On-Chip Silicon Bragg-Grating-Waveguide-Based Polymer Slot for Gas Sensing

Abstract

1. Introduction

2. Design of the SP-PSBG Structure

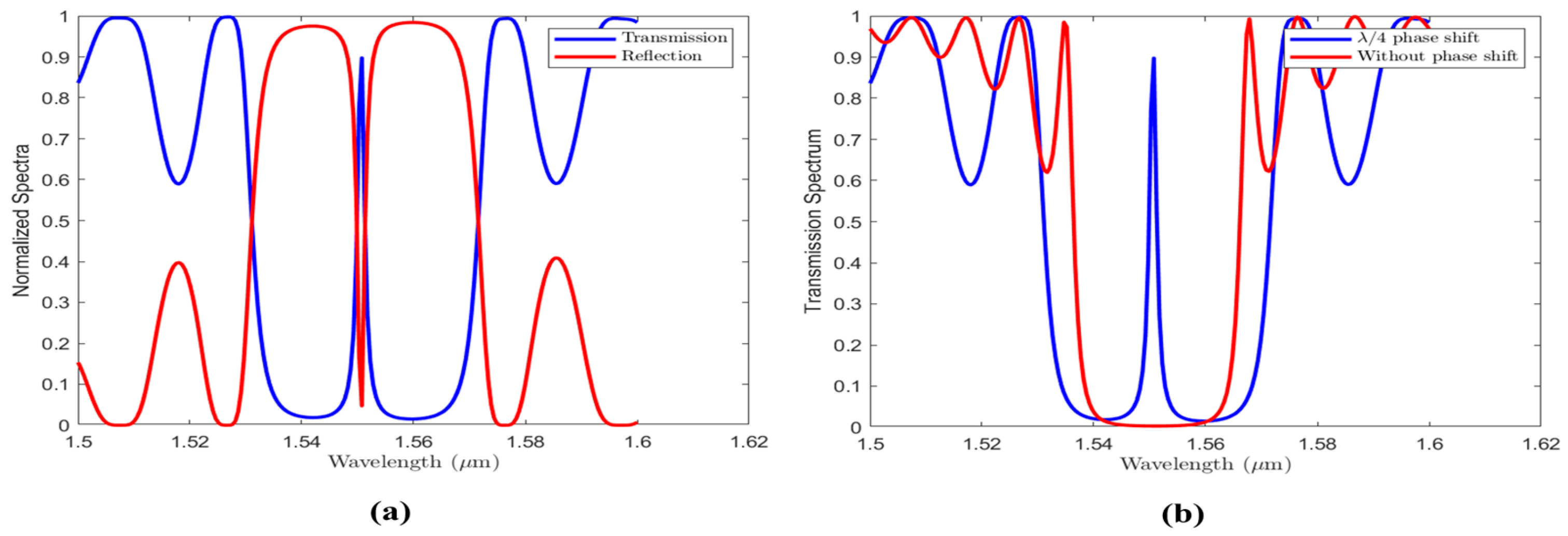

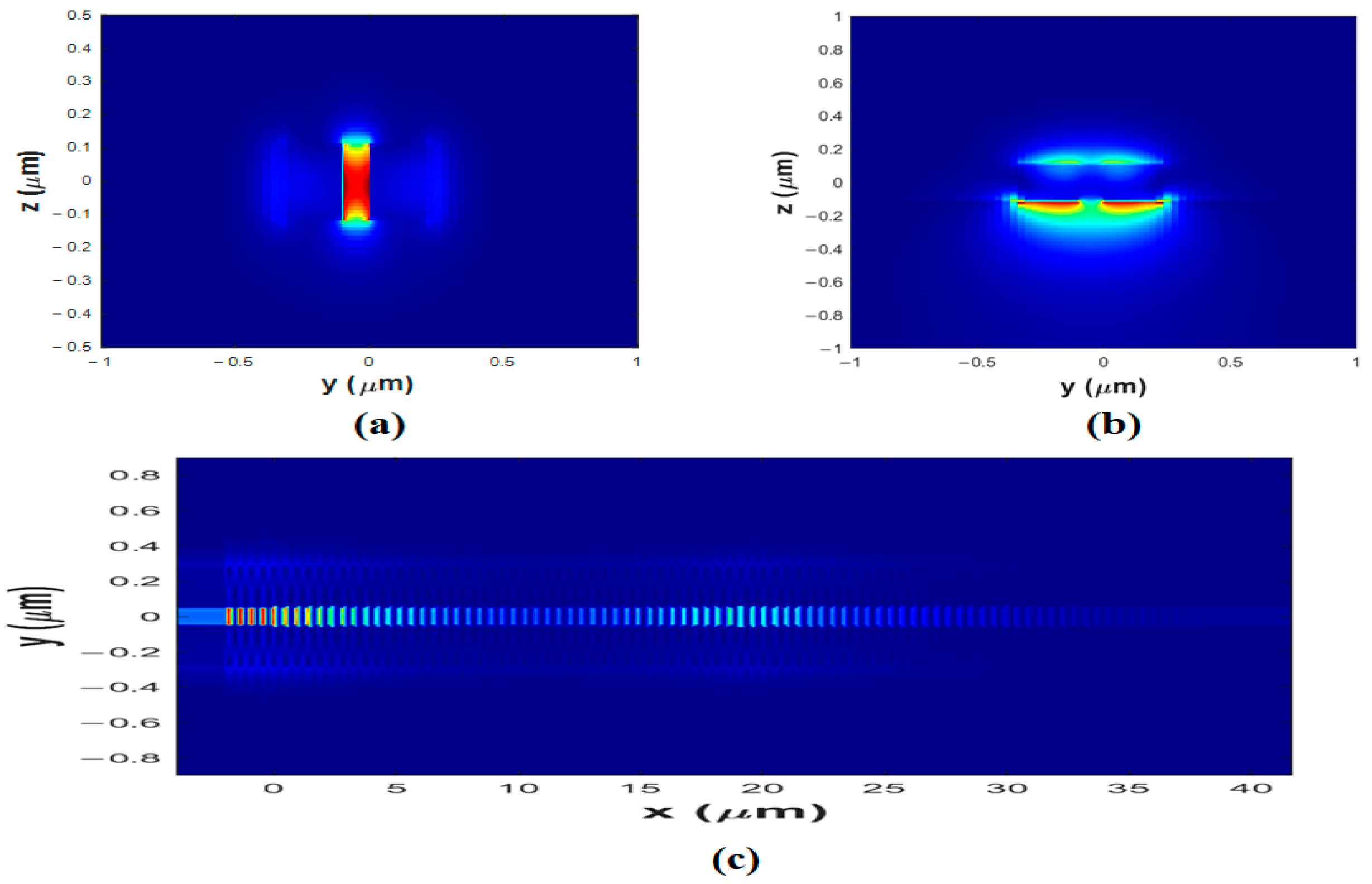

2.1. Structure Design

2.2. Theoretical Model

3. Structural Optimization Based on Maximizing the Confinement Factor

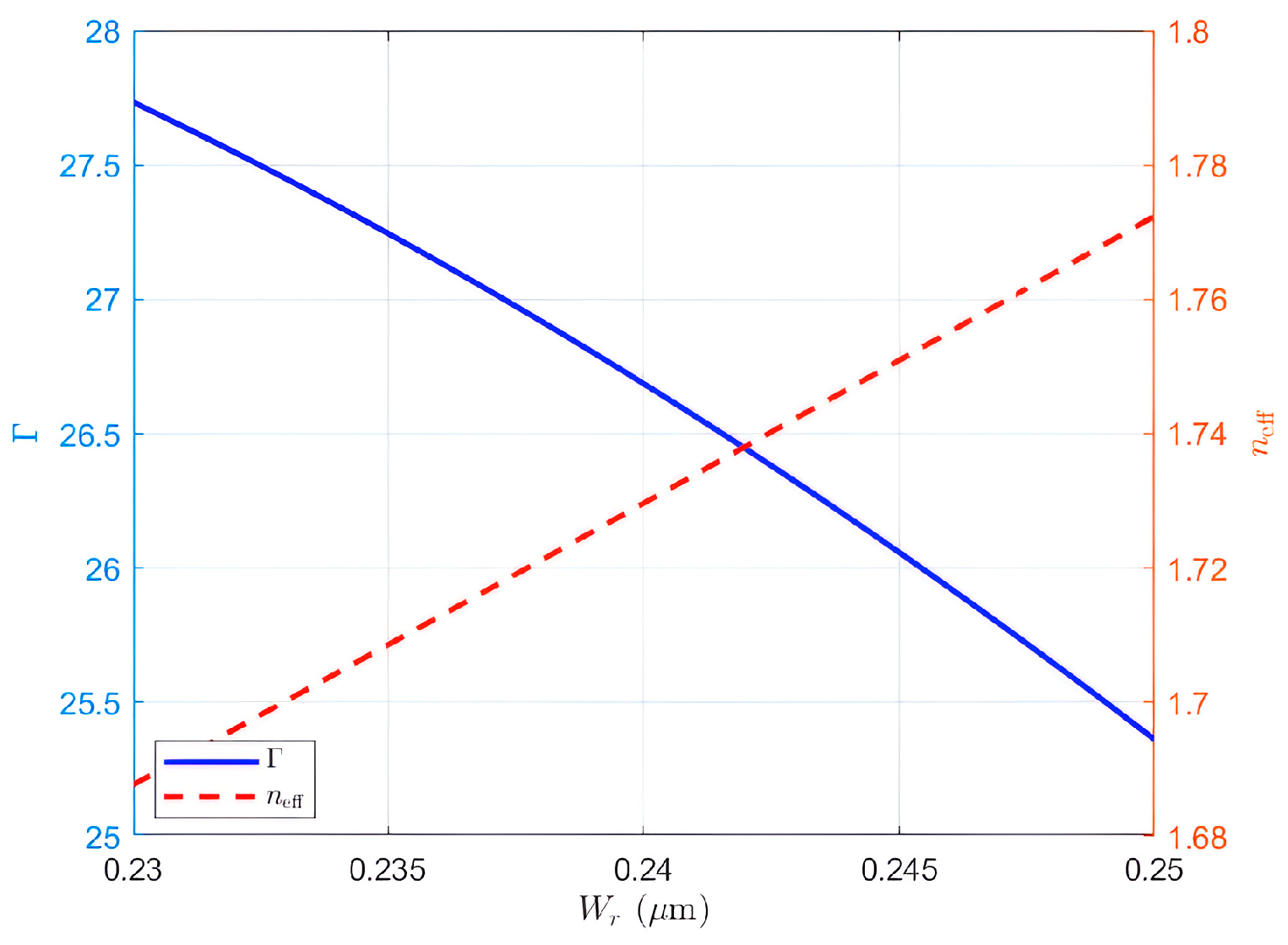

3.1. The Effect of Rail Width

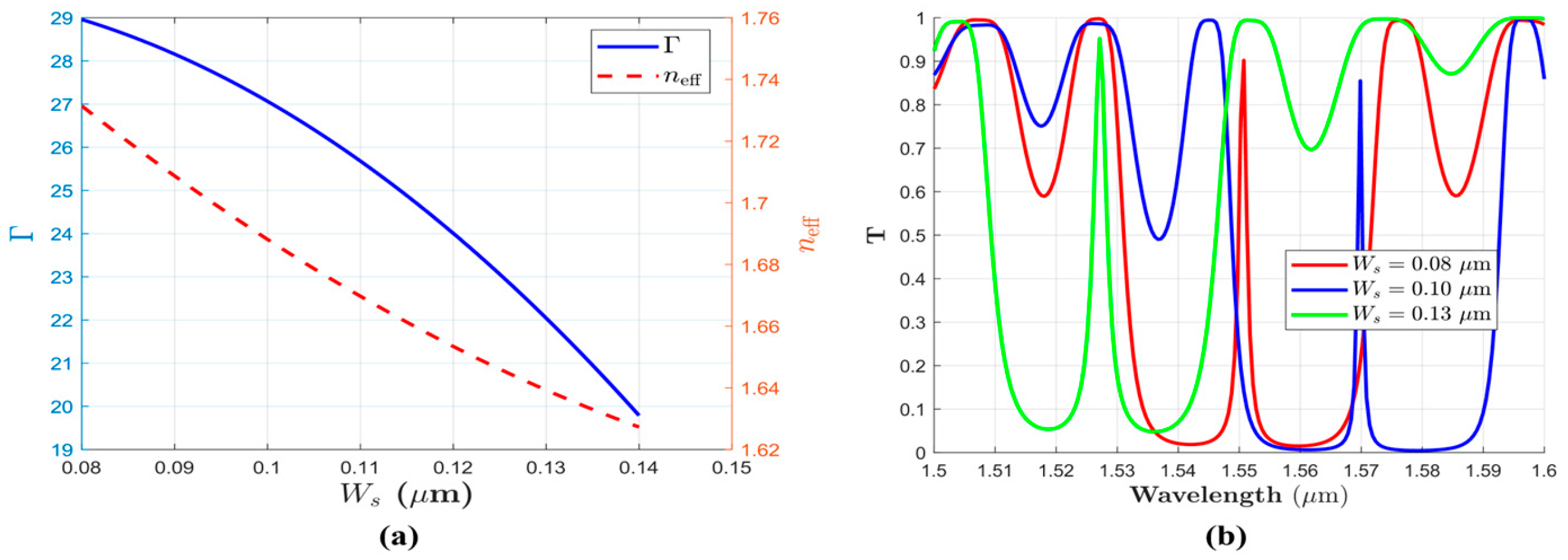

3.2. The Effect of Slot Width

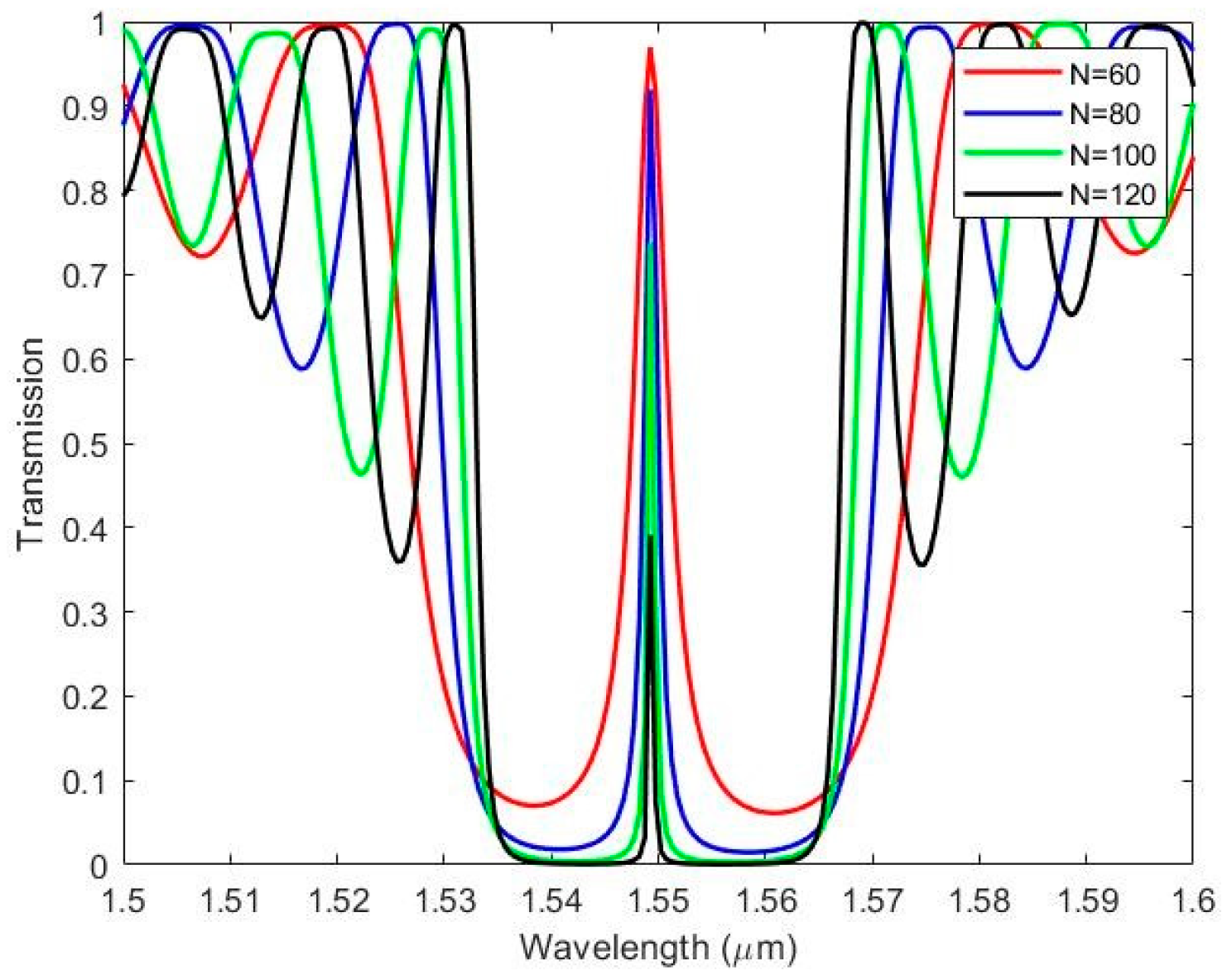

3.3. The Effect of Number of Grating

3.4. The Effect of Gratings Depth

3.5. The Effect of Duty Cycle

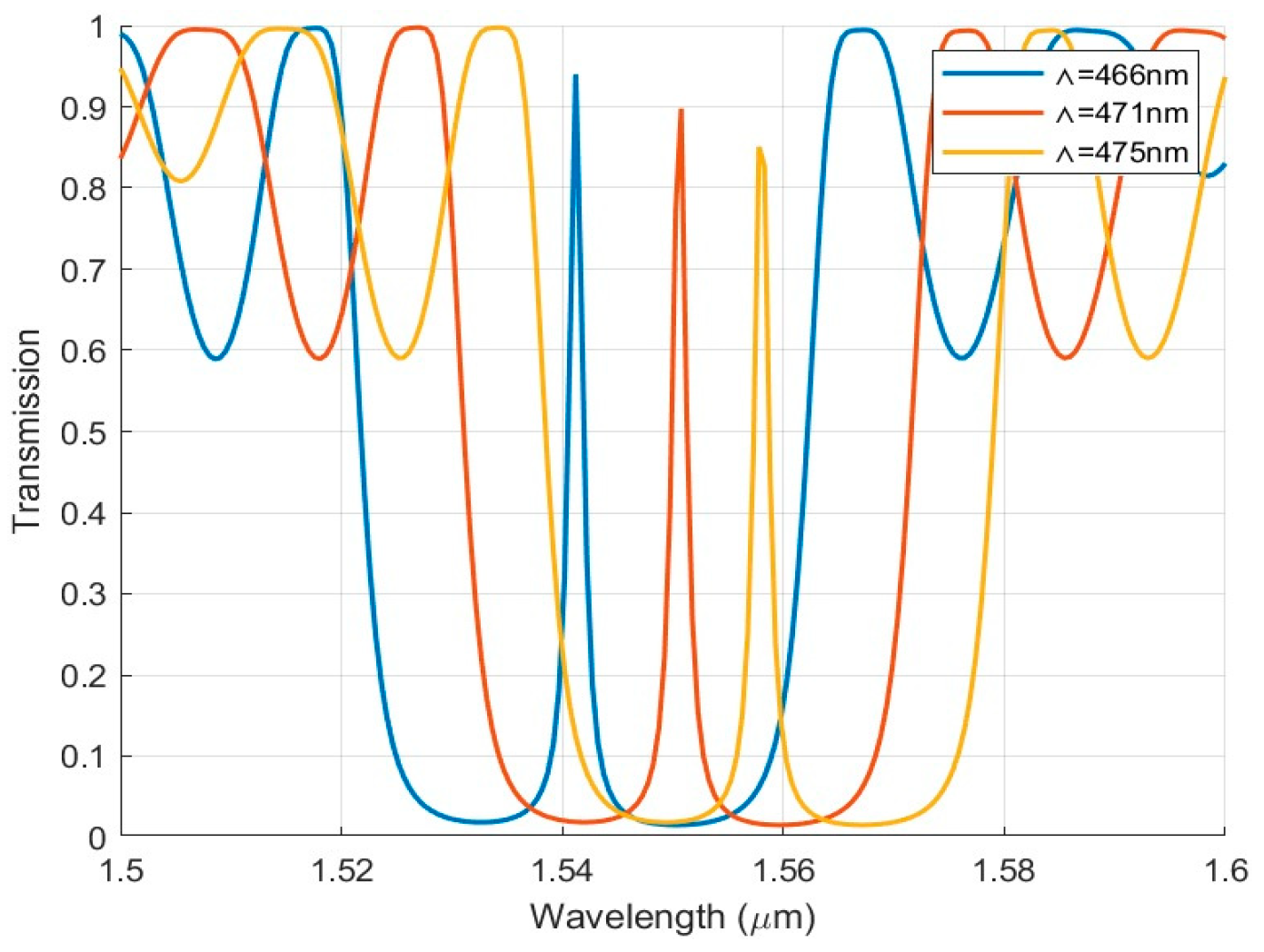

3.6. The Effect of Grating Period

4. Performance Evaluation of the SP-PSBG for Detection

5. Future Work

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qu, H.; Duan, X. Recent advances in micro detectors for micro gas chromatography. Sci. China Mater. 2019, 62, 611–623. [Google Scholar] [CrossRef]

- Rindelaub, J.; Wiley, J.; Cooper, B.; Shepson, P. Chemical characterization of -pinene secondary organic aerosol constituents using gas chromatography, liquid chromatography, and paper spray-based mass spectrometry techniques: Characterization of -pinene SOA constituents. Rapid Commun. Mass Spectrom. 2016, 30, 1627–1638. [Google Scholar] [CrossRef]

- Shaaban, H.; Mostafa, A.; Górecki, T. Green Gas and Liquid Capillary Chromatography. In The Application of Green Solvents in Separation Processes; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- McNair, H.; Miller, J.; Snow, N. Basic Gas Chromatography; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Bogue, R. Detecting gases with light: A review of optical gas sensor technologies. Sens. Rev. 2015, 35, 133–140. [Google Scholar] [CrossRef]

- Butt, M.A.; Piramidowicz, R. Integrated photonic sensors for the detection of toxic gasses—A review. Chemosensors 2024, 12, 143. [Google Scholar] [CrossRef]

- Jahromi, H.D.; Kazemi, M.; Sheikhi, M.H. Room temperature and highly sensitive acetone sensor based on lead sulfide nanosheets. Mater. Sci. Eng. B 2021, 267, 115082. [Google Scholar] [CrossRef]

- Mosahebfard, A.; Jahromi, H.D.; Sheikhi, M.H. Highly Sensitive, Room Temperature Methane Gas Sensor Based on Lead Sulfide Colloidal Nanocrystals. IEEE Sens. J. 2016, 16, 4174–4179. [Google Scholar] [CrossRef]

- Zheng, S.; Ghandehari, M.; Ou, J. Photonic crystal fiber long-period grating absorption gas sensor based on a tunable erbium-doped fiber ring laser. Sens. Actuators B Chem. 2016, 223, 324–332. [Google Scholar] [CrossRef]

- Antonacci, G.; Goyvaerts, J.; Zhao, H.; Baumgartner, B.; Lendl, B.; Baets, R. Ultra-sensitive refractive index gas sensor with functionalized silicon nitride photonic circuits. APL Photonics 2020, 5, 081301. [Google Scholar] [CrossRef]

- Bakshi, B.; Varshney, R.K.; Pal, B.P. Silicon photonics-based gas sensors and components for the Mid-IR: Design and Modelling. In Proceedings of the ICOL-2019, International Conference on Optics and Electro-Optics, Dehradun, India, 19–22 October 2019; Springer: Berlin/Heidelberg, Germany, 2021; pp. 7–10. [Google Scholar]

- Chrostowski, L.; Hochberg, M. Silicon Photonics Design: From Devices to Systems; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Tsigaridas, G.N. A study on refractive index sensors based on optical micro-ring resonators. Photonic Sens. 2017, 7, 217–225. [Google Scholar] [CrossRef]

- Gerguis, J.O.; Qi, M. Linear and passive silicon-on-insulator refractive index sensor utilizing Bragg grating-assisted Michelson interferometer. Opt. Express 2025, 33, 9102–9116. [Google Scholar] [CrossRef]

- Lotfiani, A.; Jahromi, H.D. Guided-Mode Resonance Enhanced Ge-on-Si Self-Powered Surface Illuminated Photodetector for Ultrahigh-Speed Optical Communication Systems. IEEE Sens. J. 2024, 24, 40669–40677. [Google Scholar] [CrossRef]

- Izadpour, A.R.; Jahromi, H.D.; Sheikhi, M.H. Plasmonic Enhancement of Colloidal Quantum Dot Infrared Photodetector Photosensitivity. IEEE J. Quantum Electron. 2018, 54, 7200207. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y.; Pan, J.; Huang, T.; Jin, S. Design of highly sensitive refractive index sensor based on silicon photonic Mach–Zehnder interferometer. Opt. Commun. 2023, 534, 129288. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, P.; Zhang, L. Numerical analysis of effective refractive index sensor based on slot micro-ring and Bragg grating. Int. J. Mod. Phys. B 2019, 33, 1950292. [Google Scholar] [CrossRef]

- Fernández Gavela, A.; Grajales García, D.; Ramirez, J.C.; Lechuga, L.M. Last advances in silicon-based optical biosensors. Sensors 2016, 16, 285. [Google Scholar] [CrossRef]

- Salama, N.A.; Alexeree, S.M.; Obayya, S.S.; Swillam, M.A. Silicon-based double fano resonances photonic integrated gas sensor. Sci. Rep. 2024, 14, 24811. [Google Scholar] [CrossRef]

- Liu, C.; Wang, J.; Wu, X.; Sun, X.; Qiao, Z.; Xin, Y.; Zhang, J. Design and optimization of asymmetric grating assisted slot Microring. Photonics 2022, 9, 988. [Google Scholar] [CrossRef]

- Liu, C.; Sang, C.; Wu, X.; Cai, J.; Wang, J. Grating double-slot micro-ring resonator for sensing. Opt. Commun. 2021, 499, 127280. [Google Scholar] [CrossRef]

- Koushik, K.P.; Malathi, S. Optical micro-ring resonator for detection of carbon dioxide gas. In Emerging Trends in Photonics, Signal Processing and Communication Engineering: Proceedings of ICPSPCT 2018, Bangalore, India, 18–20 July 2018; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–161. [Google Scholar]

- Dehdashti Jahromi, H. Performance analysis of transmissive modified cladding optical fibre sensors. IET Optoelectron. 2022, 16, 63–71. [Google Scholar] [CrossRef]

- Khonina, S.; Kazanskiy, N.; Butt, M.A.; Kaz’mierczak, A.; Piramidowicz, R. Plasmonic sensor based on metal-insulator-metal waveguide square ring cavity filled with functional material for the detection of CO2 gas. Opt. Express 2021, 29, 16584–16594. [Google Scholar] [CrossRef]

- Butt, M.; Kazanskiy, N.; Khonina, S. On-chip symmetrically and asymmetrically transformed plasmonic Bragg grating formation loaded with a functional polymer for filtering and CO2 gas sensing applications. Measurement 2022, 201, 111694. [Google Scholar] [CrossRef]

- Zeng, L.; Li, B.; Wen, R.; Zhang, X. Plasmonic Sensor Based on Multi Fano Resonance in Inverse T Shape Structure for Detection of CO2 Concentration. IEEE Photonics J. 2023, 15, 1–5. [Google Scholar] [CrossRef]

- Long, W.; Zhou, R.; Du, Z.; Ling, Q.; Zhang, Y.; Zhao, D.; Shao, J.; Luo, S.; Chen, D. A Dual-Band Carbon Dioxide Sensor Based on Metal–TiO2–Metal Metasurface Covered by Functional Material. Photonics 2022, 9, 855. [Google Scholar] [CrossRef]

- Reed, G.T.; Mashanovich, G.; Gardes, F.Y.; Thomson, D. Silicon optical modulators. Nat. Photonics 2010, 4, 518–526. [Google Scholar] [CrossRef]

- Mi, G.; Horvath, C.; Van, V. Silicon photonic dual-gas sensor for H2 and CO2 detection. Opt. Express 2017, 25, 16250–16259. [Google Scholar] [CrossRef]

- Mi, G.; Horvath, C.; Aktary, M.; Van, V. Silicon microring refractometric sensor for atmospheric CO2 gas monitoring. Opt. Express 2016, 24, 1773–1780. [Google Scholar] [CrossRef]

- Badri, S.H. Transmission resonances in silicon subwavelength grating slot waveguide with functional host material for sensing applications. Opt. Laser Technol. 2021, 136, 106776. [Google Scholar] [CrossRef]

- Deng, Q.; Yan, Q.; Liu, L.; Li, X.; Michel, J.; Zhou, Z. Robust polarization-insensitive strip-slot waveguide mode converter based on symmetric multimode interference. Opt. Express 2016, 24, 7347–7355. [Google Scholar] [CrossRef]

- Kulkarni, M.R.; Manoj Kumar, B.; Malghan, M.M.; Mohamedarif, G.; Honnungar, R.V. Planar Waveguide Bragg Grating Pressure Sensor—Design and Applications. In Emerging Trends in Photonics, Signal Processing and Communication Engineering: Proceedings of ICPSPCT 2018, Bangalore, India, 18–20 July 2018; Springer: Berlin/Heidelberg, Germany, 2020; pp. 53–62. [Google Scholar]

- Husko, C.; Ducharme, A.; Fahrenkopf, N.M.; Guest, J.R. Phase-shifted Bragg gratings in a foundry silicon nitride platform. OSA Contin. 2021, 4, 933–939. [Google Scholar] [CrossRef]

- Li, H.; Sun, B.; Yuan, Y.; Yang, J. Guanidine derivative polymer coated microbubble resonator for high sensitivity detection of CO2 gas concentration. Opt. Express 2019, 27, 1991–2000. [Google Scholar] [CrossRef]

- Wang, X.; Grist, S.; Flueckiger, J.; Jaeger, N.A.; Chrostowski, L. Silicon photonic slot waveguide Bragg gratings and resonators. Opt. Express 2013, 21, 19029–19039. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, W.; Vafaei, R.; Jaeger, N.A.; Chrostowski, L. Silicon-on-insulator Bragg gratings fabricated by deep UV lithography. In Proceedings of the Asia Communications and Photonics Conference and Exhibition, Shanghai, China, 8–12 December 2010; pp. 501–502. [Google Scholar]

| Ref. | Structure | Sensitivity (pm/ppm) | FWHM (nm) |

|---|---|---|---|

| [31] | Ring Resonator Coated with PHMB | - | |

| [30] | Ring Resonator Coated with PHMB | - | |

| [32] | Slotted Subwavelength Grating Filled with PHMB | 12.9 | 2.96 |

| [36] | PHMB-Coated Whispering Gallery Mode (WGM) Microbubble Resonator | 0.46 | - |

| [26] | Symmetric/Asymmetric Plasmonic Bragg Grating with PHMB (MIM waveguide) | 226 | 0.004 |

| [27] | Multi-Fano Resonance Inverse T-shaped Plasmonic Structure with PHMB | 303 | - |

| [28] | Metal–TiO–Metal Metasurface with PHMB (Dual-Band SWIR Absorber) | 109.25/42.57 | - |

| Our work | Slotted Phase-Shift Bragg Grating Filled with PHMB | 14.4 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khafagy, M.; Khafagy, M.; Hesham, P.; A. Swillam, M. On-Chip Silicon Bragg-Grating-Waveguide-Based Polymer Slot for Gas Sensing. Photonics 2025, 12, 608. https://doi.org/10.3390/photonics12060608

Khafagy M, Khafagy M, Hesham P, A. Swillam M. On-Chip Silicon Bragg-Grating-Waveguide-Based Polymer Slot for Gas Sensing. Photonics. 2025; 12(6):608. https://doi.org/10.3390/photonics12060608

Chicago/Turabian StyleKhafagy, Merna, Maira Khafagy, Passant Hesham, and Mohamed A. Swillam. 2025. "On-Chip Silicon Bragg-Grating-Waveguide-Based Polymer Slot for Gas Sensing" Photonics 12, no. 6: 608. https://doi.org/10.3390/photonics12060608

APA StyleKhafagy, M., Khafagy, M., Hesham, P., & A. Swillam, M. (2025). On-Chip Silicon Bragg-Grating-Waveguide-Based Polymer Slot for Gas Sensing. Photonics, 12(6), 608. https://doi.org/10.3390/photonics12060608