Degradation Characteristics and Mechanism of High Speed 850 nm Vertical-Cavity Surface-Emitting Laser during Accelerated Aging

Abstract

1. Introduction

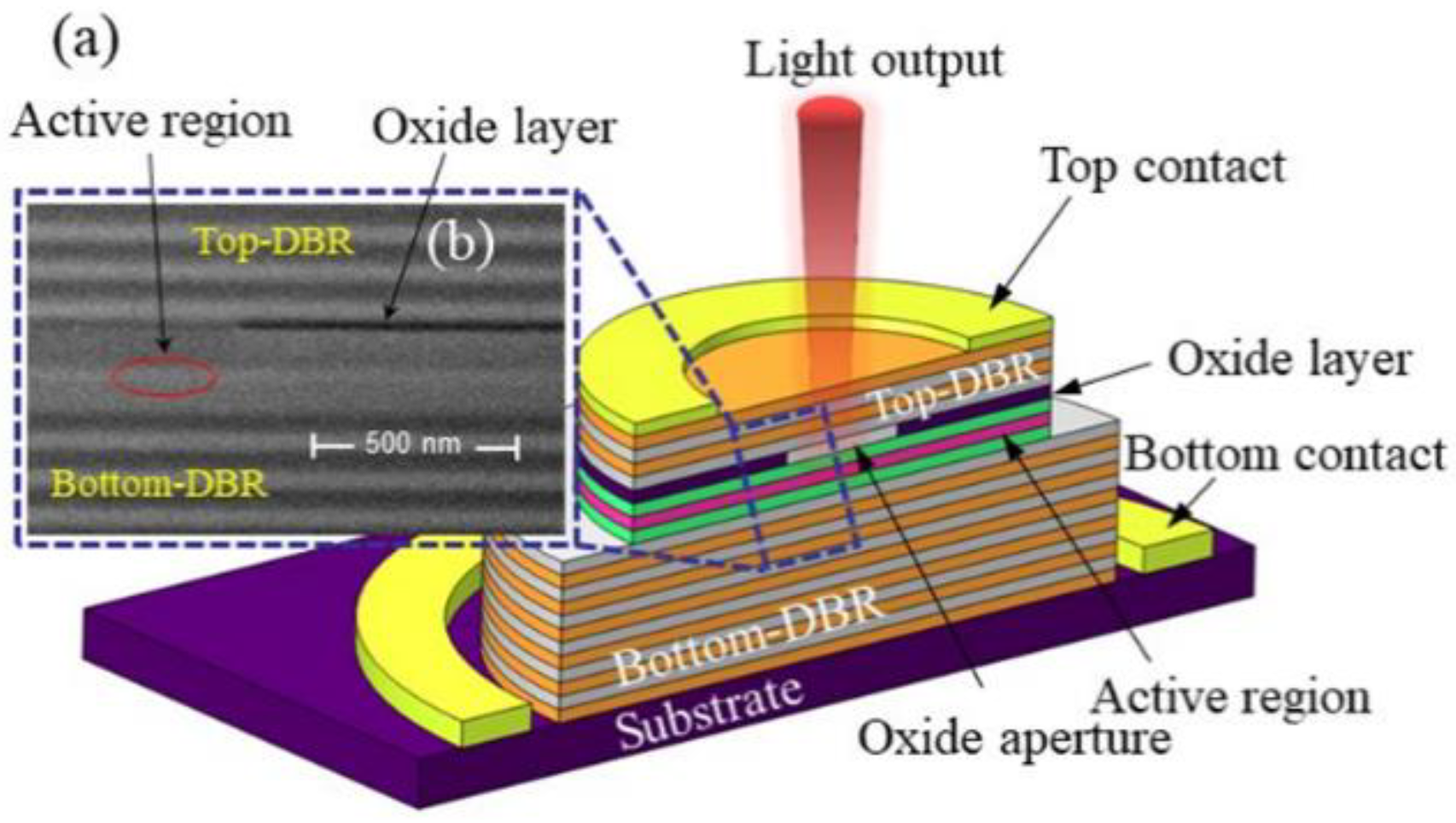

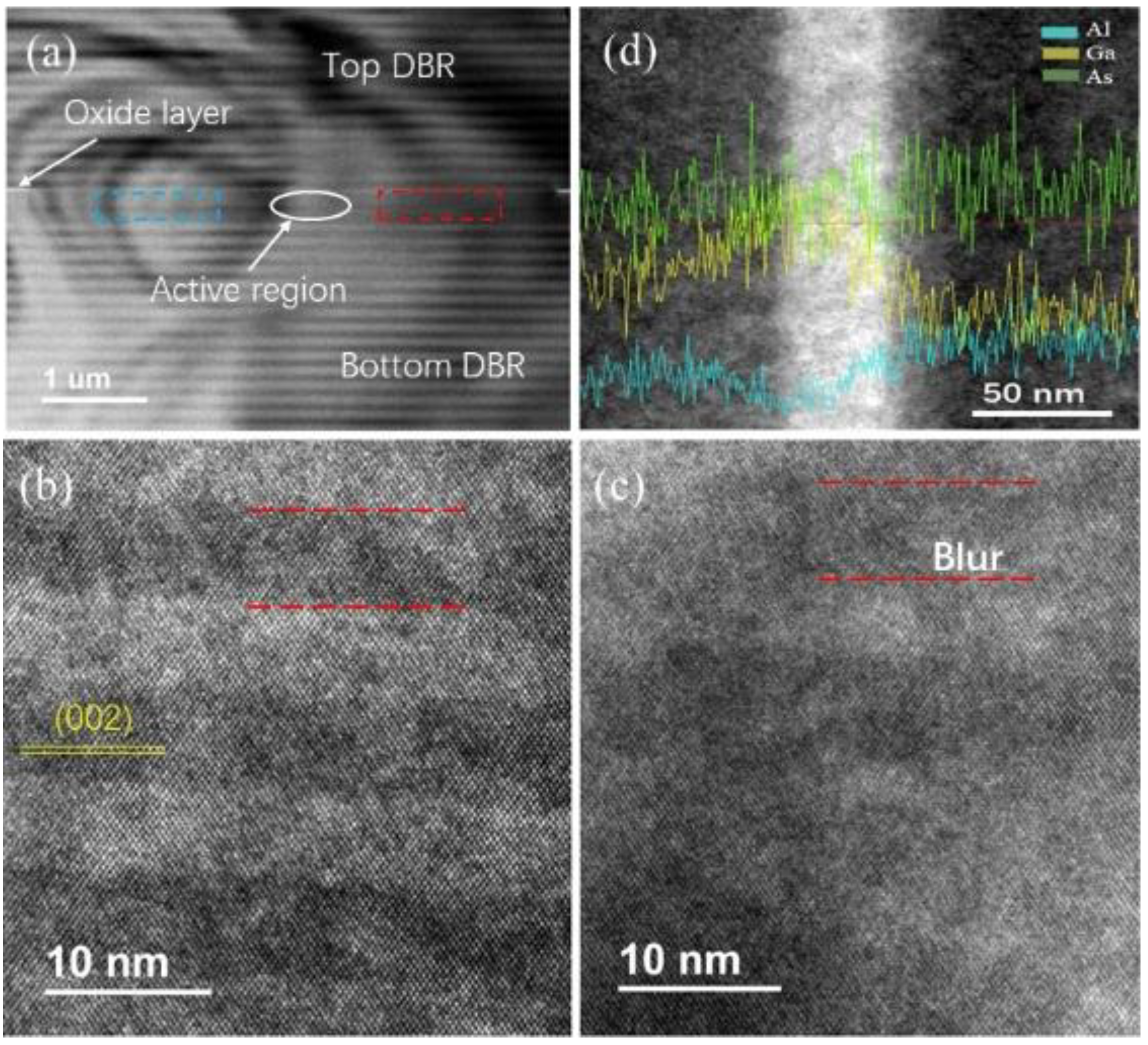

2. Device Structure and Experimental Details

3. Results and Discussion

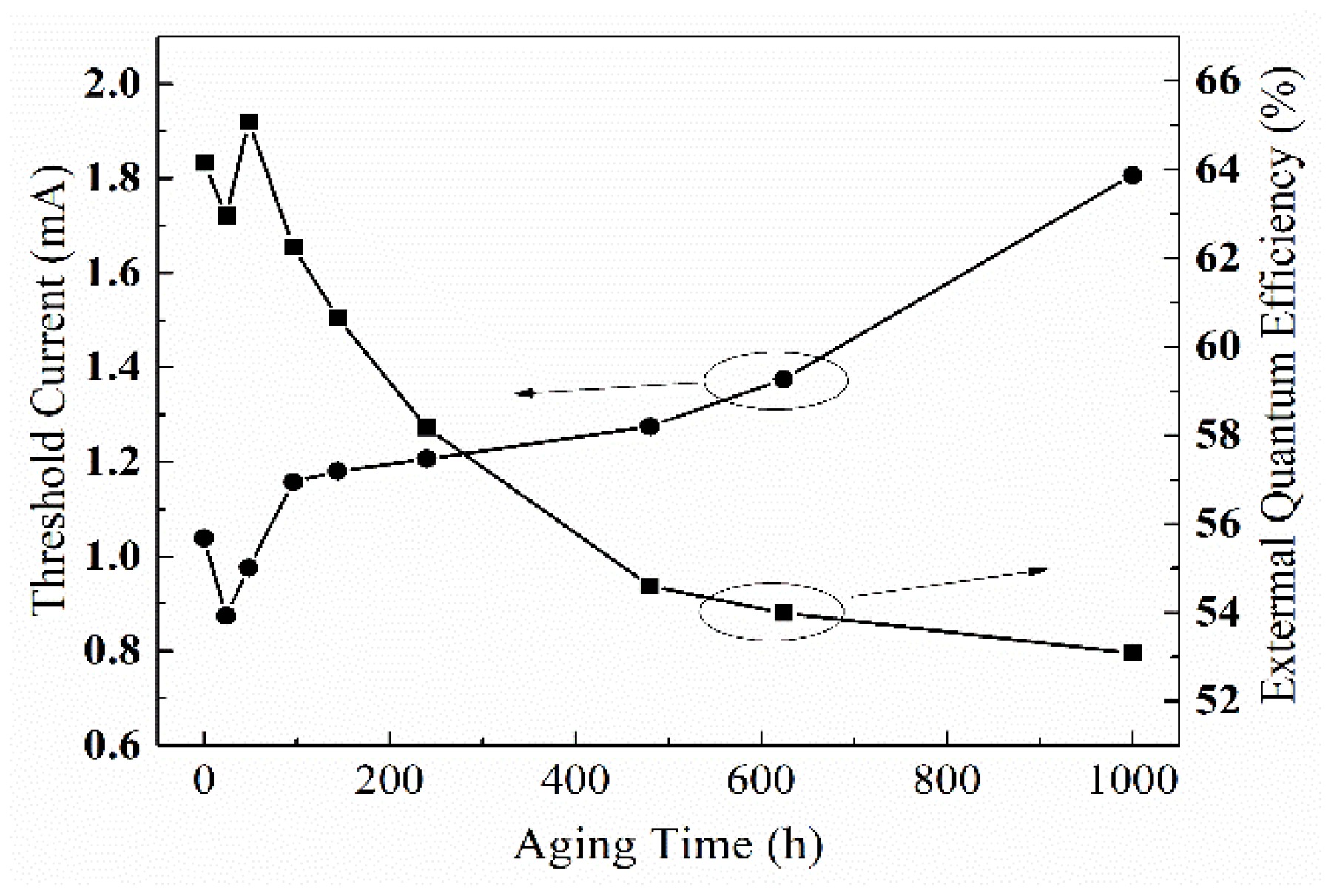

3.1. Effect of Accelerated Aging on Optical Output Characteristics

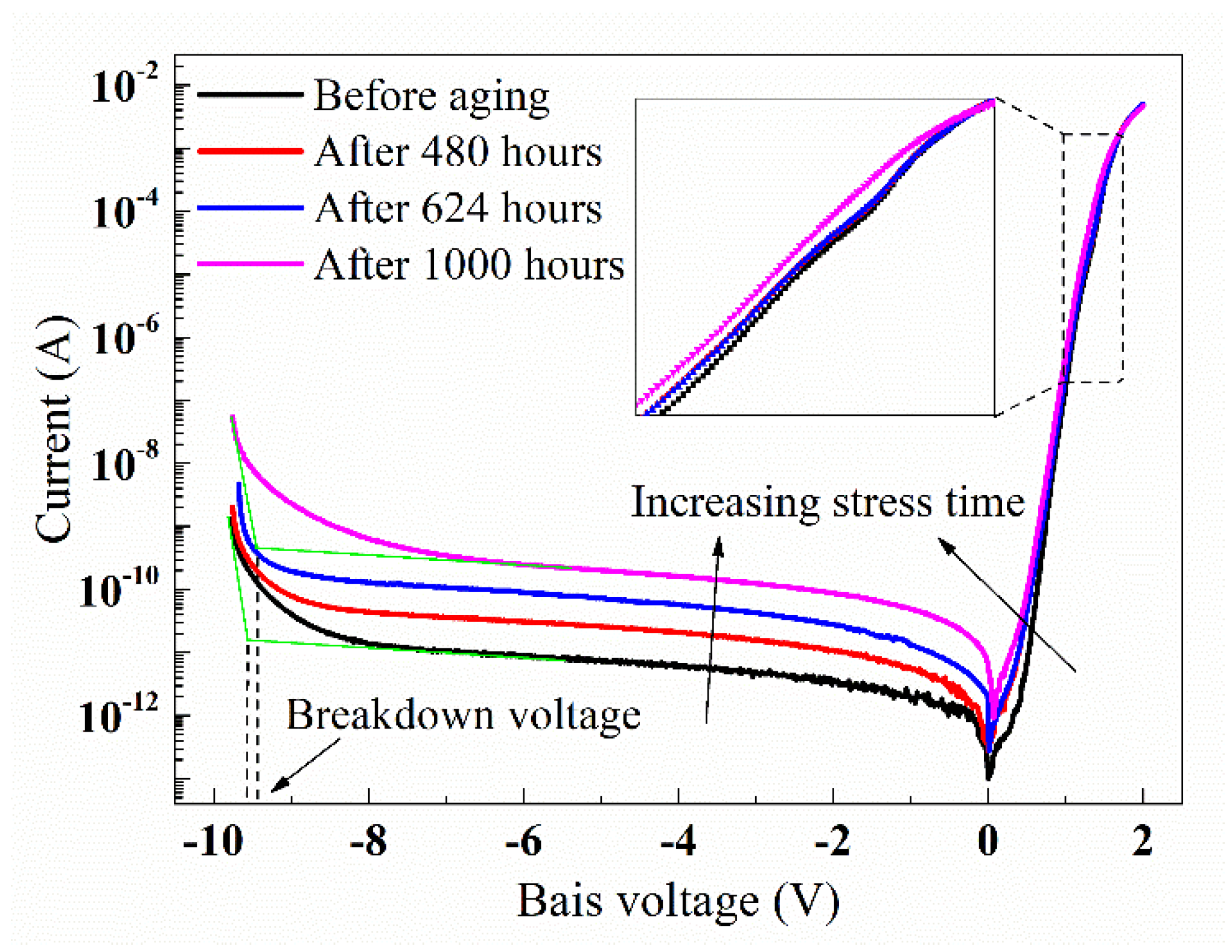

3.2. Effect of Accelerated Aging on the Forward and Reverse Current–Voltage

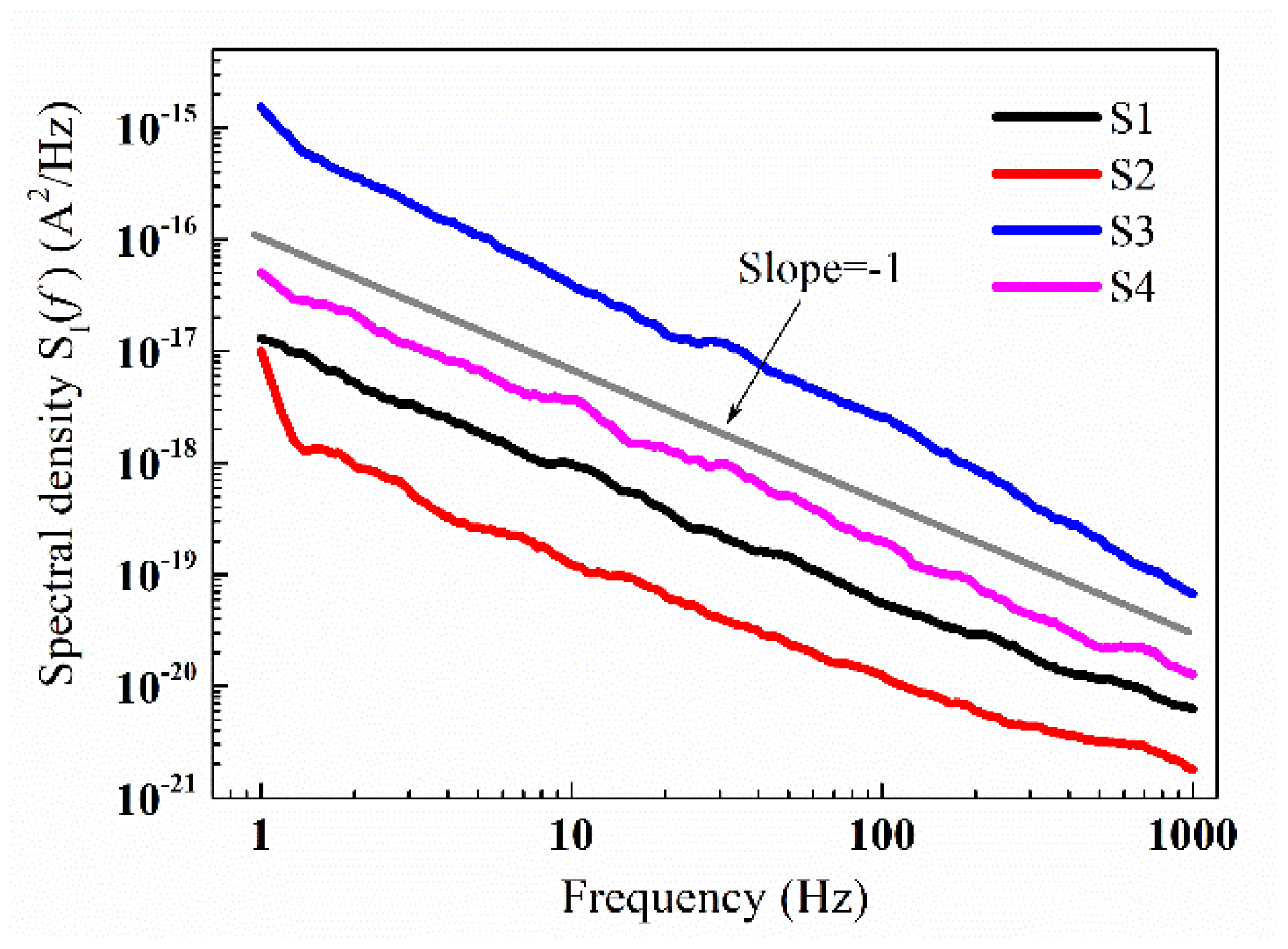

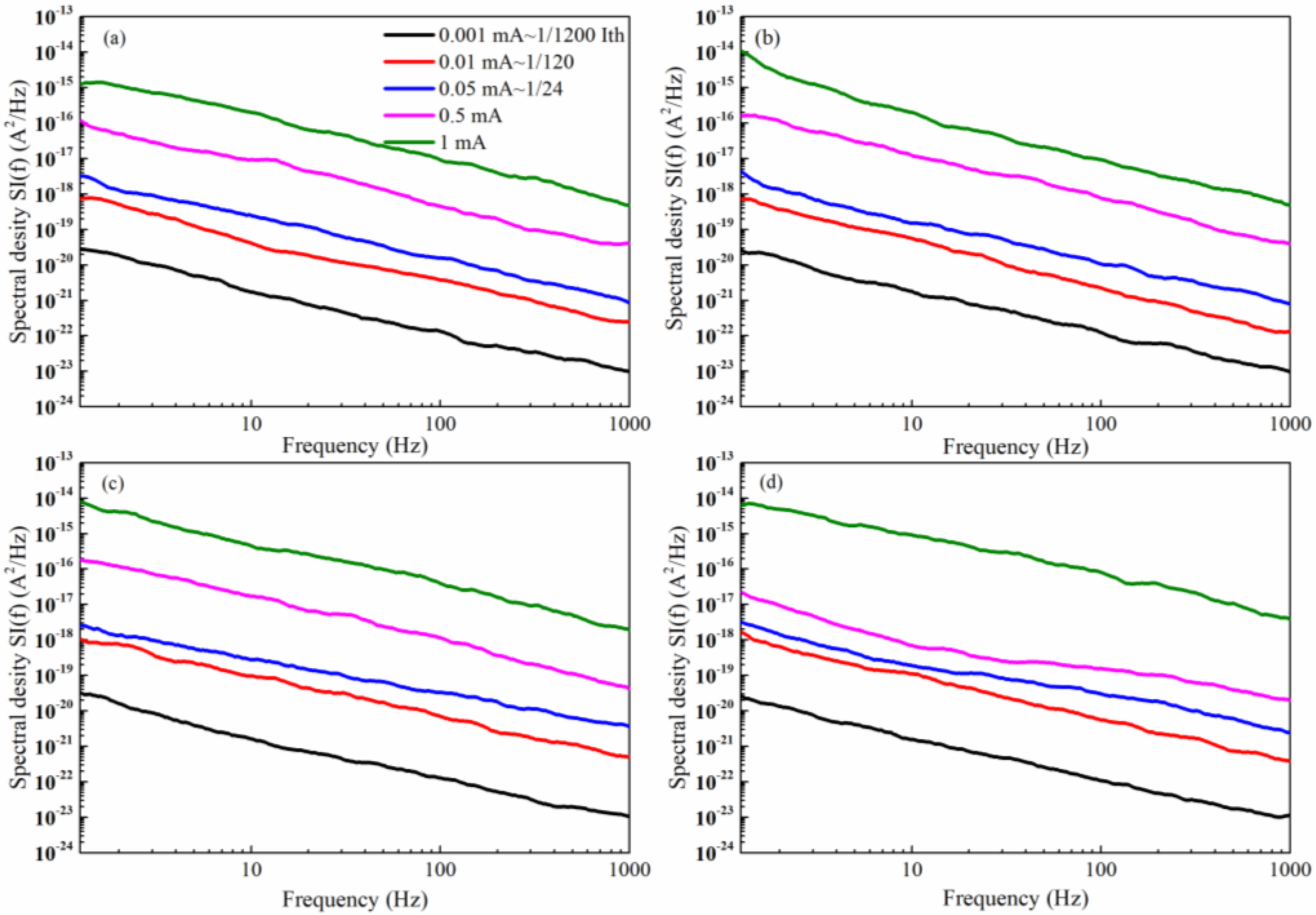

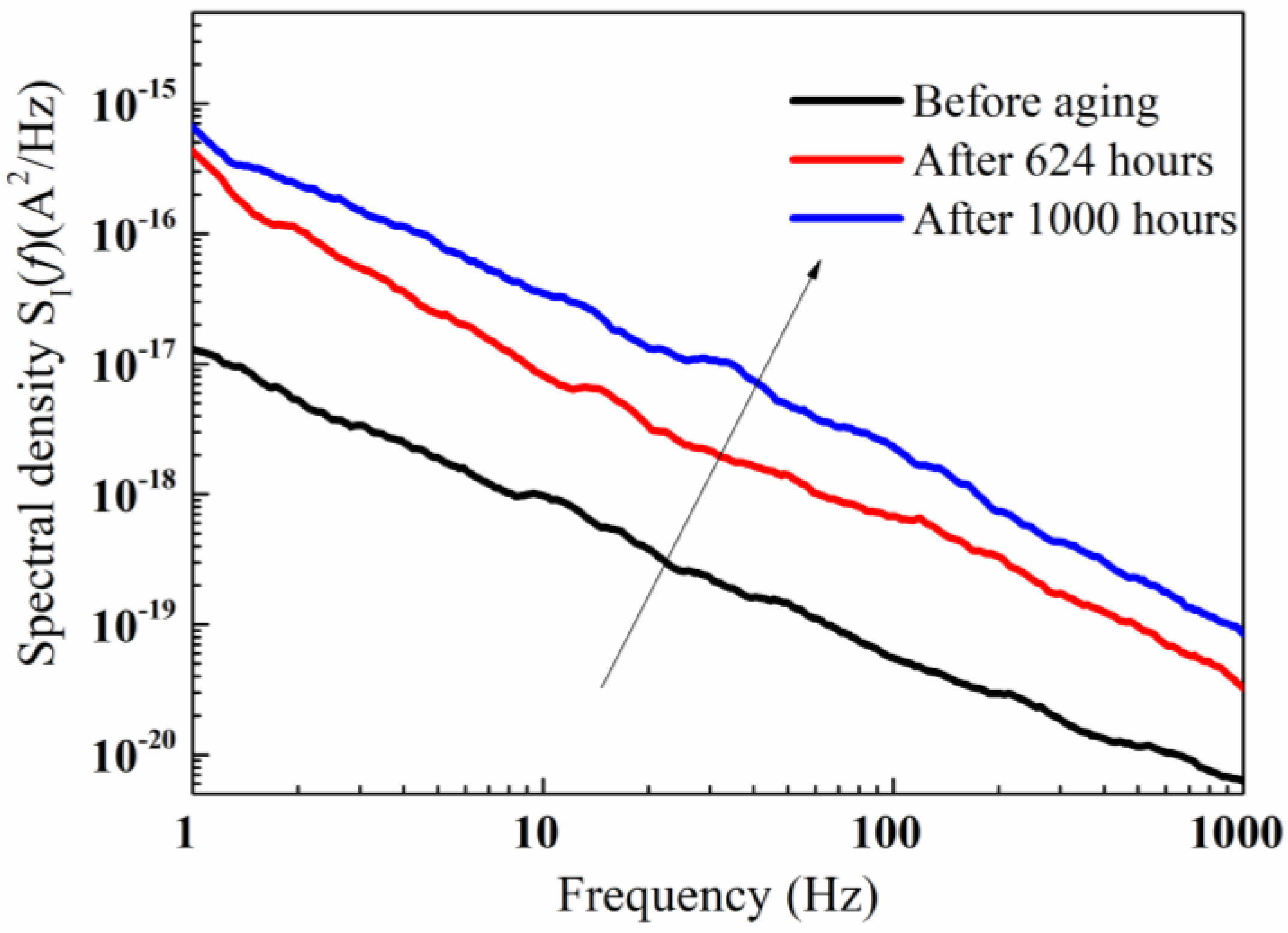

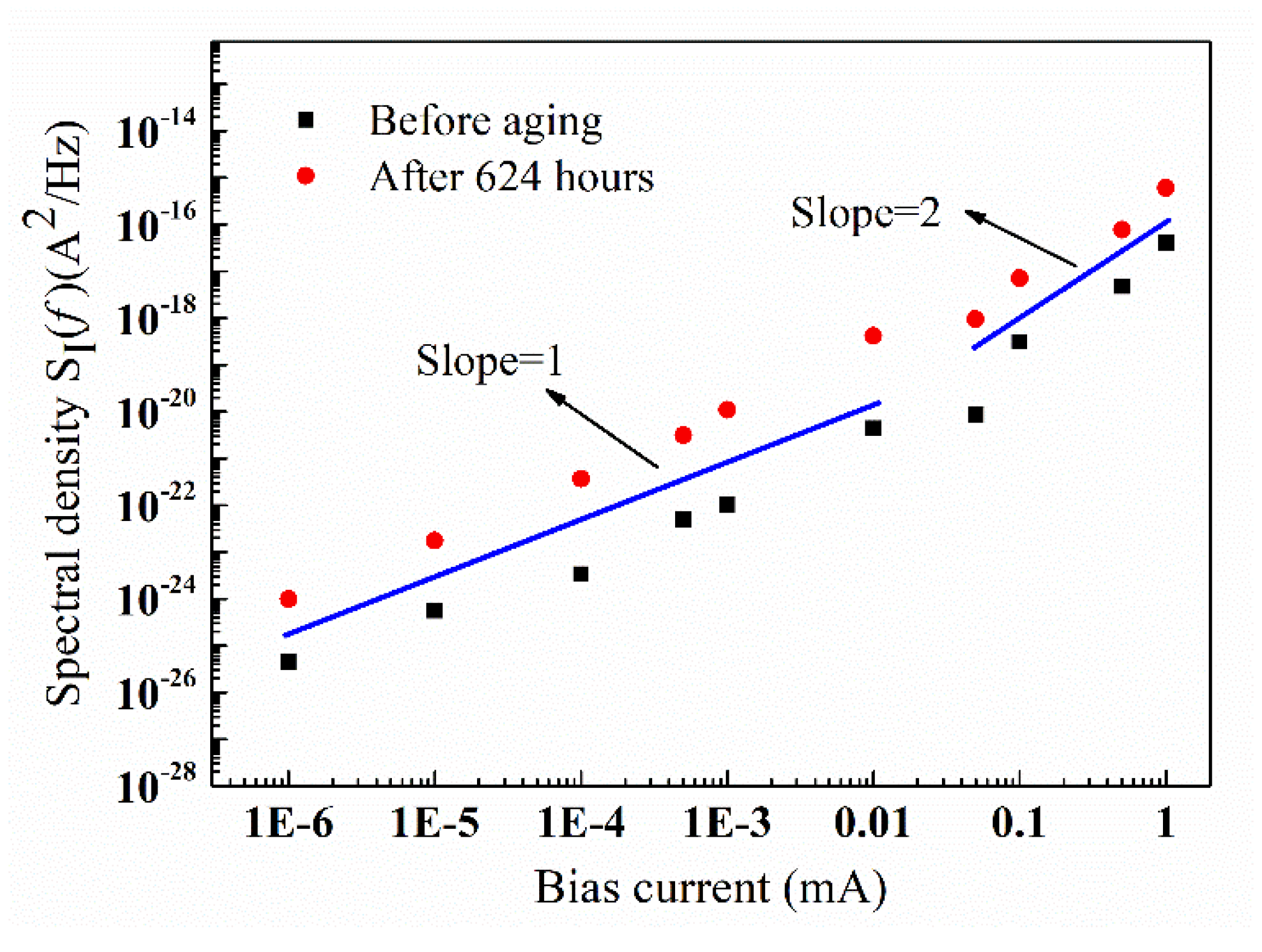

3.3. Effect of Accelerated Aging on Low-Frequency Noise

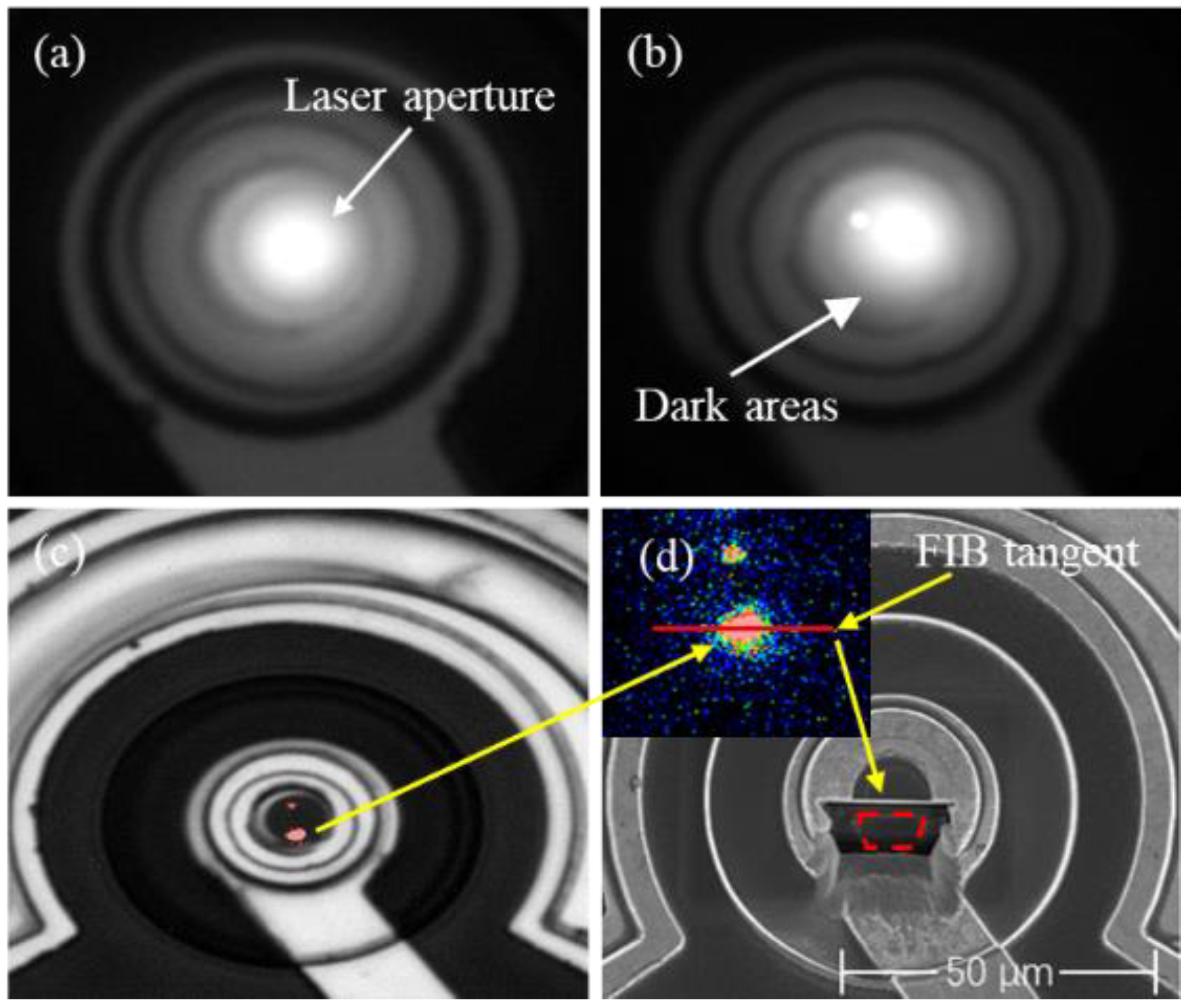

3.4. Effect of Accelerated Aging on Contagion of Defects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, A.; Wolf, P.; Lott, J.A.; Bimberg, D. Vertical-cavity surface-emitting lasers for data communication and sensing. Photonics Res. 2019, 7, 121–136. [Google Scholar] [CrossRef]

- Larisch, G.; Tian, S.; Bimberg, D. Optimization of VCSEL photon lifetime for minimum energy consumption at varying bit rates. Opt. Express 2020, 28, 18931–18937. [Google Scholar] [CrossRef] [PubMed]

- Healy, S.B.; O’Reilly, E.P.; Gustavsson, J.S.; Westbergh, P.; Haglund, Å.; Larsson, A.; Joel, A. Active Region Design for High-Speed 850-nm VCSELs. IEEE J. Quantum Electron. 2010, 46, 506–512. [Google Scholar] [CrossRef]

- Bushmaker, A.W.; Lingley, Z.; Brodie, M.; Foran, B.; Sin, Y. Optical Beam Induced Current and Time Resolved Electro-Luminescence in Vertical Cavity Surface Emitting Lasers During Accelerated Aging. IEEE Photonics J. 2019, 11, 1504011. [Google Scholar] [CrossRef]

- Koyama, F. Recent Advances of VCSEL Photonics. J. Light. Technol. 2006, 24, 4502–4513. [Google Scholar] [CrossRef]

- Kuchta, D.; Rylyakov, A.; Doany, F.; Schow, C.; Proesel, J.; Baks, C.; Westbergh, P.; Gustavsson, J.; Larsson, A. A 71-Gb/s NRZ modulated 850-nm VCSEL-based optical link. IEEE Photonics Technol. Lett. 2015, 27, 577–580. [Google Scholar] [CrossRef]

- Westbergh, P.; Safaisini, R.; Haglund, E.; Kögel, B.; Gustavsson, J.S.; Larsson, A.; Geen, M.; Lawrence, R.; Joel, A. High-speed 850 nm VCSELs with 28 GHz modulation bandwidth operating error-free up to 44 Gbit/s. Electron. Lett. 2012, 48, 1145–1147. [Google Scholar] [CrossRef]

- Xie, S.; Herrick, R.W.; Chamberlin, D.; Rosner, S.J.; McHugo, S.; Girolami, G.; Mayonte, M.; Kim, S.; Widjaja, W. Failure Mode Analysis of Oxide VCSELs in High Humidity and High Temperature. J. Light. Technol. 2003, 21, 1013. [Google Scholar]

- Rhew, K.H.; Jeon, S.C.; Lee, D.H.; Yoo, B.-S.; Yun, I. Reliability assessment of 1.55-μm vertical cavity surface emitting lasers with tunnel junction using high-temperature aging tests. Microelectron. Reliab. 2009, 49, 42–50. [Google Scholar] [CrossRef]

- Herrick, R.W.; Dafinca, A.; Farthouat, P.; Grillo, A.A.; McMahon, S.J.; Weidberg, A.R. Corrosion-Based Failure of Oxide-Aperture VCSELs. IEEE J. Quantum Elect. 2013, 49, 1045–1052. [Google Scholar] [CrossRef]

- Hasse, L.Z.; Babicz, S.; Kaczmarek, L.; Smulko, J.M.; Sedlakova, V. Quality assessment of ZnO-based varistors by 1/f noise. Microelectron. Reliab. 2014, 54, 192–199. [Google Scholar] [CrossRef]

- Del Vecchio, P.; Curutchet, A.; Deshayes, Y.; Bettiati, M.; Laruelle, F.; Labat, N.; Béchou, L. Correlation between forward-reverse low-frequency noise and atypical I–V signatures in 980 nm high-power laser diodes. Microelectron. Reliab. 2015, 55, 1741–1745. [Google Scholar] [CrossRef]

- Pralgauskaitė, S.; Palenskis, V.; Matukas, J.; Glemža, J.; Muliuk, G.; Šaulys, B.; Trinkūnas, A. Reliability investigation of light-emitting diodes via low frequency noise characteristics. Microelectron. Reliab. 2015, 55, 52–61. [Google Scholar] [CrossRef]

- Chen, X.Y.; Pedersen, A.; van Rheenen, A.D. Effect of electrical and thermal stress on low-frequency noise characteristics of laser diodes. Microelectron. Reliab. 2001, 41, 105–110. [Google Scholar] [CrossRef]

- Grüneis, F. An alternative form of Hooge’s relation for 1/f noise in semiconductor materials. Phys. Lett. A 2019, 383, 1401–1409. [Google Scholar] [CrossRef]

- Fukuda, M.; Hirono, T.; Kurosaki, T.; Kano, F. Correlation between 1/f noise and semiconductor laser degradation. Qual. Reliab. Eng. Int. 1994, 10, 351–353. [Google Scholar] [CrossRef]

- Pralgauskaite, S.; Matukas, J.; Palenskis, V.; Sermuksnis, E.; Vysniauskas, J.; Letal, G.; Mallard, R.; Smetona, S. Reliability and low-frequency noise measurements of InGaAsP MQW buried-heterostructure lasers. In Proceedings of the 14th International Conference on Microwaves, Radar and Wireless Communications. MIKON-2002. Conference Proceedings (IEEE Cat.No.02EX562), Gdansk, Poland, 20–22 May 2002; Volume 582, pp. 588–591. [Google Scholar]

- Li, Z.L.; Lai, P.T.; Choi, H.W. Reliability study on green InGaN/GaN light emitting diodes. J. Phys. Conf. Ser. 2010, 209, 012065. [Google Scholar] [CrossRef]

- Liao, W.; Gao, R.; Liu, Y.; Zhang, J.; Li, S.; Niu, H.; Yang, S.; Lai, C. Degradation Characteristics and Reliability Assessment of 1310 nm VCSEL for Microwave Photonic Link. Appl. Sci. 2022, 12, 5532. [Google Scholar] [CrossRef]

- Weeks, J.D.; Tully, J.C.; Kimerling, L.C. Theory of recombination-enhanced defect reactions in semiconductors. Phys. Rev. B 1975, 12, 3286–3292. [Google Scholar] [CrossRef]

- Botez, D.; Mawst, L.J.; Bhattacharya, A.; Lopez, J.; Li, J.; Letters, K.J.E. 66% CW wallplug efficiency from Al-free 0.98 μm-emitting diode lasers. Electron. Lett. 1996, 32, 2012–2013. [Google Scholar] [CrossRef]

- Pursiainen, O.; Linder, N.; Jaeger, A.; Oberschmid, R.; Streubel, K. Identification of aging mechanisms in the optical and electrical characteristics of light-emitting diodes. Appl. Phys. Lett. 2001, 79, 2895–2897. [Google Scholar] [CrossRef]

- Guan, J.; Guo, S.; Wang, J.; Tao, M.; Cao, J.; Gao, F. Analysis of origin of measured 1/ f noise in high-power semiconductor laser diodes far below threshold current. Microelectron. Reliab. 2016, 59, 55–59. [Google Scholar] [CrossRef]

- Vey, J.L.; Gallion, P. Semiclassical model of semiconductor laser noise and amplitude noise squeezing. I. Description and application to Fabry-Perot laser. IEEE J. Quantum Electron. 1997, 33, 2097–2104. [Google Scholar] [CrossRef]

- Wu, C.M.; Yang, E.S. Current suppression induced by conduction-band discontinuity in Al0.35Ga0.65As-GaAs N-p heterojunction diodes. J. Appl. Phys. 1980, 51, 2261. [Google Scholar] [CrossRef]

- Fabbro, R.; Haber, T.; Fasching, G.; Coppeta, R.; Pusterhofer, M.; Grogger, W. Defect localization in high-power vertical cavity surface emitting laser arrays by means of reverse biased emission microscopy. Meas. Sci. Technol. 2021, 32, 095406. [Google Scholar] [CrossRef]

- Vanzi, M.; Mura, G.; Marcello, G.; Xiao, K. ESD tests on 850nm GaAs-based VCSELs. Microelectron. Reliab. 2016, 64, 617–622. [Google Scholar] [CrossRef]

| Bias Current IB (mA) | IB/Ith | 12 mA | 15 mA | 17 mA | 20 mA | ||||

|---|---|---|---|---|---|---|---|---|---|

| Frequency Exponent Factor γ | Noise Amplitude at 1 Hz (A2/Hz) | Frequency Exponent Factor γ | Noise Amplitude at 1 Hz (A2/Hz) | Frequency Exponent Factor γ | Noise Amplitude at 1 Hz (A2/Hz) | Frequency Exponent Factor γ | Noise Amplitude at 1 Hz (A2/Hz) | ||

| 0.001 | ~1/1200 | 1.03 | 6.55 × 10−20 | 1.03 | 3.28 × 10−20 | 1.01 | 8.27 × 10−20 | 1.02 | 2.40 × 10−20 |

| 0.01 | ~1/120 | 1.09 | 7.69 × 10−19 | 1.08 | 7.42 × 10−19 | 1.01 | 1.66 × 10−18 | 1.1 | 3.06 × 10−18 |

| 0.05 | ~5/120 | 1.02 | 6.71 × 10−18 | 1.01 | 2.32 × 10−18 | 0.97 | 2.73 × 10−18 | 0.98 | 4.36 × 10−18 |

| 0.5 | ~5/12 | 1.09 | 7.23 × 10−17 | 1.03 | 2.99 × 10−16 | 1.08 | 3.32 × 10−16 | 0.95 | 3.79 × 10−17 |

| 1 | ~5/6 | 1.14 | 9.59 × 10−15 | 1.06 | 5.74 × 10−16 | 1.07 | 6.53 × 10−15 | 0.99 | 3.80 × 10−15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liao, W.; Wang, X.; Lu, G.; Yang, S.; Wei, Z. Degradation Characteristics and Mechanism of High Speed 850 nm Vertical-Cavity Surface-Emitting Laser during Accelerated Aging. Photonics 2022, 9, 801. https://doi.org/10.3390/photonics9110801

Zhang J, Liao W, Wang X, Lu G, Yang S, Wei Z. Degradation Characteristics and Mechanism of High Speed 850 nm Vertical-Cavity Surface-Emitting Laser during Accelerated Aging. Photonics. 2022; 9(11):801. https://doi.org/10.3390/photonics9110801

Chicago/Turabian StyleZhang, Jide, Wenyuan Liao, Xiaohua Wang, Guoguang Lu, Shaohua Yang, and Zhipeng Wei. 2022. "Degradation Characteristics and Mechanism of High Speed 850 nm Vertical-Cavity Surface-Emitting Laser during Accelerated Aging" Photonics 9, no. 11: 801. https://doi.org/10.3390/photonics9110801

APA StyleZhang, J., Liao, W., Wang, X., Lu, G., Yang, S., & Wei, Z. (2022). Degradation Characteristics and Mechanism of High Speed 850 nm Vertical-Cavity Surface-Emitting Laser during Accelerated Aging. Photonics, 9(11), 801. https://doi.org/10.3390/photonics9110801