Terahertz Radome Inspection

Abstract

:1. Introduction

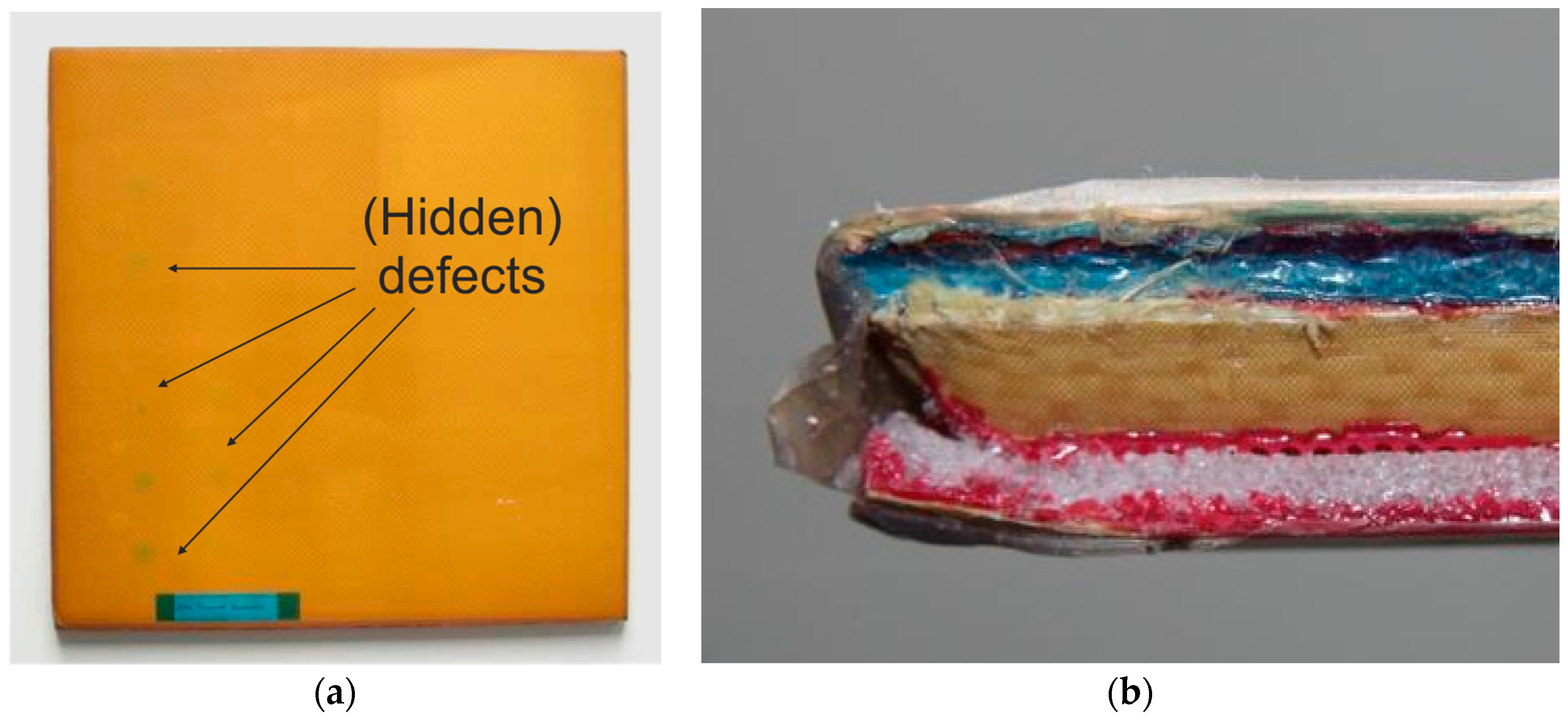

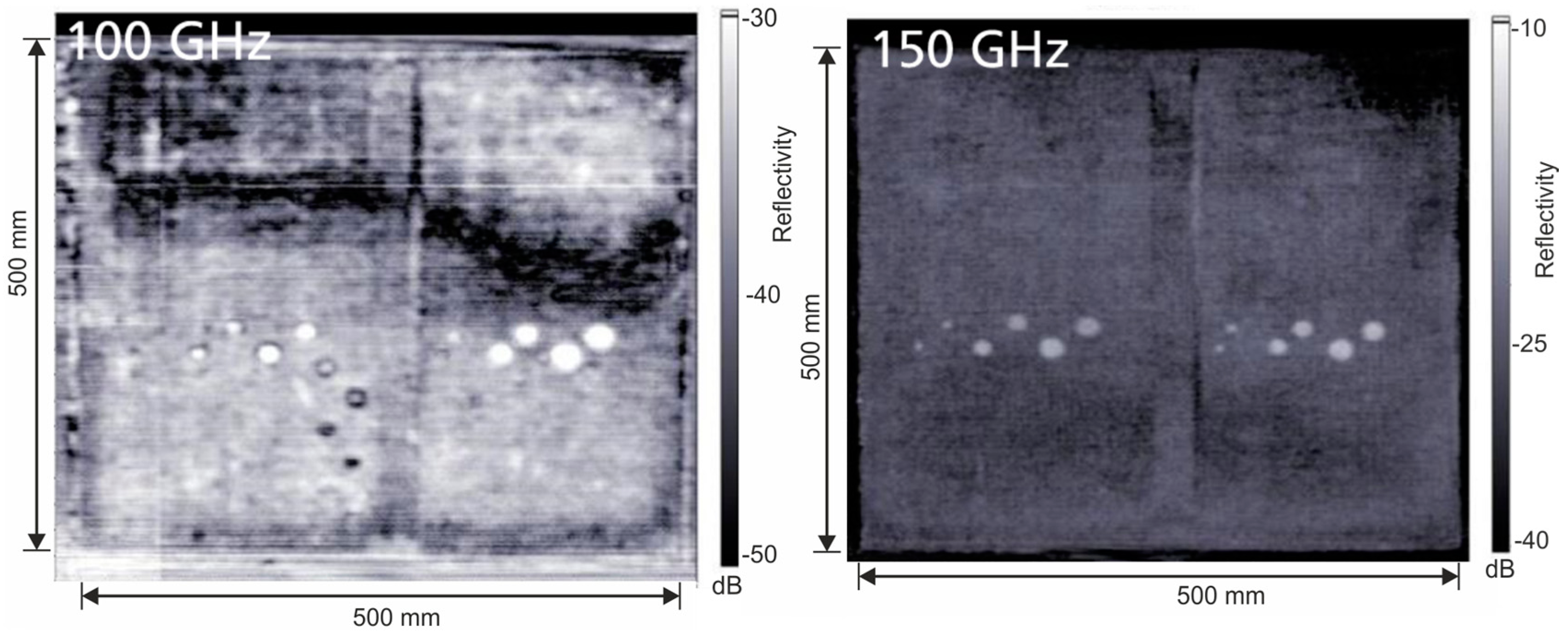

2. Preliminary Investigations

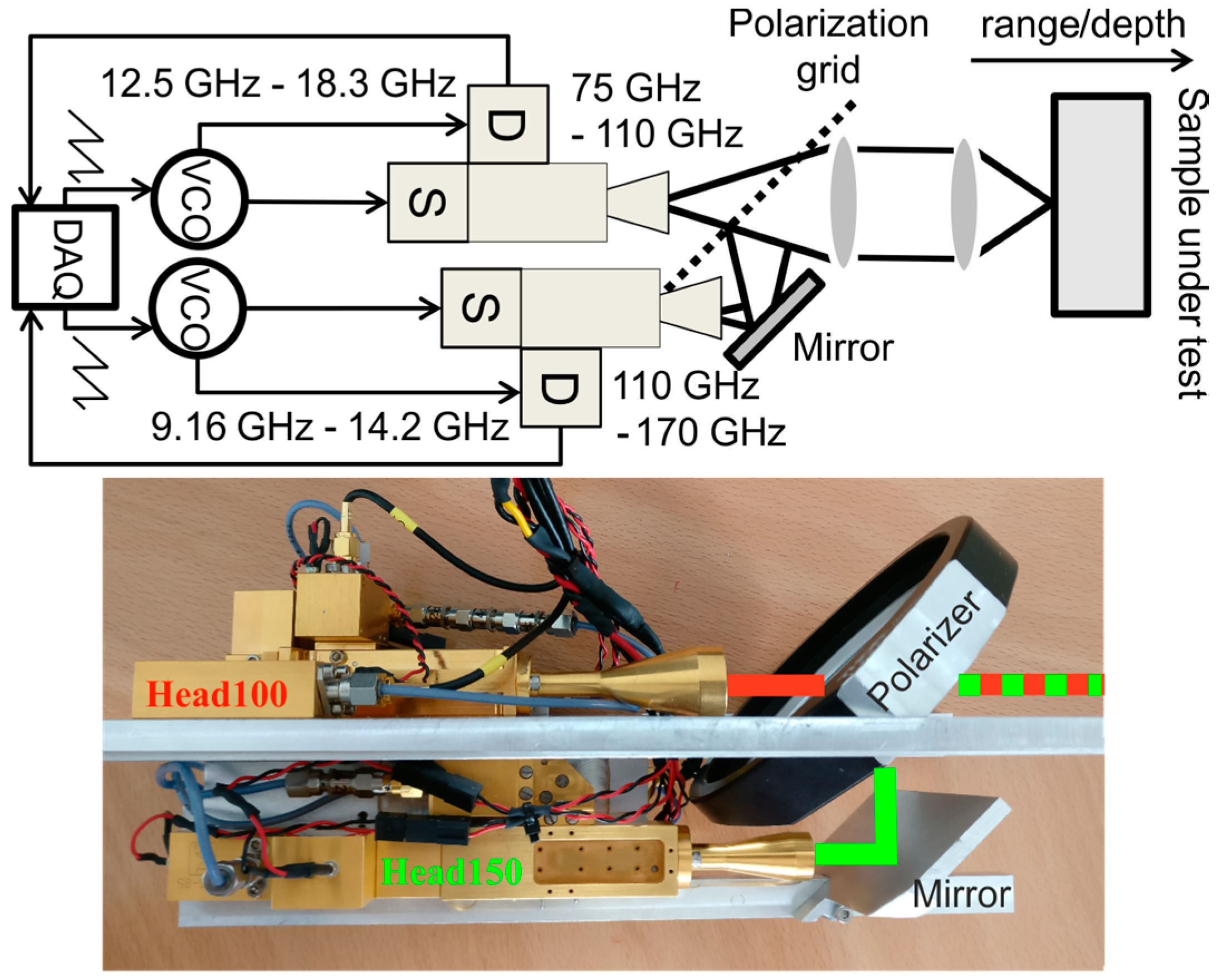

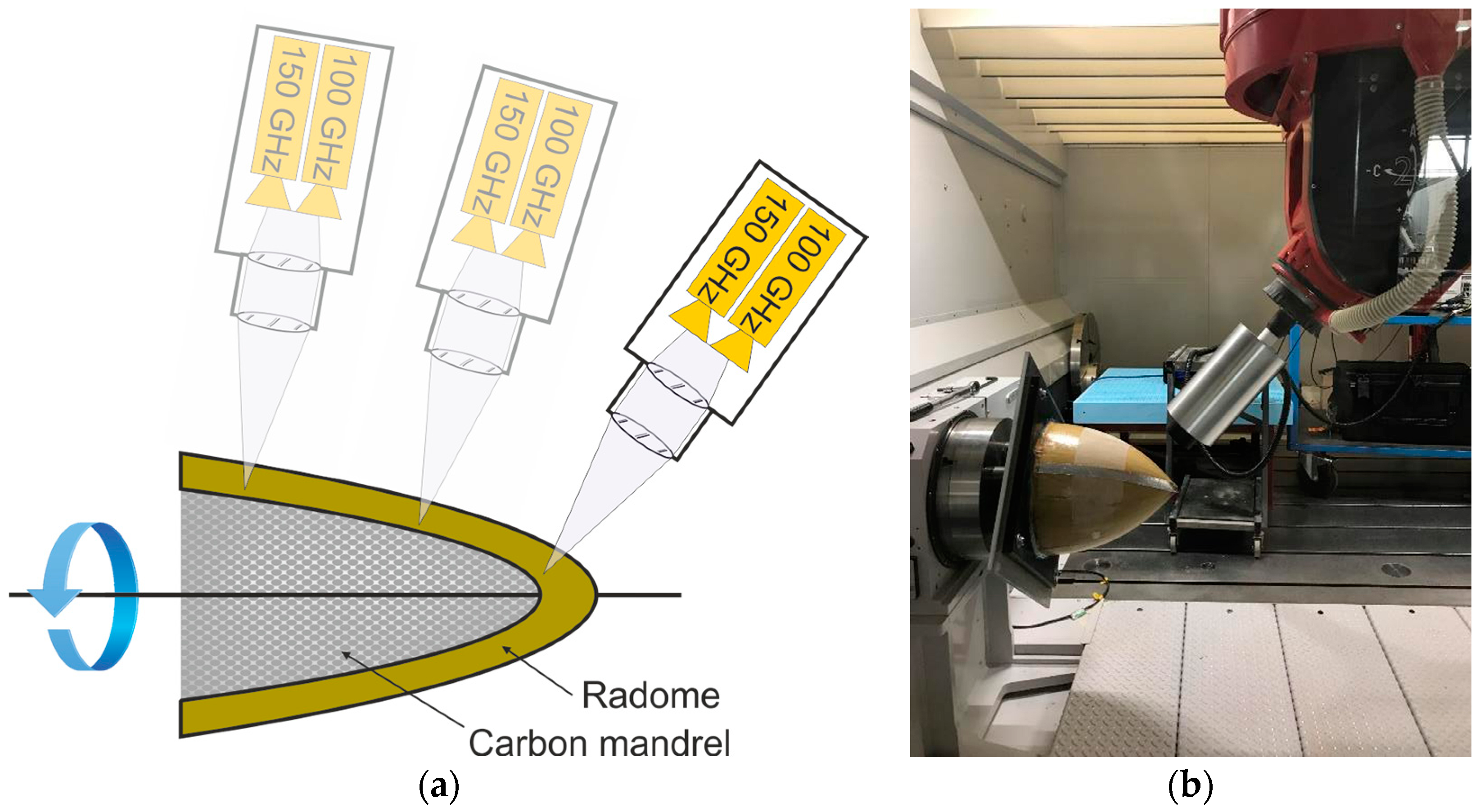

3. The Radome Inspection System

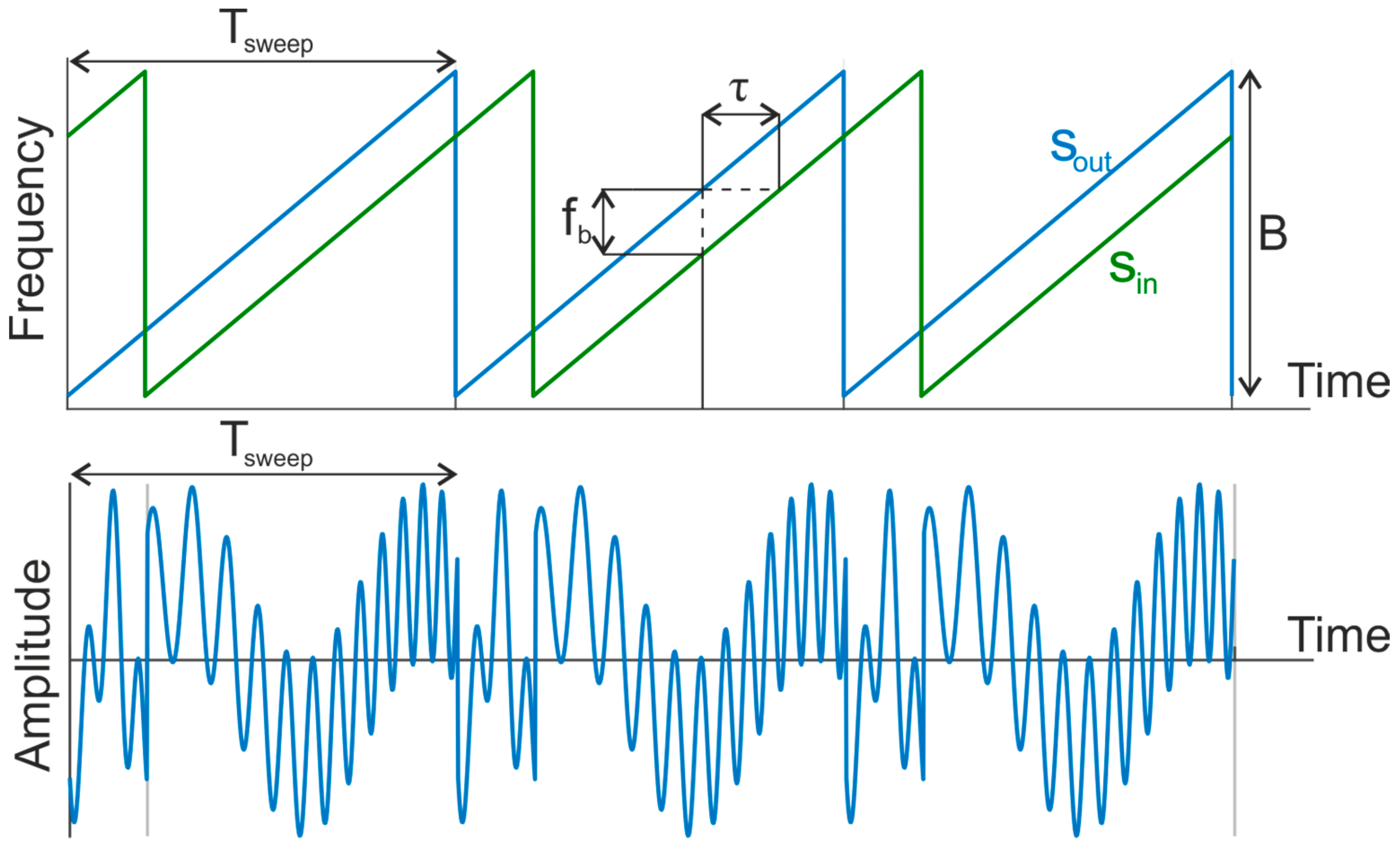

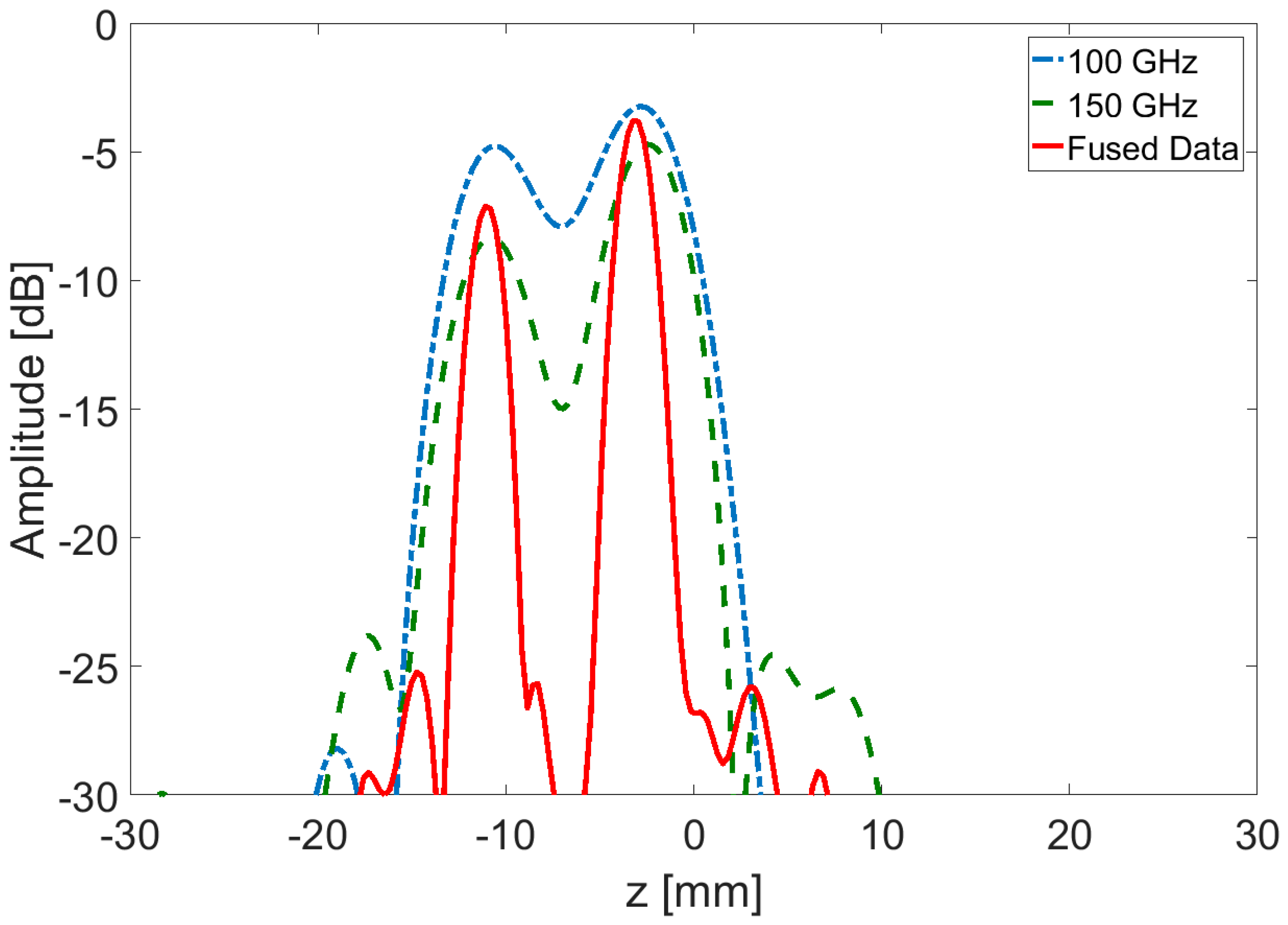

4. FMCW Measurements

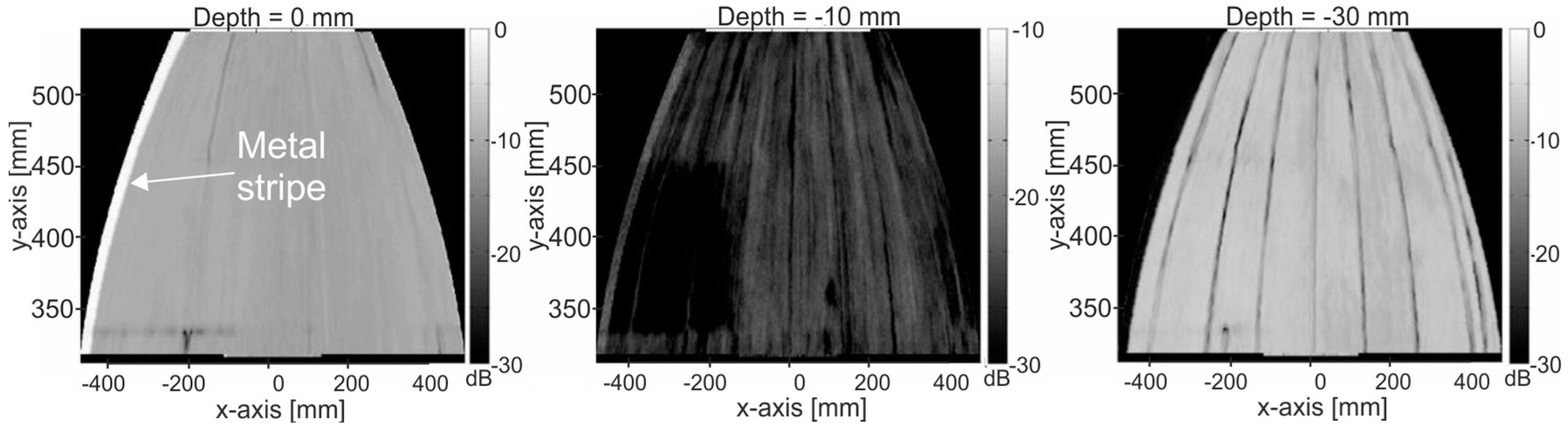

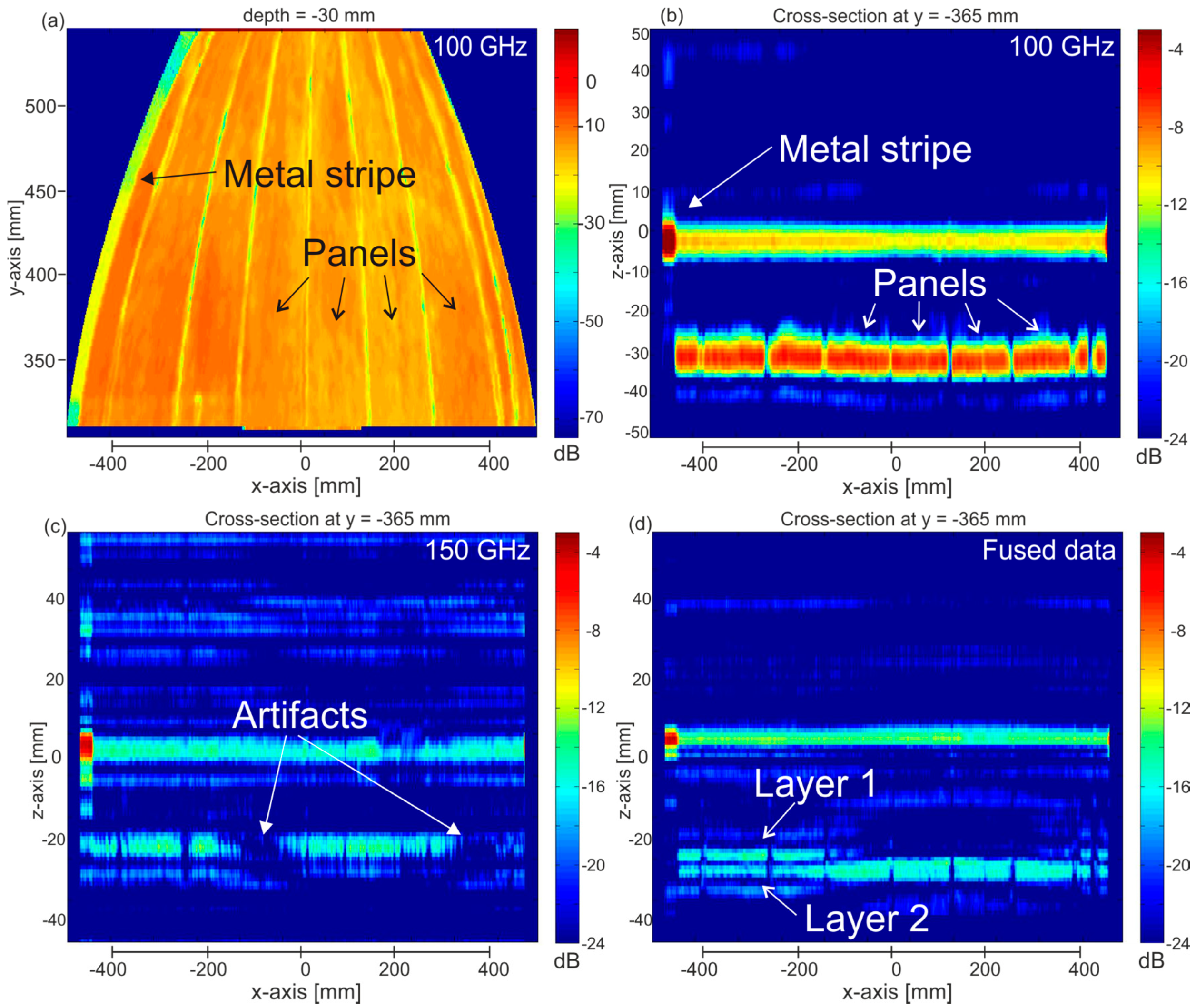

5. Imaging Results

6. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cristofani, E.; Friederich, F.; Wohnsiedler, S.; Matheis, C.; Jonuscheit, J.; Vandewal, M.; Beigang, R. Nondestructive testing potential evaluation of a terahertz frequency-modulated continuous-wave imager for composite materials inspection. Opt. Eng. 2014, 53, 031211. [Google Scholar] [CrossRef]

- Cristofani, E.; Friederich, F.; Vandewal, M.; Jonuscheit, J. Nondestructive Testing of Aeronautic Composite Structures Using Ultrawideband Radars. In Advanced Ultrawideband Radar: Signals, Targets, and Applications; Taylor, J.D., Ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 237–269. ISBN 978-1-4665-8657-4. [Google Scholar]

- Ravuria, M.; Abou-Khousa, M.A.; Kharkovsky, S.; Zoughi, R.; Austin, R. Microwave and Millimeter Wave Near-Field Methods for Evaluation of Radome Composites. AIP Conf. Proc. 2008, 975, 976–981. [Google Scholar] [CrossRef]

- Rutz, F.; Koch, M.; Khare, S.; Moneke, M.; Richter, H.; Ewert, U. Terahertz quality control of polymeric products. Int. J. Infrared Millim. Terahertz Waves 2006, 26, 547–556. [Google Scholar] [CrossRef]

- Stoik, C.; Bohn, M.; Blackshire, J. Nondestructive evaluation of aircraft composites using reflective terahertz time domain spectroscopy. NDT E Int. 2010, 43, 106–115. [Google Scholar] [CrossRef]

- Ospald, F.; Zouaghi, W.; Beigang, R.; Matheis, C.; Jonuscheit, J.; Recur, B.; Guillet, J.P.; Mounaix, P.; Vleugels, W.; Bosom, P.V.; et al. Aeronautics composite material inspection with a terahertz time-domain spectroscopy system. Opt. Eng. 2013, 53, 031208. [Google Scholar] [CrossRef]

- Abou-Khousa, M.A.; Ryley, A.; Kharkovsky, S.; Zoughi, R.; Daniels, D.; Kreitinger, N.; Steffes, G. Comparison of X-ray, Millimeter Wave, Shearography and Through-Transmission Ultrasonic Methods for Inspection of Honeycomb Composites. AIP Conf. Proc. 2007, 894, 999–1006. [Google Scholar] [CrossRef]

- Friederich, F.; Spiegel, W.; Bauer, M.; Meng, F.; Thomson, M.; Boppel, S.; Lisauskas, A.; Hils, B.; Krozer, V.; Keil, A.; et al. THz active imaging systems with real-time capabilities. IEEE Trans. Terahertz Sci. Technol. 2011, 1, 183–200. [Google Scholar] [CrossRef]

- Kittara, P.; Grimes, P.; Yassin, G.; Withington, S.; Jacobs, K.; Wulff, S. A 700-GHz SIS antipodal finline mixer fed by a Pickett-Potter horn-reflector antenna. IEEE Trans. Microwave Theory Tech. 2004, 52, 2352–2360. [Google Scholar] [CrossRef]

- Pohl, N.; Jaeschke, T.; Aufinger, K. An Ultra-Wideband 80 GHz FMCW Radar System Using a SiGe Bipolar Transceiver Chip Stabilized by a Fractional-N PLL Synthesizer. IEEE Trans. Microwave Theory Tech. 2012, 60, 757–765. [Google Scholar] [CrossRef]

- Jaeschke, T.; Bredendiek, C.; Kueppers, S.; Pohl, N. High-Precision D-Band FMCW-Radar sensor based on a wideband SiGe-Transceiver MMIC. IEEE Trans. Microwave Theory Tech. 2014, 62, 3582–3597. [Google Scholar] [CrossRef]

- Statnikov, K.; Grzyb, J.; Sarmah, N.; Heinemann, B.; Pfeiffer, U.R. A Lens-Coupled 210–270 GHz Circularly Polarized FMCW Radar Transceiver Module in SiGe Technology. In Proceedings of the 2015 European Microwave Conference (EuMC), Paris, France, 7–10 September 2015; pp. 550–553. [Google Scholar] [CrossRef]

- Baccouche, B.; Agostini, P.; Mohammadzadeh, S.; Kahl, M.; Weisenstein, C.; Jonuscheit, J.; Keil, A.; Löffler, T.; Sauer-Greff, W.; Urbansky, R.; et al. Three-dimensional Terahertz imaging with sparse multistatic line arrays. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1–11. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Friederich, F.; May, K.H.; Baccouche, B.; Matheis, C.; Bauer, M.; Jonuscheit, J.; Moor, M.; Denman, D.; Bramble, J.; Savage, N. Terahertz Radome Inspection. Photonics 2018, 5, 1. https://doi.org/10.3390/photonics5010001

Friederich F, May KH, Baccouche B, Matheis C, Bauer M, Jonuscheit J, Moor M, Denman D, Bramble J, Savage N. Terahertz Radome Inspection. Photonics. 2018; 5(1):1. https://doi.org/10.3390/photonics5010001

Chicago/Turabian StyleFriederich, Fabian, Karl Henrik May, Bessem Baccouche, Carsten Matheis, Maris Bauer, Joachim Jonuscheit, Michael Moor, David Denman, Jamie Bramble, and Nick Savage. 2018. "Terahertz Radome Inspection" Photonics 5, no. 1: 1. https://doi.org/10.3390/photonics5010001

APA StyleFriederich, F., May, K. H., Baccouche, B., Matheis, C., Bauer, M., Jonuscheit, J., Moor, M., Denman, D., Bramble, J., & Savage, N. (2018). Terahertz Radome Inspection. Photonics, 5(1), 1. https://doi.org/10.3390/photonics5010001