Reinvigorating Modern Breadmaking Based on Ancient Practices and Plant Ingredients, with Implementation of a Physicochemical Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Flours

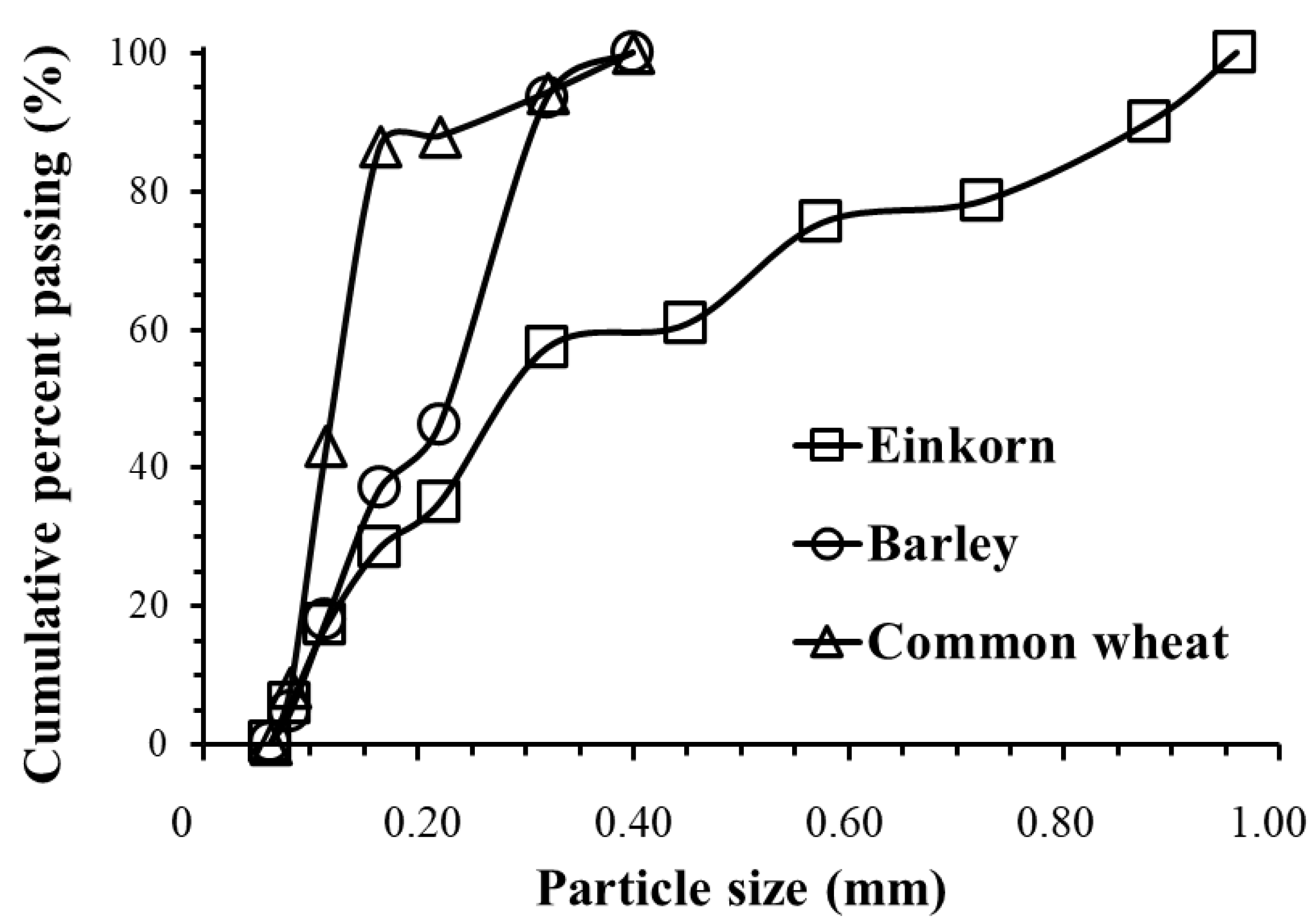

2.1.1. Particle Size Distribution

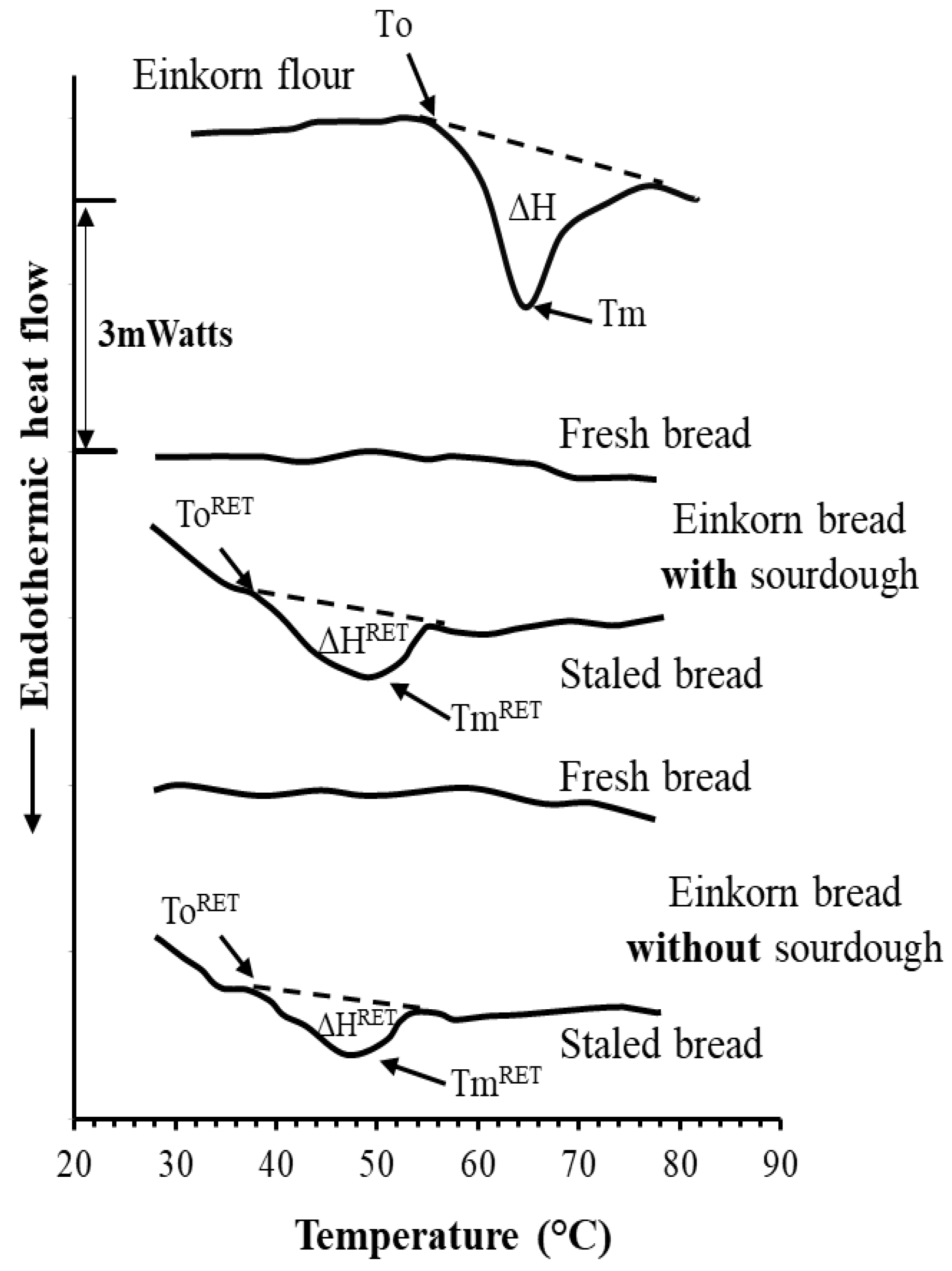

2.1.2. Calorimetric Study of Starch Gelatinization Properties

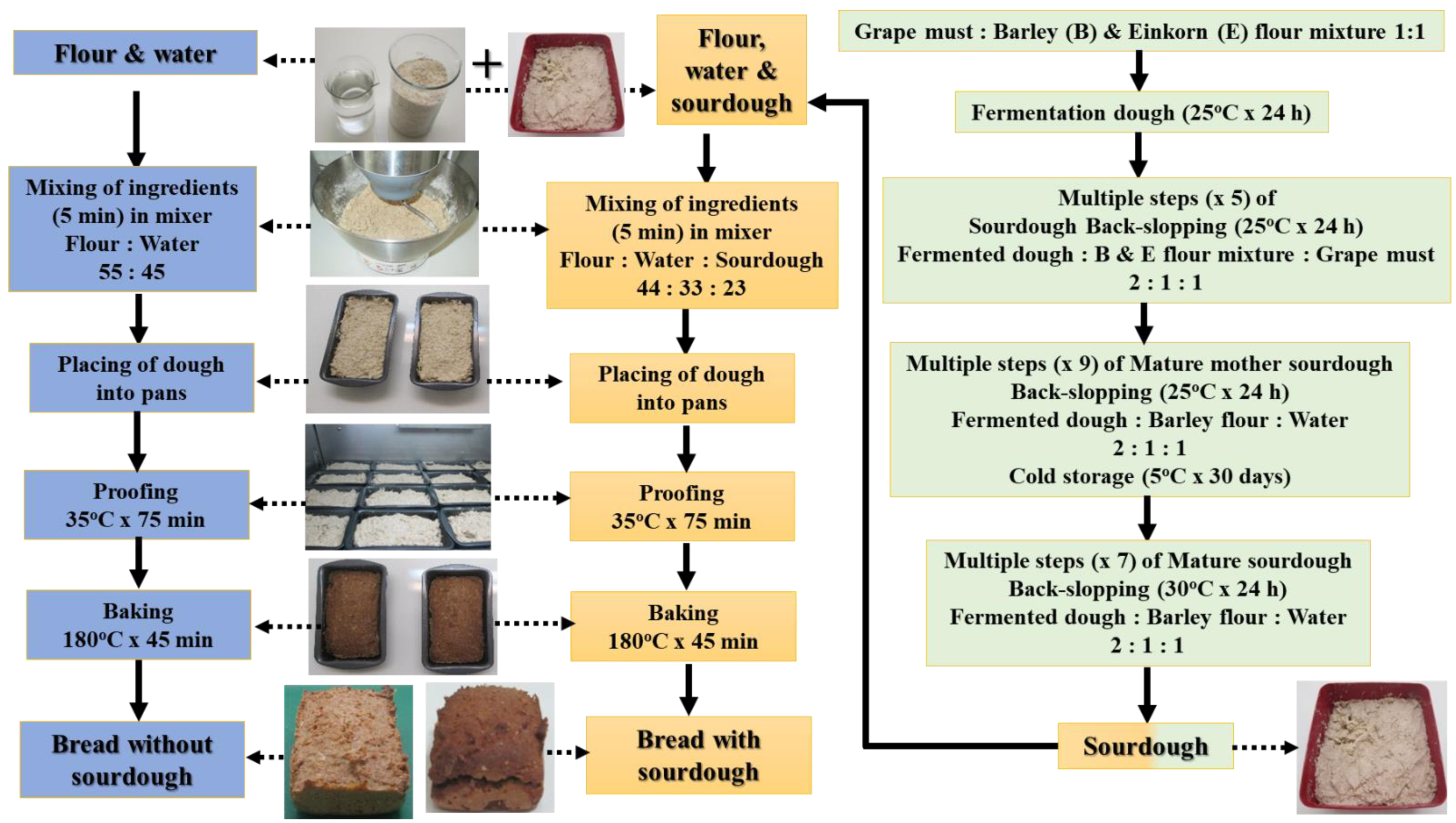

2.2. Sourdough

2.2.1. Sourdough Preparation

2.2.2. Microbiological and Physicochemical Characteristics of Sourdough

2.3. Doughs

2.3.1. Dough Preparation

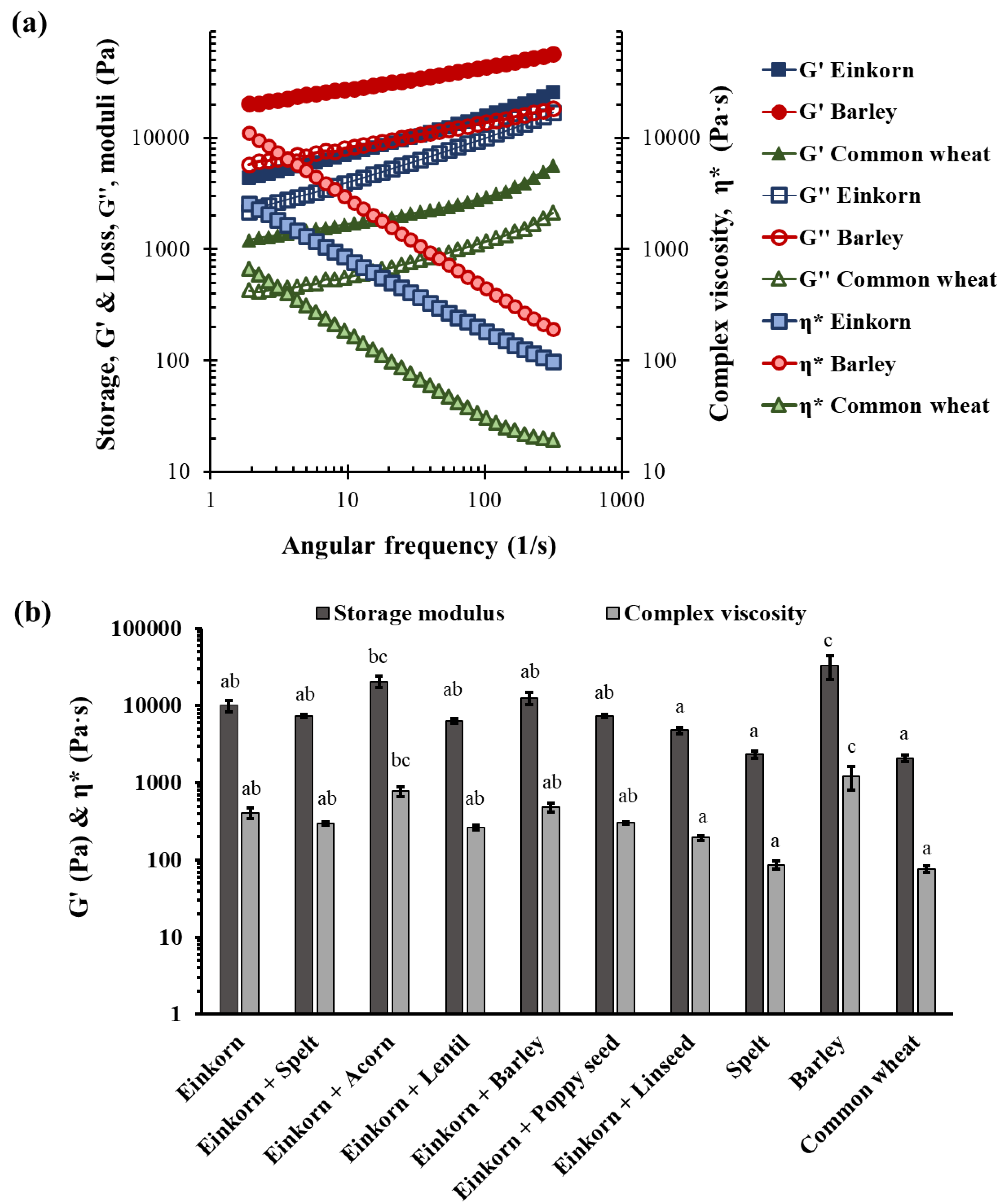

2.3.2. Dough Rheology

2.4. Breads

2.4.1. Bread Formulations

2.4.2. Breadmaking Process

2.4.3. Bread Quality Characteristics

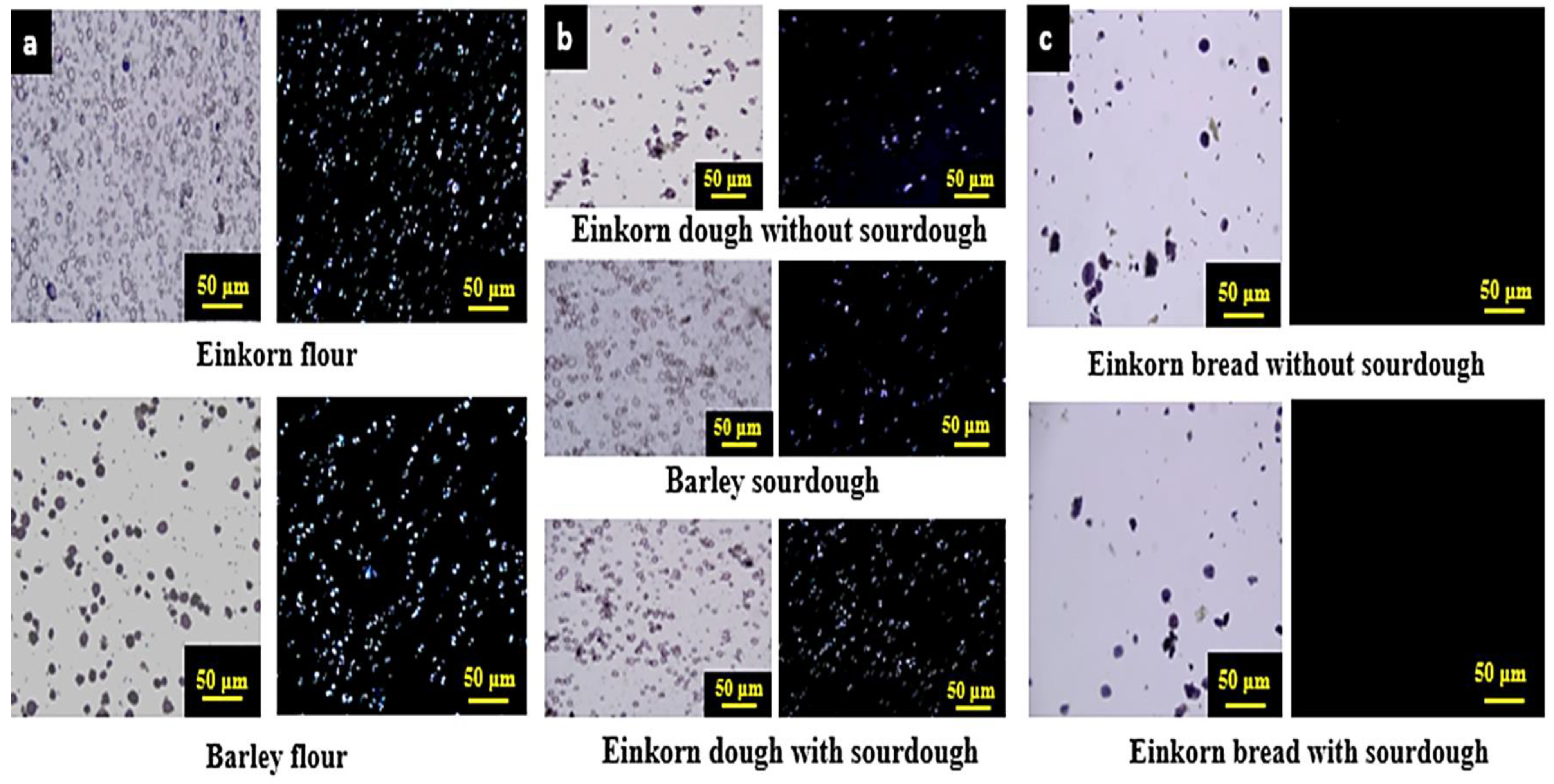

2.5. Microscopy and Changes in Starch Physical State during Breadmaking and Bread Storage

2.6. Statistical Analysis

3. Results and Discussion

3.1. Flour Properties

3.2. Microbiological and Physicochemical Characteristics of Sourdough

3.3. Dough Rheological Properties

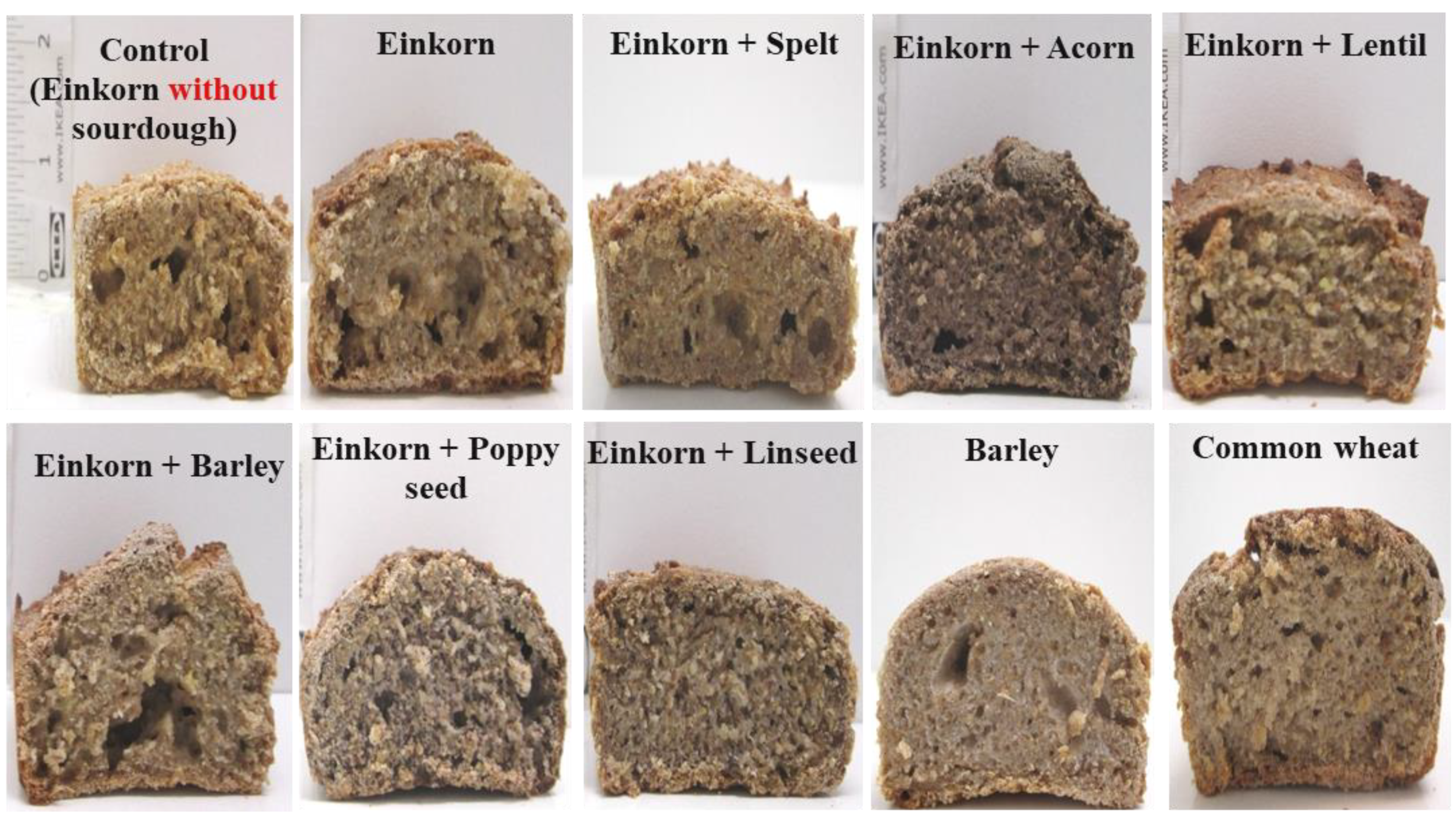

3.4. Evaluation of Bread Quality Characteristics

3.5. Starch Physical State of Fresh and Stored Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Arranz-Otaegui, A.; Carretero, L.G.; Ramsey, M.N.; Fuller, D.Q.; Richter, T. Archaeobotanical evidence reveals the origins of bread 14,400 years ago in northeastern Jordan. Proc. Natl. Acad. Sci. USA 2018, 115, 7925–7930. [Google Scholar] [CrossRef]

- Carretero, L.G.; Wollstonecroft, M.; Fuller, D.Q. A methodological approach to the study of archaeological cereal meals: A case study at Çatalhöyük East (Turkey). Veg. Hist. Archaeobot. 2017, 26, 415–432. [Google Scholar] [CrossRef] [PubMed]

- Primavera, M.; Heiss, A.G.; Valamoti, M.S.; Quarta, G.; Masieri, M.; Fiorentino, G. Inside sacrificial cakes: Plant components and production processes of food offerings at the Demeter and Persephone sanctuary of Monte Papalucio (Oria, southern Italy). Archaeol. Anthrop. Sci. 2019, 11, 1273–1287. [Google Scholar] [CrossRef]

- Valamoti, S.M.; Samuel, D.; Bayram, M.; Marinova, E. Prehistoric cereal foods from Greece and Bulgaria: Investigation of starch microstructure in experimental and archaeological charred remains. Veg. Hist. Archaeobot. 2008, 17, 265–276. [Google Scholar] [CrossRef]

- Heiss, A.G.; Antolín, F.; Berihuete Azorín, M.; Biederer, B.; Erlach, R.; Gail, N.; Griebl, M.; Linke, R.; Lochner, M.; Marinova, E.; et al. The Hoard of the Rings. “Odd” annular bread-like objects as a case study for cereal-product diversity at the Late Bronze Age hillfort site of Stillfried (Lower Austria). PLoS ONE 2019, 14. [Google Scholar] [CrossRef] [PubMed]

- Valamoti, S.M. Plant food ingredients and ‘recipes’ from Prehistoric Greece: The archaeobotanical evidence. In Plants and Culture: Seeds of the Cultural Heritage of Europe; Morel, J.P., Mercuri, A.M., Eds.; Centro Europeo per i Beni Culturali Ravello Edipuglia: Bari, Italy, 2009; pp. 25–38. [Google Scholar]

- Zohary, D.; Hopf, M.; Weiss, E. Cereals. In Domestication of Plants in the Old World: The Origin and Spread of Domesticated Plants in Southwest Asia, Europe, and the Mediterranean Basin, 4th ed.; Oxford University Press: Oxford, UK, 2012; pp. 20–74. [Google Scholar]

- Zohary, D.; Hopf, M.; Weiss, E. Pulses. In Domestication of Plants in the Old World: The Origin and Spread of Domesticated Plants in Southwest Asia, Europe, and the Mediterranean Basin, 4th ed.; Oxford University Press: Oxford, UK, 2012; pp. 75–99. [Google Scholar]

- Valamoti, S.M.; Marinova, E.; Heiss, A.G.; Hristova, I.; Petridou, C.; Popova, T.; Michou, S.; Papadopoulou, L.; Chrysostomou, P.; Darcque, P.; et al. Prehistoric cereal foods of southeastern Europe: An archaeobotanical exploration. J. Archaeol. Sci. 2019, 104, 97–113. [Google Scholar] [CrossRef]

- Longin, C.F.H.; Ziegler, J.; Schweiggert, R.; Koehler, P.; Carle, R.; Wuerschum, T. Comparative study of hulled (einkorn, emmer, and spelt) and naked wheats (durum and bread wheat): Agronomic performance and quality traits. Crop Sci. 2015, 56, 302–311. [Google Scholar] [CrossRef]

- Peña-Chocarro, L.; Zapata Peña, L.; Emilio González Urquijo, J.; Ibáñez Estévez, J.J. Einkorn (Triticum monococcum L.) cultivation in mountain communities of the western Rif (Morocco): An ethnoarchaeological project. In From Foragers to Farmers; Fairbairn, A., Weiss, E., Eds.; Oxbow Books: Oxford, UK, 2009; pp. 104–111. [Google Scholar]

- Geisslitz, S.; Wieser, H.; Scherf, K.A.; Koehler, P. Gluten protein composition and aggregation properties as predictors for bread volume of common wheat, spelt, durum wheat, emmer and einkorn. J. Cereal Sci. 2018, 83, 204–212. [Google Scholar] [CrossRef]

- Valamoti, S.M.; Chondrou, D.; Bekiaris, T.; Ninou, I.; Alonso, N.; Bofill, M.; Ivanova, M.; Laparidou, S.; McNamee, C.; Palomo, A.; et al. Plant foods, stone tools and food preparation in prehistoric Europe: An integrative approach in the context of ERC funded project PLANTCULT. J. Lithic Stud. 2020, 7, 1–21. [Google Scholar] [CrossRef]

- Dimoula, A.; Tsirtsoni, Z.; Yiouni, P.; Stagkidis, I.; Ntinou, M.; Prevost-Dermarkar, S.; Papadopoulou, E.; Valamoti, S.M. Experimental investigation of ceramic technology and plant food cooking in Neolithic northern Greece. STAR Sci. Technol. Archaeol. Res. 2019, 5, 269–286. [Google Scholar] [CrossRef]

- Heiss, A.G. Bread. In Archaeology of Food: An Encyclopedia; Metheny, K.B., Beaudry, M.C., Eds.; Rowman & Littlefield: Lanham, MD, USA, 2015; Volume 1, pp. 70–75. [Google Scholar]

- Heiss, A.G.; Pouget, N.; Wiethold, J.; Delor-Ahü, A.; Le Goff, I. Tissue-based analysis of a charred flat bread (galette) from a Roman cemetery at Saint-Memmie (Dép. Marne, Champagne-Ardenne, north-eastern France). J. Archaeol. Sci. 2015, 55, 71–82. [Google Scholar] [CrossRef]

- Valamoti, S.M.; Petridou, C.; Berihuete-Azorín, M.; Stika, H.-P.; Papadopoulou, L.; Mimi, I. Deciphering ancient ‘recipes’ from charred cereal fragments: An integrated methodological approach using experimental, ethnographic and archaeological evidence. J. Archaeol. Sci. 2021, 128, 105347. [Google Scholar] [CrossRef]

- Valamoti, S.M.; Jacomet, S.; Stika, H.P.; Heiss, A.G. The PLANTCULT Project: Identifying the plant food cultures of ancient Europe. Antiquity 2017, 91, e9. [Google Scholar] [CrossRef]

- Abdel-Aal, E.M.; Hucl, P.; Sosulski, F.W.; Bhirud, P.R. Kernel, milling and baking properties of spring-type spelt and einkorn wheats. J. Cereal Sci. 1997, 26, 363–370. [Google Scholar] [CrossRef]

- Brandolini, A.; Hidalgo, A.; Moscaritolo, S. Chemical composition and pasting properties of einkorn (Triticum monococcum L. subsp. monococcum) whole meal flour. J. Cereal Sci. 2008, 47, 599–609. [Google Scholar] [CrossRef]

- Cooper, R. Re-discovering ancient wheat varieties as functional foods. J. Tradit. Complement. Altern. Med. 2015, 5, 138–143. [Google Scholar] [CrossRef]

- Ruibal-Mendieta, N.L.; Delacroix, D.L.; Mignolet, E.; Pycke, J.M.; Marques, C.; Rozenberg, R.; Delzenne, N.M. Spelt (Triticum aestivum ssp. spelta) as a source of breadmaking flours and bran naturally enriched in oleic acid and minerals but not phytic acid. J. Agric. Food Chem. 2005, 53, 2751–2759. [Google Scholar] [CrossRef]

- Arzani, A.; Ashraf, M. Cultivated ancient wheats (Triticum spp.): A potential source of health-beneficial food products. Compr. Rev. Food Sci. Food Saf. 2017, 16, 477–488. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo, A.; Brandolini, A. Nutritional properties of einkorn wheat (Triticum monococcum L.). J. Sci. Food Agric. 2014, 94, 601–612. [Google Scholar] [CrossRef] [PubMed]

- Baik, B.K.; Ullrich, S.E. Barley for food: Characteristics, improvement, and renewed interest. J. Cereal Sci. 2008, 48, 233–242. [Google Scholar] [CrossRef]

- Lazaridou, A.; Marinopoulou, A.; Matsoukas, N.P.; Biliaderis, C.G. Impact of flour particle size and autoclaving on β-glucan physicochemical properties and starch digestibility of barley rusks as assessed by in vitro assays. Bioact. Carbohydr. Diet. Fibre 2014, 4, 58–73. [Google Scholar] [CrossRef]

- Lazaridou, A.; Marinopoulou, A.; Biliaderis, C.G. Impact of flour particle size and hydrothermal treatment on dough rheology and quality of barley rusks. Food Hydrocoll. 2019, 87, 561–569. [Google Scholar] [CrossRef]

- Boukid, F.; Zannini, E.; Carini, E.; Vittadini, E. Pulses for bread fortification: A necessity or a choice? Trends Food Sci. Technol. 2019, 88, 416–428. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Gouvinhas, I.; Nunes, M.C.; Alcides Peres, J.; Raymundo, A.; Barros, A.I. Acorn flour as a source of bioactive compounds in gluten-free bread. Molecules 2020, 25, 3568. [Google Scholar] [CrossRef] [PubMed]

- Sęczyk, Ł.; Świeca, M.; Dziki, D.; Anders, A.; Gawlik-Dziki, U. Antioxidant, nutritional and functional characteristics of wheat bread enriched with ground flaxseed hulls. Food Chem. 2017, 214, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Watkins, T.R.; Tomeo, A.C.; Struck, M.L.; Palumbo, L.; Bierenbaum, M.L. Improving atherogenic risk factors with flax seed bread. In Developments in Food Science; Charalambous, G., Ed.; Elsevier: Amsterdam, The Netherlands, 1995; Volume 37, pp. 649–658. [Google Scholar] [CrossRef]

- Petridou, C. Plant Foods from Prehistoric Greece: An Interdisciplinary Approach. Ph.D. Thesis, School of History and Archaeology, Aristotle University of Thessaloniki, Thessaloniki, Greece. unpublished, thesis in preparation.

- Bofill, M.; Chondrou, D.; Palomo, A.; Procopiou, H.; Valamoti, S.M. Processing plants for food: Experimental grinding within the ERC-project PLANTCULT. J. Lithic Stud. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Karagiannis, G. Fysiko Prozymi; Psihalos Publications: Athens, Greece, 2015. (In Greek) [Google Scholar]

- Valamoti, S.M.; Fyntikoglou, V.; Symponis, K. Plant Foods of Ancient Greece: An Inquiry into Ancient Texts and Plant Remains until the Roman Conquest; University Studio Press: Thessaloniki, Greece, unpublished, book in preparation.

- Jones, G. Charred grain from late bronze age Gla, Boiotia. Annu. Br. Sch. Athens 1995, 90, 235–238. [Google Scholar] [CrossRef]

- Valamoti, S.M. The plant remains from Makriyalos: Preliminary observations. In Neolithic Society in Greece; Hastead, P., Ed.; Sheffield Academic Press: Sheffield, UK, 1999; pp. 136–138. [Google Scholar]

- Valamoti, S.M. Plants and People in Late Neolithic and Early Bronze Age Northern Greece: An Archaeobotanical Investigation; British Archaeological Reports: Oxford, UK, 2004; Volume 1258. [Google Scholar]

- Borghi, B.; Castagna, R.; Corbellini, M.; Heun, M.; Salamini, F. Breadmaking quality of einkorn wheat (Triticum monococcum ssp. monococcum). Cereal Chem. 1996, 73, 208–214. [Google Scholar]

- Corbellini, M.; Empilli, S.; Vaccino, P.; Brandolini, A.; Borghi, B.; Heun, M.; Salamini, F. Einkorn characterization for bread and cookie production in relation to protein subunit composition. Cereal Chem. 1999, 76, 727–733. [Google Scholar] [CrossRef]

- Lomolino, G.; Morari, F.; Dal Ferro, N.; Vincenzi, S.; Pasini, G. Investigating the einkorn (Triticum monococcum) and common wheat (Triticum aestivum) bread crumb structure with X-ray microtomography: Effects on rheological and sensory properties. Int. J. Food Sci. Technol. 2017, 52, 1498–1507. [Google Scholar] [CrossRef]

- AACC International. 10–05.01 Rapeseed displacement method. In Approved Methods of the American Association of Cereal Chemists, 11th ed.; American Association of Cereal Chemists International: St. Paul, MN, USA, 2010. [Google Scholar]

- Oladunmoye, O.O.; Aworh, O.C.; Maziya-Dixon, B.; Erukainure, O.L.; Elemo, G.N. Chemical and functional properties of cassava starch, durum wheat semolina flour, and their blends. Food Sci. Nutr. 2014, 2, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Thomas, L.; Arfat, Y.A. Functional, rheological, microstructural and antioxidant properties of quinoa flour in dispersions as influenced by particle size. Food Res. Int. 2019, 116, 302–311. [Google Scholar] [CrossRef] [PubMed]

- Biliaderis, C.G. Structural transitions and related physical properties of starch. In Starch, 3rd ed.; BeMiller, J., Whistler, R., Eds.; Academic Press: Cambridge, MA, USA, 2009; pp. 293–372. [Google Scholar] [CrossRef]

- Koehler, P.; Wieser, H. Chemistry of Cereal Grains. In Handbook on Sourdough Biotechnology; Gobbetti, M., Gänzle, M., Eds.; Springer: Boston, MA, USA, 2013; pp. 11–45. [Google Scholar]

- Flipse, E.; Keetels, C.J.A.M.; Jacobsen, E.; Visser, R.G.F. The dosage effect of the wildtype GBSS allele is linear for GBSS activity but not for amylose content: Absence of amylose has a distinct influence on the physico-chemical properties of starch. Theor. Appl. Genet. 1996, 92, 121–127. [Google Scholar] [CrossRef]

- Biliaderis, C.G.; Maurice, T.J.; Vose, J.R. Starch gelatinization phenomena studied by differential scanning calorimetry. J. Food Sci. 1980, 45, 1669–1674. [Google Scholar] [CrossRef]

- Biliaderis, C.G.; Grant, D.R.; Vose, J.R. Structural characterization of legume starches. I. Studies on amylose, amylopectin and β- limit dextrins. Cereal Chem. 1981, 58, 496–502. [Google Scholar]

- Ranhotraa, G.S.; Gelrotha, J.A.; Glasera, B.K.; Lorenzb, K.J. Nutrient Composition of Spelt Wheat. J. Food Compos. Anal. 1996, 9, 81–84. [Google Scholar] [CrossRef]

- Sotomayor, C.; Frias, J.; Fornal, J.; Sadowska, J.; Urbano, G.; Vidal-Valverde, C. Lentil Starch Content and its Microscopical Structure as Influenced by Natural Fermentation. Starch 1999, 51, 152–156. [Google Scholar] [CrossRef]

- Xu, M.; Jin, Z.; Simsek, S.; Hall, C.; Rao, J.; Chen, B. Effect of germination on the chemical composition, thermal, pasting, and moisture sorption properties of flours from chickpea, lentil, and yellow pea. Food Chem. 2019, 295, 579–587. [Google Scholar] [CrossRef] [PubMed]

- Tester, R.F.; Sommerville, M.D. The effects of non-starch polysaccharides on the extent of gelatinisation, swelling and α-amylase hydrolysis of maize and wheat starches. Food Hydrocoll. 2003, 17, 41–54. [Google Scholar] [CrossRef]

- Gobbetti, M.; Corsetti, A.; Rossi, J. The sourdough microflora. Interactions between lactic acid bacteria and yeasts: Metabolism of carbohydrates. Appl. Microbiol. Biotechnol. 1994, 41, 456–460. [Google Scholar] [CrossRef]

- Corsetti, A. Technology of Sourdough Fermentation and Sourdough Applications. In Handbook on Sourdough Biotechnology; Gobbetti, M., Gänzle, M., Eds.; Springer: Boston, MA, USA, 2013; pp. 85–103. [Google Scholar] [CrossRef]

- Harth, H.; Van Kerrebroeck, S.; De Vuyst, L. Community dynamics and metabolite target analysis of spontaneous, backslopped barley sourdough fermentations under laboratory and bakery conditions. Int. J. Food Microbiol. 2016, 228, 22–32. [Google Scholar] [CrossRef] [PubMed]

- Minervini, F.; Celano, G.; Lattanzi, A.; De Angelis, M.; Gobbetti, M. Added ingredients affect the microbiota and biochemical characteristics of durum wheat type-I sourdough. Food Microbiol. 2016, 60, 112–113. [Google Scholar] [CrossRef]

- Mirsaeedghazi, H.; Emam-Djomeh, Z.; Mousavi, S.M.A. Rheometric measurement of dough rheological characteristics and factors affecting it. Int. J. Agric. Biol. 2008, 10, 112–119. [Google Scholar]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Weipert, D. The benefits of basic rheometry in studying dough rheology. Cereal Chem. 1990, 67, 311–317. [Google Scholar]

- Brennan, C.S.; Cleary, L.J. Utilisation Glucagel® in the β-glucan enrichment of breads: A physicochemical and nutritional evaluation. Food Res. Int. 2007, 40, 291–296. [Google Scholar] [CrossRef]

- Izydorczyk, M.S.; Hussain, A.; MacGregor, A.W. Effect of barley and barley components on rheological properties of wheat dough. J. Cereal Sci. 2001, 34, 251–260. [Google Scholar] [CrossRef]

- Sharma, P.; Kotari, S.L. Barley: Impact of processing on physicochemical and thermal properties—A review. Food Rev. Int. 2017, 33, 359–381. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Nunes, M.C.; Ferreira, L.M.M.; Peres, J.A.; Barros, A.I.R.N.A.; Raymundo, A. Impact of acorn flour on gluten-free dough rheology properties. Foods 2020, 9, 560. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The influence of acorn flour on rheological properties of gluten-free dough and physical characteristics of the bread. Eur. Food Res. Technol. 2015, 240, 1135–1143. [Google Scholar] [CrossRef]

- Van Bockstaele, F.; De Leyn, I.; Eeckhout, M.; Dewettinck, K. Non-linear creep-recovery measurements as a tool for evaluating the viscoelastic properties of wheat flour dough. J. Food Eng. 2011, 107, 50–59. [Google Scholar] [CrossRef]

- Cappelli, A.; Cini, E.; Guerrini, L.; Masella, P.; Angeloni, G.; Parenti, A. Predictive models of the rheological properties and optimal water content in doughs: An application to ancient grain flours with different degrees of refining. J. Cereal Sci. 2018, 83, 229–235. [Google Scholar] [CrossRef]

- Guerrini, L.; Parenti, O.; Angeloni, G.; Zanoni, B. The bread making process of ancient wheat: A semi-structured interview to bakers. J. Cereal Sci. 2019, 87, 9–17. [Google Scholar] [CrossRef]

- Marpalle, P.; Sonawane, S.K.; Arya, S.S. Effect of flaxseed flour addition on physicochemical and sensory properties of functional bread. LWT Food Sci. Technol. 2014, 58, 614–619. [Google Scholar] [CrossRef]

- Piłat, B.; Zadernowski, R. Physicochemical characteristics of linseed oil and flour. Pol. J. Nat. Sci. 2010, 25, 106–113. [Google Scholar] [CrossRef]

- Sharma, H.P.; Sharma, S.; Nema, V.P. Physico-chemical and functional properties of flour prepared from native and roasted whole linseeds. J. Pharmacogn. Phytochem. 2020, 9, 1428–1433. [Google Scholar]

- Sudha, M.L.; Begum, K.; Ramasarma, P.R. Nutritional characteristics of linseed/flaxseed (Linum usitatissimum) and its application in muffin making. J. Texture Stud. 2010, 41, 563–578. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, S.; Yadav, A.; Aman, Z.; Yadav, R.K. Physico-chemical composition of two linseed flour. J. Pharmacogn. Phytochem. 2018, 7, 57–59. [Google Scholar]

- Nergiz, C.; Ötles, S. The proximate composition and some minor constituents of poppy seeds. J. Sci. Food Agric. 1994, 66, 117–120. [Google Scholar] [CrossRef]

- Singh, K.K.; Mridula, D.; Rehal, J.; Barnwal, P. Flaxseed: A potential source of food, feed and fiber. Crit. Rev. Food Sci. 2011, 51, 210–222. [Google Scholar] [CrossRef]

- Hug-Iten, S.; Handschin, S.; Conde-Petit, B.; Escher, F. Changes in Starch Microstructure on Baking and Staling of Wheat Bread. LWT Food Sci. Technol. 1999, 32, 255–260. [Google Scholar] [CrossRef]

- Gray, J.A.; Bemiller, J.N. Bread staling: Molecular basis and control. Compr. Rev. Food Sci. Food Saf. 2003, 2, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Vouris, D.G.; Lazaridou, A.; Mandala, I.G.; Biliaderis, C.G. Wheat bread quality attributes using jet milling flour fractions. LWT Food Sci. Technol. 2018, 92, 540–547. [Google Scholar] [CrossRef]

| Sample Symbol | Flour Formulation | Sourdough (% w/w Flour Basis) |

|---|---|---|

| Control | Einkorn mixture 1 (100%) | - |

| Einkorn | Einkorn mixture (100%) | 20 |

| Einkorn + Spelt | Mixture of einkorn mixture (80%) with spelt (20%) | 20 |

| Einkorn + Acorn | Mixture of einkorn mixture (80%) with acorn (20%) | 20 |

| Einkorn + Lentil | Mixture of einkorn mixture (80%) with lentil (20%) | 20 |

| Einkorn + Barley | Mixture of einkorn mixture (80%) with barley (20%) | 20 |

| Einkorn + Poppy seed | Mixture of einkorn mixture (80%) with poppy seed (20%) | 20 |

| Einkorn + Linseed | Mixture of einkorn mixture (80%) with linseed (20%) | 20 |

| Spelt | Commercial spelt (100%) | 20 |

| Barley | Commercial barley (100%) | 20 |

| Common wheat | Commercial common wheat (Triticum aestivum) (100%) | 20 |

| Samples 1 | Το (°C) 2 | Tm (°C) 2 | ΔΗ 2 (mJ/mg of Flour) |

|---|---|---|---|

| Barley | 58.91 (±0.06) c 3 | 65.70 (±0.21) a | 3.22 (±0.09) b |

| Common wheat | 57.56 (±0.79) b | 61.61 (±1.66) a | 5.55 (±0.35) c |

| Einkorn | 59.27 (±0.08) c | 64.29 (±0.14) a | 4.27 (±1.67) bc |

| Einkorn + Lentil | 58.97 (±0.72) c | 65.56 (±0.11) a | 5.60 (±0.57) c |

| Lentil | 64.74 (±0.24) d | 73.98 (±0.39) b | 0.93 (±0.46) a |

| Einkorn + Spelt | 59.14 (±0.17) c | 64.86 (±0.52) a | 5.54 (±0.93) c |

| Spelt | 56.15 (±0.26) a | 63.42 (±1.51) a | 4.55 (±0.42) bc |

| Einkorn + Barley | 59.44 (±0.16) c | 65.10 (±1.00) a | 4.57 (±0.59) bc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sereti, V.; Lazaridou, A.; Biliaderis, C.G.; Valamoti, S.M. Reinvigorating Modern Breadmaking Based on Ancient Practices and Plant Ingredients, with Implementation of a Physicochemical Approach. Foods 2021, 10, 789. https://doi.org/10.3390/foods10040789

Sereti V, Lazaridou A, Biliaderis CG, Valamoti SM. Reinvigorating Modern Breadmaking Based on Ancient Practices and Plant Ingredients, with Implementation of a Physicochemical Approach. Foods. 2021; 10(4):789. https://doi.org/10.3390/foods10040789

Chicago/Turabian StyleSereti, Vasileia, Athina Lazaridou, Costas G. Biliaderis, and Soultana Maria Valamoti. 2021. "Reinvigorating Modern Breadmaking Based on Ancient Practices and Plant Ingredients, with Implementation of a Physicochemical Approach" Foods 10, no. 4: 789. https://doi.org/10.3390/foods10040789

APA StyleSereti, V., Lazaridou, A., Biliaderis, C. G., & Valamoti, S. M. (2021). Reinvigorating Modern Breadmaking Based on Ancient Practices and Plant Ingredients, with Implementation of a Physicochemical Approach. Foods, 10(4), 789. https://doi.org/10.3390/foods10040789