2.1. Principle of Chromatic Confocal Measurement

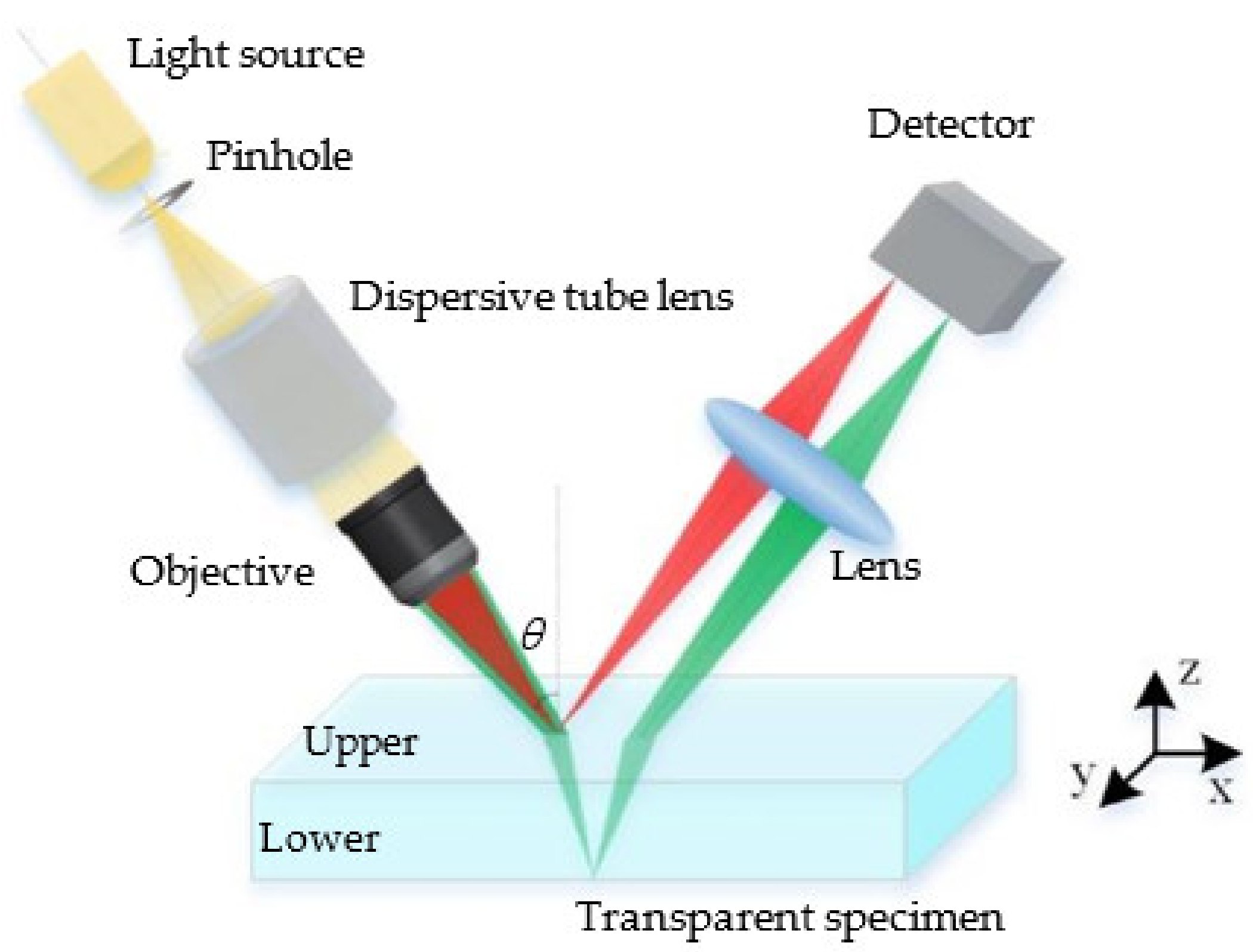

As a non-contact optical measurement method, chromatic confocal technology uses a spectral decoding technology, which is a height/displacement measurement without axial motion, as shown in

Figure 1. By establishing the corresponding relation between the axial position of the focal spot and the central wavelength of the focused light, the height/displacement values can be calculated. The schematic diagram of chromatic confocal technology is shown in

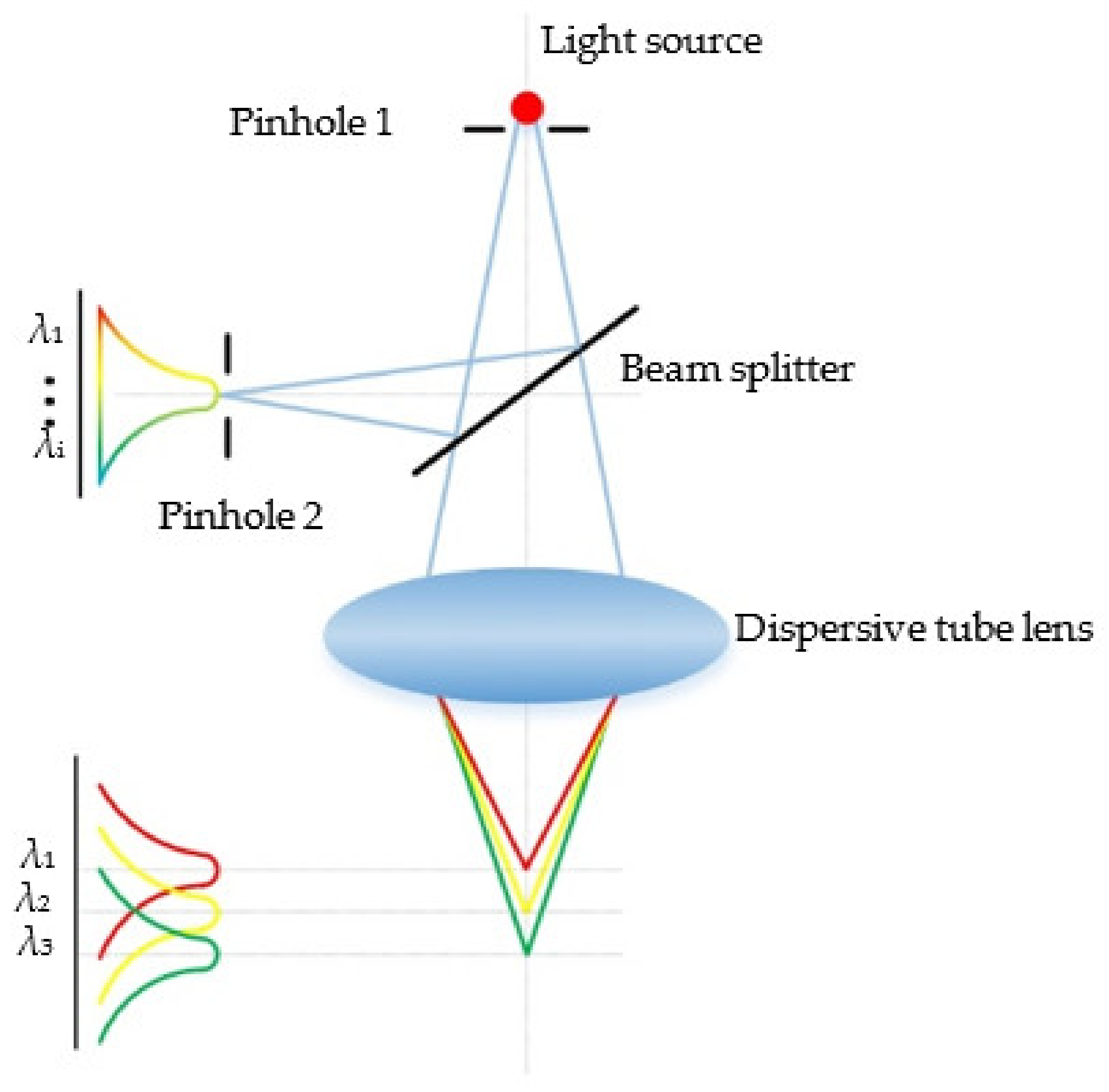

Figure 2. The polychromatic light source generates multiple wavelength components. The polychromatic light beam passes through a pinhole (pinhole 1 in

Figure 2), which modulates the light beam into a point light. Then, the light beam will enter the dispersive tube lens and be distributed along the optical axis according to the different wavelengths. Light beams with different wavelengths will be focused on different positions along the optical axis. Being reflected by the specimen surface, the light beam arrives at the beam splitter and then passes through the detection pinhole (pinhole 2 in

Figure 2) which allows only one wavelength to pass through. The height of the specimen surface can be obtained by establishing the correlation between the wavelength of the light that reaches the detector and the axial position of the focal spot.

2.2. Principle of Chromatic Confocal Measurement with Inclined Illumination

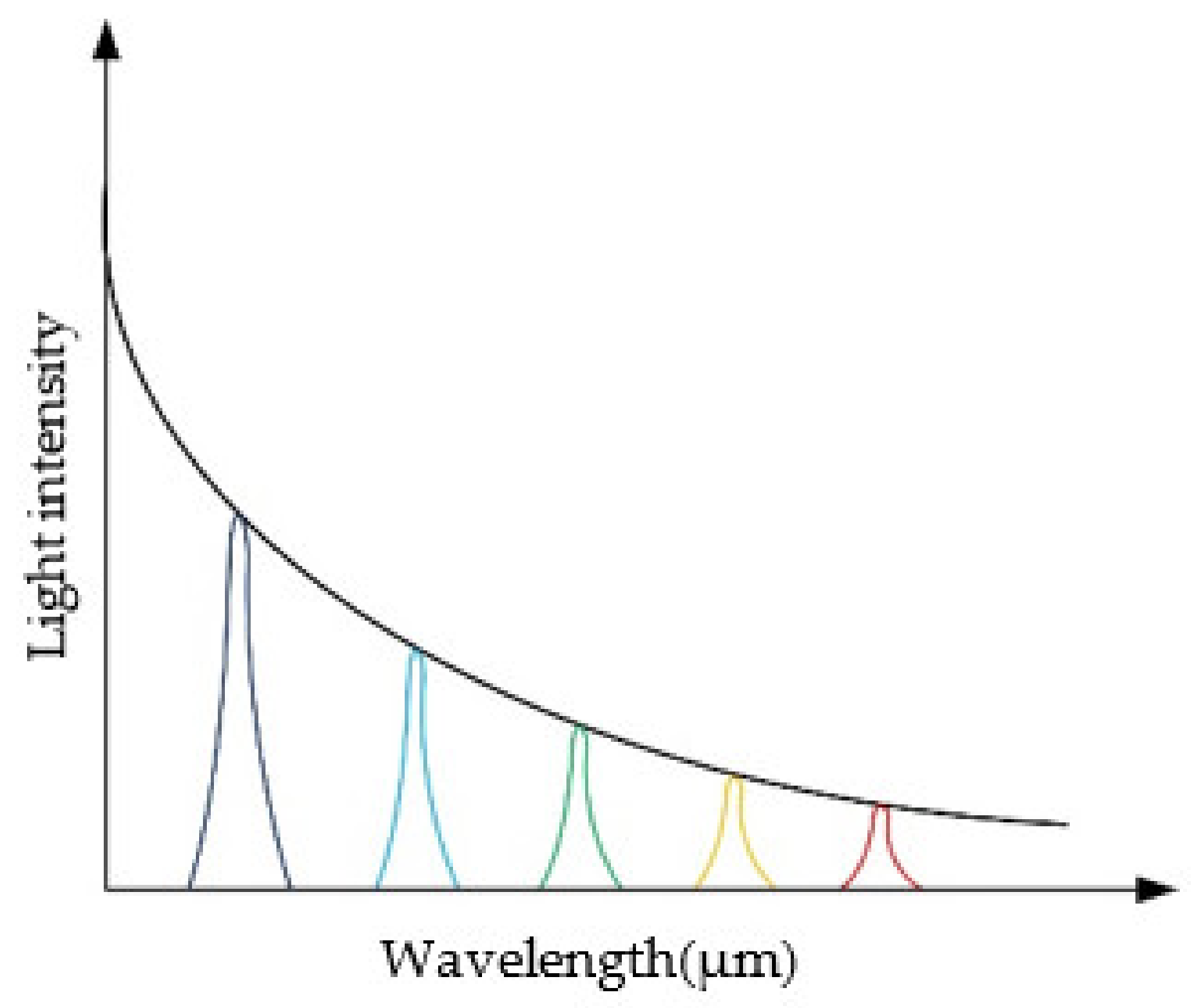

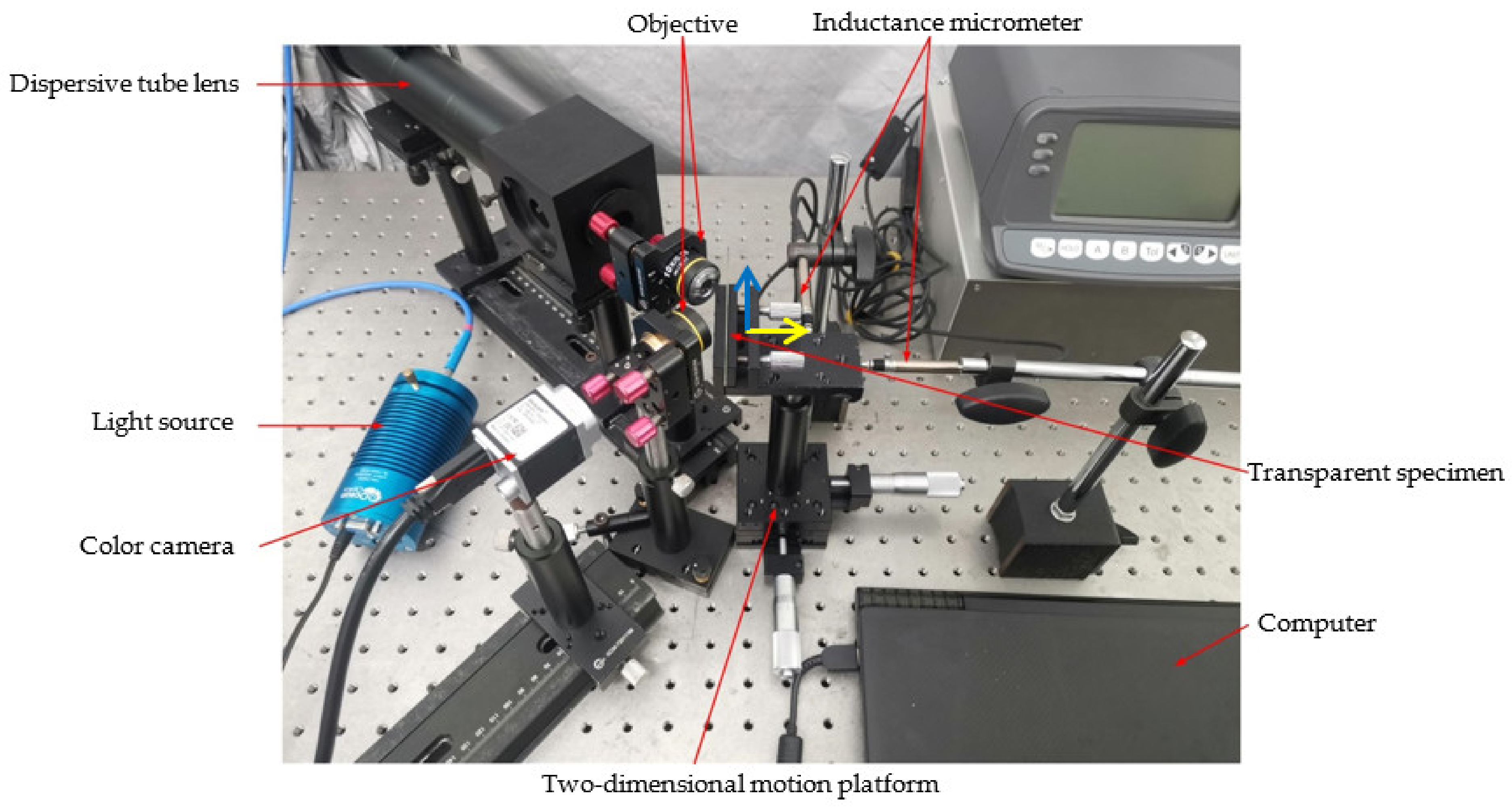

In a conventional chromatic confocal measuring system, the optical axis is set to be perpendicular to the specimen surface. When measuring a transparent specimen surface, it needs to obtain the wavelength values of the light beams which are focused on the upper and lower surfaces, respectively. However, when measuring transparent specimen, the reflecting light intensity will be very weak, as shown in

Figure 3. Beam splitters used in such configuration will further lower the effectiveness of energy down to 25%. As a result, the signal-to-noise ratio will be very low.

To solve this problem, an inclined illumination lighting path was developed to the chromatic confocal measurement system, as shown in

Figure 4.

The light beams distributed by the dispersive tube lens illuminate the specimen surface with a non-zero incidence angle θ. Compared with the vertical illumination, the extraction of wavelength will be more accurate since the signal-to-noise ratio can be significantly improved.

2.3. Thickness Calculation Model of Glass Slide

In a conventional chromatic confocal measurement system (

Figure 5), the normalized light intensity at the focal point can be expressed as follows:

where

u is the normalized axial coordinate,

λ is the wavelength of the incident light,

a is the exit pupil radius of the imaging lens, and

f represents the focal length of the lens.

The normalized axial coordinate

u can be expressed as follows:

In Equation (2), Δz is the defocusing amount, which is determined by the response function of axial light intensity in a chromatic confocal measurement system.

In an ideal chromatic confocal system, the axial position has a linear relationship with the wavelength value of the focused light. For a beam of light with a wavelength

λi, the defocusing amount is:

where

f(

λi) represents the optical axial position,

λi represents the wavelength of the focused light.

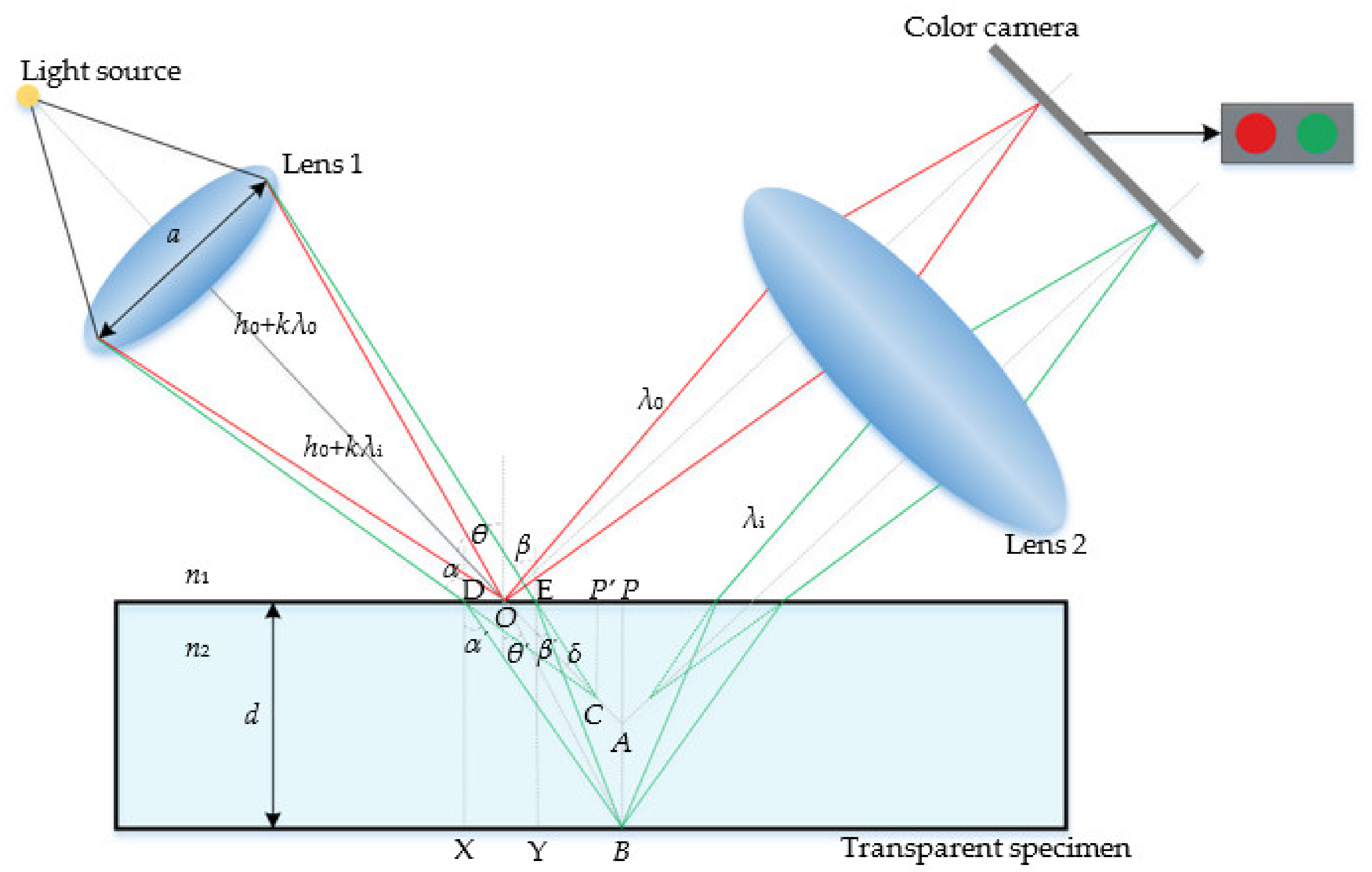

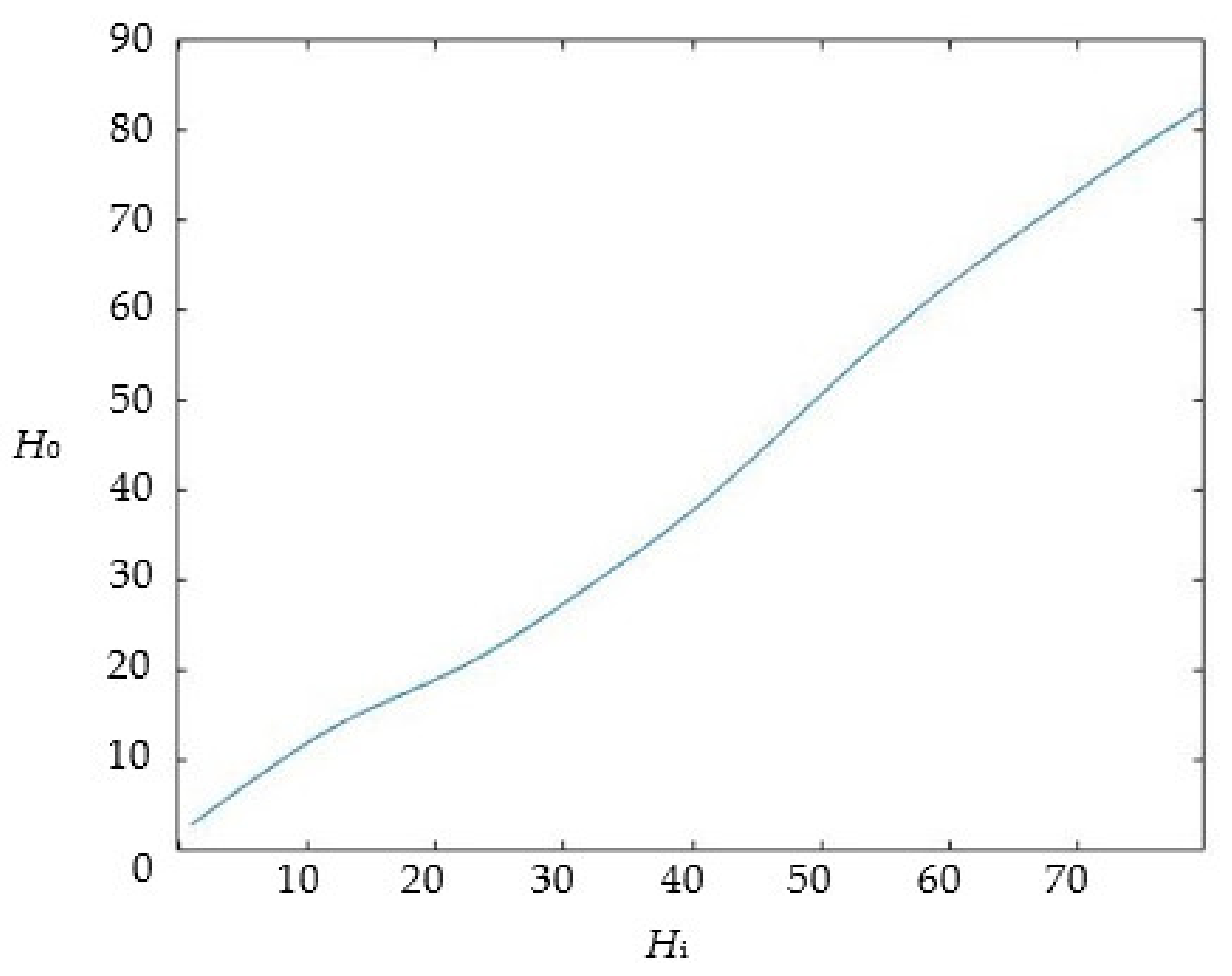

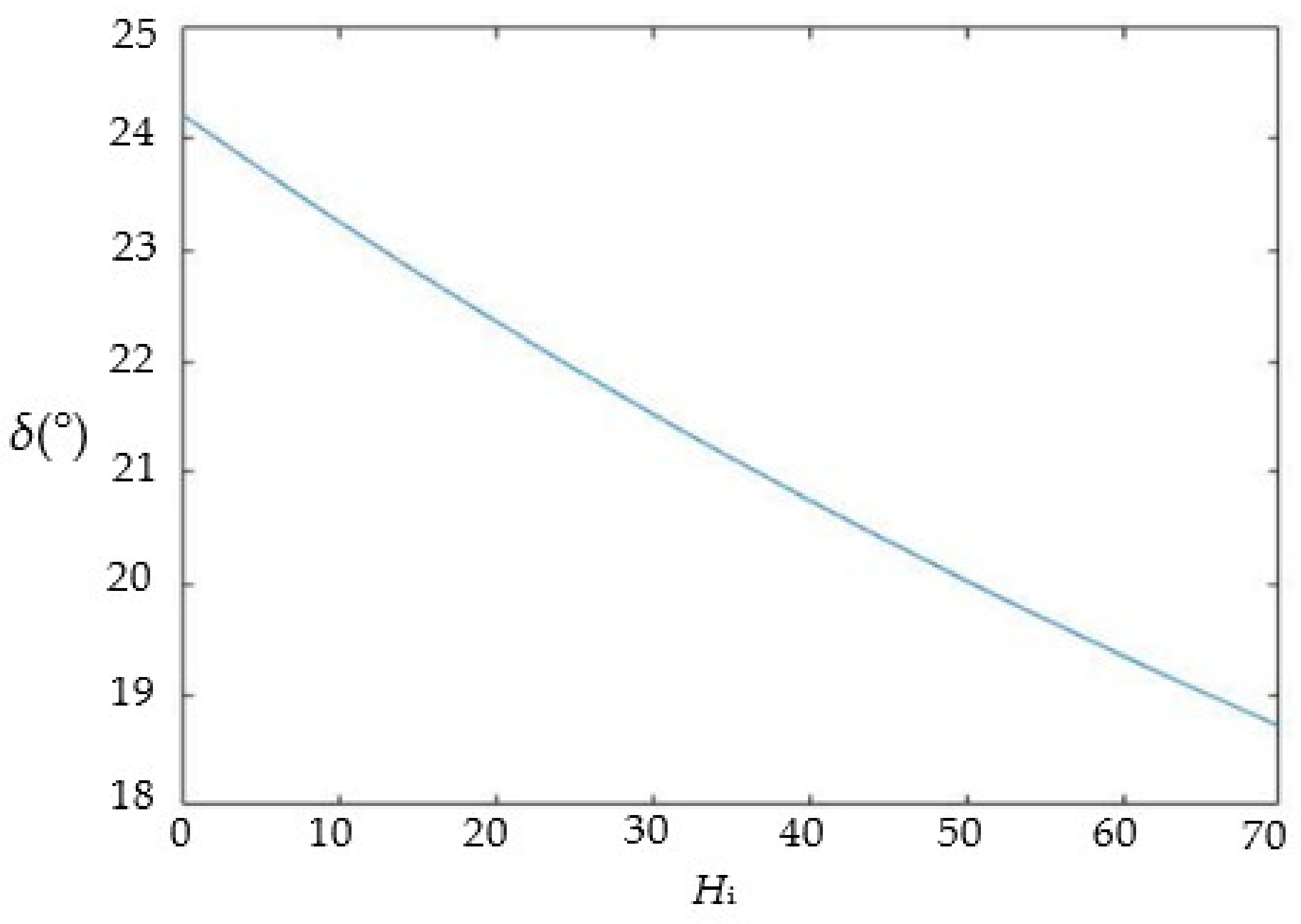

In

Figure 4, the incline angle between the optical axis of illumination path and the normal direction of the specimen surface is defined as

θ. Thus, the relationship between Δ

h and Δ

z(

λi) can be expressed as follows:

Substituting Equations (3) and (4) into Equation (1), the light intensity of the detector in

Figure 4 can be expressed as follows:

The light intensity distribution of Equation (4) is simulated, which is shown in the black curve in

Figure 6. At the same time, the light intensity distribution curves of different wavelengths are simulated, and it can be found that the black curve consists of all peak points of light intensity at every wavelength. As a result, the chromatic confocal system with inclined illumination also has good spectral frequency selection characteristics.

Based on this theoretical analysis, the thickness calculation model of a chromatic confocal system with inclined illumination is provided in the following paragraphs.

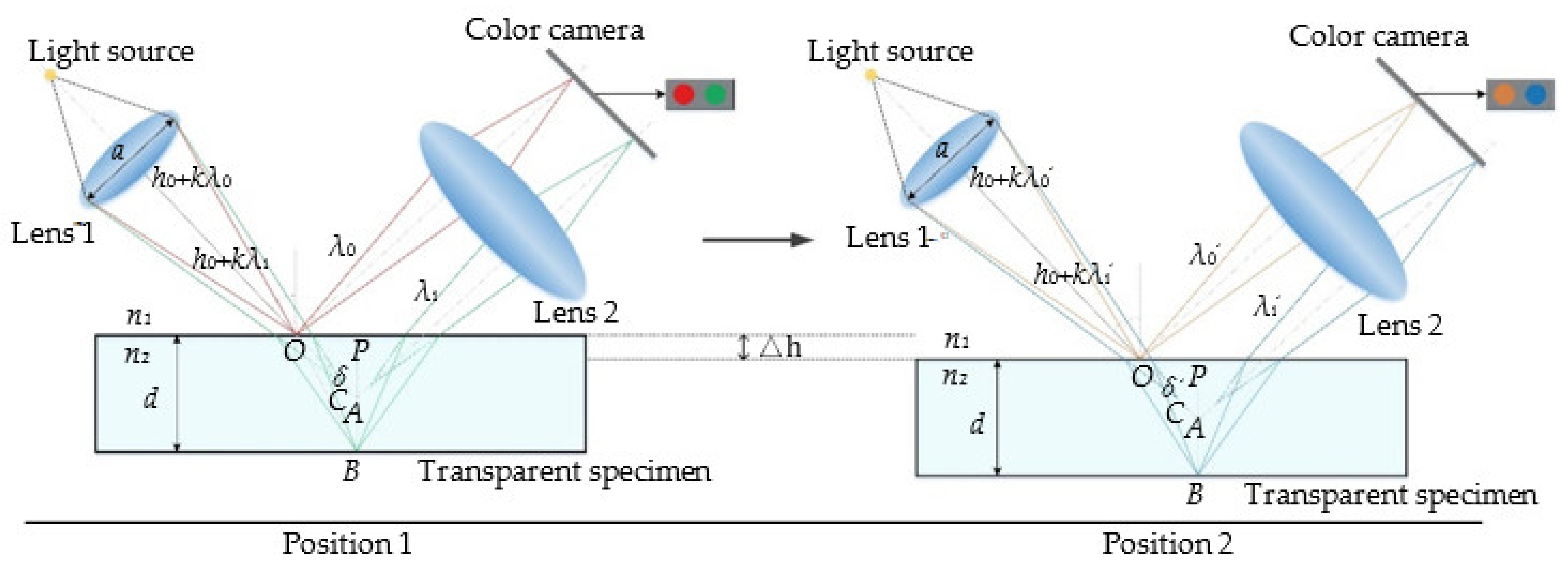

As shown in

Figure 7, there are two beams of light (wavelength

λ0 and

λi) focused on the upper and lower surfaces and the focal points are points

O and

B, respectively. If there was no transparent specimen, the light beam with the wavelength

λi would be focused on point

C. However, it is focused on the lower surfaces due to the existence of transparent specimen.

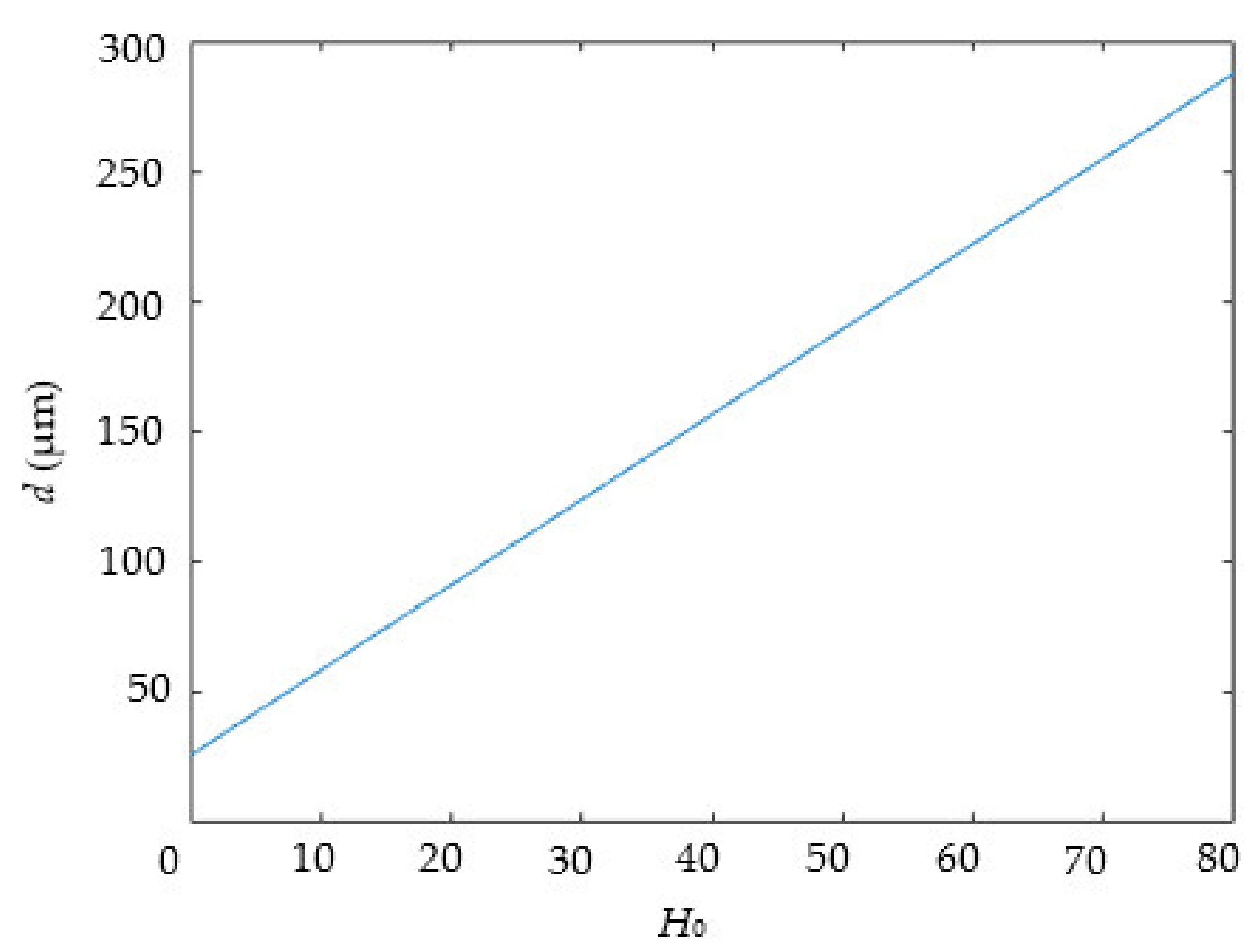

According to the trigonometric function, the following formula can be obtained:

Additionally, the thickness of the transparent specimen

d and related parameters can be expressed as:

Substituting Equation (3) into Equation (8),

α and

β can be calculated by

θ and

δ:

δ is related to the diameter of the dispersion tube lens and the distance from point

O to the dispersion tube lens. In this system,

a and

h0 can represent the two values. Therefore,

δ can be expressed as follows:

2.4. Color Conversion Algorithm

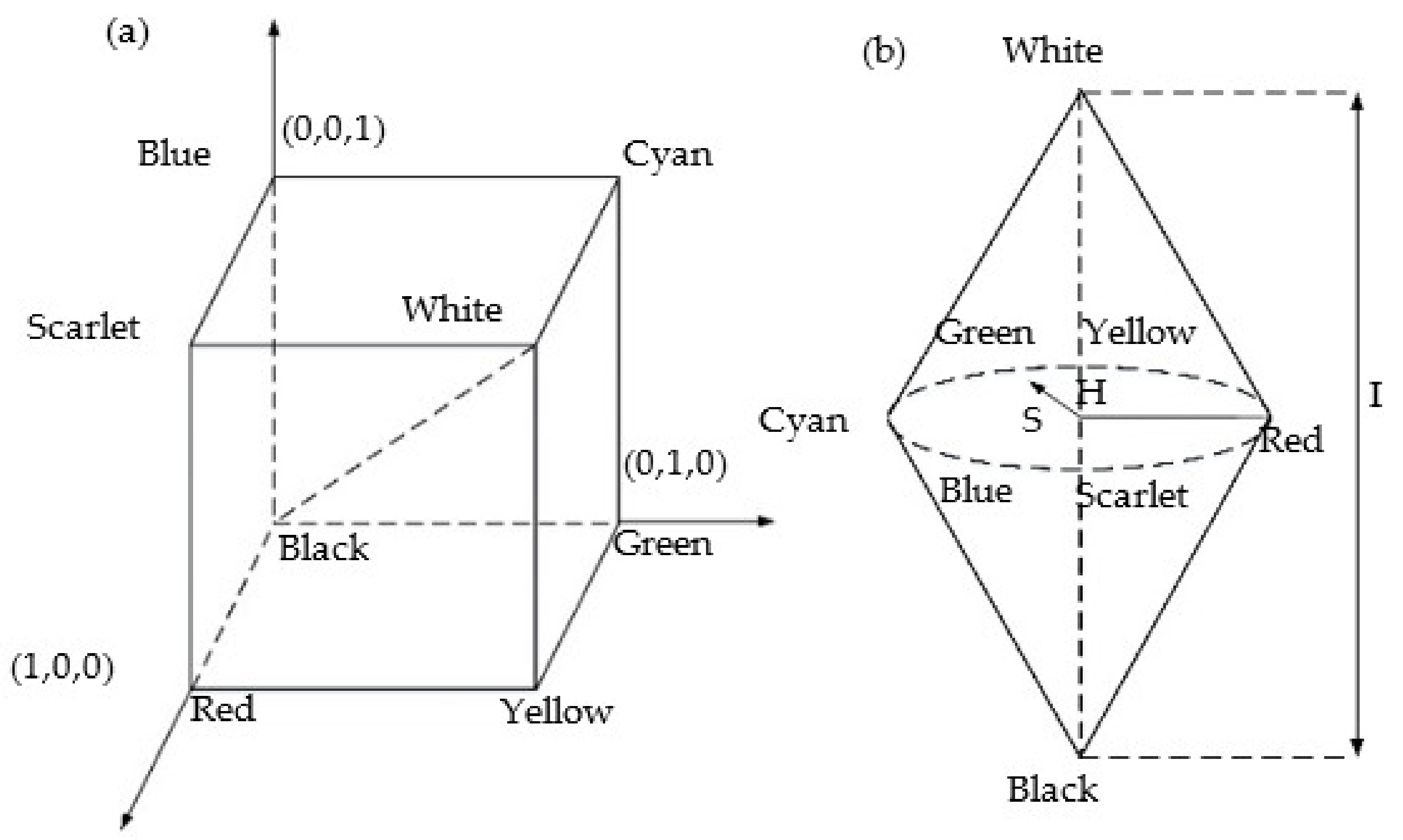

The image shows different colors because it contains

R,

G,

B values. As discussed in the above sections, the axial displacement of the specimen is related to the wavelength value of the focused light. Therefore, it is necessary to convert color information into wavelength information and a conversion algorithm is proposed to convert RGB space into HSI space, where the

H value is correlated with the wavelength. So,

H value can be directly used to represent wavelength value. The two color spaces are shown in

Figure 8.

In the HSI space,

H can be expressed as follows:

where

θ is expressed as follows:

It has been proved, theoretically and experimentally, that this color conversion algorithm can achieve micron resolution. Additionally, several articles [

20,

21] have been published using this color conversion algorithm.

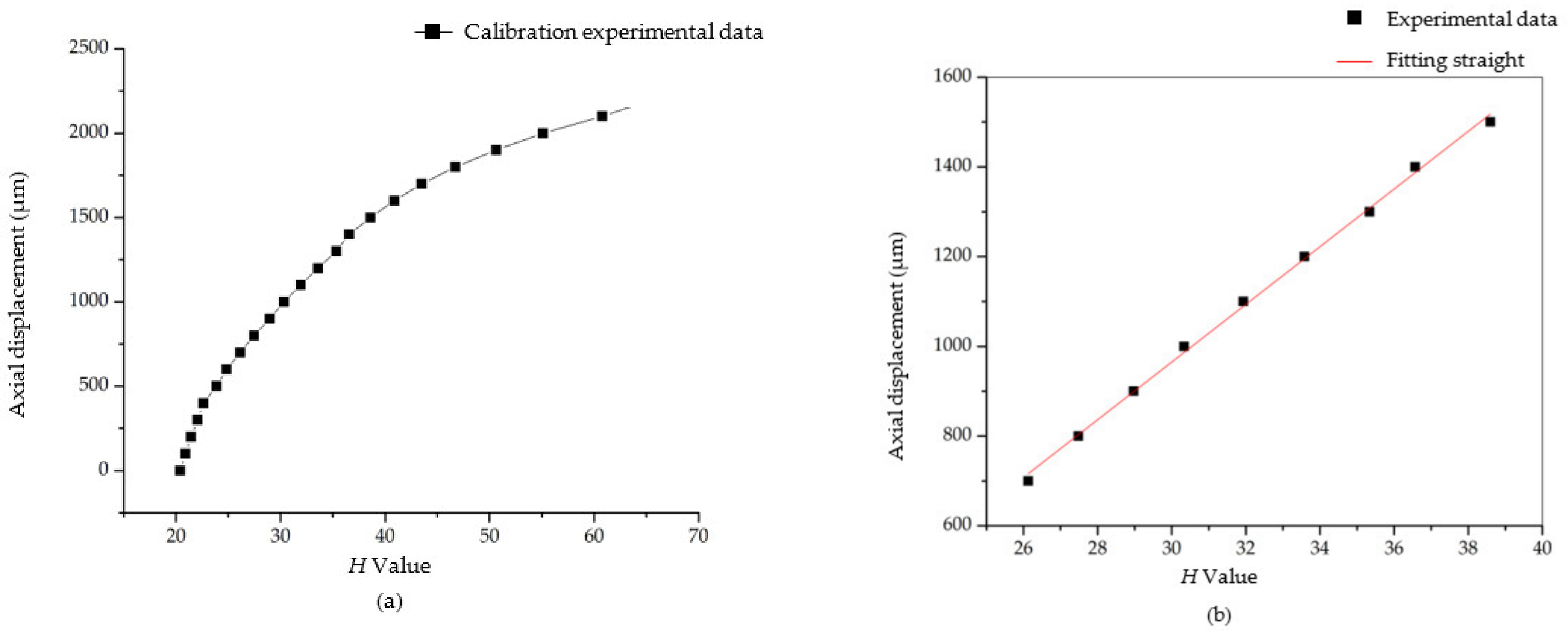

Based on the above, the wavelength can be replaced by

H value. Therefore, Equation (3) will become:

Additionally, the thickness of the transparent specimen

d becomes the following: