Meat Analogues: Relating Structure to Texture and Sensory Perception

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Selection and Preparation

2.2. Physical Characterization

2.2.1. Moisture Content and Expressible Moisture

2.2.2. Cooking Loss and Fat Absorption

2.2.3. pH

2.3. Texture Profile Analysis (TPA)

2.4. Confocal Laser Scanning Microscopy

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results and Discussion

3.1. Composition

3.2. Cooking Loss and Expressible Moisture

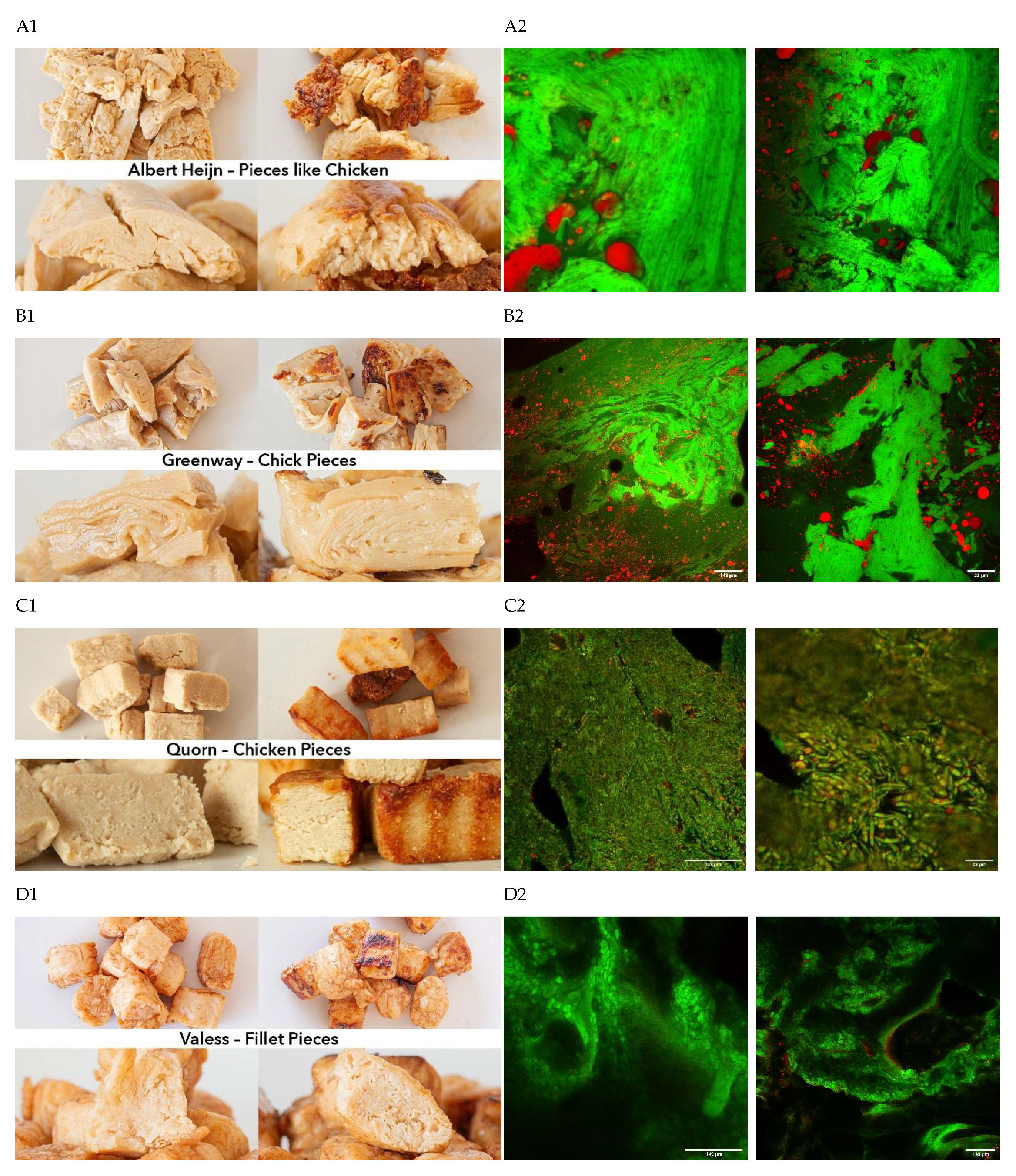

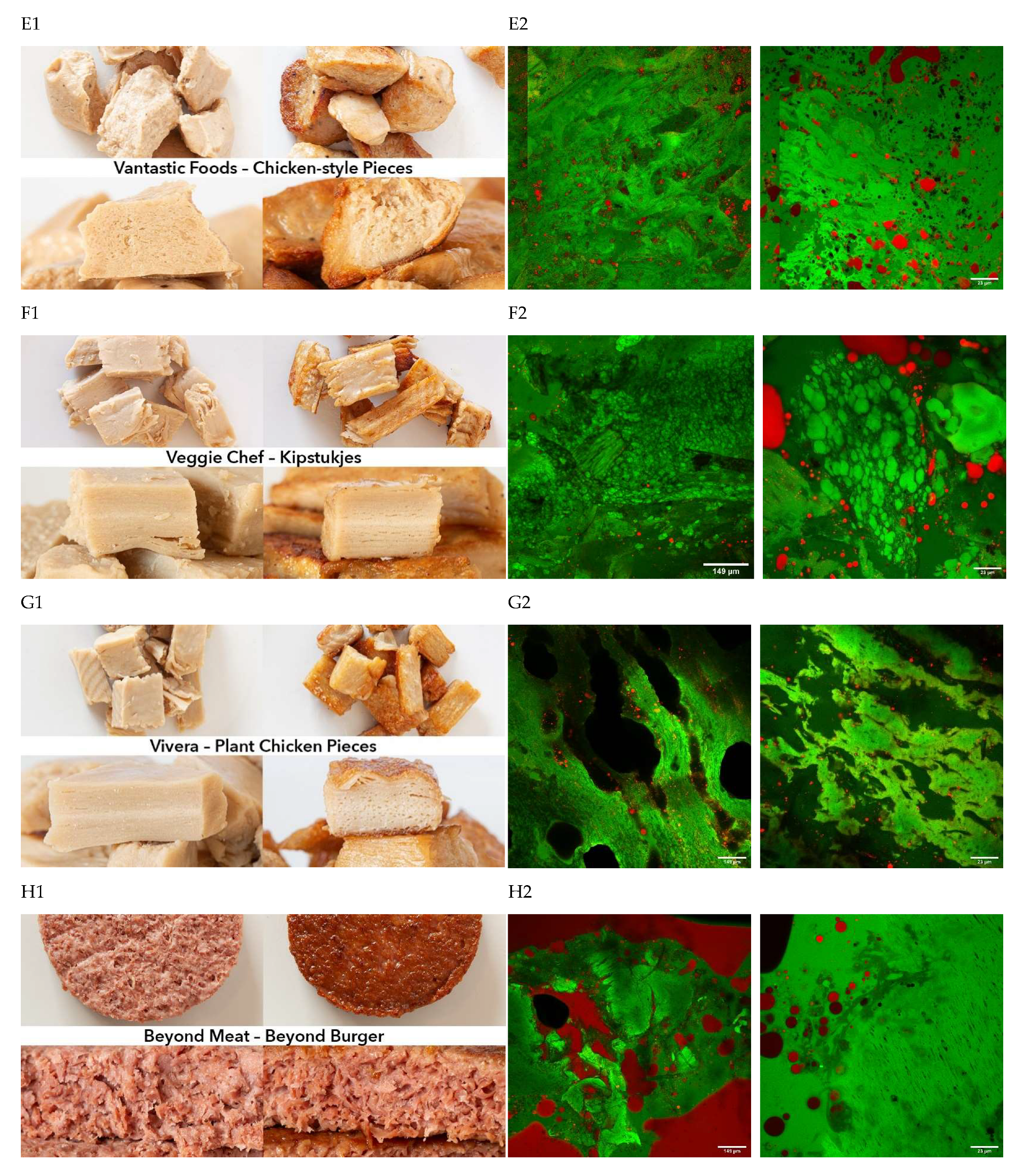

3.3. Structure of the Meat Analogues

3.4. Texture Analysis

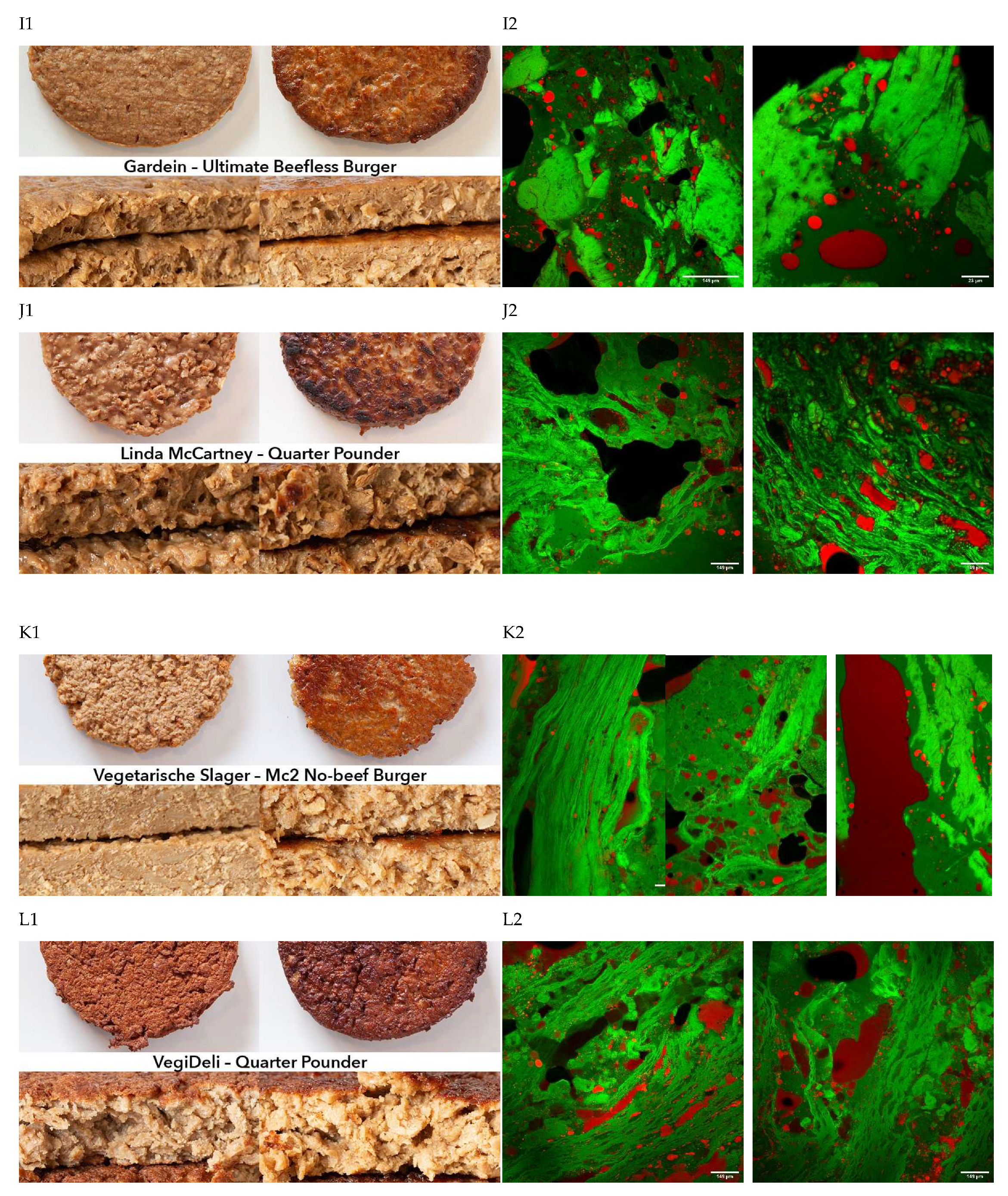

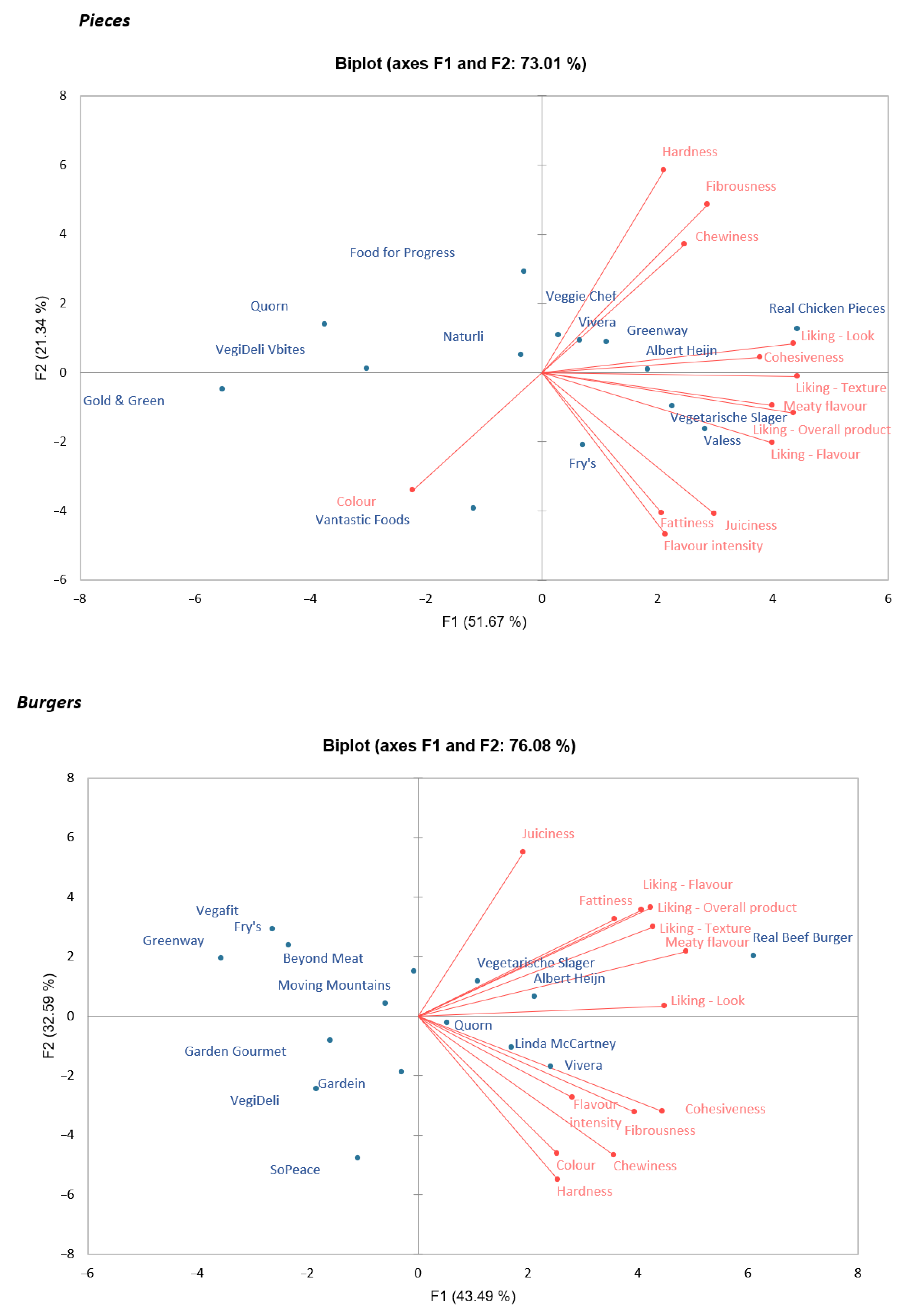

3.5. Sensory Profile

3.5.1. Evaluation of Raw Meat Analogues

3.5.2. Attributes and Liking

3.6. Relationship between Composition and Sensory Properties

3.7. Relationship between Textural Properties and Sensory Properties

3.8. Relationship between Physicochemical Properties and Sensory Properties

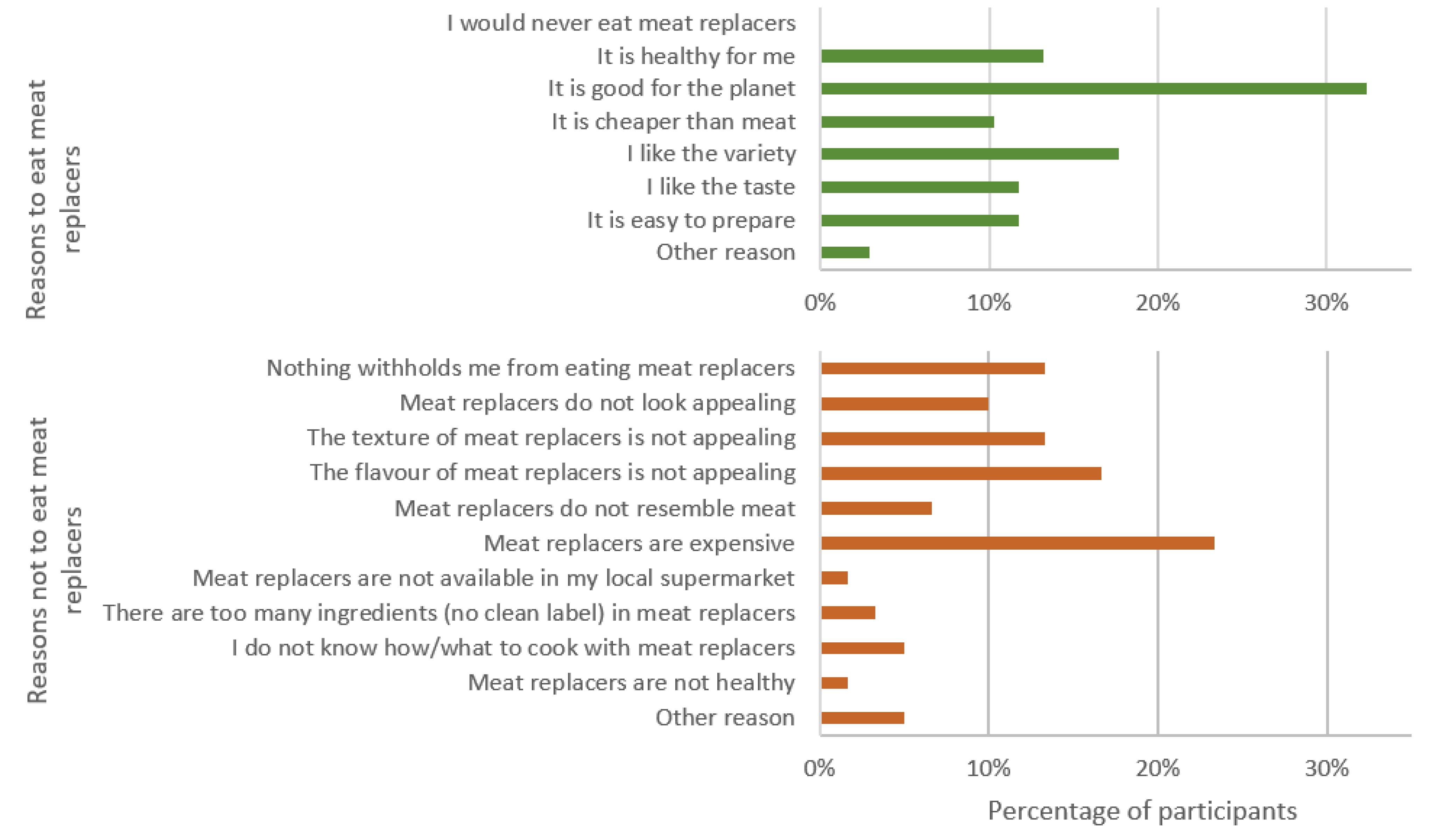

3.9. Consumer Habits and Attitudes

3.10. Implications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- RIVM. Change in Food Consumption | Voedselconsumptiepeiling 2012–2016 vs. 2007–2010. Acta Sci. Pol. 2017, 16, 169–178. [Google Scholar]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Galanakis, C.M., Ed.; Elsevier Inc.: London, UK, 2019; pp. 103–126. [Google Scholar]

- Asgar, M.A.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A.A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Aiking, H. Future protein supply. Trends Food Sci. Technol. 2011, 22, 112–120. [Google Scholar] [CrossRef]

- Stiftung, H.B. Meat Atlas—Facts and Fihures about the Animals We Eat, 1st ed.; Chemnitz, C., Becheva, S., Eds.; Heinrich Böll Foundation & Friends of the Earth Europe: Ahrensfelde, Germany, 2014; p. 68. [Google Scholar]

- De Boer, J.; Aiking, H. Strategies towards healthy and sustainable protein consumption: A transition framework at the levels of diets, dishes, and dish ingredients. Food Qual. Prefer. 2019, 73, 171–181. [Google Scholar] [CrossRef]

- Dagevos, H.; Verhoog, D.; van Horne, P.; Hoste, R. Vleesconsumptie per Hoofd van de Bevolking in The Nederland, 2005–2017; Wageningen University & Research: Wageningen, The Netherlands, 2018; p. 14. [Google Scholar]

- Hoek, A.C. Will Novel Protein Foods Beat Meat? Consumer Acceptance of Meat Substitutes—A Multidisciplinary Research Approach; Wageningen University: Wageningen, The Netherlands, 2010. [Google Scholar]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef]

- Bohrer, B.M. An investigation of the formulation and nutritional composition of modern meat analogue products. Food Sci. Hum. Wellness 2019, 8, 320–329. [Google Scholar] [CrossRef]

- Riaz, M.N. Texturized Vegetable Proteins. In Handbook of Food Proteins; Phillips, G.O., Williams, P.A., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 395–418. [Google Scholar]

- Wild, F.; Czerny, M.; Janssen, A.M.; Kole, A.P.W.; Zunabovic, M.; Domig, K.J. The evolution of a plant-based alternative to meat. Agro. Food Ind. Hi Technol. 2014, 25, 45–49. [Google Scholar]

- Krintiras, G.A.; Gadea Diaz, J.; Van Der Goot, J.; Stankiewicz, A.I.; Stefanidis, G.D. On the use of the Couette Cell technology for large scale production of textured soy-based meat replacers. J. Food Eng. 2016, 169, 205–213. [Google Scholar] [CrossRef] [Green Version]

- Dekkers, B.L.; Boom, R.M.; Goot, A.J.V.D. Structuring processes for meat analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Lai, D.-J. Low-Fat Meat Analogues and Methods for Making Same. U.S. Patent US5676987, 1997. [Google Scholar]

- Sun, P.L.; Jiang, L.Z.; Sun, Y.; Sun, Z.L.; Xie, T.M.; Cao, Y. The experimental study about the influence of extrusion system parameters on textured degree of high moisture content fibriform imitated meat. Adv. Mater. Res. 2011, 188, 250–253. Available online: https://www.scientific.net/AMR.188.250 (accessed on 19 June 2022).

- Geistlinger, T. Plant-based Meat Structured Protein Products. U.S. Patent US 2015/0296834 A1, 2015. [Google Scholar]

- Smetana, S.; Ashtari Larki, N.; Pernutz, C.; Franke, K.; Bindrich, U.; Toepfl, S.; Heinz, V. Structure design of insect-based meat analogs with high-moisture extrusion. J. Food Eng. 2018, 229, 83–85. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Grau, R.; Hamm, R. Uber das Wasserbindungsvermogen in Wasserbindung im Fleisch. Fleischwirtschaft 1957, 32, 295. [Google Scholar]

- Jonsson, A.; Sigurgisladottir, S.; Hafsteinsson, H.; Kristbergsson, K. Textural properties of raw Atlantic salmon (Salmo salar) fillets measured by different methods in comparison to expressible moisture. Aquac. Nutr. 2001, 7, 81–89. [Google Scholar] [CrossRef]

- Bourne, M.C.; Comstock, S.H. Effect of Degree of Compression on Texture Profile Parameters. J. Texture Stud. 1981, 12, 201–216. [Google Scholar] [CrossRef]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2002; p. 423. [Google Scholar]

- Trinh, T.K.; Glasgow, S. On the Texture Profile Analysis Test; Massey University: Palmerston North, New Zealand, 2012; pp. 749–760. [Google Scholar]

- Hoek, A.C.; Elzerman, J.E.; Hageman, R.; Kok, F.J.; Luning, P.A.; Graaf, C.d. Are meat substitutes liked better over time? A repeated in-home use test with meat substitutes or meat in meals. Food Qual. Prefer. 2013, 28, 253–263. [Google Scholar] [CrossRef]

- Boutrolle, I.; Delarue, J. Studying Meals in the Home and in the Laboratory; Woodhead Publishing: Thorston, UK, 2009; pp. 128–165. [Google Scholar]

- Lawless, H.T.; Heymann, H. Acceptance Testing. In Sensory Evaluation of Food, Principles and Practices, 2nd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Lubiano, M.A.; de la Rosa de Saa, S.; Montenegro, M.; Sinova, B.; Gil, M.A. Descriptive analysis of responses to items in questionnaires. Why not using a fuzzy scale? Inf. Sci. 2016, 360, 131–148. [Google Scholar] [CrossRef]

- Hoek, A.C.; Van Boekel, M.A.J.S.; Voordouw, J.; Luning, P.A. Identification of new food alternatives: How do consumers categorize meat and meat substitutes? Food Qual. Prefer. 2011, 22, 371–383. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.-H. Physicochemical and functional characteristics of plant protein-based meat analogs. J. Food Processing Preserv. 2019, 11, e14123. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; van der Groot, A.-J.; van der Sman, R.G.M. Effect of mechanical interaction on the hydration of mixed soy protein and gluten gels. Curr. Res. Food Sci. 2020, 3, 134–145. [Google Scholar] [CrossRef] [PubMed]

- Traynham, T.L.; Myers, D.J.; Carriquiry, A.L.; Johnson, L.A. Evaluation of water-holding capacity for wheat-soy flour blends. J. Am. Oil Chem. Soc. 2007, 84, 151–155. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Azad Emin, M.; Boom, R.M.; Van Der Goot, J. The phase properties of soy protein and wheat gluten in a blend for fibrous structure formation. Food Hydrocoll. 2018, 79, 273–281. [Google Scholar] [CrossRef]

- Omohimi, C.I.; Sobukola, O.P.; Sarafadeen, K.O.; Sanni, L.O. Effect of Thermo-extrusion Process Parameters on Selected Quality Attributes of Meat Analogue from Mucuna Bean Seed Flour. Niger. Food J. 2014, 32, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Mendenhall, V.T. Effect of pH and Total Pigment Concentration on the Internal Color of Cooked Ground Beef Patties. J. Food Sci. 1989, 54, 21–30. [Google Scholar] [CrossRef]

- Han, M.; Bertram, C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Cornet, S.H.V.; Edwards, D.; van der Goot, A.J.; van der Sman, R.G.M. Water release kinetics from soy protein gels and meat analogues as studied with confined compression. Innov. Food Sci. Emerg. Technol. 2020, 66, 102528. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; Jan, A.; Goot, V.D. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. J. Food Eng. 2019, 261, 32–39. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siavichay, E.G. An Investigation of High Moisture Meat Analogues as Mince-The Influence of Process Parameters and Ingredients on the Final Texture; Lund University: Lund, Sweden, 2021. [Google Scholar]

- Kaleda, A.; Talvistu, K.; Vaikma, H.; Tammik, M.L.; Rosenvald, S.; Vilu, R. Physicochemical, textural, and sensorial properties of fibrous meat analogs from oat-pea protein blends extruded at different moistures, temperatures, and screw speeds. Future Foods 2021, 4, 100092. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Snel, S.J.E.; Lesschen, J.; van der Goot, A.J.; van der Sman, R.G.M. Enhancing the water holding capacity of model meat analogues through marinade composition. J. Food Eng. 2021, 290, 110283. [Google Scholar] [CrossRef]

- Schönfeldt, H.C.; Naudé, R.T.; Bok, W.; van Heerden, S.M.; Sowden, L.; Boshoff, E. Cooking- and juiciness-related quality characteristics of goat and sheep meat. Meat Sci. 1993, 34, 381–394. [Google Scholar] [CrossRef]

- Ramadhan, K.; Huda, N.; Ahmad, R. Physicochemical and sensory characteristics of burger made from duck surimi-like material. Process. Prod. Food Saf. 2012, 91, 2316–2323. [Google Scholar] [CrossRef] [PubMed]

- Lucherk, L.W.; O’Quinn, T.G.; Legako, J.F.; Rathmann, R.J.; Brooks, J.C.; Miller, M.F. Assessment of objective measures of beef steak juiciness and their relationships to sensory panel juiciness ratings. J. Anim. Sci. 2017, 95, 2421–2437. [Google Scholar] [CrossRef] [PubMed]

- Grahl, S.; Palanisamy, M.; Strack, M.; Meier-dinkel, L.; Mörlein, D. Towards More Sustainable Meat Alternatives: How Technical Parameters Affect the Sensory Properties of Extrusion Products Derived from Soy and Algae. J. Clean. Prod. 2018, 198, 962–971. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, J.; Jiang, L.; Li, Y.; Wang, J.; Zhang, H.; Li, D.; Han, F.; Li, Q.; Wang, R.; et al. Effect of the interaction between myofibrillar protein and heat-induced soy protein isolates on gel properties. CyTA J. Food 2015, 13, 527–534. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Emin, M.A.; Schuchmann, H.P. Process conditions influencing wheat gluten polymerization during high moisture extrusion of meat analog products. J. Food Eng. 2017, 198, 28–35. [Google Scholar] [CrossRef]

- Tornberg, E. Effects of heat on meat proteins—Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Sagis, L.M.C.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Mapping the texture of plant protein blends for meat analogues. Food Hydrocoll. 2021, 118, 106753. [Google Scholar] [CrossRef]

- Issanchou, S. Consumer Expectations and Perceptions of Meat and Meat Product Quality. Meat Sci. 1996, 43, 5–19. [Google Scholar] [CrossRef]

- McIlveen, H.; Abraham, C.; Armstrong, G. Meat avoidance and the role of replacers. Nutr. Food Sci. 1999, 99, 29–36. [Google Scholar] [CrossRef]

- Glitsch, K. Consumer perceptions of fresh meat quality: Cross-national comparison. Br. Food J. 2000, 102, 177–194. [Google Scholar] [CrossRef]

- Mancini, R.A.; Hunt, M.C. Current research in meat color. Meat Sci. 2005, 71, 100–121. [Google Scholar] [CrossRef]

- King, N.J.; Whyte, R. Does it look cooked? A review of factors that influence cooked meat color. J. Food Sci. 2006, 71, R31–R40. [Google Scholar] [CrossRef]

- Rolan, T.; Mueller, I.; Mertle, T.J.; Swenson, K.J.; Conley, C.; Orcutt, M.W.; Mease, L.E. Ground Meat and Meat Analog Compositions Having Improved Nutritional Properties. U.S. Patent US 2008/0268112 A1, 2007. [Google Scholar]

- Hoek, A.C.; Luning, P.A.; Stafleu, A.; De Graaf, C. Food-related lifestyle and health attitudes of Dutch vegetarians, non-vegetarian consumers of meat substitutes, and meat consumers. Appetite 2004, 42, 265–272. [Google Scholar] [CrossRef] [PubMed]

- De Boer, J.; Hoek, A.; Elzerman, H. Social Desirability: Consumer Aspects; Aiking, H., de Boer, J., Vereijken, J., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 99–127. [Google Scholar]

- Elzerman, J.E.; van Boekel, M.A.J.S.; Luning, P.A. Exploring meat substitutes: Consumer experiences and contextual factors. Br. Food J. 2013, 115, 700–710. [Google Scholar] [CrossRef]

- Akwetey, W.Y.; Knipe, C.L. Sensory attributes and texture profile of beef burgers with gari. Meat Sci. 2012, 92, 745–748. [Google Scholar] [CrossRef]

- Huang, S.C.; Tsai, Y.F.; Chen, C.M. Effects of wheat fiber, oat fiber, and inulin on sensory and physico-chemical properties of Chinese-style sausages. Asian-Australas. J. Anim. Sci. 2011, 24, 875–880. [Google Scholar] [CrossRef]

- Everett, D.W.; Olson, N.F. Free oil and rheology of cheddar cheese containing fat globules stabilized with different proteins. J. Dairy Sci. 2003, 86, 755–763. [Google Scholar] [CrossRef]

- Ruusunen, M.; Puolanne, E. Reducing sodium intake from meat products. Meat Sci. 2005, 70, 531–541. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akin, C.; Flannery, R.J.; Darrington, F.D. Process for the Production of Meat, Poultry, and Fish analogues and the Products Thereof. U.S. Patent US3939284, 1975. [Google Scholar]

- Fickert, B.; Schieberle, P. Identification of the key odorants in barley malt (caramalt) using GC/MS techniques and odour dilution analyses. Nahr. Food 1998, 42, 371–375. [Google Scholar] [CrossRef]

- Frank, D.; Oytam, Y.; Hughes, J. Sensory Perceptions and New Consumer Attitudes to Meat; Elsevier: Amsterdam, The Netherlands, 2017; pp. 667–698. [Google Scholar]

- Fraser, R.; Brown, P.O.R.; Karr, J.; Holz-Schietinger, C.; Cohn, E. Methods and Compositions for Affecting the Flavor and Aroma Profile of Consumables. U.S. Patent US 980 8029 B2, 2017. [Google Scholar]

- Zhu, G.; Xiao, Z. Creation and imitation of a milk flavour. Food Funct. 2017, 8, 1080–1084. [Google Scholar] [CrossRef] [PubMed]

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Vmt. Vleessmaken Zijn Moeilijk na te Maken. VMT. 2020. Available online: https://www.vmt.nl/39637/vleessmaken-zijn-moeilijk-na-te-maken (accessed on 19 June 2022).

- Chumngoen, W.; Tan, F.-J. Relationships between Descriptive Sensory Attributes and Physicochemical Analysis of Broiler and Taiwan Native Chicken Breast Meat. Asian Australas. J. Anim. Sci. 2015, 28, 1028–1037. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meullenet, J.-F. Relationship between sensory and instrumental texture profile attributes. J. Sens. Stud. 1998, 13, 77–93. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion process parameters, sensory characteristics, and structural properties of a high moisture soy protein meat analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- RIVM. In Consumptie van Vlees in Nederland—SHIFT-DIETS-Project; RIVM: Bilthoven, The Netherlands, 2020; Volume 6.

- Font-i-Furnols, M.; Guerrero, L. Consumer preference, behavior and perception about meat and meat products: An overview. Meat Sci. 2014, 98, 361–371. [Google Scholar] [CrossRef]

- Anderson, E.C.; Feldman Barrett, L. Affective Beliefs Influence the Experience of Eating Meat. PLoS ONE 2016, 11, e0160424. [Google Scholar] [CrossRef] [PubMed]

- Apostolidis, C.; McLeay, F. Should we stop meating like this? Reducing meat consumption through substitution. Food Policy 2016, 65, 74–89. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.Y.; Huang, Y.; Ku, H.-P.; Lim, K.; Lin, T. Plant Based Diets: Sensory Attractiveness Increases Acceptability of Meat Substitutes; University of British Columbia Library: Vancouver, BC, Canada, 2018. [Google Scholar]

| Attribute | Description |

|---|---|

| Colour | - |

| Hardness | Force required to compress the food between the molar teeth |

| Chewiness | Toughness of the products, the amount of work required to chew the product |

| Cohesiveness | Ease of fragmentation of the product upon mastication |

| Fibrousness | Detection of fibres |

| Juiciness | Amount of moisture released by the product during mastication |

| Fattiness | Degree of how fatty the product feels in the mouth |

| Flavour intensity | - |

| Meaty flavour | - |

| Chicken Pieces | Protein Source | Protein (%) | Fat (%) | Fibre (%) | Moisture Content (%) | Burgers | Protein Source | Protein (%) | Fat (%) | Fibre (%) | Moisture Content (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Real Chicken Pieces (reference) | - | 24 | 2.0 | - | 65.69 f ± 1.70 | Ultimate Beef Burger (real beef) | - | 20.0 | 17.0 | 0.0 | 59.29 ghi ± 0.62 |

| AH—Pieces Like Chicken | Wheat (25%), pea (12%) | 23.0 | 7.0 | 0.2 | 51.73 bcd ± 1.90 | Albert Heijn —Burger Deluxe | Soy (53%), wheat (13%) | 20.0 | 5.0 | 7.5 | 51.46 c ± 0.45 |

| Food for Progress—Oumph the Chunk | Soy (23%) | 17.0 | 0.4 | 5.1 | 64.94 ef ± 2.72 | Beyond Meat —Beyond Burger | Pea, rice | 18.0 | 19.0 | 2.6 | 53.67 cde ± 0.41 |

| Fry’s—Chicken Style Strips | Wheat, soy | 18.3 | 11.8 | 5.4 | 45.29 b ± 2.74 | Fry’s—Traditional Burgers | Soy, wheat | 14.0 | 5.6 | 6.2 | 59.93 hi ± 0.72 |

| Gold & Green—Pulled Oats | Oat, pea (21%), fava bean (12%) | 30.0 | 5.9 | 2.4 | 32.78 a ± 5.04 | Gardein—Ultimate Beefless Burger | Soy, wheat, pea | 18.8 | 5.2 | 3.1 | 59.98 hi ± 0.42 |

| Greenway—Chick Pieces | Soy | 17.8 | 2.6 | 7.3 | 55.86 cd ± 4.25 | Garden Gourmet —Incredible Burger | Soy (19%), wheat | 14.4 | 13.3 | 3.8 | 60.63 i ± 0.49 |

| Naturli—Chick Free | Pea | 21 | 1.7 | 2.8 | 49.83 bc ± 3.19 | Greenway—Burger | Pea (22%), potato | 14.0 | 10.0 | - | 56.57 efg ± 0.059 |

| Quorn—Chicken Pieces | Mycoprotein (94%), egg | 15.3 | 2.8 | 5.3 | 54.75 cd ± 1.47 | Linda McCartney—Quarter Pounder | Soy (58%) | 17.3 | 11.9 | 2.4 | 54.65 def ± 1.12 |

| Valess—Fillet Pieces | Milk (76%), wheat | 16.8 | 4.8 | 4.9 | 54.98 cd ± 0.66 | Moving Mountains Veggie Burger | Pea, wheat, soy | 15.3 | 17.6 | 5.8 | 53.30 cd ± 0.43 |

| Vantastic Foods—Chicken-Style Pieces | Soy (35%), wheat (20%) | 15.0 | 9.9 | - | 56.33 cd ± 0.34 | Quorn—Supreme Vegan Burger | Wheat, pea, mycoprotein | 21.0 | 14.0 | 3.1 | 39.77 a ± 2.97 |

| Vegetarische Slager—Kipstuckjes | Soy (93%) | 19.9 | 4.4 | 7.6 | 57.75 de ± 0.78 | SoPeace—Burger | Pea (45%) | 16.5 | 11.7 | 4.4 | 57.31 fgh ± 0.86 |

| Veggie Chef—Kipstukjes | Soy (93%) | 19.4 | 0.5 | 5.6 | 55.05 cd ± 0.73 | Vegafit—Gehaktschijf | Wheat (38%), potato | 15.5 | 15.6 | 4.5 | 45.98 b ± 0.64 |

| VegiDeli VBites—Meat-Free Chicken Pieces | Wheat, soy | 26.6 | 6.7 | 4.3 | 52.02 bcd ± 0.34 | Vegetarische Slager—Mc2 No-Beef Burger | Soy, wheat | 17.0 | 8.6 | <0.5 | 51.68 cd ± 0.26 |

| Vivera—Plant Chicken Pieces | Soy (93%) | 19.0 | 0.5 | 5.6 | 54.26 cd ± 1.99 | VegiDeli—Quarter Pounder | Soy | 19.3 | 8.7 | - | 51.61 cd ± 1.82 |

| Vivera—Vegetable Burger Patty | Soy, wheat | 17.0 | 5.4 | 6.0 | 54.58 cdef ± 0.59 |

| Chicken Pieces | Cooking Loss (%) | EM (g Fluid/g Sample) (%) | Fat in EM (%) | Fat Absorption (%) | Hardness (kPa) | Springiness | Cohesiveness | Chewiness (kPa) |

|---|---|---|---|---|---|---|---|---|

| Real Chicken Pieces | 23.24 h ± 1.55 | 3.68 b ± 0.95 | 18.35 a ±5.12 | 0.042 cde ± 5.37 | 142.02 abcd ± 118.48 | 0.69 ± 0.033 | 0.40 ab ± 0.035 | 50.82 abcd ± 45.57 |

| AH—Pieces Like Chicken | 12.35 bcde ± 2.87 | 0.76 a ± 0.021 | 55.15 ab ± 12.19 | −11.34 abc ± 7.20 | 86.06 abc ± 28.97 | 0.90 ± 0.022 | 0.65 ef ± 0.031 | 56.44 abcd ± 18.66 |

| Food for Progress—Oumph the Chunk | 17.38 efg ± 1.43 | 0.67 a ± 0.13 | 69.45 b ± 11.20 | −15.37 ab ± 5.42 | 51.97 ab ± 49.20 | 0.72 ± 0.22 | 0.66 f ± 0.046 | 31.84 abcd ± 33.88 |

| Fry’s—Chicken Style Strips | 6.62 a ± 0.34 | 0.62 a ± 0.075 | 46.63 ab ± 31.17 | −17.72 a ± 1.32 | 96.76 abc ± 30.66 | 0.83 ± 0.017 | 0.49 abcde ± 0.039 | 46.79 abcd ± 12.24 |

| Gold & Green—Pulled Oats | 10.80 abc ± 0.97 | 1.04 a ± 0.58 | 40.85 ab ± 29.43 | 9.27 e ± 3.27 | 72.70 abc ± 19.74 | 0.74 ± 0.029 | 0.40 ab ± 0.047 | 24.79 abc ± 6.90 |

| Greenway—Chick Pieces | 13.28 cdef ± 3.96 | 1.44 a ± 0.46 | 66.18 b ± 7.93 | 1.80 de ± 1.69 | 199.63 cd ± 46.89 | 0.75 ± 0.18 | 0.48 abcd ± 0.065 | 87.74 cde ± 8.46 |

| Naturli—Chick Free | 11.24 abcd ± 1.66 | 1.22 a ± 0.61 | 38.33 ab ± 30.00 | 24.21 f ± 5.85 | 24.65 a ± 16.25 | 0.88 ± 0.029 | 0.63 def ± 0.036 | 14.56 a ± 8.47 |

| Quorn—Chicken Pieces | 16.41 defg ± 0.68 | 1.17 a ± 0.15 | 66.83 b ± 4.75 | −3.28 bcd ± 1.72 | 263.12 d ± 14.70 | 0.79 ± 0.023 | 0.36 a ± 0.016 | 93.63 de ± 3.96 |

| Valess—Fillet Pieces | 18.02 fgh ± 1.43 | 0.78 a ± 0.056 | 55.96 ab ± 5.39 | −10.74 abc ± 3.42 | 127.22 abc ± 22.20 | 0.67 ± 0.062 | 0.43 abc ± 0.020 | 43.70 abcd ± 11.74 |

| Vantastic Foods—Chicken-Style Pieces | 7.95 ab ± 0.31 | 0.37 a ± 0.012 | 62.81 ab ± 2.22 | 4.06 de ± 1.87 | 25.82 a ± 7.55 | 0.91 ± 0.013 | 0.54 bcdef ± 0.043 | 16.37 ab ± 5.13 |

| Vegetarische Slager—Kipstuckjes | 18.91 gh ± 2.37 | 1.06 a ± 0.29 | 80.66 b ± 5.87 | 9.40 e ± 5.15 | 117.40 abc ± 35.75 | 0.65 ± 0.17 | 0.44 abc ± 0.12 | 48.78 abcd ± 34.51 |

| Veggie Chef—Kipstukjes | 9.81 abc ± 0.57 | 0.83 a ± 0.094 | 66.58 b ± 8.32 | 1.21 cde ± 0.73 | 170.84 bcd ± 36.83 | 0.83 ± 0.059 | 0.56 cdef ± 0.093 | 94.623 de ± 22.48 |

| VegiDeli VBites—Meat-free Chicken Pieces | 9.77 abc ± 0.42 | 0.46 a ± 0.054 | 81.22 b ± 1.30 | 4.52 de ± 1.99 | 148.51 abcd ± 56.34 | 0.81 ± 0.033 | 0.60 def ± 0.026 | 83.25 bcde ± 32.22 |

| Vivera—Plant Chicken Pieces | 11.40 abcd ± 1.64 | 0.54 a ± 0.054 | 65.68 b ± 3.80 | −3.78 bcd ± 4.11 | 265.01 d ± 35.46 | 0.85 ± 0.042 | 0.52 abcdef ± 0.034 | 141.58 e ± 18.09 |

| Burgers | Cooking Loss (%) | EM (g Fluid/g Sample) (%) | Fat in EM (%) | Fat Absorption (%) | Hardness (N) | Springiness | Cohesiveness | Chewiness (N) |

| Albert Heijn—Ultimate Beef Burger (real beef) | 25.12 I ± 2.47 | 1.73 e ± 0.21 | 42.41 a ± 3.47 | −0.96 bc ± 3.01 | 210.04 abc ± 14.39 | 0.73 bc ± 0.032 | 0.36 bcde ± 0.014 | 74.55 abc ± 5.29 |

| Albert Heijn—Burger Deluxe | 6.58 ab ± 1.04 | 0.45 ab ± 0.028 | 86.51 fg ± 0.46 | 3.67 c ± 0.64 | 179.80 ab ± 25.83 | 0.73 bc ± 0.042 | 0.33 bcd ± 0.019 | 55.28 ab ± 12.43 |

| Beyond Meat—Beyond Burger | 18.92 g ± 0.14 | 0.50 ab ± 0.018 | 86.69 fg ± 1.44 | −5.31 ab ± 2.28 | 88.26 a ± 7.66 | 0.55 ab ± 0.010 | 0.31 abcd ± 0.031 | 18.95 a ± 1.40 |

| Fry’s—Traditional Burgers | 8.37 bc ± 0.26 | 0.52 ab ± 0.073 | 84.42 efg ± 2.46 | −4.90 ab ± 1.05 | 181.04 ab ± 21.59 | 0.90 c ± 0.034 | 0.36 bcde ± 0.004 | 73.66 abc ± 10.78 |

| Gardein—Ultimate Beefless Burger | 23.18 hi ± 1.17 | 0.99 d ± 0.13 | 69.65 b ± 3.99 | 4.90 c ± 1.47 | 254.51 bcd ± 62.54 | 0.73 bc ± 0.077 | 0.51 e ± 0.011 | 122.24 bcd ± 38.69 |

| Garden Gourmet—Incredible Burger | 23.18 hi ± 1.17 | 0.77 bcd ± 0.060 | 81.85 defg ± 0.045 | −8.85 a ± 1.92 | 156.44 ab ± 20.34 | 0.76 bc ± 0.059 | 0.42 cde ± 0.055 | 61.92 ab ± 17.64 |

| Greenway—Burger | 11.22 cde ± 0.084 | 0.39 a ± 0.014 | 87.32 fg ± 1.14 | −0.98 bc ± 1.24 | 92.21 a ± 14.50 | 0.40 a ± 0.047 | 0.16 a ± 0.053 | 9.40 a ± 2.78 |

| Linda McCartney—Quarter Pounder | 13.84 ef ± 1.65 | 0.92 cd ± 0.22 | 73.39 bc ± 1.36 | −0.21 bc ± 0.75 | 147.31 ab ± 47.50 | 0.67 abc | 0.35 bcd ± 0.073 | 46.74 a ± 20.18 |

| Moving Mountains—Veggie Burger | 15.23 f ± 0.88 | 0.40 a ± 0.082 | 87.40 fg ± 1.47 | −5.49 ab ± 1.72 | 127.19 ab ± 25.76 | 0.64 abc ± 0.076 | 0.38 bcde ± 0.041 | 39.19 a ± 10.76 |

| Quorn—Supreme Vegan Burger | 7.00 ab ± 0.34 | 0.45 ab ± 0.16 | 88.20 g ± 4.30 | −0.63 bc ± 1.29 | 199.78 ab ± 29.83 | 0.70 abc ± 0.019 | 0.37 bcde ± 0.033 | 65.52 ab ± 7.13 |

| SoPeace—Burger | 20.64 gh ± 0.71 | 0.61 abc ± 0.14 | 76.85 bcde ± 4.11 | −1.80 abc ± 2.73 | 395.42 d ± 129.29 | 0.77 bc ± 0.063 | 0.47 de ± 0.018 | 193.73 d ±70.20 |

| Vegafit—Gehaktschijf | 6.80 ab ± 0.32 | 0.41 a ± 0.033 | 86.40 fg ± 0.84 | 4.40 c ± 0.77 | 69.81 a ± 2.15 | 0.55 ab ± 0.044 | 0.24 ab ± 0.020 | 11.78 a ± 1.57 |

| Vegetarische Slager—Mc2 No-Beef Burger | 10.37 cd ± 0.92 | 0.62 abc ± 0.013 | 80.28 cdef ± 0.69 | 1.88 bc ± 1.19 | 177.07 ab ± 81.03 | 0.62 abc ± 0.34 | 0.36 bcde ± 0.17 | 48.27 ab ± 28.97 |

| VegiDeli—Quarter Pounder | 4.23 a ± 0.48 | 0.35 a ± 0.012 | 87.66 fg ± 1.29 | 1.64 bc ± 7.68 | 175.10 ab ± 19.12 | 0.75 bc ± 0.077 | 0.28 abc ± 0.020 | 47.26 ab ± 11.37 |

| Vivera—Vegetable Burger Patty | 13.49 def ± 0.47 | 0.66 abcd ± 0.078 | 75.17 bcd ± 4.14 | 3.29 c ± 1.60 | 352.03 cd ± 45.19 | 0.69 abc ± 0.073 | 0.44 cde ± 0.007 | 143.43 cd ± 28.08 |

| Chicken Pieces | Raw Attractiveness (Look, Smell, Colour) | Looks Like Meat | Expect Good Taste | Preparation Is Easy | Preparation Takes Long | Preparation Like Meat |

|---|---|---|---|---|---|---|

| Real Chicken Pieces | 3.89 (±1.04) f | 4.79 (±0.61) d | 4.24 (±0.75) f | 3.75 (±0.98) ab | 2.55 (±1.13) bc | 4.75 (±0.60) g |

| Quorn—Chicken Pieces | 2.33 (±1.03) ab | 1.82 (±1.02) a | 2.42 (±1.13) abc | 3.45 (±1.21) a | 2.65 (±1.32) c | 2.01 (±1.17) a |

| Food for Progress—Oumph the Chunk | 2.77 (±0.97) bcd | 3.01 (±1.21) c | 2.96 (±0.98) cde | 3.87 (±1.01) ab | 2.37 (±1.19) abc | 3.20 (±1.15) ef |

| Fry’s—Chicken Style Strips | 3.17 (±1.12) def | 2.32 (±1.14) ab | 3.25 (±1.14) de | 4.16 (±0.72) b | 1.84 (±0.93) a | 2.70 (±1.23) bcde |

| Gold & Green—Pulled Oats | 1.98 (±1.08) a | 2.10 (±1.27) a | 2.10 (±1.11) a | 3.43 (±1.24) a | 1.97 (±0.94) ab | 2.42 (±1.19) ab |

| Greenway—Chick Pieces | 2.66 (±0.97) bcd | 2.38 (±0.99) ab | 2.73 (±0.96) bcd | 3.77 (±0.90) ab | 2.01 (±0.92) ab | 2.96 (±1.01) bcde |

| Naturli—Chick Free | 2.50 (±1.06) bc | 2.37 (±1.22) ab | 2.52 (±1.04) abc | 3.96 (±0.90) ab | 1.77 (±0.83) a | 2.93 (±1.10) bcde |

| Albert Heijn—Pieces Like Chicken | 3.12 (±1.14) cde | 3.01 (±1.14) c | 3.24 (±1.10) de | 4.04 (±0.82) b | 1.87 (±0.95) a | 3.11 (±1.16) def |

| Valess—Fillet Pieces | 3.32 (±1.98) ef | 3.28 (±1.17) c | 3.35 (±1.11) e | 3.93 (±1.00) ab | 1.96 (±1.12) ab | 3.67 (±1.22) f |

| Vantastic Foods—Chicken-Style Pieces | 2.40 (±1.07) ab | 2.25 (±1.11) ab | 2.51 (±1.11) abc | 3.63 (±1.14) ab | 2.47 (±1.14) bc | 2.99 (±1.21) bcde |

| Vegetarische Slager—Kipstuckjes | 2.84 (±1.04) bcd | 2.77 (±1.05) bc | 2.99 (±1.06) cde | 3.82 (±0.90) ab | 2.19 (±0.95) abc | 3.07 (±1.15) cdef |

| Veggie Chef—Chicken Pieces | 2.48 (±1.01) b | 2.24 (±1.10) ab | 2.58 (±0.92) abc | 3.77 (±0.93) ab | 2.32 (±1.02) abc | 2.57 (±1.19) abcde |

| VegiDeli VBites—Meat-Free Chicken Pieces | 2.31 (±1.00) ab | 2.06 (±1.05) a | 2.35 (±0.97) ab | 3.81 (±1.12) ab | 2.14 (±1.13) abc | 2.49 (±1.11) abcd |

| Vivera—Plant Chicken Pieces | 2.45 (±0.97) ab | 2.03 (±1.03) a | 2.59 (±0.94) abc | 3.69 (±0.95) ab | 2.11 (±0.93) abc | 2.44 (±1.28) abc |

| Burgers | Raw Attractiveness (Look, Smell, Colour) | Looks Like Meat | Expect Good Taste | Preparation Is Easy | Preparation Takes Long | Preparation Like Meat |

| Albert Heijn—Ultimate Beef Burger (real beef) | 2.92 (±1.26) e | 4.34 (±1.01) d | 3.48 (±1.09) ef | 3.56 (±1.14) abc | 2.81 (±1.34) e | 4.68 (±0.65) e |

| Albert Heijn—Burger Deluxe | 3.62 (±0.97) f | 3.32 (±1.26) c | 3.82 (±0.78) f | 3.84 (±0.90) bc | 1.87 (±0.94) a | 2.83 (±1.20) abc |

| Beyond Meat—Beyond Burger | 2.37 (±1.14) abcd | 3.09 (±1.07) c | 2.61 (±1.22) abc | 3.23 (±1.24) a | 2.56 (±1.18) bcde | 2.71 (±1.16) abc |

| Fry’s—Traditional Burgers | 2.35 (±0.92) abcd | 2.08 (±0.94) a | 2.72 (±0.93) abcd | 3.76 (±0.97) abc | 2.30 (±1.12) abcde | 2.57 (±1.15) abc |

| Gardein—Ultimate Beefless Burger | 1.88 (±0.91) a | 1.73 (±0.83) a | 2.20 (±0.95) a | 3.69 (±1.02) abc | 2.04 (±0.97) abcd | 2.76 (±1.17) abc |

| Garden Gourmet—Incredible Burger | 2.53 (±1.19) bcde | 3.32 (±1.07) c | 2.73 (±1.16) abcd | 3.34 (±1.17) ab | 2.63 (±1.24) cde | 2.94 (±1.27) bcd |

| Greenway—Burger | 1.96 (±0.93) a | 2.04 (±0.97) a | 2.25 (±0.92) a | 3.53 (±1.03) abc | 2.41 (±1.12) abcde | 2.37 (±1.14) ab |

| Linda McCartney—Quarter Pounder | 2.25 (±0.99) ab | 2.28 (±1.10) ab | 2.47 (±0.99) ab | 3.80 (±0.99) abc | 1.87 (±0.87) a | 3.52 (±1.20) d |

| Moving Mountains—Veggie Burger | 2.32 (±1.06) abc | 2.77 (±1.09) bc | 2.62 (±1.01) abc | 3.32 (±1.28) ab | 2.67 (±1.27) de | 2.88 (±1.10) bcd |

| Quorn—Supreme Vegan Burger | 2.96 (±1.11) e | 3.35 (±1.11) c | 3.21 (±1.03) de | 3.68 (±0.89) abc | 2.31 (±1.18) abcde | 3.10 (±1.20) cd |

| SoPeace—Burger | 2.76 (±1.11) cde | 2.13 (±1.07) a | 2.90 (±1.15) bcde | 3.75 (±0.97) abc | 1.83 (±0.91) a | 2.75 (±1.24) abc |

| Vegafit—Gehaktschijf | 2.95 (±1.12) e | 2.14 (±1.05) a | 3.30 (±0.92) def | 4.00 (±0.94) c | 2.12 (±1.08) abcd | 2.17 (±1.26) a |

| Vegetarische Slager—Mc2 No-Beef Burger | 2.56 (±1.00) bcde | 2.18 (±1.06) ab | 2.90 (±1.04) bcde | 4.07 (±0.85) c | 1.94 (±0.95) ab | 2.84 (±1.23) abc |

| VegiDeli—Quarter Pounder | 2.85 (±1.27) de | 2.76 (±1.14) bc | 3.08 (±1.17) cde | 3.87 (±0.99) bc | 2.01 (±1.00) abc | 2.94 (±1.27) bcd |

| Vivera—Vegetable Burger Patty | 2.91 (±1.07) e | 2.30 (±1.05) ab | 3.09 (±0.91) cde | 3.97 (±0.88) c | 1.96 (±0.97) ab | 2.94 (±1.29) bcd |

| Chicken Pieces | Colour (Very Light–Very Dark) | Hardness (Very Soft–Very Hard) | Chewiness (Not–Very) | Cohesiveness (Not–Very) | Fibrousness (Not–Very) | Juiciness (Very Dry–Very Juicy) | Fattiness (Not–Very) | Flavour Intensity (Very Weak–Very Strong) | Meat Flavour (Not–Very) |

|---|---|---|---|---|---|---|---|---|---|

| Real Chicken Pieces | 27.67 a ± 18.80 | 55.12 f ± 20.48 | 61.94 bcde ± 20.93 | 63.21 c ± 20.25 | 64.77 e ± 26.43 | 47.82 cd ± 25.61 | 36.00 bc ± 21.04 | 57.02 cde ± 22.38 | 88.37 g ± 15.87 |

| AH—Pieces Like Chicken | 47.65 bc ±18.06 | 48.27 cdef ± 16.66 | 59.32 bcde ± 17.72 | 54.33 bc ± 19.94 | 63.78 de ± 16.08 | 50.92 d ± 21.03 | 43.00 bcd ± 21.09 | 63.51 def ± 17.53 | 56.28 de ± 23.63 |

| Food for Progress—Oumph the Chunk | 33.25 a ± 16.35 | 53.48 f ± 20.61 | 66.92 e ± 20.00 | 59.32 bc ± 21.03 | 64.08 de ± 20.94 | 45.51 cd ± 21.95 | 41.81 bcd ± 25.73 | 37.41 a ± 25.40 | 28.45 ab ± 23.59 |

| Fry’s—Chicken Style Strips | 47.45 bc ± 18.51 | 38.42 bc ± 18.60 | 43.21 a ± 23.05 | 59.04 bc ± 20.75 | 35.42 ab ± 21.73 | 56.07 de ± 21.33 | 51.40 def ± 22.62 | 57.48 cde ± 20.31 | 48.88 cde ± 27.47 |

| Gold & Green—Pulled Oats | 94.22 f ± 5.18 | 40.56 bcd ± 26.04 | 45.06 a ± 26.52 | 29.42 a ± 24.31 | 39.16 bc ± 26.84 | 28.97 ab ± 21.95 | 35.49 bc ± 23.87 | 46.15 abc ± 25.84 | 28.46 ab ± 23.83 |

| Greenway—Chick Pieces | 48.93 bcd ± 17.96 | 55.55 f ± 17.29 | 62.80 de ± 17.59 | 58.05 bc ± 20.84 | 62.57 de ± 21.77 | 54.52 de ± 22.73 | 47.85 cde ± 23.99 | 57.45 cdef ± 19.90 | 41.89 bcd ± 25.88 |

| Naturli—Chick Free | 57.24 de ± 16.04 | 48.29 cdef ± 18.99 | 65.35 e ± 16.38 | 55.99 bc ± 19.99 | 56.09 de ± 21.22 | 48.00 cd ± 26.68 | 43.89 bcd ± 25.05 | 63.24 def ± 23.21 | 36.20 abc ± 25.84 |

| Quorn—Chicken Pieces | 30.16 a ± 17.24 | 40.92 bcde ± 23.05 | 44.98 a ± 26.12 | 49.73 b ± 27.12 | 39.46 bc ± 28.89 | 19.12 a ± 18.12 | 18.66 a ± 17.98 | 50.74 bc ± 24.43 | 31.02 ab ± 29.82 |

| Valess—Fillet Pieces | 56.48 cde ± 16.27 | 41.87 bcde ± 17.86 | 50.12 ab ± 19.64 | 60.60 bc ± 19.37 | 51.52 cd ± 22.16 | 56.91 de ± 20.38 | 43.51 bcd ± 18.88 | 66.23 f ± 17.76 | 71.61 f ± 20.21 |

| Vantastic Foods—Chicken-Style Pieces | 59.25 e ± 17.78 | 20.31 a ± 15.44 | 51.58 abcd ± 30.55 | 55.06 bc ± 27.39 | 25.42 a ± 22.94 | 72.15 f ± 20.40 | 60.50 ef ± 21.54 | 64.29 ef ± 20.00 | 40.43 abc ± 28.61 |

| Vegetarische Slager—Kipstuckjes | 52.37 bcde ± 16.79 | 46.87 bcdef ± 20.33 | 64.10 e ± 18.64 | 60.25 bc ± 18.57 | 62.38 de ± 20.54 | 66.10 ef ± 20.70 | 63.06 f ± 21.83 | 66.89 f ± 19.29 | 55.94 de ± 26.82 |

| Veggie Chef—Kipstukjes | 46.37 b ± 16.86 | 50.23 def ± 18.63 | 60.67 bcde ± 18.40 | 55.08 bc ± 21.04 | 55.88 de ± 21.78 | 49.59 d ± 21.48 | 44.40 bcd ± 24.75 | 43.71 ab ± 21.21 | 48.28 cde ± 27.42 |

| VegiDeli VBites—Meat-Free Chicken Pieces | 52.42 bcde ± 18.28 | 36.86 b ± 18.34 | 50.41 abc ± 25.79 | 54.84 bc ± 22.78 | 42.86 bc ± 24.55 | 36.21 bc ± 20.88 | 32.07 b ± 21.92 | 52.96 bcde ± 21.25 | 27.34 a ± 23.09 |

| Vivera—Plant Chicken Pieces | 51.22 bcde ± 19.28 | 51.71 ef ± 20.77 | 62.52 cde ± 19.90 | 58.08 bc ± 23.26 | 62.67 de ± 22.34 | 50.39 d ± 21.75 | 46.03 cd ± 23.48 | 51.62 bcd ± 21.25 | 47.42 cde ± 27.99 |

| Burgers | Colour (Very Light–Very Dark) | Hardness (Very Soft–Very Hard) | Chewiness (Not–Very) | Cohesiveness (Not–Very) | Fibrousness (Not–Very) | Juiciness (Very Fry–Very Juicy) | Fattiness (Not–Very) | Flavour Intensity (Very Weak–Very Strong) | Meat Flavour (Not–Very) |

| Albert Heijn—Ultimate Beef Burger (real beef) | 61.34 ef ± 14.83 | 52.57 cd ± 19.12 | 62.34 ef ± 17.73 | 62.82 d ± 18.25 | 56.14 b ± 25.71 | 74.73 g ± 19.66 | 69.18 f ± 20.17 | 69.52 cd ± 15.62 | 90.83 c ± 13.25 |

| Albert Heijn—Burger Deluxe | 58.52 def ± 16.54 | 46.64 bc ± 17.03 | 48.21 bc ± 19.38 | 57.76 bcd ± 19.85 | 51.29 b ± 20.57 | 50.69 de ± 20.12 | 45.71 abcde ± 19.21 | 64.50 bcd ± 18.77 | 51.90 b ± 26.27 |

| Beyond Meat—Beyond Burger | 52.12 cde ± 15.23 | 38.84 b ± 16.94 | 49.61 bcd ± 21.75 | 48.37 abc ± 23.44 | 52.54 b ± 25.18 | 55.82 def ± 20.37 | 53.47 de ± 21.95 | 52.65 a ± 21.12 | 53.21 b ± 29.18 |

| Fry’s—Traditional Burgers | 42.26 ab ± 19.26 | 27.01 a ± 18.21 | 33.39 a ± 23.56 | 44.93 ab ± 24.76 | 28.66 a ± 21.18 | 54.70 def ± 19.06 | 48.77 bcde ± 21.55 | 55.94 ab ± 21.52 | 42.12 ab ± 26.76 |

| Gardein—Ultimate Beefless Burger | 65.56 f ± 17.86 | 56.79 de ± 18.98 | 61.01 def ± 20.10 | 59.04 cd ± 22.80 | 46.12 b ± 26.35 | 37.99 abc ± 20.83 | 38.36 ab ± 22.62 | 58.60 abc ± 20.73 | 47.03 b ± 27.46 |

| Garden Gourmet—Incredible Burger | 47.65 bc ± 19.64 | 46.48 bc ± 20.97 | 54.07 bcde ± 20.69 | 54.42 abcd ± 21.54 | 51.40 b ± 25.25 | 48.02 cd ± 22.13 | 41.45 abcd ± 21.54 | 59.32 abc 2 1.99 | 41.90 ab ± 32.01 |

| Greenway—Burger | 46.43 bc ± 17.80 | 18.45 a ± 12.85 | 31.09 a ± 24.72 | 43.68 a ± 27.68 | 28.17 a ± 21.32 | 60.47 ef ± 20.46 | 48.13 abcde ± 21.76 | 60.60 abc ± 21.59 | 41.49 ab ± 25.89 |

| Linda McCartney—Quarter Pounder | 67.94 fg ± 14.40 | 58.10 de ± 18.79 | 60.72 cdef ± 22.13 | 54.34 abcd ± 22.54 | 57.15 b ± 23.31 | 51.24 de ± 18.97 | 51.08 cde ± 22.71 | 66.80 bcd ± 17.33 | 48.50 b ± 28.41 |

| Moving Mountains—Veggie Burger | 54.47 cde ± 17.25 | 40.04 b ± 18.39 | 49.17 bcd ± 23.09 | 55.60 abcd ± 23.33 | 50.72 b ± 23.53 | 63.20 fg ± 20.19 | 57.95 ef ± 19.50 | 57.60 ab ± 21.48 | 42.59 ab ± 28.91 |

| Quorn—Supreme Vegan Burger | 60.83 ef ± 16.79 | 43.84 bc ± 17.30 | 55.68 bcdef ± 20.84 | 55.83 abcd ± 21.39 | 57.99 b ± 22.85 | 54.78 def ± 19.19 | 52.54 cde ± 20.27 | 58.41 abc ± 20.55 | 48.74 b ± 26.85 |

| SoPeace—Burger | 61.26 ef ± 18.50 | 88.45 f ± 11.56 | 67.07 f ± 28.79 | 58.01 bcd ± 31.93 | 51.89 b ± 32.60 | 28.04 a ± 21.45 | 40.79 abc ± 23.70 | 69.52 cd ± 19.85 | 31.27 a ± 25.04 |

| Vegafit—Gehaktschijf | 35.44 a ± 20.58 | 17.83 a ± 15.70 | 27.54 a ± 24.47 | 44.79 ab ± 28.98 | 23.62 a ± 21.92 | 55.80 def ± 21.86 | 42.03 abcd ± 22.28 | 62.44 abcd ± 18.89 | 28.91 a ± 23.51 |

| Vegetarische Slager—Mc2 No-Beef Burger | 50.23 bcd ± 16.71 | 41.12 b ± 19.12 | 46.35 b ± 21.31 | 53.43 abcd ± 20.90 | 48.81 b ± 23.32 | 53.89 def ± 20.94 | 48.74 bcde ± 19.28 | 65.79 bcd ± 18.05 | 51.54 b ± 28.47 |

| VegiDeli—Quarter Pounder | 75.84 g ± 15.21 | 43.73 bc ± 19.45 | 47.43 b ± 23.82 | 49.48 abcd ± 25.54 | 46.02 b ± 27.28 | 33.33 ab ± 22.38 | 36.05 a ± 21.78 | 66.43 bcd ± 22.63 | 29.00 a ± 23.67 |

| Vivera—Vegetable Burger Patty | 64.31 f ± 15.55 | 65.22 e ± 16.72 | 62.63 ef ± 19.07 | 62.98 d ± 21.03 | 52.57 b ± 22.83 | 44.40 bcd ± 20.32 | 47.42 abcde ± 21.79 | 73.58 d ± 17.21 | 50.97 b ± 26.81 |

| Chicken Pieces | Look | Texture | Flavour | Overall Liking | Grade | Like to Eat It Again |

|---|---|---|---|---|---|---|

| Real Chicken Pieces | 7.94 (±1.25) f | 7.99 (±1.04) h | 7.81 (±1.43) g | 7.94 (±1.09) g | 8.56 (±1.33) g | 1.89 (±0.40) f |

| Albert Heijn—Pieces Like chicken | 6.61 (±1.68) cde | 7.11 (±1.23) gh | 6.37 (±2.09) ef | 6.76 (±1.34) ef | 7.05 (±1.46) ef | 1.51 (±0.69) ef |

| Food for Progress—Oumph the Chunk | 6.79 (±1.64) de | 5.43 (±2.09) cde | 3.73 (±1.80) ab | 4.97 (±1.74) bc | 5.15 (±1.54) ab | 0.51 (±0.69) a |

| Fry’s—Chicken Style Strips | 6.32 (±1.82) cd | 6.63 (±1.61) fg | 6.83 (±1.93) fg | 6.79 (±1.60) ef | 7.10 (±1.73) ef | 1.45 (±0.75) de |

| Gold & Green—Pulled Oats | 4.11 (±2.44) a | 4.01 (±1.98) a | 3.49 (±1.93) a | 3.92 (±1.96) a | 4.27 (±1.82) a | 0.32 (±0.55) a |

| Greenway—Chick Pieces | 6.56 (±1.52) cde | 6.30 (±1.73) efg | 5.03 (±2.07) cd | 6.07 (±1.65) de | 5.98 (±1.71) bcd | 0.97 (±0.74) bc |

| Naturli—Chick Free | 6.54 (±1.69) cde | 5.21 (±2.15) bcd | 4.09 (±2.35) abc | 4.90 (±2.07) abc | 5.15 (±2.02) ab | 0.68 (±0.79) ab |

| Quorn—Chicken Pieces | 4.97 (±2.15) ab | 4.21 (±2.35) ab | 3.71 (±2.66) a | 4.13 (±2.15) ab | 4.46 (±2.02) a | 0.48 (±0.71) a |

| Valess—Fillet Pieces | 7.39 (±1.51) ef | 7.69 (±1.10) h | 7.59 (±1.02) g | 7.45 (±1.24) fg | 7.91 (±1.08) fg | 1.87 (±0.38) f |

| Vantastic Foods—Chicken-Style Pieces | 5.68 (±2.19) bc | 4.83 (±2.49) abc | 4.89 (±2.46) bcd | 5.32 (±2.40) cd | 5.70 (±2.19) bc | 0.96 (±0.90) bc |

| Vegetarische Slager—Kipstuckjes | 6.55 (±1.52) cde | 6.38 (±1.81) efg | 5.97 (±2.10) def | 6.24 (±1.80) de | 6.73 (±1.65) de | 1.34 (±0.75) cde |

| Veggie Chef—Chicken Pieces | Lso 6.14 (±1.45) cd | 6.06 (±1.80) def | 5.58 (±2.03) de | 5.87 (±1.56) cde | 6.29 (±1.55) cde | 1.11 (±0.78) cde |

| VegiDeli VBites—Meat-Free Chicken pieces | 4.96 (±2.00) ab | 4.42 (±2.05) abc | 3.93 (±2.09) abc | 4.30 (±1.88) ab | 4.69 (±1.84) a | 0.51 (±0.77) a |

| Vivera—Plant Chicken Pieces | 5.72 (±1.73) bc | 6.30 (±1.77) efg | 5.46 (±2.12) de | 5.99 (±1.67) de | 6.20 (±1.51) cde | 1.08 (±0.77) cd |

| Burgers | Look | Texture | Flavour | Overall Liking | Grade | Like to Eat It Again |

| Albert Heijn—Ultimate Beef Burger (real beef) | 7.87 (±1.23) e | 7.58 (±1.59) g | 7.74 (±1.50) f | 7.65 (±1.54) i | 8.44 (±1.43) h | 1.80 (±0.47) h |

| Albert Heijn—Burger Deluxe | 7.11 (±1.32) de | 6.99 (±1.53) fg | 6.87 (±1.91) ef | 6.93 (±1.44) hi | 7.35 (±1.44) g | 1.58 (±0.65) gh |

| Beyond Meat—Beyond Burger | 5.17 (±2.20) ab | 4.46 (±1.79) efg | 5.83 (±2.21) cde | 5.80 (±1.99) defg | 6.53 (±1.79) efg | 1.18 (±0.85) defg |

| Fry’s—Traditional Burgers | 5.72 (±1.80) bc | 4.93 (±2.01) bcd | 5.44 (±2.04) bcd | 5.53 (±1.83) cdefg | 5.93 (±1.65) cde | 0.92 (±0.84) bcde |

| Gardein—Ultimate Beefless Burger | 5.20 (±2.10) ab | 5.59 (±1.75) cde | 4.89 (±2.21) abc | 4.23 (±1.85) bcde | 5.51 (±1.93) bcde | 0.83 (±0.81) bcd |

| Garden Gourmet—Incredible Burger | 4.44 (±2.03) a | 5.30 (±2.03) bcd | 4.23 (±2.55) ab | 4.61 (±2.17) bc | 5.27 (±2.22) bcd | 0.76 (±0.82) bcd |

| Greenway—Burger | 4.23 (±.190) a | 4.27 (±2.06) b | 4.53 (±2.36) ab | 4.43 (±1.87) ab | 5.09 (±1.93) abc | 0.70 (±0.78) abc |

| Linda McCartney—Quarter Pounder | 6.63 (±1.50) cd | 5.99 (±2.04) def | 5.45 (±2.14) bcd | 5.90 (±1.77) efgh | 6.26 (±1.77) def | 1.06 (±0.81) cdef |

| Moving Mountains—Veggie Burger | 5.15 (±1.86) ab | 5.17 (±2.19) bcd | 4.41 (±2.36) ab | 4.80 (±2.18) bcd | 5.49 (±2.10) bcde | 0.80 (±0.87) bcd |

| Quorn—Supreme Vegan Burger | 5.63 (±1.83) bc | 5.87 (±2.23) cdef | 4.97 (±2.18) bc | 5.41 (±2.05) bcded | 6.07 (±1.93) cdef | 0.87 (±0.81) bcde |

| SoPeace—Burger | 5.90 (±1.99) bc | 2.65 (±2.09) a | 4.23 (±2.29) ab | 3.46 (±2.04) a | 4.13 (±2.07) a | 0.30 (±0.62) a |

| Vegafit—Gehaktschijf | 6.03 (±1.88) bc | 4.97 (±2.18) bcd | 6.24 (±2.22) de | 6.08 (±1.99) efgh | 6.28 (±2.09) def | 1.13 (±0.86) cdef |

| Vegetarische Slager—Mc2 No-Beef Burger | 6.35 (±1.56) cd | 6.45 (±1.80) ef | 6.49 (±2.01) de | 6.51 (±1.59) gh | 6.99 (±1.48) fg | 1.46 (±0.77) fgh |

| VegiDeli—Quarter Pounder | 6.00 (±1.73) bc | 4.86 (±1.97) bc | 3.69 (±2.17) a | 4.48 (±2.08) abc | 4.61 (±2.07) ab | 0.49 (±0.71) ab |

| Vivera—Vegetable Burger Patty | 6.31 (±1.72) cd | 5.93 (±1.87) cdef | 6.21 (±2.03) de | 6.30 (±1.64) fgh | 6.54 (±1.56) efg | 1.31 (±0.82) efg |

| Chicken Pieces | Instrumental Properties | Nutritional Values | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Sensory Attribute | Hardness | Chewiness | Cohesiveness | Springiness | Moisture Content | %EM | Fat (g) | Fibres (g) | Salt (g) |

| Hardness | 0.353 | 0.381 | 0.033 | −0.165 | 0.253 | 0.497 | −0.710 * | 0.219 | 0.252 |

| Chewiness | −0.108 | 0.191 | 0.475 | 0.360 | 0.566 | 0.423 | −0.661 * | 0.144 | 0.134 |

| Cohesiveness | 0.063 | 0.165 | 0.283 | 0.225 | 0.776 ** | −0.053 | −0.079 | 0.450 | 0.276 |

| Fibrousness | 0.182 | 0.238 | 0.163 | −0.039 | 0.408 | 0.444 | −0.578 | 0.086 | 0.269 |

| Juiciness | −0.486 | −0.075 | 0.323 | 0.508 | 0.319 | −0.092 | 0.164 | 0.317 | 0.824 ** |

| Fattiness | −0.503 | −0.044 | 0.327 | 0.533 | 0.161 | −0.034 | 0.163 | 0.336 | 0.825 ** |

| Flavour intensity | −0.268 | −0.355 | −0.150 | −0.168 | −0.051 | 0.272 | 0.440 | −0.075 | 0.575 |

| Meaty flavour | 0.033 | −0.194 | −0.401 | −0.338 | 0.107 | 0.077 | 0.277 | 0.071 | 0.763 ** |

| Burgers | Instrumental properties | Nutritional values | |||||||

| Sensory Attribute | Hardness | Chewiness | Cohesiveness | Springiness | Moisture content | %EM | Fat (g) | Fibres (g) | Salt (g) |

| Hardness | 0.857 ** | 0.837 ** | 0.827 ** | 0.823 ** | 0.325 | 0.563 * | −0.245 | −0.033 | −0.251 |

| Chewiness | 0.710 ** | 0.715 ** | 0.803 ** | 0.727 ** | 0.200 | 0.630 * | −0.134 | −0.213 | −0.575 |

| Cohesiveness | 0.668 ** | 0.687 ** | 0.768 ** | 0.668 ** | 0.104 | 0.533 | −0.388 | 0.150 | −0.599 |

| Fibrousness | 0.407 | 0.396 | 0.545 * | 0.439 | −0.121 | 0.361 | 0.099 | −0.279 | −0.721 * |

| Juiciness | −0.557 * | −0.513 | −0.420 | −0.424 | −0.424 | −0.410 | 0.418 | 0.025 | −0.012 |

| Fattiness | −0.173 | −0.139 | −0.062 | −0.043 | −0.369 | −0.255 | 0.443 | −0.024 | −0.112 |

| Flavour intensity | 0.513 | 0.481 | 0.311 | 0.366 | 0.297 | 0.387 | −0.565 | 0.300 | −0.101 |

| Meaty flavour | 0.078 | 0.100 | 0.175 | 0.171 | −0.135 | 0.299 | −0.275 | −0.185 | −0.700 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Godschalk-Broers, L.; Sala, G.; Scholten, E. Meat Analogues: Relating Structure to Texture and Sensory Perception. Foods 2022, 11, 2227. https://doi.org/10.3390/foods11152227

Godschalk-Broers L, Sala G, Scholten E. Meat Analogues: Relating Structure to Texture and Sensory Perception. Foods. 2022; 11(15):2227. https://doi.org/10.3390/foods11152227

Chicago/Turabian StyleGodschalk-Broers, Layla, Guido Sala, and Elke Scholten. 2022. "Meat Analogues: Relating Structure to Texture and Sensory Perception" Foods 11, no. 15: 2227. https://doi.org/10.3390/foods11152227

APA StyleGodschalk-Broers, L., Sala, G., & Scholten, E. (2022). Meat Analogues: Relating Structure to Texture and Sensory Perception. Foods, 11(15), 2227. https://doi.org/10.3390/foods11152227