Optical Fiber Sensing Technology for Sports Monitoring: A Comprehensive Review

Abstract

1. Introduction

2. Basic Principles and Main Types of Optical Fiber Sensing Technology for Sports Performance Monitoring

2.1. Fiber Bragg Grating Sensors

- First, cross-sensitivity between strain and temperature considerably impairs measurement accuracy. Since FBGs are responsive to both temperature and strain—which often vary simultaneously in athletic settings—signal aliasing occurs, making it difficult to distinguish physiological or mechanical signals from environmental thermal noise. Conventional FBGs exhibit a temperature sensitivity of approximately 10 pm/ [27]. In outdoor sports with substantial ambient temperature fluctuations, such as marathons and skiing, temperature variations can induce wavelength shifts exceeding 200 pm, severely interfering with strain signal interpretation. Although reference grating methods or dual-parameter matrix decoupling can be employed, these approaches increase system complexity and cost, and their real-time performance under dynamic conditions remains suboptimal [28,29].

- Second, FBG sensors are prone to nonlinear responses during high-dynamic-range and large-amplitude movements (e.g., weightlifting or jumping). When strain exceeds 5000 , nonlinear material behavior, encapsulation slippage, and changes in the photoelastic effect [30] may cause the wavelength–strain relationship to deviate from linearity, reducing measurement accuracy and often necessitating complex calibration or algorithmic compensation.

- Third, the multiplexing capability and associated costs of FBG systems limit their scalability. Although WDM is supported, the number of sensors that can be practically multiplexed is constrained by the source bandwidth and the dynamic range of the demodulator. Typically, only several dozen sensors can be serially connected along a single fiber, making large-scale multi-point monitoring challenging. Moreover, high-speed and high-precision demodulation equipment is expensive, and installation and calibration require specialized personnel, hindering widespread adoption in community or amateur sports settings [31].

- Finally, packaging reliability and long-term stability present important challenges. Packaging structures—including adhesive layers and substrate materials—may degrade or fail under repeated mechanical stress, sweat exposure, and fluctuations in temperature and humidity [32]. Additionally, fully bonded encapsulation is susceptible to stress concentration, leading to spectral broadening or chirping, which compromises measurement linearity and reliability [33,34].

2.2. Distributed Optical Fiber Sensors

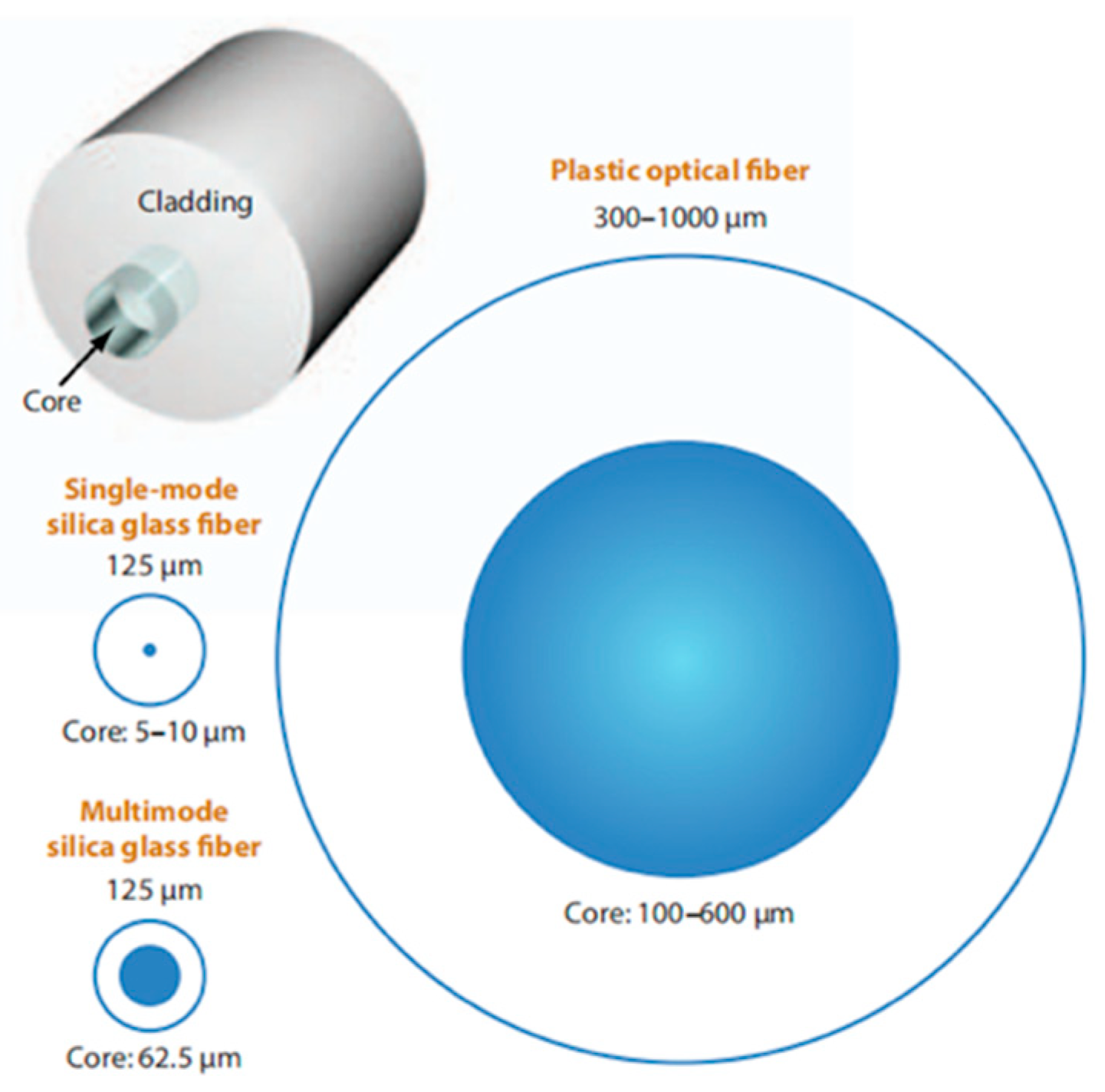

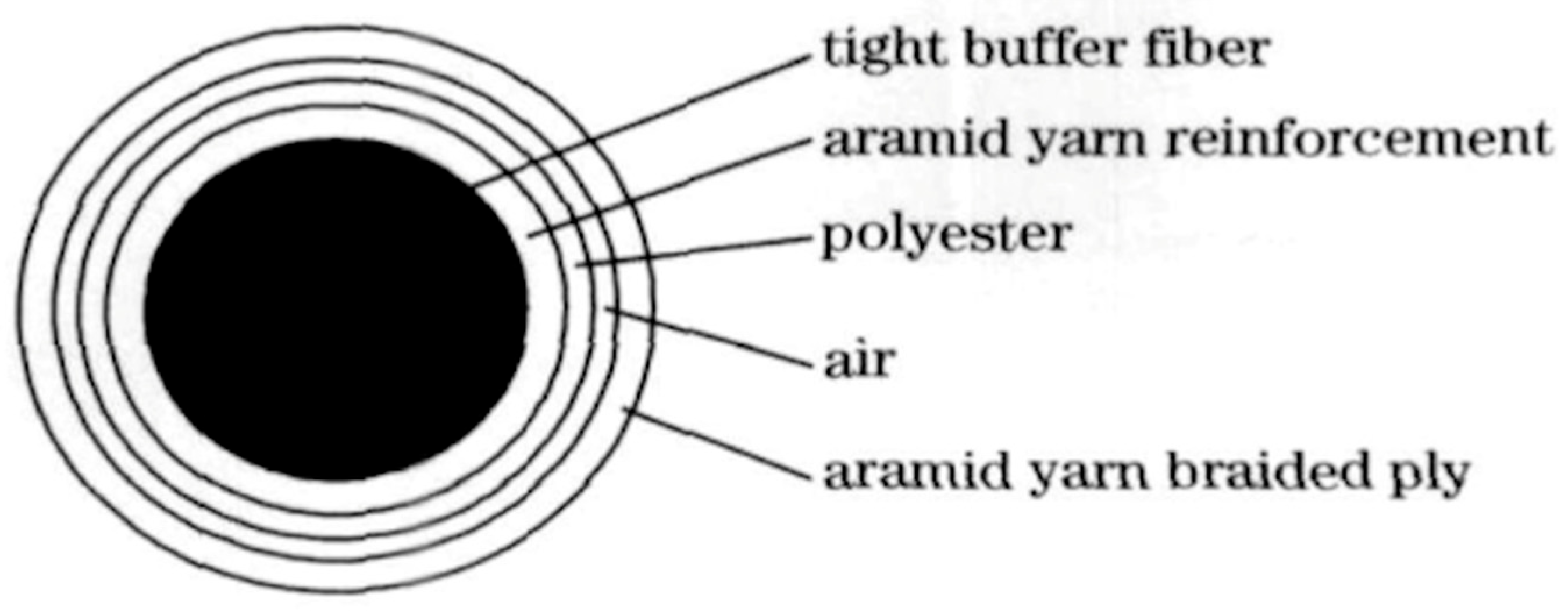

2.3. Polymer Optical Fiber Sensors

- Immunity to Interference: Optical fibers are fabricated from dielectric materials (e.g., silica, polymers), rendering them immune to electromagnetic fields. This allows stable operation in complex athletic environments—such as those with high humidity, low temperatures, or strong electromagnetic interference—making them particularly suitable for winter sports, aquatic events, and other challenging conditions [16,23].

- High Sensitivity and Real-Time Capability: These sensors exhibit high responsiveness to minute physical changes, enabling high-precision data acquisition essential for detailed sports technique analysis.

- Multi-Parameter Sensing and Multiplexing Capability: A single optical fiber can incorporate multiple sensors (e.g., an array of FBGs) to enable synchronous monitoring of multiple body segments. Different types of sensors can also be integrated into a unified system, allowing simultaneous acquisition of biomechanical and physiological parameters such as temperature, strain, and vital signs [9,21,22].

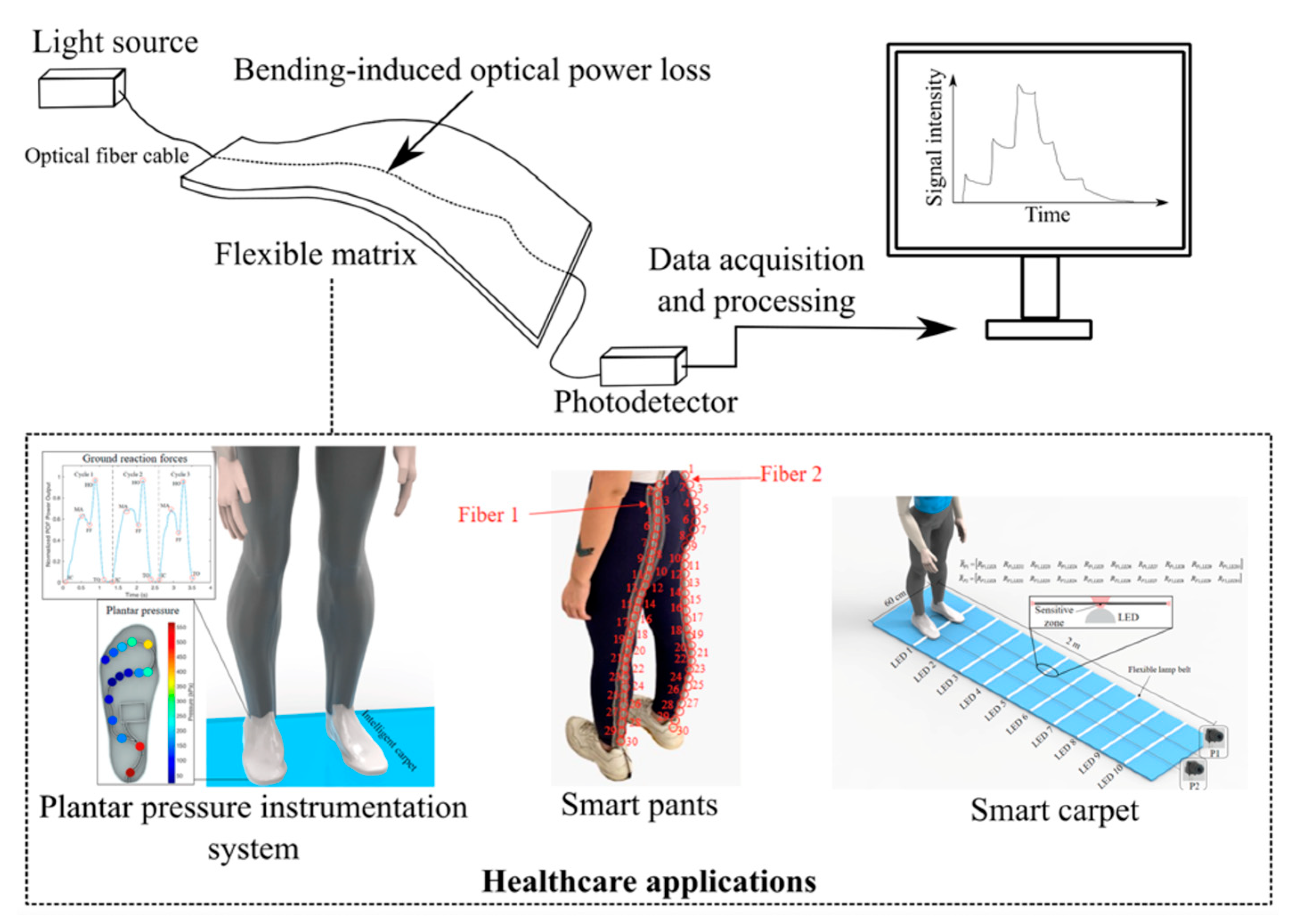

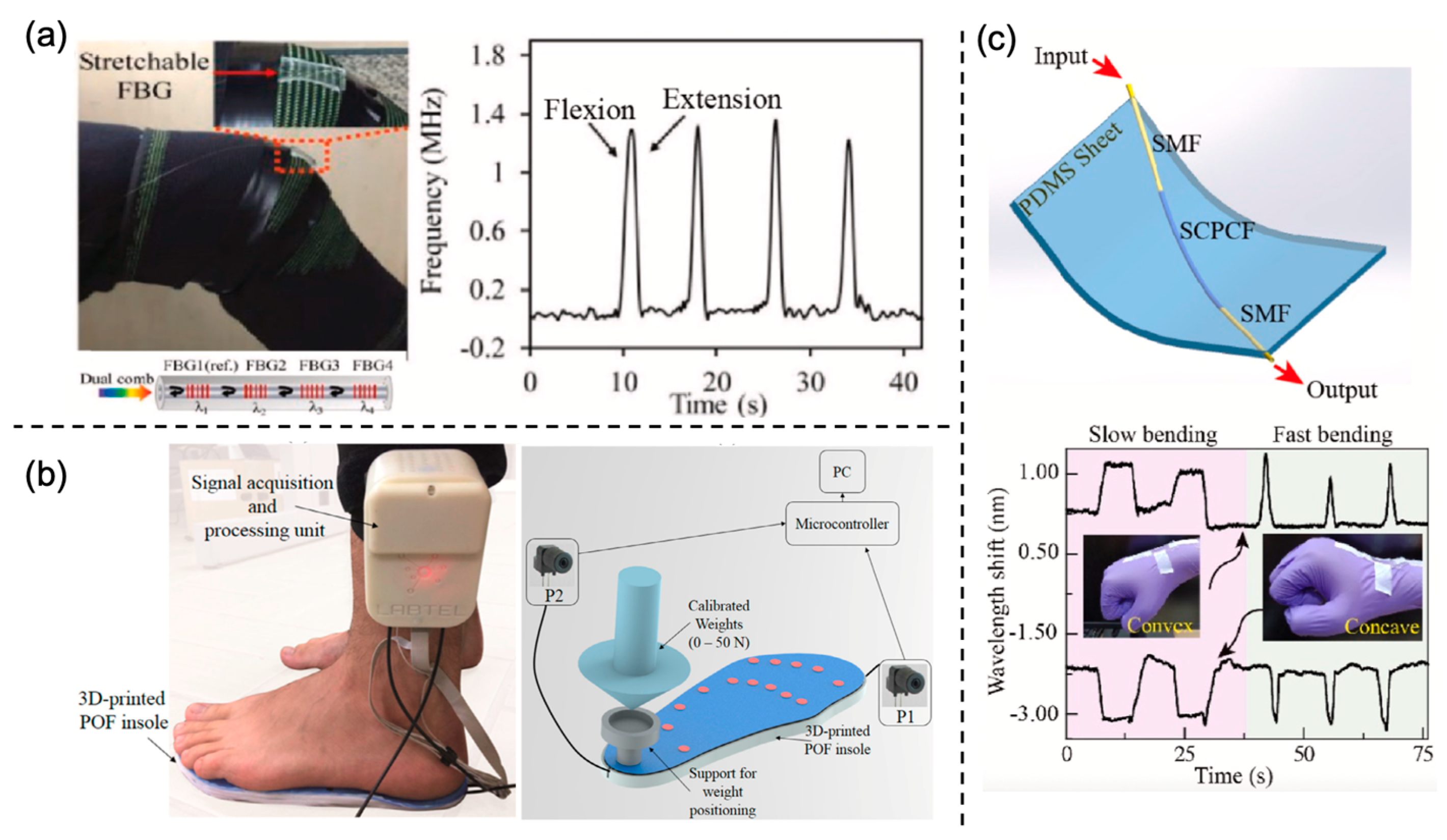

- Lightweight and Wearable Design: Optical fiber sensors are inherently lightweight and can be seamlessly embedded into textiles, significantly minimizing impediments to athlete movement. Figure 5 illustrates the monitoring of human kinetics and scientific analysis employing diverse response or sensing principles.

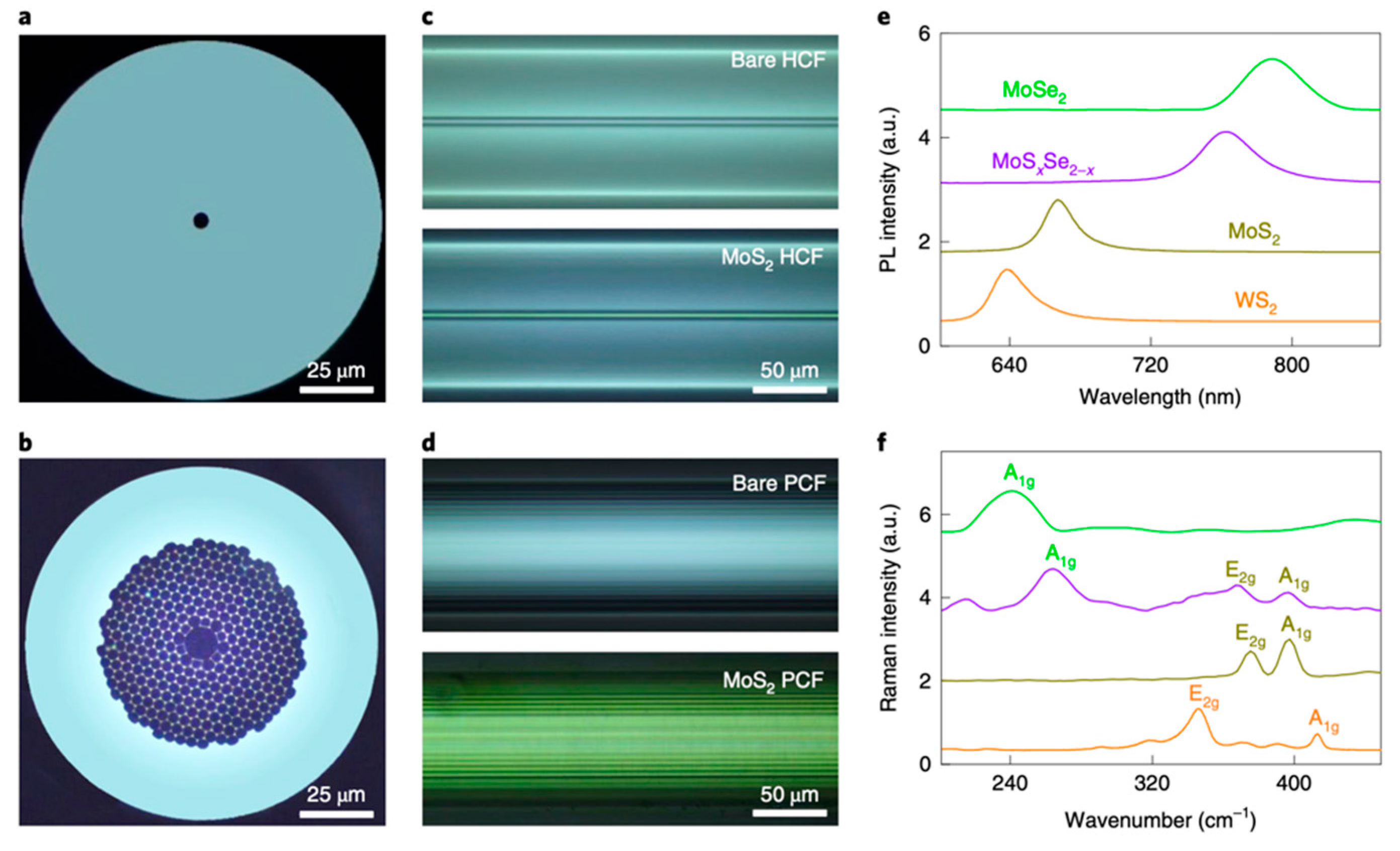

2.4. Innovative Applications of Two-Dimensional Material Integrated Optical Fibers

- Direct Growth Methods: This approach involves the in situ growth of 2D materials directly on optical fiber substrates—such as end faces, sidewalls, or within the channels of microstructured optical fibers—using techniques like chemical vapor deposition (CVD) or atomic layer deposition (ALD). The resulting material–fiber interface exhibits strong adhesion and low optical loss, which can be reduced to approximately 0.1 dB/cm. Furthermore, the significantly increased interaction length greatly enhances nonlinear optical effects, such as signal amplification by up to 300-fold, and improves sensing sensitivity [60]. This method is particularly suitable for highly sensitive distributed or point-based biochemical sensing and intracavity laser sensing.

- Transfer-Coating Method: In this method, Pre-synthesized 2D materials—in the form of thin films or nanosheet dispersions on separate substrates—are integrated onto fiber surfaces, such as grating regions, tapered zones, or D-shaped areas, via wet transfer, dry transfer, or direct coating/spin-coating techniques. This process offers greater flexibility and facilitates integration with various types of optical fibers, including flexible POF. It is well-suited for the development of wearable sensors for strain, pressure, and biochemical detection [10,59].

- Optical Field Localization and Enhancement: The high refractive index and atomic-level thickness of these materials effectively enhance the evanescent field of optical fibers, thereby improving the sensitivity of surface-based sensing schemes, such as surface plasmon resonance (SPR) and microring resonators [57,75].

- Multifunctional Sensing Mechanisms: The intrinsic properties of 2D materials—including optical characteristics such as absorption, fluorescence, and nonlinear coefficients; electrical properties such as resistance and capacitance; and mechanical properties—exhibit high sensitivity to external stimuli such as strain, molecular adsorption, and temperature. These responsive properties provide diverse pathways for signal modulation in fiber-optic sensors [58,59].

- Mechanical Reinforcement: The incorporation of high-strength materials, such as graphene, improves the durability and fatigue resistance of optical fibers, particularly polymer optical fibers, making them suitable for applications involving repeated deformation, such as those encountered in sports monitoring.

- Biocompatibility and Functionalization: Some 2D materials, including GO, exhibit good biocompatibility and possess abundant surface functional groups. These features facilitate specific biomolecular modifications, thereby extending their applicability to physiological parameter monitoring [75].

- Firstly, fabrication and integration processes: Large-scale, high-quality preparation and low-damage, high-strength integration with complex fiber structures (e.g., microstructured fiber channels, tapered regions) remain difficult. The high-temperature environment of CVD may be incompatible with the thermal properties of polymer optical fibers, causing substrate deformation or performance degradation. Transfer coating methods can easily introduce contamination, wrinkles, or cracks, increasing interfacial losses and affecting the sensor’s mechanical stability and optical performance consistency [60,77].

- Secondly, inherent material limitations: The zero-bandgap nature of graphene can lead to high dark current and low on/off ratio, affecting the signal-to-noise ratio; the carrier mobility of TMDs (e.g., MoS2) in practical devices may be lower than theoretical values due to defects and interface scattering, limiting response speed; the environmental stability of materials like black phosphorus (BP) is poor, as they are prone to degradation under humid, hot, or illuminated conditions, compromising their reliability for outdoor sports or long-term monitoring [78].

- Furthermore, temperature cross-sensitivity: Fluctuations in ambient temperature can easily interfere with the accurate measurement of target parameters like strain and pressure, necessitating complex decoupling algorithms or compensation mechanisms [79].

- Finally, practical application bottlenecks: Most research remains at the laboratory proof-of-concept stage. The durability, repeatability, cost-effectiveness of large-scale preparation, and integration methods with conventional sports equipment require further in-depth study. There is still a considerable distance to go before large-scale application in real sports scenarios becomes feasible [80,81].

3. Core Applications of Optical Fiber Sensing Technology in Sports Monitoring

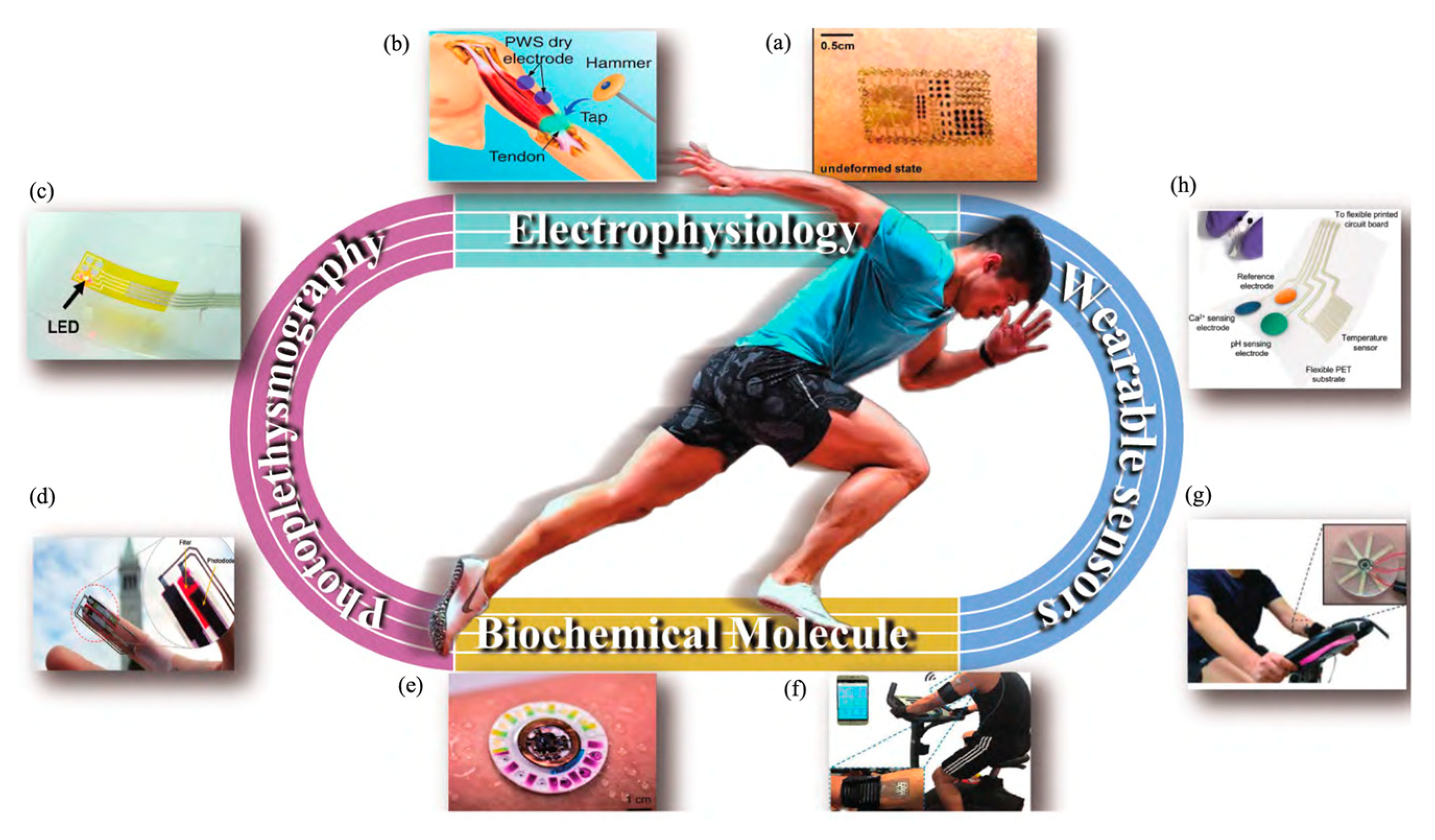

3.1. Monitoring of Human Physiological Parameters

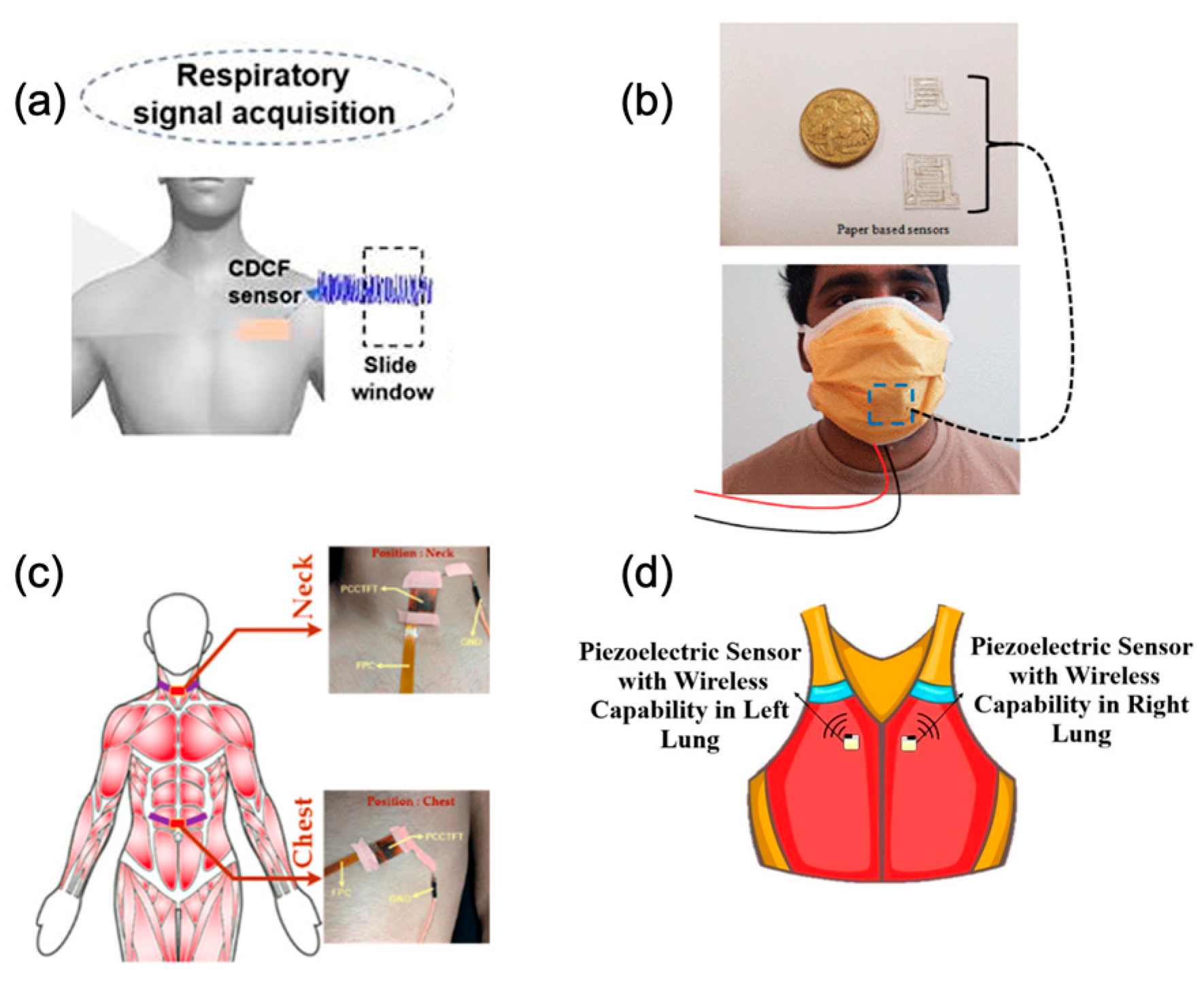

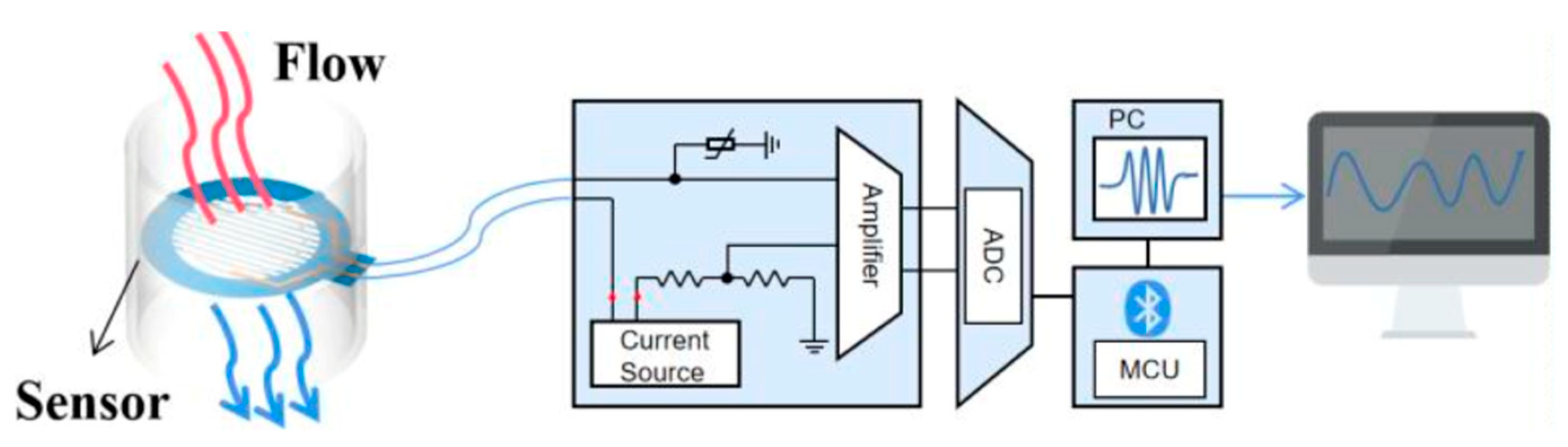

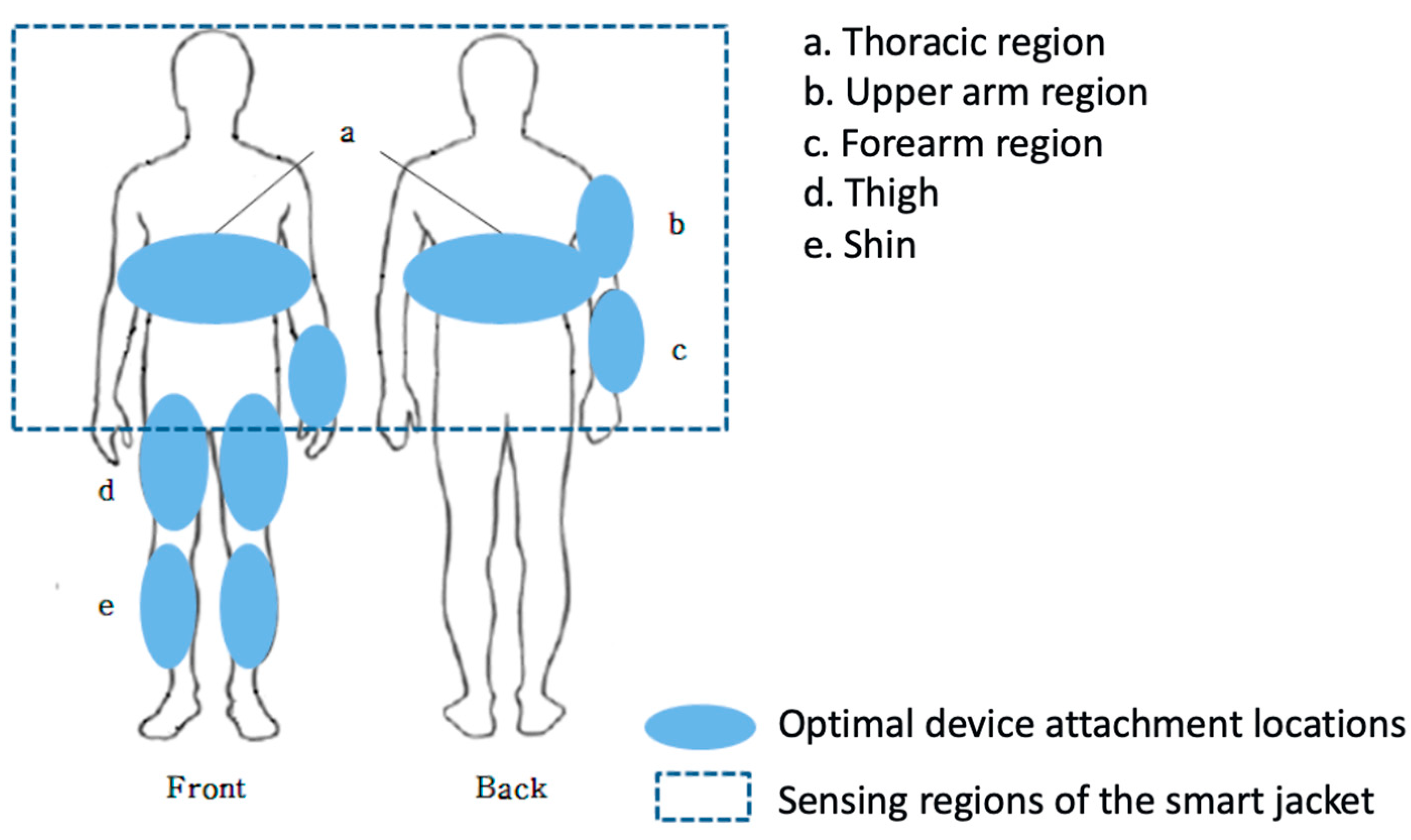

- Respiratory Monitoring: An array of FBG sensors embedded in an elastic belt or vest monitors strain variations in thoracic and abdominal circumference induced by respiration, from which respiratory frequency and depth can be derived. This approach offers notable advantages, including strong resistance to interference—making it suitable for swimming and electromagnetic environments—excellent conformity to the body, and higher accuracy compared to piezoresistive sensors [86,87], Figure 8 presents a schematic diagram of the respiratory sensor interfaced with the measurement circuit and a personal computer (PC). Integrated FBG textiles have been demonstrated for respiratory rate detection, while 3D-printed encapsulation enhances wearing comfort. An alternative low-cost strategy involves POF combined with smartphone camera-based detection of respiratory waveforms. A high-performance example is the Light Lace chest strap, which measures intensity changes in optical fiber under stretching to simultaneously determine maximal oxygen uptake (VO2max), ventilation volume, and respiratory rate. This system achieves a sampling rate ten times faster than electronic sensors and remains unaffected by sweat [87].

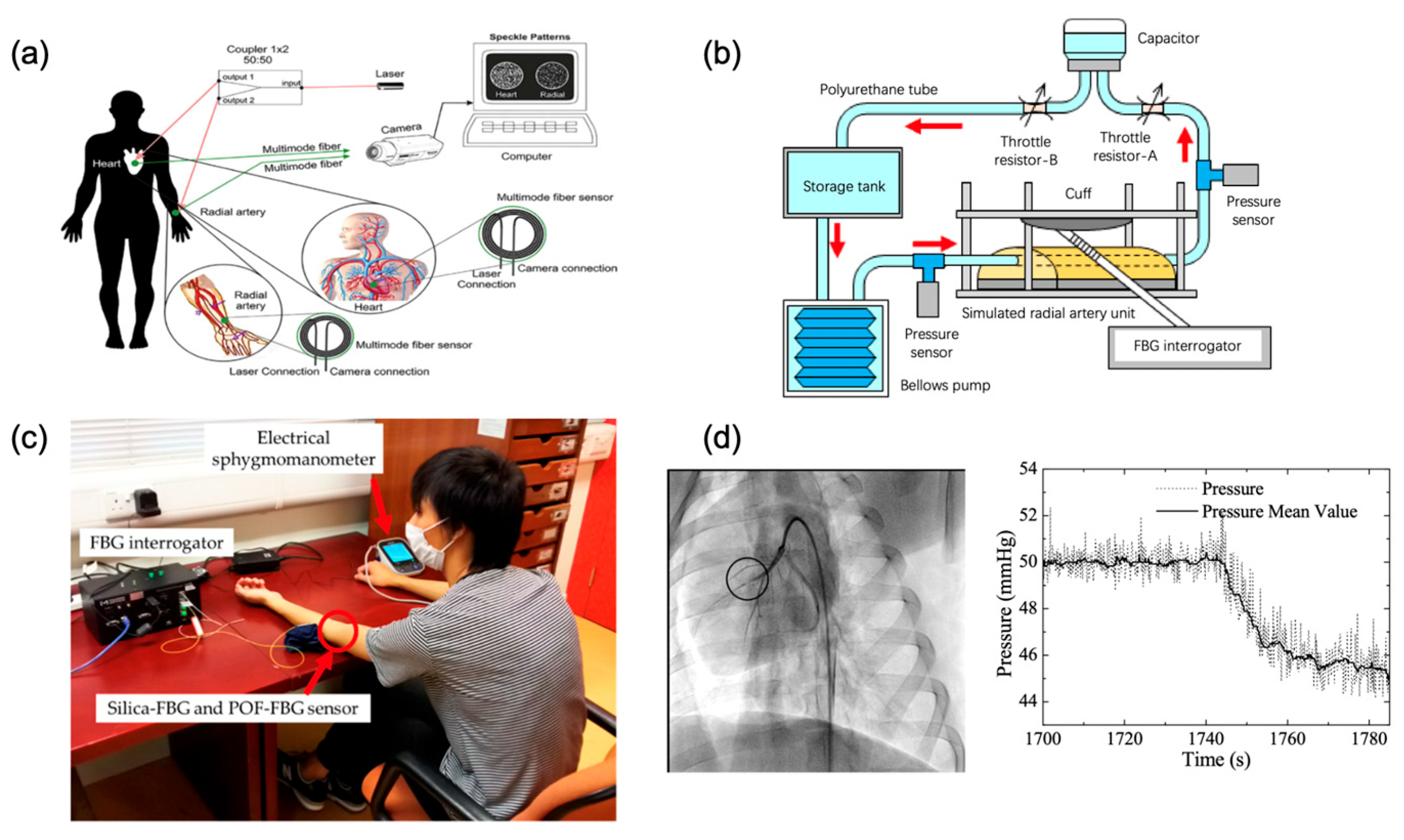

- Cardiovascular Monitoring: FBG or POF-based wristbands can monitor heart rate and radial arterial pulse waveforms. By employing signal processing algorithms, such as wavelet denoising and feature point extraction, in combination with physiological models, blood pressure can be estimated with an error margin of less than 5.8 mmHg. A system with superior performance incorporates a graphene-PDMS optical fiber wristband that derives blood pressure from radial artery pulse waveforms, achieving a deviation of approximately 2 mmHg. Figure 9 demonstrates selected practical application cases based on fiber-optic blood pressure monitoring technology. This method is further enhanced by wavelet denoising algorithms to improve robustness [99,100]. It is noteworthy that anti-interference signal processing strategies developed for FBG-based non-invasive fetal heart rate monitoring [90] offer valuable insights for enhancing the robustness of pulse wave monitoring in dynamic conditions, such as during physical activity in pregnant women.

- Temperature and Humidity Monitoring: Body Temperature Monitoring: Microfiber optic sensors encapsulated with PDMS, which exhibit a sensitivity of approximately 0.02 dBm/, are utilized for dynamic skin temperature monitoring and early warning of heat stress. Distributed FBG sensor networks integrated into smart garments enable temperature measurement through multi-point weighted averaging, achieving an accuracy of 0.2 °C [84,85]. The PDMS coating enhances adhesion to the skin and improves temperature measurement precision to 0.1 °C. Relevant developments include a Mach–Zehnder interferometer-based temperature sensor developed by Wang et al. for real-time body temperature monitoring during tumor thermotherapy, as well as a stretchable polymer optical fiber temperature sensor fabricated by Guo et al. [101]. Humidity Monitoring: Optical fibers functionalized with specialized coatings such as polyacrylamide hydrochloride/silica (PAH/SiO2) have been deployed to monitor humidity levels within sportswear. These sensors demonstrate a sensitivity of 3.02 mV/%RH, enabling accurate comparison of the moisture-wicking properties between cotton and polyester fabrics and facilitating objective evaluation of textile moisture management performance [82].

- Metabolite and Biochemical Indicator Monitoring: Fiber-optic sensor-based optical wearables also enable non-invasive monitoring of biochemical indicators in biofluids such as sweat, saliva, and tears [102]. Such monitoring facilitates the optimization of fitness regimens and daily activities. Recent developments include photonically intelligent bandages capable of simultaneously measuring pressure and pH levels in wound areas to assess healing progress. Meanwhile, sweat lactate detection remains primarily confined to laboratory-scale investigations [103].

- Multi-Parameter Simultaneous Monitoring: Optical fiber systems integrating piezoelectric sensing principles demonstrate the potential for synchronized non-invasive monitoring of multiple vital signs, such as heart rate and respiratory activity [100,104]. This capability provides a more comprehensive dataset for integrated physiological status assessment during physical exercise.

3.2. Monitoring of Biomechanical Parameters

3.2.1. Muscle Activity and Vibration Monitoring

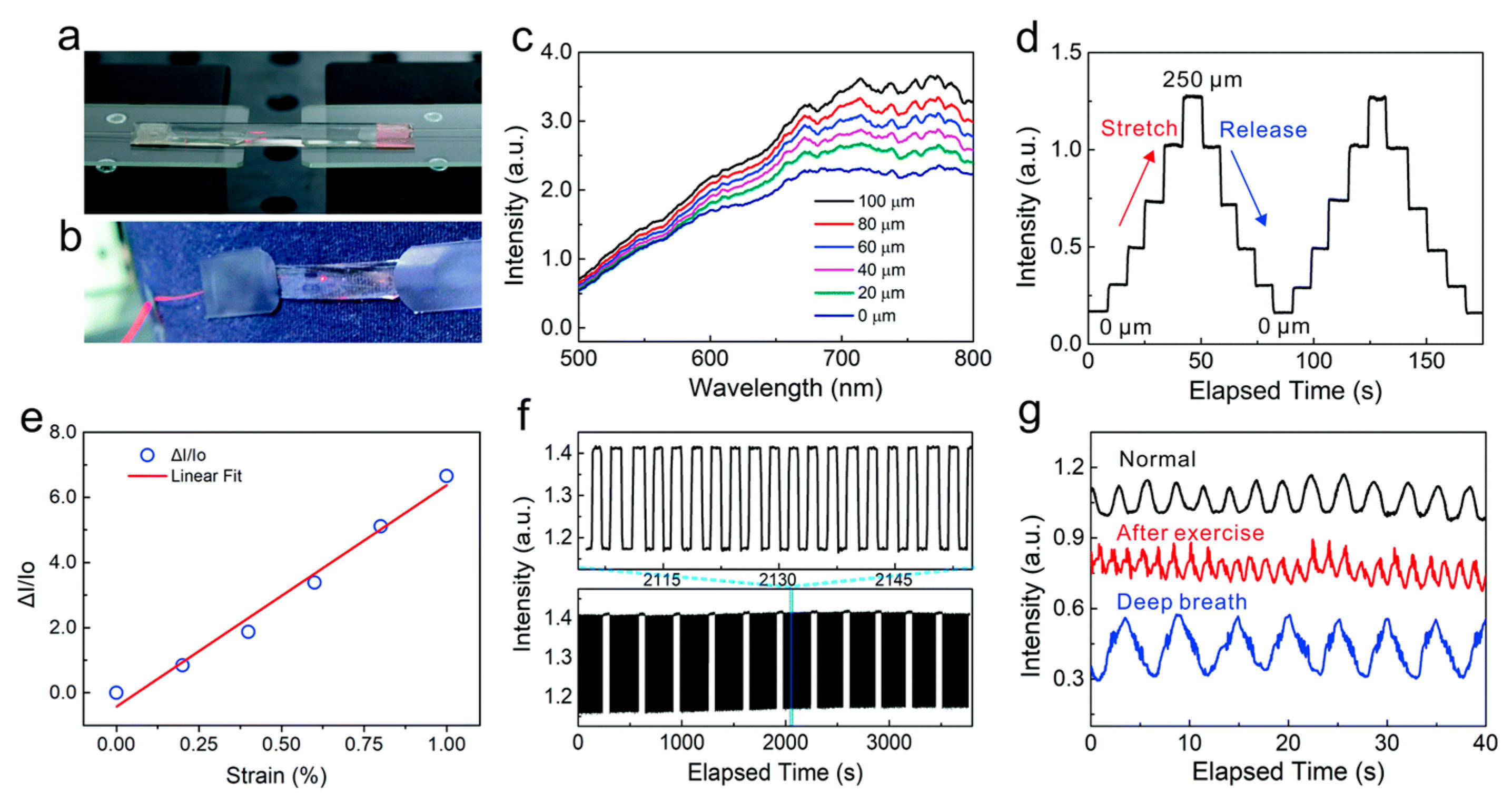

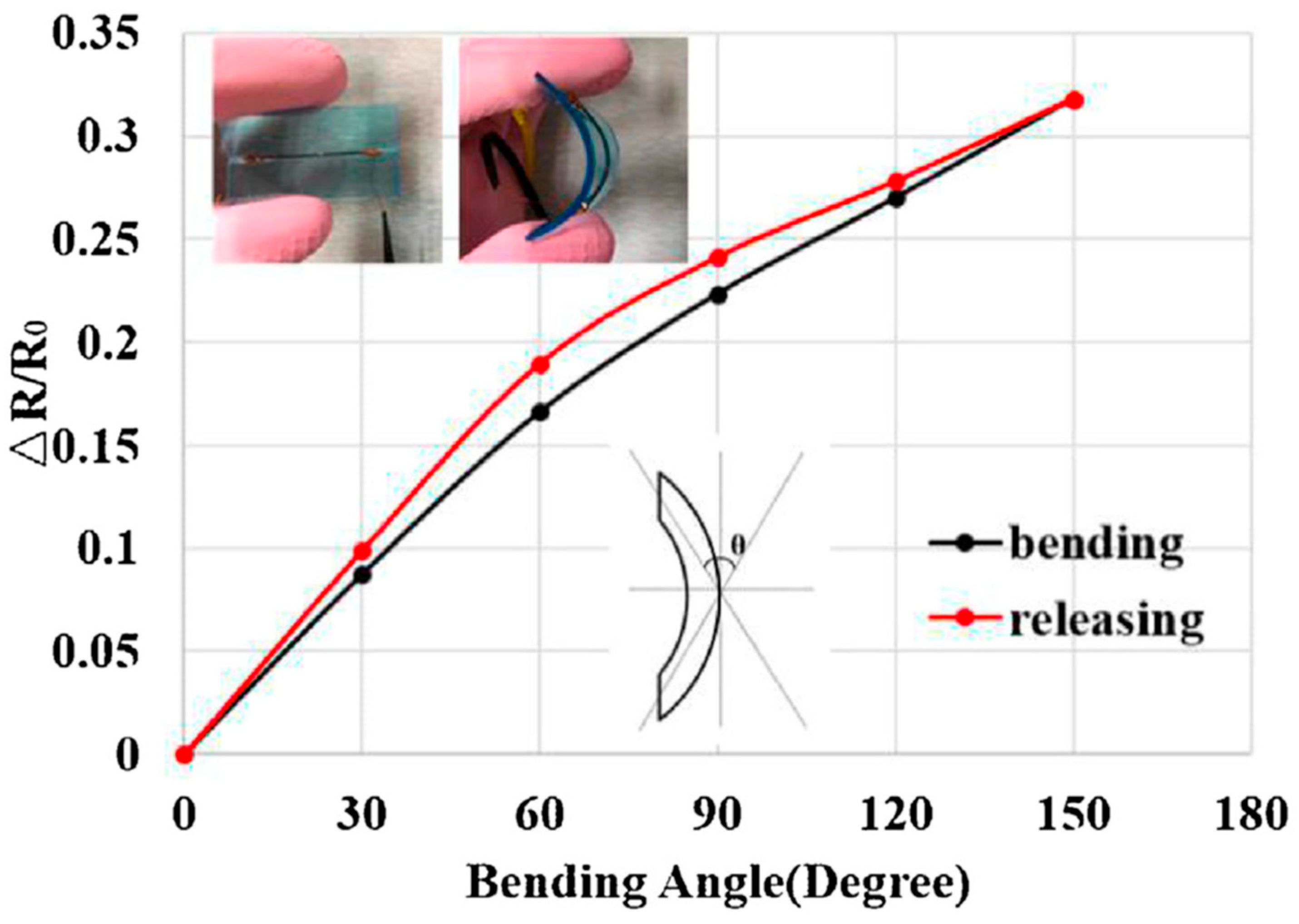

- Fiber-Optic Strain Sensing: As the core technique for directly monitoring contractile deformation, this method involves attaching highly elastic optical fibers—such as silicone-encapsulated or specialized polymer optical fibers—along the direction of muscle fibers on the skin surface. During muscle contraction, expansion of the muscle belly or increased tendon tension induces slight stretching or bending of the optical fiber. As illustrated in Figure 10, this mechanical deformation alters the internal light transmission characteristics, manifesting as optical power loss, wavelength shift, or mode coupling. Quantification of muscle contraction magnitude and dynamics is achieved by demodulating these optical variations [105]. Fiber-Optic Vibration Sensing (Based on Acceleration Principle): Muscle contraction or fatigue can generate subtle vibrations, such as muscle sound or mechanomyographic signals. Optical fiber sensors exhibit high acceleration sensitivity and can detect these minute vibrations when fixed on the muscle surface. Vibratory accelerations induce corresponding strain or phase modulation within the optical fiber, which is subsequently demodulated. This signal enables analysis of muscle activation patterns, coordination, and potential fatigue states.

- Photoplethysmography (PPG): PPG utilizes infrared light directed into subcutaneous tissue and detects variations in transmitted or reflected light intensity to assess changes in local microvascular blood volume, thereby indirectly evaluating muscle activation status. Given the strong correlation between muscular activity and localized blood flow, multiplexed PPG systems enable synchronous monitoring of activation status, timing, and relative intensity across multiple muscle groups. This provides valuable information for assessing neuromuscular function [83].

- Real-Time Fatigue Metabolite Monitoring: Fiber-optic sensing technology has been extended to the monitoring of exercise-related biochemical markers. For instance, D-shaped optical fiber SPR sensors or tilted fiber Bragg grating (TFBG) sensors can be employed for real-time in situ detection of sweat pH. Furthermore, the integration of optical sensing elements with microfluidic and electrochemical units—such as in sweat lactate sensing patches—enables dynamic and continuous monitoring of key fatigue-related metabolic indicators including glucose, lactate, and electrolytes during exercise [106]. Real-time changes in these biochemical parameters provide direct evidence for evaluating metabolic load, fatigue accumulation, and energy metabolism status under physical exertion.

- Neuromuscular Coordination Assessment: The high sensitivity and flexible nature of optical fiber sensing render it particularly suitable for capturing minute strain generated by fine muscle activities. For instance, flexible patches based on PDMS-encapsulated optical fibers have been developed and attached to the neck to unobtrusively and accurately detect micro-strain, typically less than 5%, induced by laryngeal muscle movement during speech or swallowing. The analysis of such micro-strain dynamics provides a novel methodological framework for quantitatively assessing task-specific neuromuscular control and coordination [105].

- Comprehensive Assessment: Multimodal optical fiber systems, which integrate fiber-optic strain and/or vibration sensing, PPG, and biochemical sensing, are emerging as powerful tools for investigating muscle fatigue mechanisms and conducting functional assessments. By simultaneously acquiring data on mechanical muscle activity—including contraction amplitude, frequency, and vibration spectrum—local hemodynamic responses, and changes in key metabolite concentrations, these systems enable the construction of highly detailed muscular state models. Such integrated capability facilitates accurate identification of fatigue thresholds, evaluation of the efficacy of various training interventions, and early warning of the risk of sports-related injuries.

3.2.2. Joint Angle Monitoring

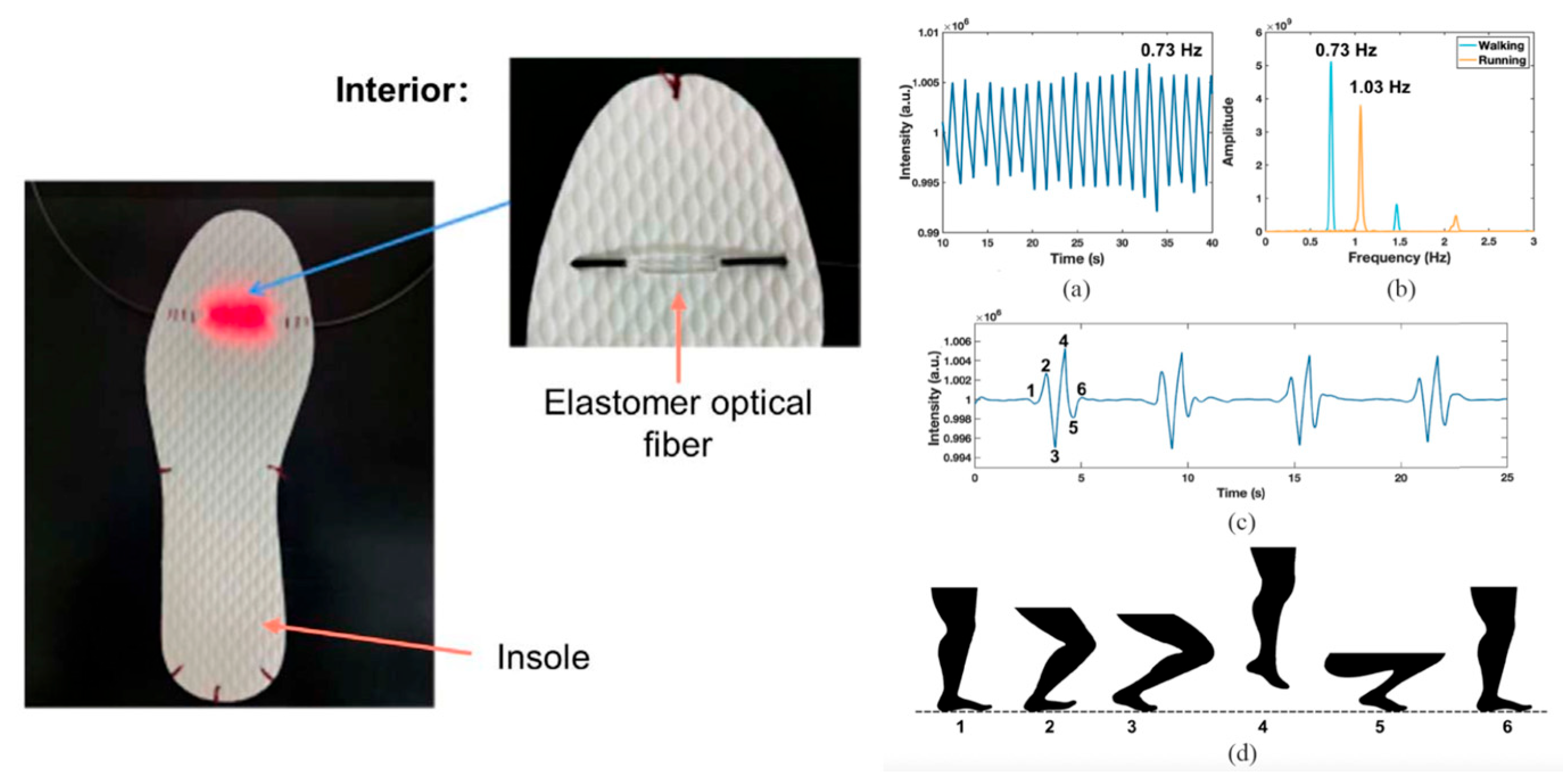

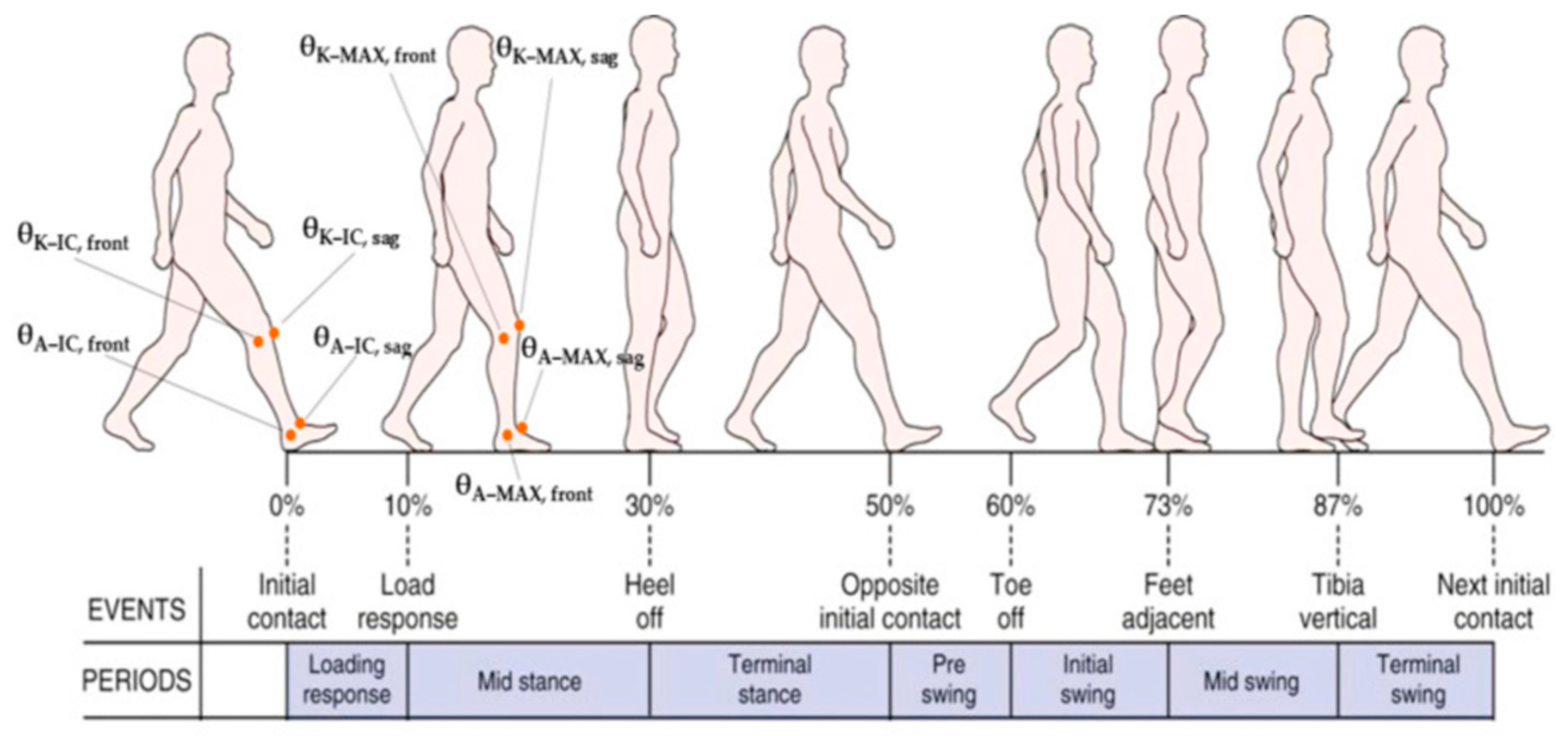

3.2.3. Whole-Body Motion and Gait Analysis

- Trunk Motion: A dual-plane biomechanical model integrated with a sparse array of optical fiber sensors can effectively detect trunk movements including forward flexion, lateral bending, and axial rotation [16]. A more advanced approach, developed by researchers from Chongqing Normal University, combines human pose tracking algorithms with simulated fiber-optic sensor data to achieve real-time three-dimensional reconstruction of body motion [110]. By tracking strain at key skeletal locations, the system translates optical signals into biomechanical parameters such as joint angles and accelerations, achieving an error rate below 2.5% and significantly outperforming conventional image-based analysis methods [110].

- Plantar Pressure Monitoring: Smart insoles integrated with high-density FBG or POF sensor arrays, such as an 8 × 8 grid, enable dynamic pressure distribution mapping with high spatial resolution up to the millimeter level and a sampling rate of 100 Hz [111], as visually demonstrated in Figure 13 [83]. Embedding POF sensors within insoles facilitates dynamic gait analysis with a sensitivity of 0.5 N/cm2 [19].

- Accurate identification of all gait phases including initial contact, stance, and push-off;

- Detection of abnormal gait patterns such as overpronation, supination, and limping;

- Analysis of foot strike patterns and center of pressure trajectory to optimize running form and prevent injuries, for example, issuing alerts when peak pressure exceeds 2.5 times body weight [89];

- Integration with intelligent algorithms and machine learning to analyze spatiotemporal pressure characteristics for early warning of foot pathologies, such as plantar fasciitis and diabetic foot, with recognition rates exceeding 90% [111].

3.3. Integration into Intelligent Sports Equipment and Protective Gear

3.4. Equipment and Environmental Monitoring

- Stress Monitoring: Real-time assessment of load distribution and torsional loads to evaluate equipment performance and structural health [24].

- Damage Warning: Detection of abnormal strain concentrations caused by microcracks—with high localization accuracy via distributed optical sensing—enabling warnings long before damage becomes visually detectable [24].

- Performance Optimization: Analysis of force distribution during rowing via FBG data from oar shafts to guide improvements in carbon fiber layup design, thereby enhancing efficiency and service life [23].

4. Integrated Applications of Optical Fiber Sensing Technology in Athletic Training and Health Monitoring

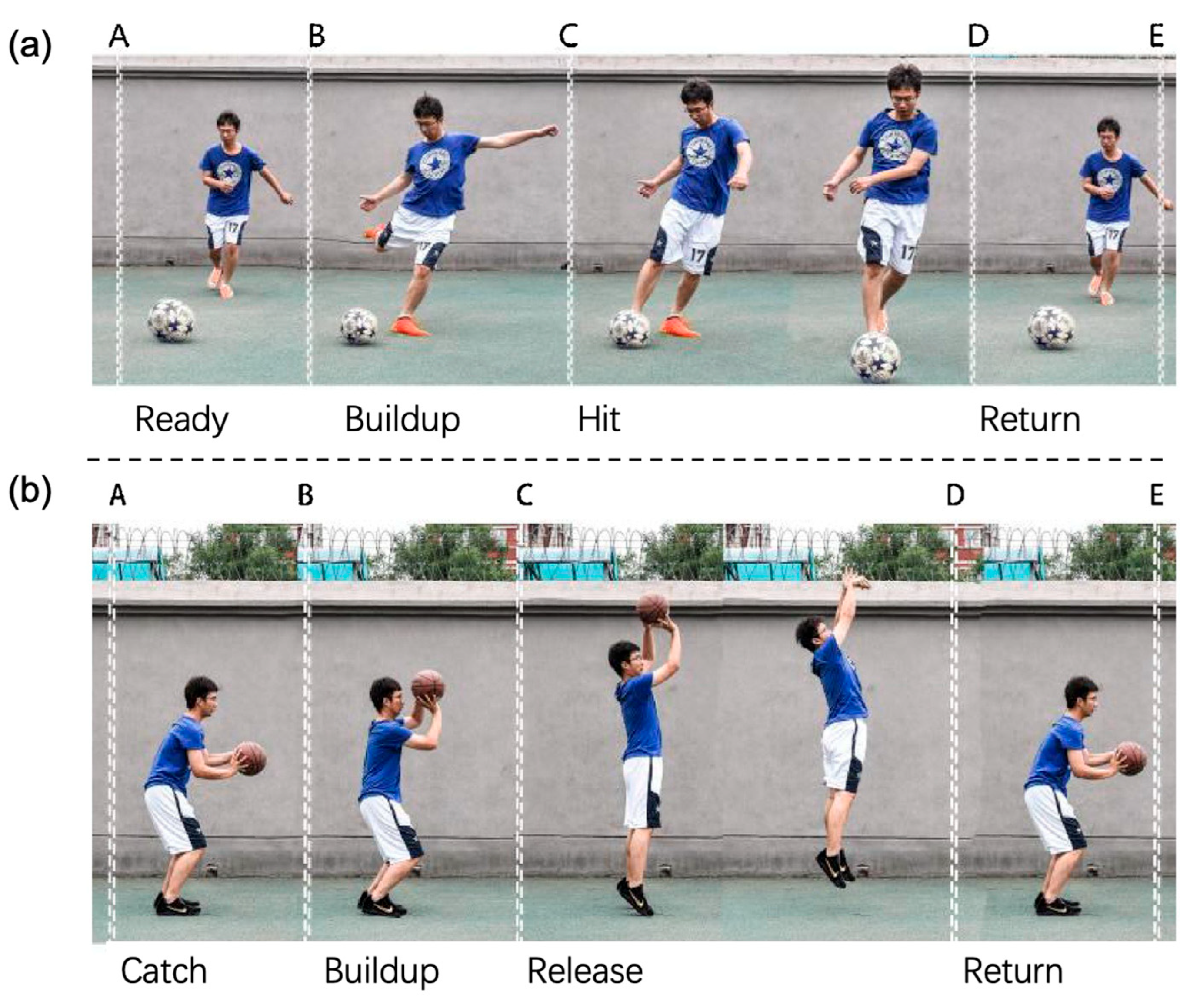

4.1. Sport-Specific Motion Posture Analysis

4.2. Monitoring of Athletic Training Load

- In strength training, FBG-based pressure transducers not only achieve accurate repetition counting (e.g., with an error margin of only 1–2 counts in push-up repetitions) [18], but also enable fine-grained analysis of deep metrics such as movement velocity, range-of-motion consistency, pressure distribution, and concentric-to-eccentric velocity ratios. This provides comprehensive feedback for strength training optimization [6].

- For endurance training, elastic optical fiber chest bands accurately monitor respiratory frequency, depth, and rhythm [86,87], revealing correlations between breathing patterns and aerobic capacity or fatigue thresholds. These metrics offer novel insights for endurance assessment and training intensity prescription [86].

- In group training settings, multi-parameter synchronous monitoring systems track exercise intensity—including acceleration, deceleration, and change-of-direction force or frequency—across multiple athletes. When combined with physiological data such as heart rate, these systems generate individualized load indices. This supports coaches in designing scientifically grounded training programs that avoid both excessive fatigue and inadequate stimulation [6].

4.3. Athletic Health and Injury Prevention

- Foot Health Screening: Optical fiber-based plantar pressure monitoring, combined with artificial intelligence analysis, enables efficient identification of structural abnormalities such as high arches and flat feet (accuracy > 97.5%) [111]. This supports the selection of appropriate footwear and the configuration of orthopedic devices.

- Sports Injury Warning: Flexible sensors (e.g., Ti3C2-based devices) attached to joints, along with machine learning algorithms, continuously record range-of-motion improvement curves [115]. These systems enable real-time monitoring of athletes’ physical status—such as joint load and muscle fatigue—facilitating the early detection of potential injury risks. Targeted preventive rehabilitation training can then be applied, helping athletes avoid training and competition interruptions due to injury, thereby improving training efficiency and competitive performance [111,119]. Optical fiber plantar pressure systems analyze real-time gait parameters including foot strike pattern, stance time, and center of pressure trajectory. By establishing individual baselines, they alert to abnormal patterns (e.g., unilateral overload or center of pressure deviation), prompting adjustments in running technique or rest scheduling to prevent injuries such as stress fractures and plantar fasciitis [89]. Knee and ankle joint angles are critical in injury prevention; specifically, the initial contact angle (IC), the maximum angle during mid-stance (MAX), and the delay between IC and MAX undergo significant changes during long-distance running and are also influenced by the type of footwear worn [167]. Furthermore, analysis of kinetic data allows for the calculation of elastic properties of ligament structures in knee extensors and plantar flexors [168].

4.4. Sports Rehabilitation and Assistive Technology Optimization

5. Challenges and Future Directions of Optical Fiber Sensing Technology in Sports Monitoring Applications

5.1. Technical Bottlenecks and Current Challenges

5.2. Emerging Research Trends

- Multi-modal Sensor Fusion: Limitations of current research, such as the inability of single physical parameters to fully reflect complex physiological and biomechanical states, are driving the field toward multi-modal information fusion. The core rationale is to enhance monitoring accuracy and robustness through complementary data. Cutting-edge research is progressively integrating optical fiber sensors—capable of monitoring pressure, strain, and acceleration—with IMUs, EMG sensors, and electrocardiography (ECG) electrodes into a unified wearable platform [6]. Such integrated systems can simultaneously capture an athlete’s external mechanical load (e.g., ground impact forces, joint angles) and internal physiological load (e.g., muscle activation level, heart rate), thereby enabling comprehensive and objective assessment of athletic performance, technique, and fatigue state. For instance, Presti et al. [117] developed a 3D-printed wearable device incorporating optical fiber strain sensors, capable of simultaneously monitoring respiration and heartbeat, demonstrating the feasibility of synchronous multi-parameter physiological acquisition.

- New Materials and Structural Innovation: From a technological evolution perspective, a prominent trend involves the deep integration of novel functional materials and microstructured optical fibers, aimed at improving sensor sensitivity, durability, comfort, and conformability to the environment or human body. Two-dimensional materials such as MXene, known for their excellent electrical conductivity and mechanical properties, are being incorporated into flexible substrates to create highly sensitive strain sensors. This significantly expands their potential for monitoring large-deformation human movements, such as joint flexion and muscle contraction [115]. Concurrently, innovations in optical fiber microstructure design, including photonic crystal fibers and fiber Bragg grating arrays, continue to enhance their unique advantages for distributed strain and temperature field monitoring [164].

- AI Deep Empowerment: The maturation of artificial intelligence (AI) and machine learning (ML) presents transformative opportunities for processing and analyzing the massive, high-dimensional, and nonlinear data generated by optical fiber sensing. Future applications will evolve beyond simple signal filtering and feature extraction toward intelligent diagnosis, prediction, and decision-making, specifically addressing bottlenecks in converting data into actionable knowledge. For example, Sun et al. [205] employed unsupervised learning to effectively enhance the signal-to-noise ratio in phase-sensitive optical time-domain reflectometry (-OTDR) systems, improving performance in distributed vibration sensing. More advanced work utilizes deep learning algorithms for movement pattern recognition and sports injury risk prediction. Lv et al. [206] designed an immersive basketball tactical training system based on digital twin and federated learning, providing a paradigm for AI-driven advanced tactical analysis.

- Miniaturization and Integration: Advances in micro-electromechanical systems (MEMS) and flexible electronics are expanding the research boundaries of optical fiber sensors, facilitating a transition from “theoretically feasible” to “practically deployable” in wearable devices. Research focuses on the high-level integration of sensing units, demodulation modules, and wireless transmission units to develop ultra-thin, flexible, and even skin-adhered monitoring devices that minimize interference with athlete movement [6,118]. A review by Erik et al. [118] extensively discusses the current state of medical wearable optical sensors, with many conclusions, such as those regarding biocompatibility and wearing comfort, being equally applicable to sports science.

- Energy Self-Supply: Current research progress indicates that achieving long-term, unobtrusive, and maintenance-free monitoring—crucial for comprehensive sports data capture—necessitates addressing energy supply challenges. Although the direct application of energy harvesting in optical fiber-based sports monitoring is still nascent, advancements in technologies such as triboelectric nanogenerators (TENGs) and photovoltaic cells are laying the groundwork for future integrated applications [207,208,209].

- Closed-loop Biofeedback: Driven by scenarios demanding personalized training and precise rehabilitation, frontier research is increasingly oriented toward constructing closed-loop systems embodying “perception–analysis–intervention.” The core concept involves using optical fiber sensors for real-time data acquisition. After analysis by AI models, immediate feedback is delivered to athletes or coaches via visual, auditory, or haptic interfaces, such as augmented reality (AR)/virtual reality (VR) devices or haptic feedback devices, to correct technical movements or adjust training load [206].

- AIoT and Digital Twin: Recent breakthroughs in 5G/6G communication, edge computing, and cloud computing have propelled the evolution of optical fiber sensing monitoring systems from isolated, localized data acquisition toward an integrated intelligent ecosystem characterized by cloud-edge-device synergy and the Internet of Everything. Under the impetus of smart sports scenarios, cutting-edge research is progressively leaning toward an integrated “device-edge-cloud” architecture. The core logic is: optical fiber sensing nodes act as perceptual endpoints at the device level, capturing ultra-high-precision data from athletes and the environment in real time. Data are wirelessly transmitted to edge computing devices (e.g., courtside gateways, smart terminals) for preliminary processing and real-time feedback. Ultimately, massive datasets converge on the cloud platform, integrating deeply with AI and digital twin technologies for in-depth mining, model training, and global decision-making. This architecture establishes optical fiber sensing systems as critical data sources within the broader AIoT [70]. Existing research suggests its evolution can be summarized along two main directions. First, global situational awareness based on optical fiber sensor networks, enabling synchronous monitoring of multiple athletes, equipment, and even venues to construct a macro-view of training and competition for tactical analysis, team load management, and scientific talent selection [163]. Second, deep integration with digital twin technology. The digital twin, a high-fidelity virtual model residing in the cloud, is dynamically updated and simulated using continuous real-time data streams from IoT sensors like optical fibers. This enables the optimization and verification of athlete state prediction, tactical simulation, and injury prevention strategies within the virtual space, ultimately feeding the optimal strategies back to athletes in the real world, forming a “perception–cognition–decision–execution” closed loop [206,210]. Future research in this area will further focus on seamless fusion of multi-source heterogeneous data, low-latency high-concurrency communication protocols, and the construction of integrated cloud-edge simulation platforms. Key breakthroughs will hinge on addressing challenges such as data security, system interoperability, and model fidelity.

5.3. Interdisciplinary Integration Prospects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pellegrini, B.; Sandbakk, Ø.; Stöggl, T.; Supej, M.; Ørtenblad, N.; Schürer, A.; Steiner, T.; Lunina, A.; Manhard, C.; Liu, H.; et al. Methodological Guidelines Designed to Improve the Quality of Research on Cross-Country Skiing. J. Sci. Sport Exerc. 2021, 3, 207–223. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Hong, R.; Qu, Y.; Gao, X.; Wang, X. Research Status and Development Trend of Lower-Limb Squat-Assistant Wearable Devices. Biomimetics 2025, 10, 258. [Google Scholar] [CrossRef]

- Elsherif, M.; Salih, A.E.; Muñoz, M.G.; Alam, F.; AlQattan, B.; Antonysamy, D.S.; Zaki, M.F.; Yetisen, A.K.; Park, S.; Wilkinson, T.D.; et al. Optical Fiber Sensors: Working Principle, Applications, and Limitations. Adv. Photonics Res. 2022, 3, 2100371. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, Z.; Dong, S.; Chen, M. Review of wearable optical fiber sensors: Drawing a blueprint for human health monitoring. Opt. Laser Technol. 2023, 161, 109227. [Google Scholar] [CrossRef]

- Tu, D.; Tang, Y.; Huang, Y.; Tang, M.; Li, L.; Li, Y.; Lu, M.; Luo, Z.; Duan, Y. Next-Generation Wearable/Implanted Sensors Based on Fiber Optic and Its Application: From in Vitro to in Vivo. ACS Sens. 2025, 10, 3818–3839. [Google Scholar] [CrossRef]

- De Fazio, R.; Mastronardi, V.M.; De Vittorio, M.; Visconti, P. Wearable Sensors and Smart Devices to Monitor Rehabilitation Parameters and Sports Performance: An Overview. Sensors 2023, 23, 1856. [Google Scholar] [CrossRef]

- Jha, R.; Mishra, P.; Kumar, S. Advancements in optical fiber-based wearable sensors for smart health monitoring. Biosens. Bioelectron. 2024, 254, 116232. [Google Scholar] [CrossRef]

- Hou, Z.; Liu, J.; Liao, Y.; Gong, J.; Li, C.; Li, M.; Liu, H.; Huang, Q. Design and application of flexible wearable sensors based on optical fibers. Talanta 2025, 297, 128576. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Zhu, J. Investigation of gesture recognition based on optical fiber Bragg grating sensors. Measurement 2023, 209, 112498. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, Y.; Qiao, M.; Ai, L.; Sun, K.; Mi, Q.; Zang, S.; Zuo, Y.; Yuan, X.; Wang, Q. Human motion monitoring in sports using wearable graphene-coated fiber sensors. Sens. Actuators A Phys. 2018, 274, 132–140. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Silva, J.; Macedo, L.; Marchesi, A.; Morau, S.; Valentino, J.; Valentim, F.; Costa, M. The role of optical fiber sensors in the new generation of healthcare devices: A review. Sens. Diagn. 2024, 3, 1135–1158. [Google Scholar] [CrossRef]

- Kuang, R.; Wang, Z.; Ma, L.; Wang, H.; Chen, Q.; Junior, A.L.; Kumar, S.; Li, X.; Marques, C.; Min, R. Smart photonic wristband for pulse wave monitoring. Opto-Electron. Sci. 2024, 3, 16–32. [Google Scholar] [CrossRef]

- Li, W.; Long, Y.; Yan, Y.; Xiao, K.; Wang, Z.; Zheng, D.; Leal-Junior, A.; Kumar, S.; Ortega, B.; Marques, C.; et al. Wearable photonic smart wristband for cardiorespiratory function assessment and biometric identification. Opto-Electron. Adv. 2025, 8, 7–29. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Diaz, C.A.R.; Avellar, L.M.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer Optical Fiber Sensors in Healthcare Applications: A Comprehensive Review. Sensors 2019, 19, 3156. [Google Scholar] [CrossRef]

- Wu, D.; Weng, L.; Zhang, X.; Guan, L.; Wu, Z. Flexible and wearable multilayer structure fiber sensor for motion and human physiological signal monitoring. Polym. Adv. Technol. 2024, 35, e6552. [Google Scholar] [CrossRef]

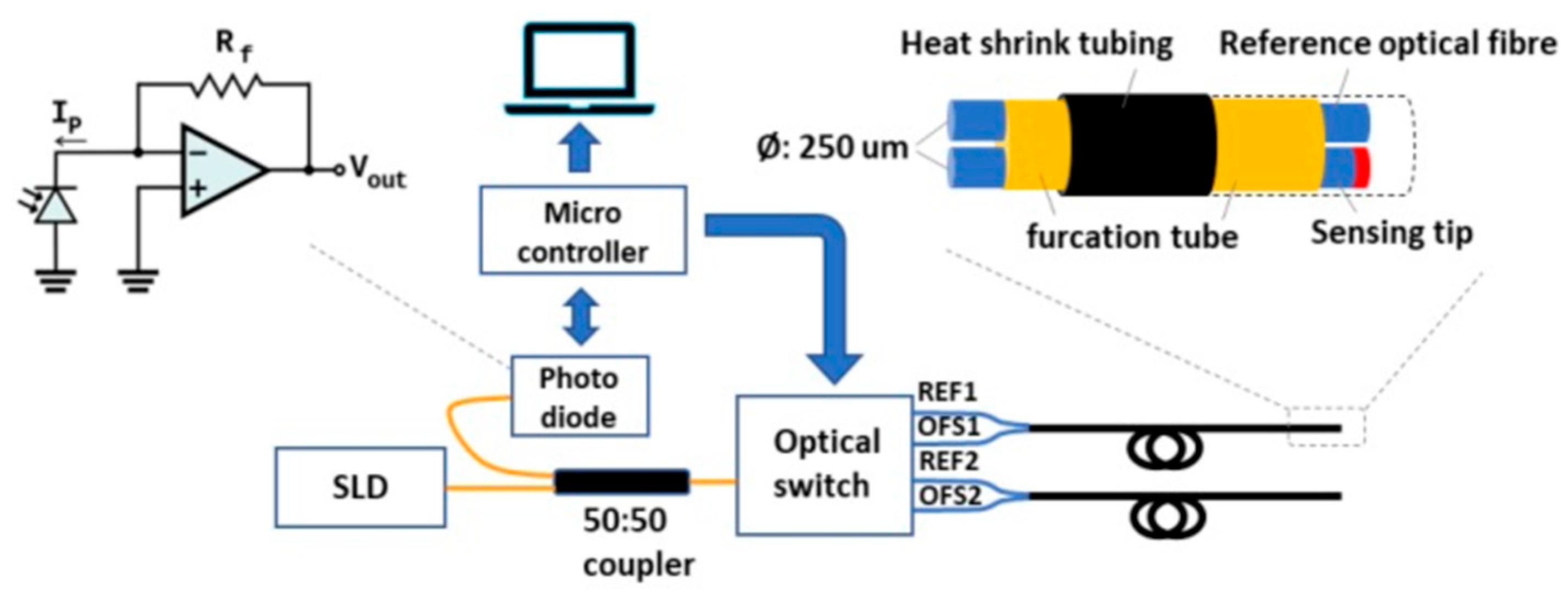

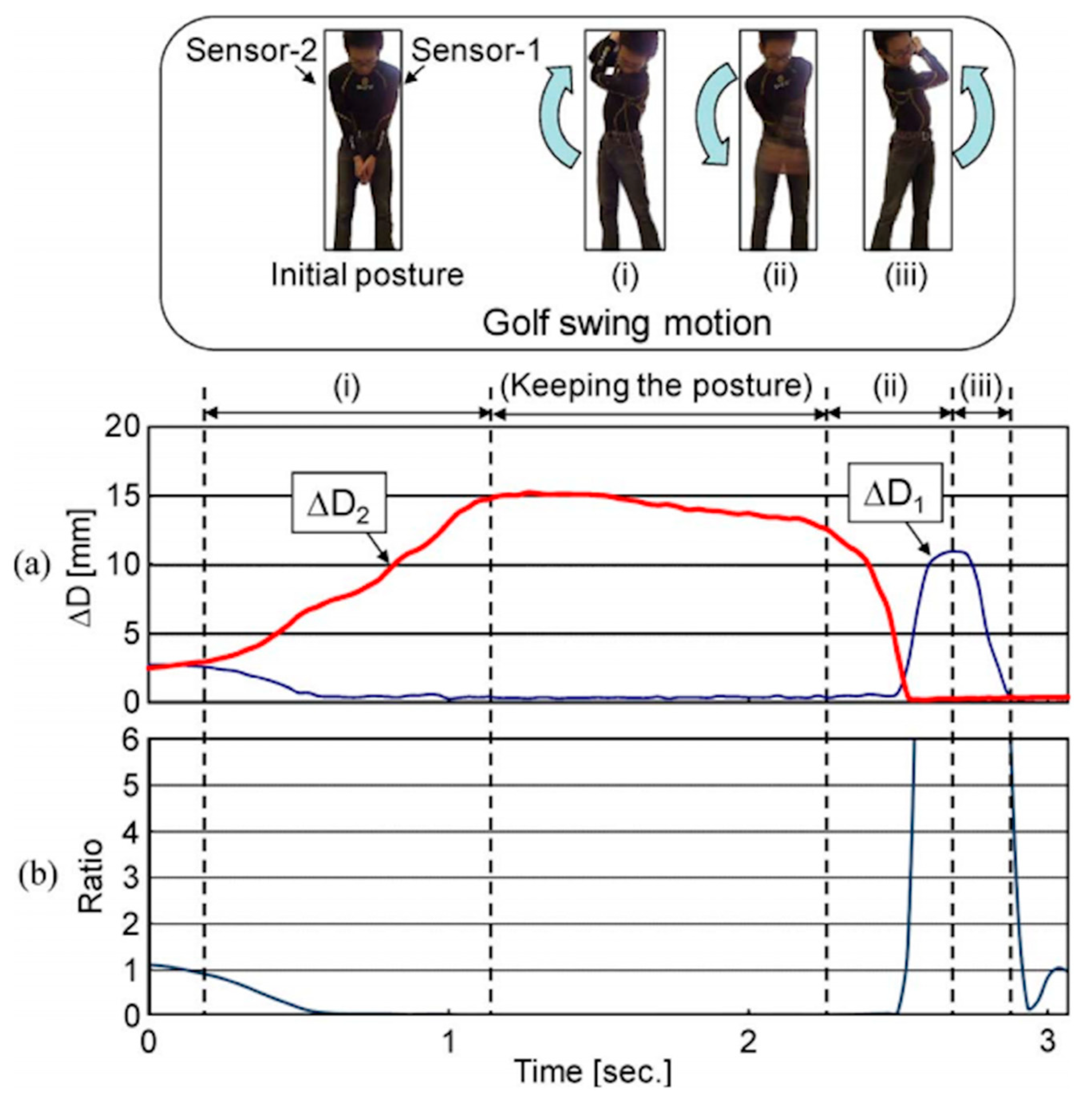

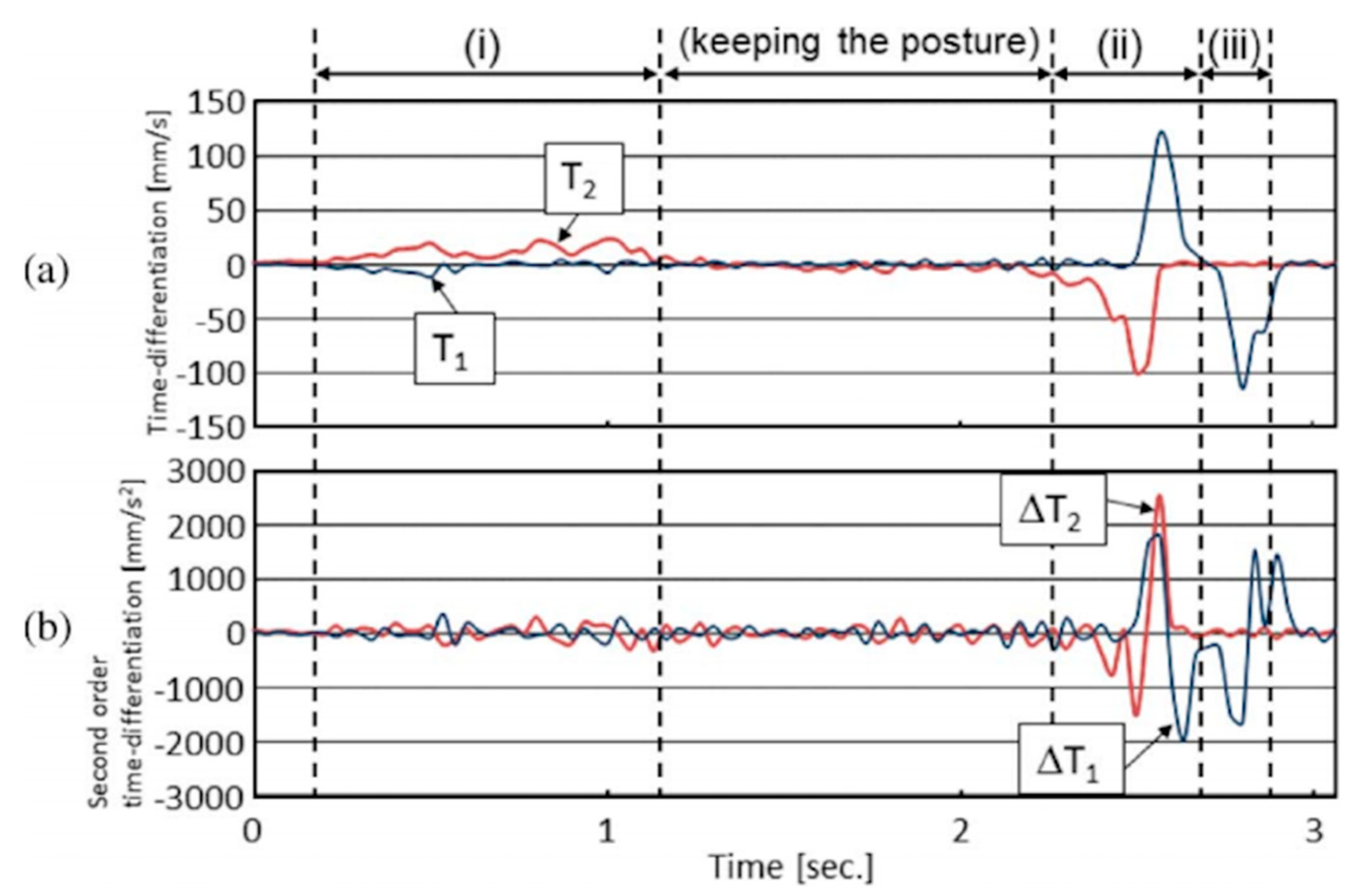

- Koyama, Y.; Nishiyama, M.; Watanabe, K. A Motion Monitor Using Hetero-Core Optical Fiber Sensors Sewed in Sportswear to Trace Trunk Motion. IEEE Trans. Instrum. Meas. 2013, 62, 828–836. [Google Scholar] [CrossRef]

- Tian, X. Research on Fiber Bragg Grating Smart Garment for Human Pulse Detection. Master’s Thesis, Tiangong University, Tainjing, China, 2016. [Google Scholar]

- Liu, B. Research on Extraction Method of Fiber Bragg Grating Evaluation Characteristics for Push-Up Exercise. Master’s Thesis, Nanchang University, Nanchang, China, 2022. [Google Scholar]

- Yin, X.; Zhang, S.; Qu, Y.; Zhang, S.; Zhang, X.; Zhao, J.; Li, X.; Zeng, H.; Wang, H.; Liu, H.; et al. High-resolution pressure sensing insole via sensitivity-tunable fibers towards gait recognition. Chem. Eng. J. 2025, 505, 159841. [Google Scholar] [CrossRef]

- Yan, F.; Hao-xiang, W.; Peng-bin, L.; Hua, Q.; Rui-zhi, P.; Hong-pu, Z.; Hua, Z. Optical fiber Bragg grating based sensing system of flexible wearable smart sleeve for tracking human arm joint movements. Meas. Sci. Technol. 2023, 34, 084010. [Google Scholar] [CrossRef]

- Biaoliao, Y.; Yuan, L.; Tian, Q. 40 Years of Optical Fiber Sensing in China. Acta Opt. Sin. 2018, 38, 10–28. [Google Scholar]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Gao, S.; Ma, S.; Xu, Y.; Wu, H.; Wang, Q. Application and Optimization of Distributed Fiber Grating-Based Flexible Wearable Sensors in the Shooting Sports. IEEE Trans. Instrum. Meas. 2024, 73, 7007308. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Zhang, H. Review of fiber Bragg grating sensor technology. Front. Optoelectron. China 2011, 4, 204–212. [Google Scholar] [CrossRef]

- Jiang, X.; Duan, Z.; Xu, T.; Mupfukirei, L.R.; Yu, Z.; Pang, B.; Wang, Y.; Ling, Q.; Chen, H.; Gu, Z.; et al. Review of fabrication and packaging of UV-induced FBGs for high temperature sensing. Opt. Fiber Technol. 2024, 86, 103855. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, C.; Chen, Y.; Xiang, Y.; Huang, T.; Shum, P.P.; Wu, Z. Fiber structures and material science in optical fiber magnetic field sensors. Front. Optoelectron. 2022, 15, 34. [Google Scholar] [CrossRef]

- Song, Z.; Wang, M.; Payne, F.P.; Salter, P.S.; Liu, T.; Elston, S.J.; Booth, M.J.; Morris, S.M.; Fells, J.A.J. Fiber Bragg Gratings with Micro-Engineered Temperature Coefficients. Adv. Opt. Mater. 2025, 13, 2402726. [Google Scholar] [CrossRef]

- Ren, N.; Li, H.; Huo, N.; Guo, S.; Li, J. Research on Temperature Sensing Characteristics of Fiber Bragg Grating in Wide Temperature Range. Curr. Opt. Photonics 2024, 8, 162–169. [Google Scholar]

- Han, X.; Shang, L.; Feng, S.; Liu, G. Elimination of temperature cross-sensitivity in torsion and curvature measurements based on arc-induced long period fiber gratings. Opt. Fiber Technol. 2025, 90, 104099. [Google Scholar] [CrossRef]

- Priyanka, C.; Kumar, M.A. Switching dynamics in -symmetric structures with saturable cubic nonlinear response. J. Opt. 2021, 23. [Google Scholar] [CrossRef]

- Jayanth, C.; Peter, S.E.; Santhosh, B.; Nandhini, V.L. Design of multiparameter fiber Bragg grating in optical transmission systems wavelength division multiplexing. J. Opt. 2024, 53, 4443–4451. [Google Scholar] [CrossRef]

- Alias, M.A.; Ahmad, H.; Samion, M.Z.; Sa’ad, M.S.M.; Sing, L.K.; Grattan, K.T.V.; Rahman, B.M.A.; Brambilla, G.; Zaini, M.K.A.; Bayang, L.; et al. Highly sensitive temperature-independent FBG-based sensor embedded in thermoplastic polyurethane using 3D printing technology for the measurements of torsion. Sens. Actuators A Phys. 2022, 346, 113889. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, S.; Xiao, Y.; Huang, S.; Hu, X.; Chen, W.; Chen, X.; Chen, H.; Zhao, N. A temperature-insensitivity multi-channel strain sensor based on chirped fiber grating loop ring-down structure. Opt. Laser Technol. 2025, 181, 111729. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, J.; Sui, Q.; Ye, Q. In-situ and real-time measurement of single-lap-joint bonded area stress distribution based on FBG reflectance spectrum analyses and self-adaptive method. Opt.—Int. J. Light Electron Opt. 2017, 131, 302–311. [Google Scholar] [CrossRef]

- Bao, X.; Chen, L. Recent Progress in Brillouin Scattering Based Fiber Sensors. Sensors 2011, 11, 4152–4187. [Google Scholar] [CrossRef]

- Masoudi, A.; Newson, T.P. Contributed Review: Distributed optical fibre dynamic strain sensing. Rev. Sci. Instrum. 2016, 87, 011501. [Google Scholar] [CrossRef]

- Schenato, L.; Herráez, M.G. A Review of Distributed Fibre Optic Sensors for Geo-Hydrological Applications. Appl. Sci. 2017, 7, 896. [Google Scholar] [CrossRef]

- Koike, Y.; Asai, M. The future of plastic optical fiber. NPG Asia Mater. 2009, 1, 22–28. [Google Scholar] [CrossRef]

- Whittaker, C.; Kalnins, C.A.G.; Ottaway, D.; Spooner, N.A.; Ebendorff-Heidepriem, H. Transmission loss measurements of plastic scintillating optical fibres. Opt. Mater. Express 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Fan, X. Research on Method of Multi Parameters Discrete Optical Fiber Sensing for Complex Temperature Environment. Ph.D. Thesis, Tianjin University, Tianjin, China, 2020. [Google Scholar]

- Guerrero-Mendez, C.D.; De Arco, L.; Pontes, M.J.; Segatto, M.E.V.; Cifuentes, C.A.; Bastos-Filho, T.F.; Diaz, C.A.R. Fatigue test on optical fiber angle sensors based on polymeric materials for flexion–extension applications. Opt. Fiber Technol. 2023, 78, 103334. [Google Scholar] [CrossRef]

- Motoharu, M.; Rei, F.; Yuki, M.; Azusa, I.; Yasuhiro, K. Evaluation of modal noise in graded-index silica and plastic optical fiber links for radio over multimode fiber systems. Opt. Express 2014, 22, 6562–6568. [Google Scholar] [CrossRef]

- Hu, Z.Z.; Sun, Q.Q.; Zhu, C.; Su, X.Q.; Chen, M.Y.; Ngiejungbwen, L.A.; Gong, T.Y.; Liang, Y. Structural design and performance testing of respiratory sensor based on optical fiber end-face coupling. Opt. Fiber Technol. 2024, 87, 103946. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, K.; Kremenakova, D.; Militky, J. Side Illumination Behavior and Mechanical Properties of Twisted End-Emitting Polymer Optical Fiber Bundles. Macromol. Mater. Eng. 2024, 310, 2400301. [Google Scholar] [CrossRef]

- Paczkowska, K.; Pacholec, Z.; Bury, P.; Błażejewski, W. Smart glass fiber hydrogen tank for high pressure: Design and sensor-based analysis. Int. J. Hydrogen Energy 2025, 147, 150018. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, D.; Chen, W.; Zhang, C. A high-sensitivity and fast-recovery strain sensor based on gradient polyurethane and electroless silver-plating on a high aspect ratio glass fibers. Chem. Eng. J. 2025, 507, 160439. [Google Scholar] [CrossRef]

- Abas, A.H.A.; Rahman, M.S.A.; Wahab, M.H.; Ahmad, N. Temperature sensitivity of polymer optical fiber: A study of PMMA, PVDF, and PI in fiber to the home network. Przegląd Elektrotechniczny 2025, 1, 102–105. [Google Scholar] [CrossRef]

- Tang, C.; Jin, W.; Xiao, X.; Qi, X.; Ma, Y.; Ma, L. Graphene-based chemiresistive hydrogen sensor for room temperature operation. Sens. Actuators B. Chem. 2025, 424, 136889. [Google Scholar] [CrossRef]

- Golshokouh, M.A.; Refahati, N.; Saffari, P.R. Effect of Silicon Nanoparticles on Moisture Absorption and Fracture Toughness of Polymethyl Methacrylate Matrix Nanocomposites. J. Compos. Sci. 2024, 8, 69. [Google Scholar] [CrossRef]

- Esmercan, C.; Kadem, F.D.; Kallweit, J.; Pätzel, M.; Gries, T. Attenuation Analysis of Polymer Optic Fibres (POF) Manufactured with Different Materials. Fibres Text. East. Eur. 2024, 32, 24–31. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Y.; Ye, J.; Xu, J.; Leng, J.; Zho, P. Pure silica fiber Raman gain enabled high-power low-quantum defect fiber laser. Opt. Laser Technol. 2023, 158, 108833. [Google Scholar] [CrossRef]

- Zhang, N.; Han, Z.Y.; Song, L.Q.; Lu, Y.M. Research on Characteristics of Plastic Materials and Plastic Optical Fiber. Adv. Mater. Res. 2013, 2489, 3–6. [Google Scholar] [CrossRef]

- Yao, N.; Wang, S. Recent progress of optical tactile sensors: A review. Opt. Laser Technol. 2024, 176, 111040. [Google Scholar] [CrossRef]

- Arifin, A.; Khaerani, R.; Lebang, A.K.; Idris, I.; Dewang, S.; Tahir, D. Low-Cost High-Sensitive Plastic Optical Fiber-Based Sensor for Detection of CO(NH2)2 Urea. J. Sens. 2022, 2022. [Google Scholar] [CrossRef]

- Ting, L.; He, D.; Chengsen, Z.; Jiawei, H.; Shouyu, W. Simply and cost-effectively fabricated AuNP-based fusion spliced transmissive optical fiber LSPR probes. Opt. Express 2021, 29, 7398–7409. [Google Scholar]

- Su, B.; Li, J.; Xu, H.; Xu, Z.; Meng, J.; Chen, X.; Li, F. Scientific athletics training: Flexible sensors and wearable devices for kineses monitoring applications. Sci. Sin. Inform. 2022, 52, 54–74. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.H.C. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef]

- Wu, L.; Chu, H.S.; Koh, W.S.; Li, E.P. Highly sensitive graphene biosensors based on surface plasmon resonance. Opt. Express 2010, 18, 14395–14400. [Google Scholar] [CrossRef]

- Zuo, Y.; Yu, W.; Liu, C.; Cheng, X.; Qiao, R.; Liang, J.; Zhou, X.; Wang, J.; Wu, M.; Zhao, Y.; et al. Optical fibres with embedded two-dimensional materials for ultrahigh nonlinearity. Nat. Nanotechnol. 2020, 15, 987–991. [Google Scholar] [CrossRef]

- Lu, H.; Tian, Z.; Jin, S.; Yu, J.; Liao, G.; Zhang, J.; Tang, J.; Luo, Y.; Chen, Z. Graphene-based all-fiber-optic temperature sensor. Photonic Instrum. Eng. 2014, 8992, 89920B. [Google Scholar]

- Luo, J.; Liu, G.-S.; Zhou, W.; Hu, S.; Chen, L.; Chen, Y.; Luo, Y.; Chen, Z. A graphene-PDMS hybrid overcoating enhanced fiber plasmonic temperature sensor with high sensitivity and fast response. J. Mater. Chem. C 2020, 8, 12893–12901. [Google Scholar] [CrossRef]

- Wang, J. Study on Key Technologies and Applications of Optical Fiber Sensor Networks for WIT120. Master’s Thesis, Huazhong University of Science & Technology, Wuhan, China, 2019. [Google Scholar]

- Sopan, N.; Pravin, P. Poly(allylamine) coated layer-by-layer assembly decorated 2D carbon backbone for highly sensitive and selective detection of Tau-441 using surface plasmon resonance biosensor. Anal. Chim. Acta 2023, 1271, 341474. [Google Scholar]

- Xue, J.; Zhang, Y.; Guang, Z.; Hu, J.; Zhao, F.; Liu, Y.; Shao, L. MoS2 surface plasmon resonance based high-resolution THz biosensor using a dual D-shaped channel micro-structured fiber. Opt. Laser Technol. 2025, 180, 111387. [Google Scholar] [CrossRef]

- Yusuf, D.; Ilhan, E. Highly sensitive MoS2/graphene based D-shaped optical fiber SPR refractive index sensor with Ag/Au grated structure. Opt. Quantum Electron. 2023, 55, 1066. [Google Scholar]

- Ma, J.; Wang, R.; Li, D.; Xu, K. MoS2-Graphene heterostructure enhanced fiber optic SPR sensor for highly sensitive glucose detection. Microchem. J. 2025, 213, 113753. [Google Scholar] [CrossRef]

- Shao, M.; Sun, H.; Zhang, R.; Li, L.; Liu, Y.; Qiao, X. In-fiber humidity sensor based on Black Phosphorus-Polyvinyl alcohol. Opt. Fiber Technol. 2022, 68, 102782. [Google Scholar] [CrossRef]

- Rahman, M.S.; Anower, M.S.; Abdulrazak, L.F.; Rahman, M.M. Modeling of a fiber-optic surface plasmon resonance biosensor employing phosphorene for sensing applications. Opt. Eng. 2019, 58, 037103. [Google Scholar] [CrossRef]

- Liu, C.; Sun, Y.; Chang, S.; Jin, J.; Hu, J.; Zhao, J. An Electrochemical Sensor for the Detection of Bisphenols Based on Mxene Embedded with Aminated Carbon Nanotubes. Electroanalysis 2025, 37, e70028. [Google Scholar] [CrossRef]

- Shinde, M.; Slaughter, G. Advanced nanocomposite-based electrochemical sensor for ultra-sensitive dopamine detection in physiological fluids. Front. Lab A Chip Technol. 2025, 4, 1549365. [Google Scholar] [CrossRef]

- Ma, J. Research on Wearable Electrochemical Sensors for the Monitoring of Biomolecules and Physiological Signals. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2024. [Google Scholar]

- Pawar, D.; Kanawade, R.; Kumar, A.; Rao, C.N.; Cao, P.; Gaware, S.; Late, D.; Kale, S.N.; Navale, S.T.; Liu, W.J.; et al. High-Performance Dual Cavity-Interferometric Volatile Gas Sensor Utilizing Graphene/PMMA Nanocomposite. Sens. Actuators B Chem. 2020, 312, 127921. [Google Scholar] [CrossRef]

- Devi, K.N.; Vadivel, S. Room temperature fiber optic gas sensor technology based Zn3(VO4)2/PMMA hybrid composites via facile hydrothermal route. Opt. Fiber Technol. 2024, 82, 103642. [Google Scholar] [CrossRef]

- Sedeeq, F.T.; Nasiri, H.; Abbasian, K.; Khodaei, H. Ultrasensitive detection of amlodipine using plasmonic optical fiber sensors enhanced with graphene oxide and chitosan nanocomposite. Sci. Rep. 2025, 15, 28662. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Xu, Y.; Lan, Y.; Ding, Y.; Pei, H. Study of nonlinear optical properties of Bi2Te3-Graphene longitudinal heterostructures and their application to fibre lasers. Opt. Mater. 2025, 164, 117035. [Google Scholar] [CrossRef]

- Yu, W.X.; Zhao, C.Y.; Hong, B.W.; Wei, F.G.; Cheng, K.S.; Xin, W.W. Research on Control Method of Graphene Layers Grown in Air Holes of Photonic Crystal Fiber Based on Raman Spectroscopy. Spectrosc. Spectr. Anal. 2020, 40, 3659–3664. [Google Scholar]

- Wang, F.; Xu, H.; Gu, Q.; Shi, C.; Zhang, L.; Wu, Z.; Deng, G.; Zhou, H.; Wee, A.T.S.; Zhou, S. A high-performance polarization-enhanced black phosphorus photodetector by a nonlocal metasurface. Opt. Lett. 2025, 50, 4098–4101. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Wen, J.; Han, Y.; Cao, P.; Chen, F.; Li, L.; Sheng, S.; Jiang, C. A cobalt carbonate hydroxide hydrate-based optics fiber sensor for humidity and temperature detection. Infrared Phys. Technol. 2025, 145, 105681. [Google Scholar] [CrossRef]

- Lv, J.; Li, W.; Meng, T.; Li, Q.; Wang, J.; Xu, X.; Wang, D.; Liu, W.; Liu, C.; Chu, P.K. Low-temperature cross-sensitivity strain sensor based on a microbubble Fabry-Pérot interferometer with a thin wall. Opt. Fiber Technol. 2023, 80, 103452. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Zhu, L.; Sun, G.; Lou, X.; Dong, M. Optical Fiber Sensor Performance Evaluation in Soft Polyimide Film with Different Thickness Ratios. Sensors 2019, 19, 790. [Google Scholar] [CrossRef]

- He, C.; Korposh, S.; Hernandez, F.U.; Liu, L.; Correia, R.; Hayes-Gill, B.R.; Morgan, S.P. Real-Time Humidity Measurement during Sports Activity using Optical Fibre Sensing. Sensors 2020, 20, 1904. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, Y.-N.; Jiang, L.; Li, L.; Li, X.; Zhao, J. Flexible Optical Fiber Sensor for Non-Invasive Continuous Monitoring of Human Physiological Signals. Small Methods 2025, 9, e2401368. [Google Scholar] [CrossRef]

- Li, H.; Yu, X.; Miao, C.; Li, E.; Xi, J.; Wang, R.; Zhang, C.; Zhang, M.; Liu, L. Research of Intelligent Clothing for Body Temperature Monitoring Based on Distributed Optical Fiber Bragg Grating Sensors. Acta Opt. Sin. 2009, 29, 208–212. [Google Scholar] [CrossRef]

- Yu, X.; Miao, C.; Li, H.; Chen, H.; Xi, J.; Yang, H.; Zhang, C. Research on Human Body Temperature Measurement Models of Intelligent Clothing Based on Optical Fiber Bragg Grating. Opt. Tech. 2011, 37, 704–708. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, Z.; Li, J.; Wang, Z.; Ren, Y.; Wang, Q.; Huang, D.; Li, Z. A Low-Cost Flexible Perforated Respiratory Sensor Based on Platinum for Continuous Respiratory Monitoring. Micromachines 2022, 13, 1743. [Google Scholar] [CrossRef] [PubMed]

- Pang, Y. Monitoring of Human Physiological Parameters Based on SMS Structure Optical Fiber Sensor. Master’s Thesis, Nanchang Hangkong University, Nanchang, China, 2022. [Google Scholar]

- Krizan, D.; Stipal, J.; Nedoma, J.; Oliveira, S.; Fajkus, M.; Cubik, J.; Siska, P.; Schena, E.; Lo Presti, D.; Marques, C. Embedding FBG sensors for monitoring vital signs of the human body: Recent progress over the past decade. APL Photonics 2024, 9, 081201. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Meng, L.; Li, H. Reserach on optic fiberception of human motion for exoskeleton robot control. Comput. Meas. Control 2015, 23, 3804–3806+3809. [Google Scholar] [CrossRef]

- Zhou, T. Research on High-Sensitivity Optical Fiber Angle Sensor for Human Joints Health Monitoring. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2024. [Google Scholar]

- Morgan, S.P.; Canfarotta, F.; Piletska, E.V.; Grillo, F.; Korposh, S.; Liu, L.; Hernandez, F.U.; Correia, R.; Norris, A.; Sinha, R.; et al. Optical fiber sensors for monitoring in critical care. Annu. Int. Conf. IEEE Eng. Med. Biol. Soc. 2019, 2019, 1139–1143. [Google Scholar]

- Lee, K.P.; Yip, J.; Yick, K.L.; Lu, C.; Lo, C.K. Textile-based fiber optic sensors for health monitoring: A systematic and citation network analysis review. Text. Res. J. 2022, 92, 2922–2934. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Z.; Xiao, K.; Ushakov, N.; Kumar, S.; Li, X.; Min, R. Portable optical fiber biosensors integrated with smartphone: Technologies, applications, and challenges [Invited]. Biomed. Opt. Express 2024, 15, 1630–1650. [Google Scholar] [CrossRef]

- Zhou, F. Research on Human Heart Rate and Respiration Rate Monitoring Based on Sandwich Multimode Optical Fiber MZI Sensor. Master’s Thesis, Chongqing University of Technology, Chongqing, China, 2024. [Google Scholar]

- Balakrishnan, V.; Dinh, T.; Foisal, A.R.M.; Nguyen, T.; Phan, H.-P.; Dao, D.V.; Nguyen, N.-T. Paper-Based Electronics Using Graphite and Silver Nanoparticles for Respiration Monitoring. IEEE Sens. J. 2019, 19, 11784–11790. [Google Scholar] [CrossRef]

- Rasheed, A.; Iranmanesh, E.; Li, W.; Xu, Y.; Zhou, Q.; Ou, H.; Wang, K. An Active Self-Driven Piezoelectric Sensor Enabling Real-Time Respiration Monitoring. Sensors 2019, 19, 3241. [Google Scholar] [CrossRef]

- Panahi, A.; Hassanzadeh, A.; Moulavi, A. Design of a low Cost, double triangle, piezoelectric sensor for respiratory monitoring applications. Sens. Bio-Sens. Res. 2020, 30, 100378. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Zhai, H.; Jin, L.; Chen, K.; Yi, Y.; Gao, Y.; Xu, L.; Zheng, Y.; Yao, S.; et al. A highly sensitive stretchable strain sensor based on multi-functionalized fabric for respiration monitoring and identification. Chem. Eng. J. 2021, 426, 130869. [Google Scholar] [CrossRef]

- Wang, Y. Research on Blood Pressure Detection Method Based on Fiber Bragg Grating Pulse Wave. Master’s Thesis, Tianjin Polytechnic University, Tianjin, China, 2017. [Google Scholar]

- Fan, J.; Zheng, Z.; Xiang, H.; Tao, J. Non-Contact Optical Fiber Probe Method for Measuring Radial Artery Pulse Wave at Human Wrist. Chin. J. Lasers 2025, 52, 1507201. [Google Scholar]

- Guo, J.; Zhou, B.; Yang, C.; Dai, Q.; Kong, L. Stretchable polymer optical fiber temperature sensor. Adv. Funct. Mater. 2019, 29, 1902898. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Jiang, N.; Fallahi, A.; Montelongo, Y.; Ruiz-Esparza, G.U.; Tamayol, A.; Zhang, Y.S.; Mahmood, I.; Yang, S.-A.; Kim, K.S.; et al. Glucose-Sensitive Hydrogel Optical Fibers Functionalized with Phenylboronic Acid. Adv. Mater. 2017, 29, 1606380. [Google Scholar] [CrossRef] [PubMed]

- Pathak, A.K.; Viphavakit, C. A review on all-optical fiber-based VOC sensors: Heading towards the development of promising technology. Sens. Actuators A Phys. 2022, 338, 113455. [Google Scholar] [CrossRef]

- Areen, A.; Mahmoud, A.A. Simultaneous piezoelectric noninvasive detection of multiple vital signs. Sci. Rep. 2020, 10, 416. [Google Scholar] [CrossRef]

- Pan, J.; Zhang, Z.; Jiang, C.; Zhang, L.; Tong, L. A multifunctional skin-like wearable optical sensor based on an optical micro-/nanofibre. Nanoscale 2020, 12, 17538–17544. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, P.; Zheng, W.; Zhao, Y. Research on optical fiber biochemical sensing technology for human health protection. Control Decis. 2023, 38, 2313–2325. [Google Scholar] [CrossRef]

- Salim, G.M.; Zawawi, M.A. Knee Joint Movement Monitoring Device Based on Optical Fiber Bending Sensor. J. Telecommun. Electron. Comput. Eng. 2018, 10, 25–29. [Google Scholar]

- Li, L.; He, R.; Soares, M.S. Polymer optical fiber for angle measurement in biomechanics. IEEE Sens. J. 2021, 21, 26793–26801. [Google Scholar] [CrossRef]

- Chen, L. Distributed fiber sensing for winter sports venue monitoring. Cold Reg. Sci. Technol. 2023, 205, 103711. [Google Scholar]

- Han, Y. A Novel Human Posture Recognition System Based on 3D Printing and Fiber Bragg Grating Sensing Technology. Master’s Thesis, Donghua University, Shanghai, China, 2018. [Google Scholar]

- Raza, T.; Tufail, M.K.; Ali, A.; Boakye, A.; Qi, X.; Ma, Y.; Ali, A.; Qu, L.; Tian, M. Wearable and Flexible Multifunctional Sensor Based on Laser-Induced Graphene for the Sports Monitoring System. ACS Appl. Mater. Interfaces 2022, 14, 54170–54181. [Google Scholar] [CrossRef]

- Liu, B. Hardware design for wearable FBG systems. IEEE Sens. J. 2023, 23, 4567–4575. [Google Scholar]

- Park, S.; Park, S.; Lee, J. A study on the modular design of smart photonic sports clothing based on optical fiber technology. Sci. Emot. Sensib. 2009, 12, 393–402. [Google Scholar]

- Shao, T. Real-Time Monitoring System for Human Physiological Parameters Based on Optical Fiber Flexible Sensing. Master’s Thesis, Changchun University of Science and Technology, Jilin, China, 2024. [Google Scholar]

- Zheng, Y. Flexible Sensor Design Strategies Based on MXene Composite Materials and Their Application in Human Health Monitoring. Ph.D. Thesis, Jilin University, Changchun, China, 2024. [Google Scholar]

- Fan, C.; Yan, Y.; Zhang, J.; Liu, Y.; Zhang, X.; Huang, F. Flexible Optical Fiber Sensor for Metacarpophalangeal Joint Motion Angle. Chin. J. Sens. Actuators 2023, 36, 1503–1508. [Google Scholar]

- Presti, D.L.; Bianchi, D.; Massaroni, C.; Coricciati, C.; Rainer, A.; Silvestri, S.; Gizzi, A.; Schena, E. Optimization and characterization of a 3D-printed wearable strain sensor for respiration and heartbeat measurements. Measurement 2024, 228, 114377. [Google Scholar] [CrossRef]

- Erik, V.; Ebrahimzadeh, E.N.; Michal, H.; Anton, K.; Vratislav, R.; Martin, D.; Helena, K. The Current State of Optical Sensors in Medical Wearables. Biosensors 2022, 12, 217. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, C.; Zheng, T.; Wu, H.; Wu, Q.; Wang, Y. Wearable Optical Fiber Sensors in Medical Monitoring Applications: A Review. Sensors 2023, 23, 6671. [Google Scholar] [CrossRef] [PubMed]

- Dejnabadi, H.; Jolles, B.M.; Aminian, K. A new approach to accurate measurement of uniaxial joint angles based on a combination of accelerometers and gyroscopes. IEEE Trans. Bio-Med. Eng. 2005, 52, 1478–1484. [Google Scholar] [CrossRef]

- Chen, Z.; Qian, D.; Xie, D.; Gao, C.; Shi, J.; Morikawa, H.; Zhu, C. Structure and Wiring Optimized TT/MT Double-Helical Fiber Sensors: Fabrication and Applications in Human Motion Monitoring and Gesture Recognition. Adv. Sci. 2025, 12, e2416564. [Google Scholar]

- Zhang, J.; Wang, X.; Bi, H.; Jiang, C.; Qian, Y.; Mo, D. High-precision dynamic gesture recognition based on microfiber sensor and EMT-Net. Sens. Actuators A Phys. 2024, 379, 115852. [Google Scholar] [CrossRef]

- Yan, W.; Liu, A.; Luo, Y.; Chen, Z.; Wu, G.; Chen, J.; Huang, Q.; Yang, Y.; Ye, M.; Guo, W. A Highly Sensitive and Stretchable Core-Shell Fiber Sensor for Gesture Recognition and Surface Pressure Distribution Monitoring. Macromol. Rapid Commun. 2024, 45, e2400109. [Google Scholar] [CrossRef] [PubMed]

- Ge, Q.-Q.; Zhou, T.; Gong, T.-Y.; Liang, Y.; Ngiejungbwen, L.A.; Chen, M.-Y. Highly sensitive measurement of finger joint angle based on a double-U tapered POF embedded in PDMS film. Opt. Fiber Technol. 2023, 76, 103236. [Google Scholar] [CrossRef]

- Luca, R.; Adrien, H.; Laurence, C.; Thierry, S. A magnetically actuated, optically sensed tensile testing method for mechanical characterization of soft biological tissues. Sci. Adv. 2023, 9, eade2522. [Google Scholar] [CrossRef]

- Atkins, C.A.; Pond, K.R.; Madsen, C.K. Investigation of an animal-in-motion-optical-sensor system for detecting biomechanical patterns in variable cattle gaits. J. Anim. Sci. 2017, 95, 8. [Google Scholar] [CrossRef][Green Version]

- Kavuncuoğlu, E.; Uzunhisarcıklı, E.; Barshan, B.; Özdemir, A.T. Investigating the Performance of Wearable Motion Sensors on recognizing falls and daily activities via machine learning. Digit. Signal Process. 2022, 126, 103365. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, H.; Hu, F.; Feng, N.; Xi, H.; Zhang, Z.; Tang, H. Accurate recognition of lower limb ambulation mode based on surface electromyography and motion data using machine learning. Comput. Methods Programs Biomed. 2020, 193, 105486. [Google Scholar] [CrossRef]

- Chapman, R.M.; Torchia, M.T.; Bell, J.-E.; Van Citters, D.W. Assessing Upper Extremity Biomechanics during Activities of Daily Living Using Inertial Measurement Units: Does our Concept of ‘Normal’ Apply? J. Biomech. Eng. 2019, 141, 041001. [Google Scholar] [CrossRef]

- Chen, H.; Schall, M.C.; Martin, S.M.; Fethke, N.B. Drift-Free Joint Angle Calculation Using Inertial Measurement Units without Magnetometers: An Exploration of Sensor Fusion Methods for the Elbow and Wrist. Sensors 2023, 23, 7053. [Google Scholar] [CrossRef]

- Potter, M.V.; Cain, S.M.; Ojeda, L.V.; Gurchiek, R.D.; McGinnis, R.S.; Perkins, N.C. Evaluation of Error-State Kalman Filter Method for Estimating Human Lower-Limb Kinematics during Various Walking Gaits. Sensors 2022, 22, 8398. [Google Scholar] [CrossRef]

- Francisco, M.; Pilar, F.; Alicia, C.; Aikaterini, K.; María, C.; Carlos, M.J. Test–Retest Reliability of a Conventional Gait Model for Registering Joint Angles during Initial Contact and Toe-Off in Healthy Subjects. Int. J. Environ. Res. Public Health 2021, 18, 1343. [Google Scholar]

- Wang, L.; Li, H.; Wang, Z.; Meng, F. Study on upper limb rehabilitation system based on surface EMG. Bio-Med. Mater. Eng. 2015, 26, S795–S801. [Google Scholar] [CrossRef]

- Huang, X. Research on Rehabilitation Assessment Methods Based on Human Gait and sEMG. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2016. [Google Scholar]

- Zhu, X.; Ren, Z.; Xu, Q.; Zhou, R.; Chen, H.; Ling, Q.; Wang, X.; Yu, Z.; Chen, D. Dual-core fiber- assemble long period fiber grating for vector bending sensing. Opt. Lasers Eng. 2025, 186, 108774. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X.; Zhou, R.; Li, R.; Li, F. Integrated all-fiber-optic sensor based on FPI and MZI composite structures for temperature and strain measurement. Optik 2024, 319, 172111. [Google Scholar] [CrossRef]

- Xu, J.; Liu, T.; Dai, X.; Su, Y.; Shi, J.; Zheng, Y.; Dai, S.; Zhang, P. Multi-mode fiber Bragg grating for simultaneous detection of strain, torsion and temperature. Opt. Laser Technol. 2024, 179, 111293. [Google Scholar] [CrossRef]

- Wang, X. Research on Gesture Recognition and Authentication Based on Novel Sensors. Master’s Thesis, Zhejiang University, Hangzhou, China, 2024. [Google Scholar]

- Li, S. Design and Application of Flexible Pressure Sensor Based on Micro-Bulge Channels. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2022. [Google Scholar]

- Fang, Z.; Senanayake, D.; Ackland, D.C. On the use of inertial measurement units and musculoskeletal modeling in the calculation of muscle and joint loading at the shoulder. Med. Eng. Phys. 2025, 142, 104342. [Google Scholar] [CrossRef]

- Fan, B.; Zhang, L.; Cai, S.; Du, M.; Liu, T.; Li, Q.; Shull, P. Influence of Sampling Rate on Wearable IMU Orientation Estimation Accuracy for Human Movement Analysis. Sensors 2025, 25, 1976. [Google Scholar] [CrossRef]

- Liu, R. Mechanism and Application Research of Flexible Optical Fiber Sensor Based on Polymer Materials. Master’s Thesis, China Jiliang University, Hangzhou, China, 2023. [Google Scholar]

- Li, J.; Liu, B.; Liu, J.; Shi, J.-L.; He, X.-D.; Yuan, J.; Wu, Q. Low-cost wearable device based D-shaped single mode fiber curvature sensor for vital signs monitoring. Sens. Actuators A Phys. 2022, 337, 113429. [Google Scholar] [CrossRef]

- Pang, W.; Ma, C.; Zhao, L.; Yang, H.; Guo, W.; Lu, M. A study on fiber Bragg grating (FBG) strain sensor based on symmetrical lever structure. Rev. Sci. Instrum. 2023, 94, 125009. [Google Scholar] [CrossRef]

- Li, W.; Zou, K.; Guo, J.; Zhang, C.; Feng, J.; You, J.; Cheng, G.; Zhou, Q.; Kong, M.; Li, G.; et al. Integrated Fibrous Iontronic Pressure Sensors with High Sensitivity and Reliability for Human Plantar Pressure and Gait Analysis. ACS Nano 2024, 18, 14672–14684. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Z.; Bai, Y.; Li, L.; Zhou, Z.; Li, T.; Zhang, T. Rational design of a laminate-structured flexible sensor for human dynamic plantar pressure monitoring. Microsyst. Nanoeng. 2024, 10, 98. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, C.; Xia, H.; An, W.; Qi, M.; Zhang, D. Layer-by-Layer Self-Assembled Honeycomb Structure Flexible Pressure Sensor Array for Gait Analysis and Motion Posture Recognition with the Assistance of the ResNet-50 Neural Network. ACS Sens. 2025, 10, 2358–2366. [Google Scholar] [CrossRef]

- Liang, A.; Dong, W.; Li, X.; Chen, X. A novel dual-mode paper fiber sensor based on laser-induced graphene and porous salt-ion for monitoring humidity and pressure of human. Chem. Eng. J. 2024, 502, 158184. [Google Scholar] [CrossRef]

- Lallès, A.P.; Moucheboeuf, G.; Doat, E.; Pillet, H.; Bonnet, X. IMU Calibration Effect on Lower Limbs Kinematics Against Optical Motion Capture in Post-Stroke Gait. IRBM 2025, 46, 100873. [Google Scholar] [CrossRef]

- Markström, J.L.; Grip, H.; Schelin, L.; Häger, C.K. Dynamic knee control and movement strategies in athletes and non-athletes in side hops: Implications for knee injury. Scand. J. Med. Sci. Sports 2019, 29, 1181–1189. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Jia, C.; Zhu, Y.; Zhao, T. An Effective Self-Powered Piezoelectric Sensor for Monitoring Basketball Skills. Sensors 2021, 21, 5144. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Long, Z.; Yang, G.; Xing, L. A Self-Powered Wearable Motion Sensor for Monitoring Volleyball Skill and Building Big Sports Data. Biosensors 2022, 12, 60. [Google Scholar] [CrossRef]

- Seshadri, D.R.; Li, R.T.; Voos, J.E.; Rowbottom, J.R.; Alfes, C.M.; Zorman, C.A.; Drummond, C.K. Wearable sensors for monitoring the internal and external workload of the athlete. npj Digit. Med. 2019, 2, 71. [Google Scholar] [CrossRef]

- Massimo, M.; Luca, F.; Francesco, G.; Massimo, D.V. Conformal, Ultra-thin Skin-Contact-Actuated Hybrid Piezo/Triboelectric Wearable Sensor Based on AlN and Parylene-Encapsulated Elastomeric Blend. Adv. Funct. Mater. 2021, 31, 2101047. [Google Scholar]

- Donahue, S.R.; Hahn, M.E. Validation of Running Gait Event Detection Algorithms in a Semi-Uncontrolled Environment. Sensors 2022, 22, 3452. [Google Scholar] [CrossRef]

- Masihi, S.; Panahi, M.; Maddipatla, D.; Hanson, A.J.; Bose, A.K.; Hajian, S.; Palaniappan, V.; Narakathu, B.B.; Bazuin, B.J.; Atashbar, M.Z. Highly Sensitive Porous PDMS-Based Capacitive Pressure Sensors Fabricated on Fabric Platform for Wearable Applications. ACS Sens. 2021, 6, 938–949. [Google Scholar] [CrossRef]

- Sergio, S. Wearable Biometric Performance Measurement System for Combat Sports. IEEE Trans. Instrum. Meas. 2017, 66, 2545–2555. [Google Scholar] [CrossRef]

- Worsey, M.T.; Espinosa, H.G.; Shepherd, J.B.; Thiel, D.V. Inertial Sensors for Performance Analysis in Combat Sports: A Systematic Review. Sports 2019, 7, 28. [Google Scholar] [CrossRef]

- García-Pinillos, F.; Ramírez-Campillo, R.; Boullosa, D.; Jiménez-Reyes, P.; Latorre-Román, P.Á. Vertical Jumping as a Monitoring Tool in Endurance Runners: A Brief Review. J. Hum. Kinet. 2021, 80, 297–308. [Google Scholar] [CrossRef]

- Gloria, C.; Luca, A.; Valentina, V.; Lorenzo, S. Accuracy and Precision of Wearable Devices for Real-Time Monitoring of Swimming Athletes. Sensors 2022, 22, 4726. [Google Scholar] [CrossRef]

- Cuperman, R.; Jansen, K.M.B.; Ciszewski, M.G. An End-to-End Deep Learning Pipeline for Football Activity Recognition Based on Wearable Acceleration Sensors. Sensors 2022, 22, 1347. [Google Scholar] [CrossRef]

- Yang, Y.; Hou, X.; Geng, W.; Mu, J.; Zhang, L.; Wang, X.; He, J.; Xiong, J.; Chou, X. Human movement monitoring and behavior recognition for intelligent sports using customizable and flexible triboelectric nanogenerator. Sci. China Technol. Sci. 2022, 65, 826–836. [Google Scholar] [CrossRef]

- Magrum, E.D.; Wagle, J.P.; DeWeese, B.H.; Sato, K.; Stone, M.H. The Use of an Optical Measurement System to Monitor Sports Performance. Sports 2018, 6, 15. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Singh, R.; Zhang, B.; Li, G.; Kumar, S. Optical Fiber-Based Wearable Sensors for Remote Health Monitoring [Invited]. Adv. Sens. Res. 2024, 3, 2400082. [Google Scholar] [CrossRef]

- Chen, X.; Yuan, G. Sports Injury Rehabilitation Intervention Algorithm Based on Visual Analysis Technology. Mob. Inf. Syst. 2021, 2021. [Google Scholar] [CrossRef]

- Chen, Z.; He, T.; Wan, L.; Ma, Z.; Xiang, Z.; Zhou, Z. A Real-time Blade Pressure Detection System Based on Optical Fiber Sensor. CN210268995U, 7 April 2020. [Google Scholar]

- Wilhoite, S.; Mutchler, J.A.; Barry, A.M.; Li, L.I. Ankle-Knee Initial Contact Angle and Latency to Maximum Angle are Affected by Prolonged Run. Int. J. Exerc. Sci. 2021, 14, 33–44. [Google Scholar] [CrossRef]

- Keitaro, K.; Daisuke, M.; Kenji, Y.; Shozo, S.; Naoya, T. Are the knee and ankle angles at contact related to the tendon properties of lower limbs in long distance runners? SpringerPlus 2016, 5, 151. [Google Scholar] [CrossRef] [PubMed]

- Yong, L. Application of Fiber Optic Biosensor in Detection of Sports Analeptic. Int. J. Bioautom. 2018, 22, 301–314. [Google Scholar]

- Snegireva, N.; Derman, W.; Patricios, J.; Welman, K.E. Awareness and Perceived Value of Eye Tracking Technology for Concussion Assessment among Sports Medicine Clinicians: A Multinational Study. Physician Sportsmed. 2020, 48, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Liang, H. Sensing Application of Single-Mode-Multimode-Single-Mode Fiber Structure in Postoperative Rehabilitation Monitoring for Fracture Patients. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2021. [Google Scholar]

- Liu, Y.; Zhang, D.; Yang, Q.; Zhao, X. Sensor Driven Integrated Software Rehabilitation Hand Based on Optical Waveguide. Autom. Instrum. 2023, 38, 115–119. [Google Scholar] [CrossRef]

- Bisht, A.; Simone, K.; Bains, J.S.; Murari, K. Distinguishing motion artifacts during optical fiber-based in-vivo hemodynamics recordings from brain regions of freely moving rodents. Neurophotonics 2024, 11, S11511. [Google Scholar] [CrossRef]

- Yücel, M.A.; Selb, J.; Boas, D.A.; Cash, S.S.; Cooper, R.J. Reducing motion artifacts for long-term clinical NIRS monitoring using collodion-fixed prism-based optical fibers. NeuroImage 2014, 85, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Xu, H.; Zhang, Z.; Yang, G.; Yan, F. Fiber-optic distributed acoustic sensing signal enhancement based on data fusion of premium sensing channels. Opt. Commun. 2025, 577, 131403. [Google Scholar] [CrossRef]

- Bangaru, S.S.; Wang, C.; Aghazadeh, F.; Muley, S.; Willoughby, S. Oxygen Uptake Prediction for Timely Construction Worker Fatigue Monitoring Through Wearable Sensing Data Fusion. Sensors 2025, 25, 3204. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, H.; Wang, P.; Jiang, B. A method for improving the signal-to-noise ratio of ΦOTDR based on time-varying filtering-based empirical mode decomposition (on line). Opt. Commun. Technol. 2025, 1–13. Available online: https://link.cnki.net/urlid/45.1160.TN.20250107.1658.002 (accessed on 23 September 2025).

- Zhou, X.; Wang, F.; Yang, C.; Zhang, Z.; Zhang, Y.; Zhang, X. Hybrid Distributed Optical Fiber Sensor for the Multi-Parameter Measurements. Sensors 2023, 23, 7116. [Google Scholar] [CrossRef]

- Yi, J.; Shang, Y.; Wang, C.; Du, Y.; Yang, J.; Sun, M.; Huang, S.; Qu, S.; Zhao, W.; Zhao, Y.; et al. An intelligent crash recognition method based on 1DResNet-SVM with distributed vibration sensors. Opt. Commun. 2023, 536, 129263. [Google Scholar] [CrossRef]

- Yang, X.; Liu, M.; Song, H.; Rao, J.; Wu, Y. A novel packaging method for FBG temperature sensors based on ultrasonic-assisted soldering technology. Sens. Actuators A Phys. 2024, 373, 115381. [Google Scholar] [CrossRef]

- Chen, H. Research on Signal Processing Algorithm of Distributed Opyical Fiber Vibration Sensor System. Master’s Thesis, Shandong University, Jinan, China, 2018. [Google Scholar]

- Sun, Z.; Shi, F.; Shi, Z.; Choi, H.W.; Liu, Y.; Wang, Y.; Yan, J. GaN Optoelectronic Integrated Chip with Multifunctions of Communication and Neuromorphic Computing. Adv. Opt. Mater. 2025, 13, 70007. [Google Scholar] [CrossRef]

- Xiong, Y.; Sadek, M.; Chu, R. Recent advances in GaN-based power devices and integration. Semicond. Sci. Technol. 2025, 40, 033002. [Google Scholar] [CrossRef]

- Ferreira, V.T.; Magri, V.P.R.; Santos, A.C.T.; Ribeiro, R.M. Optoelectronic oscillator using visible LEDs and plastic optical fibers. Appl. Opt. 2024, 63, 8796–8801. [Google Scholar] [CrossRef]

- Christ, B.; Prakashan, D.; Nadler, K.; Weigel, T.; Probst, J.; Dembski, S.; Gandhi, S. Synergistic Micro-Nano Architecture In Silica Fiber Scaffolds Accelerates Wound Healing. Adv. Healthc. Mater. 2025, e02514. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Luo, H.; Zhang, Y.; Zeng, J.; Zhao, J.; He, Y.; Wang, X.; Yuan, W. A partially PDMS-encapsulated microfiber Bragg grating for simultaneous temperature and strain measurement. Opt. Fiber Technol. 2025, 93, 104188. [Google Scholar] [CrossRef]

- Yu, Q. Design of a Pulse Monitoring System Based on Optical Fiber Sensors. Master’s Thesis, China Jiliang University, Hangzhou, China, 2022. [Google Scholar]

- Yu, L.; Yeo, J.C.; Soon, R.H.; Yeo, T.; Lee, H.H.; Lim, C.T. Highly Stretchable, Weavable, and Washable Piezoresistive Microfiber Sensors. ACS Appl. Mater. Interfaces 2018, 10, 12773–12780. [Google Scholar] [CrossRef] [PubMed]

- Lobach, I.A.; Fotiadi, A.A.; Yatseev, V.A.; Konstantinov, Y.A.; Barkov, F.L.; Claude, D.; Kambur, D.A.; Belokrylov, M.E.; Turov, A.T.; Korobko, D.A. Newest Methods and Approaches to Enhance the Performance of Optical Frequency-Domain Reflectometers. Sensors 2024, 24, 5432. [Google Scholar] [CrossRef]

- Lan, Z. Research on Optical Fiber Power Transmission Technology and Its Application in Communication Detection. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2021. [Google Scholar]

- Wang, Y.-L.; Liu, B.; Pang, Y.-N.; Liu, J.; Shi, J.-L.; Wan, S.-P.; He, X.-D.; Yuan, J.; Wu, Q. Low-Cost Wearable Sensor Based on a D-Shaped Plastic Optical Fiber for Respiration Monitoring. IEEE Trans. Instrum. Meas. 2021, 70, 4004808. [Google Scholar] [CrossRef]

- Wu, Y.T.; Gomes, M.K.; da Silva, W.H.; Lazari, P.M.; Fujiwara, E. Integrated Optical Fiber Force Myography Sensor as Pervasive Predictor of Hand Postures. Biomed. Eng. Comput. Biol. 2020, 11, 1179597220912825. [Google Scholar] [CrossRef]

- Rasheed, A.A.; Khan, R.; Alsaed, T.; Kundi, M.; Saad, M.H.M.; Sarker, M.R. Privacy-Preserving Information Fusion Technique for Device to Server-Enabled Communication in the Internet of Things: A Hybrid Approach. Comput. Mater. Contin. 2024, 80, 1305–1323. [Google Scholar]

- Menassa, M.; Wilmont, I.; Beigrezaei, S.; Knobbe, A.; Arita, V.A.; Valderrama, J.F.V.; Bridge, L.; Verschuren, W.M.M.; Rennie, K.L.; Franco, O.H.; et al. The future of healthy ageing: Wearables in public health, disease prevention and healthcare. Maturitas 2025, 196, 108254. [Google Scholar] [CrossRef] [PubMed]

- Ayena, J.C.; Bouayed, A.; Arous, M.B.; Ouakrim, Y.; Loulou, K.; Ameyed, D.; Savard, I.; Kamel, L.E.; Mezghani, N. Predicting chronic pain using wearable devices: A scoping review of sensor capabilities, data security, and standards compliance. Front. Digit. Health 2025, 7, 1581285. [Google Scholar] [CrossRef] [PubMed]

- Zongda, W.; Zhuolin, M.; Jing, Y.; Jinzhou, H.; Bin, W.; Zhiqiang, Z.; Caicai, Z.; Jiaoli, S.; Xiancheng, W. Secure Cloud Storage and Retrieval of Personal Health Data From Smart Wearable Devices With Privacy-Preserving Techniques. Int. J. Web Serv. Res. (IJWSR) 2023, 20, 1–18. [Google Scholar]

- Lu, X.; Krebber, K. Suppression of Rayleigh fading induced errors in φOTDR by different pulse widths for improving the reliability of civil infrastructure monitoring. Opt. Laser Technol. 2025, 181, 111927. [Google Scholar] [CrossRef]

- Ye, Z.; Ji, P.N.; Wang, T. Distributed fiber optic sensors placement for infrastructure-as-a-sensor. Photonic Netw. Commun. 2022, 44, 90–101. [Google Scholar] [CrossRef]

- DeGraff, J.; Liang, R.; Le, M.Q.; Capsal, J.-F.; Ganet, F.; Cottinet, P.-J. Printable low-cost and flexible carbon nanotube buckypaper motion sensors. Mater. Des. 2017, 133, 47–53. [Google Scholar] [CrossRef]

- He, W.; Li, B. The impact of data-driven metrics on training programs to improve the performance of elite basketball players. J. Comput. Methods Sci. Eng. 2025, 25, 4451–4463. [Google Scholar] [CrossRef]

- Ransom, D.; Tudor, B.; Irani, S.; Rehman, M.; Suskauer, S.; Mularoni, P.P.; Ahumada, L. Feasibility of Data Collection Via Consumer-Grade Wearable Devices in Adolescent Student Athletes: Prospective Longitudinal Cohort Study. JMIR Form. Res. 2025, 9, e54630. [Google Scholar] [CrossRef] [PubMed]

- Micó, S.I.; Aparicio, R.G.; Conesa, A.G. Effect of a physical exercise program supported by wearable technology in children with drug-resistant epilepsy. A randomized controlled trial. Seizure 2024, 121, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhang, C.; Yang, F. Should it be all wrapped up? Impact of functional area and weight on user comfort of wearable devices based on phase change materials. Ergonomics 2025, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, S.; Guo, M.; Wang, L.; Niu, W.; Gao, J. Knitted wearable with graded stiffness for directional loading to mitigate lumbar spine deconditioning in bedridden patients. Appl. Mater. Today 2025, 44, 102793. [Google Scholar] [CrossRef]

- Sun, Z.; Fang, M.; Huang, D.; Yang, H.; Zhao, C.; Li, S.; Liu, F. An unsupervised learning method to enhance SNR for distributed optical fiber vibration sensor based on phase-sensitive OTDR. Opt. Laser Technol. 2025, 180, 111570. [Google Scholar] [CrossRef]

- Lv, X.; Tao, Y.; Zhang, Y.; Xue, Y. Design of an Immersive Basketball Tactical Training System Based on Digital Twins and Federated Learning. Appl. Sci. 2025, 15, 3831. [Google Scholar] [CrossRef]

- Du, S.; Xiao, Y.; Zhang, C.; Fu, C.; Li, Q.; Hou, L.; Li, Q.; Shi, C.; Wang, X. Review: Battery charging optimization based on PVDF electret triboelectric nanogenerators. J. Mater. Sci. 2025, 60, 15492–15504. [Google Scholar] [CrossRef]

- Xiao, B. Design and Realization of Low Power Consumption Intelligent Power-Over-Fiber System. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2017. [Google Scholar]

- Mendoza, E.A.; Kempen, C.; Sun, S.; Esterkin, Y. Light weight, high-speed, and self-powered wireless fiber optic sensor (WiFOS) structural health monitor system for avionics and aerospace environments. Proc. SPIE-Int. Soc. Opt. Eng. 2014, 9202, 92020L. [Google Scholar]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]