Coupled Cavity Mid-IR Quantum Cascade Lasers Fabricated by Dry Etching

Abstract

1. Introduction

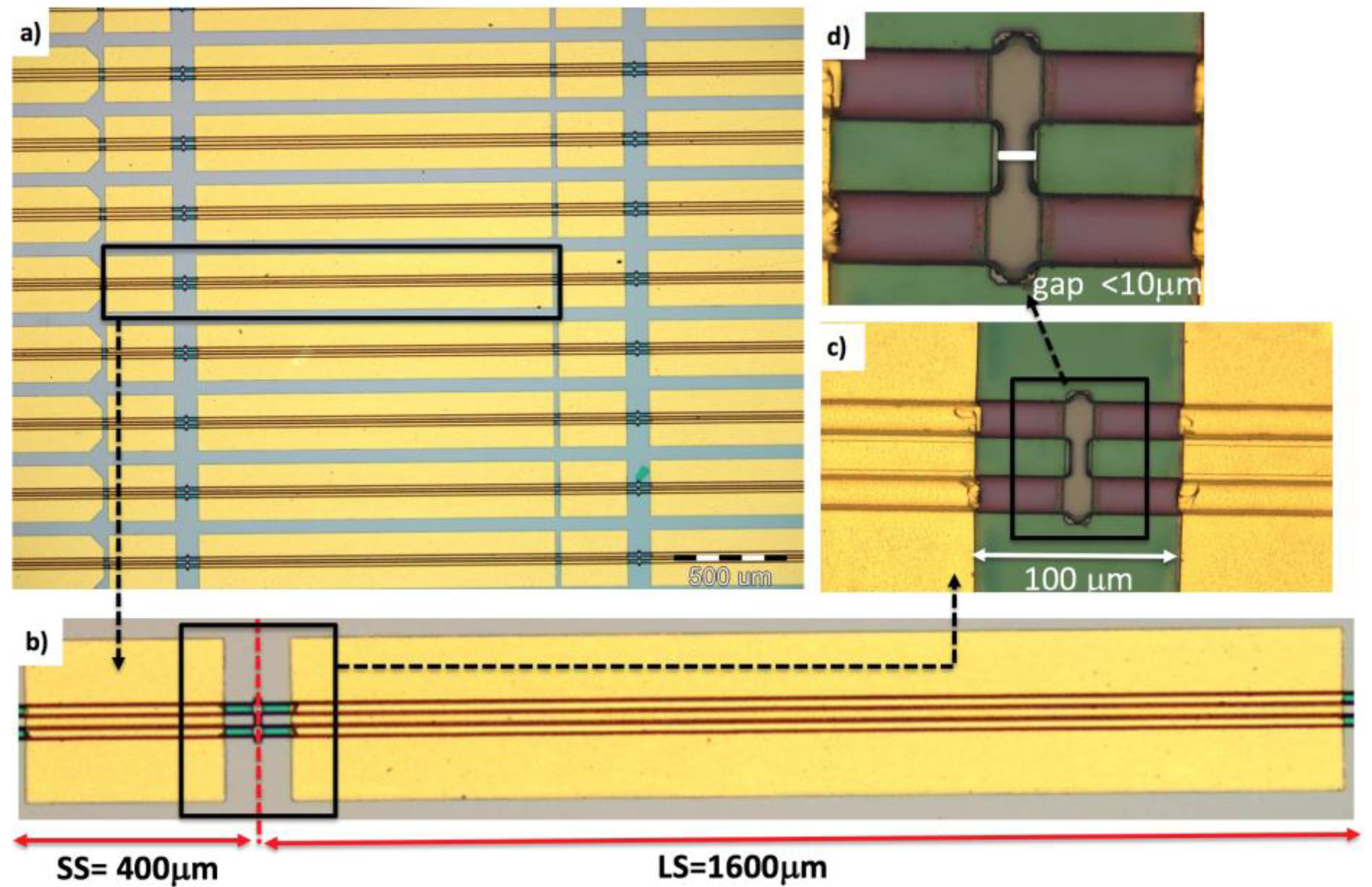

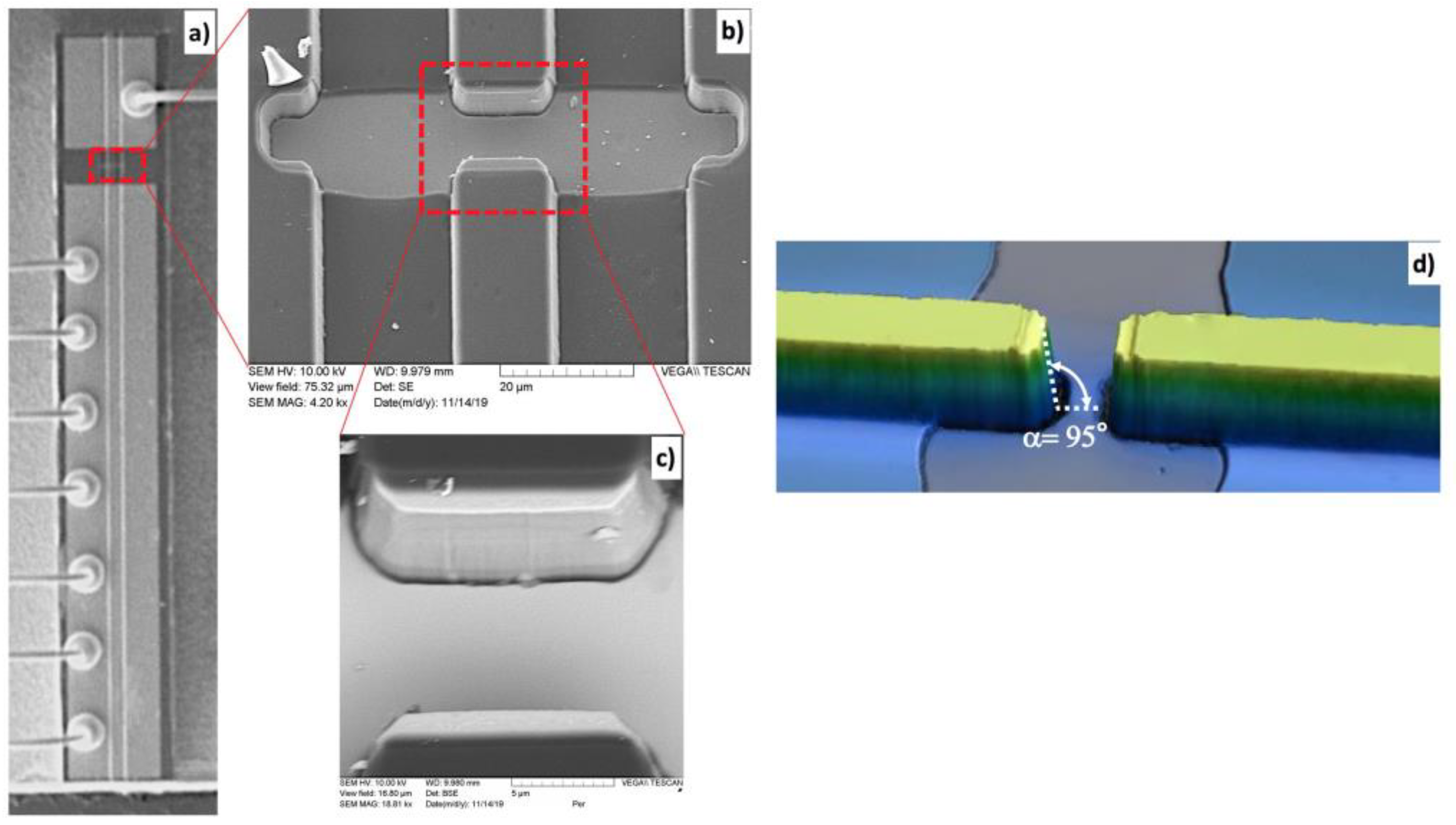

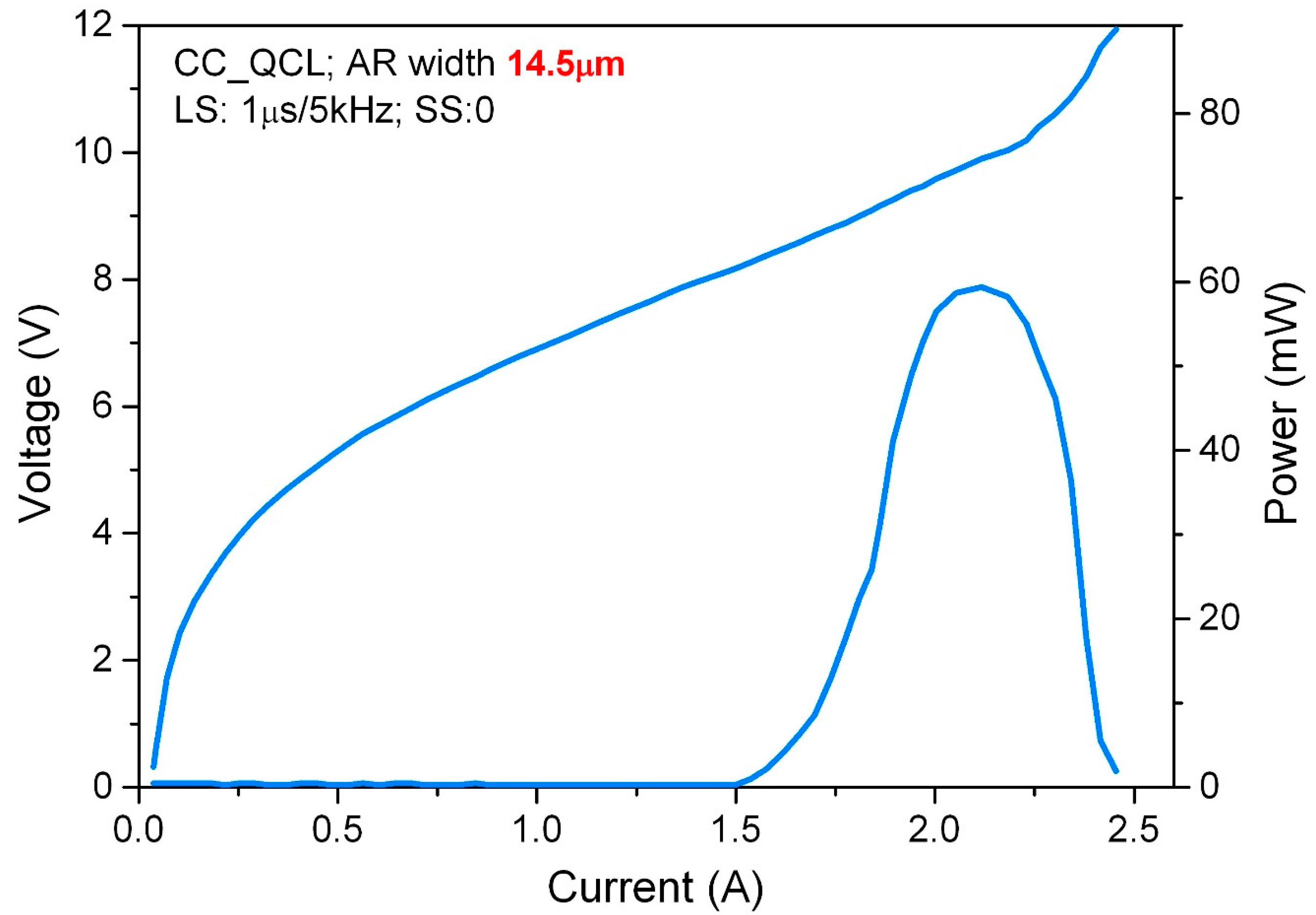

2. Investigated Devices and Fabrication Technology

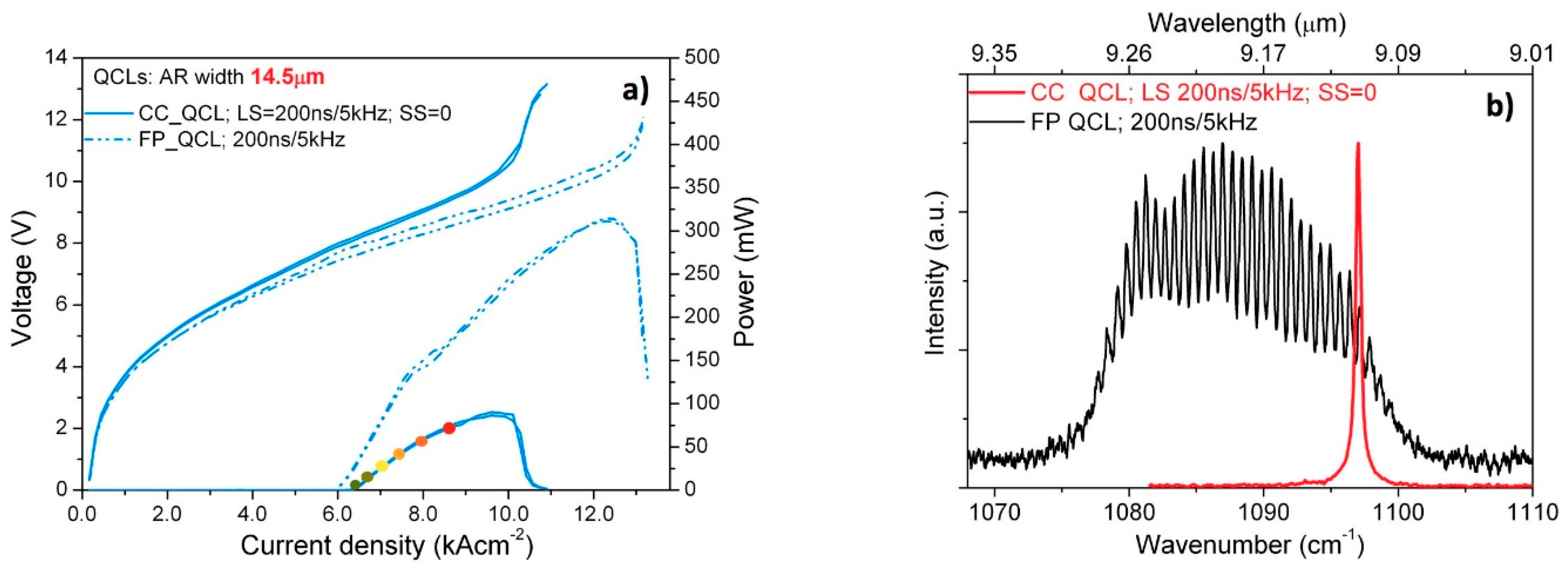

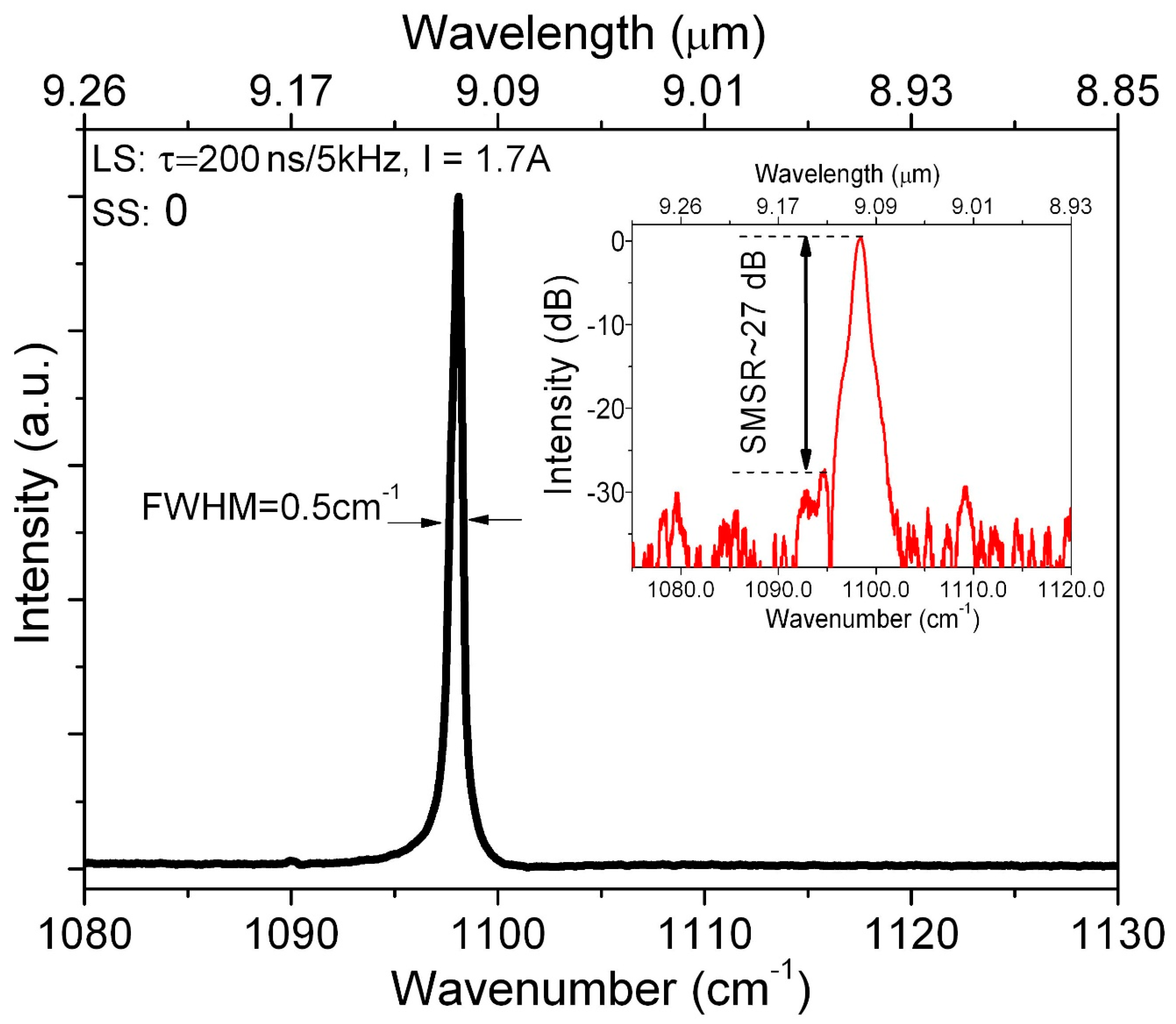

3. Experimental Results and Discussion

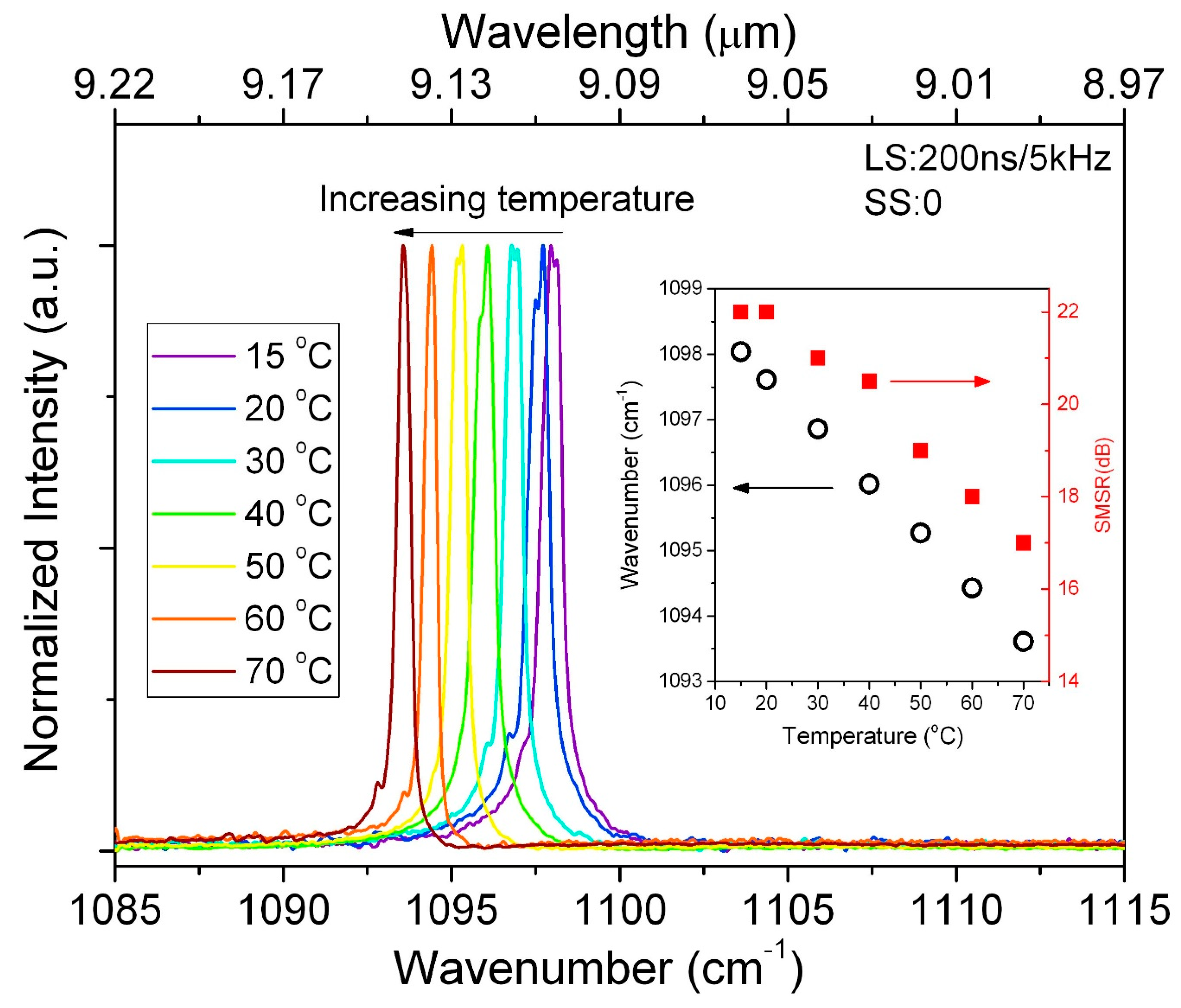

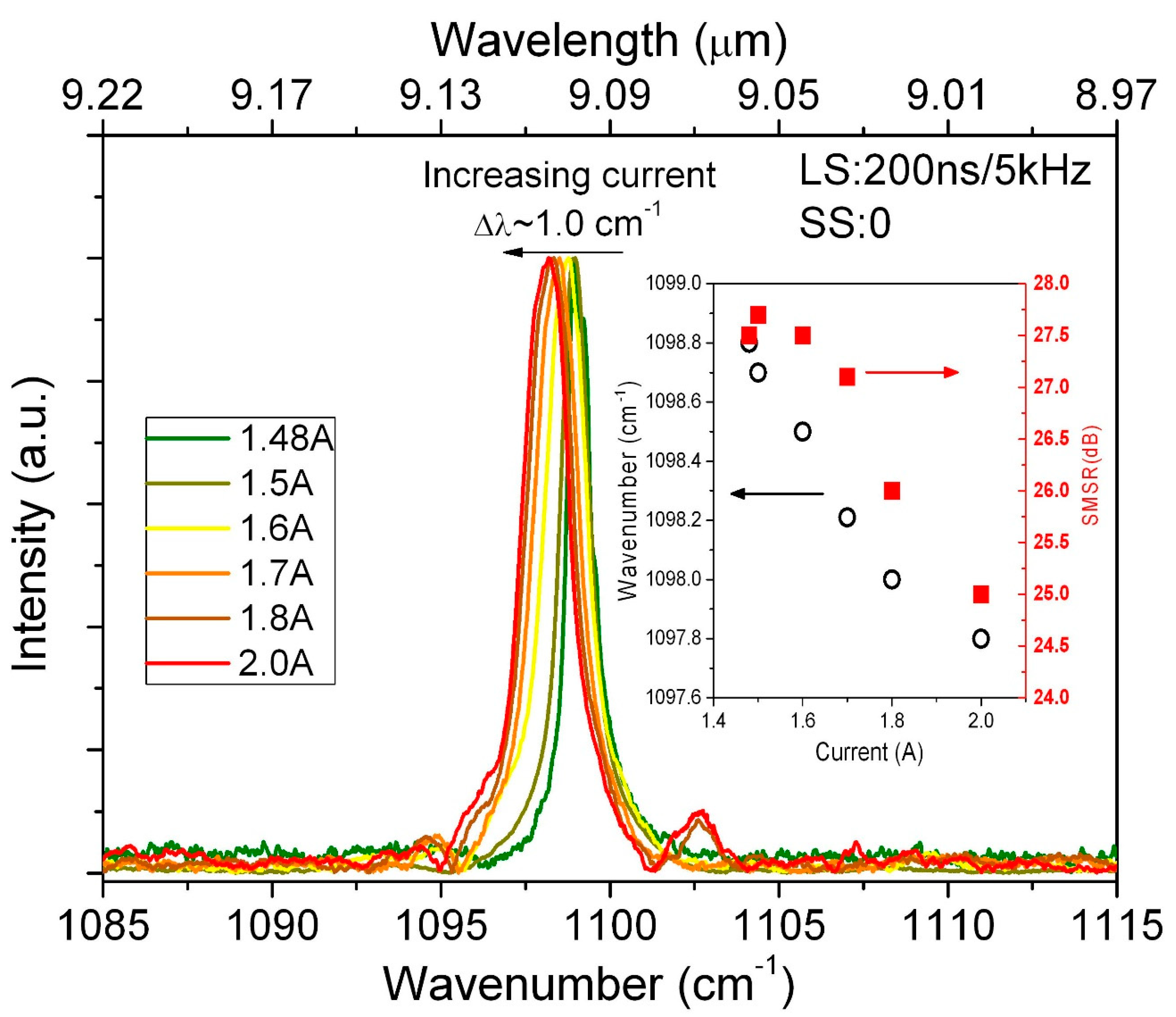

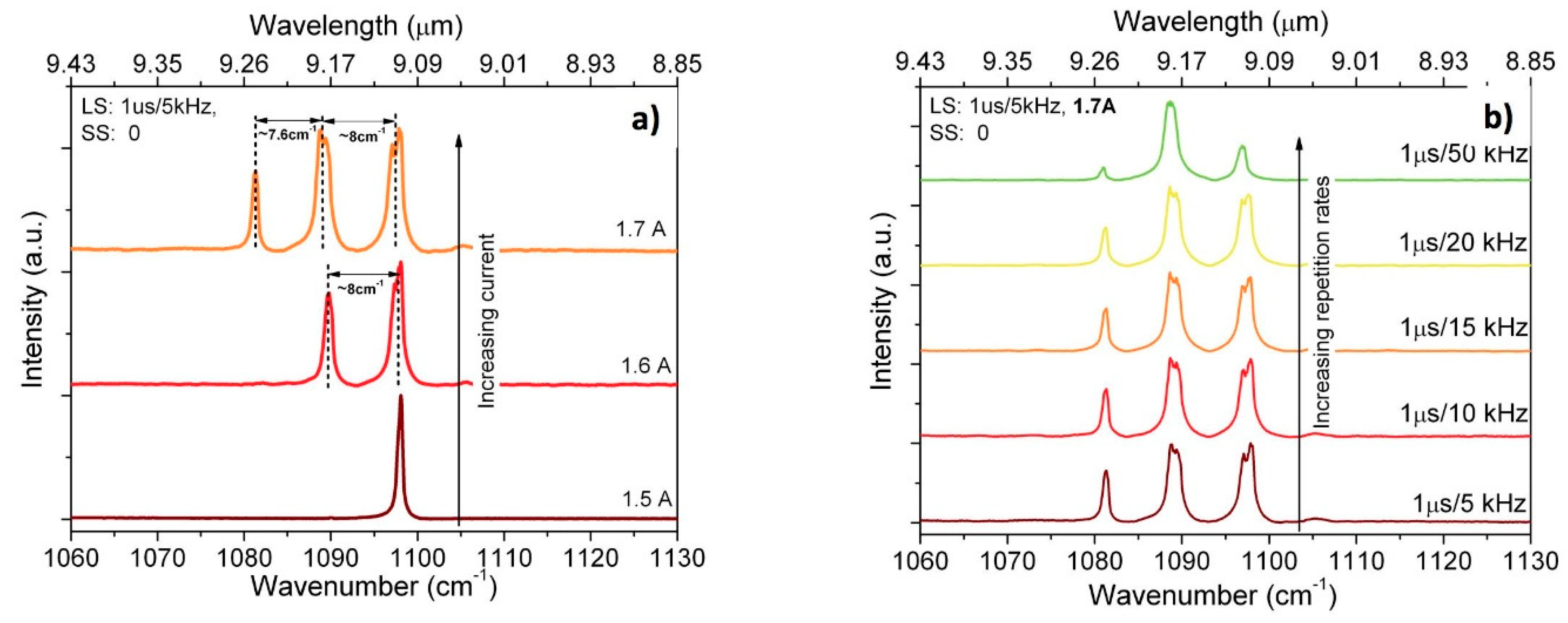

3.1. Temperature and Current Tuning of CC-QCL

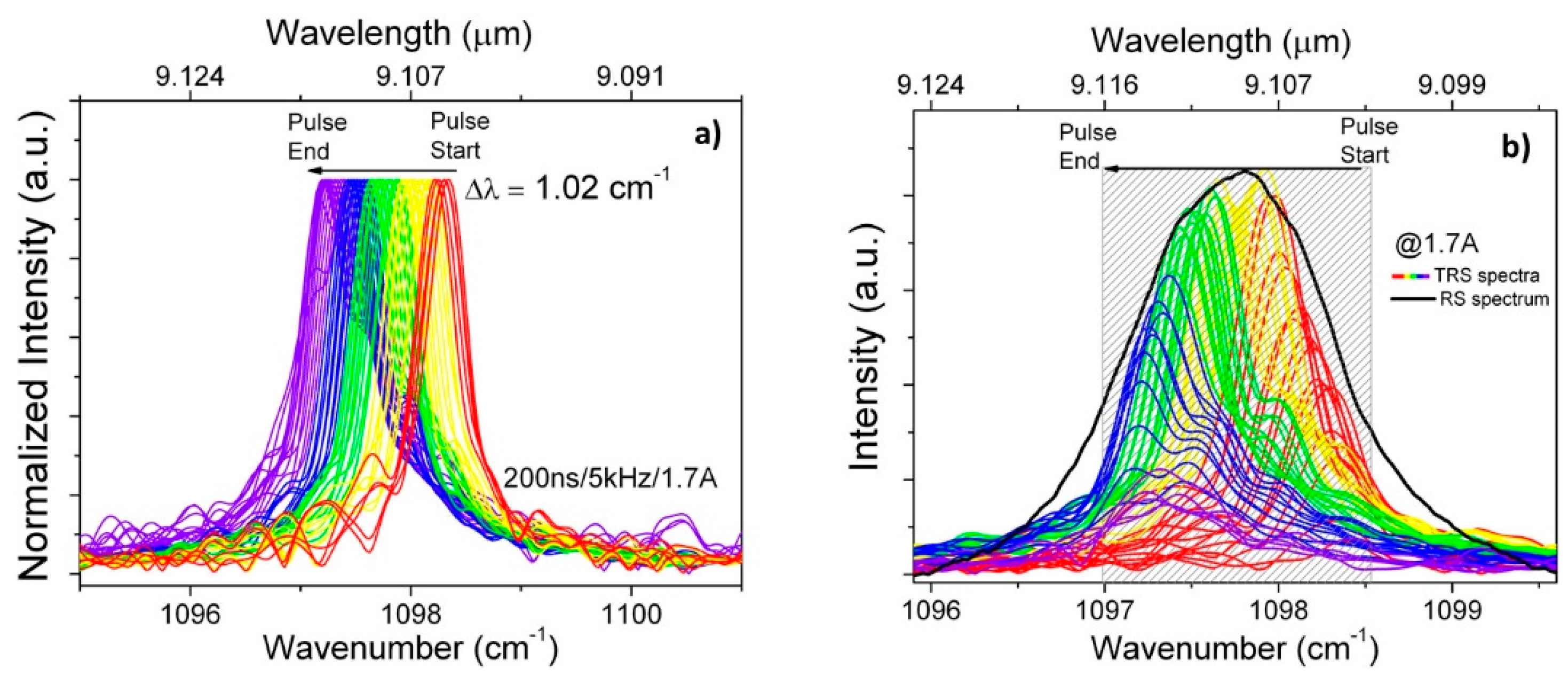

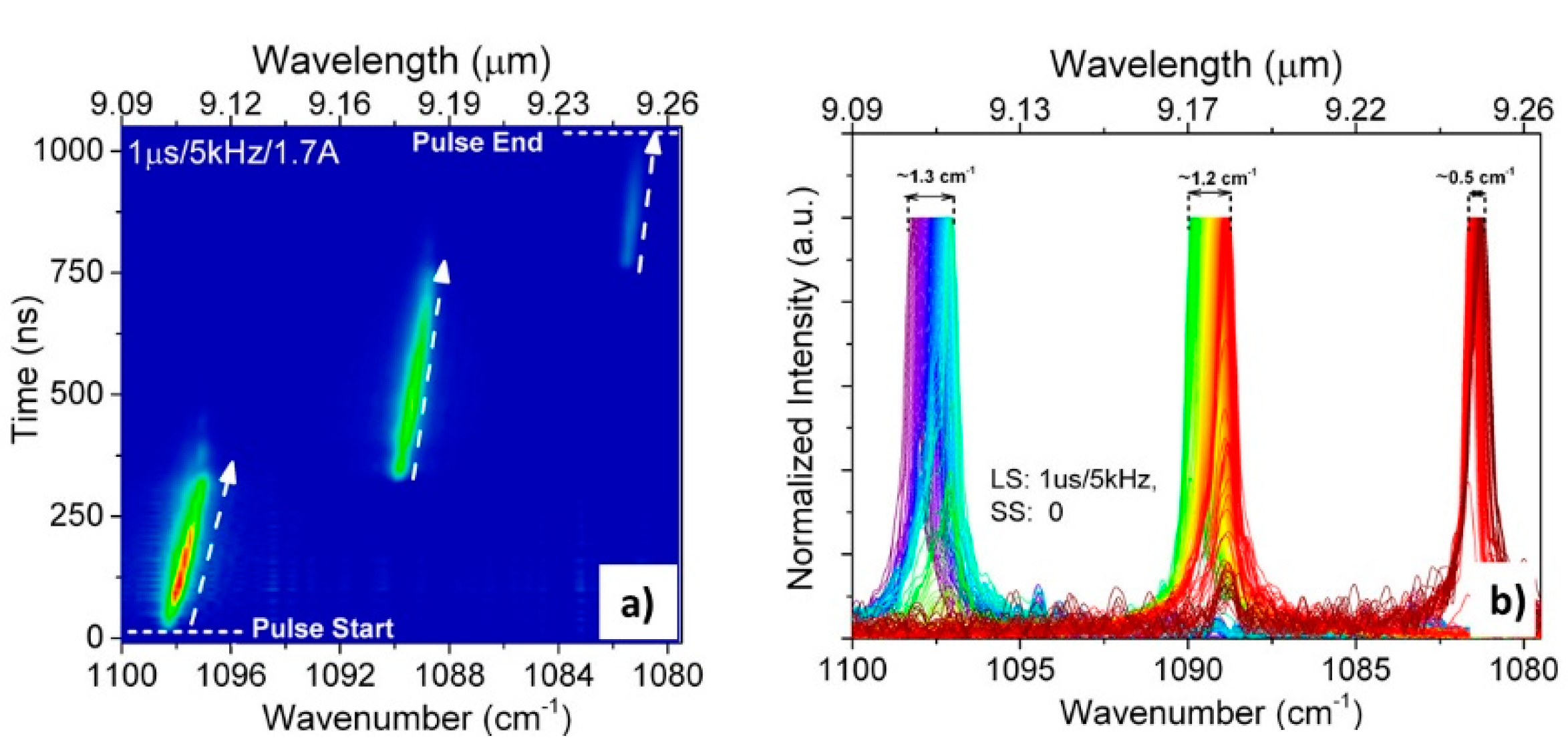

3.2. Intrapulse Tuning of CC-QCL

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Curl, R.F.; Capasso, F.; Gmachl, C.; Kosterev, A.A.; McManus, B.; Lewicki, R.; Pusharsky, M.; Wysocki, G.; Tittel, F.K. Quantum cascade lasers in chemical physics. Chem. Phys. Lett. 2010, 487, 1–18. [Google Scholar] [CrossRef]

- Menzel, L.; Kosterev, A.; Curl, R.; Tittel, F.K.; Gmachl, C.; Capasso, F.; Sivco, D.; Baillargeon, J.; Hutchinson, A.; Cho, A.; et al. Spectroscopic detection of biological NO with a quantum cascade laser. Appl. Phys. A 2001, 72, 859–863. [Google Scholar] [CrossRef] [PubMed]

- Schwaighofer, A.; Brandstetter, M.; Lendl, B. Quantum cascade lasers (QCLs) in biomedical spectroscopy. Chem. Soc. Rev. 2017, 46, 5903–5924. [Google Scholar] [CrossRef] [PubMed]

- Elia, A.; Di Franco, C.; Spagnolo, V.; Lugarà, P.M.; Scamarcio, G. Quantum Cascade Laser-Based Photoacoustic Sensor for Trace Detection of Formaldehyde Gas. Sensors 2009, 9, 2697–2705. [Google Scholar] [CrossRef]

- Lundqvist, S.; Kluczynski, P.; Weih, R.; Von Edlinger, M.; Nähle, L.; Fischer, M.; Bauer, A.; Höfling, S.; Koeth, J. Sensing of formaldehyde using a distributed feedback interband cascade laser emitting around 3493 nm. Appl. Opt. 2012, 51, 6009–6013. [Google Scholar] [CrossRef]

- Kosterev, A.A.; Tittel, F.K. Chemical sensors based on quantum cascade lasers. IEEE J. Quantum Electron. 2002, 38, 582–591. [Google Scholar] [CrossRef]

- Bugajski, M.; Pierściński, K.; Pierścińska, D.; Szerling, A.; Kosiel, K. Multimode instabilities in mid-infrared quantum cascade lasers. Photonics Lett. Pol. 2013, 5, 85–87. [Google Scholar] [CrossRef][Green Version]

- Faist, J.; Gmachl, C.; Capasso, F.; Sirtori, C.; Sivco, D.L.; Baillargeon, J.N.; Cho, A.Y. Distributed feedback quantum cascade lasers. Appl. Phys. Lett. 1997, 70, 2670–2672. [Google Scholar] [CrossRef]

- Schartner, S.; Austerer, M.; Schrenk, W.; Andrews, A.M.; Klang, P.; Strasser, G. Surface emission from episide-down short distributed-feedback quantum cascade lasers. Opt. Express 2008, 16, 11920–11929. [Google Scholar] [CrossRef]

- Hugi, A.; Maulini, R.; Faist, J. External cavity quantum cascade laser. Semicond. Sci. Technol. 2010, 25, 83001. [Google Scholar] [CrossRef]

- Höfling, S.; Reithmaier, J.; Forchel, A. Device performance and wavelength tuning behavior of ultra-short quantum-cascade microlasers with deeply etched Bragg-mirrors. IEEE J. Sel. Top. Quantum Electron. 2005, 11, 1048–1054. [Google Scholar] [CrossRef]

- Fuchs, P.; Friedl, J.; Höfling, S.; Koeth, J.; Forchel, A.; Worschech, L.; Kamp, M. Single mode quantum cascade lasers with shallow-etched distributed Bragg reflector. Opt. Express 2012, 20, 3890–3897. [Google Scholar] [CrossRef]

- Colombelli, R.; Srinivasan, K.; Troccoli, M.; Painter, O.; Gmachl, C.; Tennant, D.M.; Sergent, A.M.; Sivco, D.L.; Cho, A.Y.; Capasso, F. Quantum Cascade Surface-Emitting Photonic Crystal Laser. Science 2003, 302, 1374–1377. [Google Scholar] [CrossRef] [PubMed]

- Hugi, A.; Terazzi, R.; Bonetti, Y.; Wittmann, A.; Fischer, M.; Beck, M.; Faist, J.; Gini, E. External cavity quantum cascade laser tunable from 7.6 to 11.4 μm. Appl. Phys. Lett. 2009, 95, 61103. [Google Scholar] [CrossRef]

- Coldren, L.A. Monolithic two-section GaInAsP/InP active-optical-resonator devices formed by reactive ion etching. Appl. Phys. Lett. 1981, 38, 315–317. [Google Scholar] [CrossRef]

- Coldren, L.; Koch, T. Analysis and design of coupled-cavity lasers—Part I: Threshold gain analysis and design guidelines. IEEE J. Quantum Electron. 1984, 20, 659–670. [Google Scholar] [CrossRef]

- Coldren, L.; Koch, T. Analysis and design of coupled-cavity lasers—Part II: Transient analysis. IEEE J. Quantum Electron. 1984, 20, 671–682. [Google Scholar] [CrossRef]

- Höfling, S.; Heinrich, J.; Reithmaier, J.P.; Forchel, A.; Seufert, J.; Fischer, M.; Koeth, J. Widely tunable single-mode quantum cascade lasers with two monolithically coupled Fabry-Pérot cavities. Appl. Phys. Lett. 2006, 89, 241126. [Google Scholar] [CrossRef]

- Li, H.; Manceau, J.-M.; Andronico, A.; Jagtap, V.; Sirtori, C.; Li, L.H.; Linfield, E.H.; Davies, G.; Barbieri, S. Coupled-cavity terahertz quantum cascade lasers for single mode operation. Appl. Phys. Lett. 2014, 104, 241102. [Google Scholar] [CrossRef]

- Kundu, I.; Dean, P.; Valavanis, A.; Chen, L.; Li, L.H.; Cunningham, J.; Linfield, E.H.; Davies, G. Discrete Vernier tuning in terahertz quantum cascade lasers using coupled cavities. Opt. Express 2014, 22, 16595–16605. [Google Scholar] [CrossRef]

- Giehler, M.; Kostial, H.; Hey, R.; Grahn, H. Suppression of longitudinal modes in two-sectioned, coupled-cavity GaAs/(Al,Ga) As terahertz quantum-cascade lasers. Appl. Phys. Lett. 2007, 91, 161102. [Google Scholar] [CrossRef]

- Pierściński, K.; Pierścińska, D.; Pluska, M.; Gutowski, P.; Sankowska, I.; Karbownik, P.; Czerwinski, A.; Bugajski, M. Room temperature, single mode emission from two-section coupled cavity InGaAs/AlGaAs/GaAs quantum cascade laser. J. Appl. Phys. 2015, 118, 133103. [Google Scholar] [CrossRef]

- Czerwinski, A.; Pluska, M.; Łaszcz, A.; Ratajczak, J.; Pierściński, K.; Pierścińska, D.; Gutowski, P.; Karbownik, P.; Bugajski, M. Formation of coupled-cavities in quantum cascade lasers using focused ion beam milling. Microelectron. Reliab. 2015, 55, 2142–2146. [Google Scholar] [CrossRef]

- Pierściński, K.; Bugajski, M.; Czyszanowski, T.; Kolek, A.; Wesołowski, M.; Kuc, M.; Sarzała, R.P.; Dems, M.; Płuska, M.; Pierścińska, D.; et al. Coupled-cavity AlInAs/InGaAs/InP quantum cascade lasers fabricated by focused ion beam processing. J. Phys. Photonics 2018, 1, 015001. [Google Scholar] [CrossRef]

- Bugajski, M.; Gutowski, P.; Karbownik, P.; Trajnerowicz, A.; Pierściński, K.; Pierścińska, D.; Sankowska, I.; Kubacka-Traczyk, J.; Sakowicz, M. Room temperature AlInAs/InGaAs/inP quantum cascade lasers. Photonics Lett. Pol. 2014, 6, 142–144. [Google Scholar] [CrossRef]

- Gutowski, P.; Sankowska, I.; Słupiński, T.; Pierścińska, D.; Pierściński, K.; Kuźmicz, A.; Gołaszewska-Malec, K.; Bugajski, M. Optimization of MBE Growth Conditions of In0.52Al0.48As Waveguide Layers for InGaAs/InAlAs/InP Quantum Cascade Lasers. Materials 2019, 12, 1621. [Google Scholar] [CrossRef]

- Bugajski, M.; Gutowski, P.; Karbownik, P.; Kolek, A.; Hałdaś, G.; Pierściński, K.; Pierścińska, D.; Kubacka-Traczyk, J.; Sankowska, I.; Trajnerowicz, A.; et al. Mid-IR quantum cascade lasers: Device technology and non-equilibrium Green’s function modeling of electro-optical characteristics. Phys. Status Solidi B 2014, 251, 1144–1157. [Google Scholar] [CrossRef]

- Bugajski MKosiel, K.; Szerling, A.; Kubacka-Traczyk, J.; Sankowska, I.; Karbownik, P.; Trajnerowicz, A.; Pruszynska-Karbownik, E.; Pierscinski, K.; Pierscinska, D. GaAs/AlGaAs (similar to 9.4 mu m) quantum cascade lasers operating at 260 K. Bull. Pol. Acad. Sci. Tech. Sci. 2010, 58, 471–476. [Google Scholar]

- Pierścińska, D.; Pierściński, K.; Iwińska, M.; Kosiel, K.; Szerling, A.; Karbownik, P.; Bugajski, M. Electrical and optical characterization of mid-IR GaAs/AlGaAs quantum cascade lasers. Proc. SPIE 2012, 8432, 84321S. [Google Scholar]

- Pierściński, K.; Pierścińska, D.; Szabra, D.; Nowakowski, M.; Wojtas, J.; Mikołajczyk, J.; Bielecki, Z.; Bugajski, M. Time resolved FTIR study of spectral tuning and thermal dynamics of mid-IR QCLs. Proc. SPIE 2014, 9134, 91341L. [Google Scholar]

- Brandstetter, M.; Genner, A.; Schwarzer, C.; Mujagic, E.; Strasser, G.; Lendl, B. Time-resolved spectral characterization of ring cavity surface emitting and ridge-type distributed feedback quantum cascade lasers by step-scan FT-IR spectroscopy. Opt. Express 2014, 22, 2656–2664. [Google Scholar] [CrossRef]

- Hempel, M.; Roben, B.; Schrottke, L.; Hübers, H.-W.; Grahn, H.T. Fast continuous tuning of terahertz quantum-cascade lasers by rear-facet illumination. Appl. Phys. Lett. 2016, 108, 191106. [Google Scholar] [CrossRef]

- Kundu, I.; Dean, P.; Valavanis, A.; Chen, L.; Li, L.H.; Cunningham, J.; Linfield, E.H.; Davies, G. Quasi-continuous frequency tunable terahertz quantum cascade lasers with coupled cavity and integrated photonic lattice. Opt. Express 2017, 25, 486–496. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pierściński, K.; Pierścińska, D.; Kuźmicz, A.; Sobczak, G.; Bugajski, M.; Gutowski, P.; Chmielewski, K. Coupled Cavity Mid-IR Quantum Cascade Lasers Fabricated by Dry Etching. Photonics 2020, 7, 45. https://doi.org/10.3390/photonics7030045

Pierściński K, Pierścińska D, Kuźmicz A, Sobczak G, Bugajski M, Gutowski P, Chmielewski K. Coupled Cavity Mid-IR Quantum Cascade Lasers Fabricated by Dry Etching. Photonics. 2020; 7(3):45. https://doi.org/10.3390/photonics7030045

Chicago/Turabian StylePierściński, Kamil, Dorota Pierścińska, Aleksandr Kuźmicz, Grzegorz Sobczak, Maciej Bugajski, Piotr Gutowski, and Krzysztof Chmielewski. 2020. "Coupled Cavity Mid-IR Quantum Cascade Lasers Fabricated by Dry Etching" Photonics 7, no. 3: 45. https://doi.org/10.3390/photonics7030045

APA StylePierściński, K., Pierścińska, D., Kuźmicz, A., Sobczak, G., Bugajski, M., Gutowski, P., & Chmielewski, K. (2020). Coupled Cavity Mid-IR Quantum Cascade Lasers Fabricated by Dry Etching. Photonics, 7(3), 45. https://doi.org/10.3390/photonics7030045