Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

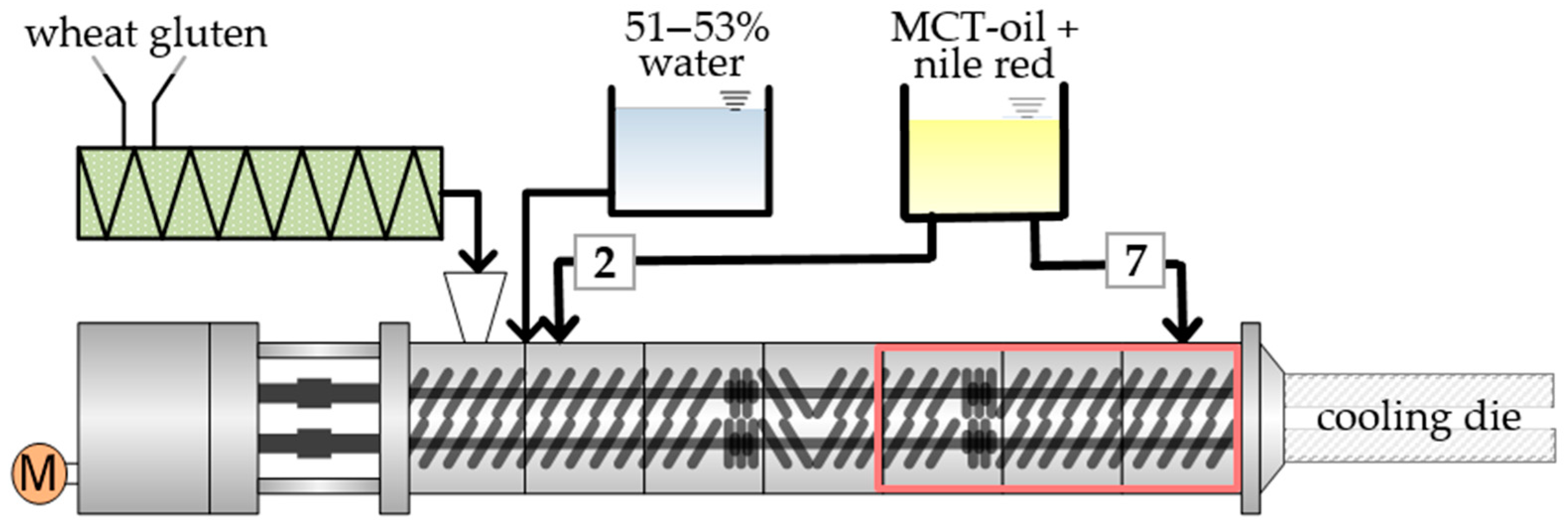

2.2. Extrusion Processing

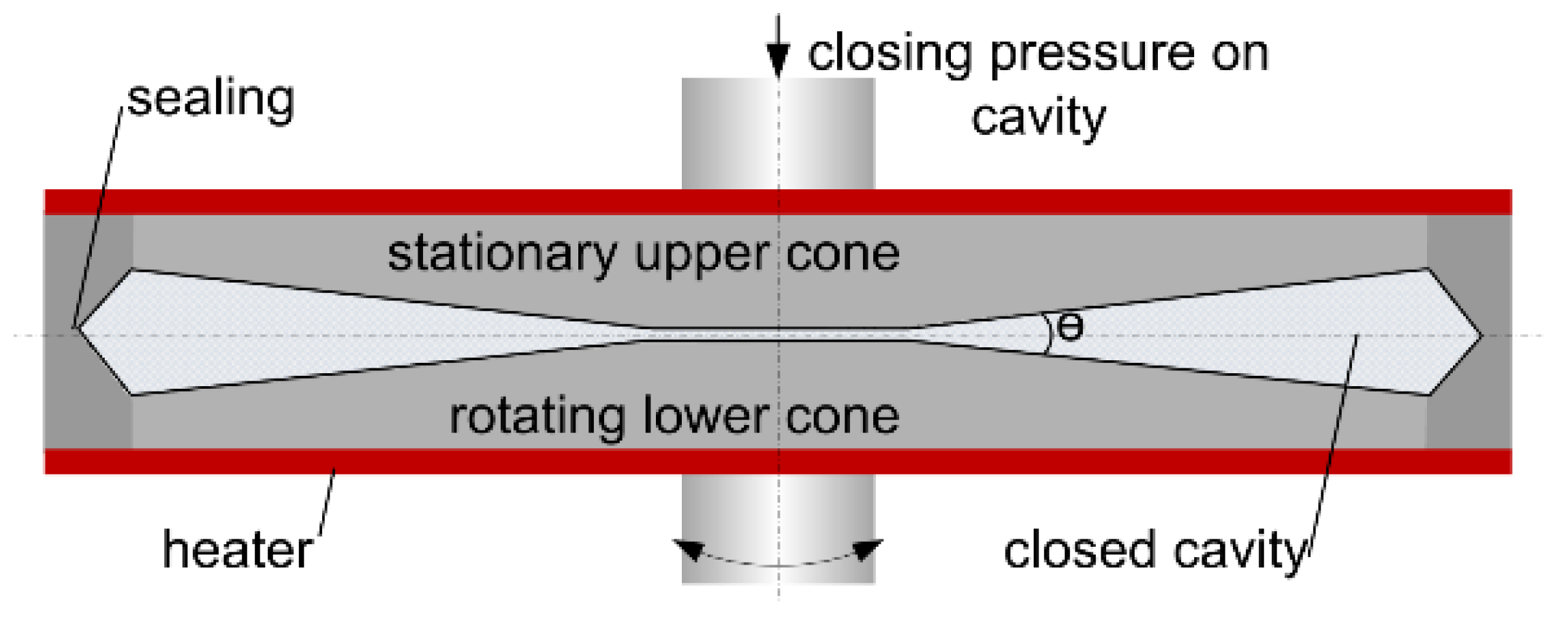

2.3. Rheological Measurements

2.4. Visualization of Anisotropic Structure

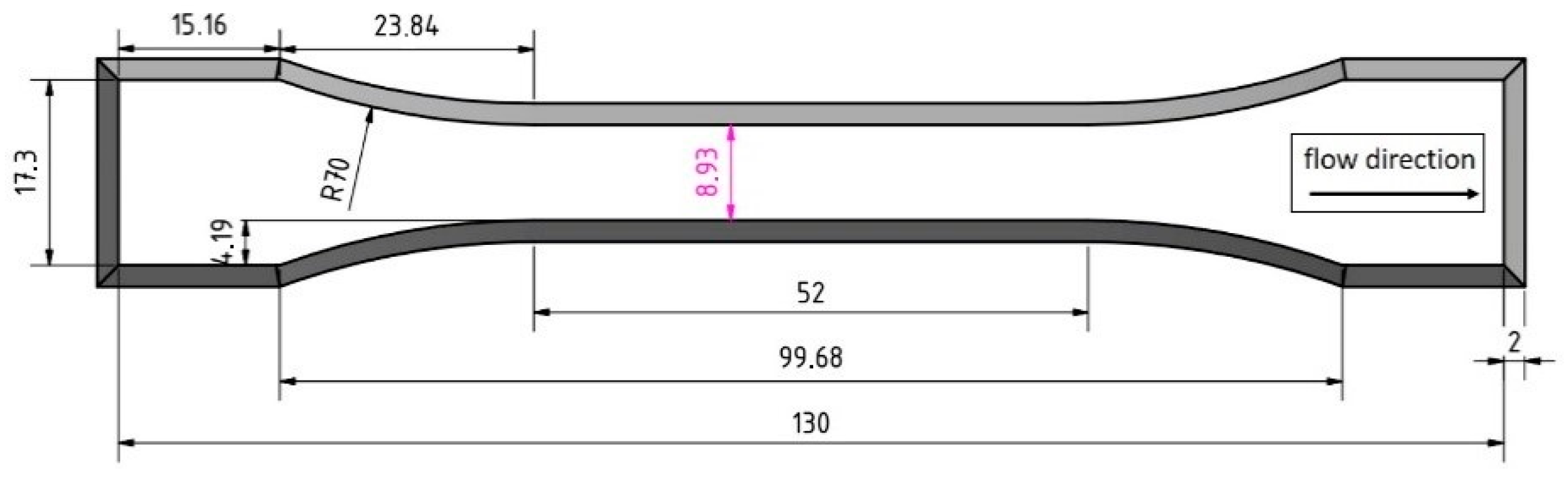

2.5. Analysis of Texture Properties

2.6. Oil Droplet Size Measurements

3. Results and Discussion

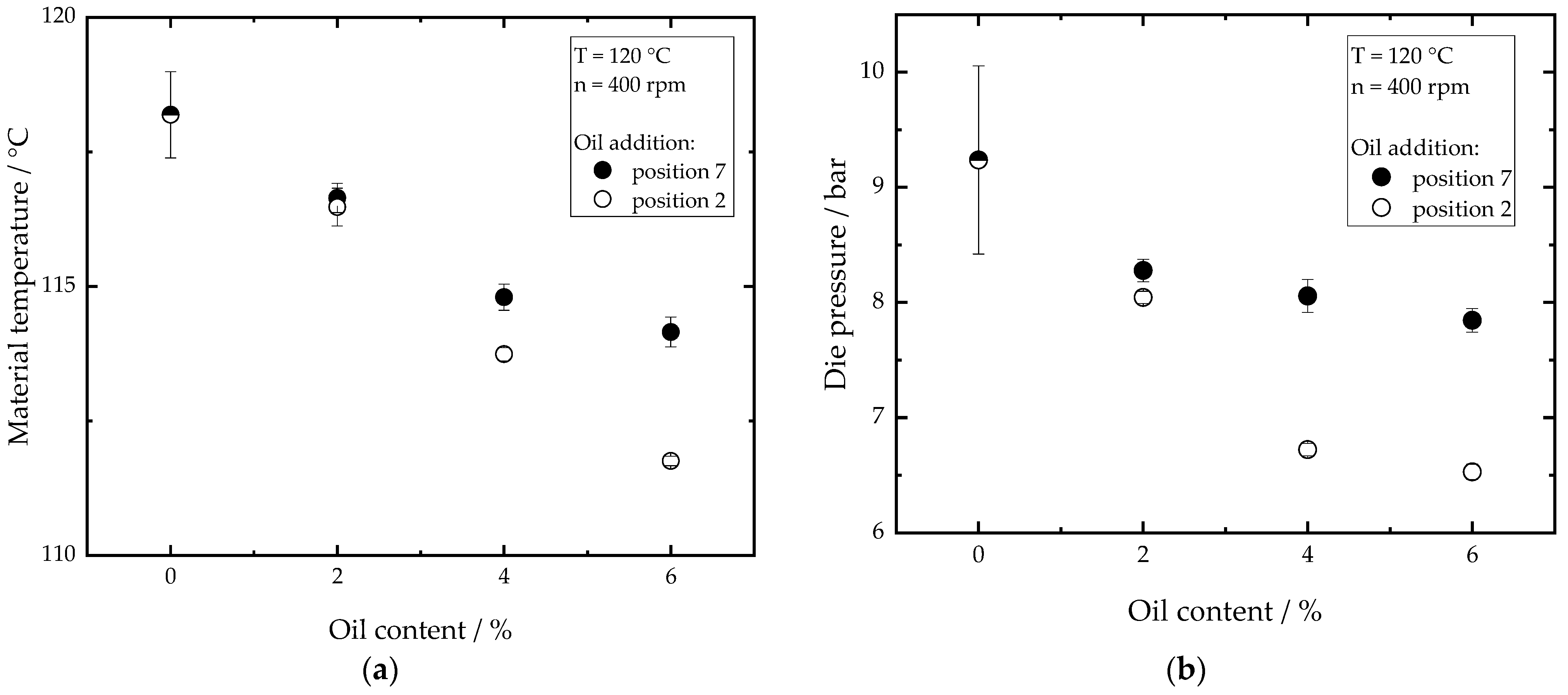

3.1. Influence of Oil Addition on the Extrusion Process Conditions

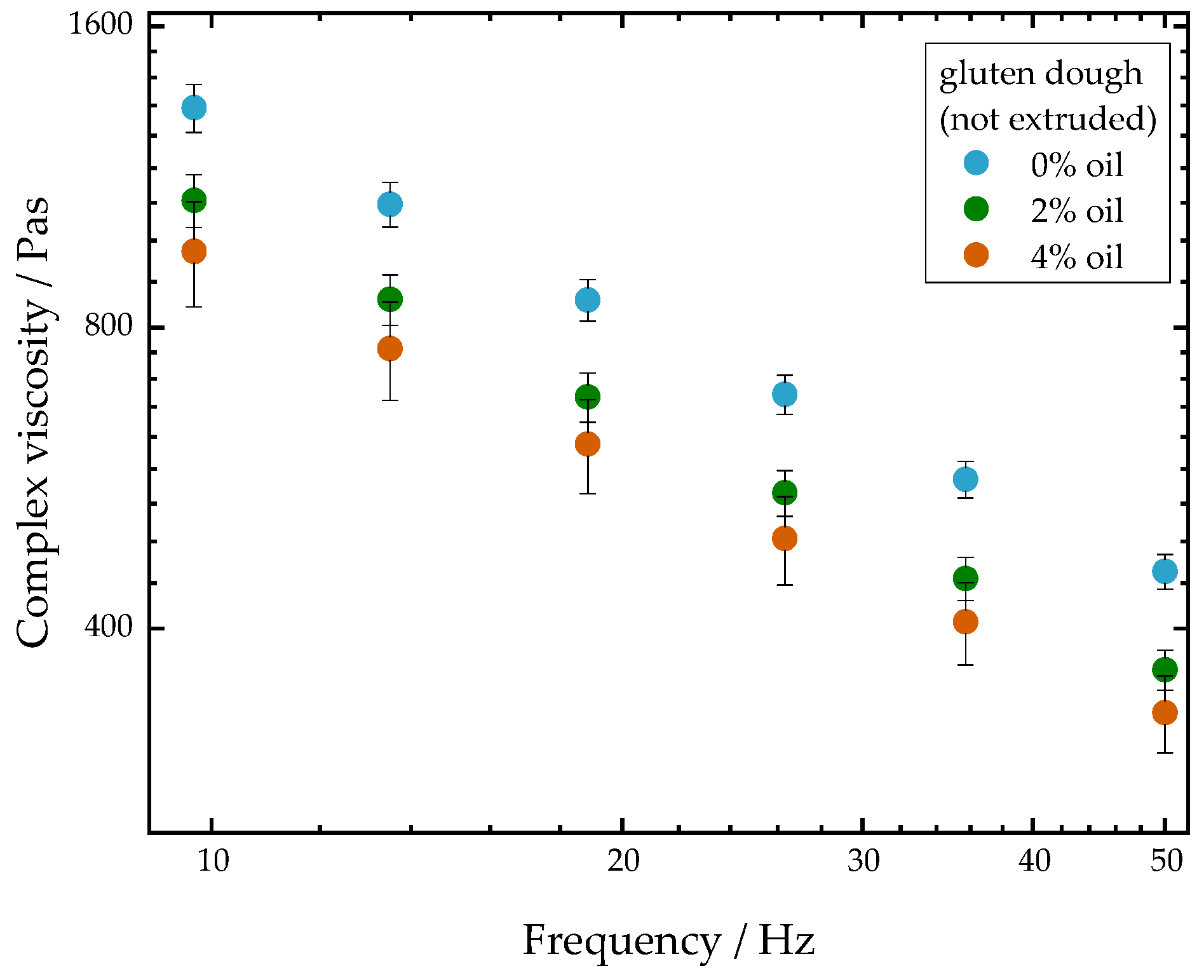

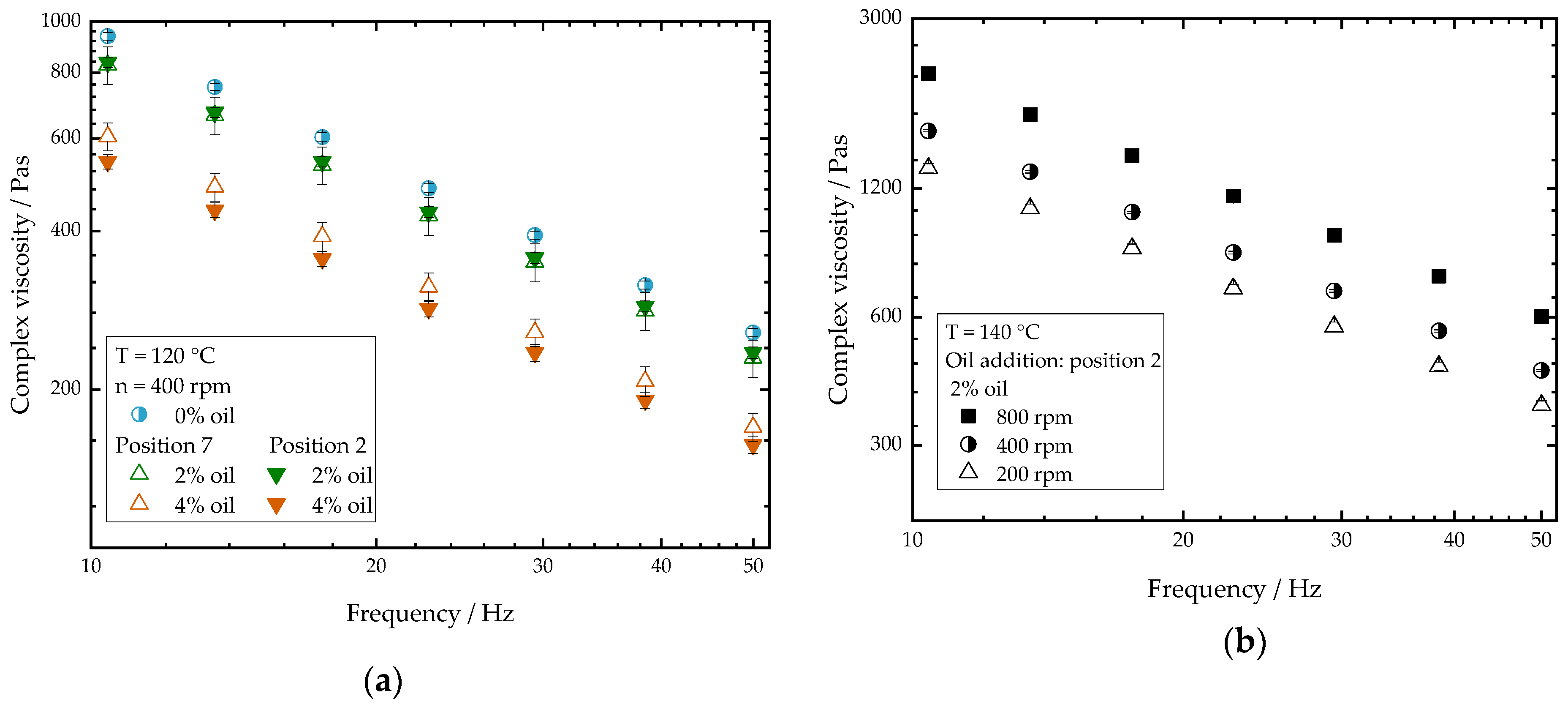

3.2. Influence of Oil Addition on the Rheological Properties

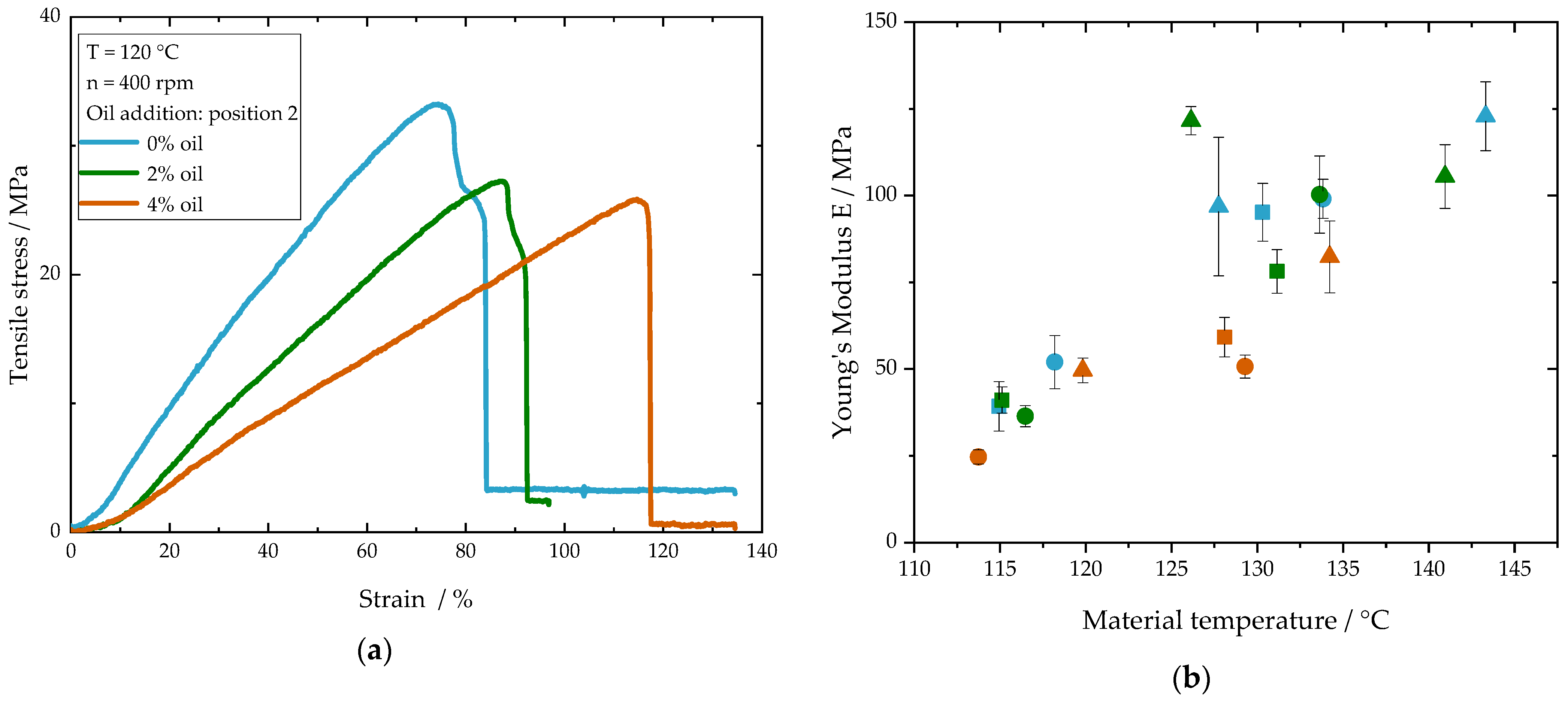

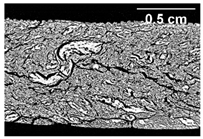

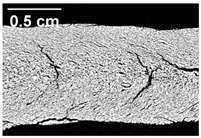

3.3. Influence of Oil on the Formation of Anisotropic Product Structure

3.4. Influence of Oil Addition on the Mechanical Properties

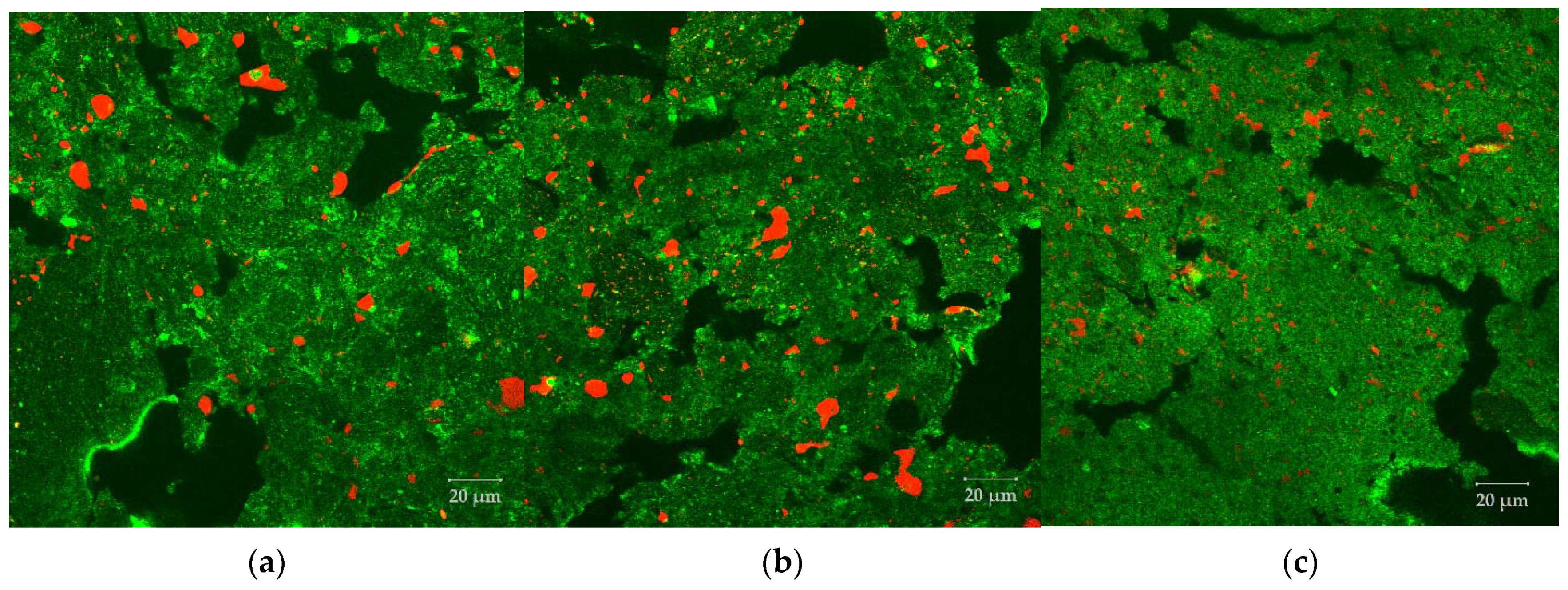

3.5. Morphology of the Oil Phase in the Protein Matrix

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elzerman, J.E.; van Boekel, M.A.J.S.; Luning, P.A. Exploring meat substitutes: Consumer experiences and contextual factors. Br. Food J. 2013, 115, 700–710. [Google Scholar] [CrossRef]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat analogues: Health promising sustainable meat substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef]

- Hathwar, S.C.; Rai, A.K.; Modi, V.K.; Narayan, B. Characteristics and consumer acceptance of healthier meat and meat product formulations-a review. J. Food Sci. Technol. 2012, 49, 653–664. [Google Scholar] [CrossRef]

- Liu, K.; Hsieh, F.-H. Protein-protein interactions during high-moisture extrusion for fibrous meat analogues and comparison of protein solubility methods using different solvent systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef] [PubMed]

- Cheftel, J.C.; Kitagawa, M.; Queguiner, C. New protein texturization processes by extrusion cooking at high moisture levels. Food Rev. Int. 1992, 8, 235–275. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High moisture extrusion cooking of pea protein isolates: Raw material characteristics, extruder responses, and texture properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Noguchi, A. Extrusion cooking of high-moisture protein foods. Extrus. Cook. 1989, 343–370. [Google Scholar]

- Pietsch, V.L.; Emin, M.A.; Schuchmann, H.P. Process conditions influencing wheat gluten polymerization during high moisture extrusion of meat analog products. J. Food Eng. 2017, 198, 28–35. [Google Scholar] [CrossRef]

- Akdogan, H. High moisture food extrusion. Int. J. Food Sci. Technol. 1999, 34, 195–207. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.-Y.; Ryu, G.-H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Bühler, J.M.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of soy protein concentrate: Influence of thermomechanical treatment on protein-protein interactions and rheological properties. J. Food Eng. 2019, 251, 11–18. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi, S.S.H.; Wang, Q. Changes in conformation and quality of vegetable protein during texturization process by extrusion. Crit. Rev. Food Sci. Nutr. 2018, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, M.; Franke, K.; Berger, R.G.; Heinz, V.; Töpfl, S. High moisture extrusion of lupin protein: Influence of extrusion parameters on extruder responses and product properties. J. Sci. Food Agric. 2019, 99, 2175–2185. [Google Scholar] [CrossRef] [PubMed]

- Hoek, A.C.; Luning, P.A.; Weijzen, P.; Engels, W.; Kok, F.J.; de Graaf, C. Replacement of meat by meat substitutes. A survey on person- and product-related factors in consumer acceptance. Appetite 2011, 56, 662–673. [Google Scholar] [CrossRef] [PubMed]

- Hoek, A.C.; van Boekel, M.A.J.S.; Voordouw, J.; Luning, P.A. Identification of new food alternatives: How do consumers categorize meat and meat substitutes? Food Qual. Prefer. 2011, 22, 371–383. [Google Scholar] [CrossRef]

- Frank, D.; Joo, S.-T.; Warner, R. Consumer Acceptability of Intramuscular Fat. Korean J. Food Sci. Anim. Resour. 2016, 36, 699–708. [Google Scholar] [CrossRef]

- Hocquette, J.F.; Gondret, F.; Baéza, E.; Médale, F.; Jurie, C.; Pethick, D.W. Intramuscular fat content in meat-producing animals: Development, genetic and nutritional control, and identification of putative markers. Anim. Int. J. Anim. Biosci. 2010, 4, 303–319. [Google Scholar] [CrossRef]

- Moloney, A.P.; Teagasc, D. The fat content of meat and meat products. Meat Process. Improv. Qual. 2002, 137–153. [Google Scholar]

- Chan, W.; McCance, R.A. Meat Poultry and Game: Fifth Supplement to the Fifth Edition of McCance and Widdowson’s the Composition of Foods; Royal Society of Chemistry: Cambridge, UK; Ministry of Agriculture Fisheries and Food: London, UK, 1995; ISBN 0851863809.

- Kumar, P.; Kumar, R.R. Product profile comparison of analogue meat nuggets versus chicken nuggets. Fleischwirtsch. Int. J. Meat Prod. Meat Process. 2011, 1, 72–74. [Google Scholar]

- Sadler, M.J. Meat alternatives—Market developments and health benefits. Trends Food Sci. Technol. 2004, 15, 250–260. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Snel, S.J.E.; Schreuders, F.K.G.; van der Sman, R.G.M.; Beyrer, M.; van der Goot, A.J. Thermo-mechanical processing of plant proteins using shear cell and high-moisture extrusion cooking. Crit. Rev. Food Sci. Nutr. 2021, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Osen, R.; Schweiggert-Weisz, U. High-Moisture Extrusion: Meat Analogues. In Reference Module in Food Science; Smithers, G.W., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-08-100596-5. [Google Scholar]

- Bounie, D.; van Hecke, E. High Moisture Extrusion: Optimisation of Texturisation through Control of Rheological and Textural Parameters. Sydney. 1997. Available online: https://www.slideserve.com/chelsea/aucun-titre-de-diapositive (accessed on 20 February 2021).

- Valle, G.D.; Vergnes, B.; Colonna, P.; Patria, A. Relations between rheological properties of molten starches and their expansion behaviour in extrusion. J. Food Eng. 1997, 31, 277–295. [Google Scholar] [CrossRef]

- Lai, L.S.; Kokini, J.L. Physicochemical changes and rheological properties of starch during extrusion. (A review). Biotechnol. Prog. 1991, 7, 251–266. [Google Scholar] [CrossRef]

- Chinnaswamy, R.; Hanna, M.A. Relationship between viscosity and expansion properties of variously extrusion-cooked corn grain components. Food Hydrocoll. 1990, 3, 423–434. [Google Scholar] [CrossRef]

- Akdogan, H.; Tomás, R.L.; Oliveira, J.C. Rheological Properties of Rice Starch at High Moisture Contents during Twin-screw Extrusion. LWT Food Sci. Technol. 1997, 30, 488–496. [Google Scholar] [CrossRef]

- Jia, F.; Wang, J.; Chen, Y.; Zhang, X.; Wang, Q.; Chen, D.; Zhang, C. Effect of oil contents on gluten network during the extrusion processing. Czech J. Food Sci. 2019, 37, 226–231. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, Y.; Jia, F.; Chen, D.; Zhang, X.; Wang, Q.; Wang, J. Effect of extrusion temperature on the protein aggregation of wheat gluten with the addition of peanut oil during extrusion. Int. J. Biol. Macromol. 2020. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Werner, R.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of wheat gluten: Relationship between process parameters, protein polymerization, and final product characteristics. J. Food Eng. 2019, 259, 3–11. [Google Scholar] [CrossRef]

- Li, M.; Lee, T.-C. Effect of Extrusion Temperature on Solubility and Molecular Weight Distribution of Wheat Flour Proteins. J. Agric. Food Chem. 1996, 44, 763–768. [Google Scholar] [CrossRef]

- Emin, M.A.; Quevedo, M.; Wilhelm, M.; Karbstein, H.P. Analysis of the reaction behavior of highly concentrated plant proteins in extrusion-like conditions. Innov. Food Sci. Emerg. Technol. 2017, 15–20. [Google Scholar] [CrossRef]

- Emin, M.A.; Schuchmann, H.P. A mechanistic approach to analyze extrusion processing of biopolymers by numerical, rheological, and optical methods. Trends Food Sci. Technol. 2017, 60, 88–95. [Google Scholar] [CrossRef]

- Gwiazda, S.; Noguchi, A.; Saio, K. Microstructural studies of texturized vegetable protein products: Effects of oil addition and transformation of raw materials in various sections of a twin screw extruder. Food Struct. 1987, 6, 8. [Google Scholar]

- Pietsch, V.L.; Karbstein, H.P.; Emin, M.A. Kinetics of wheat gluten polymerization at extrusion-like conditions relevant for the production of meat analog products. Food Hydrocoll. 2018, 85, 102–109. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. Analysis of the complex rheological properties of highly concentrated proteins with a closed cavity rheometer. Appl. Rheol. 2020, 30, 64–76. [Google Scholar] [CrossRef]

- Bourne, M. Food Texture and Viscosity: Concept and Measurement; Elsevier: San Diego, CA, USA, 2002; ISBN 0080491332. [Google Scholar]

- Dautant, F.J.; Simancas, K.; Sandoval, A.J.; Müller, A.J. Effect of temperature, moisture and lipid content on the rheological properties of rice flour. J. Food Eng. 2007, 78, 1159–1166. [Google Scholar] [CrossRef]

- Emin, M.A.; Hardt, N.; van der Goot, A.J.; Schuchmann, H.P. Formation of oil droplets in plasticized starch matrix in simple shear flow. J. Food Eng. 2012, 112, 200–207. [Google Scholar] [CrossRef]

- Wang, S.; Casulli, J.; Bouvier, J.M. Effect of dough ingredients on apparent viscosity and properties of extrudates in twin-screw extrusion-cooking. Int. J. Food Sci. Technol. 1993, 28, 465–479. [Google Scholar] [CrossRef]

- Guy, R.C.E. Raw materials for extrusion cooking processes. In The Technology of Extrusion Cooking; Frame, N.D., Ed.; Springer: Boston, MA, USA, 1994; pp. 52–72. ISBN 978-1-4613-5891-6. [Google Scholar]

- Ilo, S.; Schoenlechner, R.; Berghofe, E. Role of lipids in the extrusion cooking processes. Grasas Y Aceites 2000, 51, 97–110. [Google Scholar] [CrossRef]

- Dealy, J.M.; Read, D.J.; Larson, R.G. Structure and Rheology of Molten Polymers: From Structure to Flow Behavior and Back Again, 2nd ed.; Hanser Publications: Cincinnati, OH, USA, 2018; ISBN 9781569906118. [Google Scholar]

- Fu, J.; Mulvaney, S.J.; Cohen, C. Effect of Added Fat on the Rheological Properties of Wheat Flour Doughs. Cereal Chem. 1997, 74, 304–311. [Google Scholar] [CrossRef]

- Ganjyal, G.; Hanna, M. A Review on Residence Time Distribution (RTD) in Food Extruders and Study on the Potential of Neural Networks in RTD Modeling. J. Food Sci. 2002, 67, 1996–2002. [Google Scholar] [CrossRef]

- Emin, M.A.; Schuchmann, H.P. Droplet breakup and coalescence in a twin-screw extrusion processing of starch based matrix. J. Food Eng. 2013, 116, 118–129. [Google Scholar] [CrossRef]

- Chesters, A.K. Modelling of coalescence processes in fluid-liquid dispersions: A review of current understanding. Chem. Eng. Res. Des. 1991, 69, 259–270. [Google Scholar]

- Taylor, G.I. The formation of emulsions in definable fields of flow. Proc. R. Soc. Lond. A 1934, 146, 501–523. [Google Scholar] [CrossRef]

- Grace, H.P. Dispersion phenomena in high viscosity immiscible fluid systems and applications of static mixers as dispersion device in such systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- Emin, M.A.; Köhler, K.; Schlender, M.; Schuchmann, H.P. Characterization of Mixing in Food Extrusion and Emulsification Processes by Using CFD. In High Performance Computing in Science and Engineering’10; Nagel, W.E., Kröner, D.B., Resch, M.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 443–462. ISBN 978-3-642-15747-9. [Google Scholar]

| Addition Point | Oil Content | ||

|---|---|---|---|

| 0% | 2% | 4% | |

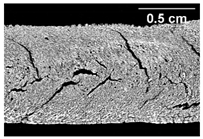

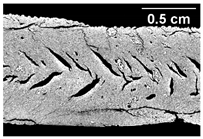

| Position 2 |  |  |  |

| Position 7 |  |  | |

| Addition Point | Oil Content | ||

|---|---|---|---|

| 0% | 2% | 4% | |

| Position 2 |  |  |  |

| Position 7 |  |  | |

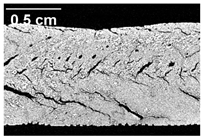

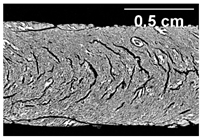

| Oil Content | Screw Speed | ||

|---|---|---|---|

| 200 rpm | 400 rpm | 800 rpm | |

| 0% |  |  |  |

| 4% |  |  |  |

| Oil Content | Screw Speed | ||

|---|---|---|---|

| 200 rpm | 400 rpm | 800 rpm | |

| 0% |  |  |  |

| 4% |  |  |  |

| Oil Content/% | Young’s Modulus/MPa | |

|---|---|---|

| Position 2 | Position 7 | |

| 0 | 52.0 ± 7.7 | 52.0 ± 7.7 |

| 2 | 36.4 ± 3.1 | 56.3 ± 5.3 |

| 4 | 24.7 ± 2.1 | 51.9 ± 5.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kendler, C.; Duchardt, A.; Karbstein, H.P.; Emin, M.A. Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues. Foods 2021, 10, 697. https://doi.org/10.3390/foods10040697

Kendler C, Duchardt A, Karbstein HP, Emin MA. Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues. Foods. 2021; 10(4):697. https://doi.org/10.3390/foods10040697

Chicago/Turabian StyleKendler, Christina, Arvid Duchardt, Heike P. Karbstein, and M. Azad Emin. 2021. "Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues" Foods 10, no. 4: 697. https://doi.org/10.3390/foods10040697

APA StyleKendler, C., Duchardt, A., Karbstein, H. P., & Emin, M. A. (2021). Effect of Oil Content and Oil Addition Point on the Extrusion Processing of Wheat Gluten-Based Meat Analogues. Foods, 10(4), 697. https://doi.org/10.3390/foods10040697