Sensory and Physicochemical Quality, Residual Fungicide Levels and Microbial Load in ‘Florida Radiance’ Strawberries from Different Disease Control Treatments Exposed to Simulated Supply Chain Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material and Disease Control Treatments

2.2. Postharvest Treatments

2.3. Sensory Analysis

2.4. Instrumental Color and Texture Analysis

2.5. Weight Loss and Dry Weight

2.6. Acidity and Soluble Solids Content

2.7. Sugar Analysis

2.8. Ascorbic Acid Analysis

2.9. Total Phenolics and Anthocyanin Analysis

2.10. Fungicide Analysis

2.11. Microbial Analysis

2.12. Statistical Analysis

3. Results

3.1. Sensory Quality

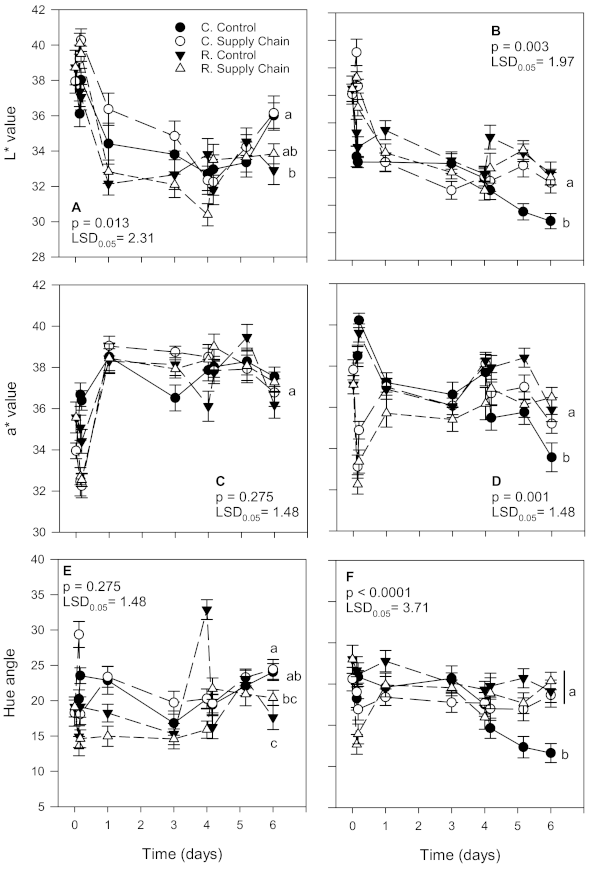

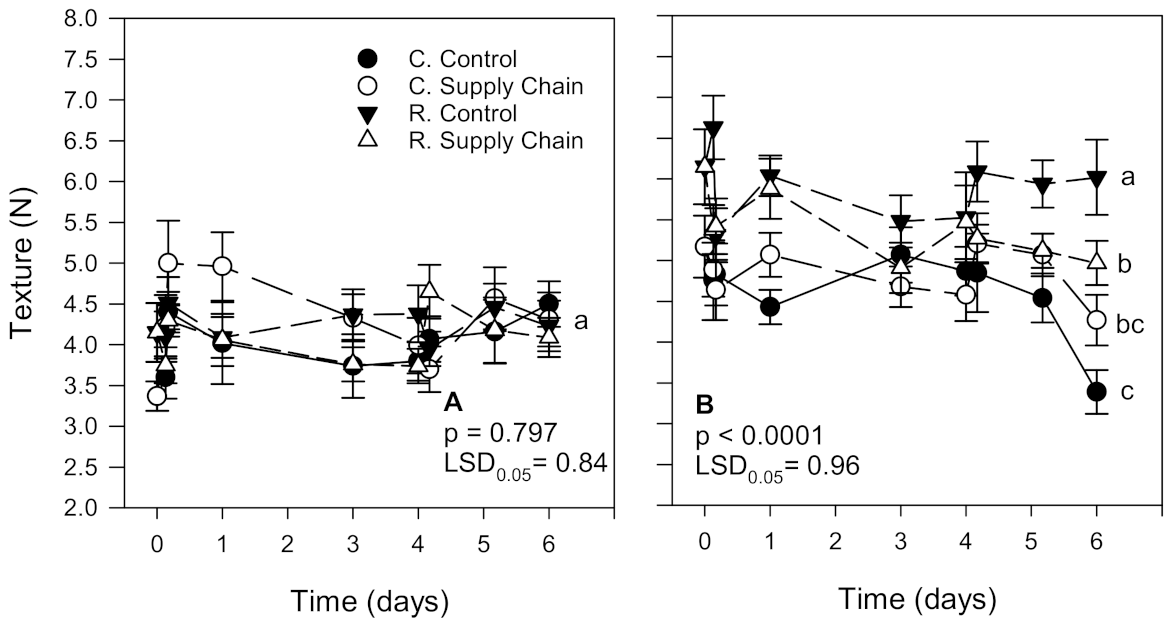

3.2. Color and Texture

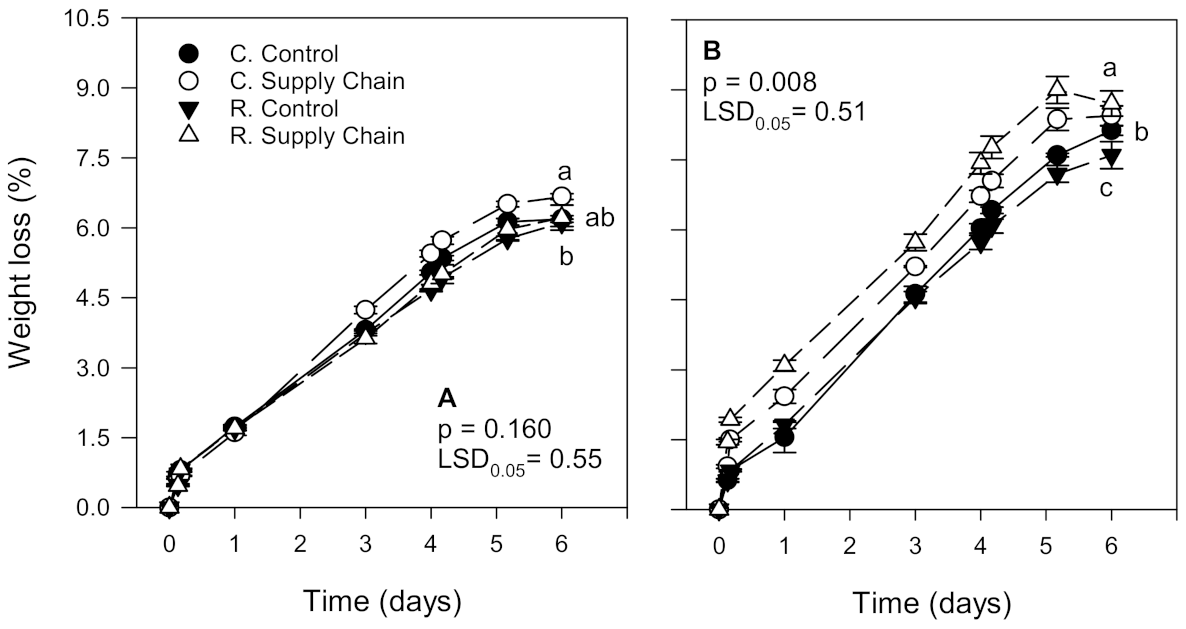

3.3. Weight Loss

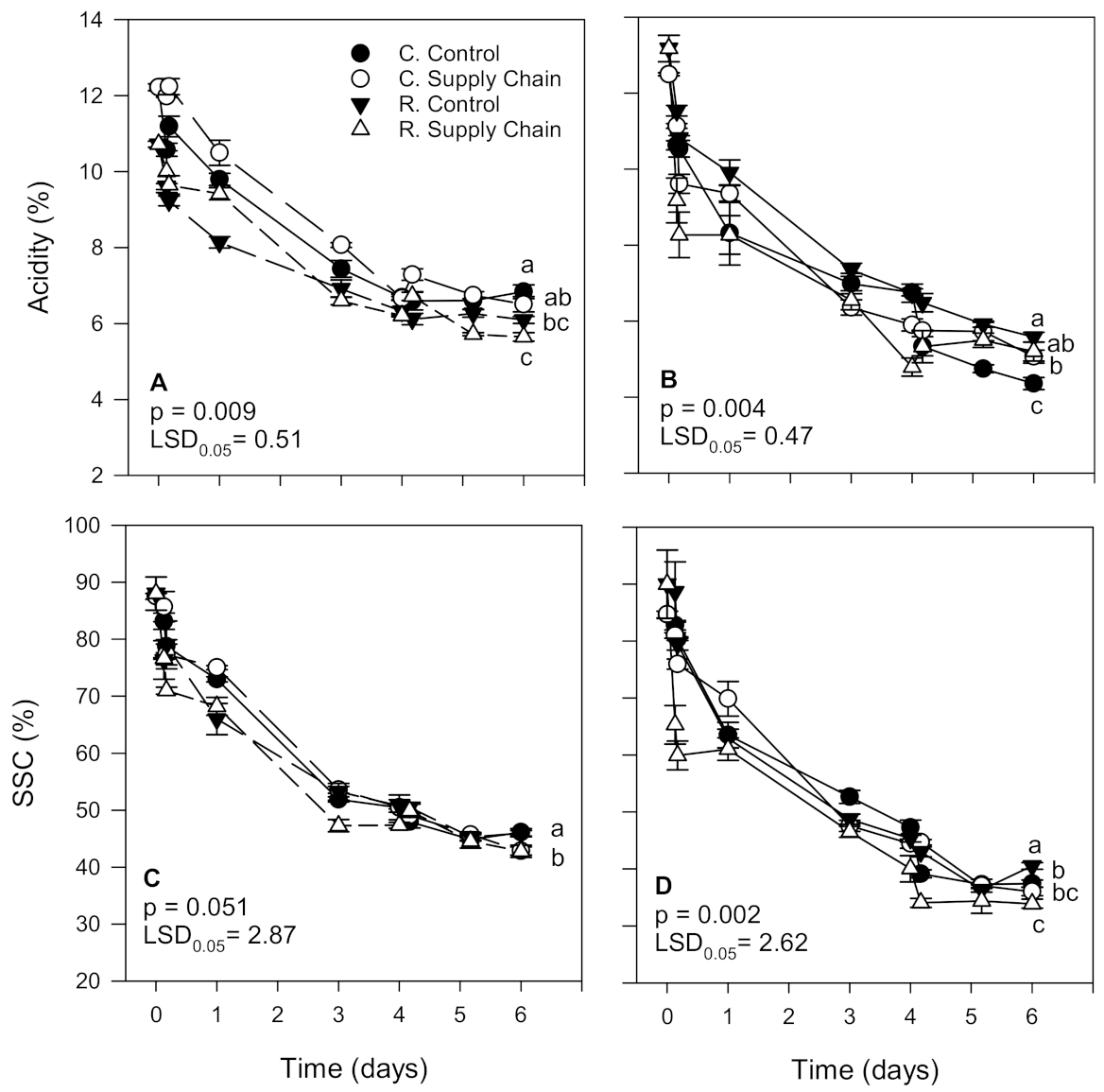

3.4. Acidity and Soluble Solids Content

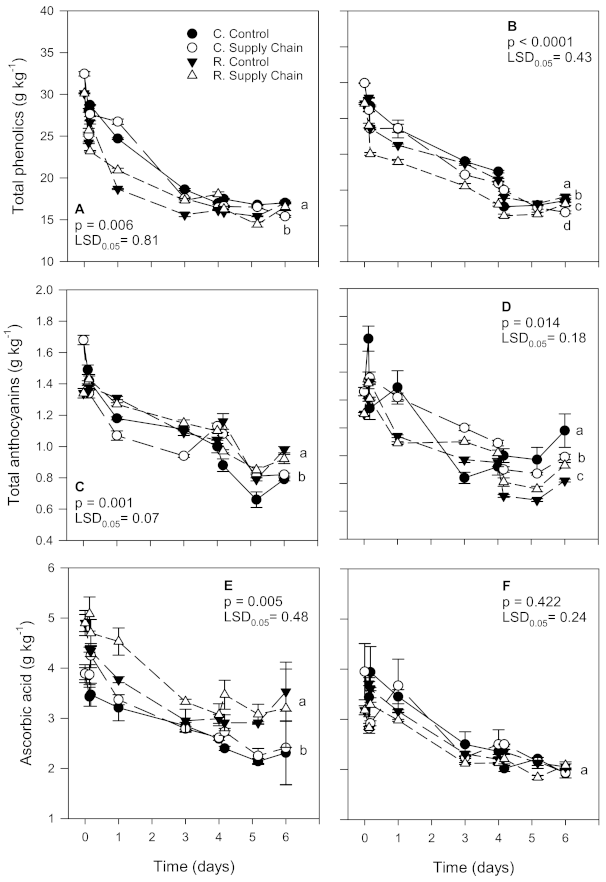

3.5. Bioactive Compounds

3.6. Sugar Profiles

3.7. Residual Fungicides

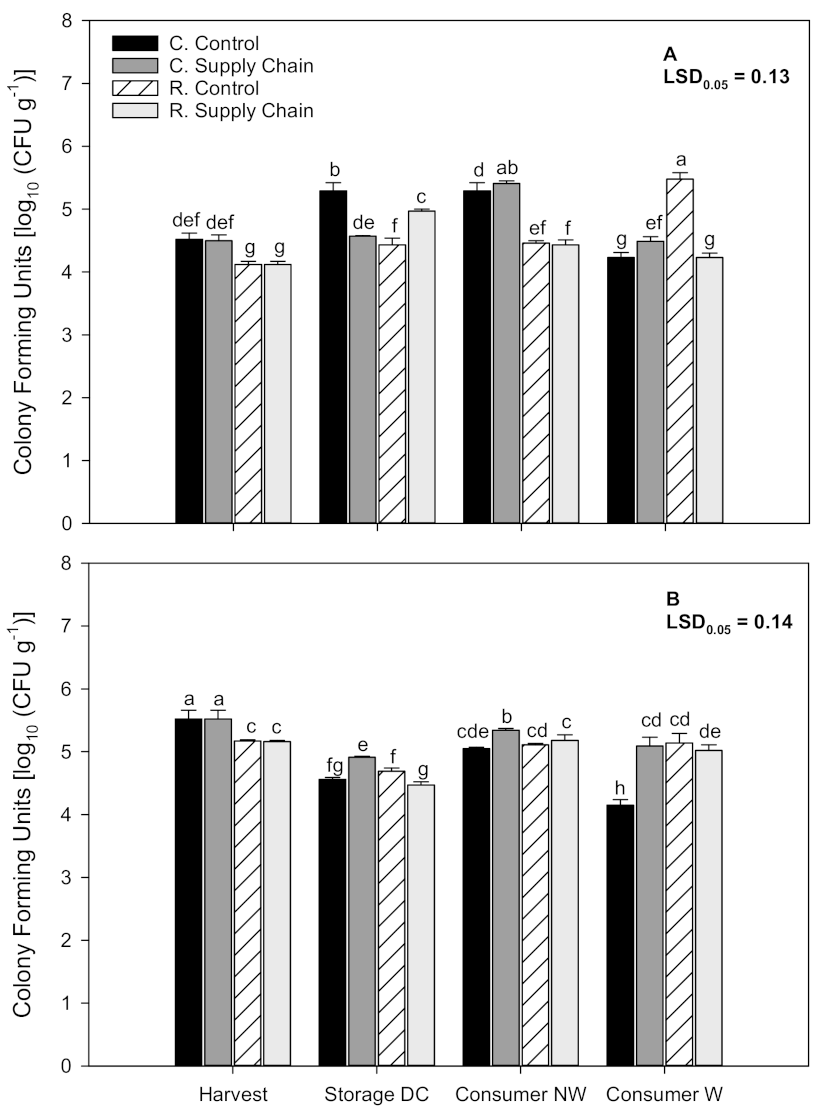

3.8. Microbial Load

4. Discussion

4.1. Effect of Cultivation Methods and Supply Chain Conditions on Sensory Quality, Color, and Texture

4.2. Effect of Cultivation Methods and Supply Chain Conditions on Chemical Attributes

4.3. Effect of Cultivation Methods and Supply Chain Conditions on Bioactive Compounds

4.4. Effect of Cultivation Methods and Supply Chain Conditions on Sugar Profiles

4.5. Effect of Cultivation Methods and Supply Chain Conditions on Residual Fungicides

4.6. Effect of Cultivation Methods and Supply Chain Conditions on Microbial Load

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Nunes, M.C.N.; Emond, J.P.; Rauth, M.; Dea, S.; Chau, K.V. Environmental conditions encountered during typical consumer retail display affect fruit and vegetable quality and waste. Postharvest Biol. Technol. 2009, 51, 232–241. [Google Scholar] [CrossRef]

- Buzby, J.C.; Hyman, J.; Stewart, H.; Wells, H.F. The value of retail-and consumer-level fruit and vegetable losses in the United States. J. Consum. Aff. 2011, 45, 492–515. [Google Scholar] [CrossRef]

- Porat, R.; Litcher, A.; Teryy, L.A.; Harker, R.; Bubzy, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef]

- Muth, M.K.; Karns, S.A.; Nilese, S.J.; Bubzy, J.C.; Wells, H.F. Consumer-Level Food Loss Estimates and Their Use in the ERS Loss-Adjusted Food Availability Data; DIANE Publishing: Darby, PA, USA, 2011; Available online: https://grist.org/wp-content/uploads/2011/11/tb1927.pdf (accessed on 25 May 2021).

- Terry, L.; Mena, C.; Williams, A.; Jenny, N.; Whitehead, P. Fruit and Vegetable Resource Maps: Mapping Fruit and Vegetable Waste through the Retail and Wholesale Supply Chain; WRAP RC008; WRAP: Banbury, UK, 2011; Available online: https://www.wrap.org.uk/retail (accessed on 18 June 2021).

- Lai, Y.; Emond, J.P.; Nunes, M.C.N. Environmental conditions encountered during distribution from the field to the store affect the quality of strawberry (‘Albion’). Proc. Fla. State Hort. Soc. 2011, 124, 213–220. [Google Scholar]

- Kelly, K.; Madden, R.; Emond, J.P.; Nunes, M.C.N. A novel approach to determine the impact level of each step along the supply chain on strawberry quality. Postharvest Biol. Technol. 2019, 147, 78–88. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Morais, A.; Brecht, J.; Sargent, S.; Bartz, J. Prompt cooling reduces incidence and severity of decay caused by Botrytis cinerea and Rhizopus stolonifer in strawberry. HortTechnology 2005, 15, 153–156. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Emond, J.P.; Brecht, J. Quality of strawberries as affected by temperature abuse during ground, in-flight and retail handling operations. Acta Hort. 2003, 604, 239–246. [Google Scholar] [CrossRef]

- Jalali, A.; Linke, M.; Geyer, M.; Mahajan, P.V. Shelf-life prediction model for strawberry based on respiration and transpiration processes. Food Packag. Shelf. 2020, 25, 100525. [Google Scholar] [CrossRef]

- Joshi, K.; Tiwari, B.; Cullen, P.J.; Frias, J.M. Predicting quality attributes of strawberry packed under modified atmosphere throughout the cold chain. Food Packag. Shelf. 2019, 21, 100354. [Google Scholar] [CrossRef]

- Flessa, S.; Lusk, D.M.; Harris, L.J. Survival of Listeria monocytogenes on fresh and frozen strawberries. Int. J. Food Micro. 2005, 101, 255–262. [Google Scholar] [CrossRef]

- Lafarga, T.; Colás-Medà, P.; Abadias, M.; Aguiló-Aguayo, I.; Bobo, G.; Viñas, I. Strategies to reduce microbial risk and improve quality of fresh and processed strawberries: A review. Innov. Food Sci. Emerg Technol. 2019, 52, 197–212. [Google Scholar] [CrossRef]

- Dai, B.; Yang, H.; Dai, X.; Wang, W.; Wu, S.; Zhao, X.; Xiao, Y. Microbial composition changes on the surface of strawberries from the field and market by 16SrDNA sequencing. J. Food Saf. 2019, 39, e12630. [Google Scholar] [CrossRef]

- Abountiolas, M.; Kelly, K.; Yagiz, Y.; Li, Z.; Mahnken, G.; Borejsza-Wysocki, W.; Marshall, M.; Sims, C.A.; Peres, N.; do Nascimento Nunes, M.C. Sensory Quality, Physicochemical Attributes, Polyphenol Profiles, and Residual Fungicides in Strawberries from Different Disease-Control Treatments. J. Agric. Food Chem. 2018, 66, 6986–6996. [Google Scholar] [CrossRef]

- Legard, D.; Xiao, C.; Mertely, J.; Chandler, C. Effects of plant spacing and cultivar on incidence of Botrytis fruit rot in annual strawberry. Plant Dis. 2000, 84, 531–538. [Google Scholar] [CrossRef]

- Cardoso, P.C.; Tomazini, A.P.B.; Stringheta, P.C.; Ribeiro, S.M.R.; Pinheiro-Sant’Ana, H.M. Vitamin C and carotenoids in organic and conventional fruits grown in Brazil. Food Chem. 2011, 126, 411–416. [Google Scholar] [CrossRef]

- Crecente-Campo, J.; Nunes-Damaceno, M.; Romero-Rodríguez, M.A.; Vázquez-Odériz, M.L. Color, anthocyanin pigment, ascorbic acid and total phenolic compound determination in organic versus conventional strawberries (Fragaria × ananassa Duch, cv Selva). J. Food Compos. Anal. 2012, 28, 23–30. [Google Scholar] [CrossRef]

- Häkkinen, S.H.; Törrönen, A.R. Content of flavonols and selected phenolic acids in strawberries and Vaccinium species: Influence of cultivar, cultivation site and technique. Food Res. Int. 2000, 33, 517–524. [Google Scholar] [CrossRef]

- Jin, P.; Wang, S.Y.; Wang, C.Y.; Zheng, Y. Effect of cultural system and storage temperature on antioxidant capacity and phenolic compounds in strawberries. Food Chem. 2011, 124, 262–270. [Google Scholar] [CrossRef]

- Reganold, J.P.; Andrews, P.K.; Reeve, J.R.; Carpenter-Boggs, L.; Schadt, C.W.; Alldredge, J.R.; Ross, C.F.; Davies, N.M.; Zhou, J. Fruit and soil quality of organic and conventional strawberry agroecosystems. PLoS ONE 2010, 5, e12346. [Google Scholar] [CrossRef]

- Abountiolas, M.; do Nascimento Nunes, M.C. Anthocyanins and in vitro antioxidant capacity of strawberries from different disease control treatments. Proc. Fla. State Hort. Soc. 2016, 129, 226–230. [Google Scholar]

- Fernandes, V.C.; Domingues, V.F.; de Freitas, V.; Delerue-Matos, C.; Mateus, N. Strawberries from integrated pest management and organic farming: Phenolic composition and antioxidant properties. Food Chem. 2012, 134, 1926–1931. [Google Scholar] [CrossRef] [PubMed]

- Cordova, L.G.; Madden, L.V.; Amiri, A.; Schnabel, G.; Peres, N.A. Meta-analysis of a web-based disease forecast system for control of anthracnose and Botrytis fruit rots of strawberry in Southeastern United States. Plant Dis. 2017, 101, 1910–1917. [Google Scholar] [CrossRef]

- Pavan, W.; Fraisse, C.; Peres, N. Development of a web-based disease forecasting system for strawberries. Comput. Electron. Agric. 2011, 75, 169–175. [Google Scholar] [CrossRef]

- MacKenzie, S.J.; Peres, N.A. Use of leaf wetness and temperature to time fungicide applications to control Botrytis fruit rot of strawberry in Florida. Plant Dis. 2012, 96, 529–536. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Guan, Z.; Whitaker, V. Optimizing yield distribution under biological and economic constraints: Florida strawberries as a model for perishable commodities. Agric. Sys. 2015, 141, 113–120. [Google Scholar] [CrossRef]

- Whitaker, V.M.; Chandler, C.K.; Santos, B.M.; Peres, N.; do Nascimento Nunes, M.C.; Plotto, A.; Sims, C.A. Advances in strawberry breeding at the University of Florida. Acta Hort. 2016, 1156, 1–6. [Google Scholar] [CrossRef]

- Pelletier, W.; Brecht, J.K.; do Nascimento Nunes, M.C.; Émond, J.-P. Quality of strawberries shipped by truck from California to Florida as influenced by postharvest temperature management practices. HortTechnology 2011, 21, 482–493. [Google Scholar] [CrossRef]

- Nunes, M.C.N. Color Atlas of Postharvest Quality of Fruits and Vegetables; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Mitcham, E. The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks; Vol. Handbook 66; USDA—ARS: Washington, DC, USA, 2016. Available online: https://www.ars.usda.gov/arsuserfiles/oc/np/commercialstorage/commercialstorage.pdf (accessed on 18 June 2021).

- Nunes, M.C.N.; Brecht, J.; Morais, A.; Sargent, S. Physical and chemical quality characteristics of strawberries after storage are reduced by a short delay to cooling. Postharvest Biol. Technol. 1995, 6, 17–28. [Google Scholar] [CrossRef]

- FAWN. Florida Automated Weather Network. 2021. Available online: https://fawn.ifas.ufl.edu (accessed on 18 June 2021).

- Godwin, S.L.; Chen, F.-C.; Chambers IV, E.; Coppings, R.; Chambers, D. A comprehensive evaluation of temperatures within home refrigerators. Food Prot. Trends. 2007, 27, 16–21. Available online: https://www.researchgate.net/profile/Fur-Chi-Chen/publication/256115808_Comprehensive_evaluation_of_temperatures_within_home_refrigerators/links/5540dfcb0cf2718618dbb655/Comprehensive-evaluation-of-temperatures-within-home-refrigerators.pdf (accessed on 18 June 2021).

- Kelly, K.; Whitaker, V.M.; Nunes, M.C.N. Physicochemical characterization and postharvest performance of the new Sensation® ‘Florida127’ strawberry compared to commercial standards. Sci. Hort. 2016, 211, 283–294. [Google Scholar] [CrossRef]

- Whitaker, V.; Lee, S.; Osorio, L.; Verma, S.; Roach, J.; Mangandi, J.; Noh, Y.-H.; Gezan, S.; Peres, N. Winterstar™ (‘FL 05-107’) strawberry. HortScience 2012, 47, 296–298. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Brecht, J.K.; Morais, A.; Sargent, S.A. Possible influences of water loss and polyphenol oxidase activity on anthocyanin content and discoloration in fresh ripe strawberry (cv. Oso Grande) during storage at 1C. J. Food Sci. 2005, 70, S79–S84. [Google Scholar] [CrossRef]

- Lehotay, S.J.; Kok, A.d.; Hiemstra, M.; Bodegraven, P.V. Validation of a fast and easy method for the determination of residues from 229 pesticides in fruits and vegetables using gas and liquid chromatography and mass spectrometric detection. J. AOAC Int. 2005, 88, 595–614. [Google Scholar] [CrossRef]

- Lesueur, C.; Knittl, P.; Gartner, M.; Mentler, A.; Fuerhacker, M. Analysis of 140 pesticides from conventional farming foodstuff samples after extraction with the modified QuECheRS method. Food Control. 2008, 19, 906–914. [Google Scholar] [CrossRef]

- Hakala, M.; Lapveteläinen, A.; Huopalahti, R.; Kallio, H.; Tahvonen, R. Effects of varieties and cultivation conditions on the composition of strawberries. J. Food Comp. Anal. 2003, 16, 67–80. [Google Scholar] [CrossRef]

- Kobi, H.; Martins, M.; Silva, P.; Souza, J.; Carneiro, J.; Heleno, F.; Queiroz, M.; Costa, N. Organic and conventional strawberries: Nutritional quality, antioxidant characteristics and pesticide residues. Fruits 2018, 73, 39–47. [Google Scholar] [CrossRef]

- Aninowski, M.; Kazimierczak, R.; Hallmann, E.; Rachtan-Janicka, J.; Fijoł-Adach, E.; Feledyn-Szewczyk, B.; Majak, I.; Leszczyńska, J. Evaluation of the potential allergenicity of strawberries in response to different farming practices. Metabolites 2020, 10, 102. [Google Scholar] [CrossRef]

- Fernandes, V.C.; Domingues, V.F.; Mateus, N.; Delerue-Matos, C. Pesticide residues in Portuguese strawberries grown in 2009–2010 using integrated pest management and organic farming. Environ. Sci. Pollut. Res. 2012, 19, 4184–4192. [Google Scholar] [CrossRef][Green Version]

- Fernandes, V.C.; Lehotay, S.J.; Geis-Asteggiante, L.; Kwon, H.; Mol, H.G.; Van der Kamp, H.; Mateus, N.; Domingues, V.F.; Delerue-Matos, C. Analysis of pesticide residues in strawberries and soils by GC-MS/MS, LC-MS/MS and two-dimensional GC-time-of-flight MS comparing organic and integrated pest management farming. Food Addit. Contam. Part A 2014, 31, 262–270. [Google Scholar] [CrossRef]

- Baker, B.P.; Benbrook, C.M.; Groth, E., 3rd; Lutz Benbrook, K. Pesticide residues in conventional, integrated pest management (IPM)-grown and organic foods: Insights from three US data sets. Food Addit. Contam. 2002, 19, 427–446. [Google Scholar] [CrossRef]

- Fernandes, V.C.; Domingues, V.F.; Mateus, N.; Delerue-Matos, C. Organochlorine pesticide residues in strawberries from integrated pest management and organic farming. J. Agric. Food Chem. 2011, 59, 7582–7591. [Google Scholar] [CrossRef] [PubMed]

- Nunes, M.C.N.; Emond, J.P. Relationship between weight loss and visual quality of fruits and vegetables. Proc. Fla. State Hort. Soc. 2007, 120, 235–245. [Google Scholar]

- Araji, S.; Grammer, T.A.; Gertzen, R.; Anderson, S.D.; Mikulic-Petkovsek, M.; Veberic, R.; Phu, M.L.; Solar, A.; Leslie, C.A.; Dandekar, A.M. Novel roles for the polyphenol oxidase enzyme in secondary metabolism and the regulation of cell death in walnut. Plant Physiol. 2014, 164, 1191–1203. [Google Scholar] [CrossRef]

- Zafra-Stone, S.; Yasmin, T.; Bagchi, M.; Chatterjee, A.; Vinson, J.A.; Bagchi, D. Berry anthocyanins as novel antioxidants in human health and disease prevention. Mol. Nutr. Food Res. 2007, 51, 675–683. [Google Scholar] [CrossRef] [PubMed]

- Giampieri, F.; Tulipani, S.; Alvarez-Suarez, J.M.; Quiles, J.L.; Mezzetti, B.; Battino, M. The strawberry: Composition, nutritional quality, and impact on human health. Nutrition 2012, 28, 9–19. [Google Scholar] [CrossRef] [PubMed]

- Giampieri, F.; Alvarez-Suarez, J.M.; Battino, M. Strawberry and human health: Effects beyond antioxidant activity. J. Agric. Food Chem. 2014, 62, 3867–3876. [Google Scholar] [CrossRef] [PubMed]

- Nile, S.H.; Park, S.W. Edible berries: Bioactive components and their effect on human health. Nutrition 2014, 30, 134–144. [Google Scholar] [CrossRef]

- Afrin, S.; Gasparrini, M.; Forbes-Hernandez, T.Y.; Reboredo-Rodriguez, P.; Mezzetti, B.; Varela-López, A.; Giampieri, F.; Battino, M. Promising health benefits of the strawberry: A focus on clinical studies. J. Agric. Food Chem. 2016, 64, 4435–4449. [Google Scholar] [CrossRef]

- Oliveira, G.; Radovanovic, N.; Nunes, M.C.N.; Fristedt, R.; Alminger, M.; Andlid, T. Extracts of Digested Berries Increase the Survival of Saccharomyces cerevisiae during H2O2 Induced Oxidative Stress. Molecules 2021, 26, 1057. [Google Scholar] [CrossRef]

- Faller, A.L.K.; Fialho, E. Polyphenol content and antioxidant capacity in organic and conventional plant foods. J. Food Comp. Anal. 2010, 23, 561–568. [Google Scholar] [CrossRef]

- Huber, M.; Rembiałkowska, E.; Średnicka, D.; Bügel, S.; van de Vijver, L.P.L. Organic food and impact on human health: Assessing the status quo and prospects of research. NJAS Wagen. J. Life Sci. 2011, 58, 103–109. [Google Scholar] [CrossRef]

- Lairon, D. Nutritional quality and safety of organic food. A review. Agron. Sustain. Dev. 2010, 30, 33–41. [Google Scholar] [CrossRef]

- Singh, R.; Rastogi, S.; Dwivedi, U.N. Phenylpropanoid metabolism in ripening fruits. Compr. Rev. Food Sci. Food Saf. 2010, 9, 398–416. [Google Scholar] [CrossRef]

- Cordenunsi, B.R.; Oliveira do Nascimento, J.R.; Genovese, M.I.; Lajolo, F.M. Influence of cultivar on quality parameters and chemical composition of strawberry fruits grown in Brazil. J. Agric. Food Chem. 2002, 50, 2581–2586. [Google Scholar] [CrossRef]

- Tang, F.H.; Lenzen, M.; McBratney, A.; Maggi, F. Risk of pesticide pollution at the global scale. Nat. Geosci. 2021, 14, 206–210. [Google Scholar] [CrossRef]

- USEPA. United States Environmental Protection Agency. Electronic Code of Federal Regulations 40 CFR Part 180. 2018. Available online: https://www.ecfr.gov/cgi-bin/text-idx?node=pt40.24.180&#se40.26.180_13 (accessed on 18 March 2018).

- Malhat, F.; Badawy, H.M.; Barakat, D.A.; Saber, A.N. Residues, dissipation and safety evaluation of chromafenozide in strawberry under open field conditions. Food Chem. 2014, 152, 18–22. [Google Scholar] [CrossRef]

- Song, L.; Zhong, Z.; Han, Y.; Zheng, Q.; Qin, Y.; Wu, Q.; He, X.; Pan, C.; Song, L.; Zhong, Z.; et al. Dissipation of sixteen pesticide residues from various applications of commercial formulations on strawberry and their risk assessment under greenhouse conditions. Ecotoxicol. Environ. Saf. 2020, 188, 109842. [Google Scholar] [CrossRef]

- Saber, A.N.; Malhat, F.M.; Badawy, H.M.; Barakat, D.A. Dissipation dynamic, residue distribution and processing factor of hexythiazox in strawberry fruits under open field condition. Food Chem. 2016, 196, 1108–1116. [Google Scholar] [CrossRef]

- Angioni, A.; Schirra, M.; Garau, V.; Melis, M.; Tuberoso, C.I.G.; Cabras, P. Residues of azoxystrobin, fenhexamid and pyrimethanil in strawberry following field treatments and the effect of domestic washing. Food Addit. Contam. 2004, 21, 1065–1070. [Google Scholar] [CrossRef]

- Winter, C.K.; Davis, S.F. Organic foods. J. Food Sci. 2006, 71, R117–R124. [Google Scholar] [CrossRef]

- Jensen, B.; Knudsen, I.M.; Andersen, B.; Nielsen, K.F.; Thrane, U.; Jensen, D.F.; Larsen, J. Characterization of microbial communities and fungal metabolites on field grown strawberries from organic and conventional production. Int. J. Food Microbiol. 2013, 160, 313–322. [Google Scholar] [CrossRef]

- Inselberg, H.; Nunes, M.C.N. Using Cannabidiol as a potential postharvest treatment to maintain quality and extend the shelf life of strawberries. Postharvest Biol. Technol. 2021, 173, 111416. [Google Scholar] [CrossRef]

| Date | Conventional | Reduced |

|---|---|---|

| 13 January 2015 | Captan + Thiram (a.i. 1 captan, thiram) | Captan + Thiram (a.i. captan, thiram) |

| 17 January 2015 | Fontelis (a.i. penthiopyrad) | Fontelis (a.i. penthiopyrad) |

| 22 January 2015 | Captan + Thiram (a.i. captan, thiram) | |

| 24 January 2015 | Merivon (a.i. fluxapyroxad, pyraclostrobin) | |

| 28 January 2015 | Captan + Thiram (a.i. captan, thiram) | |

| 4 February 2015 | Captan + Thiram (a.i. captan, thiram) | |

| 9 February 2015 | Captan + Thiram (a.i. captan, thiram) | Captan + Thiram (a.i. captan, thiram) |

| 12 February 2015 | Switch (a.i. cyprodinil, fludioxonil) | |

| 22 February 2015 | Captan + Thiram (a.i. captan, thiram) | |

| 3 March 2015 | Harvest 1 | |

| 9 March 2015 | Captan (a.i. captan) | Captan (a.i. captan) |

| 10 March 2015 | Harvest 2 | |

| 14 March 2015 | Captan (a.i. captan) | |

| Control | Supply Chain | ||||

|---|---|---|---|---|---|

| Supply Chain Steps | Duration (Days) | Temperature (°C) | RH (%) | Temperature (°C) | RH (%) |

| Harvest | 0.00 | - | - | - | - |

| Harvest to pre-cooling 2 | 0.13 | 1.5 | 85.0 | 30.0 | 60.0 |

| Pre-cooling | 0.04 (0.17) 3 | 1.5 | 85.0 | 2.0 | 70.0 |

| Cold room (grower) | 0.83 (1.00) | 1.5 | 85.0 | 1.5 | 80.0 |

| Shipping to D.C 4 | 2.00 (3.00) | 1.5 | 85.0 | 3.0 | 85.0 |

| Storage at D.C | 1.00 (4.00) | 1.5 | 85.0 | 4.0 | 80.0 |

| Transport from D.C. to store | 0.17 (4.17) | 1.5 | 85.0 | 5.0 | 83.0 |

| Store display | 1.00 (5.17) | 1.5 | 85.0 | 7.0 | 80.0 |

| Consumer 5 | 0.83 (6.00) | 1.5 | 85.0 | 4.0 | 30.0 |

| Total Duration | 6 days | ||||

| Treatment | Appearance 2 | Texture 2 | Flavor 2 | Overall Liking |

|---|---|---|---|---|

| Harvest 1 | ||||

| Conventional: control | 6.35 ± 0.17 c 3 | 6.12 ± 0.18 b | 5.81 ± 0.17 b | 5.91 ± 0.17 b |

| Conventional: supply chain | 6.70 ± 0.16 b | 6.17 ± 0.17 b | 5.79 ± 0.16 b | 5.96 ± 0.16 b |

| Reduced: control | 7.22 ± 0.14 a | 6.97 ± 0.14 a | 6.25 ± 0.17 a | 6.54 ± 0.15 a |

| Reduced: supply chain | 6.96 ± 0.15 ab | 6.40 ± 0.17 b | 5.95 ± 0.18 ab | 6.08 ± 0.18 b |

| Harvest 2 | ||||

| Conventional: control | 6.57 ± 0.16 ab | 6.63 ± 0.16 a | 6.09 ± 0.17 a | 6.24 ± 0.17 a |

| Conventional: supply chain | 6.25 ± 0.17 b | 6.11 ± 0.16 b | 5.65 ± 0.18 b | 5.83 ± 0.17 b |

| Reduced: control | 6.71 ± 0.17 a | 6.60 ± 0.16 a | 5.75 ± 0.19 ab | 6.00 ± 0.18 ab |

| Reduced: supply chain | 6.49 ± 0.16 ab | 6.34 ± 0.16 ab | 5.73 ± 0.17 ab | 6.00 ± 0.16 ab |

| Treatment | Fludioxonil (ppb) | Cyprodinil (ppb) | Pyraclostrobin (ppb) | Captan (ppb) |

|---|---|---|---|---|

| Harvest 1 | ||||

| Conventional | ||||

| Control: not washed | 18 ± 1 c | 20 ± 1 c | ND 2 | 4634 ± 36 b |

| Control: washed | 10 ± 1 e | 9 ± 1 f | ND | 3752 ± 757 c |

| Supply chain: not washed | 28 ± 3 a | 35 ± 1 a | 20 ± 1 | 4878 ± 428 b |

| Supply chain: washed | 21 ± 0 b | 29 ± 1 b | ND | 3131 ± 117 c |

| Reduced | ||||

| Control: not washed | 16 ± 1 cd | 19 ± 0 c | ND | 1634 ± 134 d |

| Control: washed | 9 ± 0 e | 12 ± 1 e | ND | 857 ± 61 e |

| Supply chain: not washed | 8 ± 0 e | 8 ± 1 f | ND | 6316 ± 213 a |

| Supply chain: washed | 14 ± 1 d | 16 ± 0 d | ND | 522 ± 22 e |

| Harvest 2 | ||||

| Conventional | ||||

| Control: not washed | 10 ± 1 b | 8 ± 1 bc | ND. | 5589 ± 289 a |

| Control: washed | 5 ± 0 e | 7 ± 0 c | ND. | 3363 ± 30 bc |

| Supply chain: not washed | 6 ± 0 d | 7 ± 0 c | ND. | 6535 ± 148 a |

| Supply chain: washed | 3 ± 0 f | 6 ± 0 d | ND. | 3572 ± 264 bc |

| Reduced | ||||

| Control: not washed | 9 ± 1 c | 7 ± 0 c | ND. | 5683 ± 1205 a |

| Control: washed | 5 ± 0 e | 6 ± 0 d | ND. | 2416 ± 78 cd |

| Supply chain: not washed | 24 ± 1 a | 26 ± 0 a | ND. | 3849 ± 416 d |

| Supply chain: washed | 5 ± 0 e | 8 ± 0 b | ND. | 1561 ± 102 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelly, K.; Yagiz, Y.; Li, Z.; Mahnken, G.; Borejsza-Wysocki, W.; Marshall, M.; A. Sims, C.; Peres, N.; do Nascimento Nunes, M.C. Sensory and Physicochemical Quality, Residual Fungicide Levels and Microbial Load in ‘Florida Radiance’ Strawberries from Different Disease Control Treatments Exposed to Simulated Supply Chain Conditions. Foods 2021, 10, 1442. https://doi.org/10.3390/foods10071442

Kelly K, Yagiz Y, Li Z, Mahnken G, Borejsza-Wysocki W, Marshall M, A. Sims C, Peres N, do Nascimento Nunes MC. Sensory and Physicochemical Quality, Residual Fungicide Levels and Microbial Load in ‘Florida Radiance’ Strawberries from Different Disease Control Treatments Exposed to Simulated Supply Chain Conditions. Foods. 2021; 10(7):1442. https://doi.org/10.3390/foods10071442

Chicago/Turabian StyleKelly, Katrina, Yavuz Yagiz, Zheng Li, Gail Mahnken, Wlodzimierz Borejsza-Wysocki, Maurice Marshall, Charles A. Sims, Natalia Peres, and Maria Cecilia do Nascimento Nunes. 2021. "Sensory and Physicochemical Quality, Residual Fungicide Levels and Microbial Load in ‘Florida Radiance’ Strawberries from Different Disease Control Treatments Exposed to Simulated Supply Chain Conditions" Foods 10, no. 7: 1442. https://doi.org/10.3390/foods10071442

APA StyleKelly, K., Yagiz, Y., Li, Z., Mahnken, G., Borejsza-Wysocki, W., Marshall, M., A. Sims, C., Peres, N., & do Nascimento Nunes, M. C. (2021). Sensory and Physicochemical Quality, Residual Fungicide Levels and Microbial Load in ‘Florida Radiance’ Strawberries from Different Disease Control Treatments Exposed to Simulated Supply Chain Conditions. Foods, 10(7), 1442. https://doi.org/10.3390/foods10071442