Effects of Pectin on the Physicochemical Properties and Freeze-Thaw Stability of Waxy Rice Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Isolation of Waxy Rice Starch

2.3. Pasting Properties

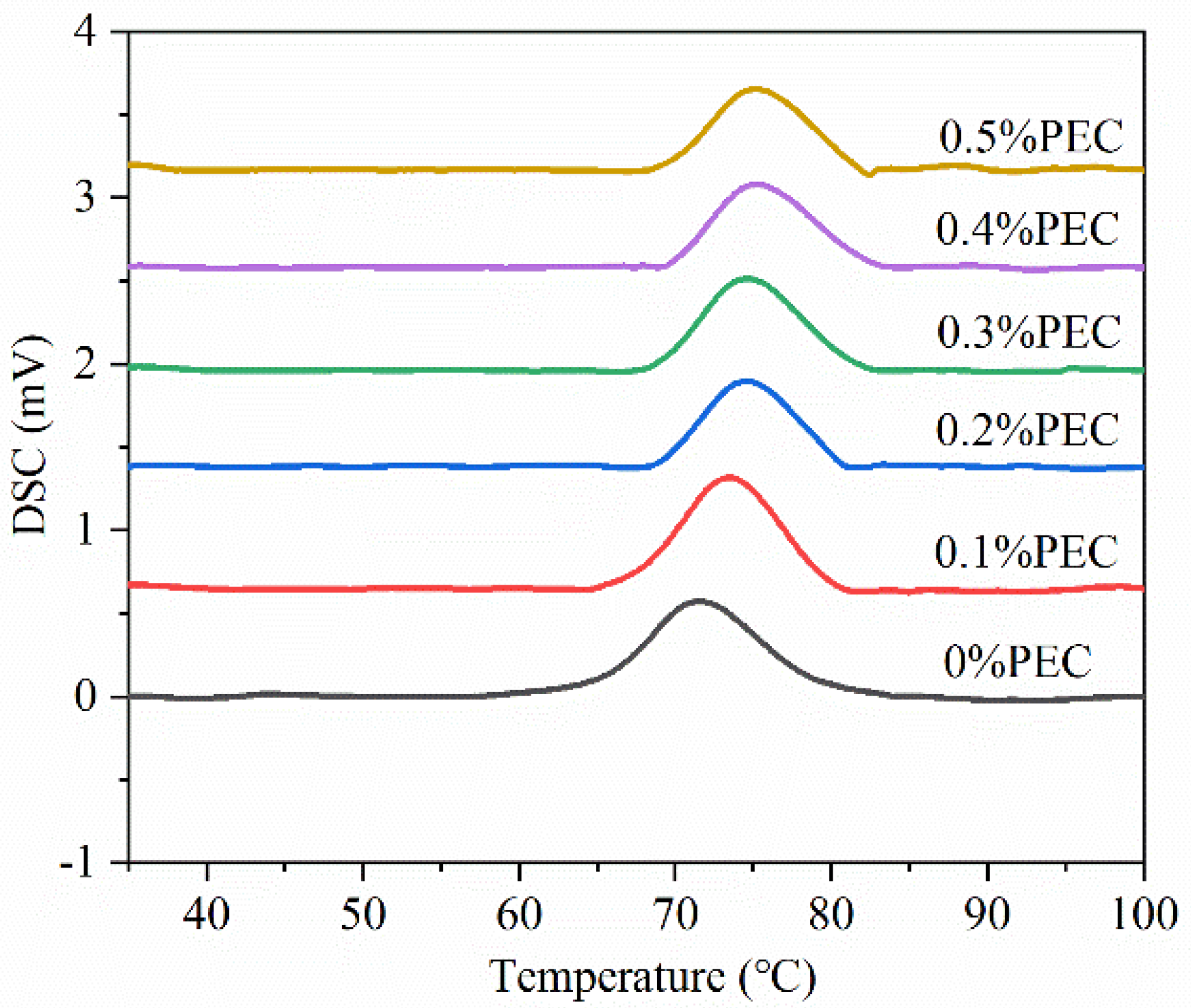

2.4. Thermal Properties

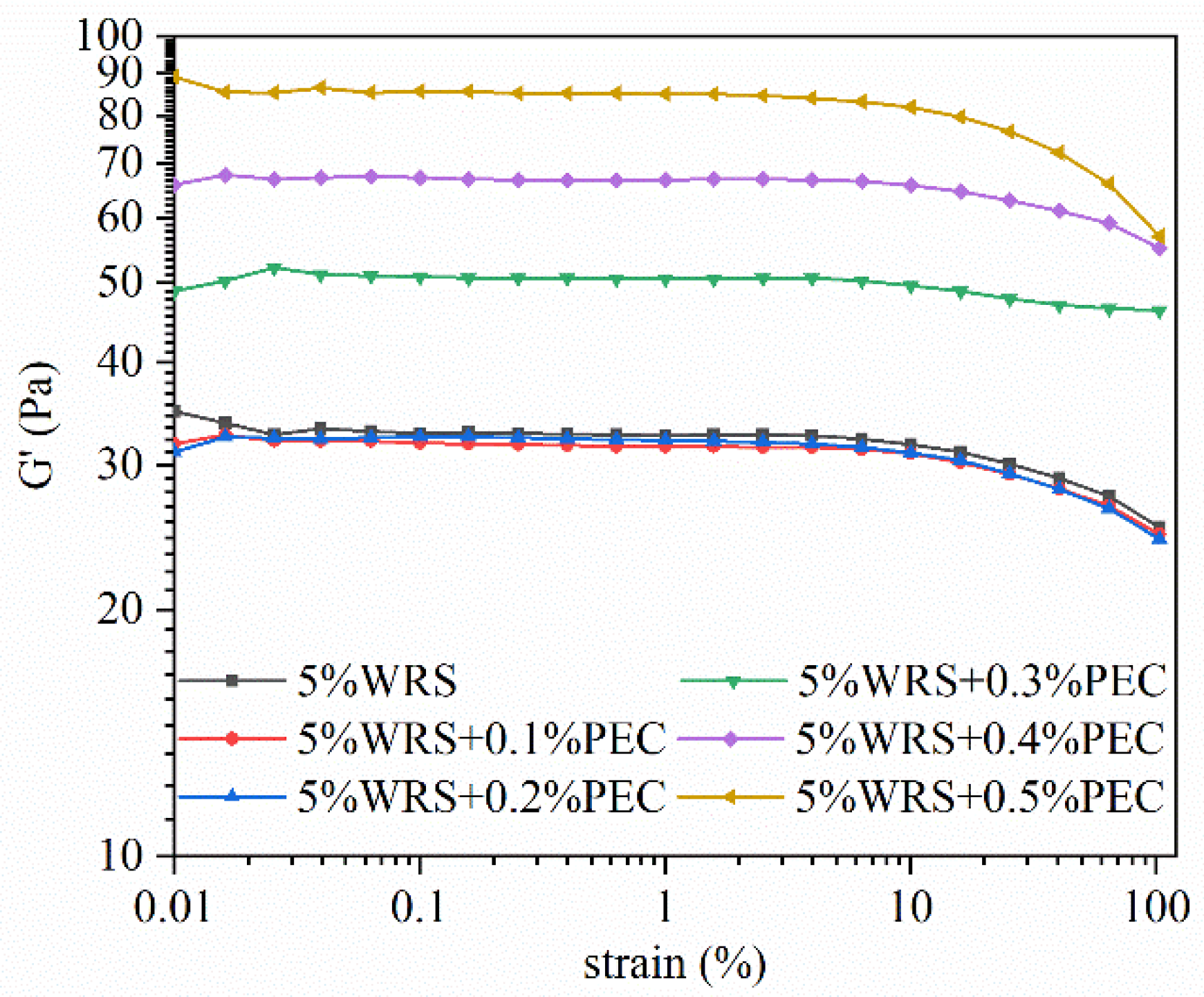

2.5. Rheological Properties

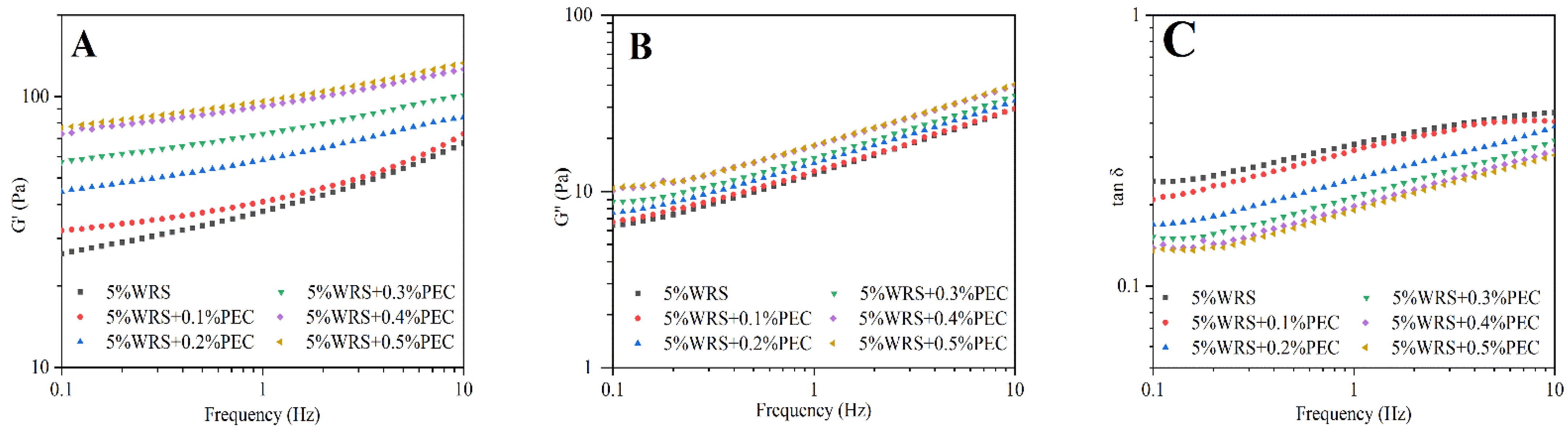

2.5.1. Frequency Sweep Test

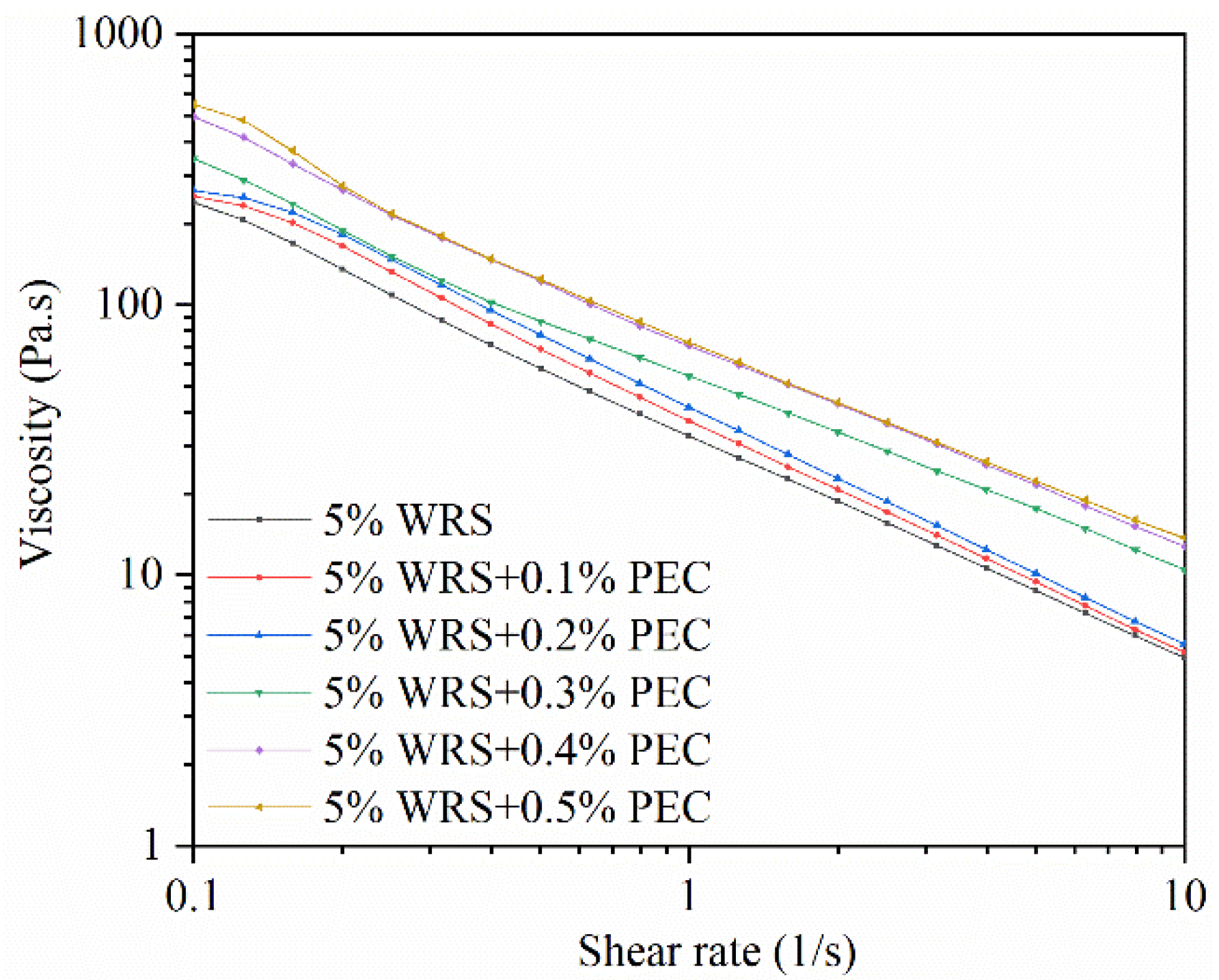

2.5.2. Flow Sweep Test

2.6. Paste Clarity

2.7. Textural Properties

2.8. Freeze-Thaw Stability

2.9. Statistical Analysis

3. Results and Discussion

3.1. Pasting Properties

3.2. Thermal Properties

3.3. Dynamic Rheological Properties

3.4. Steady Shear Rheological Properties

3.5. Paste Clarity

3.6. Textural Properties

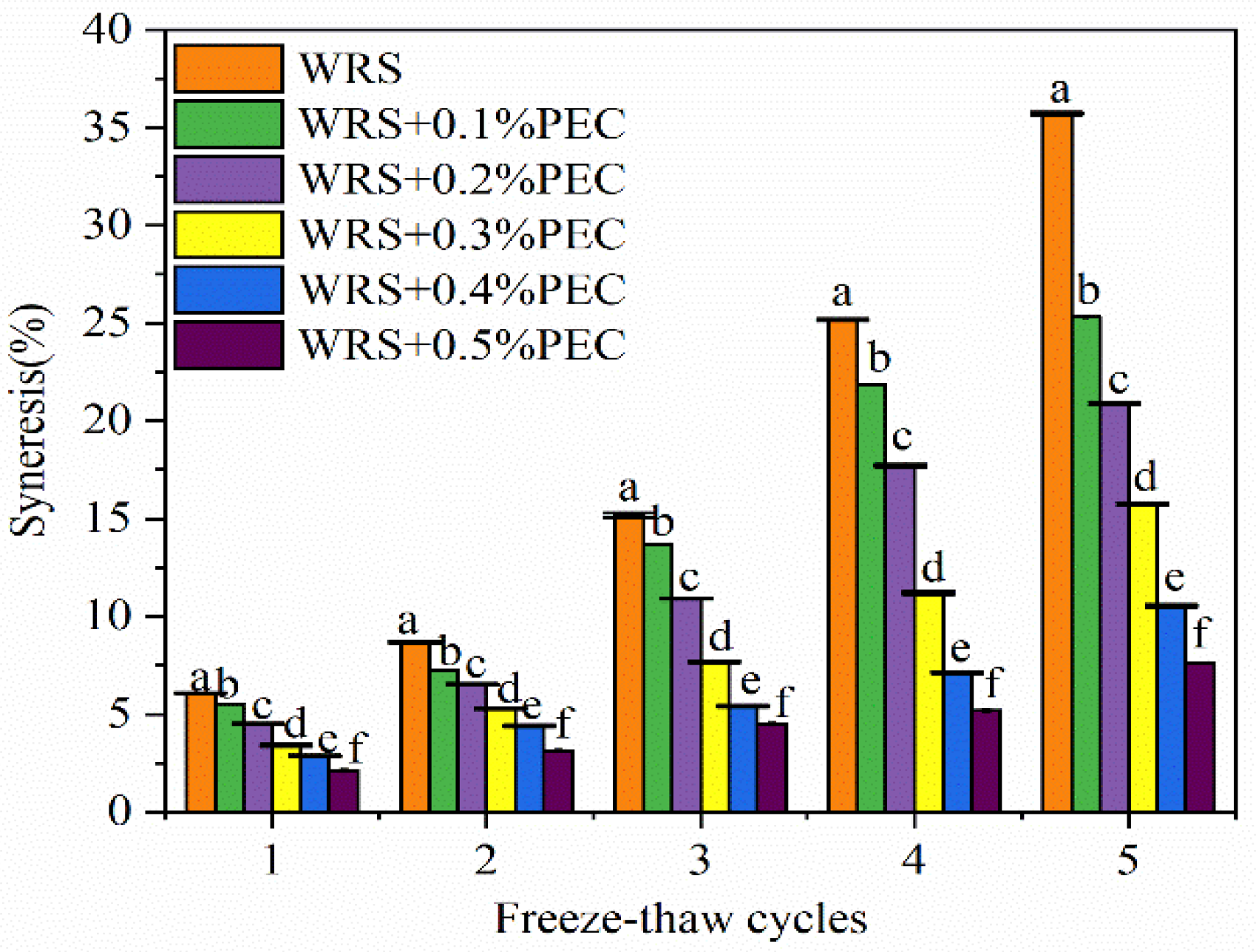

3.7. Freeze-Thaw Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sasaki, T.; Kohyama, K.; Suzuki, Y.; Okamoto, K.; Noel, T.R.; Ring, S.G. Physicochemical characteristics of waxy rice starch influencing the in vitro digestibility of a starch gel. Food Chem. 2009, 116, 137–142. [Google Scholar] [CrossRef]

- Jinsong, B.; Corke, H.; Mei, S. Genetic diversity in the physicochemical properties of waxy rice (Oryza sativa L) starch. J. Sci. Food Agric. 2004, 84, 1299–1306. [Google Scholar] [CrossRef]

- Sarka, E.; Dvoracek, V. Waxy starch as a perspective raw material (a review). Food Hydrocoll. 2017, 69, 402–409. [Google Scholar] [CrossRef]

- Zhang, B.; Bai, B.; Pan, Y.; Li, X.M.; Cheng, J.S.; Chen, H.Q. Effects of pectin with different molecular weight on gelatinization behavior, textural properties, retrogradation and in vitro digestibility of corn starch. Food Chem. 2018, 264, 58–63. [Google Scholar] [CrossRef]

- Wu, Y.; Niu, M.; Xu, H.L. Pasting behaviors, gel rheological properties, and freeze-thaw stability of rice flour and starch modified by green tea polyphenols. LWT Food Sci. Technol. 2020, 118, 108796. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Li, M.J.; You, X.R.; Fang, F.; Li, B.Z. Impacts of guar and xanthan gums on pasting and gel properties of high-amylose corn starches. Int. J. Biol. Macromol. 2020, 146, 1060–1068. [Google Scholar] [CrossRef]

- Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Shahzad, S.A.; Ababtain, I.A. Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods 2020, 9, 909. [Google Scholar] [CrossRef]

- Dangi, N.; Yadav, B.S.; Yadav, R.B. Pasting, rheological, thermal and gel textural properties of pearl millet starch as modified by guar gum and its acid hydrolysate. Int. J. Biol. Macromol. 2019, 139, 387–396. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch-hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Chen, L.; Tong, Q.Y.; Ren, F.; Zhu, G.L. Pasting and rheological properties of rice starch as affected by pullulan. Int. J. Biol. Macromol. 2014, 66, 325–331. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.H.; Shen, M.Y.; Luo, Y.; Ren, Y.M.; Han, X.Y.; Xie, J.H. Effect of Mesona chinensis polysaccharide on the pasting, rheological, and structural properties of tapioca starch varying in gelatinization temperatures. Int. J. Biol. Macromol. 2020, 156, 137–143. [Google Scholar] [CrossRef]

- Liu, B.; Zhu, S.; Zhong, F.; Yokoyama, W.; Huang, D.; Li, Y. Modulating storage stability of binary gel by adjusting the ratios of starch and kappa-carrageenan. Carbohydr. Polym. 2021, 268, 118264. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Liu, W.; Liu, C.M.; Li, T.; Liang, R.H.; Luo, S.J. Pectin Modifications: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1684–1698. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.J.; Chen, R.Y.; Huang, L.; Liang, R.H.; Liu, C.M.; Chen, J. Investigation on the influence of pectin structures on the pasting properties of rice starch by multiple regression. Food Hydrocoll. 2017, 63, 580–584. [Google Scholar] [CrossRef]

- Xie, F.; Gu, B.-J.; Saunders, S.R.; Girish, M.G. High methoxyl pectin enhances the expansion characteristics of the corn starch relative to the low methoxyl pectin. Food Hydrocoll. 2021, 110, 106131. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Y.; Xie, Q.; Li, X.; Zhang, B.; Chen, H. Evaluation studies on effects of pectin with different concentrations on the pasting, rheological and digestibility properties of corn starch. Food Chem. 2019, 274, 319–323. [Google Scholar] [CrossRef] [PubMed]

- Nawab, A.; Alam, F.; Hasnain, A. Functional properties of cowpea (Vigna unguiculata) starch as modified by guar, pectin, and xanthan gums. Starch/Starke 2014, 66, 832–840. [Google Scholar] [CrossRef]

- Pan, L.H.; Xing, J.L.; Zhang, H.; Luo, X.H.; Chen, Z.X. Electron beamirradiation as a tool for rice grain storage and its effects on the physicochemical properties of rice starch. Int. J. Biol. Macromol. 2020, 164, 2915–2921. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Zhang, H.; Xia, Y.; Ai, L. Effects of tamarind seed polysaccharide on gelatinization, rheological, and structural properties of corn starch with different amylose/amylopectin ratios. Food Hydrocoll. 2020, 105, 105854. [Google Scholar] [CrossRef]

- Tao, X.Q.; Zhang, Y.L.; Chen, F.; Huang, Y.X.; Chen, P. Effects of sucrose on pasting, thermal, rheological and textural properties of native and alcohol-alkali-treated waxy rice starch. Int. J. Biol. Macromol. 2021, 166, 108–116. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Lutfi, Z.; Nawab, A.; Alam, F.; Hasnain, A.; Haider, S.Z. Influence of xanthan, guar, CMC and gum acacia on functional properties of water chestnut (Trapa bispinosa) starch. Int. J. Biol. Macromol. 2017, 103, 220–225. [Google Scholar] [CrossRef]

- Dangi, N.; Yadav, B.S.; Yadav, R.B. Pectin and its acid hydrolysate for the modification of hydration, pasting, thermal and rheological properties of barley starch. Int. J. Biol. Macromol. 2020, 152, 969–980. [Google Scholar] [CrossRef]

- Correa, M.J.; Ferrero, C. Thermal behaviour of wheat starch and flour at different water levels: Effect of pectins, modified celluloses and NaCl. Starch/Starke 2015, 67, 338–347. [Google Scholar] [CrossRef]

- Shahzad, S.A.; Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A. Effect of Hydrocolloid Gums on the Pasting, Thermal, Rheological and Textural Properties of Chickpea Starch. Foods 2019, 8, 687. [Google Scholar] [CrossRef] [Green Version]

- Witczak, T.; Witczak, M.; Ziobro, R. Effect of inulin and pectin on rheological and thermal properties of potato starch paste and gel. J. Food Eng. 2014, 124, 72–79. [Google Scholar] [CrossRef]

- Liu, S.C.; Lin, L.H.; Shen, M.Y.; Wang, W.J.; Xiao, Y.H.; Xie, J.H. Effect of Mesona chinensis polysaccharide on the pasting, thermal and rheological properties of wheat starch. Int. J. Biol. Macromol. 2018, 118, 945–951. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Wang, Y.S.; Chen, H.H.; Li, Q.Q.; Wang, Q. The gelatinization and retrogradation properties of wheat starch with the addition of stearic acid and sodium alginate. Food Hydrocoll. 2018, 81, 77–86. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, R.; Chen, Z.X.; Zhong, Q.X. Amylopectin-Sodium Palmitate Complexes as Sustainable Nanohydrogels with Tunable Size and Fractal Dimensions. J. Agric. Food Chem. 2020, 68, 3796–3805. [Google Scholar] [CrossRef] [PubMed]

- Viturawong, Y.; Achayuthakan, P.; Suphantharika, M. Gelatinization and rheological properties of rice starch/xanthan mixtures: Effects of molecular weight of xanthan and different salts. Food Chem. 2008, 111, 106–114. [Google Scholar] [CrossRef]

- Ma, S.P.; Zhu, P.L.; Wang, M.C.; Wang, F.T.; Wang, N.F. Effect of konjac glucomannan with different molecular weights on physicochemical properties of corn starch. Food Hydrocoll. 2019, 96, 663–670. [Google Scholar] [CrossRef]

- Yousefi, A.R.; Zahedi, Y.; Razavi, S.M.A.; Ghasemian, N. Influence of sage seed gum on some physicochemical and rheological properties of wheat starch. Starch/Starke 2017, 69, 1600356. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, H.; Yang, H.; Zhao, S.; Liu, Y.; Liu, R. Effects of salts on the gelatinization and retrogradation properties of maize starch and waxy maize starch. Food Chem. 2017, 214, 319–327. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.X.; Xu, B.J. A comparative study on texture, gelatinisation, retrogradation and potential food application of binary gels made from selected starches and edible gums. Food Chem. 2019, 296, 100–108. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Xu, B.; Ren, G.; Li, P.; Li, X.; Han, S.; Liu, J. Effects of inulin with different degree of polymerization on gelatinization and retrogradation of wheat starch. Food Chem. 2017, 229, 35–43. [Google Scholar] [CrossRef]

- Huang, S.; Wang, N.; Zhang, Y.; Zhang, F.S.; Zheng, J. Physical, thermal and structural properties of rice starch as affected by the addition of bamboo shoot shell fibres. Int. J. Food Sci. Technol. 2020, 55, 3658–3669. [Google Scholar] [CrossRef]

- Ye, J.; Hu, X.; Zhang, F.; Fang, C.; Liu, C.; Luo, S. Freeze-thaw stability of rice starch modified by Improved Extrusion Cooking Technology. Carbohydr. Polym. 2016, 151, 113–118. [Google Scholar] [CrossRef]

- White, P.J.; Abbas, I.R.; Johnson, L.A. Freeze-thaw stability and refrigerated-storage retrogradation of starches. Starch/Starke 1989, 41, 176–180. [Google Scholar] [CrossRef]

| Pectin Concentration % | Peak Viscosity (cP) | Trough (cP) | Final Viscosity (cP) | Breakdown (cP) | Setback (cP) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|

| 0 | 3415.5 ± 0.5 f | 1654.5 ± 1.5 f | 2228.5 ± 2.5 f | 1761.0 ± 1.0 a | 574.0 ± 1.0 a | 75.2 ± 0.4 d |

| 0.1 | 3454.0 ± 1.0 e | 1821.0 ± 2.0 e | 2244.0 ± 3.0 e | 1633.0 ± 1.0 b | 423.0 ± 1.0 b | 76.7 ± 0.4 c |

| 0.2 | 3478.5 ± 1.5 d | 1884.0 ± 3.0 d | 2294.5 ± 2.5 d | 1594.5 ± 1.5 c | 410.5 ± 0.5 c | 77.1 ± 0.0 b, c |

| 0.3 | 3505.0 ± 2.0 c | 1927.5 ± 2.5 c | 2320.0 ± 3.0 c | 1577.5 ± 0.5 d | 392.5 ± 0.5 d | 78.0 ± 0.1 a, b |

| 0.4 | 3529.0 ± 2.0 b | 1966.5 ± 3.5 b | 2348.0 ± 3.0 a | 1562.5 ± 1.5 e | 381.5 ± 0.5 e | 78.2 ± 0.3 a |

| 0.5 | 3548.5 ± 1.5 a | 1997.5 ± 3.5 a | 2362.5 ± 2.5 a | 1551.0 ± 5.0 f | 365.0 ± 1.0 f | 78.7 ± 0.0 a |

| Pectin Concentration (%) | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| 0 | 65.38 ± 0.34 f | 71.63 ± 0.31 e | 78.50 ± 0.15 c | 6.20 ± 0.02 a |

| 0.1 | 66.84 ± 0.12 e | 72.53 ± 0.03 d | 77.26 ± 0.03 b | 5.34 ± 0.01 b |

| 0.2 | 68.01 ± 0.12 d | 73.92 ± 0.01 c | 78.65 ± 0.01 b | 4.68 ± 0.02 c |

| 0.3 | 69.77 ± 0.16 c | 74.22 ± 0.16 b, c | 79.28 ± 0.14 a, b | 4.26 ± 0.01 d |

| 0.4 | 68.92 ± 0.11 b | 74.55 ± 0.11 a, b | 79.56 ± 0.28 a | 3.24 ± 0.01 e |

| 0.5 | 70.90 ± 0.06 a | 74.81 ± 0.10 a | 79.72 ± 0.45 a | 3.09 ± 0.01 f |

| PEC Concentration (%) | K (Pa.sn) | n | R2 | Transmittance (%) |

|---|---|---|---|---|

| 0 | 41.36 ± 2.07 d | 0.11 ± 0.01 b | 0.976 | 7.00 ± 0.33 a |

| 0.1 | 42.7 4± 0.98 c, d | 0.13 ± 0.02 b | 0.982 | 6.17 ± 0.42 b |

| 0.2 | 46.74 ± 1.20 c | 0.14 ± 0.01 b | 0.985 | 4.63 ± 0.19 c |

| 0.3 | 57.54 ± 0.92 b | 0.25 ± 0.00 a | 0.988 | 3.93 ± 0.09 d |

| 0.4 | 72.12 ± 0.71 a | 0.26 ± 0.01 a | 0.999 | 2.43 ± 0.21 e |

| 0.5 | 74.86 ± 0.48 a | 0.24 ± 0.00 a | 0.997 | 1.37 ± 0.12 f |

| PEC Concentration | Hardness | Adhesiveness | Springiness | Cohesiveness | Gumminess |

|---|---|---|---|---|---|

| (%) | (g) | (g·s) | (g) | ||

| 0 | 206.26 ± 5.84 a | 66.51 ± 1.32 a | 1.28 ± 0.00 a | 0.94 ± 0.03 a | 114.94 ± 1.95 a |

| 0.1 | 197.34 ± 1.37 b | 60.05 ± 3.84 b | 1.27 ± 0.01a, b | 0.93 ± 0.01 a | 103.98 ± 2.41 b |

| 0.2 | 187.51 ± 1.54 c | 52.66 ± 2.87 c | 1.26 ± 0.00 a, b | 0.92 ± 0.01 a | 101.72 ± 1.78 b |

| 0.3 | 186.58 ± 2.76 c | 44.95 ± 1.74 d | 1.24 ± 0.01 a, b, c | 0.88 ± 0.01 b | 98.84 ± 2.77 b |

| 0.4 | 157.00 ± 2.14 d | 36.62 ± 1.46 e | 1.25 ± 0.01 b, c | 0.86 ± 0.02 b | 90.63 ± 3.09 c |

| 0.5 | 137.63 ± 2.19 e | 32.78 ± 0.74 e | 1.21 ± 0.04 c | 0.85 ± 0.01 b | 75.06 ± 3.51 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, Y.; Xing, J.; Luo, X.; Zhang, H.; Yang, K.; Shao, X.; Chen, K.; Li, Y. Effects of Pectin on the Physicochemical Properties and Freeze-Thaw Stability of Waxy Rice Starch. Foods 2021, 10, 2419. https://doi.org/10.3390/foods10102419

Zhai Y, Xing J, Luo X, Zhang H, Yang K, Shao X, Chen K, Li Y. Effects of Pectin on the Physicochemical Properties and Freeze-Thaw Stability of Waxy Rice Starch. Foods. 2021; 10(10):2419. https://doi.org/10.3390/foods10102419

Chicago/Turabian StyleZhai, Yuheng, Jiali Xing, Xiaohu Luo, Hao Zhang, Kai Yang, Xingfeng Shao, Kaihe Chen, and Yanan Li. 2021. "Effects of Pectin on the Physicochemical Properties and Freeze-Thaw Stability of Waxy Rice Starch" Foods 10, no. 10: 2419. https://doi.org/10.3390/foods10102419

APA StyleZhai, Y., Xing, J., Luo, X., Zhang, H., Yang, K., Shao, X., Chen, K., & Li, Y. (2021). Effects of Pectin on the Physicochemical Properties and Freeze-Thaw Stability of Waxy Rice Starch. Foods, 10(10), 2419. https://doi.org/10.3390/foods10102419