Impact of Device Topology on the Performance of High-Speed 1550 nm Wafer-Fused VCSELs

Abstract

1. Introduction

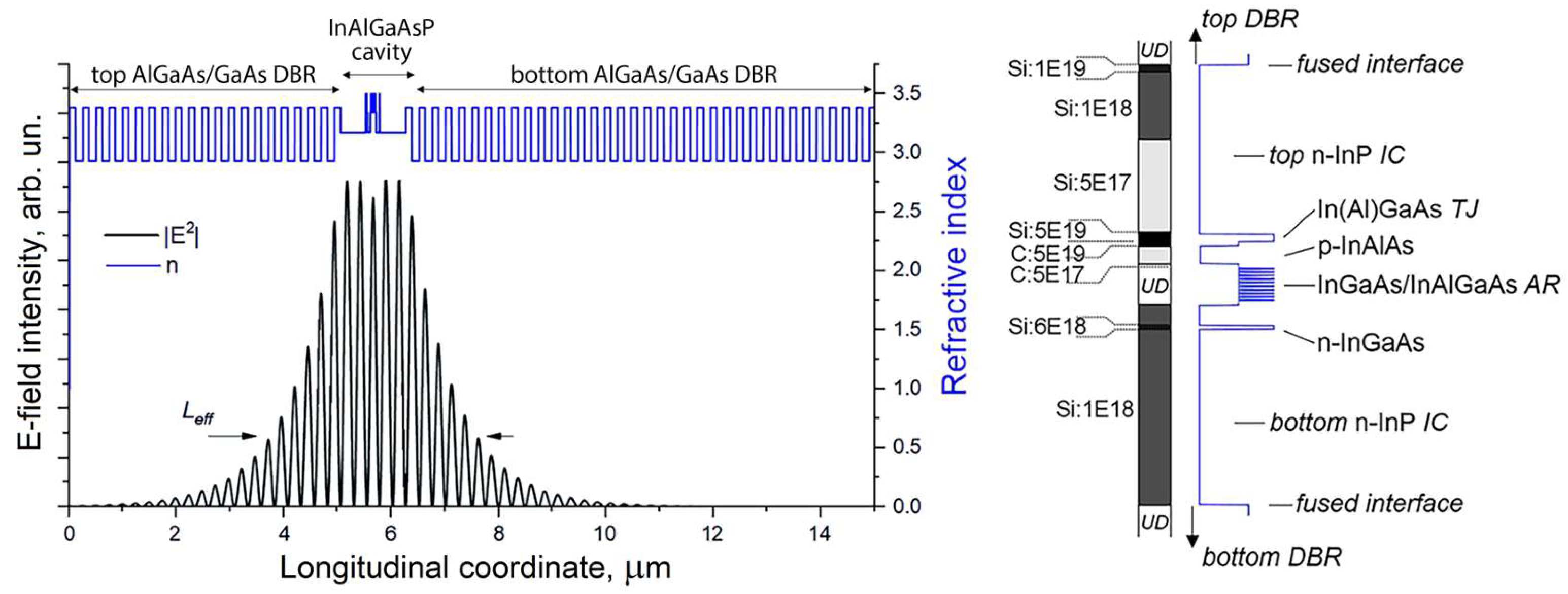

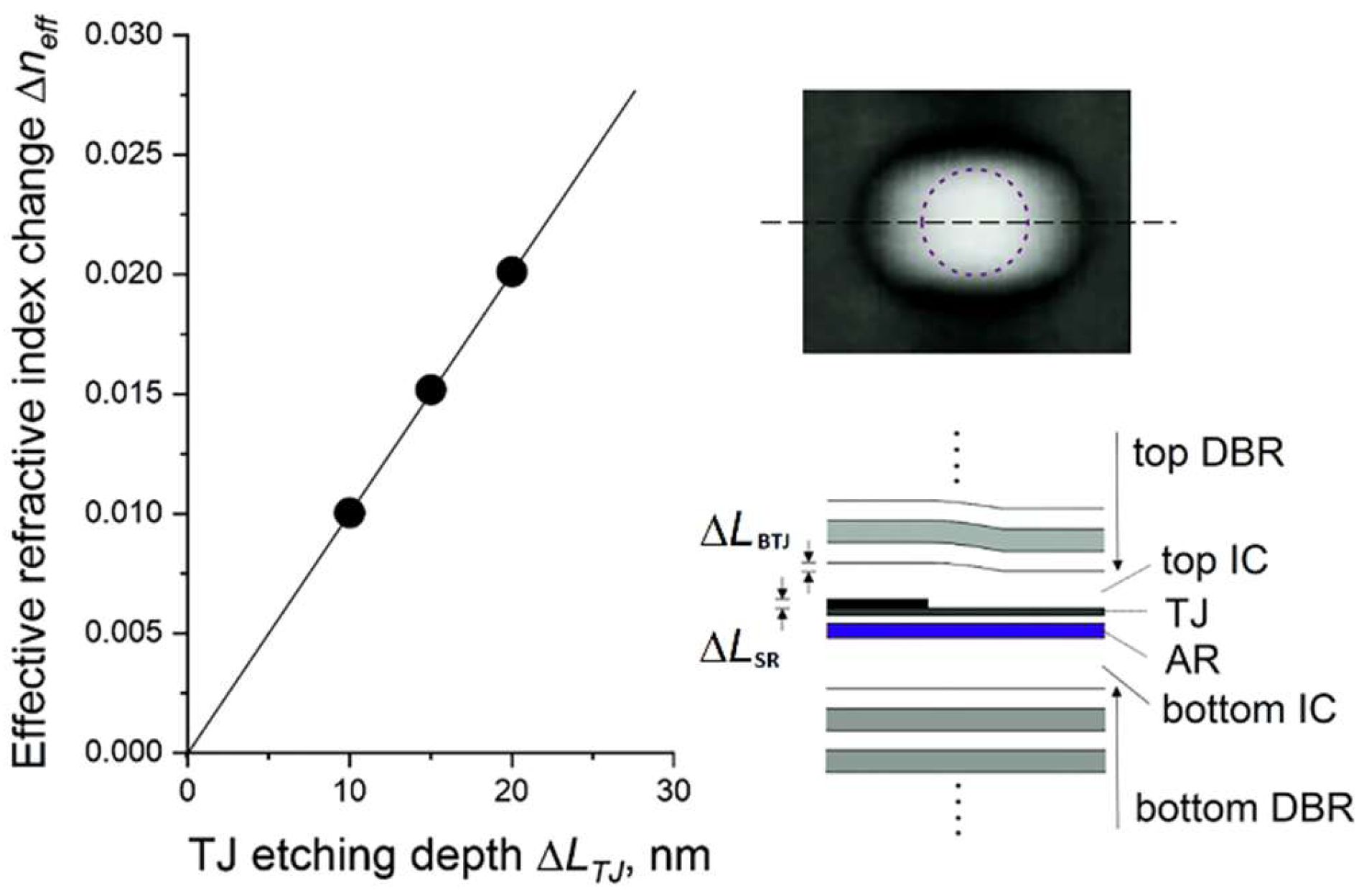

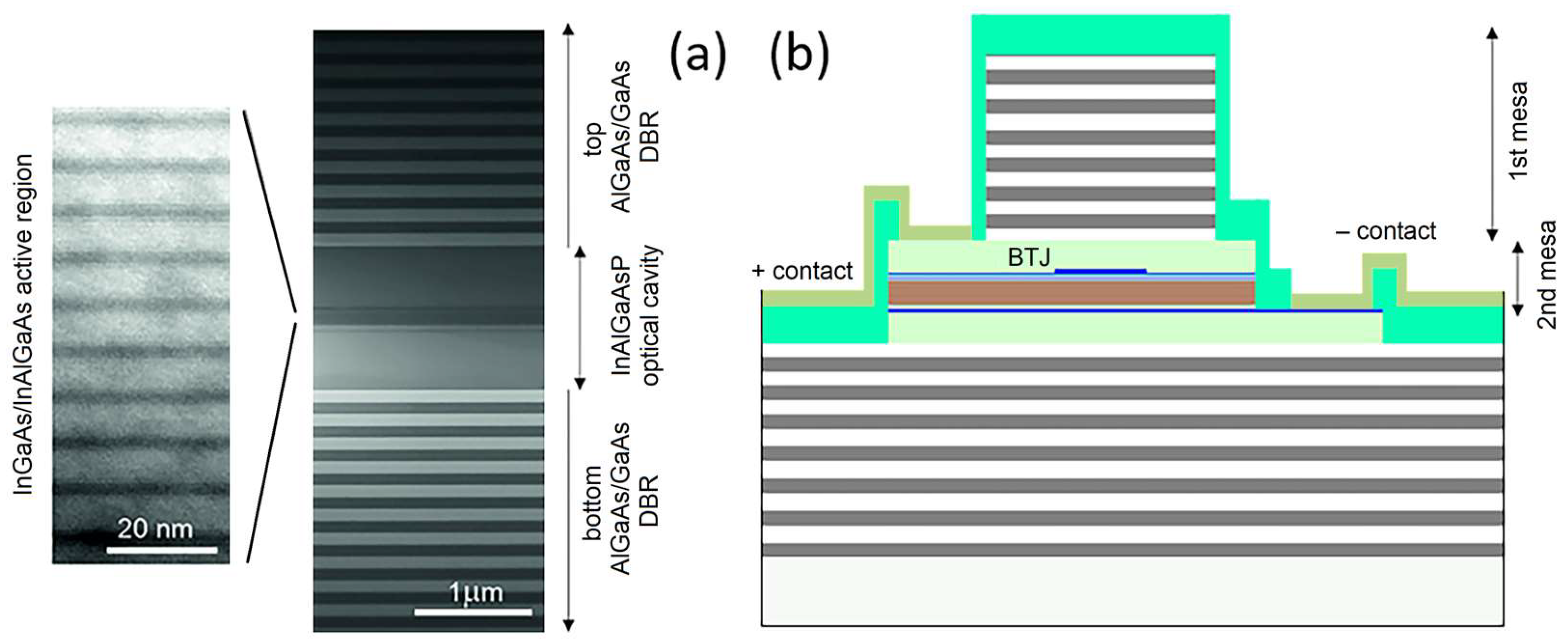

2. VCSEL Structure and Fabrication

3. Results and Discussion

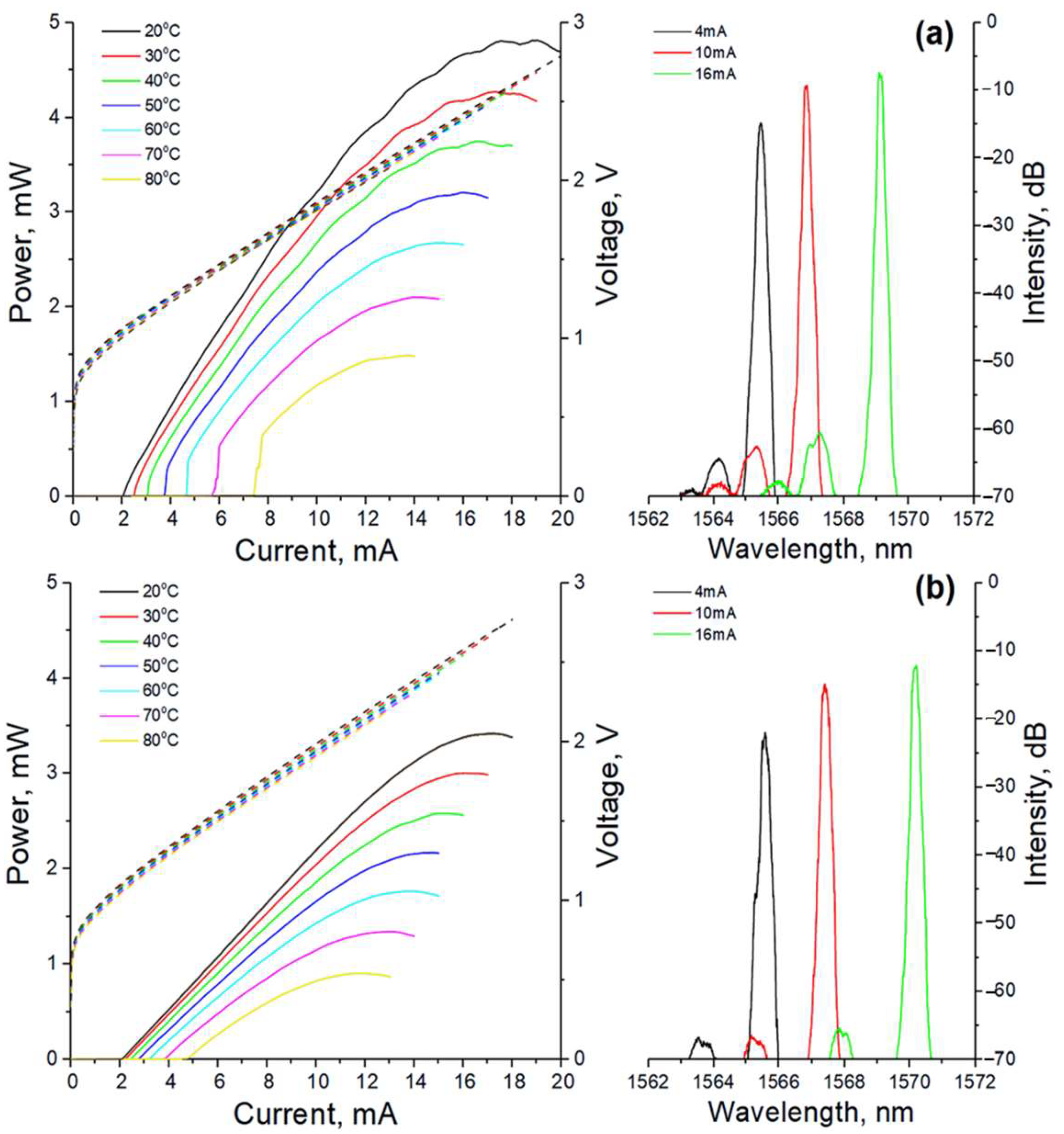

3.1. Static Characteristics

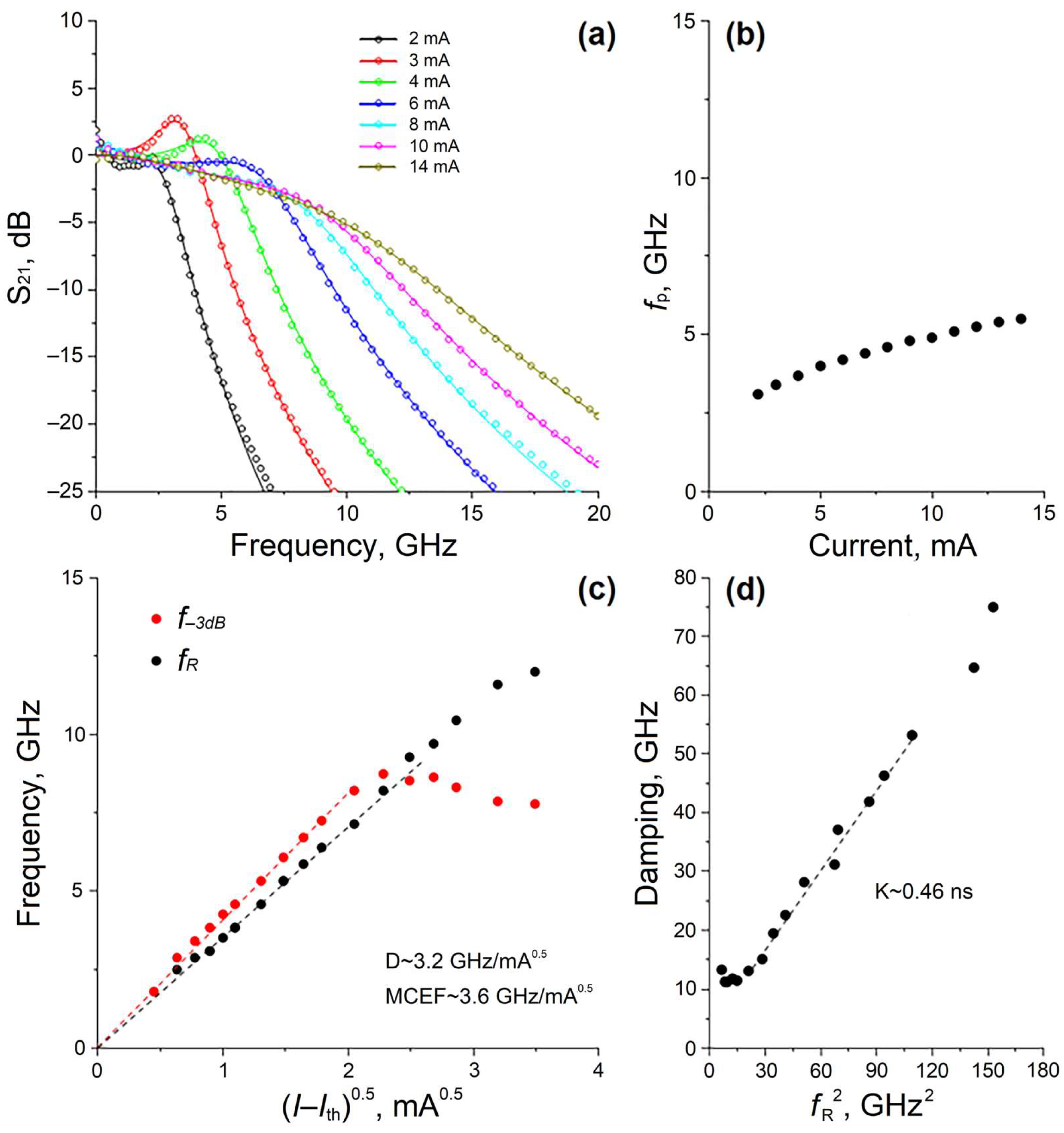

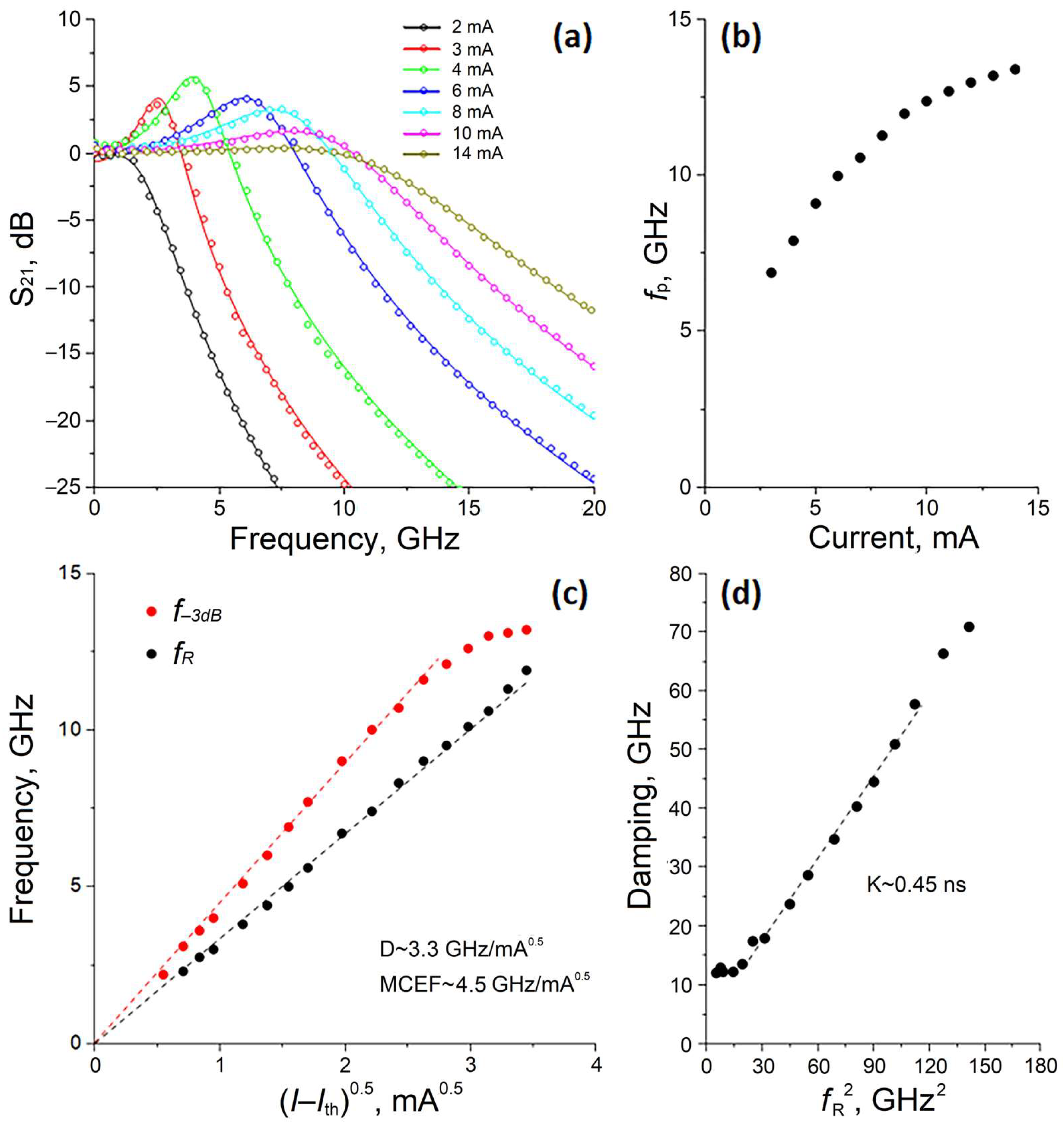

3.2. Small-Signal Modulation

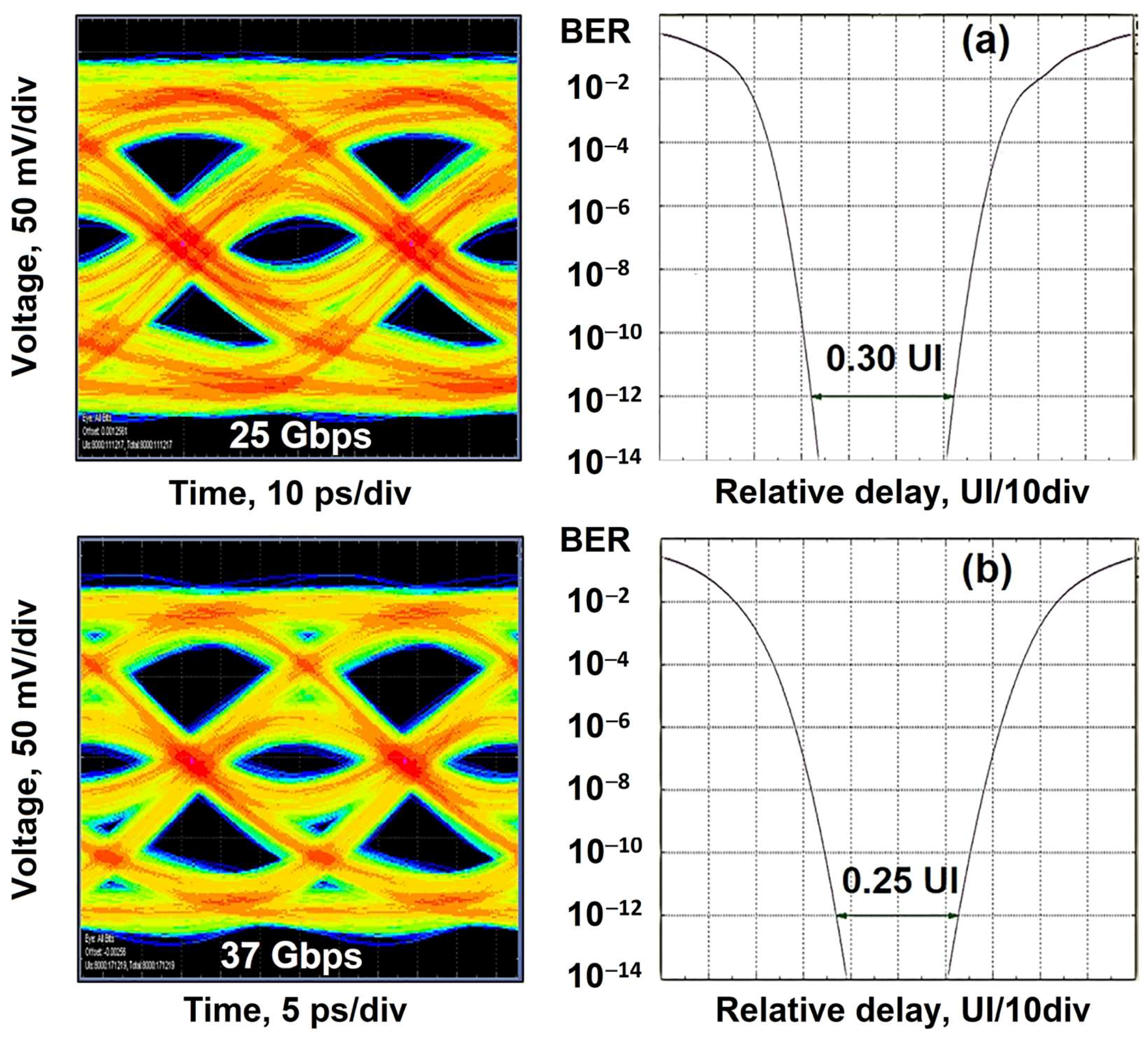

3.3. Large-Signal Modulation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thraskias, C.A.; Lallas, E.N.; Neumann, N.; Schares, L.; Offrein, B.J.; Henker, R.; Plettemeier, D.; Ellinger, F.; Leuthold, J.; Tomkos, I. Survey of photonic and plasmonic interconnect technologies for intra-datacenter and high-performance computing communications. IEEE Commun. Surv. Tutor. 2018, 20, 2758–2783. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Sharkia, A.; Casper, B.; Mirabbasi, S.; Shekhar, S. Silicon-photonics microring links for datacenters—Challenges and opportunities. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 194–203. [Google Scholar] [CrossRef]

- Datacenters to Get a High Fiber Bandwidth Diet. Available online: https://www.nextplatform.com/2016/03/18/datacenters-get-high-fiber-bandwidth-diet/ (accessed on 14 April 2023).

- Kanakis, G.; Iliadis, N.; Soenen, W.; Moeneclaey, B.; Argyris, N.; Kalavrouziotis, D.; Spiga, S.; Bakopoulos, P.; Avramopoulos, H. High-speed VCSEL-based transceiver for 200 GbE short-reach intra-datacenter optical interconnects. Appl. Sci. 2019, 9, 2488. [Google Scholar] [CrossRef]

- Kuchta, D.M.; Huynh, T.N.; Doany, F.E.; Schares, L.; Baks, C.W.; Neumeyr, C.; Daly, A.; Kogel, B.; Rosskopf, J.; Ortsiefer, M. Error-free 56 Gb/s NRZ modulation of a 1530-nm VCSEL link. J. Lightwave Technol. 2016, 34, 3275–3282. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, J.; Agrell, E.; Lin, R.; Wosinska, L. Enabling technologies for optical data center networks: Spatial division multiplexing. J. Lightwave Technol. 2020, 38, 18–30. [Google Scholar] [CrossRef]

- Liu, A.; Wolf, P.; Lott, J.A.; Bimberg, D. Vertical-cavity surface-emitting lasers for data communication and sensing. Photonics Res. 2019, 7, 121–136. [Google Scholar] [CrossRef]

- Charlier, J.C.; Krüger, S. Long-wavelength VCSELs ready to benefit 40/100-GbE modules. Lightwave 2023, 28, 2–7. Available online: https://www.lightwaveonline.com/optical-tech/article/16649511/longwavelengthvcsels-ready-to-benefit-40100gbe-module (accessed on 14 April 2023).

- Park, M.-R.; Kwon, O.-K.; Han, W.-S.; Lee, K.-H.; Park, S.-J.; Yoo, B.-S. All-epitaxial InAlGaAs-InP VCSELs in the 1.3–1.6-μm wavelength range for CWDM band applications. IEEE Photonics Technol. Lett. 2006, 18, 1717–1719. [Google Scholar] [CrossRef]

- Babichev, A.; Blokhin, S.; Kolodeznyi, E.; Karachinsky, L.; Novikov, I.; Egorov, A.; Tian, S.-C.; Bimberg, D. Long-wavelength VCSELs: Status and prospects. Photonics 2023, 10, 268. [Google Scholar] [CrossRef]

- Sirbu, A.; Suruceanu, G.; Iakovlev, V.; Mereuta, A.; Mickovic, Z.; Caliman, A.; Kapon, E. Reliability of 1310 nm wafer fused VCSELs. IEEE Photonics Technol. Lett. 2013, 25, 1555–1558. [Google Scholar] [CrossRef]

- Rao, Y.; Yang, W.; Chase, C.; Huang, M.C.; Worland, D.P.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Willner, A.E.; Chang-Hasnain, C.J. Long-wavelength VCSEL using high-contrast grating. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1701311. [Google Scholar] [CrossRef]

- Rao, Y.; Chase, C.; Huang, M.C.Y.; Khaleghi, S.; Chitgarha, M.R.; Ziyadi, M.; Worland, D.P.; Willner, A.E.; Chang-Hasnain, C.J. Tunable 1550-nm VCSEL using high contrast gratings. In Proceedings of the IEEE Photonics Conference 2012, Burlingame, CA, USA, 23–27 September 2012; pp. 864–865. [Google Scholar] [CrossRef]

- Paul, S.; Haidar, M.T.; Cesar, J.; Malekizandi, M.; Kögel, B.; Neumeyr, C.; Ortsiefer, M.; Küppers, F. Far-field, linewidth and thermal characteristics of a high-speed 1550-nm MEMS tunable VCSEL. Opt. Express 2016, 24, 13142–13156. [Google Scholar] [CrossRef] [PubMed]

- Zogal, K.H. MEMS weit abstimmbare VCSEL bei 1.55 μm und 1.95 μm. Ph.D. Thesis, Technische Universität, Darmstadt, Germany, 9 February 2017. Available online: https://tuprints.ulb.tu-darmstadt.de/6026/1/Dissertation_Zogal.pdf (accessed on 21 April 2023).

- Hofmann, W.; Müller, M.; Nadtochiy, A.; Meltzer, C.; Mutig, A.; Böhm, G.; Rosskopf, J.; Bimberg, D.; Amann, M.-C.; Chang-Hasnain, C. 22-Gb/s long wavelength VCSELs. Opt. Express 2009, 17, 17547–17554. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, W. High-speed buried tunnel junction vertical-cavity surface-emitting lasers. IEEE Photonics J. 2010, 2, 802–815. [Google Scholar] [CrossRef]

- Dohle, R.; Henning, G.; Wallrodt, M.; Gréus, C.; Neumeyr, C. Advanced packaging technology for novel 1-dimensional and 2-dimensional VCSEL Arrays. IMAPSource Proceedings 2021, 1, 000265–000270. [Google Scholar] [CrossRef]

- VCSEL advancements power 3d sensing. Available online: https://www.photonics.com/Articles/VCSELs_Increase_Power_and_Wavelength_for_3D/a68069 (accessed on 29 May 2023).

- Vertilas GmbH InP long wavelength VCSELs. Available online: https://epic-assoc.com/wp-content/uploads/2021/12/Christian-Neumeyr-Vertilas.pdf (accessed on 29 May 2023).

- Muller, M.; Hofmann, W.; Grundl, T.; Horn, M.; Wolf, P.; Nagel, R.D.; Ronneberg, E.; Bohm, G.; Bimberg, D.; Amann, M.C. 1550-nm High-speed short-cavity VCSELs. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1158–1166. [Google Scholar] [CrossRef]

- Pang, X.; Van Kerrebrouck, J.; Ozolins, O.; Lin, R.; Udalcovs, A.; Zhang, L.; Spiga, S.; Amann, M.C.; Van Steenberge, G.; Gan, L.; et al. 7× 100 Gbps PAM-4 transmission over 1-km and 10-km single mode 7-core fiber using 1.5-μm SM-VCSEL. In Proceedings of the 2018 Optical Fiber Communications Conference and Exposition (OFC), San Diego, CA, USA, 11–15 March 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Spiga, S.; Schoke, D.; Andrejew, A.; Müller, M.; Boehm, G.; Amann, M.-C. Single-mode 1.5-µm VCSELs with 22-GHz small-signal bandwidth. In OSA Technical Digest, Proceedings of the Optical Fiber Communication Conference 2016, Anaheim, CA, USA, 20–22 March 2016; Paper Tu3D.4; Optica Publishing Group: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Spiga, S.; Soenen, W.; Andrejew, A.; Schoke, D.M.; Yin, X.; Bauwelinck, J.; Boehm, G.; Amann, M.-C. Single-mode high-speed 1.5-μm VCSELs. J. Lightwave Technol. 2017, 35, 727–733. [Google Scholar] [CrossRef]

- Zhang, L.; Van Kerrebrouck, J.; Lin, R.; Pang, X.; Udalcovs, A.; Ozolins, O.; Spiga, S.; Amann, M.-C.; Van Steenberge, G.; Gan, L.; et al. Nonlinearity tolerant high-speed DMT transmission with 1.5-μm single-mode VCSEL and multi-core fibers for optical interconnects. J. Lightwave Technol. 2019, 37, 380–388. [Google Scholar] [CrossRef]

- Zhang, L.; Van Kerrebrouck, J.; Ozolins, O.; Lin, R.; Pang, X.; Udalcovs, A.; Spiga, S.; Amann, M.C.; Gan, L.; Tang, M.; et al. Experimental demonstration of 503.61-Gbit/s DMT over 10-km 7-core fiber with 1.5-μm SM-VCSEL for optical interconnects. In Proceedings of the 2018 European Conference on Optical Communication (ECOC), Rome, Italy, 23–27 September 2018. [Google Scholar] [CrossRef]

- Pang, X.; Van Kerrebrouck, J.; Ozolins, O.; Lin, R.; Udalcovs, A.; Zhang, L.; Spiga, S.; Amann, M.C.; Van Steenberge, G.; Gan, L.; et al. High-speed SDM interconnects with directly-modulated 1.5-μm VCSEL enabled by low-complexity signal processing techniques. In OSA Technical Digest, Proceedings of the Advanced Photonics 2018 (BGPP, IPR, NP, NOMA, Sensors, Networks, SPPCom, SOF), Signal Processing in Photonic Communications 2018, Zurich, Switzerland, 2–5 July 2018; Paper SpTh2G.4; Optica Publishing Group: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Spiga, S.; Schoke, D.; Andrejew, A.; Boehm, G.; Amann, M.C. Effect of cavity length, strain, and mesa capacitance on 1.5-μm VCSELs performance. J. Lightwave Technol. 2017, 35, 3130–3141. [Google Scholar] [CrossRef]

- Fabrega, J.M.; Vílchez, F.J.; Svaluto Moreolo, M.; Martínez, R.; Quispe, A.; Nadal, L.; Casellas, R.; Vilalta, R.; Muñoz, R.; Neumeyr, C.; et al. Experimental demonstration of a metro area network with terabit-capable sliceable bit-rate-variable transceivers using directly modulated VCSELs and coherent detection. J. Opt. Commun. Netw. 2023, 15, A103–A113. [Google Scholar] [CrossRef]

- Multi-Core, Multi-Level, DWM-Enabled Embedded Optical Engine for Terabit Board-to-Board and Rack-to-Rack Parallel Optics. Available online: https://cordis.europa.eu/docs/projects/cnect/8/318228/080/deliverables/002-MIRAGEshortpresentation.pdf (accessed on 29 May 2023).

- Van Kerrebrouck, J.; Pang, X.; Ozolins, O.; Lin, R.; Udalcovs, A.; Zhang, L.; Li, H.; Spiga, S.; Amann, M.-C.; Gan, L.; et al. High-speed PAM4-based optical SDM interconnects with directly modulated long-wavelength VCSEL. J. Lightwave Technol. 2019, 37, 356–362. [Google Scholar] [CrossRef]

- Grundl, T.; Debernardi, P.; Muller, M.; Grasse, C.; Ebert, P.; Geiger, K.; Ortsiefer, M.; Bohm, G.; Meyer, R.; Amann, M.-C. Record Single-mode, high-power VCSELs by inhibition of spatial hole burning. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1700913. [Google Scholar] [CrossRef]

- Caliman, A.; Mereuta, A.; Suruceanu, G.; Iakovlev, V.; Sirbu, A.; Kapon, E. 8 mW fundamental mode output of wafer-fused VCSELs emitting in the 1550-nm band. Opt. Express 2011, 19, 16996. [Google Scholar] [CrossRef] [PubMed]

- Ellafi, D.; Iakovlev, V.; Sirbu, A.; Suruceanu, G.; Mickovic, Z.; Caliman, A.; Mereuta, A.; Kapon, E. Control of cavity lifetime of 1.5 µm wafer-fused VCSELs by digital mirror trimming. Opt. Express 2014, 22, 32180–32187. [Google Scholar] [CrossRef]

- Babichev, A.V.; Karachinsky, L.Y.; Novikov, I.I.; Gladyshev, A.G.; Blokhin, S.A.; Mikhailov, S.; Iakovlev, V.; Sirbu, A.; Stepniak, G.; Chorchos, L.; et al. 6-mW single-mode high-speed 1550-nm wafer-fused VCSELs for DWDM application. IEEE J. Quantum Electron. 2017, 53, 1–8. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Kuzmenkov, A.G.; Maleev, N.A.; Ustinov, V.M.; Kolodeznyi, E.S.; Rochas, S.S.; Babichev, A.V.; Novikov, I.I.; et al. Influence of output optical losses on the dynamic characteristics of 1.55-μm wafer-fused vertical-cavity surface-emitting lasers. Semiconductors 2019, 53, 1104–1109. [Google Scholar] [CrossRef]

- Gruendl, T.; Mueller, M.; Amann, M.-C. New standards in high-speed and tunable long wavelength VCSELs. In Proceedings of the SPIE Photonics Europe, Brussels, Belgium, 16–19 April 2012; Volume 8432, p. 843203. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Bobrov, M.A.; Maleev, N.A.; Blokhin, A.A.; Kuz’menkov, A.G.; Vasil’ev, A.P.; Rochas, S.S.; Gladyshev, A.G.; Babichev, A.V.; Novikov, I.I.; et al. A vertical-cavity surface-emitting laser for the 1.55-μm spectral range with tunnel junction based on n++-InGaAs/p++-InGaAs/p++-InAlGaAs layers. Tech. Phys. Lett. 2020, 46, 854–858. [Google Scholar] [CrossRef]

- Babichev, A.; Blokhin, S.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Bobrov, M.; Maleev, N.; Andryushkin, V.; Kolodeznyi, E.; et al. Single-mode high-speed 1550 nm wafer fused VCSELs for narrow WDM systems. IEEE Photonics Technol. Lett. 2023, 35, 297–300. [Google Scholar] [CrossRef]

- Bell, G.R.; Kaijaks, N.S.; Dixon, R.J.; McConville, C.F. Atomic hydrogen cleaning of polar III–V semiconductor surfaces. Surf. Sci. 1998, 401, 125–137. [Google Scholar] [CrossRef]

- Seidel, U.; Schimper, H.-J.; Kollonitsch, Z.; Möller, K.; Schwarzburg, K.; Hannappel, T. Growth of an InGaAs/GaAsSb tunnel junction for an InP-based low band gap tandem solar cell. J. Cryst. Growth 2007, 298, 777–781. [Google Scholar] [CrossRef]

- Sirbu, A.; Iakovelv, V.; Mereuta, A.; Caliman, A.; Suruceanu, G.; Kapon, E. Wafer-fused heterostructures: Application to vertical cavity surface-emitting lasers emitting in the 1310 nm band. Semicond. Sci. Technol. 2010, 26, 014016. [Google Scholar] [CrossRef]

- Hadley, G.R. Effective index model for vertical-cavity surface-emitting lasers. Opt. Lett. 1995, 20, 1483–1485. [Google Scholar] [CrossRef] [PubMed]

- Michalzik, R. VCSELs: Fundamentals, Technology and Applications of Vertical-Cavity Surface-Emitting Lasers; Springer Series in Optical Sciences; Springer: Berlin, Germany, 2013; p. 560. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Bobrov, M.A.; Blokhin, A.A.; Vasil’ev, A.P.; Kuz’menkov, A.G.; Maleev, N.A.; Rochas, S.S.; Gladyshev, A.G.; Babichev, A.V.; Novikov, I.I.; et al. The effect of a saturable absorber in long-wavelength vertical-cavity surface-emitting lasers fabricated by wafer fusion technology. Tech. Phys. Lett. 2020, 46, 1257–1262. [Google Scholar] [CrossRef]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 832. [Google Scholar] [CrossRef]

- Spiga, S.; Schoke, D.; Andrejew, A.; Boehm, G.; Amann, M.-C. Enhancing the small-signal bandwidth of single-mode 1.5-μm VCSELs. In Proceedings of the 2016 IEEE Optical Interconnects Conference (OI), San Diego, CA, USA, 9–11 May 2016. [Google Scholar] [CrossRef]

- Amann, M.C.; Hofmann, W. InP-based long-wavelength VCSELs and VCSEL arrays. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 861–868. [Google Scholar] [CrossRef]

- Maute, M.; Amann, M.C. Long-wavelength VCSELs. In Proceedings of the 16th IPRM. 2004 International Conference on Indium Phosphide and Related Materials, 2004, Kagoshima, Japan, 31 May–4 June 2004; pp. 695–699. [Google Scholar] [CrossRef]

- Spiga, S.; Amann, M.C. High-speed InP-based long-wavelength VCSELs. In Green Photonics and Electronics; Eisenstein, G., Bimberg, D., Eds.; Springer: Cham, Switzerland, 2017; Volume 3, pp. 17–35. [Google Scholar] [CrossRef]

- Grasse, C.; Mueller, M.; Gruendl, T.; Boehm, G.; Roenneberg, E.; Wiecha, P.; Rosskopf, J.; Ortsiefer, M.; Meyer, R.; Amann, M.C. AlGaInAsPSb-based high-speed short-cavity VCSEL with single-mode emission at 1.3 μm grown by MOVPE on InP substrate. J. Cryst. Growth 2013, 370, 217–220. [Google Scholar] [CrossRef]

- Müller, M.; Grasse, C.; Saller, K.; Gründl, T.; Böhm, G.; Ortsiefer, M.; Amann, M.C. 1.3 μm high-power short-cavity VCSELs for high-speed applications. In Proceedings of the Conference on Lasers and Electro-Optics 2012, San Jose, CA, USA, 6–11 May 2012; p. CW3N-2. [Google Scholar] [CrossRef]

- Hofmann, W. InP-Based Long-Wavelength VCSELs and VCSEL Arrays for High-Speed Optical Communication. Doktor-Ingenieurs Thesis, Technische Universität München, München, Germany, 26 January 2009. Available online: https://d-nb.info/999941925/34 (accessed on 14 April 2023).

- Muller, M.; Hofmann, W.; Bohm, G.; Amann, M.C. Short-cavity long-wavelength VCSELs with modulation bandwidths in excess of 15 GHz. IEEE Photonics Technol. Lett. 2009, 21, 1615–1617. [Google Scholar] [CrossRef]

- Meyer, R.; Meissner, P.; Amann, M.-C.; Zogal, K.; Nagel, R.D.; Gruendl, T.; Geiger, K.; Grasse, C.; Ortsiefer, M.; Mueller, M.; et al. High-Speed and high-power vertical-cavity surface-emitting lasers based on InP suitable for telecommunication and gas sensing. In Proceedings of SPIE, Proceedings of the SPIE Remote Sensing, Toulouse, France, 20–23 September 2010; Society of Photo-Optical Instrumentation Engineers (SPIE): Bellingham, WA, USA, 2010; Volume 7828, p. 782807. [Google Scholar] [CrossRef]

- Spiga, S.; Andrejew, A.; Boehm, G.; Amann, M.-C. Single-mode 1.5-µm VCSELs with small-signal bandwidth beyond 20 GHz. In Proceedings of the 2016 18th International Conference on Transparent Optical Networks (ICTON), Trento, Italy, 10–14 July 2016. [Google Scholar] [CrossRef]

- Blokhin, S.A.; Babichev, A.V.; Gladyshev, A.G.; Karachinsky, L.Y.; Novikov, I.I.; Blokhin, A.A.; Bobrov, M.A.; Maleev, N.A.; Andryushkin, V.V.; Denisov, D.V.; et al. High power single mode 1300-nm superlattice based VCSEL: Impact of the buried tunnel junction diameter on performance. IEEE J. Quantum Electron. 2022, 58, 2400115. [Google Scholar] [CrossRef]

- Lamothe, E. Analysis and Control of Optical Modes in VCSELs and VCSEL-Arrays. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 1 November 2013. [Google Scholar] [CrossRef]

- Volet, N. Optical Mode Control in Long-Wavelength Vertical-Cavity Surface-Emitting Lasers. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 4 April 2014. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babichev, A.; Blokhin, S.; Gladyshev, A.; Karachinsky, L.; Novikov, I.; Blokhin, A.; Bobrov, M.; Kovach, Y.; Kuzmenkov, A.; Nevedomsky, V.; et al. Impact of Device Topology on the Performance of High-Speed 1550 nm Wafer-Fused VCSELs. Photonics 2023, 10, 660. https://doi.org/10.3390/photonics10060660

Babichev A, Blokhin S, Gladyshev A, Karachinsky L, Novikov I, Blokhin A, Bobrov M, Kovach Y, Kuzmenkov A, Nevedomsky V, et al. Impact of Device Topology on the Performance of High-Speed 1550 nm Wafer-Fused VCSELs. Photonics. 2023; 10(6):660. https://doi.org/10.3390/photonics10060660

Chicago/Turabian StyleBabichev, Andrey, Sergey Blokhin, Andrey Gladyshev, Leonid Karachinsky, Innokenty Novikov, Alexey Blokhin, Mikhail Bobrov, Yakov Kovach, Alexander Kuzmenkov, Vladimir Nevedomsky, and et al. 2023. "Impact of Device Topology on the Performance of High-Speed 1550 nm Wafer-Fused VCSELs" Photonics 10, no. 6: 660. https://doi.org/10.3390/photonics10060660

APA StyleBabichev, A., Blokhin, S., Gladyshev, A., Karachinsky, L., Novikov, I., Blokhin, A., Bobrov, M., Kovach, Y., Kuzmenkov, A., Nevedomsky, V., Maleev, N., Kolodeznyi, E., Voropaev, K., Vasilyev, A., Ustinov, V., Egorov, A., Han, S., Tian, S.-C., & Bimberg, D. (2023). Impact of Device Topology on the Performance of High-Speed 1550 nm Wafer-Fused VCSELs. Photonics, 10(6), 660. https://doi.org/10.3390/photonics10060660