Modeling Dual-SiOxN Thin-Film Edge Coupler with Ultra-Low Loss and Large Alignment Tolerance

Abstract

1. Introduction

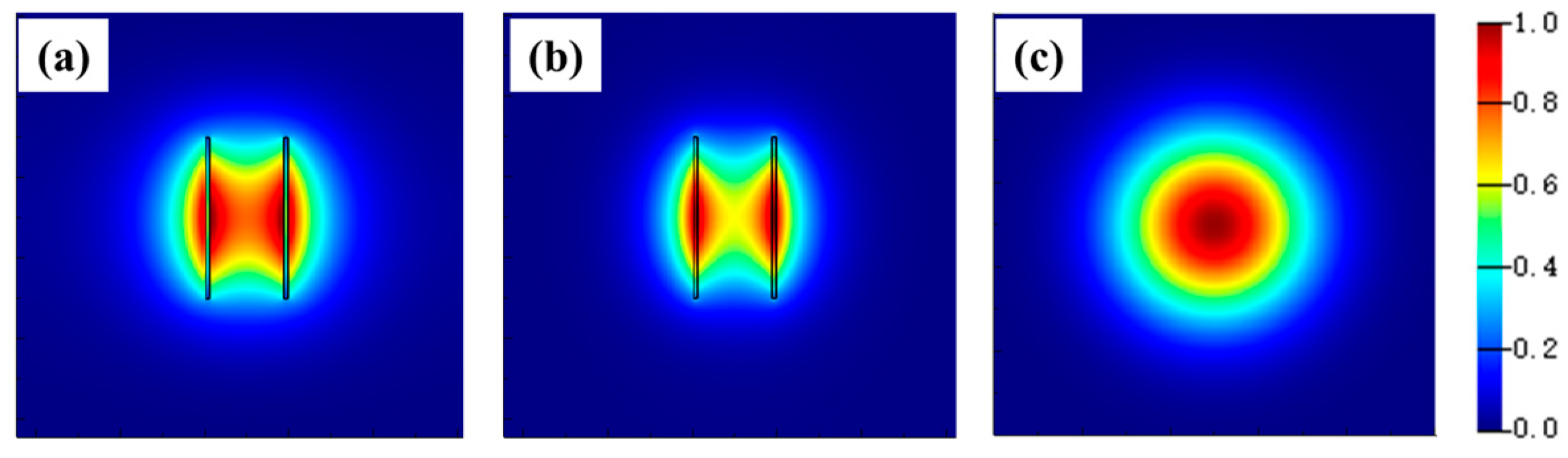

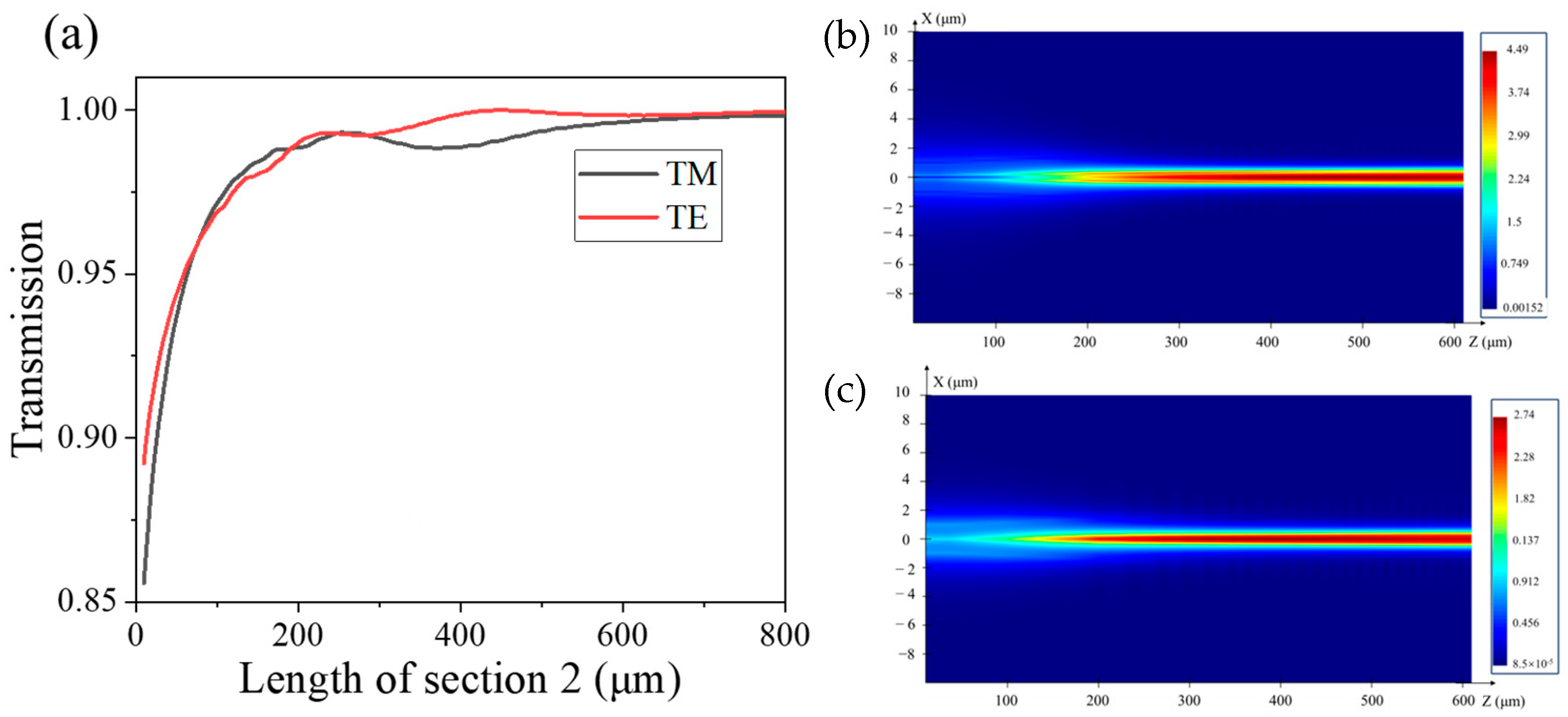

2. Device Design and Analysis

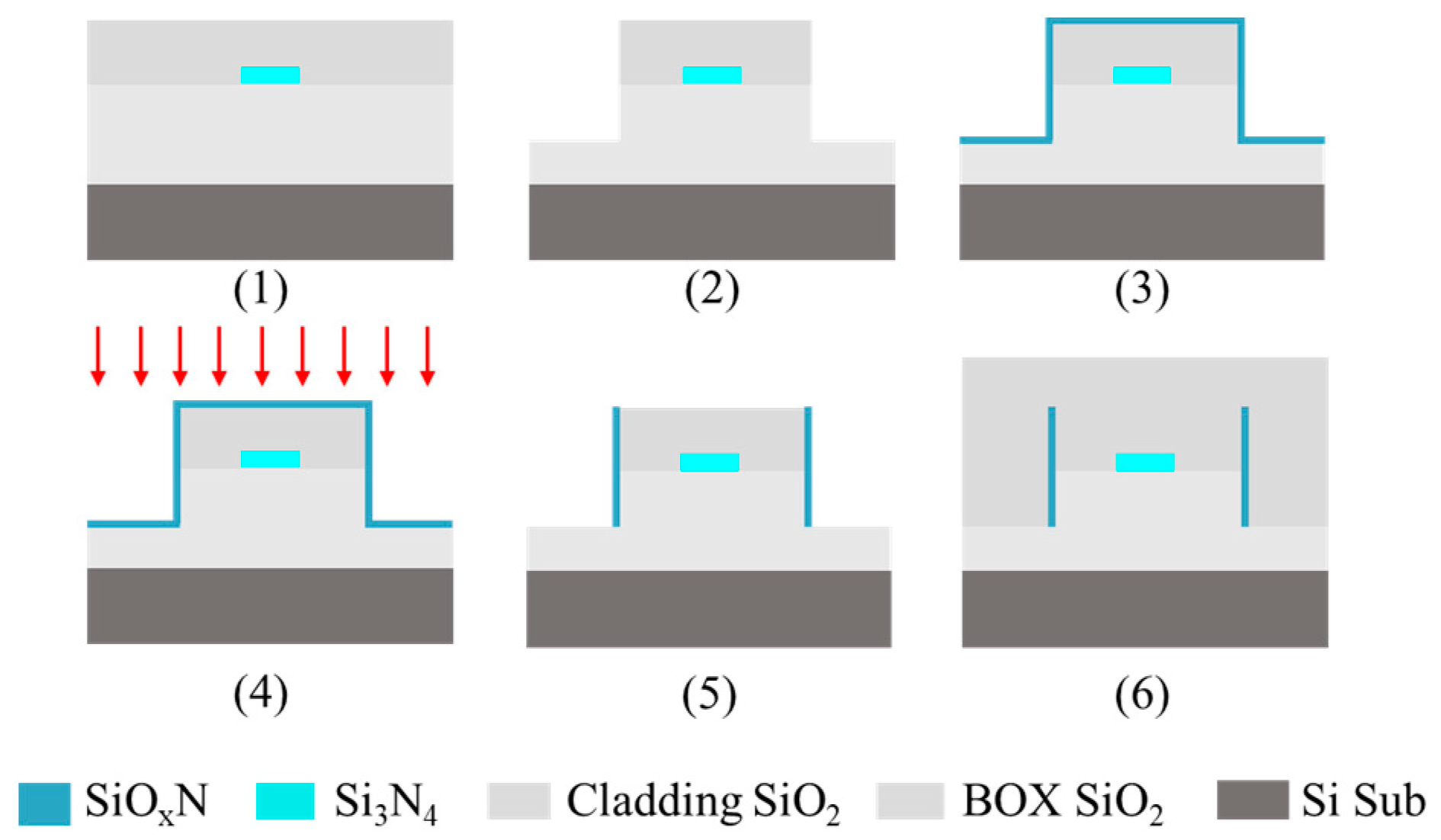

2.1. Development and Description of the Model

2.2. Modeling Methods

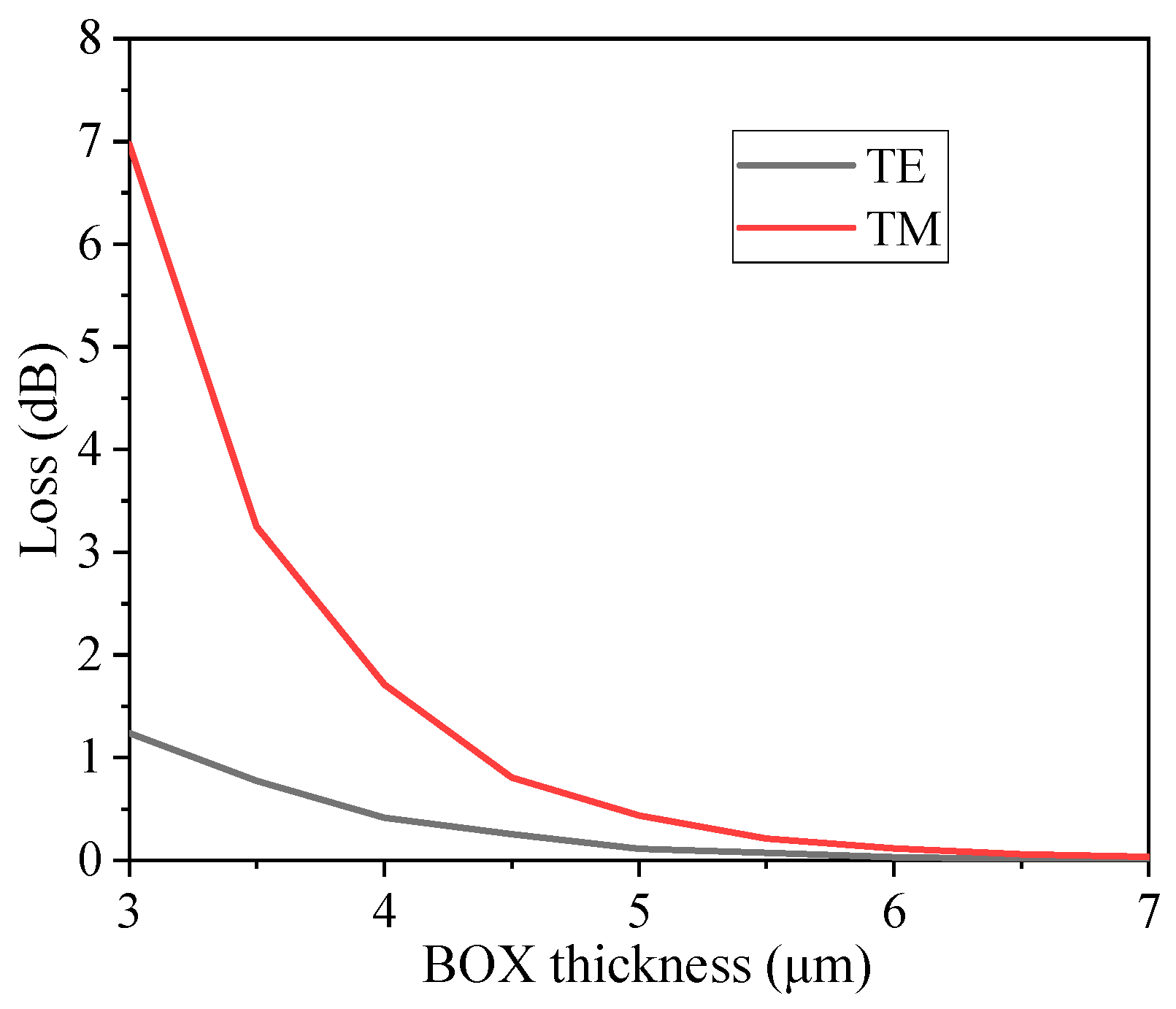

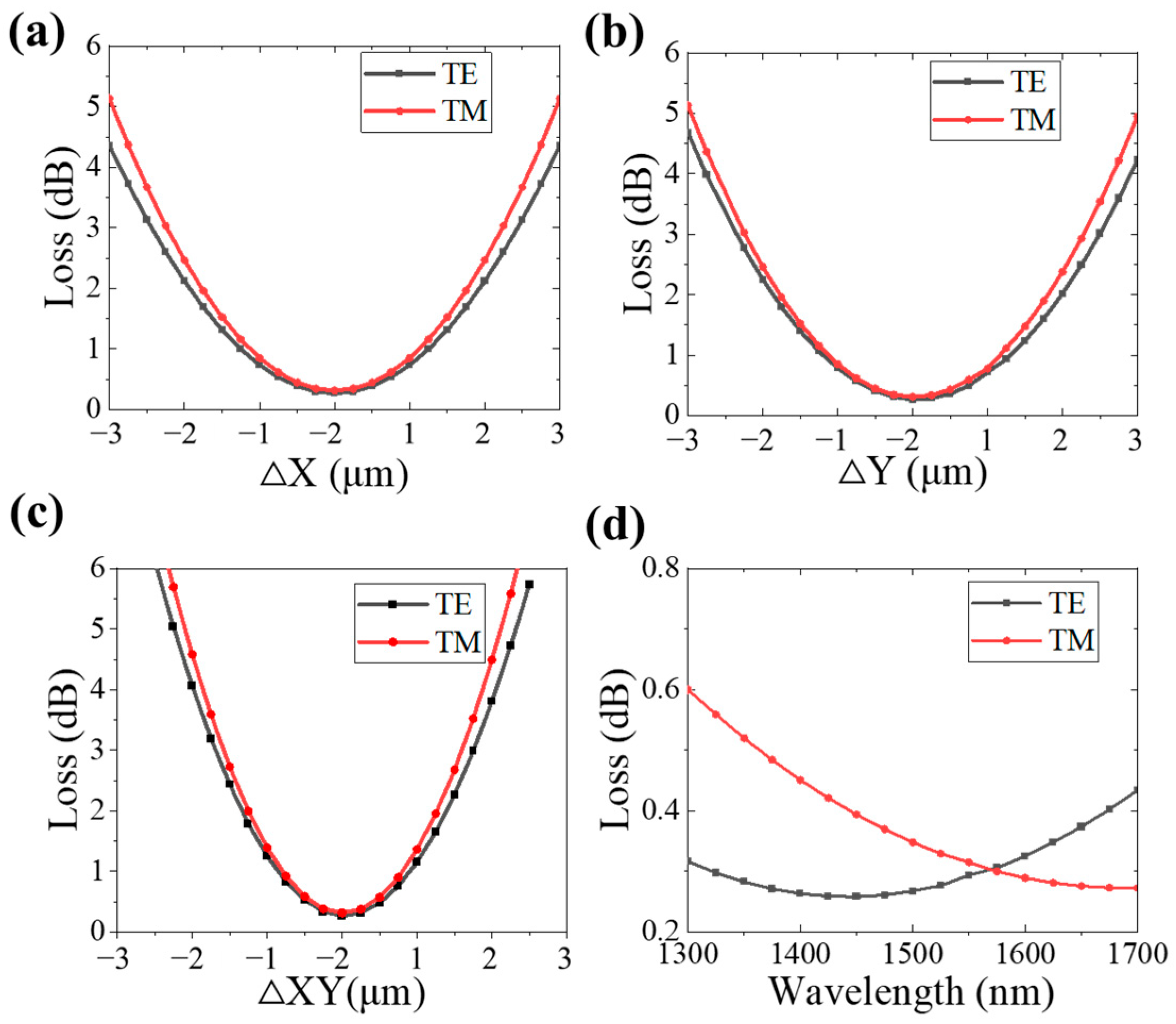

2.3. Modeling Results

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiang, C.; Jin, W.; Bowers, J.E. Silicon nitride passive and active photonic integrated circuits: Trends and prospects. Photonics Res. 2022, 10, A82–A96. [Google Scholar] [CrossRef]

- Bauters, J.F.; Heck, M.J.; John, D.; Tien, M.C.; Li, G.; Barton, J.S.; Leinse, A.; Heideman, R.G.; Blumenthal, D.J.; Bowers, J.E. Silicon on ultra-low-loss waveguide photonic integration platform. Opt. Express 2013, 21, 544–555. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, R.; Lacava, C.; Bianchi, G.M.; Ramirez, J.M.; Vezzoni, M.; Fontana, G.; Minkov, A.; Frigerio, J.; Carbone, L.; Galli, M.; et al. Coupling strategies for silicon photonics integrated chips. Photonics Res. 2019, 7, 201–239. [Google Scholar] [CrossRef]

- Mu, X.; Zhuang, L.; Fan, Y.; Hoekman, M.; Leinse, A.; Roeloffzen, C.G. Edge couplers in silicon photonic integrated circuits: A review. Appl. Sci. 2020, 10, 1538. [Google Scholar] [CrossRef]

- Bhandari, B.; Shrestha, S.; Khanna, R.; McKinney, J.R.; Zhou, W. Compact and broadband edge coupler based on multi-stage silicon nitride tapers. IEEE Photon. J. 2020, 12, 1–11. [Google Scholar] [CrossRef]

- Suchoski, P.; Ramaswamy, R. Design of single-mode step-tapered waveguide sections. IEEE J. Quantum Electron. 1987, 23, 205–211. [Google Scholar] [CrossRef]

- Dewanjee, A.; Rahman, A.B.M.; Poletti, F.; Rahman, M.S.; Sessions, N.P. Demonstration of a compact bilayer inverse taper coupler for Si-photonics with enhanced polarization insensitivity. Opt. Express 2016, 24, 28194–28203. [Google Scholar] [CrossRef]

- Kruse, K.; Middlebrook, C.T. Polymer taper bridge for silicon waveguide to single mode waveguide coupling. Opt. Commun. 2016, 362, 87–95. [Google Scholar] [CrossRef]

- Doylend, J.K.; Knights, A.P. Design and simulation of an integrated fiber-to-chip coupler for silicon-on-insulator waveguides. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 1363–1370. [Google Scholar] [CrossRef]

- Voigt, K.; Brulis, V.; Petermann, K.; Zimmermann, L. Study of backend waveguide arrays for adiabatic coupling to Si waveguides. In Proceedings of the 2017 IEEE 14th International Conference on Group IV Photonics (GFP), Berlin, Germany, 23–25 August 2017; pp. 143–144. [Google Scholar]

- Holly, R.; Tönshoff, P.; Völkel, R.; Herzig, H.P. Fabrication of silicon 3D taper structures for optical fibre to chip interface. Microelectron. Eng. 2007, 84, 1248–1251. [Google Scholar] [CrossRef]

- Shiraishi, K.; Takahashi, S.; Ishikawa, Y.; Yamashita, K. A silicon-based spot-size converter between single-mode fibers and Si-wire waveguides using cascaded tapers. Appl. Phys. Lett. 2007, 91, 141112. [Google Scholar] [CrossRef]

- Fang, Q.; Song, J.; Ding, J.F.; Lo, G.Q.; Kwong, D.L. Suspended optical fiber-to-waveguide mode size converter for silicon photonics. Opt. Express 2010, 18, 7763–7769. [Google Scholar] [CrossRef]

- Chen, L.; Doerr, C.R.; Chen, Y.-K.; Liow, T.Y. Low-loss and broadband cantilever couplers between standard cleaved fibers and high-index-contrast Si3N4 or Si waveguides. IEEE Photon. Technol. Lett. 2010, 22, 1744–1746. [Google Scholar] [CrossRef]

- Fang, Q.; Song, J.; Wu, H.; Lo, G.-Q.; Kwong, D.-L. Mode-size converter with high coupling efficiency and broad bandwidth. Opt. Express 2011, 19, 21588–21594. [Google Scholar] [CrossRef] [PubMed]

- Shiu, W.; Vacar, J.; Yu, H.; Choi, T.; Rossel, C. Advanced self-aligned double patterning development for sub-30-nm DRAM manufacturing. Opt. Microlithogr. XXII SPIE 2009, 7274, 72743U. [Google Scholar]

- Chen, R.; Li, Y.C.; Cai, J.M.; Cao, K.; Lee, H.B.R. Atomic level deposition to extend Moore’s law and beyond. Int. J. Extrem. Manuf. 2020, 2, 022002. [Google Scholar] [CrossRef]

- Rim, K. Strained Si CMOS (SS CMOS) technology: Opportunities and challenges. Solid-State Electron. 2003, 47, 1133–1139. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Papes, M.; Hsieh, M.; Chrostowski, L.; Shekhar, S. Fiber-chip edge coupler with large mode size for silicon photonic wire waveguides. Opt. Express 2016, 24, 5026–5038. [Google Scholar] [CrossRef]

- Xu, L.H.; Shi, Y. Ultra-compact polarization-independent directional couplers utilizing a subwavelength structure. Opt. Lett. 2017, 42, 5202–5205. [Google Scholar] [CrossRef] [PubMed]

- Halir, R.; Bock, P.J.; Cheben, P.; Ortega-Moñux, A.; Alonso-Ramos, C.; Schmid, J.H.; Lapointe, J.; Xu, D.-X.; Wangüemert-Pérez, J.G.; Molina-Fernández, I.; et al. Waveguide sub-wavelength structures: A review of principles and applications. Laser Photonics Rev. 2015, 9, 25–49. [Google Scholar] [CrossRef]

- Zhu, X.; Li, G.; Wang, X.; Li, Y.; Davidson, R.; Little, B.E.; Chu, S.T. Low-loss fiber-to-chip edge coupler for silicon nitride integrated circuits. Opt. Express 2023, 31, 10525–10532. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, Y.; Cao, X.; Wang, L.; Mu, C.; Li, M.; Zhu, N.; Chen, W. High-Efficiency and Compact Polarization-Insensitive Multi-Segment Linear Silicon Nitride Edge Coupler. Photonics 2023, 10, 510. [Google Scholar] [CrossRef]

- Mu, X.; Wu, S.; Cheng, L.; Tu, X.; Fu, H.Y. A Compact Adiabatic Silicon Photonic Edge Coupler Based on Silicon Nitride/Silicon Trident Structure. In Proceedings of the 2019 18th International Conference on Optical Communications and Networks (ICOCN), Huangshan, China, 5–8 August 2019; pp. 1–3. [Google Scholar]

- Sun, S.; Chen, Y.; Sun, Y.; Liu, F.; Cao, L. Novel Low-Loss Fiber-Chip Edge Coupler for Coupling Standard Single Mode Fibers to Silicon Photonic Wire Waveguides. Photonics 2021, 8, 79. [Google Scholar] [CrossRef]

| Device Structure | Coupling Loss TE/TM | PDL | MFD | 3dB Tolerance | Waveguide Type | Experiment |

|---|---|---|---|---|---|---|

| Inverse taper [5] | 0.36/0.56 dB | 0.2 dB | 4 μm | ±1.75 μm | 500 nm Si3N4 | Yes |

| Multiple-taper design [7] | 1.5/2 dB | 1 dB | 5 μm | Not shown | 220 nm Silicon | Yes |

| Silica glass waveguide [23] | 0.6/0.8 dB | 0.2 dB | 10.4 μm | ±4.5 μm | 750 nm Si3N4 | Yes |

| Multi-Segment Inverse-taper [24] | 0.22/0.31 dB | 0.09 dB | 3.2 um | ±1.4 μm | 400 nm Si3N4 | No |

| Trident layers [25] | 0.91 dB (TE) | / | 3.2 um | Not shown | 400 nm Si3N4 | No |

| Multiple layer structure [26] | 0.62/0.44 dB | 0.25 dB | 8.2 μm | Not shown | 220 nm Silicon | No |

| This work | 0.29/0.31 | 0.02 dB | 6 μm | ±2.5 μm | 400 nm Si3N4 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Fu, X.; Zhang, L.; Han, Z. Modeling Dual-SiOxN Thin-Film Edge Coupler with Ultra-Low Loss and Large Alignment Tolerance. Photonics 2025, 12, 136. https://doi.org/10.3390/photonics12020136

Chen Z, Fu X, Zhang L, Han Z. Modeling Dual-SiOxN Thin-Film Edge Coupler with Ultra-Low Loss and Large Alignment Tolerance. Photonics. 2025; 12(2):136. https://doi.org/10.3390/photonics12020136

Chicago/Turabian StyleChen, Zhaozhen, Xin Fu, Lei Zhang, and Zhengsheng Han. 2025. "Modeling Dual-SiOxN Thin-Film Edge Coupler with Ultra-Low Loss and Large Alignment Tolerance" Photonics 12, no. 2: 136. https://doi.org/10.3390/photonics12020136

APA StyleChen, Z., Fu, X., Zhang, L., & Han, Z. (2025). Modeling Dual-SiOxN Thin-Film Edge Coupler with Ultra-Low Loss and Large Alignment Tolerance. Photonics, 12(2), 136. https://doi.org/10.3390/photonics12020136