Long-Cavity M-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Monolithic Curved Mirror †

Abstract

1. Introduction

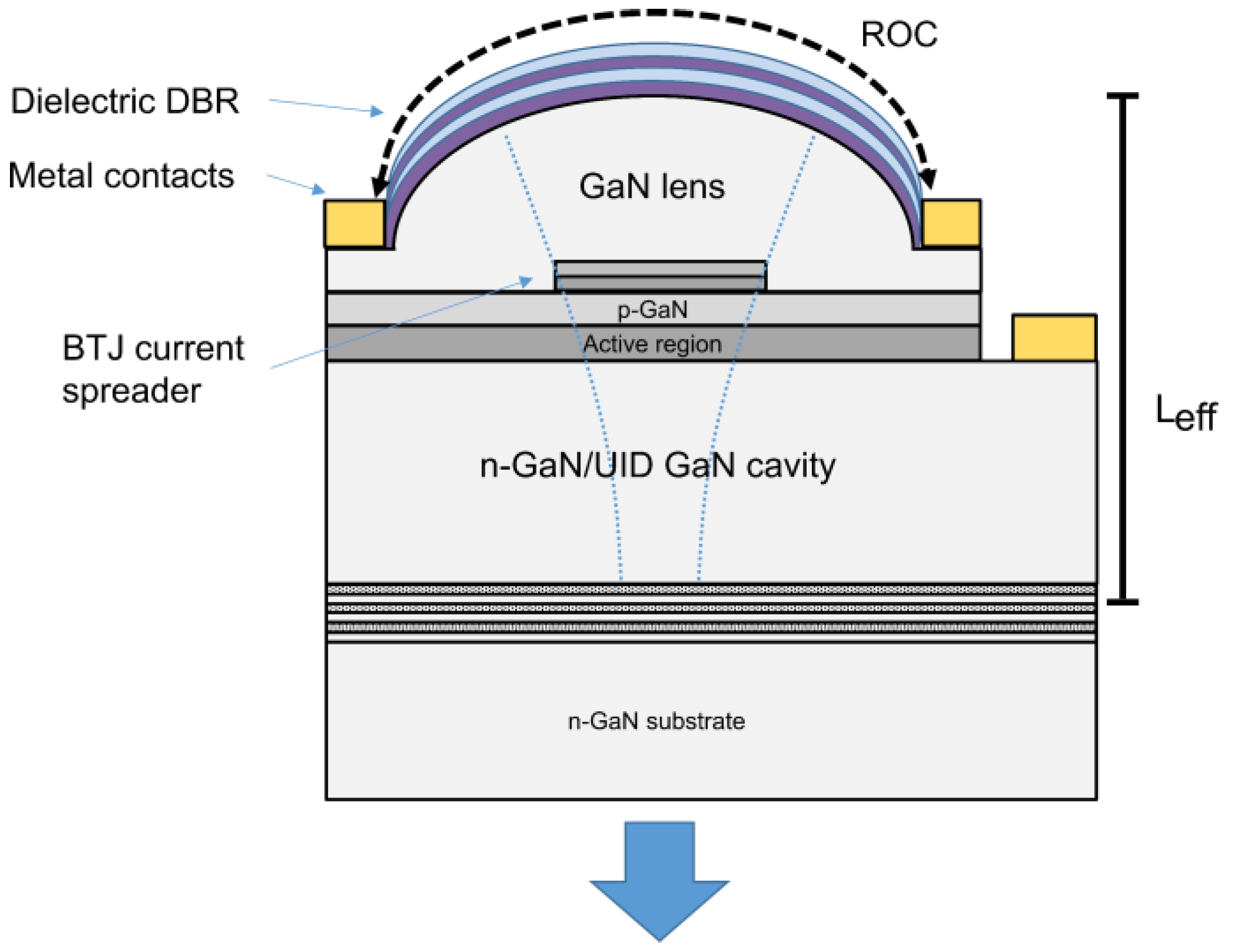

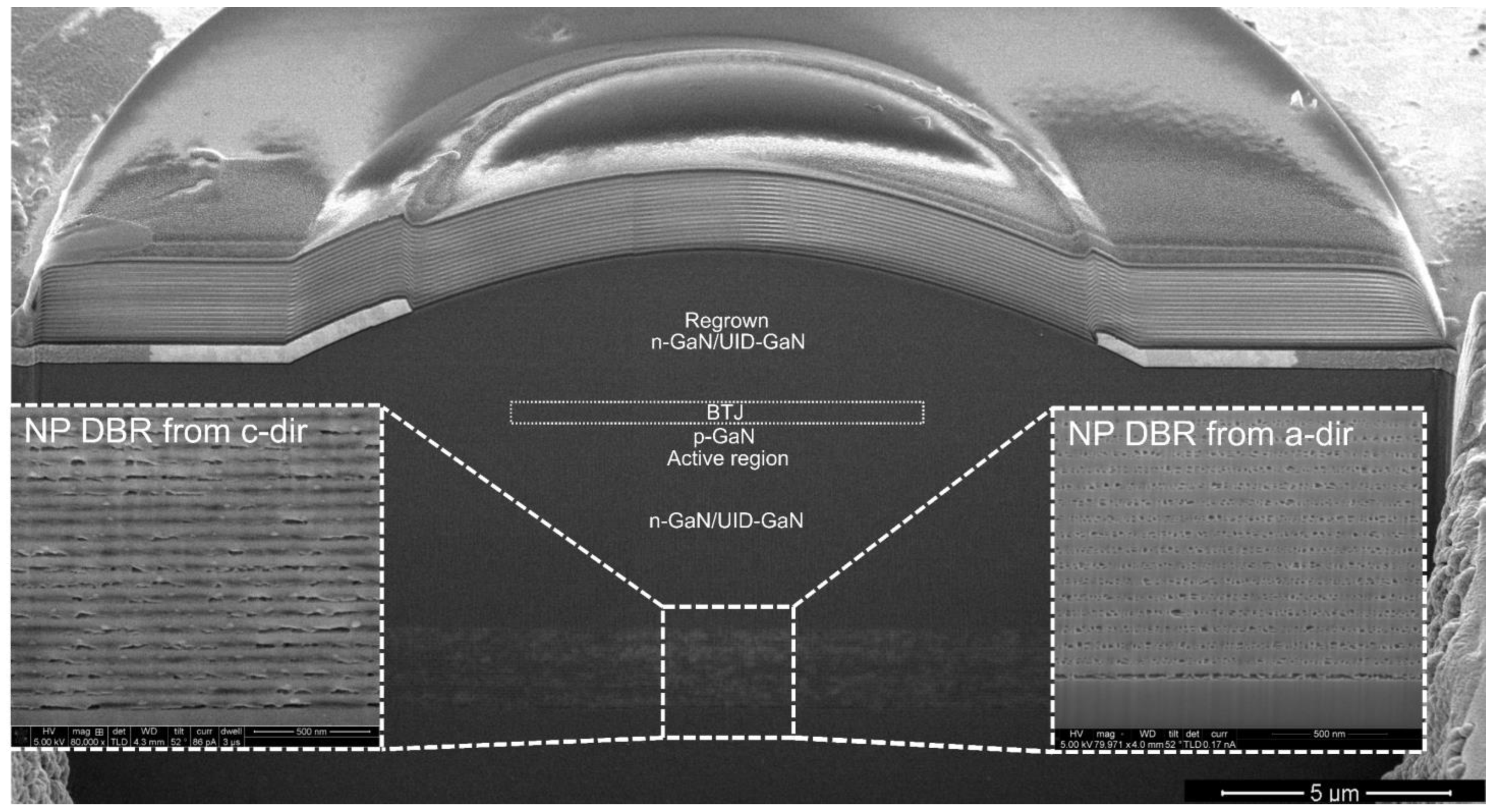

2. Materials and Methods

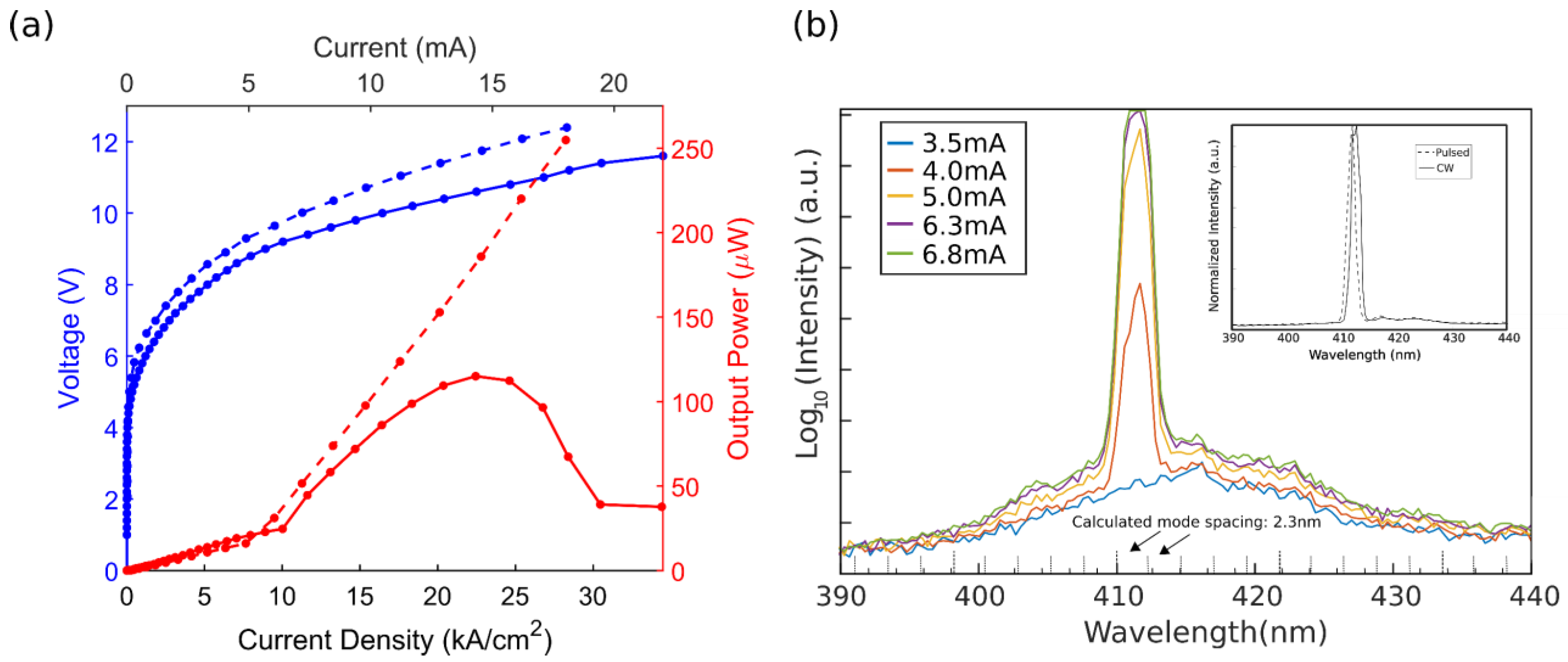

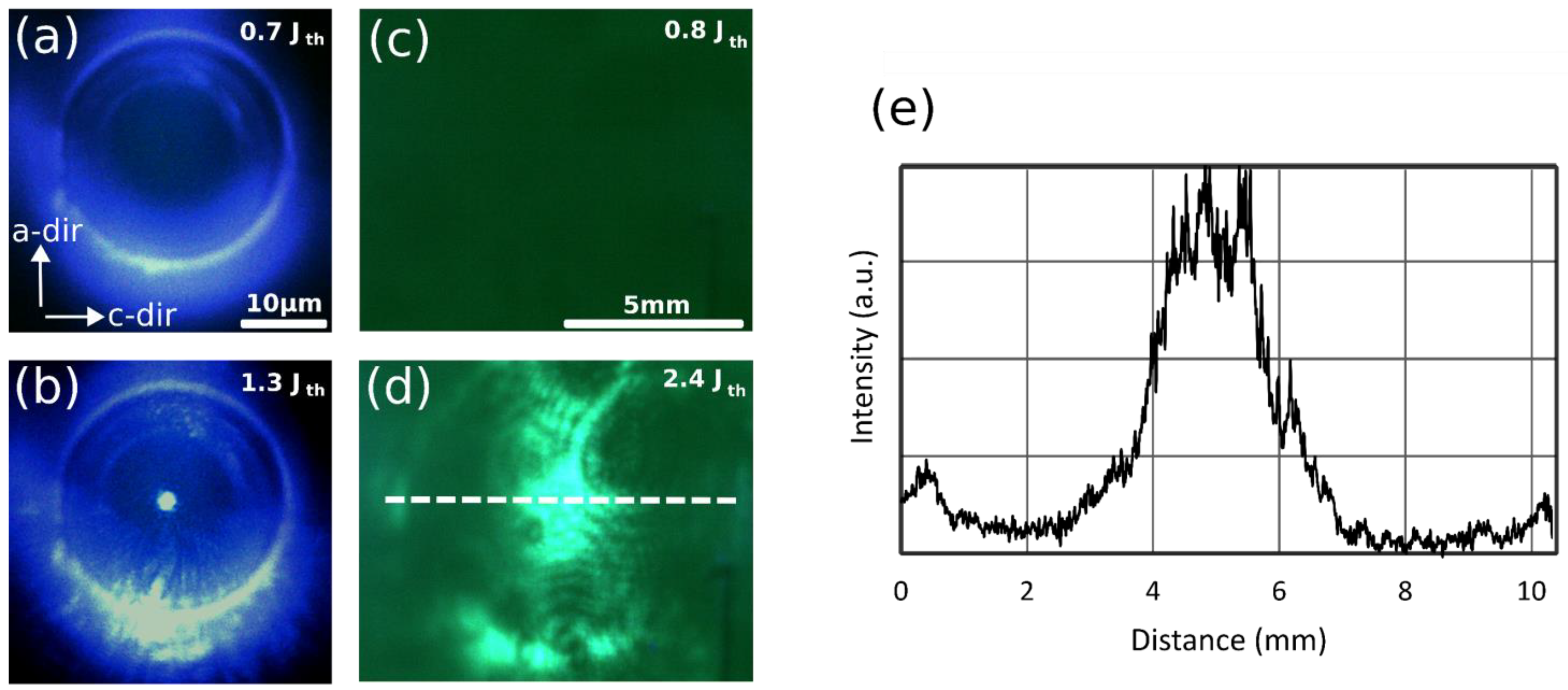

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michalzik, R. VCSELs: Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-24985-3. [Google Scholar]

- Hayashi, N.; Ogimoto, J.; Matsui, K.; Furuta, T.; Akagi, T.; Iwayama, S.; Takeuchi, T.; Kamiyama, S.; Iwaya, M.; Akasaki, I. A GaN-Based VCSEL with a Convex Structure for Optical Guiding. Phys. Status Solidi A 2018, 215, 1700648. [Google Scholar] [CrossRef]

- Kuramoto, M.; Kobayashi, S.; Akagi, T.; Tazawa, K.; Tanaka, K.; Saito, T.; Takeuchi, T. High-Power GaN-Based Vertical-Cavity Surface-Emitting Lasers with AlInN/GaN Distributed Bragg Reflectors. Appl. Sci. 2019, 9, 416. [Google Scholar] [CrossRef]

- Leonard, J.T.; Cohen, D.A.; Yonkee, B.P.; Farrell, R.M.; Margalith, T.; Lee, S.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Nonpolar III-Nitride Vertical-Cavity Surface-Emitting Lasers Incorporating an Ion Implanted Aperture. Appl. Phys. Lett. 2015, 107, 011102. [Google Scholar] [CrossRef]

- Kearns, J.A.; Back, J.; Cohen, D.A.; DenBaars, S.P.; Nakamura, S. Demonstration of Blue Semipolar (2021) GaN-Based Vertical-Cavity Surface-Emitting Lasers. Opt. Express 2019, 27, 23707. [Google Scholar] [CrossRef]

- ElAfandy, R.T.; Kang, J.-H.; Li, B.; Kim, T.K.; Kwak, J.S.; Han, J. Room-Temperature Operation of c-Plane GaN Vertical Cavity Surface Emitting Laser on Conductive Nanoporous Distributed Bragg Reflector. Appl. Phys. Lett. 2020, 117, 011101. [Google Scholar] [CrossRef]

- Elafandy, R.T.; Kang, J.-H.; Mi, C.; Kim, T.K.; Kwak, J.S.; Han, J. Study and Application of Birefringent Nanoporous GaN in the Polarization Control of Blue Vertical-Cavity Surface-Emitting Lasers. ACS Photonics 2021, 8, 1041–1047. [Google Scholar] [CrossRef]

- Kiyohara, K.; Odawara, M.; Takeuchi, T.; Kamiyama, S.; Iwaya, M.; Akasaki, I.; Saito, T. Room-Temperature Continuous-Wave Operations of GaN-Based Vertical-Cavity Surface-Emitting Lasers with Buried GaInN Tunnel Junctions. Appl. Phys. Express 2020, 13, 111003. [Google Scholar] [CrossRef]

- Kearns, J.A.; Back, J.; Palmquist, N.C.; Cohen, D.A.; DenBaars, S.P.; Nakamura, S. Inhomogeneous Current Injection and Filamentary Lasing of Semipolar (2021¯) Blue GaN-Based Vertical-Cavity Surface-Emitting Lasers with Buried Tunnel Junctions. Phys. Status Solidi (A) 2019, 217, 1900718. [Google Scholar] [CrossRef]

- Hamaguchi, T.; Tanaka, M.; Nakajima, H. A Review on the Latest Progress of Visible GaN-Based VCSELs with Lateral Confinement by Curved Dielectric DBR Reflector and Boron Ion Implantation. Jpn. J. Appl. Phys. 2019, 58, SC0806. [Google Scholar] [CrossRef]

- Nakajima, H.; Hamaguchi, T.; Tanaka, M.; Ito, M.; Jyokawa, T.; Matou, T.; Hayashi, K.; Ohara, M.; Kobayashi, N.; Watanabe, H.; et al. Single Transverse Mode Operation of GaN-Based Vertical-Cavity Surface-Emitting Laser with Monolithically Incorporated Curved Mirror. Appl. Phys. Express 2019, 12, 084003. [Google Scholar] [CrossRef]

- Hamaguchi, T.; Nakajima, H.; Tanaka, M.; Ito, M.; Ohara, M.; Jyoukawa, T.; Kobayashi, N.; Matou, T.; Hayashi, K.; Watanabe, H.; et al. Sub-Milliampere-Threshold Continuous Wave Operation of GaN-Based Vertical-Cavity Surface-Emitting Laser with Lateral Optical Confinement by Curved Mirror. Appl. Phys. Express 2019, 12, 044004. [Google Scholar] [CrossRef]

- Ito, M.; Hamaguchi, T.; Makino, T.; Hayashi, K.; Kearns, J.; Ohara, M.; Kobayashi, N.; Nagane, S.; Sato, K.; Nakamura, Y.; et al. Highly Efficient Operation and Uniform Characteristics of Curved Mirror Vertical-Cavity Surface-Emitting Lasers. Appl. Phys. Express 2022, 16, 012006. [Google Scholar] [CrossRef]

- Hamaguchi, T.; Tanaka, M.; Mitomo, J.; Nakajima, H.; Ito, M.; Ohara, M.; Kobayashi, N.; Fujii, K.; Watanabe, H.; Satou, S.; et al. Lateral Optical Confinement of GaN-Based VCSEL Using an Atomically Smooth Monolithic Curved Mirror. Sci. Rep. 2018, 8, 10350. [Google Scholar] [CrossRef]

- Kogelnik, H.; Li, T. Laser Beams and Resonators. Appl. Opt. AO 1966, 5, 1550–1567. [Google Scholar] [CrossRef]

- Hwang, D.; Mughal, A.; Wong, M.; Alhassan, A.; Nakamura, S.; Denbaars, S. Micro-Light-Emitting Diodes with III–Nitride Tunnel Junction Contacts Grown by Metalorganic Chemical Vapor Deposition. Appl. Phys. Express 2018, 11, 012102. [Google Scholar] [CrossRef]

- Wong, M.S.; Palmquist, N.C.; Jiang, J.; Chan, P.; Lee, C.; Li, P.; Kang, J.H.; Baek, Y.H.; Kim, C.H.; Cohen, D.A.; et al. Effects of Activation Method and Temperature to III-Nitride Micro-Light-Emitting Diodes with Tunnel Junction Contacts Grown by Metalorganic Chemical Vapor Deposition. Appl. Phys. Lett. 2021, 119, 202102. [Google Scholar] [CrossRef]

- Kioupakis, E.; Rinke, P.; Van de Walle, C.G. Determination of Internal Loss in Nitride Lasers from First Principles. Appl. Phys. Express 2010, 3, 082101. [Google Scholar] [CrossRef]

- Nussbaum, P.; Völkel, R.; Herzig, H.P.; Eisner, M.; Haselbeck, S. Design, Fabrication and Testing of Microlens Arrays for Sensors and Microsystems. Pure Appl. Opt. 1997, 6, 617–636. [Google Scholar] [CrossRef]

- Kuwano, Y.; Kaga, M.; Morita, T.; Yamashita, K.; Yagi, K.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I. Lateral Hydrogen Diffusion at P-GaN Layers in Nitride-Based Light Emitting Diodes with Tunnel Junctions. Jpn. J. Appl. Phys. 2013, 52, 08JK12. [Google Scholar] [CrossRef]

- Palmquist, N.C.; Anderson, R.; Kearns, J.A.; Back, J.; Trageser, E.; Gee, S.; Denbaars, S.P.; Nakamura, S. Continuous-Wave Operation of Long-Cavity m-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Curved Mirror and Nanoporous GaN DBR. In Proceedings of the Gallium Nitride Materials and Devices XVIII, San Francisco, CA, USA, 15 March 2023; Volume 12421, pp. 127–135. [Google Scholar]

- Wong, M.S.; Hwang, D.; Alhassan, A.I.; Lee, C.; Ley, R.; Nakamura, S.; DenBaars, S.P. High Efficiency of III-Nitride Micro-Light-Emitting Diodes by Sidewall Passivation Using Atomic Layer Deposition. Opt. Express OE 2018, 26, 21324–21331. [Google Scholar] [CrossRef]

- Zhang, C.; Park, S.H.; Chen, D.; Lin, D.-W.; Xiong, W.; Kuo, H.-C.; Lin, C.-F.; Cao, H.; Han, J. Mesoporous GaN for Photonic Engineering—Highly Reflective GaN Mirrors as an Example. ACS Photonics 2015, 2, 980–986. [Google Scholar] [CrossRef]

- Braun, M.M.; Pilon, L. Effective Optical Properties of Non-Absorbing Nanoporous Thin Films. Thin Solid Films 2006, 496, 505–514. [Google Scholar] [CrossRef]

- Anderson, R.; Cohen, D.; Zhang, H.; Trageser, E.; Palmquist, N.; Nakamura, S.; DenBaars, S. Nano-Porous GaN Cladding and Scattering Loss in Edge Emitting Laser Diodes. Opt. Express OE 2022, 30, 2759–2767. [Google Scholar] [CrossRef]

- Leonard, J.T.; Young, E.C.; Yonkee, B.P.; Cohen, D.A.; Margalith, T.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Demonstration of a III-Nitride Vertical-Cavity Surface-Emitting Laser with a III-Nitride Tunnel Junction Intracavity Contact. Appl. Phys. Lett. 2015, 107, 091105. [Google Scholar] [CrossRef]

- Yariv, A. Optical Electronics, 3rd ed.; Saunders College Publishing: Philadelphia, PA, USA, 1991; ISBN 978-1-60049-013-2. [Google Scholar]

- Mishkat-Ul-Masabih, S.M.; Aragon, A.A.; Monavarian, M.; Luk, T.S.; Feezell, D.F. Electrically Injected Nonpolar GaN-Based VCSELs with Lattice-Matched Nanoporous Distributed Bragg Reflector Mirrors. Appl. Phys. Express 2019, 12, 036504. [Google Scholar] [CrossRef]

- Ke, Y.; Wang, C.-J.; Shiu, G.-Y.; Chen, Y.-Y.; Lin, Y.-S.; Chen, H.; Han, J.; Lin, C.-F. Polarization Properties of InGaN Vertical-Cavity Surface-Emitting Laser with Pipe Distributed Bragg Reflector. IEEE Trans. Electron. Devices 2022, 69, 201–204. [Google Scholar] [CrossRef]

- Hamaguchi, T.; Hoshina, Y.; Hayashi, K.; Tanaka, M.; Ito, M.; Ohara, M.; Jyoukawa, T.; Kobayashi, N.; Watanabe, H.; Yokozeki, M.; et al. Room-Temperature Continuous-Wave Operation of Green Vertical-Cavity Surface-Emitting Lasers with a Curved Mirror Fabricated on (2021) Semi-Polar GaN. Appl. Phys. Express 2020, 13, 041002. [Google Scholar] [CrossRef]

- Kearns, J.; Hamaguchi, T.; Hayashi, K.; Ohara, M.; Makino, T.; Ito, M.; Kobayashi, N.; Jyoukawa, T.; Nakayama, E.; Nagane, S.; et al. Longitudinal Mode Control in Long Cavity VCSELs with a Curved Mirror. Appl. Phys. Express 2022, 15, 072009. [Google Scholar] [CrossRef]

- Leonard, J.T.; Yonkee, B.P.; Cohen, D.A.; Megalini, L.; Lee, S.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Nonpolar III-Nitride Vertical-Cavity Surface-Emitting Laser with a Photoelectrochemically Etched Air-Gap Aperture. Appl. Phys. Lett. 2016, 108, 031111. [Google Scholar] [CrossRef]

- Castiglia, A.; Carlin, J.-F.; Grandjean, N. Role of Stable and Metastable Mg–H Complexes in p-Type GaN for Cw Blue Laser Diodes. Appl. Phys. Lett. 2011, 98, 213505. [Google Scholar] [CrossRef]

- Aldaz, R.I.; Wiemer, M.W.; Miller, D.A.B.; Harris, J.S. Monolithically-Integrated Long Vertical Cavity Surface Emitting Laser Incorporating a Concave Micromirror on a Glass Substrate. Opt. Express OE 2004, 12, 3967–3971. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, K.; Hamaguchi, T.; Kearns, J.A.; Kobayashi, N.; Ohara, M.; Makino, T.; Nagane, S.; Sato, K.; Nakamura, Y.; Hoshina, Y.; et al. Narrow Emission of Blue GaN-Based Vertical-Cavity Surface-Emitting Lasers With a Curved Mirror. IEEE Photonics J. 2022, 14, 1–5. [Google Scholar] [CrossRef]

- Kuramoto, M.; Kobayashi, S.; Tazawa, K.; Tanaka, K.; Akagi, T.; Saito, T. In-Phase Supermode Operation in GaN-Based Vertical-Cavity Surface-Emitting Laser. Appl. Phys. Lett. 2019, 115, 041101. [Google Scholar] [CrossRef]

| Growth Step | Layer | Thickness (nm) | Doping Conc. (cm−3) | Abs. Coeff. (cm−1) |

|---|---|---|---|---|

| SiO2/Ta2O5 DBR (16–periods) | 67.5/45.5 | NA | 0 | |

| GaN | 1700 | UID | 2 | |

| 3rd | n-GaN | 1810 | 8 × 1018 | 2 |

| 2nd | n++–GaN | 8 | 1.5 × 1020 | 235 |

| 1st | p++–GaN | 10.5 | 2.5 × 1020 | 180 |

| p-GaN | 80 | 1 × 1019 | 80 | |

| p-AlGaN EBL | 10 | 1 × 1019 | 27 | |

| GaN barrier | 5 | UID | 2 | |

| GaN/InGaN QW (2x) | 3/8 | UID | 0 | |

| n-GaN | 2500 | 8 × 1018 | 2 | |

| GaN | 3860 | UID | 2 | |

| n+–GaN/GaN DBR (24–periods) | 48.4/40.4 | 5 × 1019/UID | 0/0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palmquist, N.C.; Anderson, R.; Kearns, J.A.; Back, J.; Trageser, E.; Gee, S.; Denbaars, S.P.; Nakamura, S. Long-Cavity M-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Monolithic Curved Mirror. Photonics 2023, 10, 646. https://doi.org/10.3390/photonics10060646

Palmquist NC, Anderson R, Kearns JA, Back J, Trageser E, Gee S, Denbaars SP, Nakamura S. Long-Cavity M-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Monolithic Curved Mirror. Photonics. 2023; 10(6):646. https://doi.org/10.3390/photonics10060646

Chicago/Turabian StylePalmquist, Nathan C., Ryan Anderson, Jared A. Kearns, Joonho Back, Emily Trageser, Stephen Gee, Steven P. Denbaars, and Shuji Nakamura. 2023. "Long-Cavity M-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Monolithic Curved Mirror" Photonics 10, no. 6: 646. https://doi.org/10.3390/photonics10060646

APA StylePalmquist, N. C., Anderson, R., Kearns, J. A., Back, J., Trageser, E., Gee, S., Denbaars, S. P., & Nakamura, S. (2023). Long-Cavity M-Plane GaN-Based Vertical-Cavity Surface-Emitting Lasers with a Topside Monolithic Curved Mirror. Photonics, 10(6), 646. https://doi.org/10.3390/photonics10060646