The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index

Abstract

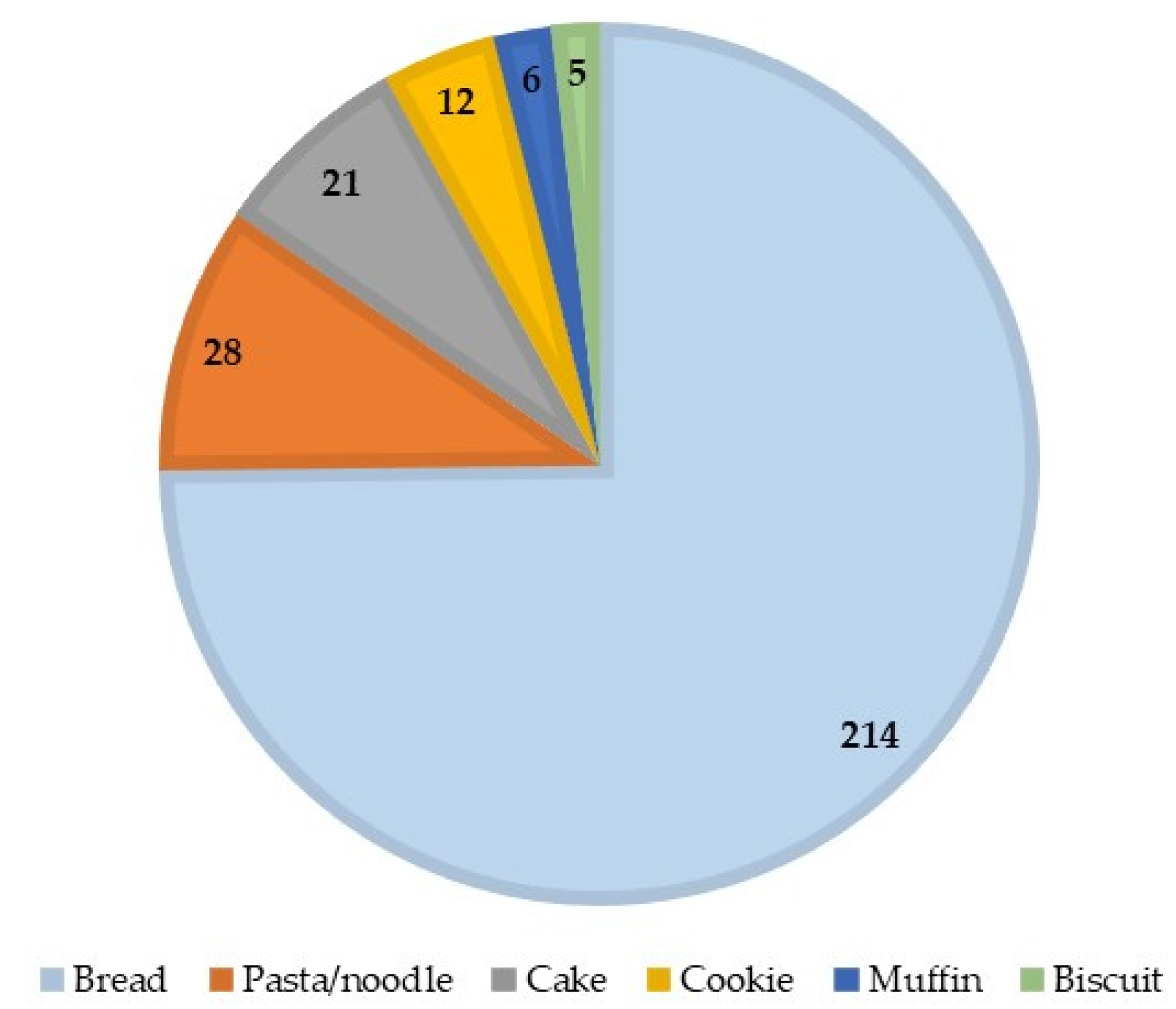

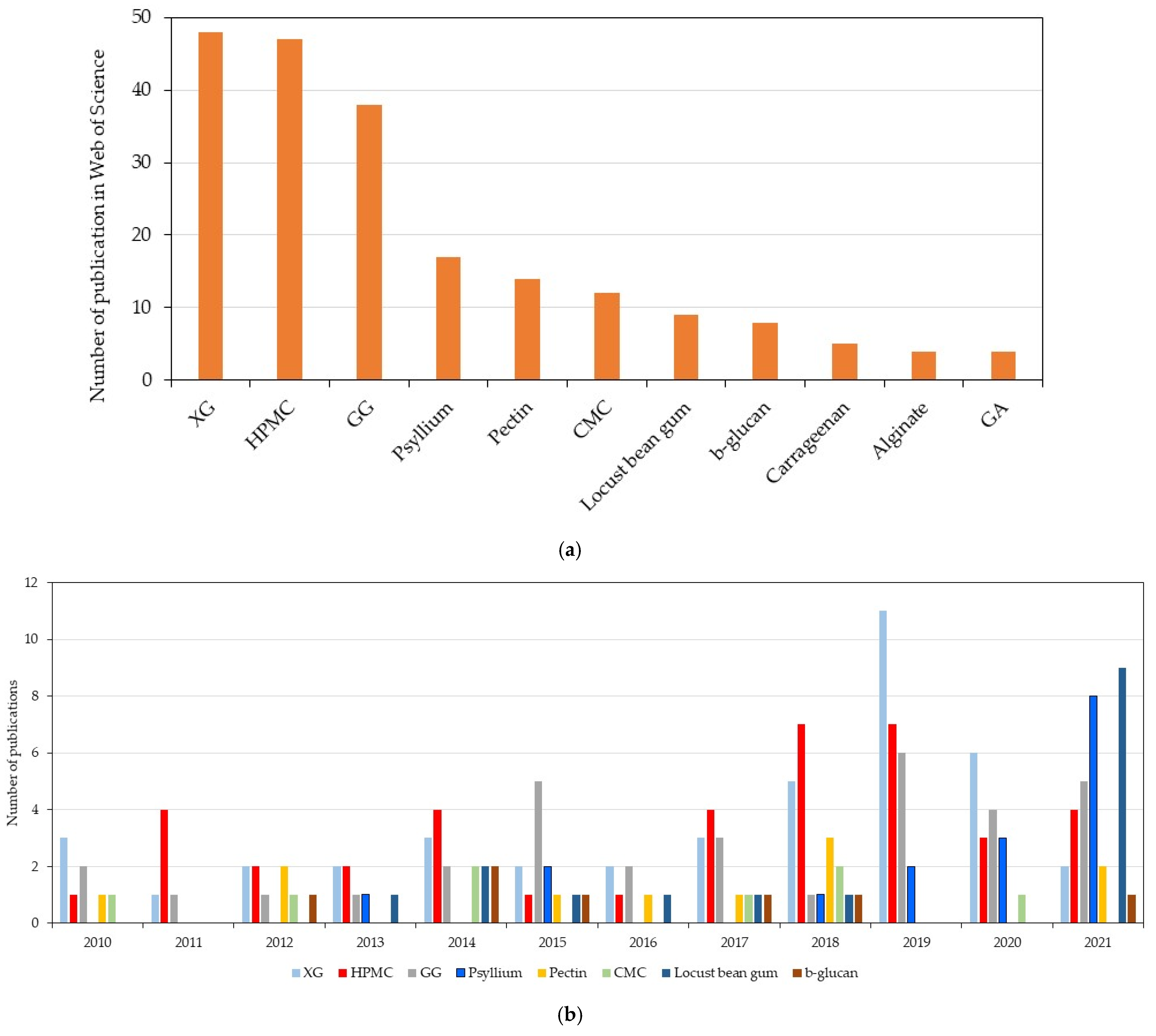

:1. Introduction

2. Hydrocolloids in GF Bread

2.1. Effect of Hydrocolloids on Dough Rheology

2.2. Effect of Hydrocolloids on Bread Hardness

2.3. Effect of Hydrocolloids on Bread Specific Volume

2.4. Staling of GF Bread in the Presence of Hydrocolloids

2.5. Estimated Glycemic Index of GF Bread in the Presence of Hydrocolloids

3. Hydrocolloids in GF Pasta/Noodles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CMC | carboxymethyl cellulose |

| GA | gum arabic |

| GF | gluten-free |

| GG | guar gum |

| GI | Glycemic Index |

| G’ | elastic (storage) modulus |

| G” | viscous (loss) modulus |

| HPMC | hydroxypropyl methylcellulose |

| PGA | propylene glycol alginate |

| RVA | Rapid Visco Analyzer |

| XG | xanthan gum |

References

- Padalino, L.; Conte, A.; Del Nobile, M.A. Overview on the general approaches to improve gluten-free pasta and bread. Foods 2016, 5, 87. [Google Scholar] [CrossRef] [Green Version]

- Zoghi, A.; Mirmahdi, R.S.; Mohammadi, M. The role of hydrocolloids in the development of gluten-free cereal-based products for coeliac patients: A review. Int. J. Food Sci. Technol. 2021, 56, 3138–3147. [Google Scholar] [CrossRef]

- Gao, Y.P.; Janes, M.E.; Chaiya, B.; Prinyawiwatkul, W.; Brennan, M.A.; Brennan, C.S.; Prinyawiwatkul, W. Gluten-free bakery and pasta products: Prevalence and quality improvement. Int. J. Food Sci. Technol. 2018, 53, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Anton, A.A.; Artfield, S.D. Hydrocolloids in gluten-free breads: A review. Int. J. Food Sci. Nutr. 2008, 59, 11–23. [Google Scholar] [CrossRef]

- Salehi, F. Improvement of gluten-free bread and cake properties using natural hydrocolloids: A review. Food Sci. Nutr. 2019, 7, 3391–3402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Filipčev, B.; Pojić, M.; Šimurina, O.; Mišan, A.; Mandić, A. Psyllium as an improver in gluten-free breads: Effect on volume, crumb texture, moisture binding and staling kinetics. LWT 2021, 151, 112156. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. A systematic review of gluten-free dough and bread: Dough rheology, bread characteristics, and improvement strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Sabanis, D.; Tzia, C. Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci. Technol. Int. 2010, 17, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Morreale, F.; Garzón, R.; Rosell, C.M. Understanding the role of hydrocolloids viscosity and hydration in developing gluten-free bread. A study with hydroxypropylmethylcellulose. Food Hydrocoll. 2018, 77, 629–635. [Google Scholar] [CrossRef]

- Hager, A.-S.; Arendt, E.K. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll. 2013, 32, 195–203. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Axel, C.; Arendt, E.K. Water absorption as a prediction tool for the application of hydrocolloids in potato starch-based bread. Food Hydrocoll. 2018, 81, 129–138. [Google Scholar] [CrossRef]

- Funami, T.; Kataoka, Y.; Omoto, T.; Goto, Y.; Asai, I.; Nishinari, K. Food hydrocolloids control the gelatinization and retrogradation behavior of starch. 2a. Functions of guar gums with different molecular weights on the gelatinization behavior of corn starch. Food Hydrocoll. 2005, 19, 15–24. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Crockett, R.; Ie, P.; Vodovotz, Y. Effects of soy protein isolate and egg white solids on the physicochemical properties of gluten-free bread. Food Chem. 2011, 129, 84–91. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Varzakas, T. High Protein Substitutes for Gluten in Gluten-Free Bread. Foods 2021, 10, 1997. [Google Scholar] [CrossRef]

- Belorio, M.; Gómez, M. Effect of hydration on gluten-free breads made with hydroxypropyl methylcellulose in comparison with psyllium and xanthan gum. Foods 2020, 9, 1548. [Google Scholar] [CrossRef] [PubMed]

- Sahin, A.S.; Wiertz, J.; Arendt, E.K. Evaluation of a new method to determine the water addition level in gluten-free bread systems. J. Cereal Sci. 2020, 93, 102971. [Google Scholar] [CrossRef]

- Demirkesen, L.; Mert, B.; Sumnu, G.; Sahin, S. Rheological properties of gluten-free bread formulations. J. Food Eng. 2010, 96, 295–303. [Google Scholar] [CrossRef]

- Capriles, V.D.; Arêas, J.A.G. Novel approaches in gluten-free breadmaking: Interface between food science, nutrition, and health. Compr. Rev. Food Sci. Food Saf. 2014, 13, 871–890. [Google Scholar] [CrossRef]

- Torbica, A.; Hadnađev, M.; Dapčević, T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocoll. 2010, 24, 626–632. [Google Scholar] [CrossRef]

- Baldino, N.; Laitano, F.; Lupi, F.R.; Curcio, S.; Gabriele, D. Effect of HPMC and CMC on rheological behavior at different temperatures of gluten-free bread formulations based on rice and buckwheat flours. Eur. Food Res. Technol. 2018, 244, 1829–1842. [Google Scholar] [CrossRef]

- Mancebo, C.M.; San Miguel, M.Á.; Martínez, M.M.; Gómez, M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 2015, 61, 8–15. [Google Scholar] [CrossRef]

- Ozturk, O.K.; Mert, B. The effects of microfluidization on rheological and textural properties of gluten-free corn breads. Food Res. Int. 2018, 105, 782–792. [Google Scholar] [CrossRef]

- Phan-Thien, N.; Safari-Ardi, M. Linear viscoelastic properties of flour-water doughs at different water concentrations. J. Non Newton. Fluid Mech. 1998, 74, 137–150. [Google Scholar] [CrossRef]

- Fanari, F.; Desogus, F.; Scano, E.A.; Carboni, G.; Grosso, M. The effect of the relative amount of ingredients on the rheological properties of semolina doughs. Sustainability 2020, 12, 2705. [Google Scholar] [CrossRef] [Green Version]

- Zhong, Q.; Ikeda, S. Viscoelastic properties of concentrated aqueous ethanol suspensions of alpha-zein. Food Hydrocoll. 2012, 28, 46–52. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Incorporation of several additives into gluten free breads: Effect on dough properties and bread quality. J. Food Eng. 2012, 111, 590–597. [Google Scholar] [CrossRef]

- Peressini, D.; Pin, M.; Sensidoni, A. Rheology and breadmaking performance of rice-buckwheat batters supplemented with hydrocolloids. Food Hydrocoll. 2011, 25, 340–349. [Google Scholar] [CrossRef]

- Zhao, F.; Li, Y.; Li, C.; Ban, X.; Cheng, L.; Hong, Y.; Gu, Z.; Li, Z. Co-supported hydrocolloids improve the structure and texture quality of gluten-free bread. LWT 2021, 152, 112248. [Google Scholar] [CrossRef]

- Ari Akin, P.; Miller, R.A. Starch–hydrocolloid interaction in chemically leavened gluten-free sorghum bread. Cereal Chem. 2017, 94, 897–902. [Google Scholar] [CrossRef]

- Santos, F.G.; Capriles, V.D. Relationships between dough thermomechanical parameters and physical and sensory properties of gluten-free bread texture during storage. LWT 2021, 139, 110577. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Torres, M.D. Effect of chia (Sativa hispanica L.) and hydrocolloids on the rheology of gluten-free doughs based on chestnut flour. LWT 2013, 50, 160–166. [Google Scholar] [CrossRef]

- Calle, J.; Benavent-Gil, Y.; Rosell, C.M. Development of gluten free breads from Colocasia esculenta flour blended with hydrocolloids and enzymes. Food Hydrocoll. 2020, 98, 105243. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Kotwaliwale, N.; Navale, S.A. Selection and incorporation of hydrocolloid for gluten-free leavened millet breads and optimization of the baking process thereof. LWT 2020, 119, 108878. [Google Scholar] [CrossRef]

- Mohammadi, M.; Sadeghnia, N.; Azizi, M.-H.; Neyestani, T.-R.; Mortazavian, A.M. Development of gluten-free flat bread using hydrocolloids: Xanthan and CMC. J. Ind. Eng. Chem. 2014, 20, 1812–1818. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res. Int. 2018, 111, 544–555. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez-Sandoval, E.; Cortes-Rodriguez, M.; Manjarres-Pinzon, K. Effect of hydrocolloids on the pasting profiles of tapioca starch mixtures and the baking properties of gluten-free cheese bread. J. Food Process. Preserv. 2015, 39, 1672–1681. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Effect of hydrocolloids on gluten-free batter properties and bread quality. Int. J. Food Sci. Technol. 2010, 45, 2306–2312. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Influence of different hydrocolloids on dough thermo-mechanical properties and in vitro starch digestibility of gluten-free steamed bread based on potato flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mezaize, S.; Chevallier, S.; Le Bail, A.; De Lamballerie, M. Optimization of gluten-free formulations for french-style breads. J. Food Sci. 2009, 74, E140–E146. [Google Scholar] [CrossRef]

- Moradi, M.; Bolandi, M.; Arabameri, M.; Karimi, M.; Baghaei, H.; Nahidi, F.; Eslami Kanafi, M. Semi-volume gluten-free bread: Effect of guar gum, sodium caseinate and transglutaminase enzyme on the quality parameters. J. Food Meas. Charact. 2021, 15, 2344–2351. [Google Scholar] [CrossRef]

- Fratelli, C.; Santos, F.G.; Muniz, D.G.; Habu, S.; Braga, A.R.C.; Capriles, V.D. Psyllium improves the quality and shelf life of gluten-free bread. Foods 2021, 10, 954. [Google Scholar] [CrossRef]

- Santos, F.G.; Aguiar, E.V.; Braga, A.R.C.; Alencar, N.M.M.; Rosell, C.M.; Capriles, V.D. An integrated instrumental and sensory approach to describe the effects of chickpea flour, psyllium, and their combination at reducing gluten-free bread staling. Food Packag. Shelf Life 2021, 28, 100659. [Google Scholar] [CrossRef]

- Cohn, A.; Sofia, A.M.; Kupfer, S.S. Type 1 diabetes and celiac disease: Clinical overlap and new insights into disease pathogenesis. Curr. Diab. Rep. 2014, 14, 517. [Google Scholar] [CrossRef] [Green Version]

- Segura, M.E.M.; Rosell, C.M. Chemical composition and starch digestibility of different gluten-free breads. Plant. Foods Hum. Nutr. 2011, 66, 224–230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romão, B.; Falcomer, A.L.; Palos, G.; Cavalcante, S.; Botelho, R.B.A.; Nakano, E.Y.; Raposo, A.; Shakeel, F.; Alshehri, S.; Mahdi, W.A.; et al. Glycemic index of gluten-free bread and their main ingredients: A systematic review and meta-analysis. Foods 2021, 10, 506. [Google Scholar] [CrossRef]

- Capriles, V.D.; Arêas, J.A.G. Effects of prebiotic inulin-type fructans on structure, quality, sensory acceptance and glycemic response of gluten-free breads. Food Funct. 2013, 4, 104–110. [Google Scholar] [CrossRef]

- Capriles, V.D.; Arêas, J.A.G. Approaches to reduce the glycemic response of gluten-free products: In vivo and in vitro studies. Food Funct. 2016, 7, 1266–1272. [Google Scholar] [CrossRef] [PubMed]

- Bender, D.; Schönlechner, R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Ramos, L.; Alonso-Hernando, A.; Martínez-Castro, M.; Morán-Pérez, J.A.; Cabrero-Lobato, P.; Pascual-Maté, A.; Téllez-Jiménez, E.; Mujico, J.R. Sourdough biotechnology applied to gluten-free baked goods: Rescuing the tradition. Foods 2021, 10, 1498. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. Crit. Rev. Food Sci. Nutr. 2021, 1–13. [Google Scholar] [CrossRef]

- de la Hera, E.; Rosell, C.M.; Gomez, M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014, 151, 526–531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, H.J.M.; Liu, Q.; Lim, S.T. Texture and in vitro digestibility of white rice cooked with hydrocolloids. Cereal Chem. 2007, 84, 246–249. [Google Scholar] [CrossRef]

- Thondre, P.S.; Monro, J.A.; Mishra, S.; Henry, C.J.K. High molecular weight barley β-glucan decreases particle breakdown in chapattis (Indian flat breads) during in vitro digestion. Food Res. Int. 2010, 43, 1476–1481. [Google Scholar] [CrossRef]

- Ho, L.H.; Tan, T.C.; Aziz, N.A.A.; Bhat, R. In vitro starch digestibility of bread with banana (Musa acuminata X balbisiana ABB cv. Awak) pseudo-stem flour and hydrocolloids. Food Biosci. 2015, 12, 10–17. [Google Scholar] [CrossRef]

- Dartois, A.; Singh, J.; Kaur, L.; Singh, H. Influence of guar gum on the in vitro starch digestibility—Rheological and microstructural characteristics. Food Biophys. 2010, 5, 149–160. [Google Scholar] [CrossRef]

- Ellis, P.R.; Burley, V.J.; Leeds, A.R.; Peterson, D.B. A guar enriched wholemeal bread reduces postprandial glucose and insulin responses. J. Hum. Nutr. Diet. 1988, 1, 77–84. [Google Scholar] [CrossRef]

- Montemurro, M.; Pontonio, E.; Rizzello, C.G. Design of a “clean-label” gluten-free bread to meet consumers demand. Foods 2021, 10, 462. [Google Scholar] [CrossRef]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Effect of ingredients on the quality of gluten-free steamed bread based on potato flour. J. Food Sci. Technol. 2019, 56, 2863–2873. [Google Scholar] [CrossRef]

- Fratelli, C.; Muniz, D.G.; Santos, F.G.; Capriles, V.D. Modelling the effects of psyllium and water in gluten-free bread: An approach to improve the bread quality and glycemic response. J. Funct. Foods 2018, 42, 339–345. [Google Scholar] [CrossRef]

- Santos, F.G.; Aguiar, E.V.; Rosell, C.M.; Capriles, V.D. Potential of chickpea and psyllium in gluten-free breadmaking: Assessing bread’s quality, sensory acceptability, and glycemic and satiety indexes. Food Hydrocoll. 2021, 113, 106487. [Google Scholar] [CrossRef]

- Gasparre, N.; Rosell, C.M. Role of hydrocolloids in gluten free noodles made with tiger nut flour as non-conventional powder. Food Hydrocoll. 2019, 97, 105194. [Google Scholar] [CrossRef]

- Padalino, L.; Mastromatteo, M.; De Vita, P.; Ficco, D.B.M.; Del Nobile, M.A. Effects of hydrocolloids on chemical properties and cooking quality of gluten-free spaghetti. Int. J. Food Sci. Technol. 2013, 48, 972–983. [Google Scholar] [CrossRef]

- Cai, J.; Chiang, J.H.; Tan, M.Y.P.; Saw, L.K.; Xu, Y.; Ngan-Loong, M.N. Physicochemical properties of hydrothermally treated glutinous rice flour and xanthan gum mixture and its application in gluten-free noodles. J. Food Eng. 2016, 186, 1–9. [Google Scholar] [CrossRef]

- Chauhan, A.; Saxena, D.C.; Singh, S. Effect of hydrocolloids on microstructure, texture and quality characteristics of gluten-free pasta. Food Meas. 2017, 11, 1188–1195. [Google Scholar] [CrossRef]

- Romero, H.M.; Santra, D.; Rose, D.; Zhang, Y. Dough rheological properties and texture of gluten-free pasta based on proso millet flour. J. Cereal Sci. 2017, 74, 238–243. [Google Scholar] [CrossRef]

- Milde, L.B.; Chigal, P.S.; Olivera, J.E.; González, K.G. Incorporation of xanthan gum to gluten-free pasta with cassava starch. Physical, textural and sensory attributes. LWT 2020, 131, 109674. [Google Scholar] [CrossRef]

- De Arcangelis, E.; Cuomo, F.; Trivisonno, M.C.; Marconi, E.; Messia, M.C. Gelatinization and pasta making conditions for buckwheat gluten-free pasta. J. Cereal Sci. 2020, 95, 103073. [Google Scholar] [CrossRef]

| Type of Hydrocolloid | Level Used * | Other Ingredients | Type of the Rheological Test | Effect | References |

|---|---|---|---|---|---|

| GG | 1% | chestnut flour with 4% chia flour | Creep-recovery (rheometer) | Improved the dough elasticity by 65.9% | [34] |

| HPMC | 2% | Improved the dough elasticity by 64.8% | |||

| Tragacanth gum | 1% | Improved dough elasticity by 45.8% | |||

| XG–GG (mix) | 0.5% | 100% rice flour, 8% sugar, 8% shortening, 2% salt, 1% instant yeast, 150% water | Frequency sweep | Increased elastic and viscous moduli | [20] |

| CMC | 1% | 70% rice flour, 30% buckwheat flour, 85% water | Frequency sweep | Increased complex modulus, improved the internal structure, increased the crumb porosity, similar to the standard wheat bread | [23] |

| HPMC | 1% | 70% rice flour, 30% buckwheat flour, 85% water | |||

| HPMC | 1% | 70% rice flour, 30% buckwheat flour, 100% water | |||

| HPMC | 1–1.5% | 75% corn starch, 25% rice flour, 2% yeast, 4% sunflower oil, 4% sucrose, 2% salt, 75–85% water | Shear properties, Power law | Improved viscosity | [10] |

| GG | |||||

| Carrageenan | |||||

| XG | |||||

| HPMC | 5.5% | 22.2% corn meal, 77.8% corn starch, 5.5% sugar, 2.2% salt, 1.1% yeast, 83.3% water | Strain and frequency sweep measurements | Increased elastic and viscous moduli | [25] |

| XG | 4% | 90% sorghum flour, 10% potato starch, 100% water, 6% sugar, 3% baking powder, 1.5% salt | RVA | Lowered viscosity 2.8 vs. 3.4 cP (control) | [32] |

| HPMC | 3% | 90% sorghum flour, 10% tapioca starch, 100% water, 6% sugar, 3% baking powder, 1.5% salt | 3.3 vs. 3.4 cP (control) | ||

| XG | 3% | 90% sorghum flour, 10% rice starch, 100% water, 6% sugar, 3% baking powder, 1.5% salt | 3.0 vs. 3.4 cP (control) | ||

| Psyllium and HPMC | 0–4% and 2–4% | 100% rice flour, 3% yeast, 1.8% salt, 10% oil, 5% sugar, 90–110% water | Dynamic oscillatory and creep-recovery test | Psyllium incorporation reduced the pasting temperature and compliance values and increased elastic and viscous moduli | [24] |

| XG | 0.5–1.5% | 60% rice flour, 40% buckwheat flour, 1.5% salt, 4.4% oil, 5.3% yeast, 80–90% water | Frequency sweep test | Elastic modulus from 4 to 22 times higher than control | [30] |

| PGA | 0.5–1.5% | Elastic modulus from 1.5 to 3 times higher than control | |||

| XG | 0.5% | 45% rice flour, 45% cassava starch, 10% soy flour, 2% salt, 2% shortening, 3%yeast, 75% water | Large deformation and frequency sweep | Resistance: 35.6 vs. 46.3 g (control) | [29] |

| Carrageenan | 0.5% | Increased moduli Elastic: 60.8 vs. 29.7 kPa (control) Viscous: 12.9 vs. 6.8 kPa (control) | |||

| XG, CMC | 1% and 2% | rice flour, corn starch, sodium caseinate, fresh yeast, sunflower oil, salt, sugar, 140–150% water | Oscillation measurements | Increased elasticity | [15] |

| Type of Hydrocolloid | Level Used * | Other Ingredients * | Hardness, g or N ** | References |

|---|---|---|---|---|

| Carrageenan | 0.5% | 40% rice flour, 40% corn flour, 20% soy flour, 2% salt, 2% shortening, 3% compressed yeast, 158% water (flour basis). | 818 vs. 720 g | [40] |

| Alginate | 0.5% | 723 vs. 720 g | ||

| XG | 0.5% | 402 vs. 720 g | ||

| CMC | 0.5% | 639 vs. 720 g | ||

| Gelatine | 0.5% | 730 vs. 720 g | ||

| HPMC | 2% | 100% potato flour, 70% water, 1% yeast | 28.9 vs. 58.3 N | [41] |

| CMC | 1% | 32.7 vs. 58.3 N | ||

| XG | 2% | 24.1 vs. 58.3 N | ||

| Apple pectin | 1% | 33.6 vs. 58.3 N | ||

| HPMC | 2% | 100% rhizome flour, 227% water, 1.5% salt, 3% yeast, 2% sugar, 2% oil | 316 vs. 263 g | [35] |

| HPMC, XG, GG | 0.29%, 0.21%, 0.50% | 323 vs. 263 g | ||

| XG | 1.5% | 58.3% corn starch, 25% rice flour, 16.7% soy flour, 3.3% pre-gelatinized corn starch, 3.3% vegetable oil, 1.7% egg white, 1.6% salt, 1.6% sugar, 1.3% yeast, 0.42% sodium stearoyl lactylate | 5.1 vs. 26.2% | [37] |

| XG, CMC | 1%, 1% | 5.7 vs. 26.2% | ||

| HPMC | 1.5% | 75% corn starch, 25% rice flour, 2% yeast, 4% sunflower oil, 4% sucrose, 2% salt, 80% water | 2.96 vs. 4.9% | [10] |

| GG | 1.5% | 3.46 vs. 4.9% | ||

| Carrageenan | 1.5% | 3.94 vs. 4.9% | ||

| GG | 5% | 100% fresh cheese, 50% tapioca starch, 20% pre-cooked corn flour, 10% margarine, 6% sugar, 97% milk | 16.5 vs. 20.0% | [39] |

| XG | 0.5% | 45% rice flour, 45% cassava starch, 10% soy flour, 2% salt, 2% shortening, 3% yeast, 75% water | 162 vs. 249 g | [29] |

| CMC | 0.5% | 113 vs. 249 g | ||

| Carrageenan | 0.5% | 132 vs. 249 g | ||

| Alginate | 0.5% | 141 vs. 249 g | ||

| GG | 1.9% | 50% rice flour, 15% corn flour, 30.6% cornstarch, 4.4% potato starch, 1.6% salt, 5.1% yeast, 5.9% oil, 83.6% g water | 2.91 vs. 6 N | [42] |

| HPMC | 2.3% | 1.86 vs. 6 N |

| Type of Hydrocolloid | Level Used | Other Ingredients * | Specific Volume, cm3/g ** | References |

|---|---|---|---|---|

| Carrageenan | 0.5% | 40% rice flour, 40% corn flour, 20% soy flour, 2% salt, 2% shortening, 3% compressed yeast, 158% water | 2.6 vs. 2.4 | [40] |

| Alginate | 0.5% | 2.5 vs. 2.4 | ||

| XG | 0.5% | 2.9 vs. 2.4 | ||

| CMC | 0.5% | 2.6 vs. 2.4 | ||

| Gelatine | 0.5% | 2.5 vs. 2.4 | ||

| HPMC | 2% | 100% potato flour, 70% water, 1% yeast | 2 vs. 1.25 | [41] |

| CMC | 1% | 1.75 vs. 1.25 | ||

| XG | 2% | 1.85 vs. 1.25 | ||

| Apple pectin | 1% | 1.6 vs. 1.25 | ||

| HPMC | 1.5% | 75% corn starch, 25% rice flour, 2% yeast, 4% sunflower oil, 4% sucrose, 2% salt, 80% water for 1.5% hydrocolloid/85% water for 2% hydrocolloid | 2.9 vs. 2.68 | [10] |

| HPMC | 2% | 2.85 vs. 2.68 | ||

| GG | 1.5% | 2.85 vs. 2.68 | ||

| GG | 2.5% | 100% fresh cheese, 50% tapioca starch, 20% pre-cooked corn flour, 10% margarine, 6% sugar, 68% milk | 2.4 vs. 2.1 | [39] |

| XG | 0.5% | 45% rice flour, 45% cassava starch, 10% soy flour, 2% salt, 2% shortening, 3%yeast, 75% water | 1.86 vs. 1.98 | [29] |

| CMC | 0.5% | 2.14 vs. 1.98 | ||

| Carrageenan | 0.5% | 2.38 vs. 1.98 | ||

| Alginate | 0.5% | 1.99 vs. 1.98 | ||

| GG | 1.9% | 50% rice flour, 15% corn flour, 30.6% cornstarch, 4.4% potato starch, 1.6% salt, 5.1% yeast, 5.9% oil, 83.6% water | 2.82 vs. 2.47 | [42] |

| HPMC | 2.3% | 3.33 vs. 2.47 | ||

| CMC | 1% | rice flour, corn starch, sodium caseinate, fresh yeast, sunflower oil, salt, sugar, 140% water | 2.67 vs. 2.19 | [15] |

| Agarose | 1% | 2.62 vs. 2.19 | ||

| β-glucan | 1% | 2.68 vs. 2.19 | ||

| Pectin | 2% | rice flour, corn starch, sodium caseinate, fresh yeast, sunflower oil, salt, sugar, 150% water | 2.52 vs. 2.21 | [15] |

| Type of Hydrocolloid | Level Used | Other Ingredients | GI Value | Method * | References |

|---|---|---|---|---|---|

| None | - | 100% potato flour, 70% water, 1% yeast | 73.3 | in vitro starch digestibility glucose | [41] |

| Apple pectin | 0.5% | 65.1 | |||

| 1% | 64.8 | ||||

| 2% | 65.1 | ||||

| HPMC | 0.5% | 65.0 | |||

| 1% | 60.5 | ||||

| 2% | 58.9 | ||||

| CMC | 0.5% | 66.2 | |||

| 1% | 68.4 | ||||

| 2% | 66.6 | ||||

| XG | 0.5% | 62.7 | |||

| 1% | 62.7 | ||||

| 2% | 63.3 | ||||

| None | - | 100% flour (50% Colocasia flour blended with 50% pre-treated Colocasia flour), 227% water, 1.5% salt, 3% compressed yeast, 2% sugar, 2% oil | 23.9 | in vitro starch digestibility white bread | [35] |

| HPMC | 2% | 23.1 | |||

| HPMC + XG + GG | 0.29 + 0.21 + 0.50% | 26.2 | |||

| HPMC | 1.68% | 100% potato flour, 4.84% pregelatinized potato flour, 5.87% egg white protein, 69.69% water | 55.2 | in vitro starch digestibility | [61] |

| None | - | 75% rice flour, 25% cassava starch, 25% whole egg, 10.5% whole milk powder, 6% white cane sugar, 6% soy oil, 2% salt, 0.8% dry yeast, 117.86% water | 66.5 | in vivo white wheat bread | [62] |

| Psyllium | 17.14% | 50 | |||

| XG + CMC | 0.3%, 0.3% | 75% chickpea flour, 25% cassava starch, 6% white cane sugar, 2% salt, 0.8% dry yeast, 0.1% calcium propionate, 25% whole eggs, 6% soybean oil, 125% water | 79.2 | in vivo rice bread | [63] |

| Psyllium | 5.5% | 74.6 |

| Type of Hydrocolloid/Obtained Product | Level Used | Other Ingredients | Type of the Rheological Test | Effect | References |

|---|---|---|---|---|---|

| XG, GG, CMC/noodles | 0.5% | Tiger nut flour | Mixolab rheological behavior: mixing, heating and cooling consistency, extrusion force | Improved dough extensibility; XGgavehigher firmness, reduced adhesiveness, increased chewiness and resilience | [64] |

| Gellan Gum, CMC, Pectin PEC, Agar, Tapioca starch, Guar seed flour and Chitosan/spaghetti | 2.0% | Maize flour and naked oat | Elongation and shear viscosity (capillary rheometer) | Improved cooking quality and texture properties (adhesiveness, cooking loss, hardness). Chitosan: reduced glycemic index. CMC and agar: reducing the blood cholesterol. | [65] |

| XG/noodle | 5% | Rice flour, glutinous rice flour | Pasting properties (RVA); Frequency sweep test (controlled-stress rheometer); Dough development characteristics: water absorption, development time, stability, softening (DoughLab equipment) | Enhanced tensile strength, peak viscosity, gel strength. Increased chewiness and hardness. | [66] |

| GG, gum acacia and gum tragacanth/pasta | 0.5–1% | Amaranth flour | Pasting properties (RVA) | GG and gum tragacanth: increased peak, trough, breakdown and final viscosities. Gum acacia: reverse trend. | [67] |

| GG, XG, sodium alginate | 1% and 2% | Proso millet flour | Frequency sweep tests (controlled stress rheometer) | Improved dough rheology (increased viscosity and elasticity at 2% addition) Improved pasta network strength by GG and XG addition | [68] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Culetu, A.; Duta, D.E.; Papageorgiou, M.; Varzakas, T. The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods 2021, 10, 3121. https://doi.org/10.3390/foods10123121

Culetu A, Duta DE, Papageorgiou M, Varzakas T. The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods. 2021; 10(12):3121. https://doi.org/10.3390/foods10123121

Chicago/Turabian StyleCuletu, Alina, Denisa Eglantina Duta, Maria Papageorgiou, and Theodoros Varzakas. 2021. "The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index" Foods 10, no. 12: 3121. https://doi.org/10.3390/foods10123121

APA StyleCuletu, A., Duta, D. E., Papageorgiou, M., & Varzakas, T. (2021). The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods, 10(12), 3121. https://doi.org/10.3390/foods10123121