Heat and Mass Transfer Modeling to Predict Temperature Distribution during Potato Frying after Pre-Treatment with Pulsed Electric Field

Abstract

:1. Introduction

2. Materials and Methods

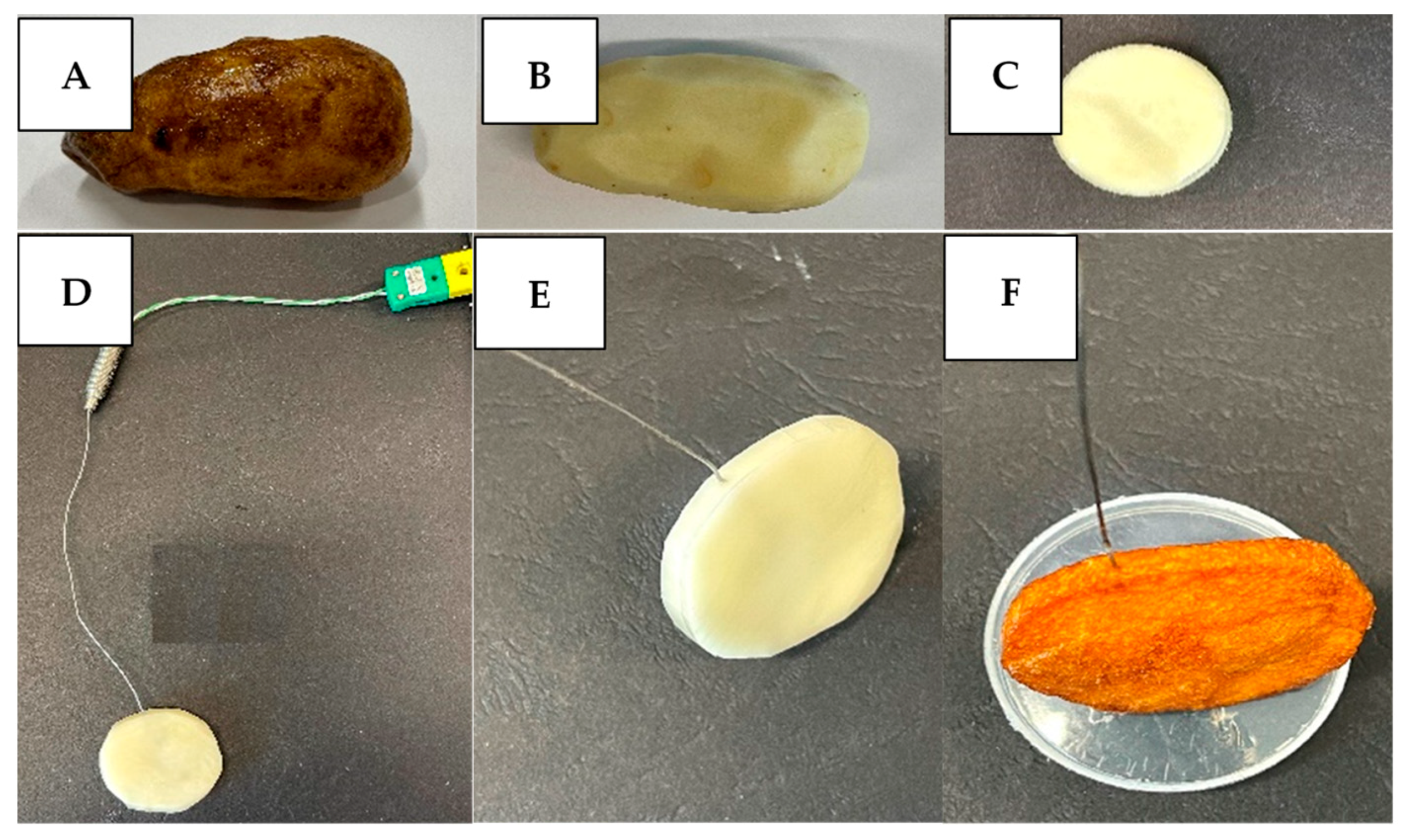

2.1. Sample Preparation and PEF Treatment

2.2. Moisture Content Measurement

2.3. Thermal Conductivity Measurements

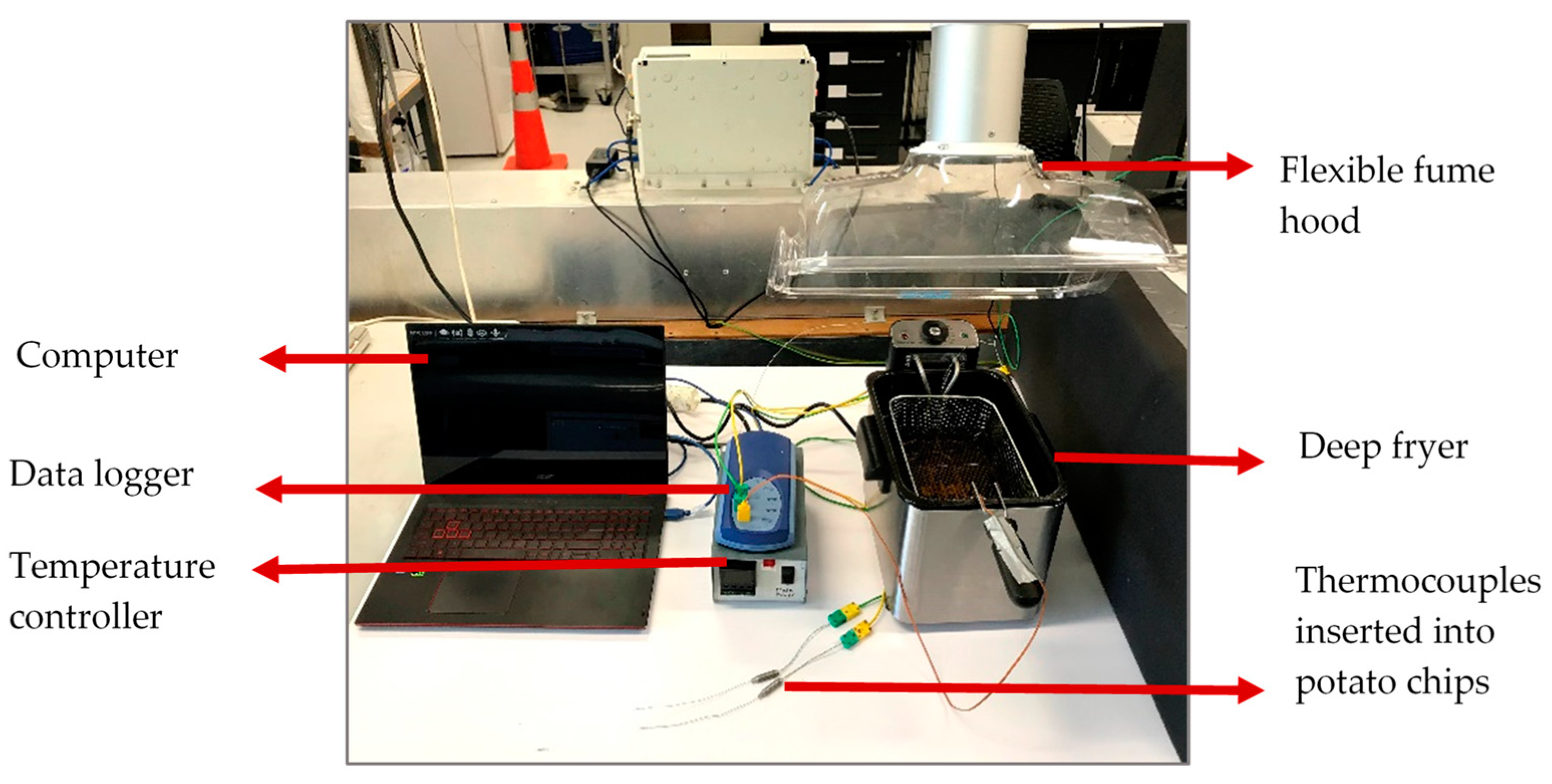

2.4. Potato Frying Experiment

2.5. Measurement of Water Boiling Temperature of Potato

3. Mathematical Modeling

3.1. VSN Method

3.2. Enthalpy Method

3.3. Approximate Quasi-Steady State

4. Results and Discussion

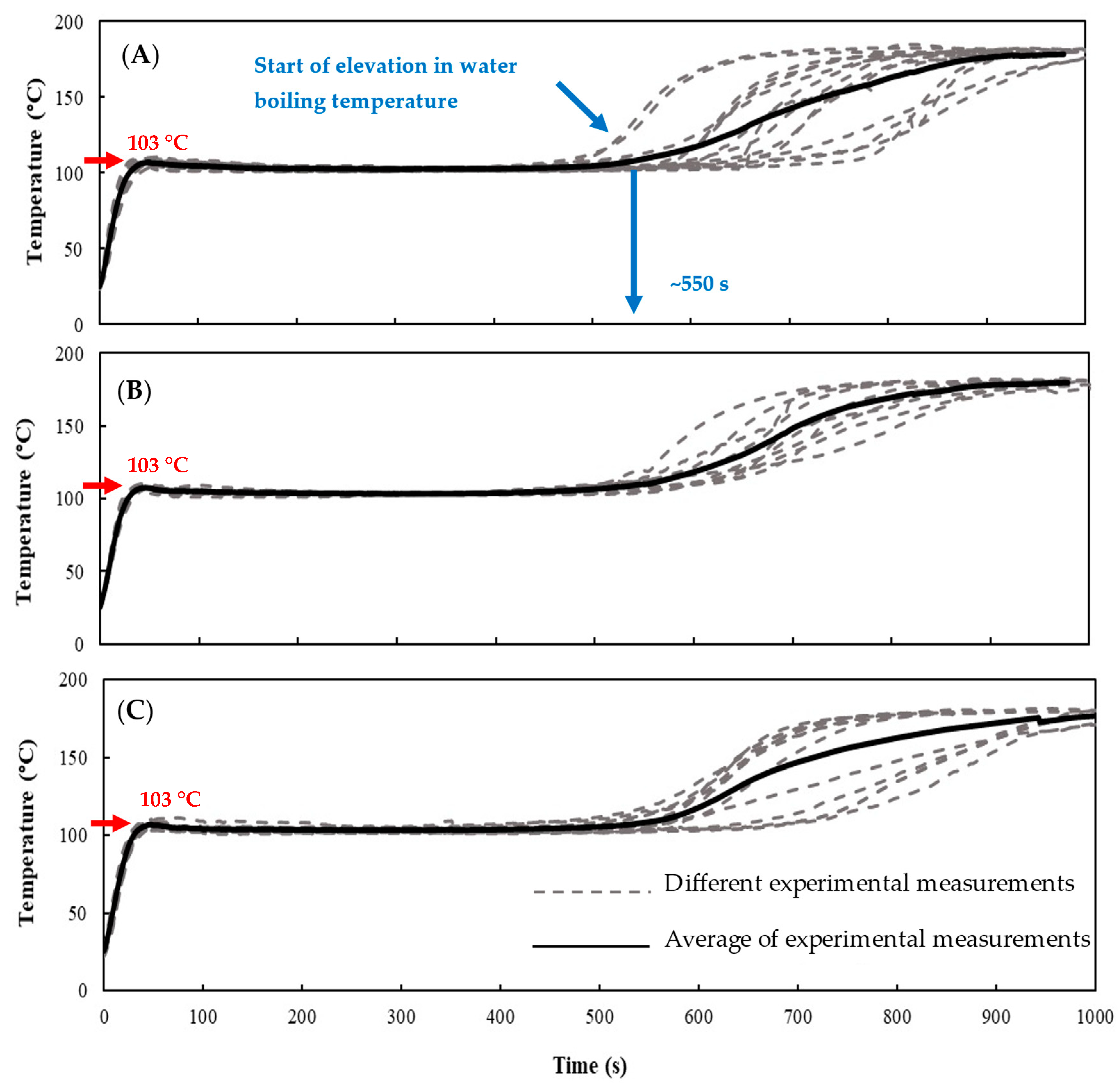

4.1. Experimental Measurements

4.1.1. Effect of PEF Pre-Treatment on the Moisture Content, Thermal Conductivity and the Temperature-Time Profile of Potatoes during Frying

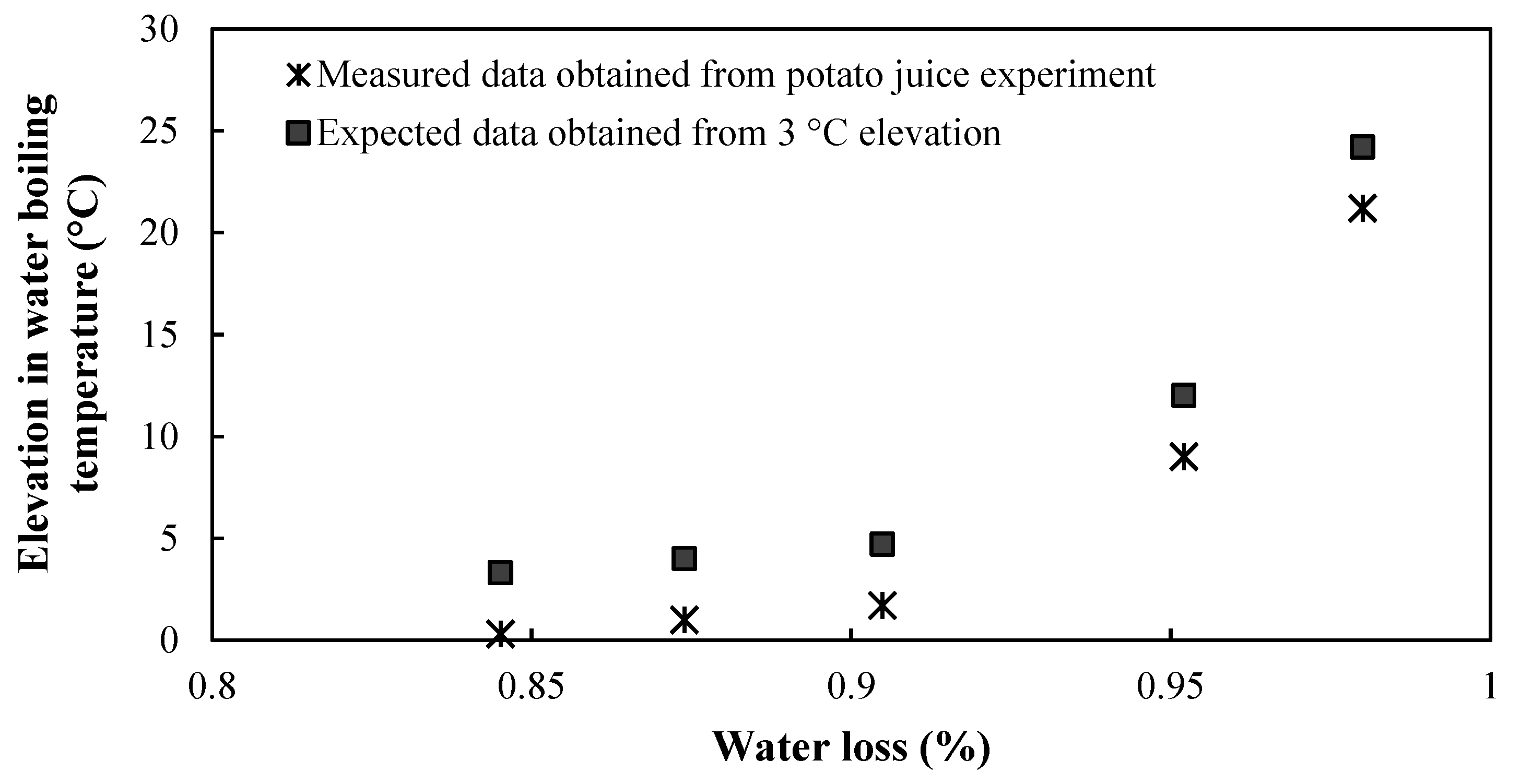

4.1.2. Increase in the Boiling Temperature of Water in Potato during Frying

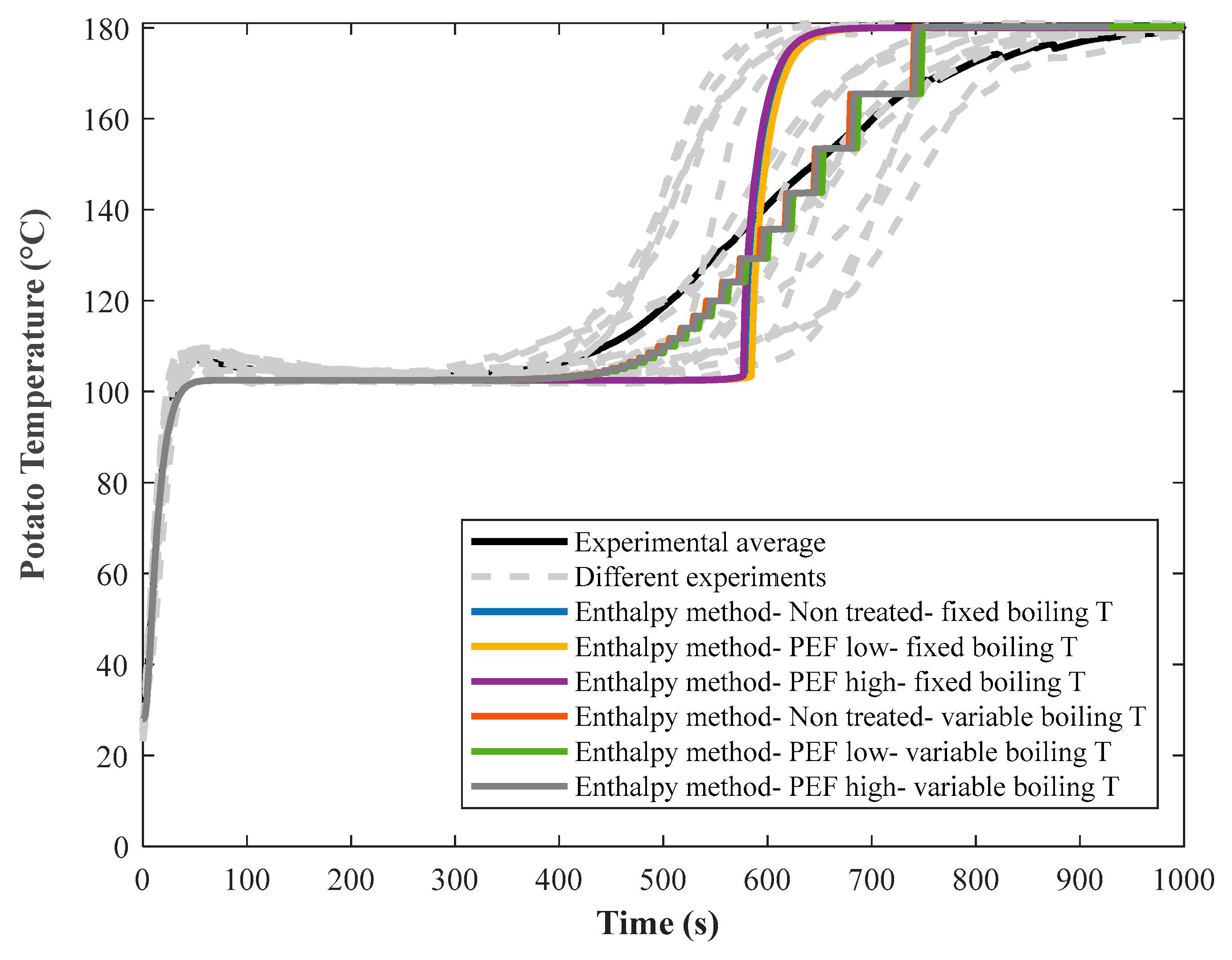

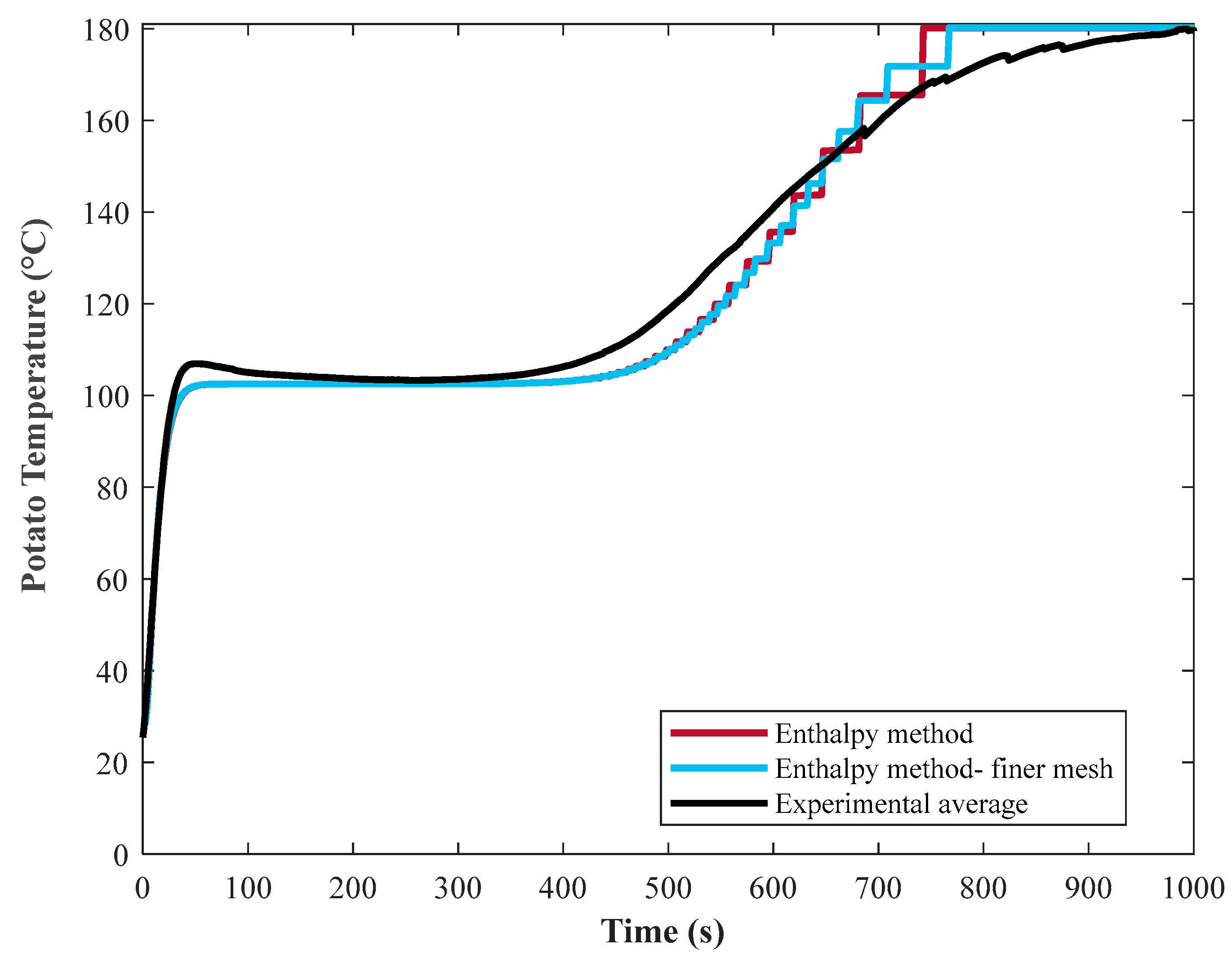

4.2. Mathematical Modeling Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| C | specific heat capacity (J/kg∙K) |

| H | convection/boiling heat transfer coefficient (W/m2∙K) |

| H | enthalpy (J/kg) |

| k | thermal conductivity of potato (W/m∙K) |

| t | time (s) |

| J | number of spatial increments in the crust and core regions |

| T | temperature (°C) |

| w | moisture content (dimensionless) |

| X | crust fraction (dimensionless) |

| y | distance from the surface of potato disc sample (m) |

| Y | distance of the interface from surface of potato disc sample which separates the core and crust regions (m) |

| Greek symbols | |

| α | thermal diffusivity of potato (m2/s) |

| δ | full thickness of the potato disc (m) |

| ε | an arbitrary value representing half the phase change temperature (°C) |

| θ | difference between temperature and the water boiling temperature (°C) |

| Δ | increment |

| ρ | density (kg/m3) |

| λw | latent heat of boiling of water (J/kg) |

| Subscripts | |

| b | boiling |

| co | core |

| cr | crust |

| i | initial state |

| j | space increment |

| n | time increment |

| mushy | a region with a mixture of core and crust |

| o | oil |

| p | potato |

| s | surface of the potato disc sample |

References

- Sumnu, S.G.; Sahin, S. Advances in Deep-Fat Frying of Foods; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Farid, M.; Kizilel, R. A new approach to the analysis of heat and mass transfer in drying and frying of food products. Chem. Eng. Process. Process Intensif. 2009, 48, 217–223. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, J.; Zhang, T.; Fan, L. Effects of frying temperature and pore profile on the oil absorption behavior of fried potato chips. Food Chem. 2021, 345, 128832. [Google Scholar] [CrossRef] [PubMed]

- Farid, M.M.; Chen, X.D. The analysis of heat and mass transfer during frying of food using a moving boundary solution procedure. Heat Mass Transf. Stoffuebertrag. 1998, 34, 69–77. [Google Scholar] [CrossRef]

- Chan, D.-S. Computer simulation with a temperature-step frying approach to mitigate acrylamide formation in French fries. Foods 2020, 9, 200. [Google Scholar] [CrossRef] [Green Version]

- Farinu, A.; Baik, O.-D. Convective mass transfer coefficients in finite element simulations of deep fat frying of sweetpotato. J. Food Eng. 2008, 89, 187–194. [Google Scholar] [CrossRef]

- Dincer, I. Modelling for heat and mass transfer parameters in deep-frying of products. Heat Mass Transf. Stoffuebertrag. 1996, 32, 109–113. [Google Scholar] [CrossRef]

- Costa, R.M.; Oliveira, F.A.R. Modelling the kinetics of water loss during potato frying with a compartmental dynamic model. J. Food Eng. 1999, 41, 177–185. [Google Scholar] [CrossRef]

- Farkas, B.E.; Singh, R.P.; Rumsey, T.R. Modeling heat and mass transfer in immersion frying. I, Model development. J. Food Eng. 1996, 29, 211–226. [Google Scholar] [CrossRef]

- Farid, M.M. A new approach in the calculation of heat transfer with phase change. In Proceedings of the 9th International Congress on Energy and Environment, Miami, FL, USA, 11–13 December 1989; pp. 1–19. [Google Scholar]

- Murray, W.D.; Landis, F. Numerical and machine solutions of transient heat-conduction problems involving melting or freezing: Part I—Method of analysis and sample solutions. J. Heat Transfer 1959, 81, 106–112. [Google Scholar] [CrossRef]

- Southern, C.R.; Farid, M.M.; Chen, X.D.; Howard, B.; Eyres, L. Thermal validation of a simple moving boundary model to determine the frying time of a thin potato crisp. Heat Mass Transf. Stoffuebertrag. 2000, 36, 407–412. [Google Scholar] [CrossRef]

- Botero-Uribe, M.; Fitzgerald, M.; Gilbert, R.G.; Midgley, J. Effect of pulsed electrical fields on the structural properties that affect french fry texture during processing. Trends Food Sci. Technol. 2017, 67, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Fauster, T.; Schlossnikl, D.; Rath, F.; Ostermeier, R.; Teufel, F.; Toepfl, S.; Jaeger, H. Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. J. Food Eng. 2018, 235, 16–22. [Google Scholar] [CrossRef]

- Toepfl, S.; Heinz, V.; Knorr, D. Overview of pulsed electric field processing for food. In Emerging Technologies for Food Processing; Elsevier: Amsterdam, The Netherlands, 2005; pp. 69–97. [Google Scholar]

- Raso, J.; Frey, W.; Ferrari, G.; Pataro, G.; Knorr, D.; Teissie, J.; Miklavčič, D. Recommendations guidelines on the key information to be reported in studies of application of PEF technology in food and biotechnological processes. Innov. Food Sci. Emerg. Technol. 2016, 37, 312–321. [Google Scholar] [CrossRef] [Green Version]

- Oey, I.; Roohinejad, S.; Leong, S.Y.; Faridnia, F.; Lee, P.Y.; Kethireddy, V. Pulsed electric field processing: Its technological opportunities and consumer perception. Food Process. Technol. 2016, 447–516. [Google Scholar]

- Xu, Z.; Leong, S.Y.; Farid, M.; Silcock, P.; Bremer, P.; Oey, I. Understanding the frying process of plant-based foods pretreated with pulsed electric fields using frying models. Foods 2020, 9, 949. [Google Scholar] [CrossRef] [PubMed]

- Farid, M.; Butcher, S. A generalized correlation for heat and mass transfer in freezing, drying, frying, and freeze drying. Dry. Technol. 2003, 21, 231–247. [Google Scholar] [CrossRef]

- Voller, V.R. A general enthalpy method for modeling solidification phenomena. TMS Annu. Meet. 2010, 23, 113–122. [Google Scholar]

- Ananthanarayanan, L.; Lahiri, A.K. An ADI enthalpy method for two dimensional solidification. Int. Commun. Heat Mass Transf. 1992, 19, 629–637. [Google Scholar] [CrossRef]

- Erchiqui, F.; Kaddami, H.; Slaoui-Hasnaoui, F.; Koubaa, A. 3D finite element enthalpy method for analysis of phytosanitary treatment of wood by microwave. Eur. J. Wood Wood Prod. 2020, 78, 577–591. [Google Scholar] [CrossRef]

- Smith, M.C.; Farid, M. A single correlation for the prediction of dehydration time in drying and frying of samples having different geometry and size. J. Food Eng. 2004, 63, 265–271. [Google Scholar] [CrossRef]

- Liu, T.; Dodds, E.; Leong, S.Y.; Eyres, G.T.; Burritt, D.J.; Oey, I. Effect of pulsed electric fields on the structure and frying quality of “kumara” sweet potato tubers. Innov. Food Sci. Emerg. Technol. 2017, 39, 197–208. [Google Scholar] [CrossRef]

- Pedreschi, F.; Hernández, P.; Figueroa, C.; Moyano, P. Modeling water loss during frying of potato slices. Int. J. Food Prop. 2005, 8, 289–299. [Google Scholar] [CrossRef]

- Kaparaju, P.; Rintala, J. Anaerobic co-digestion of potato tuber and its industrial by-products with pig manure. Resour. Conserv. Recycl. 2005, 43, 175–188. [Google Scholar] [CrossRef]

- Southern, C.R.; Chen, X.D.; Farid, M.M.; Howard, B.; Eyres, L. Determining internal oil uptake and water content of fried thin potato crisps. Food Bioprod. Process. Trans. Inst. Chem. Eng. Part C 2000, 78, 119–125. [Google Scholar] [CrossRef]

- Lacroix, M. Numerical simulation of a shell-and-tube latent heat thermal energy storage unit. Sol. Energy 1993, 50, 357–367. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. Experimental and mathematical modeling of an air-PCM heat exchanger operating under static and dynamic loads. Energy Build. 2019, 202, 109354. [Google Scholar] [CrossRef]

- Farid, M. A unified approach to the heat and mass transfer in melting, solidification, frying and different drying processes. Chem. Eng. Sci. 2001, 56, 5419–5427. [Google Scholar] [CrossRef]

- Carson, J.K. Review of effective thermal conductivity models for foods. Int. J. Refrig. 2006, 29, 958–967. [Google Scholar] [CrossRef]

- Sablani, S.S.; Rahman, M.S. Using neural networks to predict thermal conductivity of food as a function of moisture content, temperature and apparent porosity. Food Res. Int. 2003, 36, 617–623. [Google Scholar] [CrossRef]

- Costa, R.M.; Oliveira, F.A.R.; Boutcheva, G. Structural changes and shrinkage of potato during frying. Int. J. food Sci. Technol. 2001, 36, 11–23. [Google Scholar] [CrossRef]

- Pravisani, C.I.; Calvelo, A. Minimum cooking time for potato strip frying. J. Food Sci. 1986, 51, 614–617. [Google Scholar] [CrossRef]

- Tressler, C.J.; Zimmerman, W.I.; Willits, C.O. Boiling-point elevation of sucrose solutions. J. Phys. Chem. 1941, 45, 1242–1245. [Google Scholar] [CrossRef]

- Bialik, M.; Sedin, P.; Theliander, H. Boiling point rise calculations in sodium salt solutions. Ind. Eng. Chem. Res. 2008, 47, 1283–1287. [Google Scholar] [CrossRef]

- Dellarosa, N.; Ragni, L.; Laghi, L.; Tylewicz, U.; Rocculi, P.; Dalla Rosa, M. Time domain nuclear magnetic resonance to monitor mass transfer mechanisms in apple tissue promoted by osmotic dehydration combined with pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2016, 37, 345–351. [Google Scholar] [CrossRef]

- Tylewicz, U.; Aganovic, K.; Vannini, M.; Toepfl, S.; Bortolotti, V.; Dalla Rosa, M.; Oey, I.; Heinz, V. Effect of pulsed electric field treatment on water distribution of freeze-dried apple tissue evaluated with DSC and TD-NMR techniques. Innov. Food Sci. Emerg. Technol. 2016, 37, 352–358. [Google Scholar] [CrossRef]

- Faridnia, F.; Burritt, D.J.; Bremer, P.J.; Oey, I. Innovative approach to determine the effect of pulsed electric fields on the microstructure of whole potato tubers: Use of cell viability, microscopic images and ionic leakage measurements. Food Res. Int. 2015, 77, 556–564. [Google Scholar] [CrossRef]

- Liu, C.; Grimi, N.; Lebovka, N.; Vorobiev, E. Effects of pulsed electric fields treatment on vacuum drying of potato tissue. Lwt 2018, 95, 289–294. [Google Scholar] [CrossRef]

- Bordin, K.; Tomihe Kunitake, M.; Kazue Aracava, K.; Silvia Favaro Trindade, C. Changes in food caused by deep fat frying-A review. Arch. Latinoam. Nutr. 2013, 63, 5–13. [Google Scholar]

) and 3 °C temperature correction expected (■) due to the effect of steam bubble nucleation in the superheated interface separating crust and core.

) and 3 °C temperature correction expected (■) due to the effect of steam bubble nucleation in the superheated interface separating crust and core.

) and 3 °C temperature correction expected (■) due to the effect of steam bubble nucleation in the superheated interface separating crust and core.

) and 3 °C temperature correction expected (■) due to the effect of steam bubble nucleation in the superheated interface separating crust and core.

| Property | Core | Crust | Reference |

|---|---|---|---|

| Thermal conductivity of potato, k (W/m∙K) | 0.73 | 0.11 | Current work |

| Potato density, ρ (kg/m3) | 1132 | 386 | [4] |

| Specific heat capacity of potato, Cp (kJ/kg∙K) | 3.450 | 1.790 | [4] |

| Parameter | Value | ||

| Convection heat transfer coefficient | 250 W/m2∙K | [4] | |

| Boiling heat transfer coefficient | 500 W/m2∙K | [4] | |

| Initial moisture content | 0.738 | Current work |

| Potato Surface | Potato Center | Overall Average † | |||||

|---|---|---|---|---|---|---|---|

| Average * | Min | Max | Average * | Min | Max | ||

| Untreated | 72.7± 2.8 | 69.8 | 76.9 | 74.3 ± 3.3 | 70.1 | 81.6 | 73.5 |

| PEF Low | 75.6 ± 4.2 | 71.2 | 80.2 | 73.3 ± 3.1 | 68.1 | 76.0 | 74.4 |

| PEF High | 73.6 ± 4.7 | 68.6 | 80.2 | 73.1 ± 3.8 | 68.3 | 79.0 | 73.3 |

| Fresh Potato | Fried Potato | |||||

|---|---|---|---|---|---|---|

| Average * | Min | Max | Average * | Min | Max | |

| Untreated | 0.73 ± 0.04 | 0.68 | 0.75 | 0.11 ± 0.01 | 0.10 | 0.11 |

| PEF Low | 0.73 ± 0.03 | 0.71 | 0.76 | 0.11 ± 0.01 | 0.10 | 0.11 |

| PEF High | 0.78 ± 0.01 | 0.77 | 0.78 | 0.10 ± 0.00 | 0.10 | 0.10 |

| Experimental Measurements | Average * | Min | Max |

|---|---|---|---|

| Initial potato mass before drying (g) | 6.4 ± 0.9 | 5.6 | 7.5 |

| Initial water mass (g) a | 4.8 ± 0.7 | 4.0 | 5.6 |

| Water remained after partial frying (g) b | 1.0 ± 0.3 | 0.6 | 1.4 |

| % of water remaining after partial frying c | 21.0 ± 5.3 | 14.0 | 28.0 |

| % of water removed after partial frying d | 79.0 ± 5.4 | 71.5 | 85.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholamibozanjani, G.; Leong, S.Y.; Oey, I.; Bremer, P.; Silcock, P.; Farid, M. Heat and Mass Transfer Modeling to Predict Temperature Distribution during Potato Frying after Pre-Treatment with Pulsed Electric Field. Foods 2021, 10, 1679. https://doi.org/10.3390/foods10081679

Gholamibozanjani G, Leong SY, Oey I, Bremer P, Silcock P, Farid M. Heat and Mass Transfer Modeling to Predict Temperature Distribution during Potato Frying after Pre-Treatment with Pulsed Electric Field. Foods. 2021; 10(8):1679. https://doi.org/10.3390/foods10081679

Chicago/Turabian StyleGholamibozanjani, Gohar, Sze Ying Leong, Indrawati Oey, Phil Bremer, Patrick Silcock, and Mohammed Farid. 2021. "Heat and Mass Transfer Modeling to Predict Temperature Distribution during Potato Frying after Pre-Treatment with Pulsed Electric Field" Foods 10, no. 8: 1679. https://doi.org/10.3390/foods10081679

APA StyleGholamibozanjani, G., Leong, S. Y., Oey, I., Bremer, P., Silcock, P., & Farid, M. (2021). Heat and Mass Transfer Modeling to Predict Temperature Distribution during Potato Frying after Pre-Treatment with Pulsed Electric Field. Foods, 10(8), 1679. https://doi.org/10.3390/foods10081679