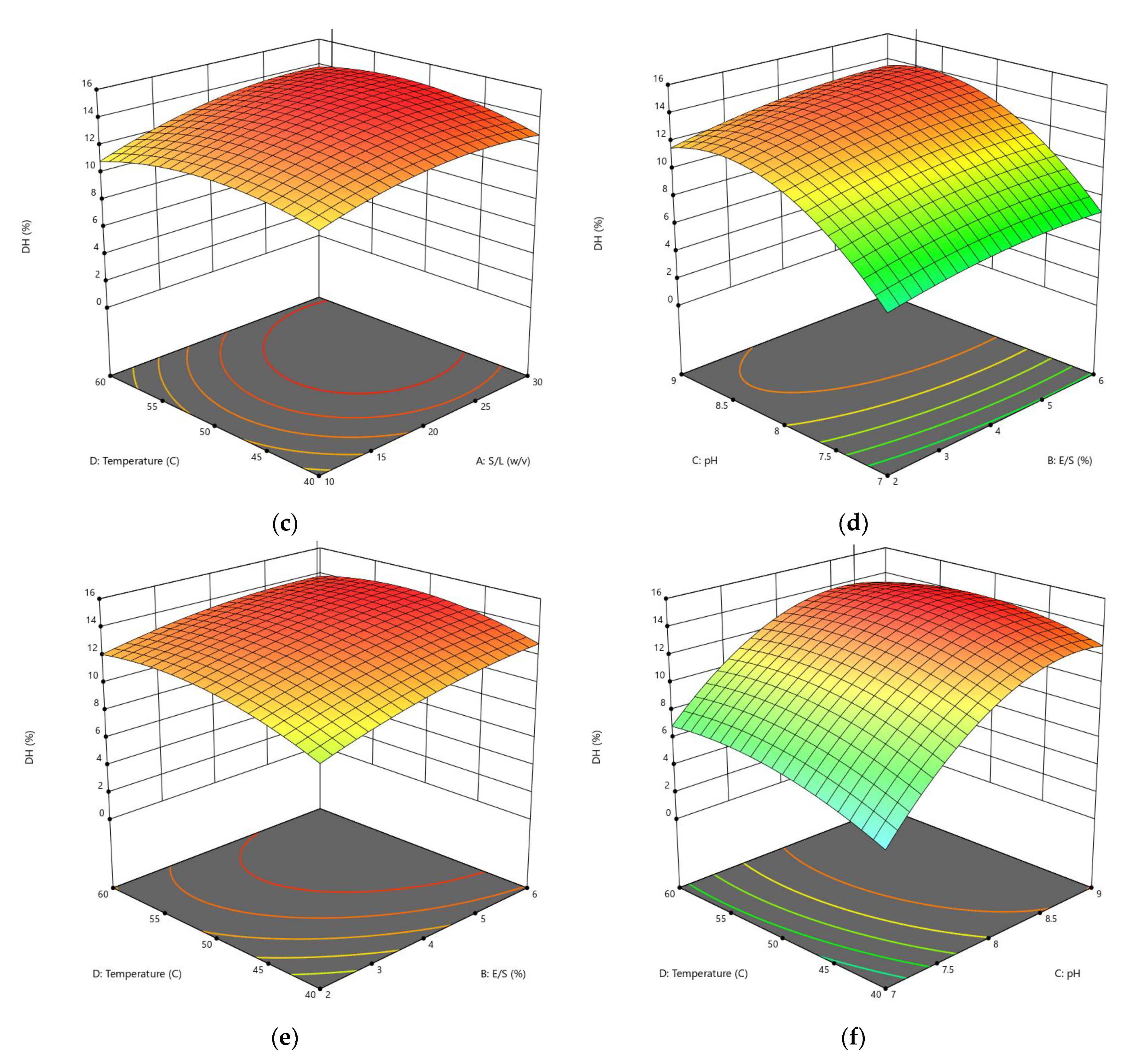

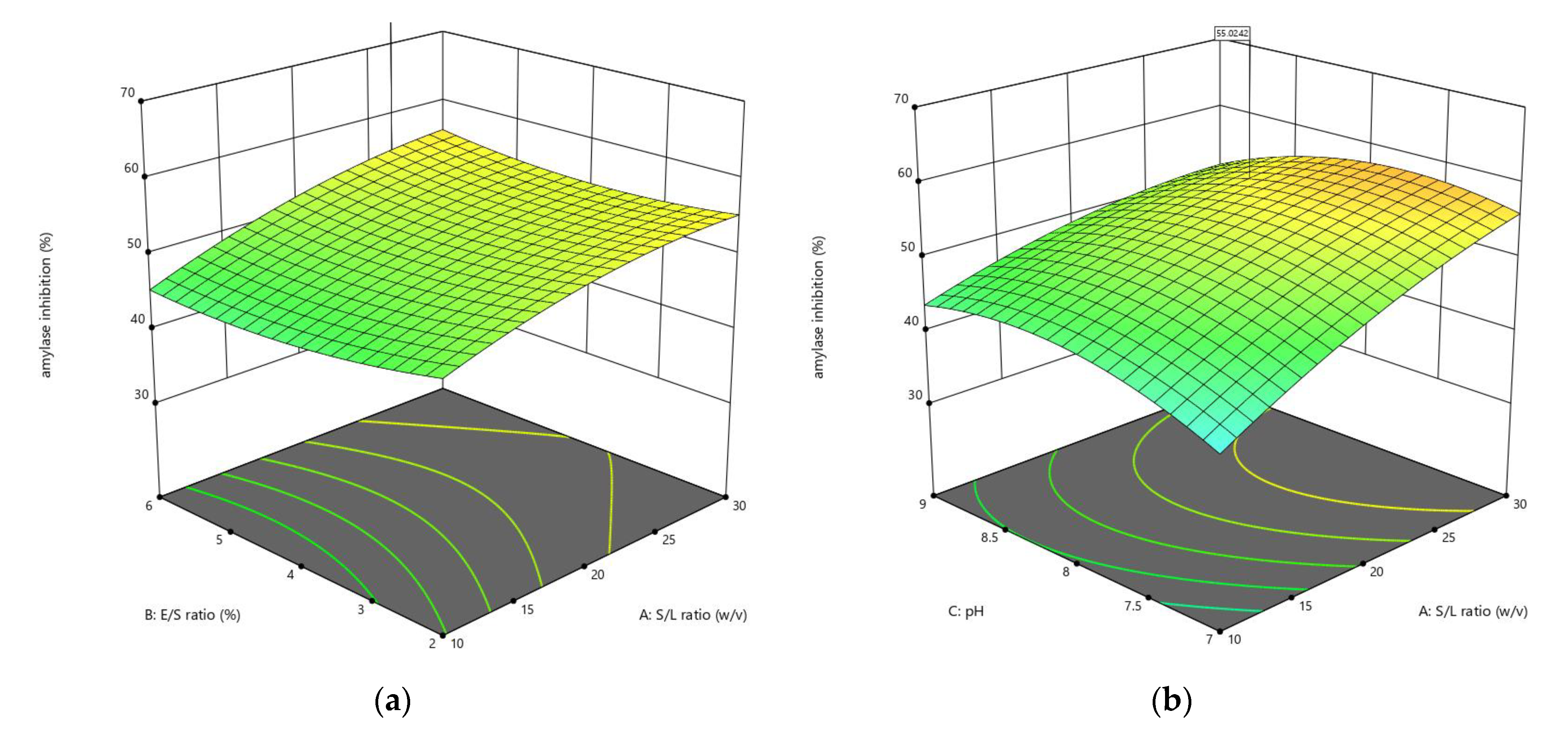

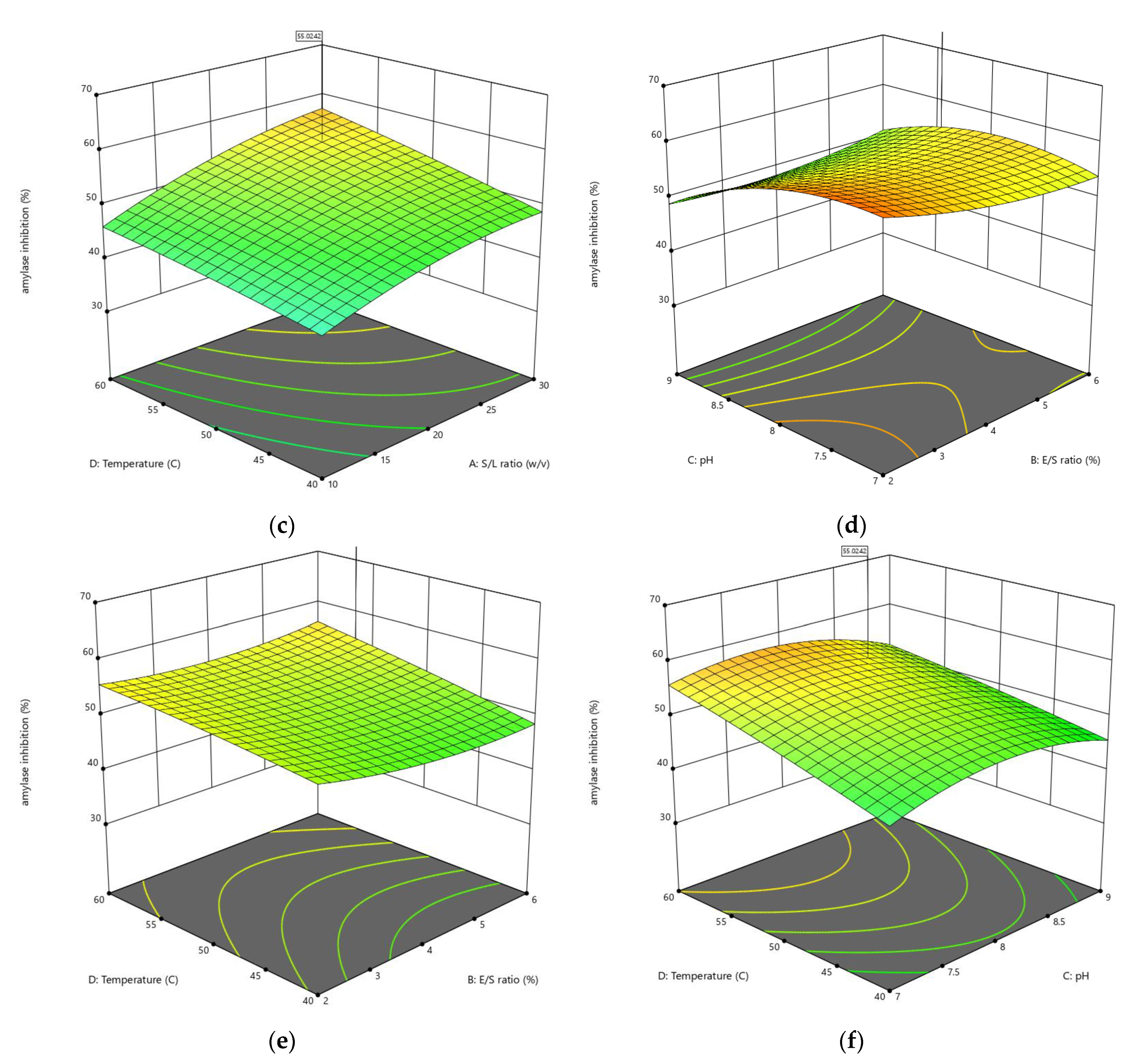

3.1.2. Influences of Parameters on α-Amylase Inhibition

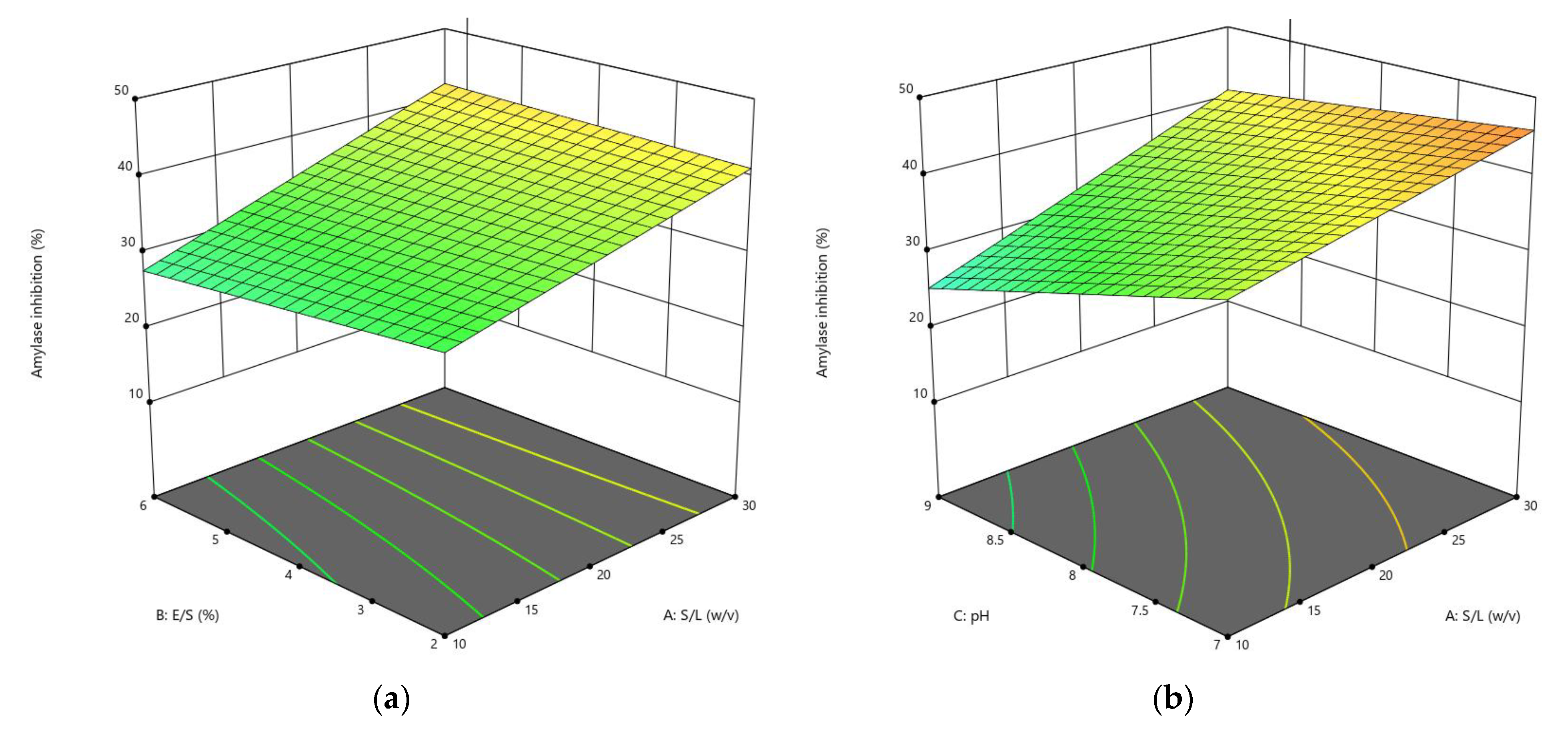

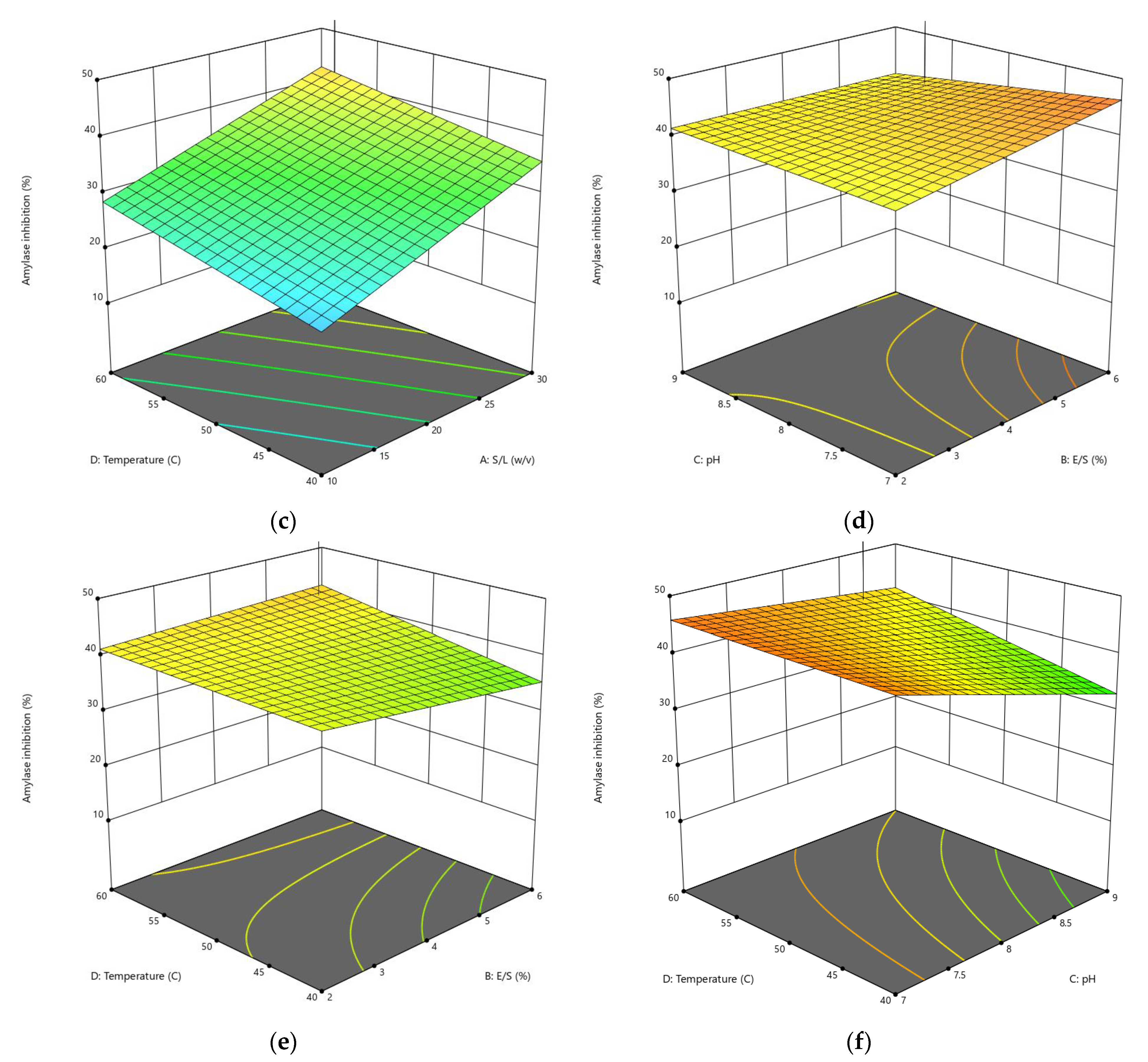

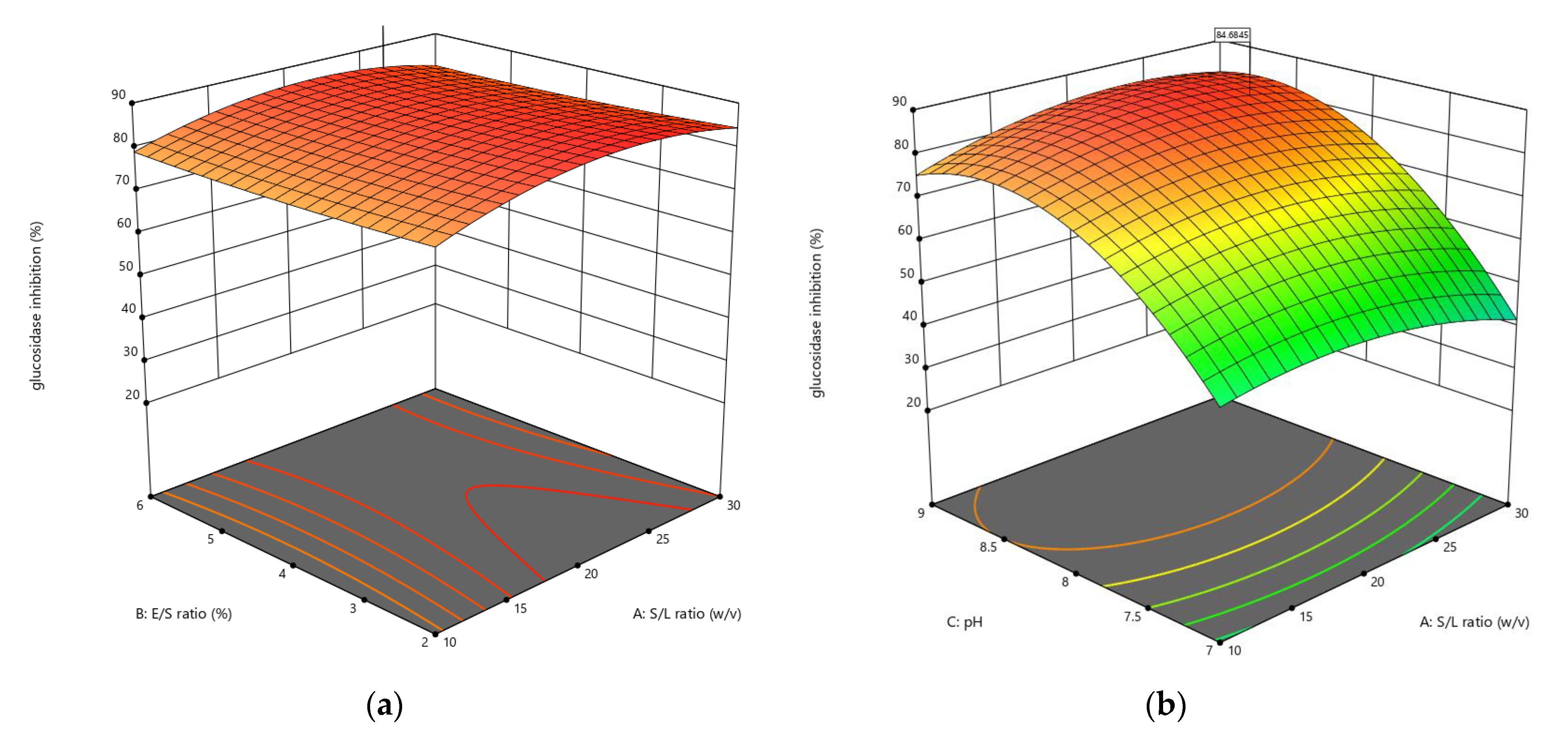

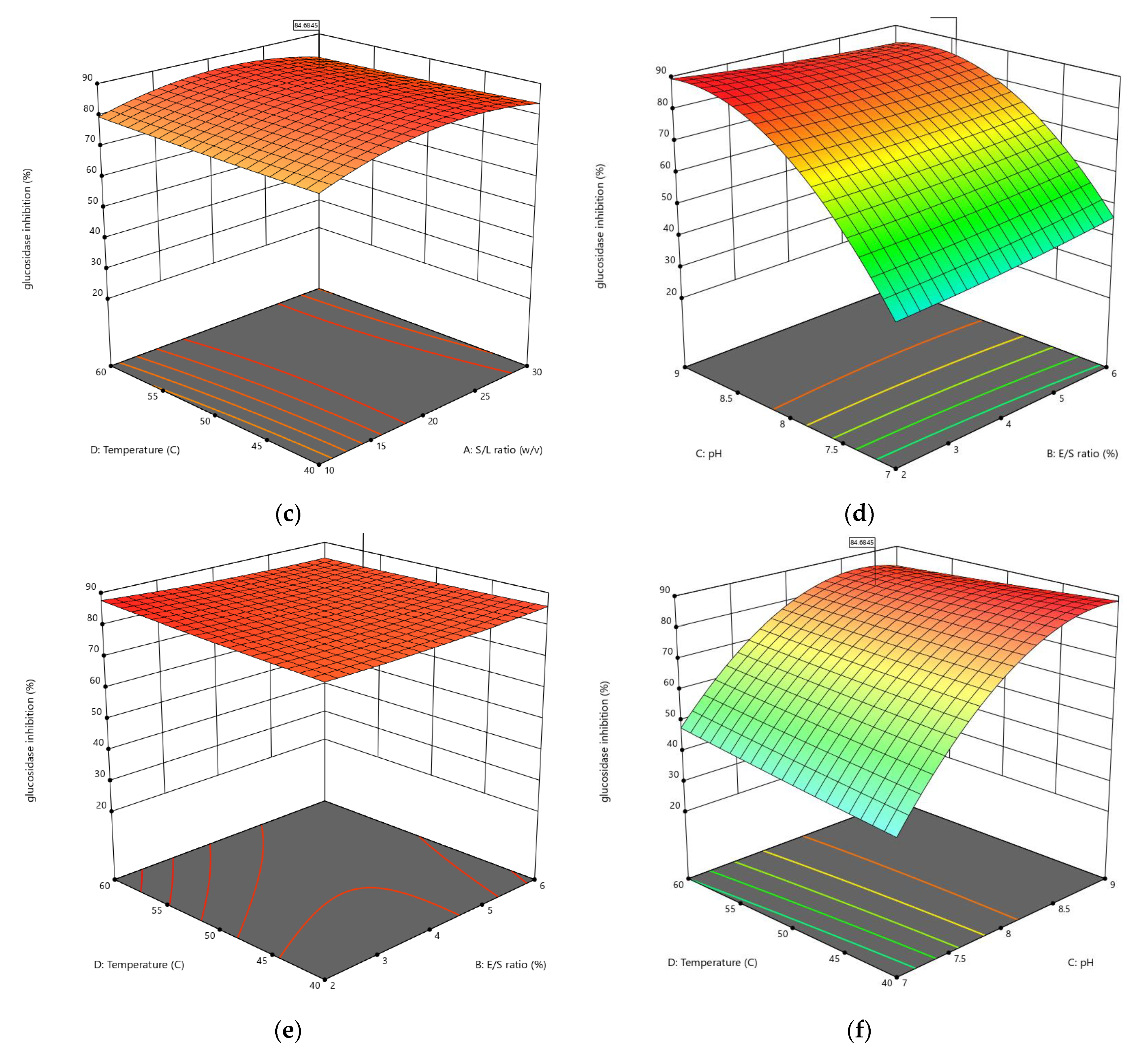

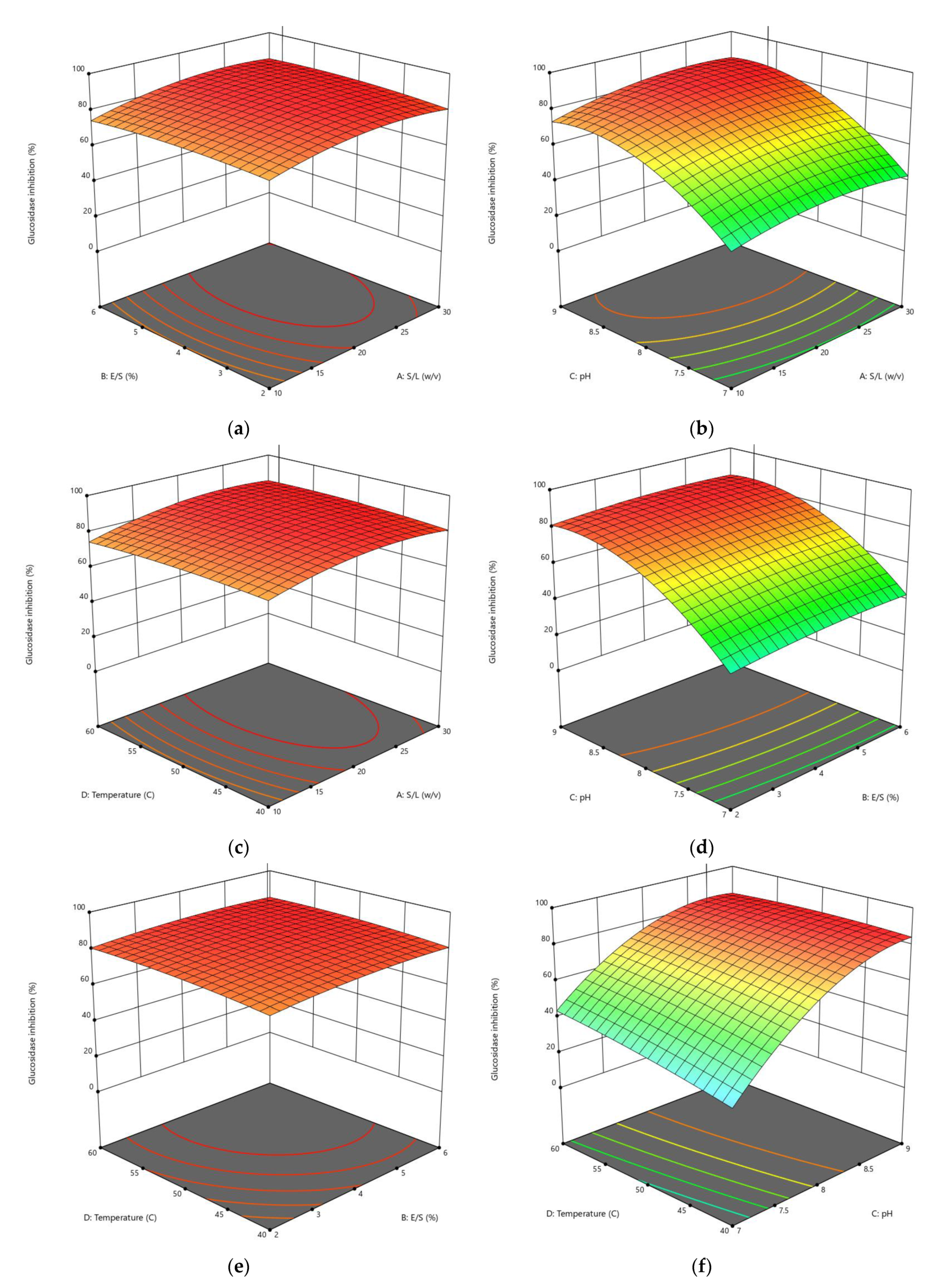

3.1.3. Influences of Parameters on α-Glucosidase Inhibition

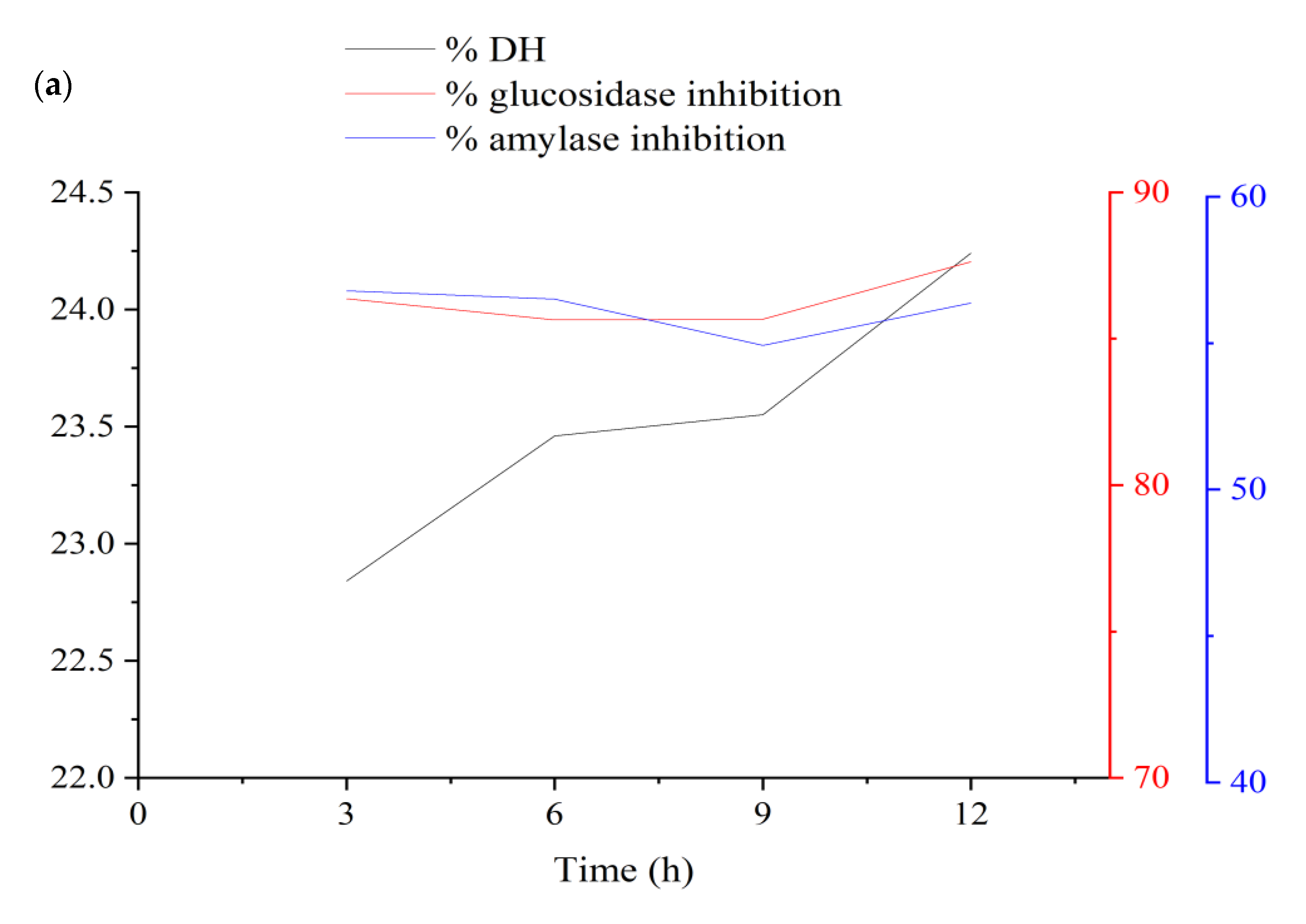

3.1.4. Verification and Optimization

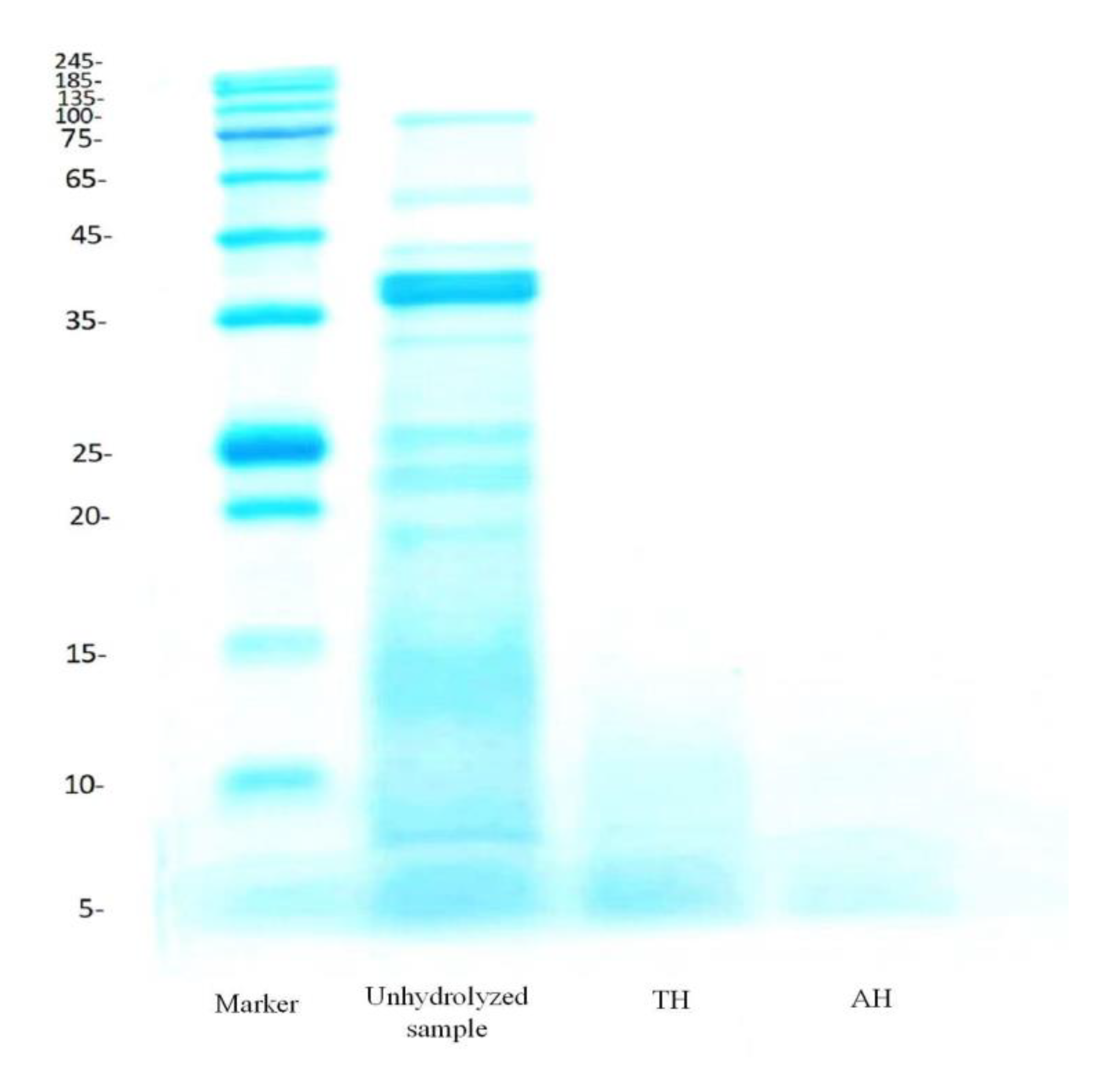

3.2. Protein Patterns by SDS-PAGE

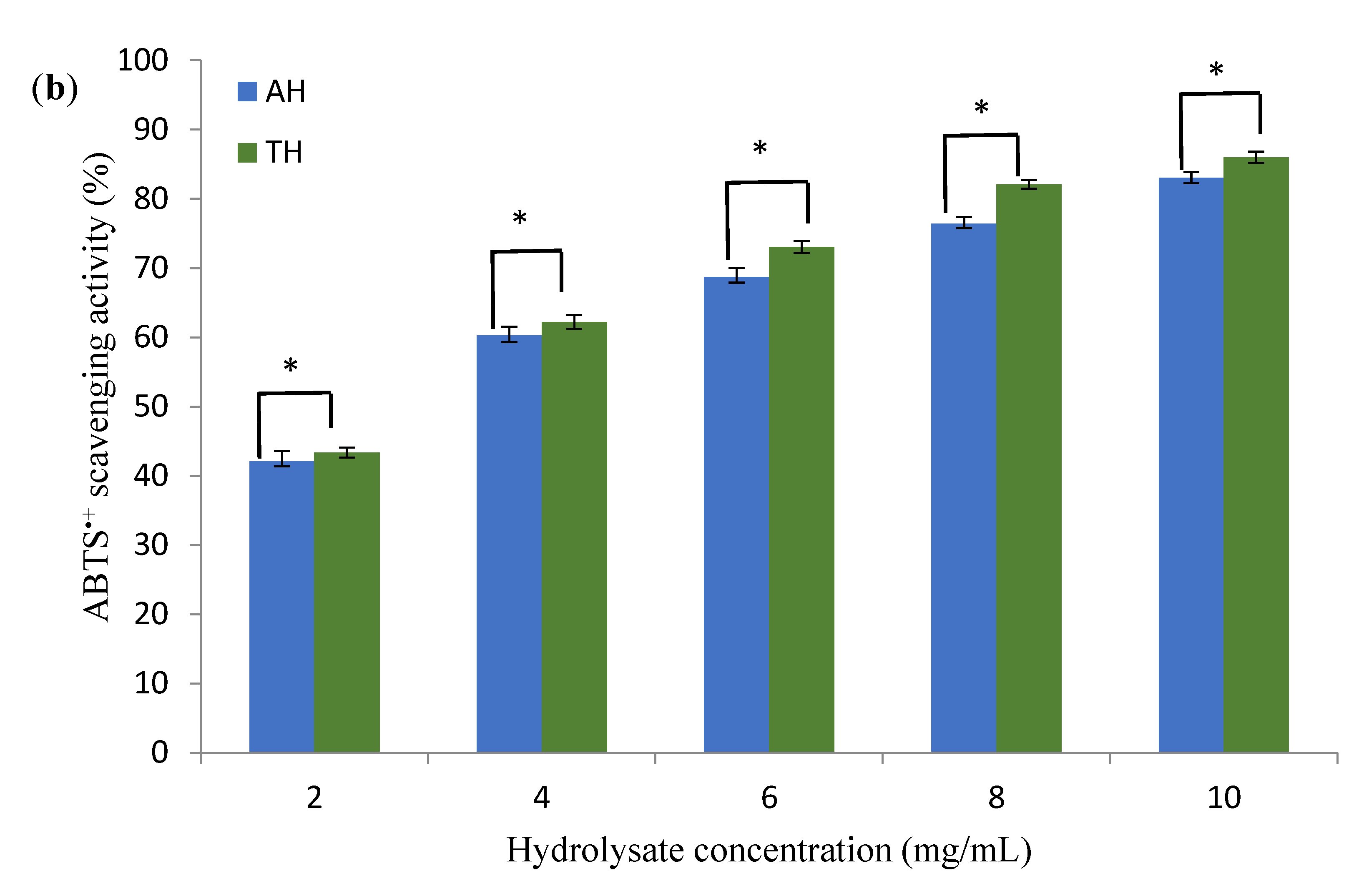

3.3. Antioxidant Activity of Hydrolysates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marthandam Asokan, S.; Wang, T.; Su, W.-T.; Lin, W.-T. Antidiabetic effects of a short peptide of potato protein hydrolysate in STZ-induced diabetic mice. Nutrients 2019, 11, 779. [Google Scholar] [CrossRef]

- Ademiluyi, A.O.; Oboh, G. Soybean phenolic-rich extracts inhibit key-enzymes linked to type 2 diabetes (α-amylase and α-glucosidase) and hypertension (angiotensin I converting enzyme) in vitro. Exp. Toxicol. Pathol. 2013, 65, 305–309. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, H.; Pan, X.; Orfila, C.; Lu, W.; Ma, Y. Preparation of bioactive peptides with antidiabetic, antihypertensive, and antioxidant activities and identification of α-glucosidase inhibitory peptides from soy protein. Food Sci. Nutr. 2019, 7, 1848–1856. [Google Scholar] [CrossRef]

- Antony, P.; Vijayan, R. Bioactive Peptides as Potential Nutraceuticals for Diabetes Therapy: A Comprehensive Review. Int. J. Mol. Sci. 2021, 22, 9059. [Google Scholar] [CrossRef]

- Zaccardi, F.; Webb, D.R.; Yates, T.; Davies, M.J. Pathophysiology of type 1 and type 2 diabetes mellitus: A 90-year perspective. Postgrad. Med. J. 2016, 92, 63–69. [Google Scholar] [CrossRef]

- Tomita, T. Apoptosis of pancreatic β-cells in Type 1 diabetes. Bosn. J. Basic Med. Sci. 2017, 17, 183. [Google Scholar] [CrossRef]

- Oseguera-Toledo, M.E.; de Mejia, E.G.; Amaya-Llano, S.L. Hard-to-cook bean (Phaseolus vulgaris L.) proteins hydrolyzed by alcalase and bromelain produced bioactive peptide fractions that inhibit targets of type-2 diabetes and oxidative stress. Food Res. Int. 2015, 76, 839–851. [Google Scholar] [CrossRef]

- Qaseem, A.; Barry, M.J.; Humphrey, L.L.; Forciea, M.A.; Clinical Guidelines Committee of the American College of Physicians; Fitterman, N.; Horwitch, C.; Kansagara, D.; McLean, R.M.; Wilt, T.J. Oral pharmacologic treatment of type 2 diabetes mellitus: A clinical practice guideline update from the American College of Physicians. Ann. Intern. Med. 2017, 166, 279–290. [Google Scholar] [CrossRef]

- Connolly, A.; Piggott, C.O.; FitzGerald, R.J. In vitro α-glucosidase, angiotensin converting enzyme and dipeptidyl peptidase-IV inhibitory properties of brewers’ spent grain protein hydrolysates. Food Res. Int. 2014, 56, 100–107. [Google Scholar] [CrossRef]

- Karimi, A.; Azizi, M.H.; Ahmadi Gavlighi, H. Fractionation of hydrolysate from corn germ protein by ultrafiltration: In vitro antidiabetic and antioxidant activity. Food Sci. Nutr. 2020, 8, 2395–2405. [Google Scholar] [CrossRef]

- Ramadhan, A.H.; Nawas, T.; Zhang, X.; Pembe, W.M.; Xia, W.; Xu, Y. Purification and identification of a novel antidiabetic peptide from Chinese giant salamander (Andrias davidianus) protein hydrolysate against α-amylase and α-glucosidase. Int. J. Food Prop. 2017, 20, S3360–S3372. [Google Scholar] [CrossRef]

- Noman, A.; Wang, Y.; Zhang, C.; Abed, S.M. Antioxidant Activity of Hybrid Sturgeon (Huso dauricus × Acipenser schrenckii) Protein Hydrolysate Prepared Using Bromelain, Its Fractions and Purified Peptides. Pol. J. Food Nutr. Sci. 2022, 72, 79–89. [Google Scholar] [CrossRef]

- Manzanares, P.; Gandía, M.; Garrigues, S.; Marcos, J.F. Improving health-promoting effects of food-derived bioactive peptides through rational design and oral delivery strategies. Nutrients 2019, 11, 2545. [Google Scholar] [CrossRef]

- Dong, X.; Li, J.; Jiang, G.; Li, H.; Zhao, M.; Jiang, Y. Effects of combined high pressure and enzymatic treatments on physicochemical and antioxidant properties of peanut proteins. Food Sci. Nutr. 2019, 7, 1417–1425. [Google Scholar] [CrossRef]

- Yolmeh, M.; Jafari, S.M. Applications of response surface methodology in the food industry processes. Food Bioprocess Technol. 2017, 10, 413–433. [Google Scholar] [CrossRef]

- Adler-Nissen, J. Enzymic Hydrolysis of Food Proteins; Elsevier Applied Science Publishers: Barking, UK, 1986. [Google Scholar]

- Zhang, L.; Song, C.; Chang, J.; Wang, Z.; Meng, X. Optimization of protein hydrolysates production from defatted peanut meal based on physicochemical characteristics and sensory analysis. LWT 2022, 163, 113572. [Google Scholar] [CrossRef]

- Bahadori, M.B.; Dinparast, L.; Zengin, G.; Sarikurkcu, C.; Bahadori, S.; Asghari, B.; Movahhedin, N. Functional components, antidiabetic, anti-Alzheimer’s disease, and antioxidant activities of Salvia syriaca L. Int. J. Food Prop. 2017, 20, 1761–1772. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Wang, B.; Li, Z.-R.; Chi, C.-F.; Zhang, Q.-H.; Luo, H.-Y. Preparation and evaluation of antioxidant peptides from ethanol-soluble proteins hydrolysate of Sphyrna lewini muscle. Peptides 2012, 36, 240–250. [Google Scholar] [CrossRef]

- Liu, F.-F.; Li, Y.-Q.; Sun, G.-J.; Wang, C.-Y.; Liang, Y.; Zhao, X.-Z.; He, J.-X.; Mo, H.-Z. Influence of ultrasound treatment on the physicochemical and antioxidant properties of mung bean protein hydrolysate. Ultrason. Sonochem. 2022, 84, 105964. [Google Scholar] [CrossRef]

- Bahari, A.N.; Saari, N.; Salim, N.; Ashari, S.E. Response factorial design analysis on papain-generated hydrolysates from Actinopyga lecanora for determination of antioxidant and antityrosinase activities. Molecules 2020, 25, 2663. [Google Scholar] [CrossRef]

- Villamil, O.; Váquiro, H.; Solanilla, J.F. Fish viscera protein hydrolysates: Production, potential applications and functional and bioactive properties. Food Chem. 2017, 224, 160–171. [Google Scholar] [CrossRef]

- See, S.; Hoo, L.; Babji, A. Optimization of enzymatic hydrolysis of Salmon (Salmo salar) skin by Alcalase. Int. Food Res. J. 2011, 18, 1359–1365. [Google Scholar]

- Gao, R.; Shen, Y.; Shu, W.; Bai, F.; Jin, W.; Wang, J.; Yuan, L. Optimization of enzymatic conditions of sturgeon muscles and their anti-inflammatory potential. J. Food Qual. 2020, 2020, 9698134. [Google Scholar] [CrossRef]

- Ktari, N.; Fakhfakh, N.; Balti, R.; Ben Khaled, H.; Nasri, M.; Bougatef, A. Effect of degree of hydrolysis and protease type on the antioxidant activity of protein hydrolysates from cuttlefish (Sepia officinalis) by-products. J. Aquat. Food Prod. Technol. 2013, 22, 436–448. [Google Scholar] [CrossRef]

- Ngoh, Y.-Y.; Gan, C.-Y. Enzyme-assisted extraction and identification of antioxidative and α-amylase inhibitory peptides from Pinto beans (Phaseolus vulgaris cv. Pinto). Food Chem. 2016, 190, 331–337. [Google Scholar] [CrossRef]

- Admassu, H.; Gasmalla, M.A.; Yang, R.; Zhao, W. Identification of bioactive peptides with α-amylase inhibitory potential from enzymatic protein hydrolysates of red seaweed (Porphyra spp.). J. Agric. Food Chem. 2018, 66, 4872–4882. [Google Scholar] [CrossRef] [PubMed]

- Famuwagun, A.A.; Alashi, A.M.; Gbadamosi, O.S.; Taiwo, K.A.; Oyedele, D.; Adebooye, O.C.; Aluko, R.E. Antioxidant and enzymes inhibitory properties of Amaranth leaf protein hydrolyzates and ultrafiltration peptide fractions. J. Food Biochem. 2021, 45, e13396. [Google Scholar] [CrossRef]

- Awosika, T.O.; Aluko, R.E. Inhibition of the in vitro activities of α-amylase, α-glucosidase and pancreatic lipase by yellow field pea (Pisum sativum L.) protein hydrolysates. Int. J. Food Sci. Technol. 2019, 54, 2021–2034. [Google Scholar] [CrossRef]

- Fadimu, G.J.; Farahnaky, A.; Gill, H.; Truong, T. Influence of ultrasonic pretreatment on structural properties and biological activities of lupin protein hydrolysate. Int. J. Food Sci. Technol. 2022, 57, 1729–1738. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; de Mejia, E.G. Optimization, identification, and comparison of peptides from germinated chickpea (Cicer arietinum) protein hydrolysates using either papain or ficin and their relationship with markers of type 2 diabetes. Food Chem. 2022, 374, 131717. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Yin, Y.; Zhao, W.; Yu, Y.; Liu, B.; Liu, J.; Chen, F. Novel peptides derived from egg white protein inhibiting alpha-glucosidase. Food Chem. 2011, 129, 1376–1382. [Google Scholar] [CrossRef]

- Zaky, A.A.; Liu, Y.; Han, P.; Ma, A.; Jia, Y. Effect of flavorzyme digestion on the antioxidant capacities of ultra-filtrated rice bran protein hydrolyzates. J. Food Process. Preserv. 2020, 44, e14551. [Google Scholar] [CrossRef]

- Phongthai, S.; Lim, S.-T.; Rawdkuen, S. Optimization of microwave-assisted extraction of rice bran protein and its hydrolysates properties. J. Cereal Sci. 2016, 70, 146–154. [Google Scholar] [CrossRef]

- Ghribi, A.M.; Sila, A.; Przybylski, R.; Nedjar-Arroume, N.; Makhlouf, I.; Blecker, C.; Attia, H.; Dhulster, P.; Bougatef, A.; Besbes, S. Purification and identification of novel antioxidant peptides from enzymatic hydrolysate of chickpea (Cicer arietinum L.) protein concentrate. J. Funct. Foods 2015, 12, 516–525. [Google Scholar] [CrossRef]

- Karami, Z.; Peighambardoust, S.H.; Hesari, J.; Akbari-Adergani, B.; Andreu, D. Antioxidant, anticancer and ACE-inhibitory activities of bioactive peptides from wheat germ protein hydrolysates. Food Biosci. 2019, 32, 100450. [Google Scholar] [CrossRef]

- Sarbon, N.M.; Badii, F.; Howell, N.K. Purification and characterization of antioxidative peptides derived from chicken skin gelatin hydrolysate. Food Hydrocoll. 2018, 85, 311–320. [Google Scholar] [CrossRef]

- Latorres, J.; Rios, D.; Saggiomo, G.; Wasielesky, W.; Prentice-Hernandez, C. Functional and antioxidant properties of protein hydrolysates obtained from white shrimp (Litopenaeus vannamei). J. Food Sci. Technol. 2018, 55, 721–729. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Coded Level | ||

|---|---|---|---|

| −1 | 0 | +1 | |

| Solid/liquid ratio (w/v, X1) | 1:10 | 1:20 | 1:30 |

| Enzyme/substrate ratio (w/w, X2) | 2 | 4 | 6 |

| pH (X3) | 7 | 8 | 9 |

| Temperature (X4) | 40 | 50 | 60 |

| Source | Sum of Squares | Degree of Freedom | Mean of Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Alcalase | |||||

| DH | |||||

| Model | 985.28 | 14 | 70.38 | 11.20 | <0.0001 |

| Residual | 94.22 | 15 | 6.28 | ||

| Pure error | 0.1070 | 5 | 0.0214 | ||

| Lack of fit | 94.11 | 10 | 9.41 | 439.77 | <0.0001 |

| Total | 1079.50 | 29 | |||

| R2 | 0.9127 | Adj. R2 | 0.8313 | ||

| α-Amylase inhibition | |||||

| Model | 1101.75 | 14 | 78.70 | 5.81 | 0.0008 |

| Residual | 203.05 | 15 | 13.54 | ||

| Pure error | 11.92 | 5 | 2.38 | ||

| Lack of fit | 191.12 | 10 | 19.11 | 8.02 | 0.0165 |

| Total | 1304.79 | 29 | |||

| R2 | 0.8444 | Adj. R2 | 0.6991 | ||

| α-Glucosidase inhibition | |||||

| Model | 12933.34 | 14 | 923.81 | 41.00 | <0.0001 |

| Residual | 338.01 | 15 | 22.53 | ||

| Pure error | 3.98 | 5 | 0.7954 | ||

| Lack of fit | 334.04 | 10 | 33.40 | 42.00 | 0.0003 |

| Total | 13271.36 | 29 | |||

| R2 | 0.9745 | Adj. R2 | 0.9508 | ||

| Trypsin | |||||

| DH | |||||

| Model | 433.92 | 14 | 30.99 | 27.31 | <0.0001 |

| Residual | 17.02 | 15 | 1.13 | ||

| Pure error | 0.0000 | 5 | 0.0000 | ||

| Lack of fit | 17.02 | 10 | 1.70 | ||

| Total | 450.94 | 29 | |||

| R2 | 0.9623 | Adj. R2 | 0.9270 | ||

| α-Amylase inhibition | |||||

| Model | 1229.94 | 10 | 122.99 | 9.19 | <0.0001 |

| Residual | 254.33 | 19 | 13.39 | ||

| Pure error | 0.0000 | 5 | 0.0000 | ||

| Lack of fit | 254.33 | 14 | 18.17 | ||

| Total | 1484.27 | 29 | |||

| R2 | 0.8287 | Adj. R2 | 0.7385 | ||

| α-Glucosidase inhibition | |||||

| Model | 14264.56 | 14 | 1018.90 | 46.72 | <0.0001 |

| Residual | 327.15 | 15 | 21.81 | ||

| Pure error | 0.6474 | 5 | 0.1295 | ||

| Lack of fit | 326.50 | 10 | 32.65 | 252.17 | <0.0001 |

| Total | 14591.71 | 29 | |||

| R2 | 0.9776 | Adj. R2 | 0.9567 | ||

| Run | Independent Variables | Alcalase | Trypsin | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | Y1 | Y2 | Y3 | Y1 | Y2 | Y3 | |

| 1 | 30 | 2 | 7 | 60 | 8.45 | 63.26 | 38.19 | 3.88 | 34.75 | 35.54 |

| 2 | 20 | 4 | 8 | 50 | 18.64 | 54.72 | 79.38 | 2.70 | 37.53 | 23.61 |

| 3 | 30 | 6 | 9 | 60 | 15.03 | 52.68 | 84.97 | 3.52 | 49.44 | 25.72 |

| 4 | 10 | 2 | 9 | 40 | 15.39 | 43.11 | 79.50 | 9.34 | 32.32 | 75.17 |

| 5 | 10 | 2 | 7 | 40 | 3.71 | 49.58 | 21.97 | 12.60 | 34.79 | 75.73 |

| 6 | 30 | 6 | 7 | 60 | 11.71 | 57.51 | 41.05 | 3.75 | 39.98 | 27.84 |

| 7 | 20 | 4 | 8 | 50 | 18.99 | 55.14 | 77.28 | 3.42 | 37.01 | 24.87 |

| 8 | 34.14 | 4 | 8 | 50 | 22.86 | 56.50 | 77.53 | 5.36 | 37.55 | 37.54 |

| 9 | 5.86 | 4 | 8 | 50 | 13.28 | 34.94 | 58.80 | 9.84 | 33.43 | 82.21 |

| 10 | 20 | 4 | 8 | 50 | 18.72 | 51.97 | 77.41 | 12.60 | 34.79 | 75.73 |

| 11 | 20 | 6.82 | 8 | 50 | 20.56 | 52.06 | 78.25 | 12.60 | 34.79 | 74.85 |

| 12 | 30 | 2 | 9 | 60 | 10.10 | 49.31 | 83.59 | 12.60 | 34.79 | 75.73 |

| 13 | 10 | 2 | 9 | 60 | 12.66 | 48.38 | 81.70 | 11.18 | 45.23 | 78.73 |

| 14 | 10 | 6 | 9 | 60 | 17.04 | 43.75 | 78.23 | 8.82 | 27.91 | 73.46 |

| 15 | 20 | 4 | 8 | 50 | 18.74 | 51.97 | 77.41 | 14.38 | 40.62 | 78.34 |

| 16 | 30 | 6 | 9 | 40 | 22.93 | 43.33 | 85.87 | 11.15 | 31.43 | 78.54 |

| 17 | 10 | 6 | 9 | 40 | 21.12 | 44.24 | 76.56 | 12.60 | 34.79 | 75.73 |

| 18 | 10 | 2 | 7 | 60 | 7.63 | 48.43 | 45.90 | 0.86 | 48.42 | 14.54 |

| 19 | 30 | 2 | 7 | 40 | 4.19 | 53.06 | 23.97 | 12.66 | 34.62 | 77.29 |

| 20 | 20 | 4 | 8 | 50 | 18.85 | 51.89 | 78.73 | 8.91 | 36.64 | 75.18 |

| 21 | 20 | 4 | 8 | 35.86 | 13.25 | 47.02 | 78.17 | 12.60 | 34.79 | 75.73 |

| 22 | 20 | 4 | 8 | 64.14 | 22.43 | 50.21 | 80.06 | 8.03 | 25.69 | 59.76 |

| 23 | 30 | 6 | 7 | 40 | 6.05 | 46.57 | 32.56 | 4.34 | 39.50 | 38.45 |

| 24 | 20 | 4 | 8 | 50 | 18.59 | 51.97 | 77.41 | 11.35 | 14.50 | 78.13 |

| 25 | 20 | 4 | 6.59 | 50 | 4.90 | 44.84 | 23.97 | 12.92 | 38.55 | 81.01 |

| 26 | 10 | 6 | 7 | 40 | 5.19 | 30.53 | 43.77 | 10.79 | 26.55 | 75.23 |

| 27 | 10 | 6 | 7 | 60 | 9.90 | 43.26 | 50.03 | 12.14 | 40.44 | 84.82 |

| 28 | 30 | 2 | 9 | 40 | 17.96 | 47.67 | 87.73 | 6.35 | 49.64 | 41.47 |

| 29 | 20 | 4 | 9.41 | 50 | 21.71 | 39.16 | 76.56 | 10.20 | 39.29 | 75.22 |

| 30 | 20 | 1.17 | 8 | 50 | 12.76 | 52.80 | 81.98 | 13.72 | 32.98 | 75.71 |

| Parameters | Alcalase | Trypsin | ||

|---|---|---|---|---|

| Predicted | Actual | Predicted | Actual | |

| DH | 20.48 | 22.84 | 14.02 | 14.63 |

| α-amylase inhibition | 55.02 | 56.78 | 42.15 | 40.80 |

| α-glucosidase inhibition | 84.68 | 86.37 | 84.54 | 86.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AL-Bukhaiti, W.Q.; Al-Dalali, S.; Noman, A.; Qiu, S.; Abed, S.M.; Qiu, S.-X. Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases. Foods 2022, 11, 3303. https://doi.org/10.3390/foods11203303

AL-Bukhaiti WQ, Al-Dalali S, Noman A, Qiu S, Abed SM, Qiu S-X. Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases. Foods. 2022; 11(20):3303. https://doi.org/10.3390/foods11203303

Chicago/Turabian StyleAL-Bukhaiti, Wedad Q., Sam Al-Dalali, Anwar Noman, Silin Qiu, Sherif M. Abed, and Sheng-Xiang Qiu. 2022. "Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases" Foods 11, no. 20: 3303. https://doi.org/10.3390/foods11203303

APA StyleAL-Bukhaiti, W. Q., Al-Dalali, S., Noman, A., Qiu, S., Abed, S. M., & Qiu, S.-X. (2022). Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases. Foods, 11(20), 3303. https://doi.org/10.3390/foods11203303