Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Osmotic Dehydration (OD) Pretreatment

2.2.1. Experimental Design

2.2.2. Evaluation of Osmotic Pretreatment Progress

2.2.3. Reuse of Osmotic Solution

2.3. Air-Drying Process

2.4. Monitoring of Quality Characteristics

2.4.1. Chroma and Texture Analysis

2.4.2. Analysis of Nutritional Compounds

2.4.3. Determination of Bioactive Compounds

2.4.4. Sensory Evaluation

2.5. Accelerated Shelf-Life Determination

2.6. Data Analysis

2.6.1. Mathematical Modelling of Osmotic Dehydration

2.6.2. Mathematical Modelling on the Air-Drying Processing of the Figs

2.6.3. Evaluation of Energy Consumption during Air-Drying

2.6.4. Mathematical Modelling on the Shelf-Life Determination of the Figs

2.7. Statistical Analysis

3. Results

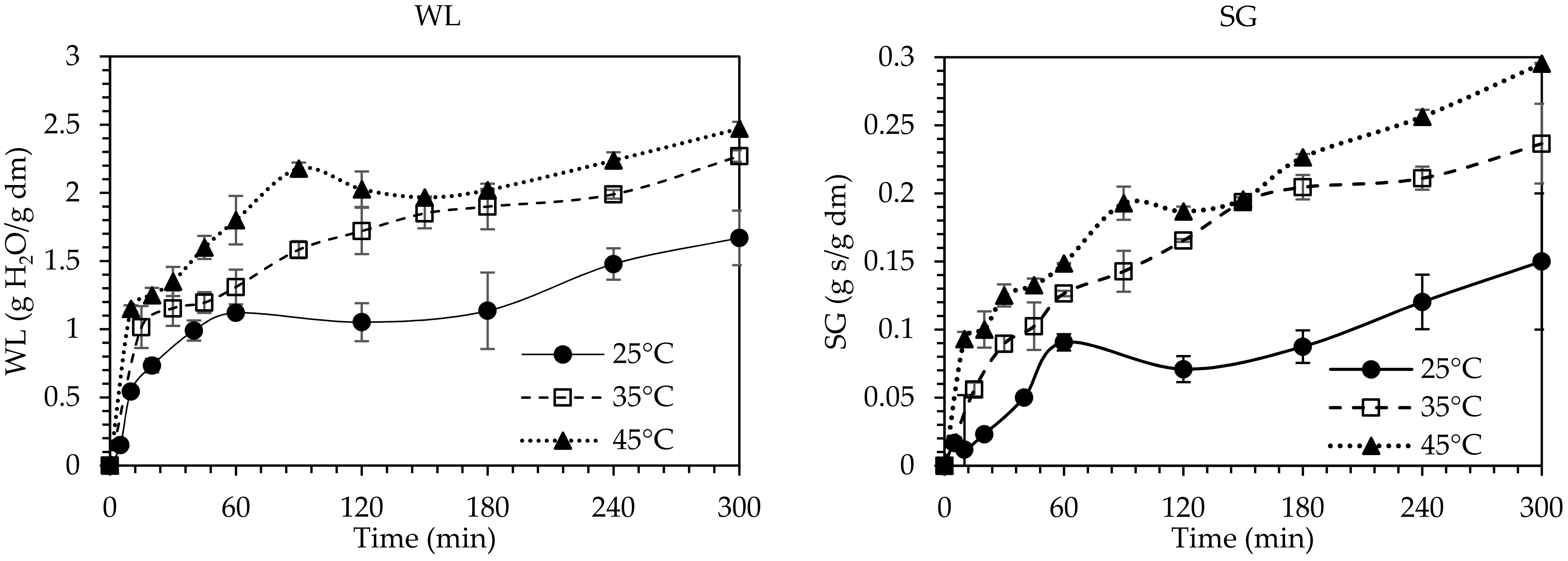

3.1. Osmotic Dehydration of Figs

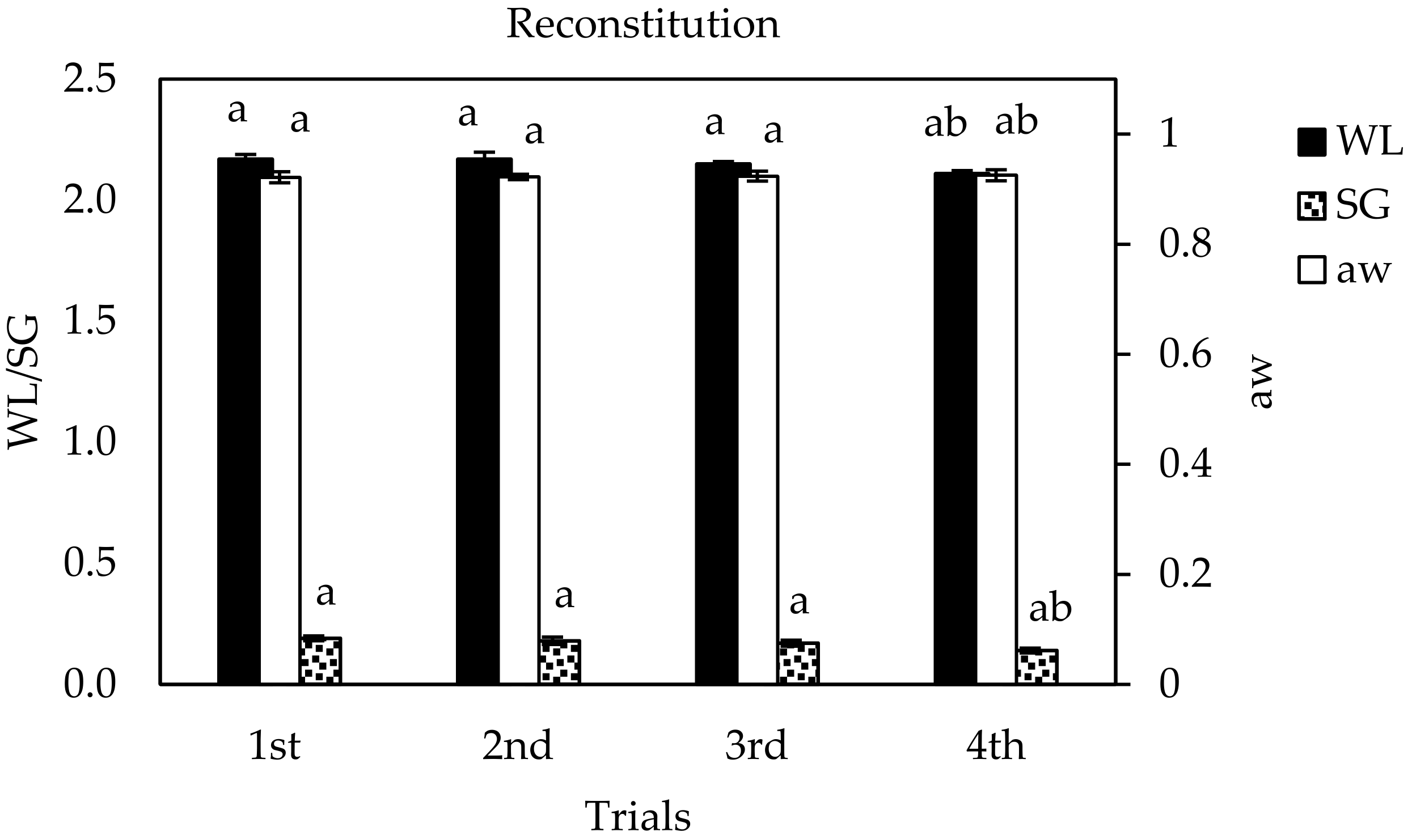

Assessment of Reconstitution of OD Solution on the Effectiveness of OD Processing

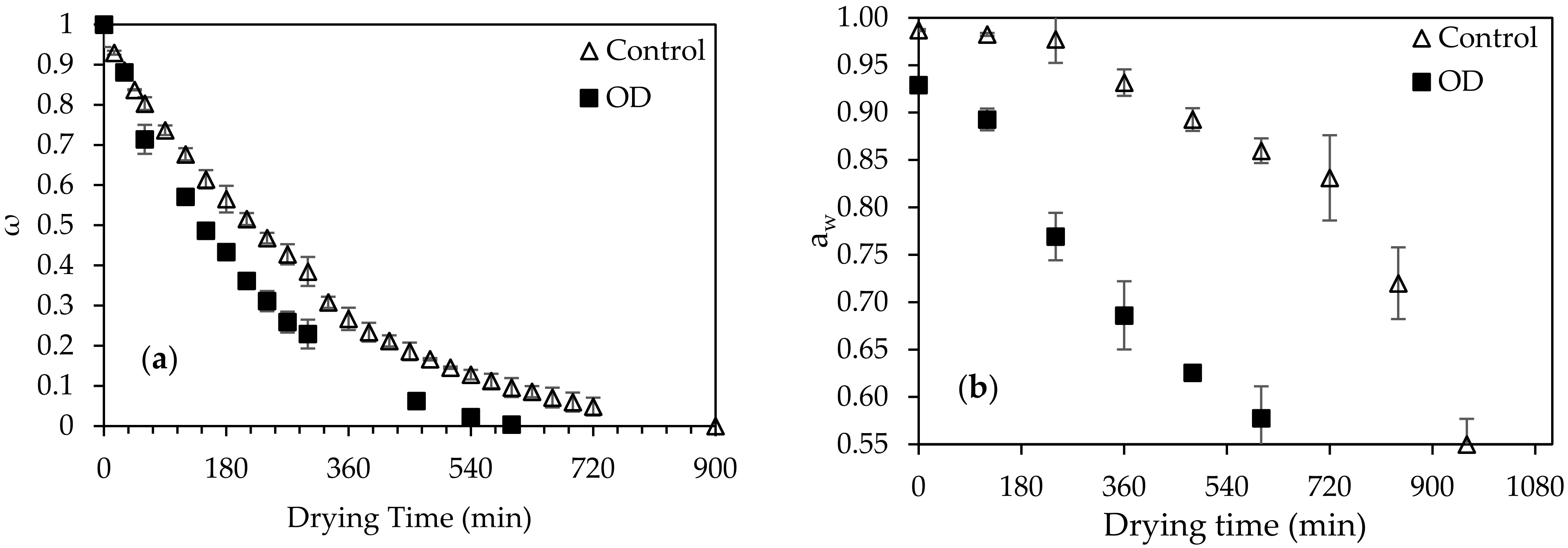

3.2. Air-Drying Processing of Osmotic Dehydrated and Untreated Figs

3.3. Energy Savings and Yield Increase of the Combined Use of Osmotic Dehydration and Air-Drying on Figs

3.4. Cost-Effectiveness Analysis of OD-Assisted Air Drying of Fig Halves

3.5. Quality Evaluation of Osmotic Pretreated and Untreated Air-Dried Figs

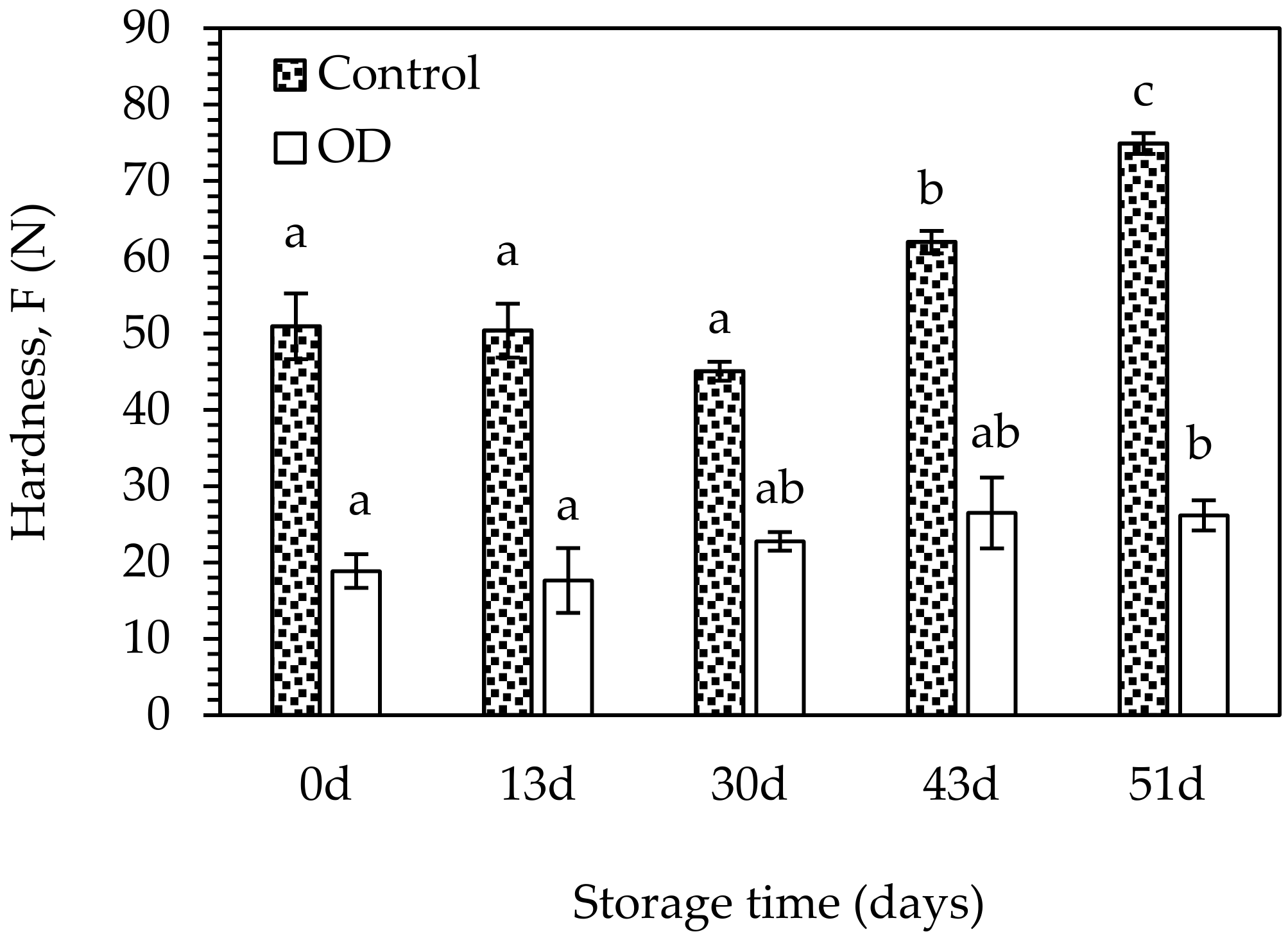

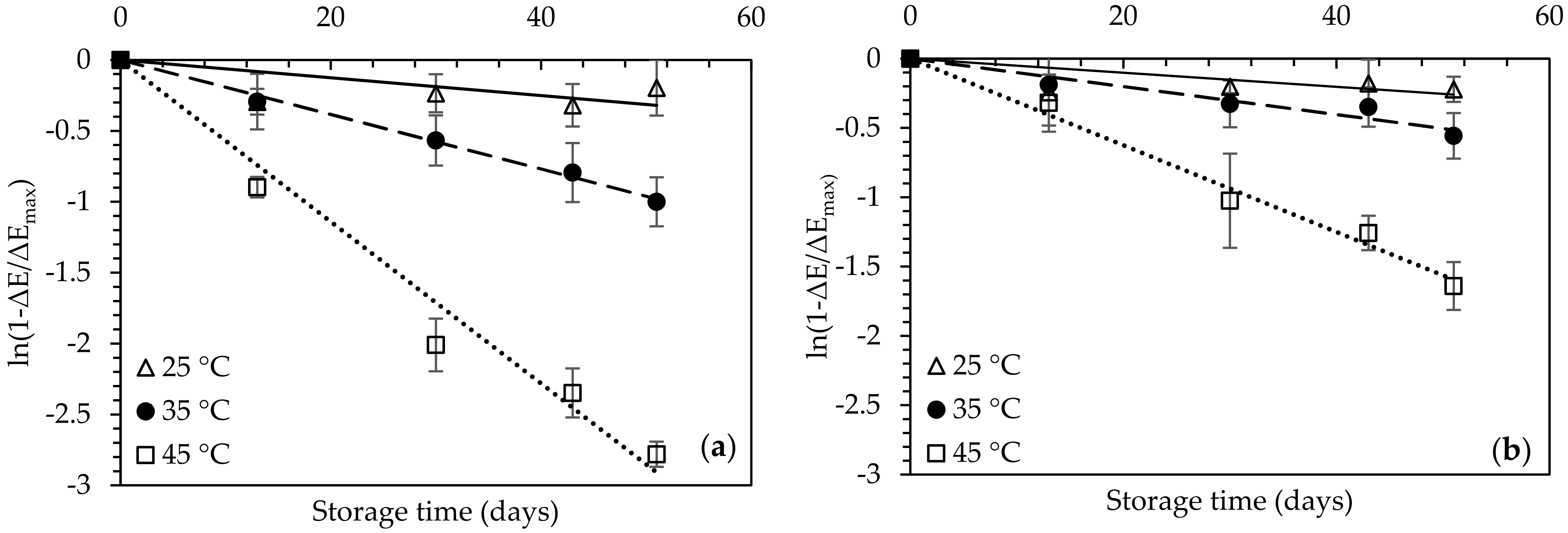

3.6. Shelf-Life Determination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naikwadi, P.M.; Chavan, U.D.; Pawar, V.D.; Amarowicz, R. Studies on dehydration of figs using different sugar syrup treatments. J. Food Sci. Technol. 2010, 47, 442–445. [Google Scholar] [CrossRef][Green Version]

- Silva, J.M.; Cantu, M.G.; Rodrigues, V.; Mazutti, M.A. Influence of osmotic pre-treatment on convective drying kinetics of figs. Int. J. Food Eng. 2013, 9, 187–196. [Google Scholar] [CrossRef]

- Mujić, I.; Kralj, M.B.; Jokić, S.; Jug, T.; Šubarić, D.; Vidović, S.; Zivković, J.; Jarni, K. Characterisation of volatiles in dried white varieties figs (Ficus carica L.). J. Food Sci. Technol. 2014, 51, 1837–1846. [Google Scholar] [CrossRef]

- Bantle, M.; Eikevik, T.M. A study of the energy efficiency of convective drying systems assisted by ultrasound in the production of clipfish. J. Clean. Prod. 2014, 65, 217–223. [Google Scholar] [CrossRef]

- Chen, Z.G.; Guo, X.Y.; Wu, T. A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrason. Sonochemistry 2016, 30, 28–34. [Google Scholar] [CrossRef]

- Cohen, J.S.; Yang, T.C. Progress in food dehydration. Trends Food Sci. Technol. 1995, 6, 20–25. [Google Scholar] [CrossRef]

- Llavata, B.; García-Pérez, J.V.; Simal, S.; Cárcel, J.A. Innovative pre-treatments to enhance food drying: A current review. Curr. Opin. Food Sci. 2020, 35, 20–26. [Google Scholar] [CrossRef]

- Torreggiani, D.; Bertolo, G. Osmotic pre-treatments in fruit processing: Chemical, physical and structural effects. J. Food Eng. 2001, 49, 247–253. [Google Scholar] [CrossRef]

- de Mello, R.E., Jr.; Corrêa, J.L.G.; Lopes, F.J.; de Souza, A.U.; da Silva, K.C.R. Kinetics of the pulsed vacuum osmotic dehydration of green fig (Ficus carica L.). Heat Mass Transf. 2019, 55, 1685–1691. [Google Scholar] [CrossRef]

- Torreggiani, D. Osmotic dehydration in fruit and vegetable processing. Food Res. Int. 1993, 26, 59–68. [Google Scholar] [CrossRef]

- da Costa Ribeiro, A.S.; Aguiar-Oliveira, E.; Maldonado, R.R. Optimization of osmotic dehydration of pear followed by conventional drying and their sensory quality. LWT Food Sci. Technol. 2016, 72, 407–415. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.K.; Pantelaiaki, K.; Andreou, V.; Katsaros, G.J.; Taoukis, P.S. Osmotic pretreatment for the production of novel dehydrated tomatoes and cucumbers. J. Food Process. Preserv. 2019, 43, e13968. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.; Chalkia, A.; Taoukis, P. Application of osmotic dehydration to improve the quality of dried goji berry. J. Food Eng. 2018, 232, 36–43. [Google Scholar] [CrossRef]

- Mandala, I.G.; Anagnostaras, E.F.; Oikonomou, C.K. Influence of osmotic dehydration conditions on apple air-drying kinetics and their quality characteristics. J. Food Eng. 2005, 69, 307–316. [Google Scholar] [CrossRef]

- Fernandes, F.A.; Rodrigues, S.; Gaspareto, O.C.; Oliveira, E.L. Optimization of osmotic dehydration of bananas followed by air-drying. J. Food Eng. 2006, 77, 188–193. [Google Scholar] [CrossRef]

- Garcia, C.C.; Mauro, M.A.; Kimura, M. Kinetics of osmotic dehydration and air-drying of pumpkins (Cucurbita moschata). J. Food Eng. 2007, 82, 284–291. [Google Scholar] [CrossRef]

- Teles, U.M.; Fernandes, F.A.; Rodrigues, S.; Lima, A.S.; Maia, G.A.; Figueiredo, R.W. Optimization of osmotic dehydration of melons followed by air-drying. Int. J. Food Sci. Technol. 2006, 41, 674–680. [Google Scholar] [CrossRef]

- Giannoglou, M.; Koumandraki, H.; Andreou, V.; Dermesonlouoglou, E.; Katsaros, G.; Taoukis, P. Combined Osmotic and Air Dehydration for the Production of Shelf-Stable White Cheese. Food Bioprocess. Technol. 2020, 13, 1435–1446. [Google Scholar] [CrossRef]

- Andreou, V.; Tsironi, T.; Dermesonlouoglou, E.; Katsaros, G.; Taoukis, P. Combinatory effect of osmotic and high pressure processing on shelf life extension of animal origin products—Application to chilled chicken breast fillets. Food Packag. Shelf Life 2018, 15, 43–51. [Google Scholar] [CrossRef]

- Niranjan, T.; Rajender, G.; Reddy, P.; Reddy, V.; Kumar, A.; Krishna, V. Study on osmotic dehydration of fig fruit (Ficus carica) Slices Mediated Tray Drying. Int. J. Curr. Microbiol. App. Sci. 2018, 7, 3198–3205. [Google Scholar] [CrossRef]

- El-Gendy, M.A. Evaluation of quality attributes of dehydrated figs prepared by osmotic-drying process. Egypt J. Agric. Res. 2014, 92, 337–347. [Google Scholar]

- Vasconcelos, J.I.; Andrade, S.A.; Maciel, M.I.; Guerra, N.B.; Vasconcelos, M.A. Osmotic dehydration of the I ndian fig (Opuntia ficus indica) with binary and ternary solutions. Int. J. Food Sci. Technol. 2012, 47, 2359–2365. [Google Scholar] [CrossRef]

- Villalobos, M.C.; Serradilla, M.J.; Martín, A.; Ruíz-Moyano, S.; Casquete, R.; Hernández, A.; Córdoba, M.G. Use of efficient drying methods to improve the safety and quality of dried fig. J. Food Process. Preserv. 2019, 43, e13853. [Google Scholar] [CrossRef]

- Şahin, U.; Öztürk, H.K. Effects of pulsed vacuum osmotic dehydration (PVOD) on drying kinetics of figs (Ficus carica L). Innov. Food Sci. Emerg. Technol. 2016, 36, 104–111. [Google Scholar] [CrossRef]

- Pereira, C.; López-Corrales, M.; Serradilla, M.J.; del Carmen Villalobos, M.; Ruiz-Moyano, S.; Martín, A. Influence of ripening stage on bioactive compounds and antioxidant activity in nine fig (Ficus carica L.) varieties grown in Extremadura, Spain. J. Food Compos. Anal. 2017, 64, 203–212. [Google Scholar] [CrossRef]

- Efthimiadou, A.; Katsenios, N.; Chanioti, S.; Giannoglou, M.; Djordjevic, N.; Katsaros, G. Effect of foliar and soil application of plant growth promoting bacteria on growth, physiology, yield and seed quality of maize under Mediterranean conditions. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Sturm, K.; Koron, D.; Stampar, F. The composition of fruit of different strawberry varieties depending on maturity stage. Food Chem. 2003, 83, 417–422. [Google Scholar] [CrossRef]

- Andreou, V.; Psarianos, M.; Dimopoulos, G.; Tsimogiannis, D.; Taoukis, P. Effect of pulsed electric fields and high pressure on improved recovery of high-added-value compounds from olive pomace. J. Food Sci. 2020, 85, 1500–1512. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Marinova, D.; Ribarova, F.; Atanassova, M. Total phenolics and total flavonoids in Bulgarian fruits and vegetables. J. Univ. Chem. Technol. Metall. 2005, 40, 255–260. [Google Scholar]

- Rastogi, N.K.; Raghavarao, K.S.M.S. Water and solute diffusion coefficients of carrot as a function of temperature and concentration during osmotic dehydration. J. Food Eng. 1997, 34, 429–440. [Google Scholar] [CrossRef]

- Crank, J. Diffuision in a plane sheet. In The Mathematics of Diffusion, 2nd ed.; Crank, J., Ed.; Oxford University Press: New York, NY, USA, 1975; pp. 47–48. [Google Scholar]

- Motevali, A.; Minaei, S.; Khoshtagaza, M.H. Evaluation of energy consumption in different drying methods. Energy Convers. Manag. 2011, 52, 1192–1199. [Google Scholar] [CrossRef]

- da Conceição Silva, M.A.; da Silva, Z.E.; Mariani, V.C.; Darche, S. Mass transfer during the osmotic dehydration of West Indian cherry. LWT Food Sci. Technol. 2012, 45, 246–252. [Google Scholar] [CrossRef]

- Chauhan, O.P.; Singh, A.; Singh, A.; Raju, P.S.; Bawa, A.S. Effects of osmotic agents on colour, textural, structural, thermal, and sensory properties of apple slices. Int. J. Food Prop. 2011, 14, 1037–1048. [Google Scholar] [CrossRef]

- Pereira, L.M.; Ferrari, C.C.; Mastrantonio, S.D.S.; Rodrigues, A.C.C.; Hubinger, M.D. Kinetic aspects, texture, and color evaluation of some tropical fruits during osmotic dehydration. Dry. Technol. 2006, 24, 475–484. [Google Scholar] [CrossRef]

- Taiwo, K.A.; Eshtiaghi, M.N.; Ade-Omowaye, B.I.; Knorr, D. Osmotic dehydration of strawberry halves: Influence of osmotic agents and pretreatment methods on mass transfer and product characteristics. Int. J. Food Sci. Technol. 2003, 38, 693–707. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Lukaszuk, A. Effect of osmotic dewatering on rheological properties of apple subjected to convective drying. J. Food Eng. 2000, 45, 119–126. [Google Scholar] [CrossRef]

- Najafi, A.H.; Yusof, Y.A.; Rahman, R.A.; Ganjloo, A.; Ling, C.N. Effect of osmotic dehydration process using sucrose solution at mild temperature on mass transfer and quality attributes of red pitaya (Hylocereus polyrhizusis). Int. Food Res. J. 2014, 21, 625–630. [Google Scholar]

- Castelló, M.L.; Fito, P.J.; Chiralt, A. Changes in respiration rate and physical properties of strawberries due to osmotic dehydration and storage. J. Food Eng. 2010, 97, 64–71. [Google Scholar] [CrossRef]

- Tregunno, N.B.; Goff, H.D. Osmodehydrofreezing of apples: Structural and textural effects. Food Res. Int. 1996, 29, 471–479. [Google Scholar] [CrossRef]

- Garcıa-Martınez, E.; Martınez-Monzó, J.; Camacho, M.M.; Martınez-Navarrete, N. Characterisation of reused osmotic solution as ingredient in new product formulation. Food Res. Int. 2002, 35, 307–313. [Google Scholar] [CrossRef]

- Valdez-Fragoso, A.; Mujica-Paz, H.; Giroux, F.; Welti-Chanes, J. Reuse of sucrose syrup in pilot-scale osmotic dehydration of apple cubes. J. Food Process. Eng. 2002, 25, 125–139. [Google Scholar] [CrossRef]

- Eren, İ.; Kaymak-Ertekin, F. Optimization of osmotic dehydration of potato using response surface methodology. J. Food Eng. 2007, 79, 344–352. [Google Scholar] [CrossRef]

- Alibas, I. Microwave, air and combined microwave–air-drying parameters of pumpkin slices. LWT Food Sci. Technol. 2007, 40, 1445–1451. [Google Scholar] [CrossRef]

- Yadav, A.K.; Singh, S.V. Osmotic dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2014, 51, 1654–1673. [Google Scholar] [CrossRef] [PubMed]

- Shamaei, S.; Emam-Djomeh, Z.; Moini, S. Ultrasound-assisted osmotic dehydration of cranberries: Effect of finish drying methods and ultrasonic frequency on textural properties. J. Texture Stud. 2012, 43, 133–141. [Google Scholar] [CrossRef]

- Singh, S.; Raina, C.S.; Bawa, A.S.; Saxena, D.C. Effect of pretreatments on drying and rehydration kinetics and color of sweet potato slices. Dry. Technol. 2006, 24, 1487–1494. [Google Scholar] [CrossRef]

- Phisut, N.; Rattanawedee, M.; Aekkasak, K. Effect of osmotic dehydration process on the physical, chemical and sensory properties of osmo-dried cantaloupe. Int. Food Res. J. 2013, 20, 189–196. [Google Scholar]

| T (°C) | Dew (m2 s−1) | Des (m2 s−1) | ||

|---|---|---|---|---|

| Ratio 1/4 | Ratio 1/6 | Ratio 1/4 | Ratio 1/6 | |

| 25 | 0.94 × 10−10 ± 1.05 × 10−11 Aa | 0.95 × 10−10 ± 1.73 × 10−11 Aa | 0.56 × 10−10 ± 1.40 × 10−11 Aa | 0.43 × 10−10 ± 1.65 × 10−8 Aa |

| 35 | 1.66 × 10−10 ± 1.35 × 10−11 Ba | 1.63 × 10−10 ± 3.53 × 10−11 Ba | 1.19 × 10−10 ± 2.32 × 10−11 Ba | 1.12 × 10−10 ± 1.14 × 10−11 Ba |

| 45 | 2.10 × 10−10 ± 1.67 × 10−11 Ca | 2.11 × 10−10 ± 3.28 × 10−11 Ca | 1.53 × 10−10 ± 2.94 × 10−11 Ca | 1.48 × 10−7 ± 2.59 × 10−11 Ca |

| T (°C) | Deff (m2 s−1) | |

|---|---|---|

| Control | OD | |

| 70 | 0.95 × 10−10 ± 1.05 × 10−11 a | 1.21 × 10−10 ± 1.73 × 10−11 a |

| 60 | 0.88 × 10−10 ± 1.35 × 10−11 a | 0.97 × 10−10 ± 0.53 × 10−11 a |

| 50 | 0.55 × 10−10 ± 0.67 × 10−11 b | 0.77 × 10−10 ± 0.28 × 10−11 b |

| Drying Temperature (°C) | |||

|---|---|---|---|

| TDR (h) | 50 °C | 60 °C | 70 °C |

| Control | 36.5 ± 1.2 aA | 21.2 ± 0.8 bA | 16.1 ± 0.8 cC |

| OD | 19.1 ± 2.4 aB | 12.0 ± 1.5 bB | 11.2 ± 0.9 bB |

| Quality Parameters | OD-Pretreated Figs | Untreated Figs |

|---|---|---|

| Firmness (N) | 18.87 ± 2.84 a | 31.84 ± 4.14 b |

| Color (flesh) | ||

| L* | 29.61 ± 1.58 a | 33.03 ± 1.98 b |

| a* | 14.24 ± 2.33 a | 14.09 ± 3.25 a |

| b* | 19.93 ± 2.51 a | 18.82 ± 3.17 a |

| Color (skin) | ||

| L* | 25.36 ± 3.28 a | 24.47 ± 2.84 a |

| a* | 3.99 ± 0.89 a | 4.17 ± 0.91 a |

| b* | 6.44 ± 2.86 a | 6.83 ± 3.15 a |

| Nutritional Parameter | OD-Pretreated Figs | Untreated Figs |

|---|---|---|

| Total phenolic content (mg CAE/100 g d.w.) | 26.34 ± 0.25 b | 22.31 ± 0.26 a |

| Total flavonoids (mg catechin/100 g d.w.) | 5.16 ± 0.33 b | 4.47 ± 0.11 a |

| Antioxidant capacity (mg Trolox/100 g d.w.) | 14.18 ± 0.16 b | 13.14 ± 0.05 a |

| Total fibers (g/100 g d.w.) | 10.50 ± 0.85 a | 8.52 ± 1.22 a |

| Proteins (g/100 g d.w.) | 9.33 ± 0.82 a | 11.01 ± 0.95 a |

| Glucose (mg/100 g d.w.) | 0.73 ± 0.05 b | 0.64 ± 0.08 a |

| Fructose (mg/100 g d.w.) | 1.43 ± 0.02 b | 1.25 ± 0.06 a |

| Glycerol (mg/100 g d.w.) | 3.00 ± 0.56 a | - |

| Ascorbic acid (mg/100 g d.w.) | 15.61 ± 3.61 a | 33.94 ± 2.21 b |

| Citric acid (mg/g d.w.) | 9.20 ± 1.12 a | 15.8 ± 0.25 b |

| Tartaric acid (mg/100 g d.w.) | 1.65 ± 0.28 a | 3.03 ± 0.91 b |

| Malic acid (mg/100 g d.w.) | 2.75 ± 0.17 a | 8.15 ± 1.52 b |

| Lactic acid (mg/100 g d.w.) | 0.72 ± 0.12 a | 1.12 ± 0.22 b |

| Storage Temperature (°C) | K (d−1) | |

|---|---|---|

| Control | OD | |

| 25 | 0.0053 ± 0.0005 aA | 0.0041 ± 0.0004 aB |

| 35 | 0.0192 ± 0.0012 bA | 0.0101 ± 0.0025 bB |

| 45 | 0.0570 ± 0.0095 cA | 0.0313 ± 0.0087 bB |

| Ea (kJ mol−1) | 93.6 ± 3.6 A | 79.9 ± 5.6 B |

| Shelf-life determination at 25 °C (d) | 297 ± 15 A | 411 ± 22 B |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andreou, V.; Thanou, I.; Giannoglou, M.; Giannakourou, M.C.; Katsaros, G. Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying. Foods 2021, 10, 1846. https://doi.org/10.3390/foods10081846

Andreou V, Thanou I, Giannoglou M, Giannakourou MC, Katsaros G. Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying. Foods. 2021; 10(8):1846. https://doi.org/10.3390/foods10081846

Chicago/Turabian StyleAndreou, Varvara, Ioanna Thanou, Marianna Giannoglou, Maria C. Giannakourou, and George Katsaros. 2021. "Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying" Foods 10, no. 8: 1846. https://doi.org/10.3390/foods10081846

APA StyleAndreou, V., Thanou, I., Giannoglou, M., Giannakourou, M. C., & Katsaros, G. (2021). Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying. Foods, 10(8), 1846. https://doi.org/10.3390/foods10081846