Thermal Lensing and Laser-Induced Damage in Special Pure Chalcogenide Ge35As10S55 and Ge20As22Se58 Glasses under Quasi-CW Fiber Laser Irradiation at 1908 nm

Abstract

1. Introduction

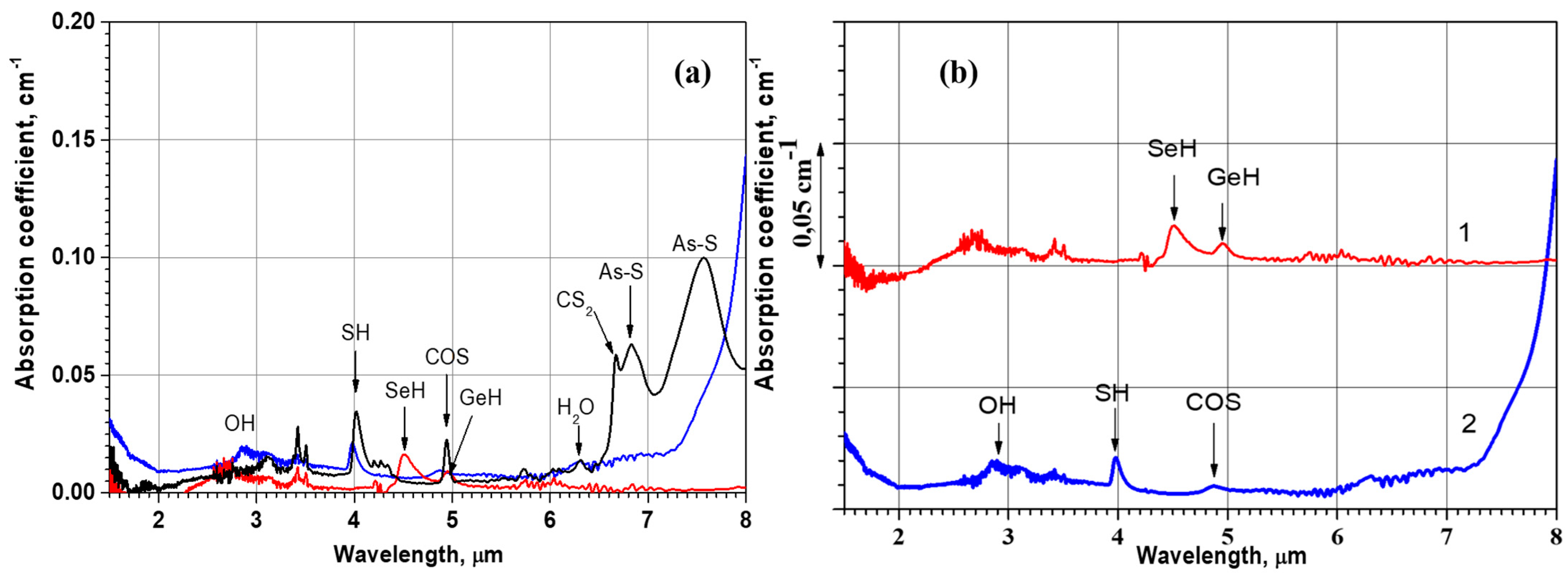

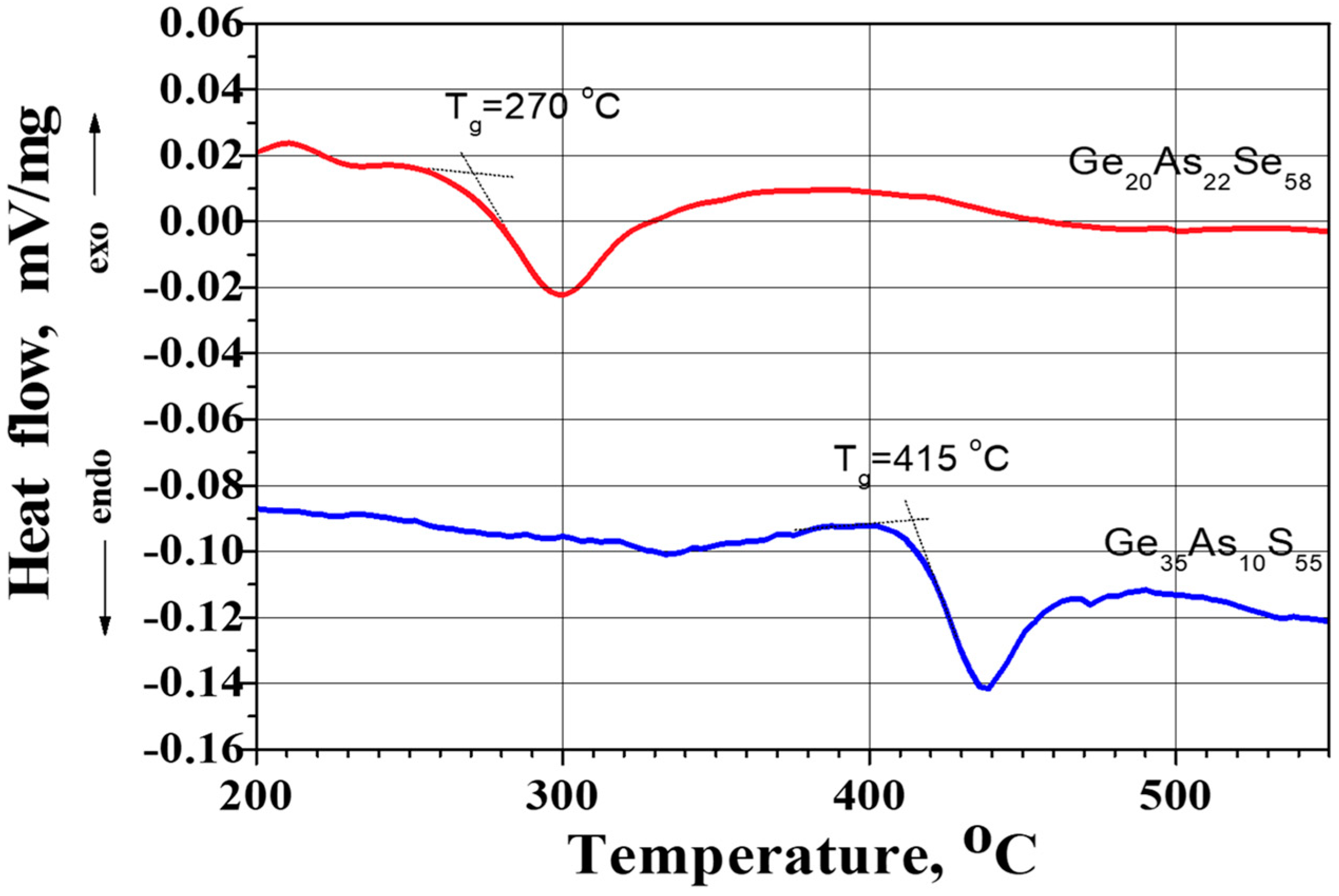

2. Glass Preparation

3. Experimental Techniques and Results

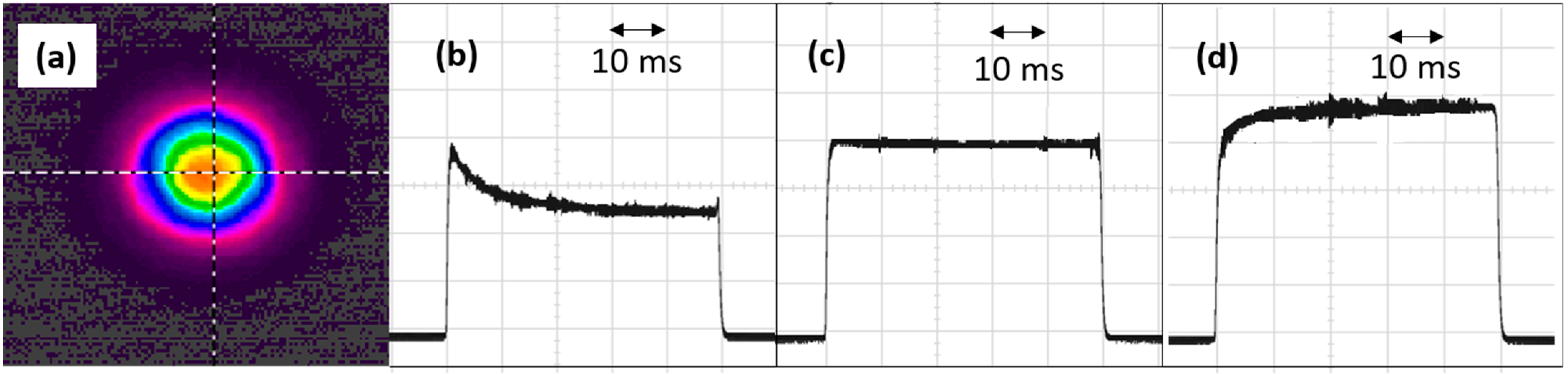

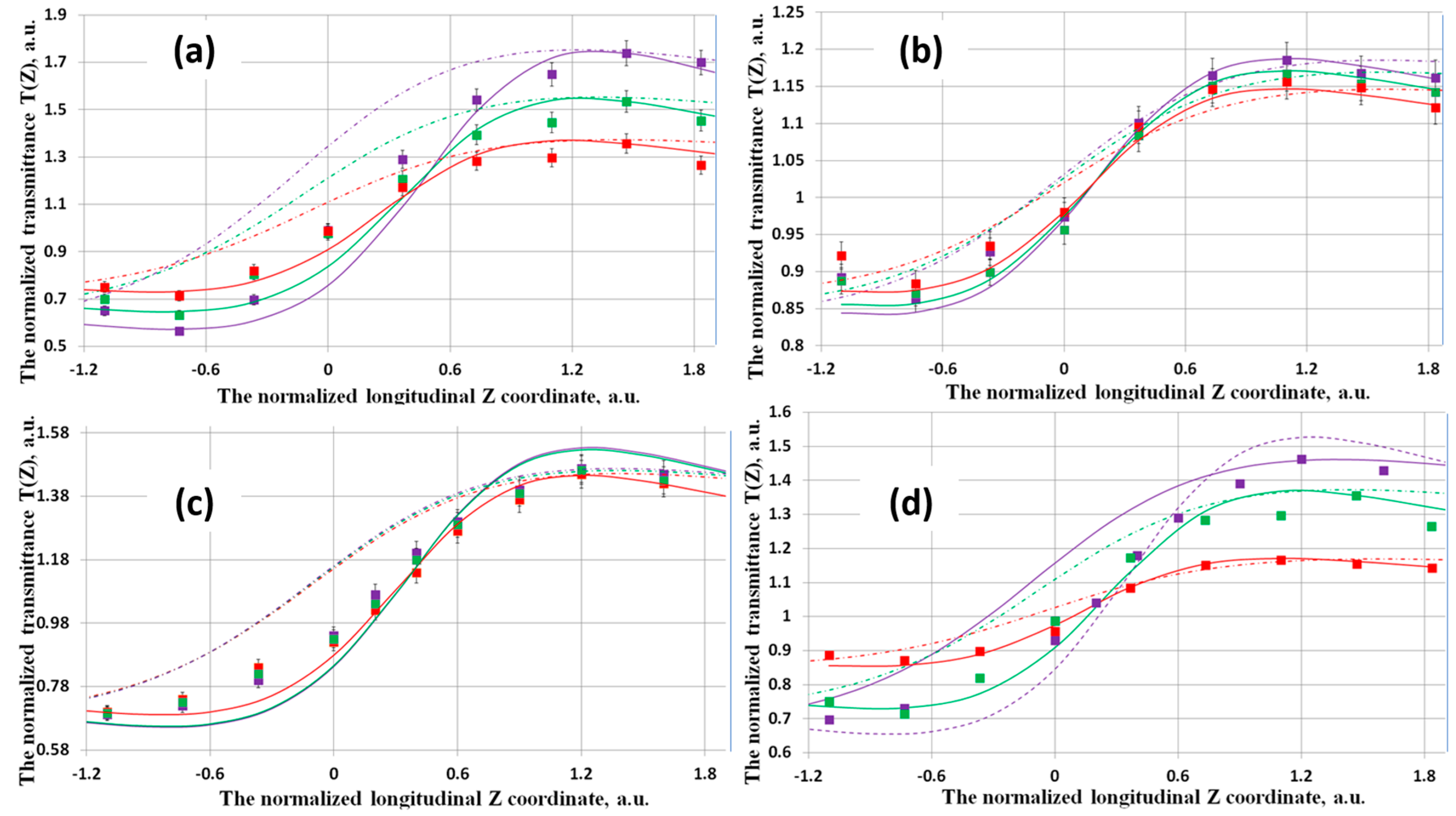

3.1. Thermal Lens Z-Scanning

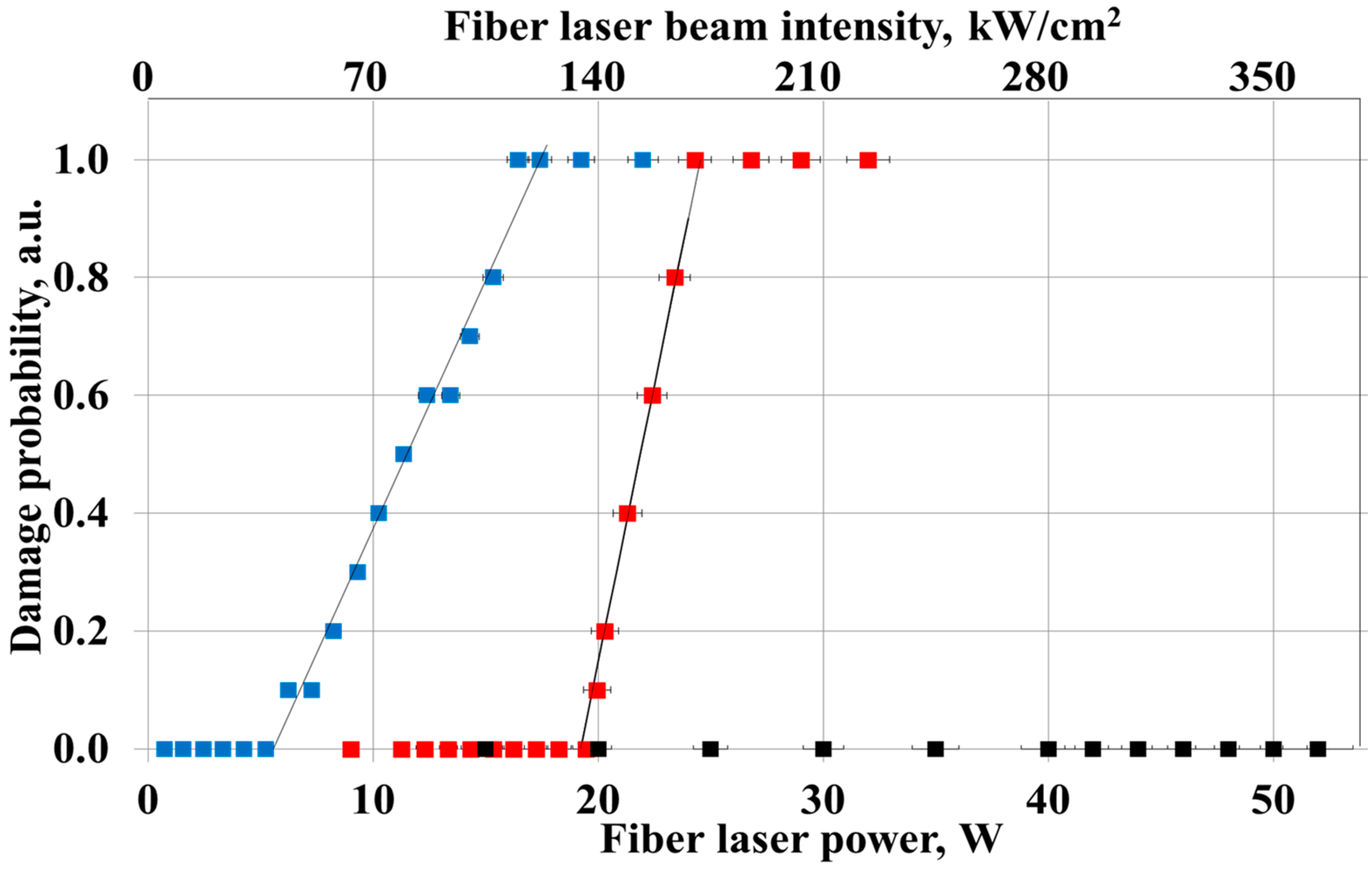

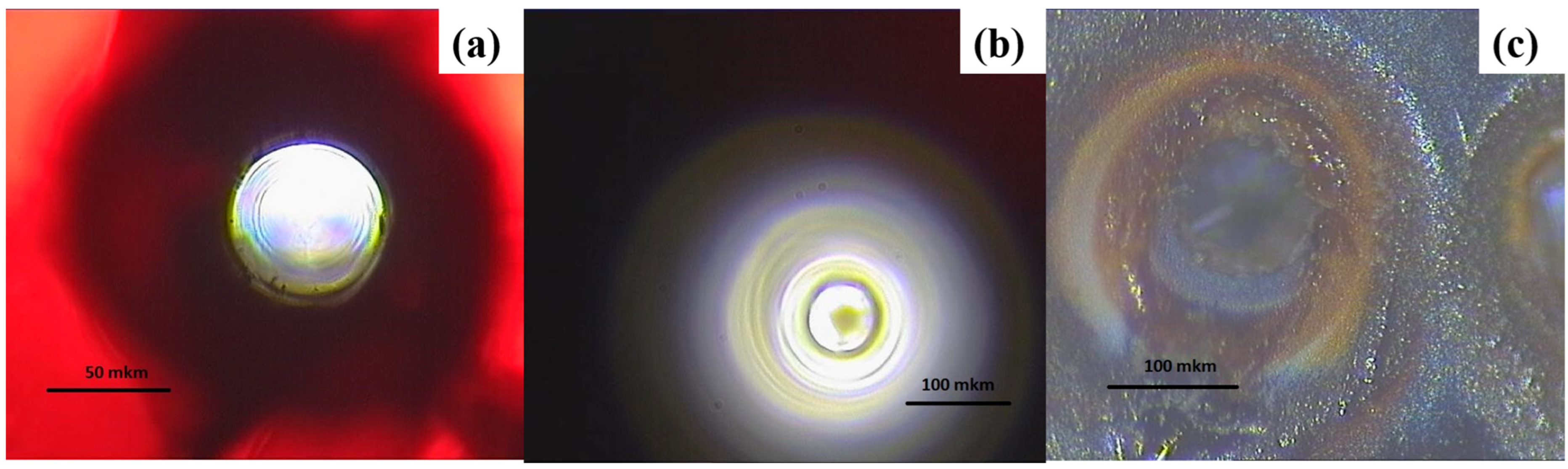

3.2. Laser-Induced Damage Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gattass, R.R.; Shaw, L.B.; Nguyen, V.Q.; Pureza, P.C.; Aggarwal, I.D.; Sanghera, J.S. All-Fiber Chalcogenide-Based Mid-Infrared Supercontinuum Source. Opt. Fiber Technol. 2012, 18, 345–348. [Google Scholar] [CrossRef]

- Kedenburg, S.; Steinle, T.; Mörz, F.; Steinmann, A.; Giessen, H. High-power mid-infrared high repetition-rate supercontinuum source based on a chalcogenide step-index fiber. Opt. Lett. 2015, 40, 2668–2671. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Wang, X.; Dai, S.; Pan, Z.; Liu, S.; Sun, L.; Zhang, P.; Liu, Z.; Nie, Q.; Shen, X.; et al. 1.5–14 μm midinfrared supercontinuum generation in a low-loss Te-based chalcogenide step-index fiber. Opt. Lett. 2016, 41, 5222–5225. [Google Scholar] [CrossRef] [PubMed]

- Shiryaev, V.S.; Sukhanov, M.V.; Velmuzhov, A.P.; Karaksina, E.V.; Kotereva, T.V.; Snopatin, G.E.; Denker, B.I.; Galagan, B.I.; Sverchkov, S.E.; Koltashev, V.V.; et al. Core-clad terbium doped chalcogenide glass fiber with laser action at 5.38 μm. Non-Cryst. Solids 2021, 567, 120939. [Google Scholar] [CrossRef]

- Churbanov, M.F.; Denker, B.I.; Galagan, B.I.; Koltashev, V.V.; Plotnichenko, V.G.; Sukhanov, M.V.; Sverchkov, S.E.; Velmuzhov, A.P. Comparison of 4.5–6 μm luminescent and lasing properties of rare earth dopants in chalcogenide glasses. J. Lumin. 2022, 245, 118756. [Google Scholar] [CrossRef]

- Denker, B.I.; Galagan, B.I.; Koltashev, V.V.; Plotnichenko, V.G.; Snopatin, G.E.; Sukhanov, M.V.; Sverchkov, S.E.; Velmuzhov, A.P. Continuous Tb-doped fiber laser emitting at ~5.25 µm. Opt. Laser Technol. 2022, 154, 108355. [Google Scholar] [CrossRef]

- Sincore, A.; Cook, J.; Tan, F.; Abouraddy, A.F.; Richardson, M.C.; Schepler, K.L. Practical limits of power transmission through single-mode chalcogenide fibers. Opt. Eng. 2018, 57, 111807. [Google Scholar] [CrossRef]

- Zhang, M.; Li, T.; Yang, Y.; Tao, H.; Zhang, X.; Yuan, X.; Yang, Z. Femtosecond laser induced damage on Ge-As-S chalcogenide glasses. Opt. Mater. Express 2019, 9, 555. [Google Scholar] [CrossRef]

- Ma, W.; Wang, L.; Zhang, P.; Xu, Y.; Zhu, L.; Xu, P.; Chen, F.; Dai, S. Surface damage and threshold determination of Ge–As–Se glasses in femtosecond pulsed laser micromachining. J. Am. Ceram. Soc. 2019, 103, 94–102. [Google Scholar] [CrossRef]

- Zhang, M.; Li, L.; Li, T.; Fang Wang, F.; Tian, K.; Tao, H.; Feng, X.; Yang, A.; Yang, Z. Mid-infrared supercontinuum generation in chalcogenide fibers with high laser damage threshold. Opt. Express 2019, 27, 29287. [Google Scholar] [CrossRef]

- Ristau, D. (Ed.) Laser-Induced Damage in Optical Materials; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- You, C.; Dai, S.; Zhang, P.; Xu, Y.; Wang, Y.; Xu, D.; Wang, R. Mid-infrared femtosecond laser-induced damages in As2S3 and As2Se3 chalcogenide glasses. Sci. Rep. 2017, 7, 6497. [Google Scholar] [CrossRef] [PubMed]

- Kamensky, V.A.; Scripachev, I.V.; Snopatin, G.E.; Pushkin, A.A.; Churbanov, M.F. High-Power As-S Glass Fiber Delivery Instrument for Pulse YAG:Er Laser Radiation. Appl. Opt. 1998, 37, 5596–5599. [Google Scholar] [CrossRef] [PubMed]

- Sparks, M. Optical Distortion by Heated Windows in HighPower Laser Systems. J. Appl. Phys. 1971, 42, 5029–5046. [Google Scholar] [CrossRef]

- Gleason, B.; Richardson, K.; Sisken, L. Refractive Index and Thermo-Optic Coefficients of Ge–As–Se Chalcogenide Glasses”, International. J. Appl. Glass Sci. 2016, 7, 374–383. [Google Scholar] [CrossRef]

- Gleason, B. Designing Optical Properties in Infrared Glass. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2015. [Google Scholar]

- Terziyska, B.; Misiorek, H.; Vateva, E. Low-temperature thermal conductivity of GexAs40−xS60 glasses. Solid State Commun. 2005, 134, 349–353. [Google Scholar] [CrossRef]

- Plotnichenko, V.G.; Philippovskiy, D.V.; Sokolov, V.O.; Sukhanov, M.V.; Velmuzhov, A.P.; Churbanov, M.F.; Dianov, E.M. Infrared luminescence in Bi-doped Ge–S and As–Ge–S chalcogenide glasses and fibers. Opt. Mater. 2014, 4, 366–374. [Google Scholar] [CrossRef]

- Sukhanov, M.V.; Storozheva, T.I.; Evdokimov, I.I.; Pimenov, V.G.; Sozin, A.Y.; Kotereva, T.V. Fine Purification of Monoisotopic 32S and 34S. Inorg. Mater. 2017, 53, 142–147. [Google Scholar] [CrossRef]

- Velmuzhov, A.P.; Sukhanov, M.V.; Zernova, N.S.; Shiryaev, V.S.; Kotereva, T.V.; Ketkova, L.A.; Evdokimov, I.I.; Kurganova, A.E. Preparation of Ge20Se80 glasses with low hydrogen and oxygen impurities content for middle IR fiber optics. J. Non-Cryst. Solids 2019, 521, 119505. [Google Scholar] [CrossRef]

- Devyatykh, G.G.; Churbanov, M.F.; Shiryaev, V.S.; Snopatin, G.E.; Gerasimenko, V.V. Impurity Inclusions in Extra-Pure Arsenic and Chalcogens. Inorg. Mater. 1998, 34, 902–906. [Google Scholar]

- Snopatin, G.E.; Shiryaev, V.S.; Plotnichenko, G.E.; Dianov, E.M.; Churbanov, M.F. High-Purity Chalcogenide Glasses for Fiber Optics. Inorg. Mater. 2009, 45, 1439–1460. [Google Scholar] [CrossRef]

- Shiryaev, V.S.; Smetanin, S.V.; Ovchinnikov, D.K.; Churbanov, M.F.; Kryukova, E.B.; Plotnichenko, V.G. Effects of oxygen and carbon impurities on the optical transmission of As2Se3 glass. Inorg. Mater. 2005, 41, 308–314. [Google Scholar] [CrossRef]

- Nishii, J.; Yamashita, T.; Yamagishi, T. Oxide impurity absorptions in Ge-Se-Te glass fibres. J. Mater. Sci. 1989, 24, 4293–4297. [Google Scholar] [CrossRef]

- Sheik-Bahae, M.; Said, A.A.; Wei, T.H.; Hagan, D.J.; Van Stryland, E.W. ‘Sensitive measurement of optical nonlinearities using a single beam. IEEE J. Quantum Electron. 1990, 26, 760–769. [Google Scholar] [CrossRef]

- Sant’Anna Cuppo, F.L.; Figueiredo Neto, A.M.; Gomez, S.L.; Palffy-Muhoray, P. Thermal-lens model compared with the Sheik-Bahae formalism in interpreting Z-scan experiments on lyotropic liquid crystals. J. Opt. Soc. Am. 2002, 19, 1342–1348. [Google Scholar] [CrossRef]

- Jacinto, C.; Messias, D.N.; Andrade, A.A.; Lima, S.M.; Baesso, M.L.; Catunda, T. Thermal lens and Z-scan measurements: Thermal and optical properties of laser glasses—A review. J. Non-Cryst. Solids 2006, 352, 3582–3597. [Google Scholar] [CrossRef]

- Dancus, I.; Petris, A.; Doia, P.; Fazio, E.; Vlad, V.I. Z-Scan measurement of thermal optical nonlinearities. Proc. SPIE 2007, 6785, 67851F. [Google Scholar]

- Sheldon, S.J.; Knight, L.V.; Thorne, J.M. Laser-induced thermal lens effect: A new theoretical model. Appl. Opt. 1982, 21, 1663–1669. [Google Scholar] [CrossRef]

- Carter, C.A.; Harris, J.M. Comparison of models describing the thermal lens effect. Appl. Opt. 1984, 23, 476–481. [Google Scholar] [CrossRef]

- Zanuto, V.S.; dos Santos, J.F.M.; Baesso, M.L.; Catunda, T. Single-beam time-resolved cw thermal Z-scan analysis applied in solids. Opt. Laser Technol. 2021, 142, 107248. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Z.; Lucas, P.; Wang, Y.; Zhijie Yang, Z.; Yang, A.; Zhang, B.; Tao, H. Composition dependence of physical and optical properties in Ge-As-S chalcogenide glasses. J. Non-Cryst. Solids 2016, 440, 38–42. [Google Scholar] [CrossRef]

- Aio, L.G.; Efimov, A.M.; Kokorina, V.F. Refractive index of chalcogenide glasses over a wide range of compositions. J. Non-Cryst. Solids 1978, 27, 299–307. [Google Scholar] [CrossRef]

- Zhua, L.; Yang, D.; Wang, L.; Zenga, J.; Zhang, Q.; Xiea, M.; Zhang, P.; Daia, S. Optical and thermal stability of Ge-as-Se chalcogenide glasses for femtosecond laser writing. Opt. Mater. 2018, 85, 220–225. [Google Scholar] [CrossRef]

- Masselin, P.; Coq, D.L.; Bychkova, E. Refractive index variations induced by femtosecond laser direct writing in the bulk of As2S3 glass at high repetition rate. Opt. Mater. 2011, 33, 872–876. [Google Scholar] [CrossRef]

- Rodney, W.S.; Malitson, I.H.; King, T.A. Refractive Index of Arsenic Trisulfide. J. Opt. Soc. Am. 1958, 48, 633–636. [Google Scholar] [CrossRef]

- ISO 21254-2:2011; Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold Part 2: Threshold Determination. European Committee for Standardization: Brussels, Belgium, 2011.

- Kumta, P.N.; Risbud, S.H. Rare-earth chalcogenides—An emerging class of optical materials. J. Mater. Sci. 1994, 29, 1135–1158. [Google Scholar] [CrossRef]

- Lidaris LIDT Service. The R-on-1 Test. 2019. Available online: https://lidaris.com/tests/r-on-1-lidt-test/ (accessed on 27 February 2023).

- Yudin, N.N.; Antipov, O.L.; Gribenyukov, A.I.; Aronov, I.D.; Podzivalov, S.N.; Zinoviev, M.M.; Voronin, L.A.; Zhuravleva, E.V.; Zykova, M.P. Effect of postgrowth processing technology and laser radiation parameters at wavelengths of 2091 and 1064 nm on the laser-induced damage threshold in ZnGeP2 single crystal. Quantum Electron. 2021, 51, 306–316. [Google Scholar] [CrossRef]

- Yudin, N.; Antipov, O.; Eranov, I.; Gribenyukov, A.; Verozubova, G.; Lei, Z.; Zinoviev, M.; Podzivalov, S.; Slyunko, E.; Voevodin, V.; et al. Laser-induced damage threshold of single crystal ZnGeP2 at 2.1 µm: The effect of crystal lattice quality at various pulse widths and repetition rate. Crystals 2022, 12, 652. [Google Scholar] [CrossRef]

- Yudin, N.; Antipov, O.; Balabanov, S.; Eranov, I.; Getmanovskiy, Y.; Slyun’ko, E. Effects of Processing Technology of CVD-ZnSe, Cr2+: ZnSe, and Fe2+: ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively-Pulsed Laser at 2.1 µm. Ceramics 2022, 5, 459–471. [Google Scholar] [CrossRef]

- Crisp, M.D. Laser-Induced Surface Damage of Transparent Dielectrics. IEEE J. Quantum Electron. 1974, QE-10, 57–62. [Google Scholar] [CrossRef]

- Hu, Y.; Tian, K.; Li, T.; Zhang, M.; Ren, H.; Qi, S.; Yang, A.; Feng, X.; Yang, Z. Mid-infrared nonlinear optical performances of Ge-Sb-S chalcogenide glasses. Opt. Mater. Express 2021, 11, 695–706. [Google Scholar] [CrossRef]

- Sharma, P.; Katyal, S.C. Effect of tellurium addition on the physical properties of germanium selenide glassy semiconductors. J. Phys. B 2008, 403, 3667–3671. [Google Scholar] [CrossRef]

- Zha, C.; Wang, R.; Smith, A.; Prasad, A.; Jarvis, R.A.; Luther-Davies, B. Optical properties and structural correlations of GeAsSe chalcogenide glasses. J. Mater. Sci: Mater. Electron. 2007, 18, S389–S392. [Google Scholar] [CrossRef]

- Romanova, E.; Kuzyutkina, Y.; Shiryaev, V.; Abdel-Moneim, N.; Furniss, D.; Benson, T.; Seddon, A.; Guizard, S. Measurement of the non-linear optical coefficients of chalcogenide glasses near the fundamental absorption band edge. J. Non-Cryst. Solids 2018, 480, 13–17. [Google Scholar] [CrossRef]

- Kolobov, A.V.; Tanaka, K. Photoinduced Phenomena in Amorphous Chalcogenides: From Phenomenology to Nanoscale. In Handbook of Advanced Electronic and Photonic Materials and Devices; Nalwa, H.S., Ed.; Academic Press: San Diego, CA, USA, 2001; pp. 47–90. [Google Scholar] [CrossRef]

- Anheier, N.C.; Johnson, B.R.; Sundaram, S.K. Laser Writing in Arsenic Trisulfide Glass. In Non-Crystalline Materials for Optoelectronics, Optoelectronic Materials and Devices, Volume 1; INOE Publishing House: Bucharest, Romania, 2004; pp. 259–297. [Google Scholar]

- Feltz, A. Amorphous Inorganic Materials and Glasses; VCH Verlagsgesellschaft mbH: Weinheim, Germany, 1993. [Google Scholar]

| Power, W | Ge35As10S55 | Ge20.5As22Se58 | As2S3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ɵ | Ɵ/P, W−1 | n2T, cm2/W (×10−9) | Ɵ | Ɵ/P, W−1 | n2T, cm2/W (×10−9) | Ɵ | Ɵ/P, W−1 | n2T, cm2/W (×10−9) | |

| 0.69 | 0.37/0.7 | 0.54/1.02 | 10.6/20.6 | ||||||

| 1.07 | 0.42/0.72 | 0.39/0.67 | 8.0/13.8 | ||||||

| 1.47 | 0.43/0.73 | 0.29/0.49 | 6.0/10.1 | ||||||

| 0.79 | 0.14/0.26 | 0.18/0.33 | 3.4/6.6 | ||||||

| 1.34 | 0.16/0.3 | 0.12/0.22 | 2.6/4.8 | ||||||

| 1.71 | 0.17/0.32 | 0.1/0.19 | 2.0/3.8 | ||||||

| 1.31 | 0.32/0.6 | 0.25/0.46 | 4.8/9.2 | ||||||

| 2.05 | 0.44/0.84 | 0.22/0.41 | 4.2/8.2 | ||||||

| 2.77 | 0.57/1.07 | 0.21/0.38 | 4.0/7.8 | ||||||

| Ge35As10S55 | Ge20.5As22Se58 | As2S3 | |

|---|---|---|---|

| Thermal conductivity, KT, W/(m·K) | 0.153 [31] | 0.2–0.3 [14] | 0.17 [32] |

| Specific heat capacity, Cp, J/(g K) | 0.33 [14] | 0.46 [32] | |

| Density, ρ, g/cm3 | 2.96 [31] | 4.4–4.52 [14] | 3.20 [33] |

| Refractive index, n0 | 2.315 at 1.55 µm [17] 2.239 at 6 µm [34] | 2.53 at 4.5 µm [14] 2.631 aт 1.8 (for Ge17As20Se58) [32] | 2.43 at 1908 nm [33] |

| Thermo-optical coefficient, (∂n/∂T), K−1 | 7.52 × 10−6 K−1 at 1908 nm [35] | ||

| Thermal expansion coefficient, βT, K−1 | 17.4 × 10−6 [14] | 25 × 10−6 K −1 [36] | |

| Temperature coefficient of the optical path length change, (∂s/∂T), K−1 | 3.8 × 10−5 at 4.5 µm [14] | 5.39 × 10−5 at 4.5 µm [35,36] |

| Ge35As10S55 | Ge20.5As22Se58 | As2S3 | |

|---|---|---|---|

| Zero-probability LIDT for incident power/intensity, Pth0/Ith0, (W/W·cm−2) | 5/35 | 19/133 | Nondetermined |

| 100%-probability LIDT for incident power/intensity, Pth100/Ith100 (W/W·cm−2) | 17/117 | 24/168 | Nondetermined |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antipov, O.; Dobrynin, A.; Getmanovskiy, Y.; Karaksina, E.; Shiryaev, V.; Sukhanov, M.; Kotereva, T. Thermal Lensing and Laser-Induced Damage in Special Pure Chalcogenide Ge35As10S55 and Ge20As22Se58 Glasses under Quasi-CW Fiber Laser Irradiation at 1908 nm. Photonics 2023, 10, 252. https://doi.org/10.3390/photonics10030252

Antipov O, Dobrynin A, Getmanovskiy Y, Karaksina E, Shiryaev V, Sukhanov M, Kotereva T. Thermal Lensing and Laser-Induced Damage in Special Pure Chalcogenide Ge35As10S55 and Ge20As22Se58 Glasses under Quasi-CW Fiber Laser Irradiation at 1908 nm. Photonics. 2023; 10(3):252. https://doi.org/10.3390/photonics10030252

Chicago/Turabian StyleAntipov, Oleg, Anton Dobrynin, Yuri Getmanovskiy, Ella Karaksina, Vladimir Shiryaev, Maksim Sukhanov, and Tatiana Kotereva. 2023. "Thermal Lensing and Laser-Induced Damage in Special Pure Chalcogenide Ge35As10S55 and Ge20As22Se58 Glasses under Quasi-CW Fiber Laser Irradiation at 1908 nm" Photonics 10, no. 3: 252. https://doi.org/10.3390/photonics10030252

APA StyleAntipov, O., Dobrynin, A., Getmanovskiy, Y., Karaksina, E., Shiryaev, V., Sukhanov, M., & Kotereva, T. (2023). Thermal Lensing and Laser-Induced Damage in Special Pure Chalcogenide Ge35As10S55 and Ge20As22Se58 Glasses under Quasi-CW Fiber Laser Irradiation at 1908 nm. Photonics, 10(3), 252. https://doi.org/10.3390/photonics10030252