Silicon-Based On-Chip Light Sources: A Review

Abstract

1. Introduction

2. Hybrid III-V/Si Bonding Laser

2.1. Quantum Well and Nanowire

2.2. Quantum Dots

2.3. InP

3. Al2O3

3.1. Microring Resonator Lasers

3.2. DBR and DFB

4. LiNbO3

5. TeO2

6. Ta2O5

7. Outlook and Summary

- Materials

- 2.

- Pump schemes

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Shekhar, S.; Bogaerts, W.; Chrostowski, L.; Bowers, J.E.; Hochberg, M.; Soref, R.; Shastri, B.J. Roadmapping the next generation of silicon photonics. Nat. Commun. 2024, 15, 751. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Chen, W.; He, X.; Ma, D. Photonics in a Time of Rapid Growth: Silicon Based Optoelectronics in China. IEEE Photonics J. 2024, 16, 0600109. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, W.; Feng, J.; Yang, F.; Ma, D.; He, X.; Li, D.; Hou, H.; Shuai, Y.; Cui, W. Silicon based optoelectronics and its frontier advances. Acta Opt. Sin. 2024, 1, 21–38. [Google Scholar] [CrossRef]

- Hao, Y.; Xiang, S.; Han, G.; Zhang, J.; Ma, X.; Zhu, Z.; Guo, X.; Zhang, Y.; Han, Y.; Song, Z.; et al. Recent progress of integrated circuits and optoelectronic chips. Sci. China Inf. Sci. 2021, 64, 201401. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, R.; Wang, W.; Yan, K.; Yang, Z.; Song, M.; Wu, D.; Xu, P.; Wang, X.; Wang, R. On-chip Er-Doped Ta2O5 waveguide amplifiers with a high internal net gain. Opt. Lett. 2023, 48, 5799–5802. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Fang, Z.; Wu, C.; Zhu, S.; Xu, P.; Doylend, J.K.; Deshmukh, S.; Pop, E.; Dunham, S.; Li, M.; et al. Nonvolatile Electrically Reconfigurable Integrated Photonic Switch Enabled by a Silicon PIN Diode Heater. Adv. Mater. 2020, 32, 2001218. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Zheng, J.; Doylend, J.K.; Majumdar, A. Low-Loss and Broadband Nonvolatile Phase-Change Directional Coupler Switches. ACS Photonics 2019, 6, 553–557. [Google Scholar] [CrossRef]

- Feng, D.; Liao, S.; Dong, P.; Feng, N.-N.; Liang, H.; Zheng, D.; Kung, C.-C.; Fong, J.; Shafiiha, R.; Cunningham, J.; et al. High-speed Ge photodetector monolithically integrated with large cross-section silicon-on-insulator waveguide. Appl. Phys. Lett. 2009, 95, 261105. [Google Scholar] [CrossRef]

- Miarabbas Kiani, K.; Frankis, H.C.; Naraine, C.M.; Bonneville, D.B.; Knights, A.P.; Bradley, J.D.B. Lasing in a Hybrid Rare-Earth Silicon Microdisk. Laser Photonics Rev. 2021, 16, 2100348. [Google Scholar] [CrossRef]

- Zhou, Z.; Ou, X.; Fang, Y.; Alkhazraji, E.; Xu, R.; Wan, Y.; Bowers, J.E. Prospects and applications of on-chip lasers. eLight 2023, 3, 1297–1321. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Li, D.-S.; Yang, D.-R. Research progress of silicon light source. Acta Phys. Sin. 2015, 64, 204208-01–204208-18. [Google Scholar] [CrossRef]

- Rong, H.; Xu, S.; Kuo, Y.-H.; Sih, V.; Cohen, O.; Raday, O.; Paniccia, M. Low-threshold continuous-wave Raman silicon laser. Nat. Photonics 2007, 1, 232–237. [Google Scholar] [CrossRef]

- Heck, M.J.R.; Bauters, J.F.; Davenport, M.L.; Doylend, J.K.; Jain, S.; Kurczveil, G.; Srinivasan, S.; Tang, Y.; Bowers, J.E. Hybrid Silicon Photonic Integrated Circuit Technology. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 6100117. [Google Scholar] [CrossRef]

- Li, N.; Xin, M.; Su, Z.; Magden, E.S.; Singh, N.; Notaros, J.; Timurdogan, E.; Purnawirman, P.; Bradley, J.D.B.; Watts, M.R. A Silicon Photonic Data Link with a Monolithic Erbium-Doped Laser. Sci. Rep. 2020, 10, 1114. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Zhang, Z.; Yang, Z.; Wang, W.; Yan, K.; Song, M.; Wang, R. Erbium-doped Ga2O3 waveguide for optical amplification. Appl. Phys. Lett. 2023, 123, 151109. [Google Scholar] [CrossRef]

- Pollnau, M.; Bradley, J.D.B. Optically pumped rare-earth-doped Al2O3 distributed-feedback lasers on silicon [Invited]. Opt. Express 2018, 26, 24164–24189. [Google Scholar] [CrossRef] [PubMed]

- Hermans, A.; Van Gasse, K.; Kuyken, B. On-chip optical comb sources. APL Photonics 2022, 7, 100901. [Google Scholar] [CrossRef]

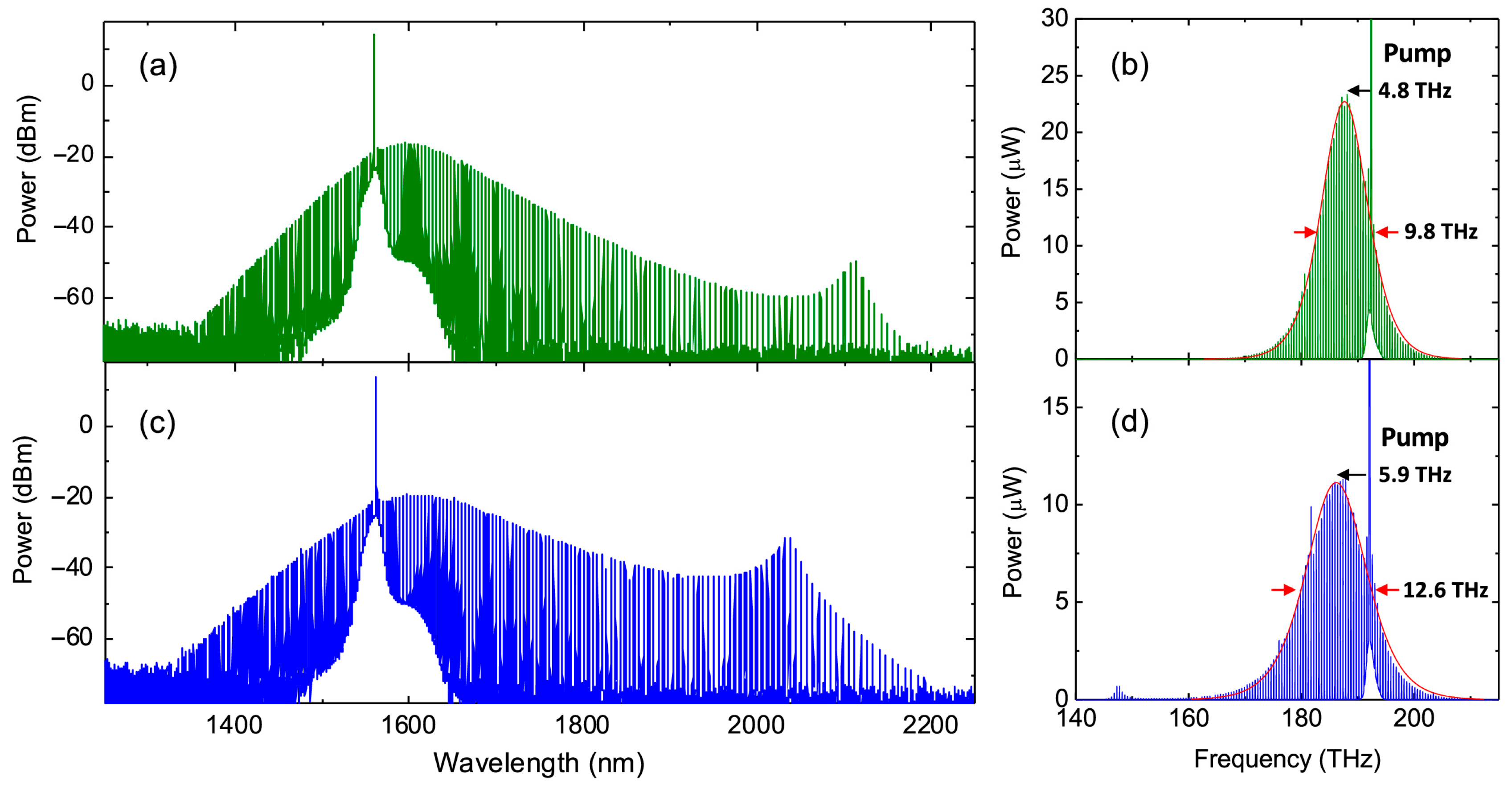

- Chen, P.; Long, Z.; Cheng, Q.; Song, M.; Wang, W.; Liu, R.; Zhang, Z.; Xia, K.; Yang, Z.; Qian, L.; et al. On-Chip Supercontinuum Generation Pumped by Short Wavelength Fiber Lasers. Photonics 2024, 11, 440. [Google Scholar] [CrossRef]

- Ferrara, M.A.; Sirleto, L. Integrated Raman Laser: A Review of the Last Two Decades. Micromachines 2020, 11, 330. [Google Scholar] [CrossRef] [PubMed]

- Tournié, E.; Monge Bartolome, L.; Rio Calvo, M.; Loghmari, Z.; Díaz-Thomas, D.A.; Teissier, R.; Baranov, A.N.; Cerutti, L.; Rodriguez, J.-B. Mid-infrared III–V semiconductor lasers epitaxially grown on Si substrates. Light Sci. Appl. 2022, 11, 165. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Cao, V.; Liao, M.; Lu, Y.; Liu, Z.; Tang, M.; Chen, S.; Seeds, A.; Liu, H. Recent progress in epitaxial growth of III–V quantum-dot lasers on silicon substrate. J. Semicond. 2019, 40, 101302. [Google Scholar] [CrossRef]

- Li, N.; Chen, G.; Ng, D.K.T.; Lim, L.W.; Xue, J.; Ho, C.P.; Fu, Y.H.; Lee, L.Y.T. Integrated Lasers on Silicon at Communication Wavelength: A Progress Review. Adv. Opt. Mater. 2022, 10, 2201008. [Google Scholar] [CrossRef]

- Cerutti, L.; Rodriguez, J.B.; Tournie, E. GaSb-Based Laser, Monolithically Grown on Silicon Substrate, Emitting at 1.55 um at Room Temperature. IEEE Photonics Technol. Lett. 2010, 22, 553–555. [Google Scholar] [CrossRef]

- Saxena, D.; Mokkapati, S.; Parkinson, P.; Jiang, N.; Gao, Q.; Tan, H.H.; Jagadish, C. Optically pumped room-temperature GaAs nanowire lasers. Nat. Photonics 2013, 7, 963–968. [Google Scholar] [CrossRef]

- Wang, J.; Ren, X.; Deng, C.; Hu, H.; He, Y.; Cheng, Z.; Ma, H.; Wang, Q.; Huang, Y.; Duan, X.; et al. Extremely Low-Threshold Current Density InGaAs/AlGaAs Quantum-Well Lasers on Silicon. J. Light. Technol. 2015, 33, 3163–3169. [Google Scholar] [CrossRef]

- Spott, A.; Peters, J.; Davenport, M.L.; Stanton, E.J.; Merritt, C.D.; Bewley, W.W.; Vurgaftman, I.; Kim, C.S.; Meyer, J.R.; Kirch, J.; et al. Quantum cascade laser on silicon. Optica 2016, 3, 545–551. [Google Scholar] [CrossRef]

- Feng, M.; Wang, J.; Zhou, R.; Sun, Q.; Gao, H.; Zhou, Y.; Liu, J.; Huang, Y.; Zhang, S.; Ikeda, M.; et al. On-Chip Integration of GaN-Based Laser, Modulator, and Photodetector Grown on Si. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 8200305. [Google Scholar] [CrossRef]

- Feng, M.; He, J.; Sun, Q.; Gao, H.; Li, Z.; Zhou, Y.; Liu, J.; Zhang, S.; Li, D.; Zhang, L.; et al. Room-temperature electrically pumped InGaN-based microdisk laser grown on Si. Opt. Express 2018, 26, 5043–5051. [Google Scholar] [CrossRef] [PubMed]

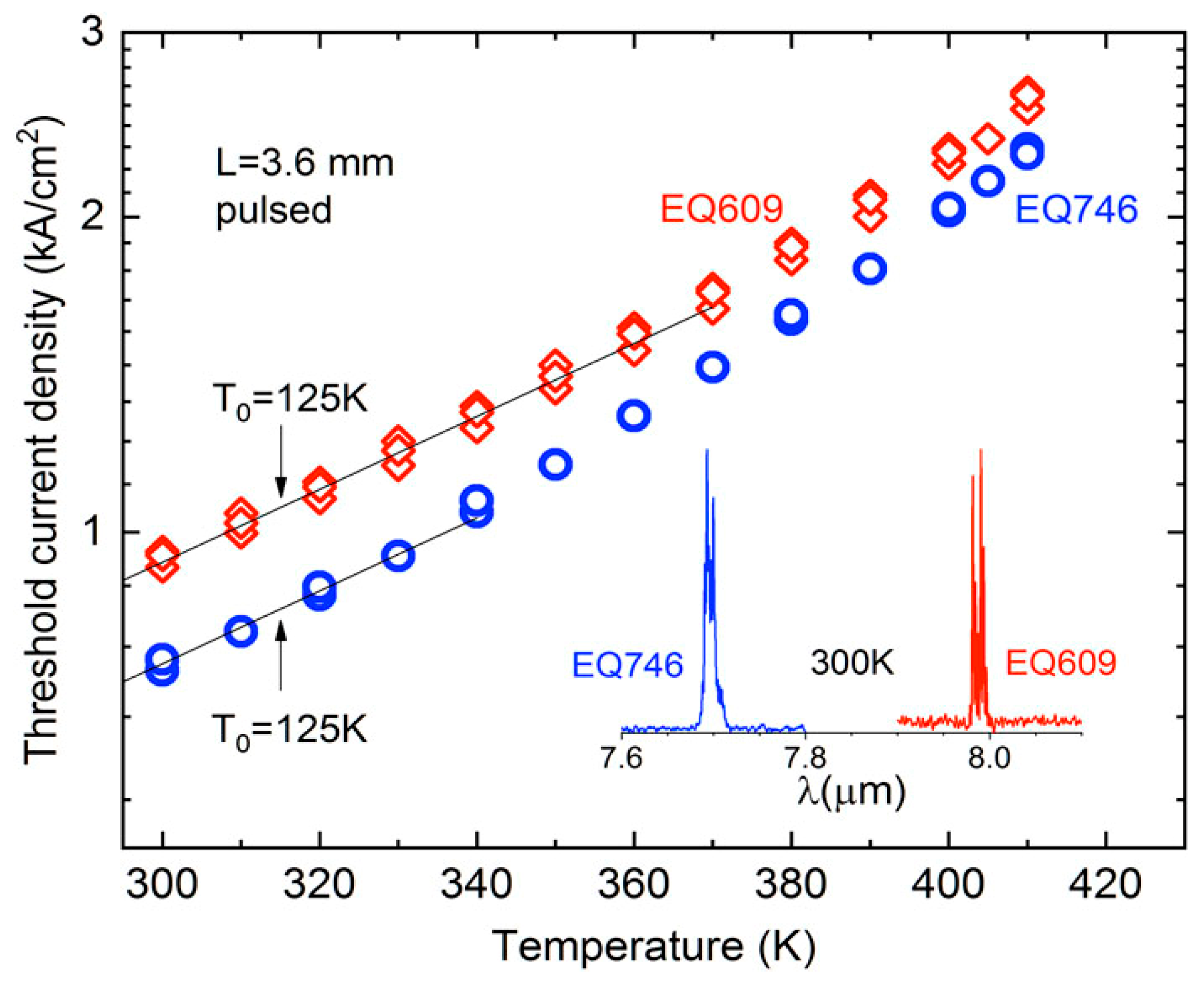

- Nguyen-Van, H.; Baranov, A.N.; Loghmari, Z.; Cerutti, L.; Rodriguez, J.-B.; Tournet, J.; Narcy, G.; Boissier, G.; Patriarche, G.; Bahriz, M.; et al. Quantum cascade lasers grown on silicon. Sci. Rep. 2018, 8, 7206. [Google Scholar] [CrossRef] [PubMed]

- Loghmari, Z.; Rodriguez, J.B.; Baranov, A.N.; Rio-Calvo, M.; Cerutti, L.; Meguekam, A.; Bahriz, M.; Teissier, R.; Tournié, E. InAs-based quantum cascade lasers grown on on-axis (001) silicon substrate. APL Photonics 2020, 5, 041302. [Google Scholar] [CrossRef]

- Lee, A.D.; Qi, J.; Mingchu, T.; Yunyan, Z.; Seeds, A.J.; Huiyun, L. InAs/GaAs Quantum-Dot Lasers Monolithically Grown on Si, Ge, and Ge-on-Si Substrates. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1901107. [Google Scholar] [CrossRef]

- Chen, S.; Li, W.; Wu, J.; Jiang, Q.; Tang, M.; Shutts, S.; Elliott, S.N.; Sobiesierski, A.; Seeds, A.J.; Ross, I.; et al. Electrically pumped continuous-wave III–V quantum dot lasers on silicon. Nat. Photonics 2016, 10, 307–311. [Google Scholar] [CrossRef]

- Chen, S.; Liao, M.; Tang, M.; Wu, J.; Martin, M.; Baron, T.; Seeds, A.; Liu, H. Electrically pumped continuous-wave 13 µm InAs/GaAs quantum dot lasers monolithically grown on on-axis Si (001) substrates. Opt. Express 2017, 25, 4632–4639. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.Y.; Peters, J.; Huang, X.; Jung, D.; Norman, J.; Lee, M.L.; Gossard, A.C.; Bowers, J.E. Electrically pumped continuous-wave 13 μm quantum-dot lasers epitaxially grown on on-axis (001) GaP/Si. Opt. Lett. 2017, 42, 338–341. [Google Scholar] [CrossRef] [PubMed]

- Shang, C.; Feng, K.; Hughes, E.T.; Clark, A.; Debnath, M.; Koscica, R.; Leake, G.; Herman, J.; Harame, D.; Ludewig, P.; et al. Electrically pumped quantum-dot lasers grown on 300 mm patterned Si photonic wafers. Light Sci. Appl. 2022, 11, 299. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, S.; Fujii, T.; Hasebe, K.; Takeda, K.; Sato, T.; Kakitsuka, T. Directly Modulated DFB Laser on SiO2 /Si Substrate for Datacenter Networks. J. Light. Technol. 2015, 33, 1217–1222. [Google Scholar] [CrossRef]

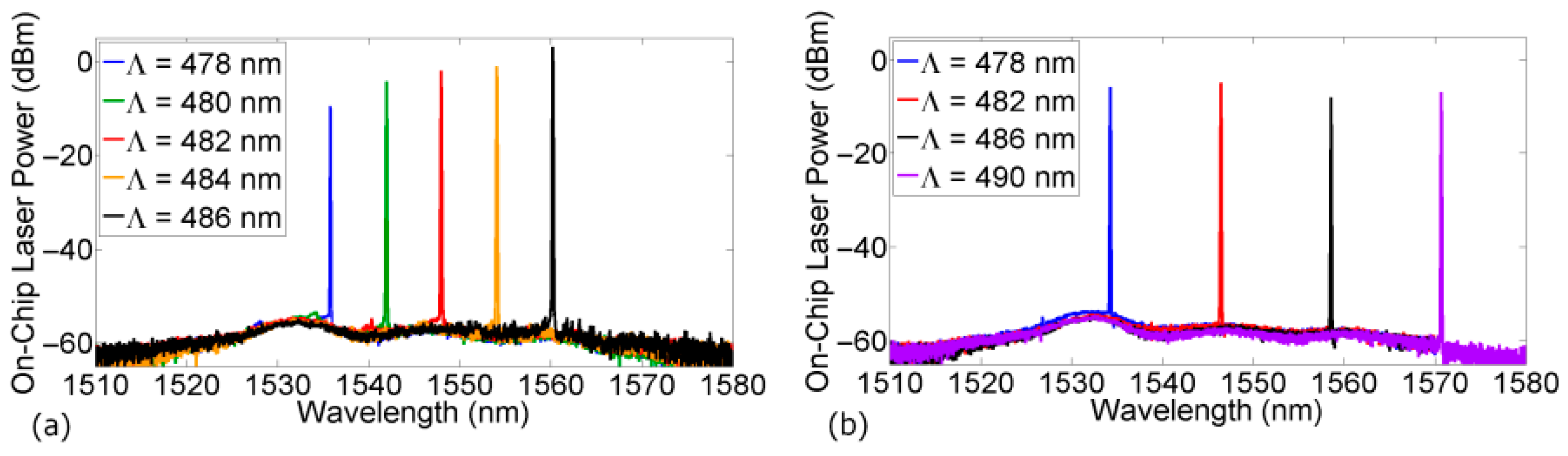

- Wang, Z.; Tian, B.; Pantouvaki, M.; Guo, W.; Absil, P.; Van Campenhout, J.; Merckling, C.; Van Thourhout, D. Room-temperature InP distributed feedback laser array directly grown on silicon. Nat. Photonics 2015, 9, 837–842. [Google Scholar] [CrossRef]

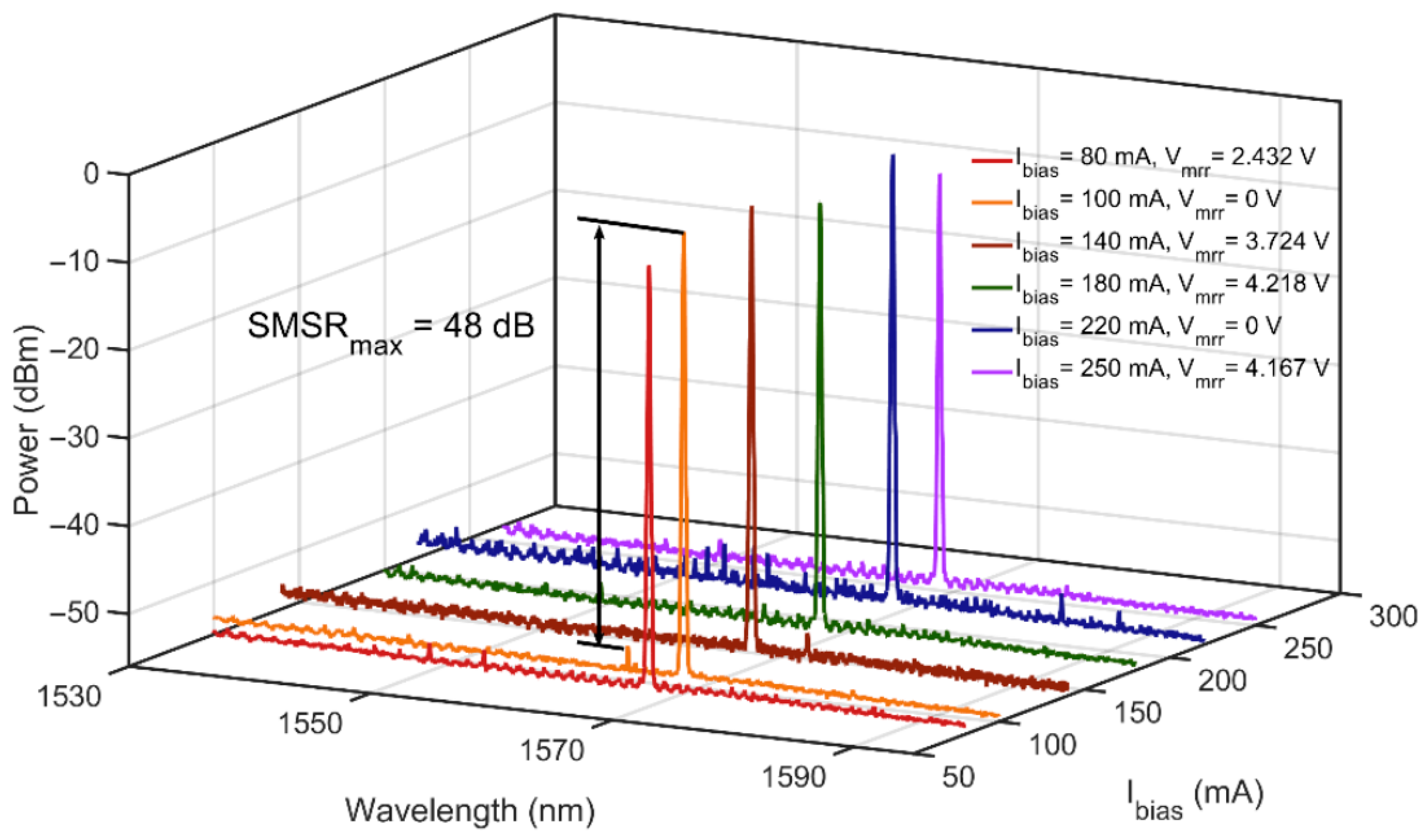

- Wang, J.; Li, X.; Guo, X.; Loh, T.-H.; Ranno, L.; Liu, C.; Rusli; Wang, H.; Brian Sia, J.X. Scalable single-microring hybrid III-V/Si lasers for emerging narrow-linewidth applications. Opt. Express 2024, 32, 26751–26762. [Google Scholar] [CrossRef] [PubMed]

- Duprez, H.; Descos, A.; Ferrotti, T.; Sciancalepore, C.; Jany, C.; Hassan, K.; Seassal, C.; Menezo, S.; Ben Bakir, B. 1310 nm hybrid InP/InGaAsP on silicon distributed feedback laser with high side-mode suppression ratio. Opt. Express 2015, 23, 8489–8497. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, A.; Verbist, J.; Van Kerrebrouck, J.; Lelarge, F.; Duan, G.-H.; Yin, X.; Bauwelinck, J.; Roelkens, G.; Morthier, G. 28 Gb/s direct modulation heterogeneously integrated C-band InP/SOI DFB laser. Opt. Express 2015, 23, 26479–26485. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, A.; Spatharakis, C.; Kanakis, G.; Andre, N.S.; Louchet, H.; Katumba, A.; Verbist, J.; Avramopoulos, H.; Bienstman, P.; Yin, X.; et al. High Speed Direct Modulation of a Heterogeneously Integrated InP/SOI DFB Laser. J. Light. Technol. 2016, 34, 1683–1687. [Google Scholar] [CrossRef]

- Crosnier, G.; Sanchez, D.; Bouchoule, S.; Monnier, P.; Beaudoin, G.; Sagnes, I.; Raj, R.; Raineri, F. Hybrid indium phosphide-on-silicon nanolaser diode. Nat. Photonics 2017, 11, 297–300. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, C.; Xiong, B.; Wang, J.; Hao, Z.; Wang, L.; Han, Y.; Li, H.; Luo, Y.; Xiao, Y.; et al. An InP-based vortex beam emitter with monolithically integrated laser. Nat. Commun. 2018, 9, 2652. [Google Scholar] [CrossRef] [PubMed]

- Tran, M.A.; Huang, D.; Guo, J.; Komljenovic, T.; Morton, P.A.; Bowers, J.E. Ring-Resonator Based Widely-Tunable Narrow-Linewidth Si/InP Integrated Lasers. IEEE J. Sel. Top. Quantum Electron. 2020, 26, 1500514. [Google Scholar] [CrossRef]

- Wong, W.W.; Su, Z.; Wang, N.; Jagadish, C.; Tan, H.H. Epitaxially Grown InP Micro-Ring Lasers. Nano Lett. 2021, 21, 5681–5688. [Google Scholar] [CrossRef] [PubMed]

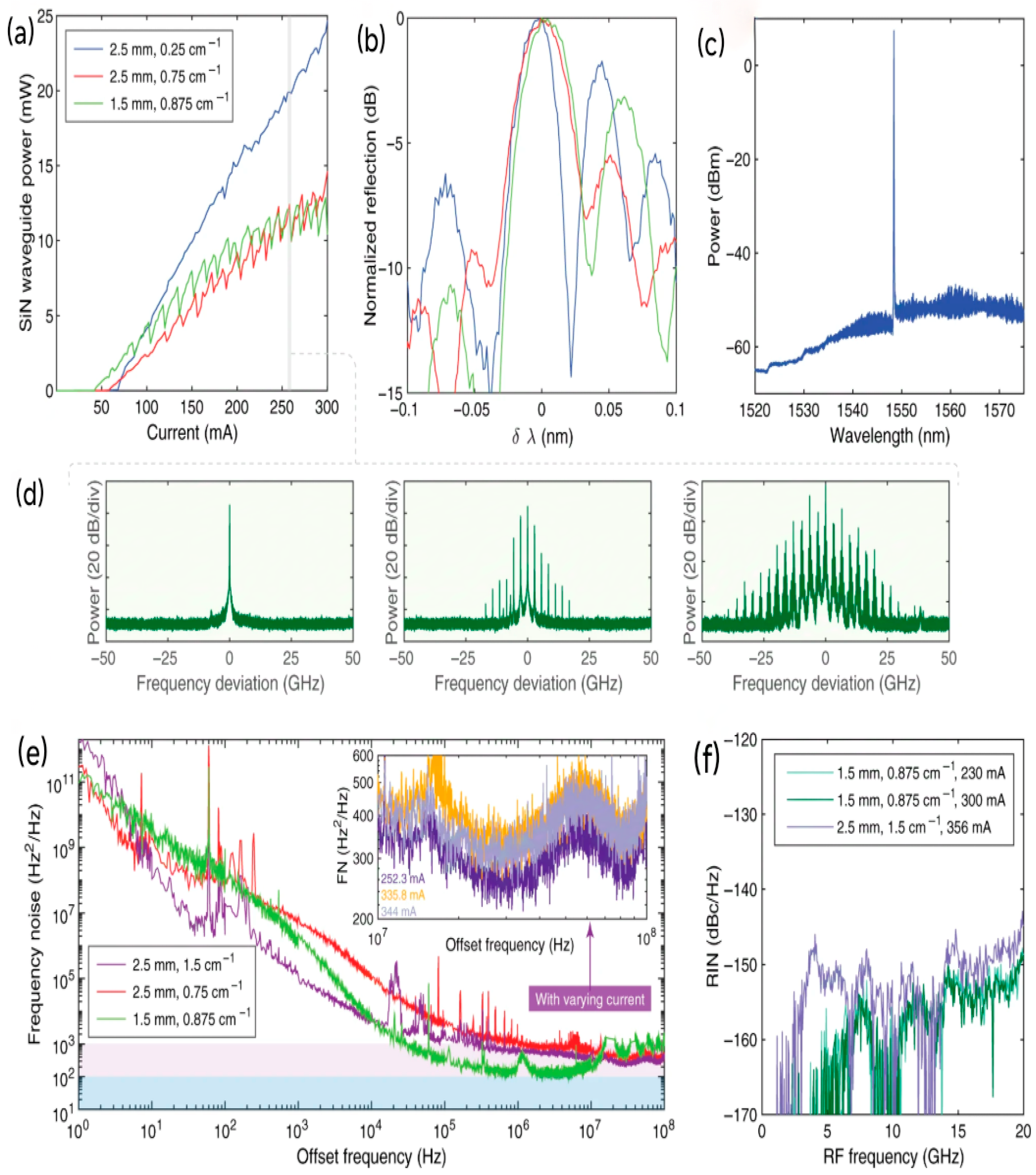

- Xiang, C.; Guo, J.; Jin, W.; Wu, L.; Peters, J.; Xie, W.; Chang, L.; Shen, B.; Wang, H.; Yang, Q.-F.; et al. High-performance lasers for fully integrated silicon nitride photonics. Nat. Commun. 2021, 12, 6650. [Google Scholar] [CrossRef] [PubMed]

- Kikuchi, T.; Hiratani, T.; Fujiwara, N.; Inoue, N.; Nitta, T.; Eissa, M.; Mitarai, T.; Wang, Y.; Oiso, Y.; Nishiyama, N.; et al. III–V gain region/Si waveguide hybrid lasers with InP-based two-storied ridge structure by direct bonding technology. Jpn. J. Appl. Phys. 2022, 61, 052002. [Google Scholar] [CrossRef]

- Hendriks, W.A.P.M.; Chang, L.; van Emmerik, C.I.; Mu, J.; de Goede, M.; Dijkstra, M.; Garcia-Blanco, S.M. Rare-earth ion doped Al2O3 for active integrated photonics. Adv. Phys. X 2020, 6, 1833753. [Google Scholar] [CrossRef]

- van den Hoven, G.N.; Koper, R.J.I.M.; Polman, A.; van Dam, C.; van Uffelen, J.W.M.; Smit, M.K. Net optical gain at 1.53 μm in Er-doped Al2O3 waveguides on silicon. Appl. Phys. Lett. 1996, 68, 1886–1888. [Google Scholar] [CrossRef]

- Bradley, J.; Stoffer, R.; Agazzi, L.; Ay, F.; Wörhoff, K.; Pollnau, M. Integrated Al2O3: Er3+ ring lasers on silicon with wide wavelength selectivity. Opt. Lett. 2009, 35, 73–75. [Google Scholar] [CrossRef] [PubMed]

- Bradley, J.D.B.; Hosseini, E.S.; Purnawirman; Su, Z.; Adam, T.N.; Leake, G.; Coolbaugh, D.; Watts, M.R. Monolithic erbium- and ytterbium-doped microring lasers on silicon chips. Opt. Express 2014, 22, 12226–12237. [Google Scholar] [CrossRef] [PubMed]

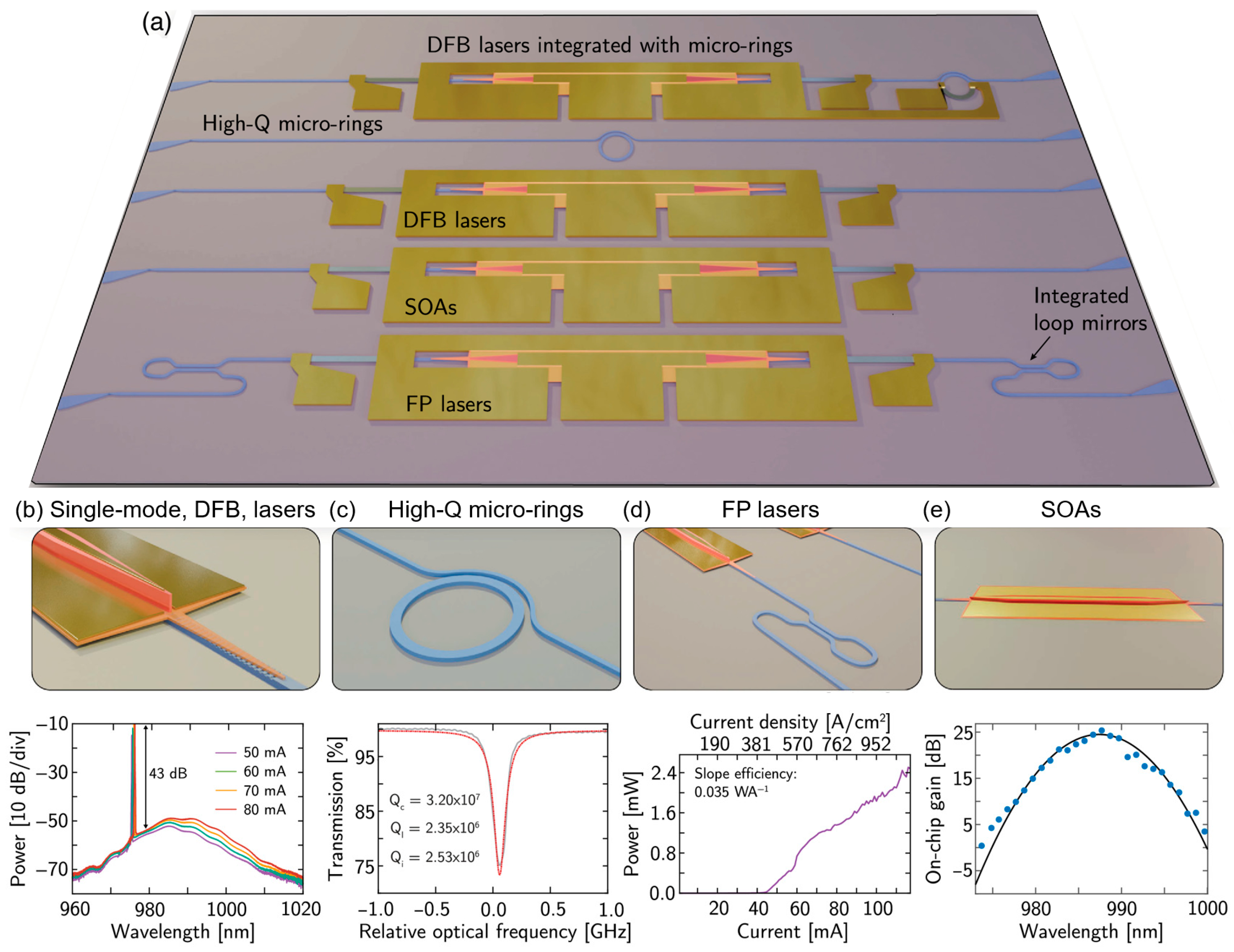

- Wang, Y.; Holguín-Lerma, J.A.; Vezzoli, M.; Guo, Y.; Tang, H.X. Photonic-circuit-integrated titanium:sapphire laser. Nat. Photonics 2023, 17, 338–345. [Google Scholar] [CrossRef]

- Yang, J.; Van Gasse, K.; Lukin, D.M.; Guidry, M.A.; Ahn, G.H.; White, A.D.; Vučković, J. Titanium:sapphire-on-insulator integrated lasers and amplifiers. Nature 2024, 630, 853–859. [Google Scholar] [CrossRef] [PubMed]

- Purnawirman; Sun, J.; Adam, T.N.; Leake, G.; Coolbaugh, D.; Bradley, J.D.B.; Hosseini, E.S.; Watts, M.R. C- and L-band erbium-doped waveguide lasers with wafer-scale silicon nitride cavities. Opt. Lett. 2013, 38, 1760–1762. [Google Scholar] [CrossRef] [PubMed]

- Belt, M.; Huffman, T.; Davenport, M.L.; Li, W.; Barton, J.S.; Blumenthal, D.J. Arrayed narrow linewidth erbium-doped waveguide-distributed feedback lasers on an ultra-low-loss silicon-nitride platform. Opt. Lett. 2013, 38, 4825–4828. [Google Scholar] [CrossRef] [PubMed]

- Belt, M.; Blumenthal, D.J. Erbium-doped waveguide DBR and DFB laser arrays integrated within an ultra-low-loss Si3N4 platform. Opt. Express 2014, 22, 10655–10660. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, E.S.; Baldycheva, A.; Sun, J.; Bradley, J.; Adam, T.; Leake, G.; Coolbaugh, D.; Watts, M. Erbium-doped laser with multi-segmented silicon nitride structure. In Proceedings of the Optical Fiber Communication Conference, San Francisco, CA, USA, 9–13 March 2014. [Google Scholar] [CrossRef]

- Purnawirman; Li, N.; Magden, E.S.; Singh, G.; Singh, N.; Baldycheva, A.; Hosseini, E.S.; Sun, J.; Moresco, M.; Adam, T.N.; et al. Ultra-narrow-linewidth Al2O3:Er3+ lasers with a wavelength-insensitive waveguide design on a wafer-scale silicon nitride platform. Opt. Express 2017, 25, 13705–13713. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Li, N.; Salih Magden, E.; Byrd, M.; Purnawirman; Adam, T.N.; Leake, G.; Coolbaugh, D.; Bradley, J.D.B.; Watts, M.R. Ultra-compact and low-threshold thulium microcavity laser monolithically integrated on silicon. Opt. Lett. 2016, 41, 5708–5711. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Purnawirman; Bradley, J.D.B.; Li, N.; Magden, E.S.; Moresco, M.; Adam, T.N.; Leake, G.; Coolbaugh, D.; Watts, M.R. Resonant pumped erbium-doped waveguide lasers using distributed Bragg reflector cavities. Opt. Lett. 2016, 41, 1189–1192. [Google Scholar] [CrossRef] [PubMed]

- Purnawirman; Li, N.; Magden, E.S.; Singh, G.; Moresco, M.; Adam, T.N.; Leake, G.; Coolbaugh, D.; Bradley, J.D.B.; Watts, M.R. Wavelength division multiplexed light source monolithically integrated on a silicon photonics platform. Opt. Lett. 2017, 42, 1772–1775. [Google Scholar] [CrossRef] [PubMed]

- Magden, E.S.; Li, N.; Purnawirman; Bradley, J.D.B.; Singh, N.; Ruocco, A.; Petrich, G.S.; Leake, G.; Coolbaugh, D.D.; Ippen, E.P.; et al. Monolithically-integrated distributed feedback laser compatible with CMOS processing. Opt. Express 2017, 25, 18058–18065. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Singh, G.; Magden, E.S.; Su, Z.; Singh, N.; Moresco, M.; Leake, G.; Bradley, J.D.B.; Watts, M.R. Reliable Integrated Photonic Light Sources Using Curved Al2O3:Er3+ Distributed Feedback Lasers. IEEE Photonics J. 2017, 9, 1504708. [Google Scholar] [CrossRef]

- Notaros, J.; Watts, M.R.; Li, N.; Poulton, C.V.; Su, Z.; Byrd, M.J.; Magden, E.S.; Timurdogan, E.; Baiocco, C.; Fahrenkopf, N.M. CMOS-Compatible Optical Phased Array Powered by a Monolithically-Integrated Erbium Laser. J. Light. Technol. 2019, 37, 5982–5987. [Google Scholar] [CrossRef]

- Li, N.; Purnawirman; Su, Z.; Salih Magden, E.; Callahan, P.T.; Shtyrkova, K.; Xin, M.; Ruocco, A.; Baiocco, C.; Ippen, E.P.; et al. High-power thulium lasers on a silicon photonics platform. Opt. Lett. 2017, 42, 1181–1184. [Google Scholar] [CrossRef] [PubMed]

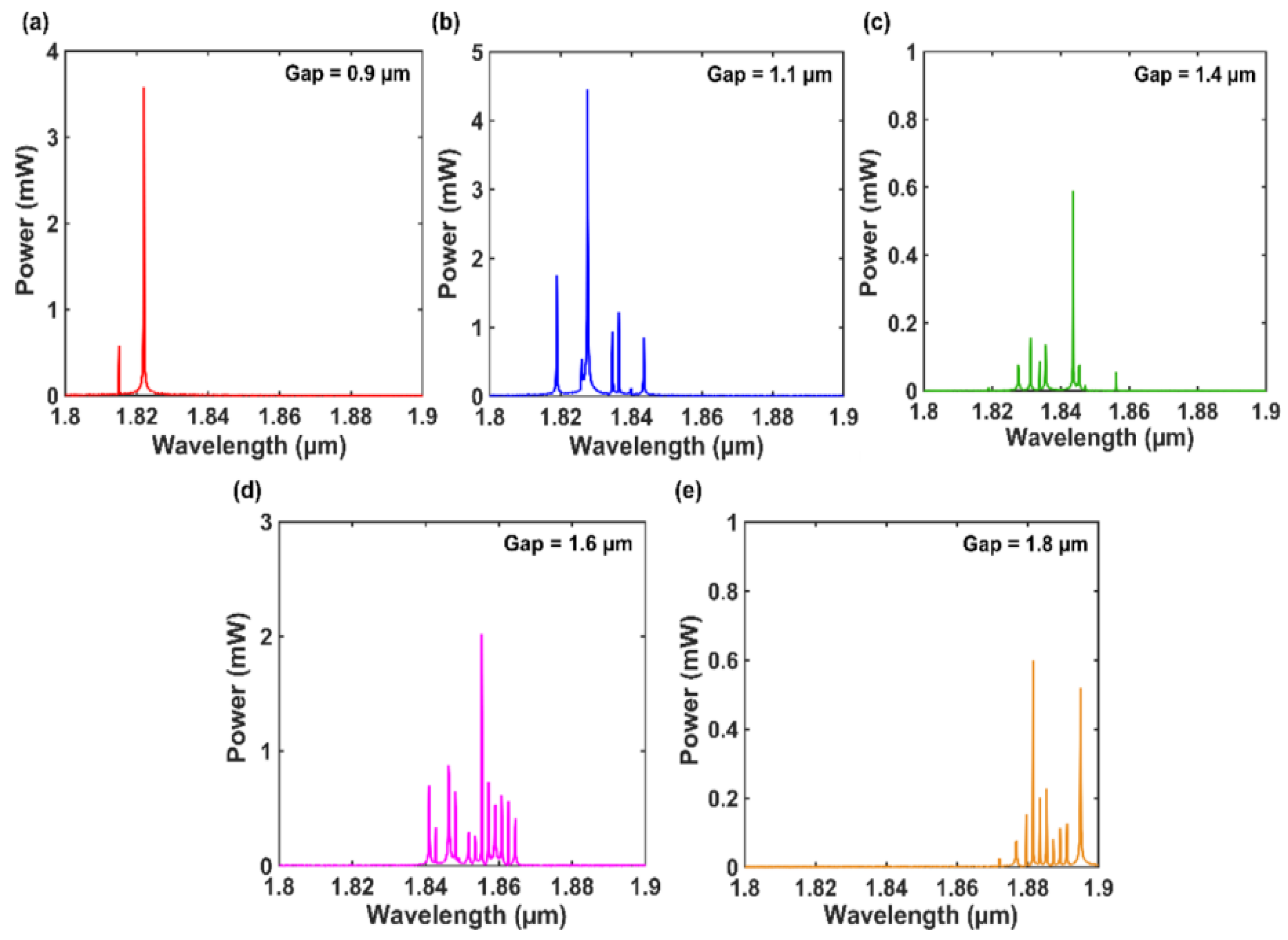

- Li, N.; Magden, E.S.; Su, Z.; Singh, N.; Ruocco, A.; Xin, M.; Byrd, M.; Callahan, P.T.; Bradley, J.D.B.; Baiocco, C.; et al. Broadband 2-µm emission on silicon chips: Monolithically integrated Holmium lasers. Opt. Express 2018, 26, 2220–2230. [Google Scholar] [CrossRef] [PubMed]

- Becker, P.; Brinkmann, R.; Dinand, M.; Sohler, W.; Suche, H. Er-diffused Ti:LiNbO3 waveguide laser of 1563 and 1576 nm emission wavelengths. Appl. Phys. Lett. 1992, 61, 1257–1259. [Google Scholar] [CrossRef]

- Amin, J.; Hempstead, M.; Roman, J.E.; Wilkinson, J.S. Tunable coupled-cavity waveguide laser at room temperature in Nd-diffused Ti:LiNbO3. Opt. Lett. 1994, 19, 1541–1543. [Google Scholar] [CrossRef] [PubMed]

- Amin, J.; Aust, J.A.; Sanford, N.A. Z-propagating waveguide lasers in rare-earth-doped Ti:LiNbO3. Appl. Phys. Lett. 1996, 69, 3785–3787. [Google Scholar] [CrossRef]

- Jones, J.; De Sandro, J.; Hempstead, M.; Shepherd, D.; Large, A.; Tropper, A.; Wilkinson, J. Channel waveguide laser at 1 μm in Yb-indiffused LiNbO3. Phys. Rev. Lett. 1995, 20, 1477–1479. [Google Scholar] [CrossRef]

- Baumann, I.; Brinkmann, R.; Dinand, M.; Sohler, W.; Westenhofer, S. Ti: Er: LiNbO3 waveguide laser of optimized efficiency. IEEE J. Quantum Electron. 1996, 32, 1695–1706. [Google Scholar] [CrossRef]

- Balsamo, S.; Maio, S.; Montrosset, I.; Suche, H.; Sohler, W. Q-switched Ti: Er: LiNbO3 waveguide laser. Opt. Quantum Electron. 1999, 31, 29–33. [Google Scholar] [CrossRef]

- Das, B.K.; Suche, H.; Sohler, W. Single-frequency Ti:Er:LiNbO3 distributed Bragg reflector waveguide laser with thermally fixed photorefractive cavity. Appl. Phys. B 2001, 73, 439–442. [Google Scholar] [CrossRef]

- Di Paolo, R.; Cantelar, E.; Pernas, P.; Lifante, G.; Cusso, F. Continuous wave waveguide laser at room temperature in Nd3+-doped Zn: LiNbO3. Appl. Phys. Lett. 2001, 79, 4088–4090. [Google Scholar] [CrossRef][Green Version]

- Fujimura, M.; Tsuchimoto, H.; Suhara, T. Yb-diffused LiNbO3 annealed/proton-exchanged waveguide lasers. IEEE Photonics Technol. Lett. 2005, 17, 130–132. [Google Scholar] [CrossRef]

- Fujimura, M.; Tsuchimoto, H.; Suhara, T. Yb:LiNbO3 Annealed/Proton-Exchanged Waveguide Lasers Pumped by InGaAs Laser Diode at 980 nm Wavelength. Jpn. J. Appl. Phys. 2007, 46, 5447–5449. [Google Scholar] [CrossRef]

- Fujimura, M.; Tsuchimoto, H.; Suhara, T. Yb-indiffused LiNbO3 annealed/proton-exchanged waveguide lasers. Electron. Commun. Jpn. 2007, 90, 10–17. [Google Scholar] [CrossRef]

- Matsuura, H.; Takagi, T. Development of a Low-Noise Yellow-Green Laser Using a Yb-Doped Double-Clad Fiber Laser and a Periodically Poled LiNbO3 Waveguide Crystal. Jpn. J. Appl. Phys. 2011, 50, 032701. [Google Scholar] [CrossRef]

- Sher, S.M.; Pintus, P.; Di Pasquale, F.; Bianconi, M.; Montanari, G.B.; De Nicola, P.; Sugliani, S.; Prati, G. Design of 980 nm-Pumped Waveguide Laser for Continuous Wave Operation in Ion Implanted Er:LiNbO3. IEEE J. Quantum Electron. 2011, 47, 526–533. [Google Scholar] [CrossRef]

- George, M.; Ricken, R.; Quiring, V.; Sohler, W. In-band pumped Ti:Tm:LiNbO3 waveguide amplifier and low threshold laser. Laser Photonics Rev. 2012, 7, 122–131. [Google Scholar] [CrossRef]

- Jin, S.; Xu, L.; Li, Y. Spatially Modulated Gain Erbium-Doped Ti:LiNbO3 Waveguide Laser. IEEE Photonics Technol. Lett. 2014, 26, 1515–1517. [Google Scholar] [CrossRef]

- Tan, Y.; de Aldana, J.R.V.; Chen, F. Femtosecond laser-written lithium niobate waveguide laser operating at 1085 nm. Opt. Eng. 2014, 53, 107109. [Google Scholar] [CrossRef]

- Das, B.; Suche, H.; Sohler, W. Single frequency Ti: Er: LiNbO3 distributed Bragg reflector (DBR)-waveguide laser with two integrated photorefractive gratings. In Proceedings of the European Conference on Integrated Optics, Paderborn, Germany, April 2001; pp. 87–90. [Google Scholar] [CrossRef]

- Martínez de Mendívil, J.; del Hoyo, J.; Solís, J.; Lifante, G. Ridge waveguide laser in Nd:LiNbO3 by Zn-diffusion and femtosecond-laser structuring. Opt. Mater. 2016, 62, 353–356. [Google Scholar] [CrossRef]

- Brüske, D.; Suntsov, S.; Rüter, C.E.; Kip, D. Efficient Nd:Ti:LiNbO3 ridge waveguide lasers emitting around 1085 nm. Opt. Express 2019, 27, 8884–8889. [Google Scholar] [CrossRef] [PubMed]

- Snigirev, V.; Riedhauser, A.; Lihachev, G.; Churaev, M.; Riemensberger, J.; Wang, R.N.; Siddharth, A.; Huang, G.; Möhl, C.; Popoff, Y.; et al. Ultrafast tunable lasers using lithium niobate integrated photonics. Nature 2023, 615, 411–417. [Google Scholar] [CrossRef] [PubMed]

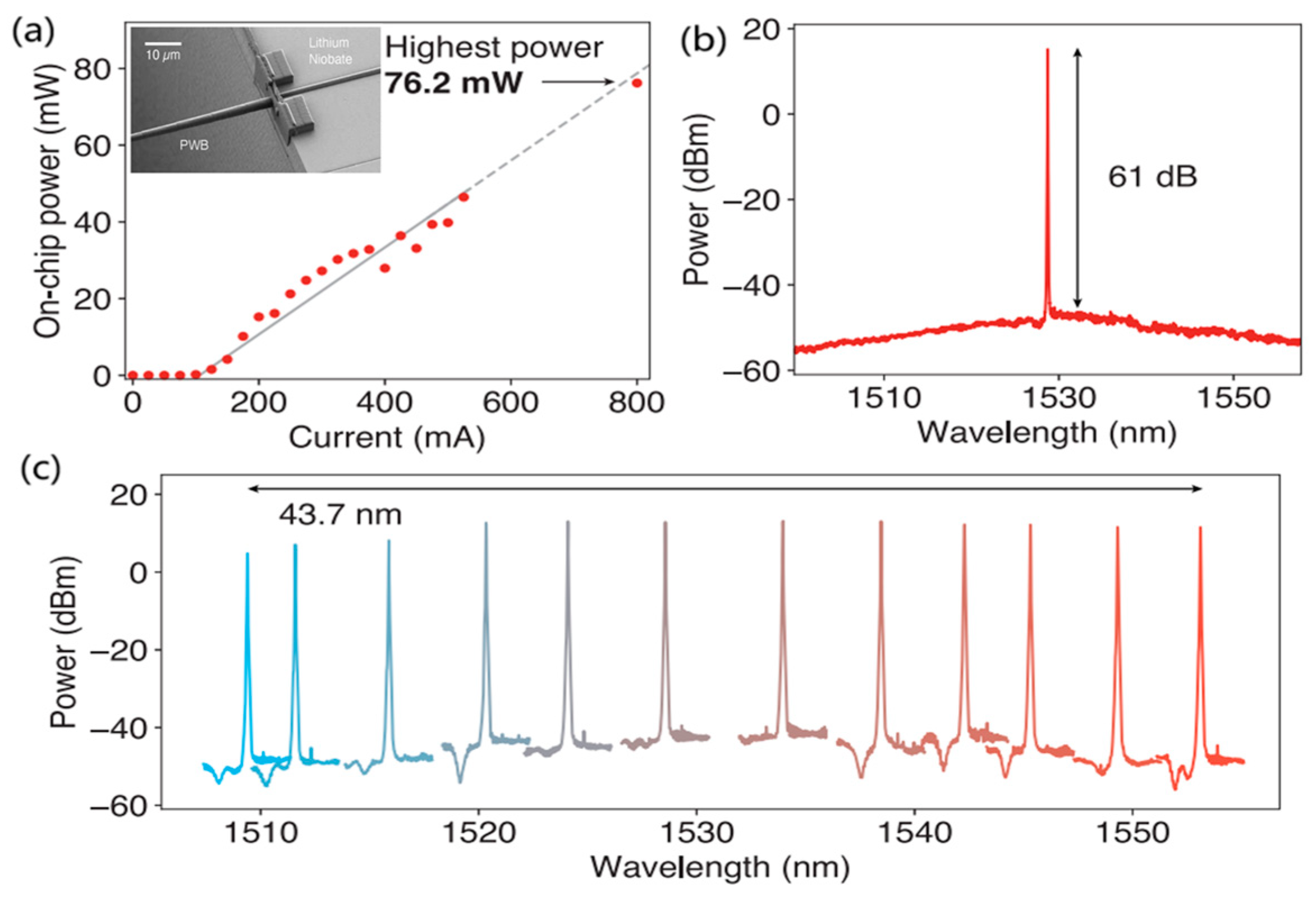

- Franken, C.A.A.; Cheng, R.; Powell, K.; Kyriazidis, G.; Rosborough, V.; Musolf, J.; Shah, M.; Barton, D.R.; Hills, G.; Johansson, L.; et al. High-power and narrow-linewidth laser on thin-film lithium niobate enabled by photonic wire bonding. APL Photonics 2025, 10, 026107. [Google Scholar] [CrossRef]

- Jha, A.; Richards, B.; Jose, G.; Teddy-Fernandez, T.; Joshi, P.; Jiang, X.; Lousteau, J. Rare-earth ion doped TeO2 and GeO2 glasses as laser materials. Prog. Mater. Sci. 2012, 57, 1426–1491. [Google Scholar] [CrossRef]

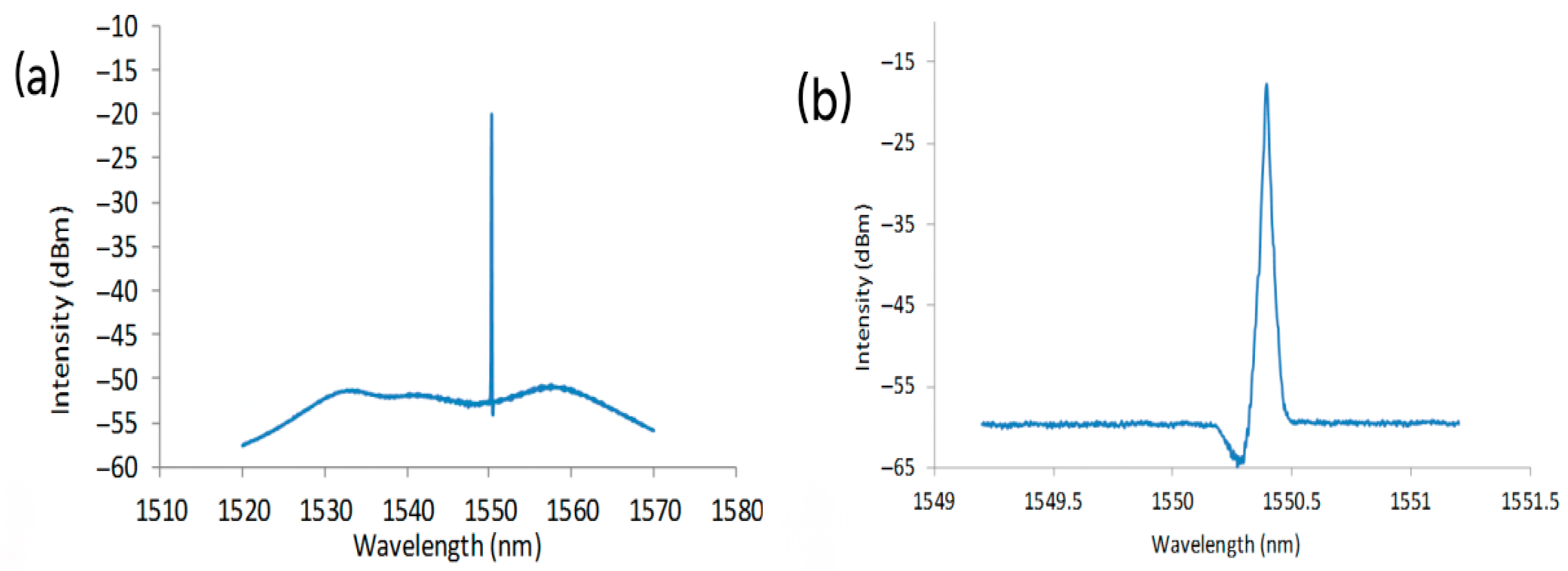

- Vu, K.; Farahani, S.; Madden, S. 980 nm pumped erbium doped tellurium oxide planar rib waveguide laser and amplifier with gain in S, C and L band. Opt. Express 2015, 23, 747–755. [Google Scholar] [CrossRef] [PubMed]

- Miarabbas Kiani, K.; Frankis, H.C.; Mateman, R.; Leinse, A.; Knights, A.P.; Bradley, J.D.B. Thulium-doped tellurium oxide microring lasers integrated on a low-loss silicon nitride platform. Opt. Mater. Express 2021, 11, 3656–3665. [Google Scholar] [CrossRef]

- Segat Frare, B.L.; Torab Ahmadi, P.; Hashemi, B.; Bonneville, D.B.; Mbonde, H.M.; Frankis, H.C.; Knights, A.P.; Mascher, P.; Bradley, J.D.B. On-chip hybrid erbium-doped tellurium oxide–silicon nitride distributed Bragg reflector lasers. Appl. Phys. B 2023, 129, 158. [Google Scholar] [CrossRef]

- Unal, B.; Netti, M.C.; Hassan, M.A.; Ayliffe, P.J.; Charlton, M.D.B.; Lahoz, F.; Perney, N.M.B.; Shepherd, D.P.; Chao-Yi, T.; Wilkinson, J.S.; et al. Neodymium-doped tantalum pentoxide waveguide lasers. IEEE J. Quantum Electron. 2005, 41, 1565–1573. [Google Scholar] [CrossRef]

- Subramani, A.Z.; Oton, C.J.; Shepherd, D.P.; Wilkinson, J.S. Erbium-Doped Waveguide Laser in Tantalum Pentoxide. IEEE Photonics Technol. Lett. 2010, 22, 1571–1573. [Google Scholar] [CrossRef]

- Aghajani, A.; Murugan, G.S.; Sessions, N.P.; Apostolopoulos, V.; Wilkinson, J.S. Waveguide lasers in ytterbium-doped tantalum pentoxide on silicon. Opt. Lett. 2015, 40, 2549–2552. [Google Scholar] [CrossRef] [PubMed]

- Tong, A.S.K.; Mitchell, C.J.; Aghajani, A.; Sessions, N.; Senthil Murugan, G.; Mackenzie, J.I.; Wilkinson, J.S. Spectroscopy of thulium-doped tantalum pentoxide waveguides on silicon. Opt. Mater. Express 2020, 10, 2201–2211. [Google Scholar] [CrossRef]

- Jung, H.; Yu, S.-P.; Carlson, D.R.; Drake, T.E.; Briles, T.C.; Papp, S.B. Tantala Kerr nonlinear integrated photonics. Optica 2021, 8, 811–817. [Google Scholar] [CrossRef]

- Liu, J.; Hou, Q.; Zhou, Y.; Dai, Q.; Liu, Z.; Wang, M.; Gao, R.; Fang, Z.; Lin, J.; Cheng, Y. On-chip microlaser and waveguide amplifier on thin film erbium-doped tantalum pentoxide. Chin. Opt. Lett. 2025, 23, 071302. [Google Scholar] [CrossRef]

- Nader, N.; Stanton, E.J.; Brodnik, G.M.; Jahan, N.; Weight, S.C.; Williams, L.M.; Eshaghian Dorche, A.; Silverman, K.L.; Nam, S.W.; Papp, S.B.; et al. Heterogeneous tantala photonic integrated circuits for sub-micron wavelength applications. Optica 2025, 12, 585–593. [Google Scholar] [CrossRef]

- Vogelbacher, F.; Sagmeister, M.; Kraft, J.; Zhou, X.; Huang, J.; Li, M.; Jiang, K.-J.; Song, Y.; Unterrainer, K.; Hainberger, R. Slot-Waveguide Silicon Nitride Organic Hybrid Distributed Feedback Laser. Sci. Rep. 2019, 9, 18438. [Google Scholar] [CrossRef] [PubMed]

- Pris, A.D.; Utturkar, Y.; Surman, C.; Morris, W.G.; Vert, A.; Zalyubovskiy, S.; Deng, T.; Ghiradella, H.T.; Potyrailo, R.A. Towards high-speed imaging of infrared photons with bio-inspired nanoarchitectures. Nat. Photonics 2012, 6, 195–200. [Google Scholar] [CrossRef]

- Gather, M.C.; Yun, S.H. Bio-optimized energy transfer in densely packed fluorescent protein enables near-maximal luminescence and solid-state lasers. Nat. Commun. 2014, 5, 5722. [Google Scholar] [CrossRef] [PubMed]

| Material | Threshold (Threshold Intensity) | Working Wavelength | Maximum Output Power | Pumping Scheme | Ref. |

|---|---|---|---|---|---|

| GaSb | 5000 A/cm2 | 1550 nm | 12 mW | Electrical | [23] |

| GaAs | 207 μJ /cm2 per pulse | 830–870 nm | / | Optical | [24] |

| GaAs | 313 A/cm2 | 976.8 nm | >300 mW | Electrical | [25] |

| InP | 0.9 mA | 1526–1532 nm | 0.93 mW | Electrical | [36] |

| InP | 22 ± 2.1 mW | 930.5 nm | 6.4 mW | Optical | [37] |

| InP | 52 mA | 1563–1566 nm | 16.4 mW | Electrical | [38] |

| InAs/GaAs | 650 A/cm2 | 1290 nm | / | Electrical | [31] |

| InAs/GaAs | 62.5 A/ cm2 | 1310 nm | >105 mW | Electrical | [32] |

| InAs/GaAs | 425 A/cm2 | 1285–1292 nm | 43 mW | Electrical | [33] |

| InAs/GaAs | 860 A/cm2 | 1280 nm | 110 mW | Electrical | [34] |

| InAs/GaAs | 47.5 mA | 1300 nm | 126.6 mW | Electrical | [35] |

| InGaAs/InAlAs | 387–388 mA | 4800 nm | 31 mW | Electrical | [26] |

| GaN | 700 mA | 405 nm | / | Electrical | [27] |

| InGaN | 250–1600 mA | 412.4 nm | / | Electrical | [28] |

| InAs/AlSb | 920–950 A/cm2 | 8000 nm | / | Electrical | [30] |

| InAs/AlSb | 1300 A/cm2 | 1050–1110 nm | >100 mW/facet | Electrical | [29] |

| InP | 36 mA | 1310 nm | 22 mW | Electrical | [39] |

| InP | 17 mA | 1566 nm | 6 mW | Electrical | [40] |

| InP | 17 mA | 1566 nm | 6 mW | Electrical | [41] |

| InP | 100 μA | 1560 nm | 95 ± 2 μW | Electrical | [42] |

| InP | 51 mA | 1544 nm | / | Electrical | [43] |

| InP | 100 mA | 1480–1590 nm | 3 mW | Electrical | [44] |

| InP | 50 μJ/cm2 per pulse | 870–910 nm | / | Optical | [45] |

| InP | 42 mA | 1548 nm | >10 mW | Electrical | [46] |

| InP | 30 mA | 1541–1589 nm | / | Electrical | [47] |

| Cavity Type | Rare-Earth Dopant | Laser Wavelength | Maximal Slope Efficiency | Maximal Laser Output Power | Linewidth | Reference |

|---|---|---|---|---|---|---|

| Ring | Er/Yb | 1560 nm/1042 nm | 0.3%/8.4% | 2.4 µW/100 µW | / | [51] |

| Ring | Tm | 1760–1920 nm | 24% | 230 µW | / | [59] |

| Ring | Ti | 790–930 nm | 2.9% | 1.8 mW | 140 kHz | [53] |

| DFB | Er | 1543 nm | 0.006% | 9 µW | 501 kHz | [55] |

| DFB | Er | 1560 nm | 0.77% | 270 µW | / | [56] |

| DFB | Er | 1563 nm | 2.2% | 1.0 mW | / | [60] |

| DFB | Er | 1563–1580 nm | / | 20 µW | / | [61] |

| DFB | Er | 1553 nm | 1.3% | 2.6 mW | / | [62] |

| DFB | Er | 1592 nm | 0.7% | 1.2 mW | / | [63] |

| DFB | Er | 1599 nm | 0.01% | / | / | [64] |

| dps-DFB | Er | 1565 nm | 2.9% | 5.43 mW | 5.3 kHz | [58] |

| qps-DFB | Er | 1536, 1566, 1596 nm | 0.6% | 0.76 mW | 30.4 kHz | [58] |

| DFB | Tm | 1861 nm | 14% | 267 mW | / | [65] |

| DFB | Ho | 2022–2101 nm | 2% | 15 mW | / | [66] |

| DBR | Er | 1536, 1561, 1596 nm | 2.6% | 5.1 mW | / | [54] |

| DBR | Er | 1546 nm | 5.2% | 2.1 mW | / | [56] |

| DBR | Er | 1564 nm | 0.02% | / | / | [14] |

| DBR | Tm | 1881 nm | 23% | 387 mW | / | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Yang, J.; Cheng, Z.; Zhang, S.; Yang, Z.; Bai, S.; Wang, R. Silicon-Based On-Chip Light Sources: A Review. Photonics 2025, 12, 732. https://doi.org/10.3390/photonics12070732

Yang Y, Yang J, Cheng Z, Zhang S, Yang Z, Bai S, Wang R. Silicon-Based On-Chip Light Sources: A Review. Photonics. 2025; 12(7):732. https://doi.org/10.3390/photonics12070732

Chicago/Turabian StyleYang, Yongqi, Jiaqi Yang, Zhouyang Cheng, Shuyan Zhang, Zhen Yang, Shengchuang Bai, and Rongping Wang. 2025. "Silicon-Based On-Chip Light Sources: A Review" Photonics 12, no. 7: 732. https://doi.org/10.3390/photonics12070732

APA StyleYang, Y., Yang, J., Cheng, Z., Zhang, S., Yang, Z., Bai, S., & Wang, R. (2025). Silicon-Based On-Chip Light Sources: A Review. Photonics, 12(7), 732. https://doi.org/10.3390/photonics12070732