Model-Based Evaluation of a Data-Driven Control Strategy: Application to Ibuprofen Crystallization

Abstract

1. Introduction

2. Materials and Methods

2.1. Crystallization Modeling

2.2. Radial Basis Functions Network

2.3. Desired Trajectory, RBF Structure and Data Treatment

2.4. RBF Strategies for Crystallization Processes

2.4.1. Growing Window Methodology

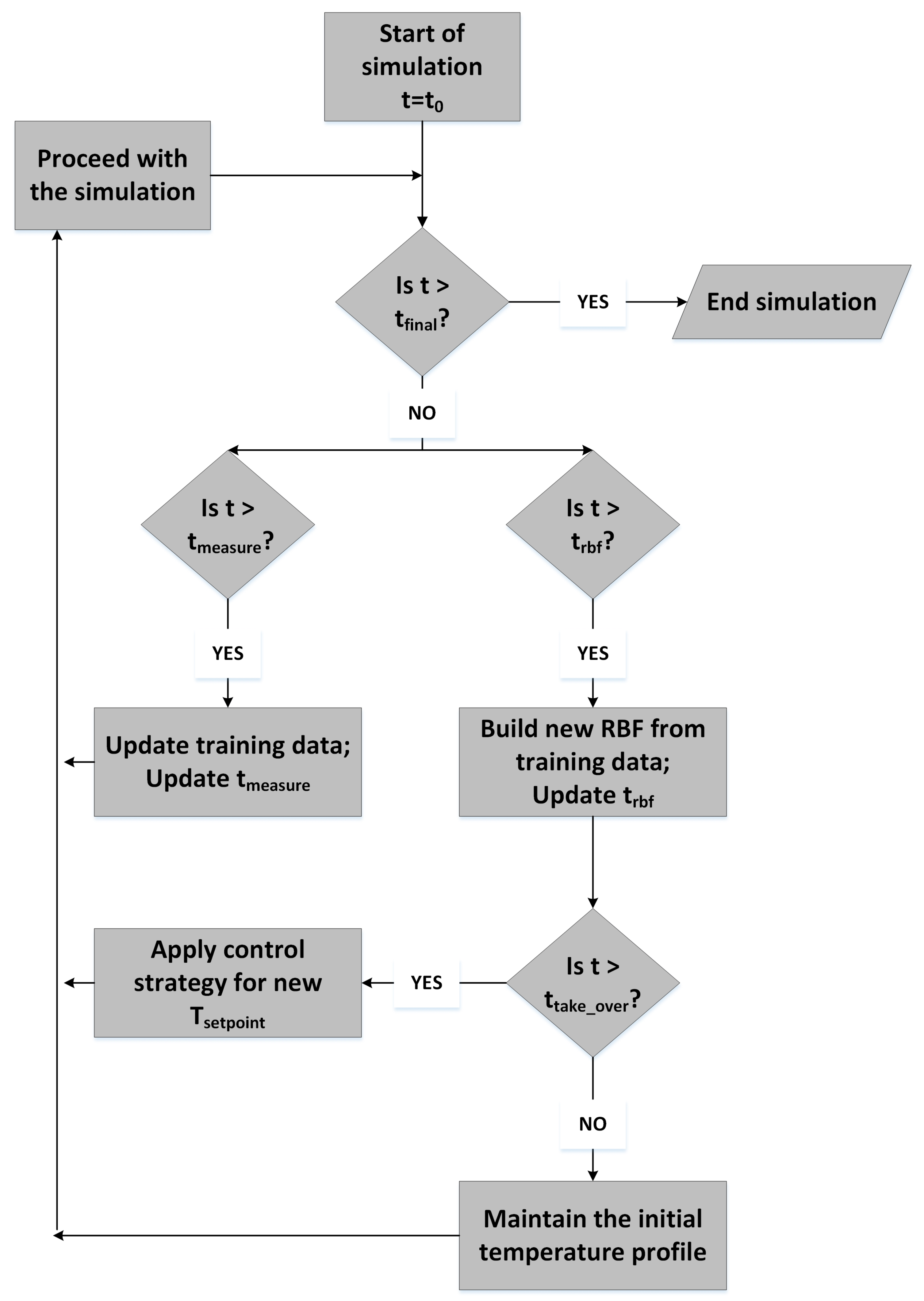

- Measurement time (): This represents the time of the experiment or simulation in which new data are available for the process variables being measured and/or tracked. For this work, mean crystal size, time and temperature are the measured variables. Depending on each system, different sensors might have different sampling times, which lead to the highest of these measuring times being defined as the highest amongst the measured process variables. Once this value is achieved, the upcoming measurement time is updated to the system, until the experiment/simulation is finished.

- Take over time (): This represents the time at which the RBF control takes over the initial system. Due to the fact that no initial historical data are available, the RBF model has no training data to provide a feasible solution or even a solution at all. Therefore, there is the need to allow the system to initially collect enough data until the RBF is suitable to take over and assume the temperature setpoint control.

- RBF build time (): This represents the time series in which a new RBF model is built from the training data available. The initial value for the coincides with the , and once it is reached, a new value is updated to the system until the experiment/simulation is finished.

- End of experiment (): This represents the end of the experiment/simulation, defining how many RBF implementations have been used and how much data has been collected.

2.4.2. Moving Window Methodology

- Maximum data size (): this represents the maximum length of the training data stored for RBF assembly, within a n × m matrix (n representing the different inputs, and m the input observations).

2.4.3. Golden Batch Methodology

2.5. RBF Soft Sensor and Predictive Control

2.5.1. RBF Soft Sensor

2.5.2. RBF Predictive Control

2.6. Case Study Application

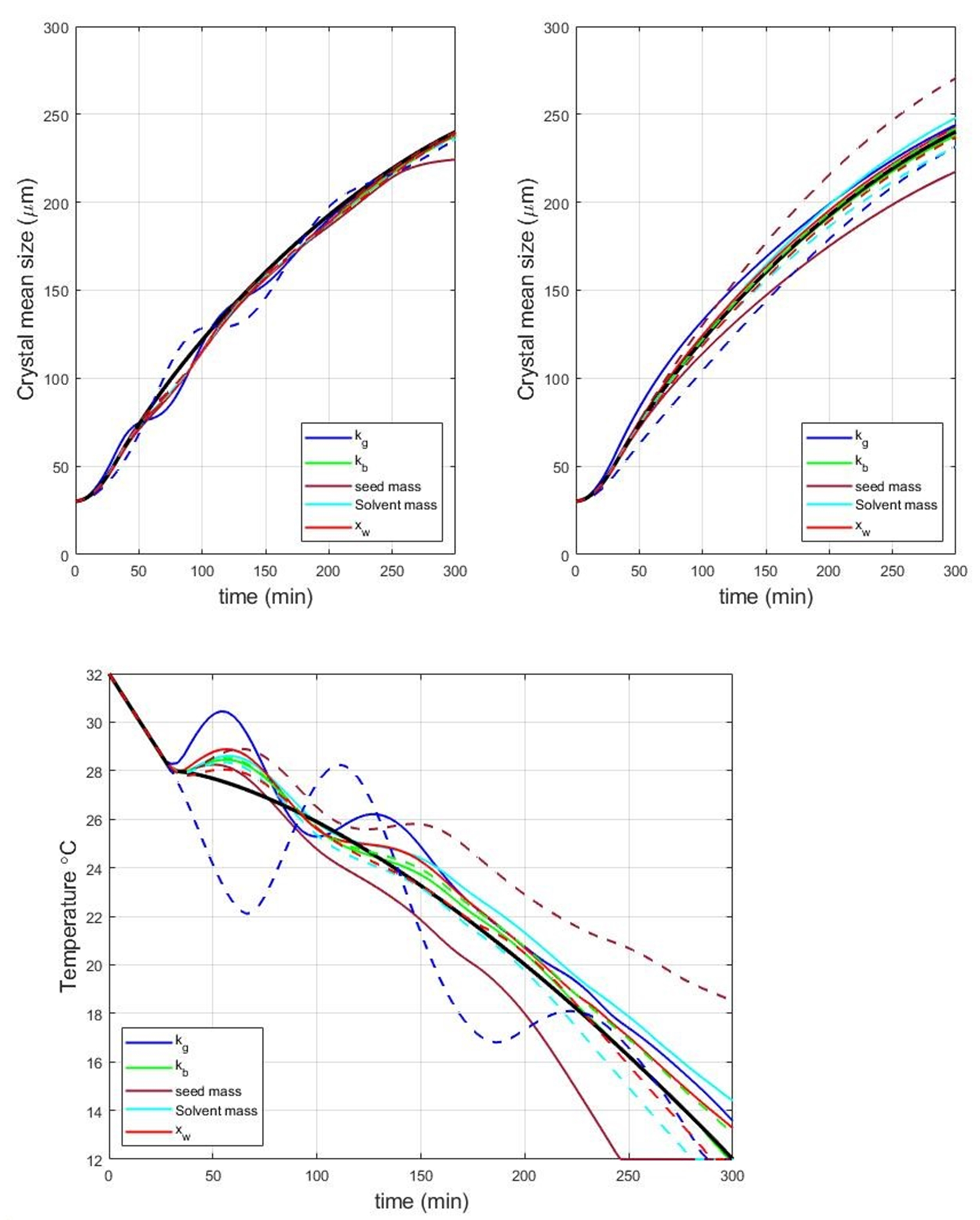

3. Results

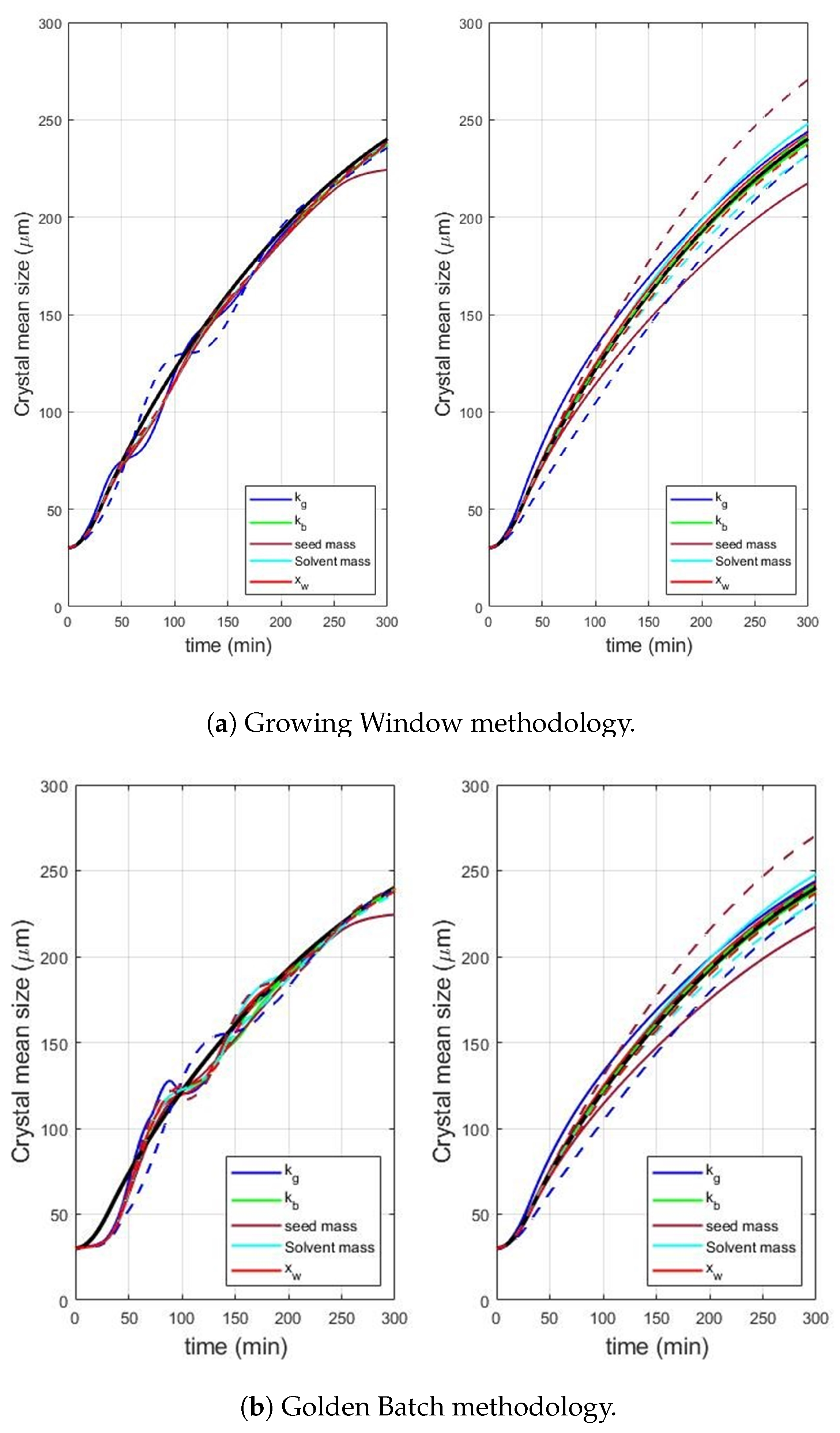

3.1. RBF Validation

3.2. RBF Soft Sensor Application

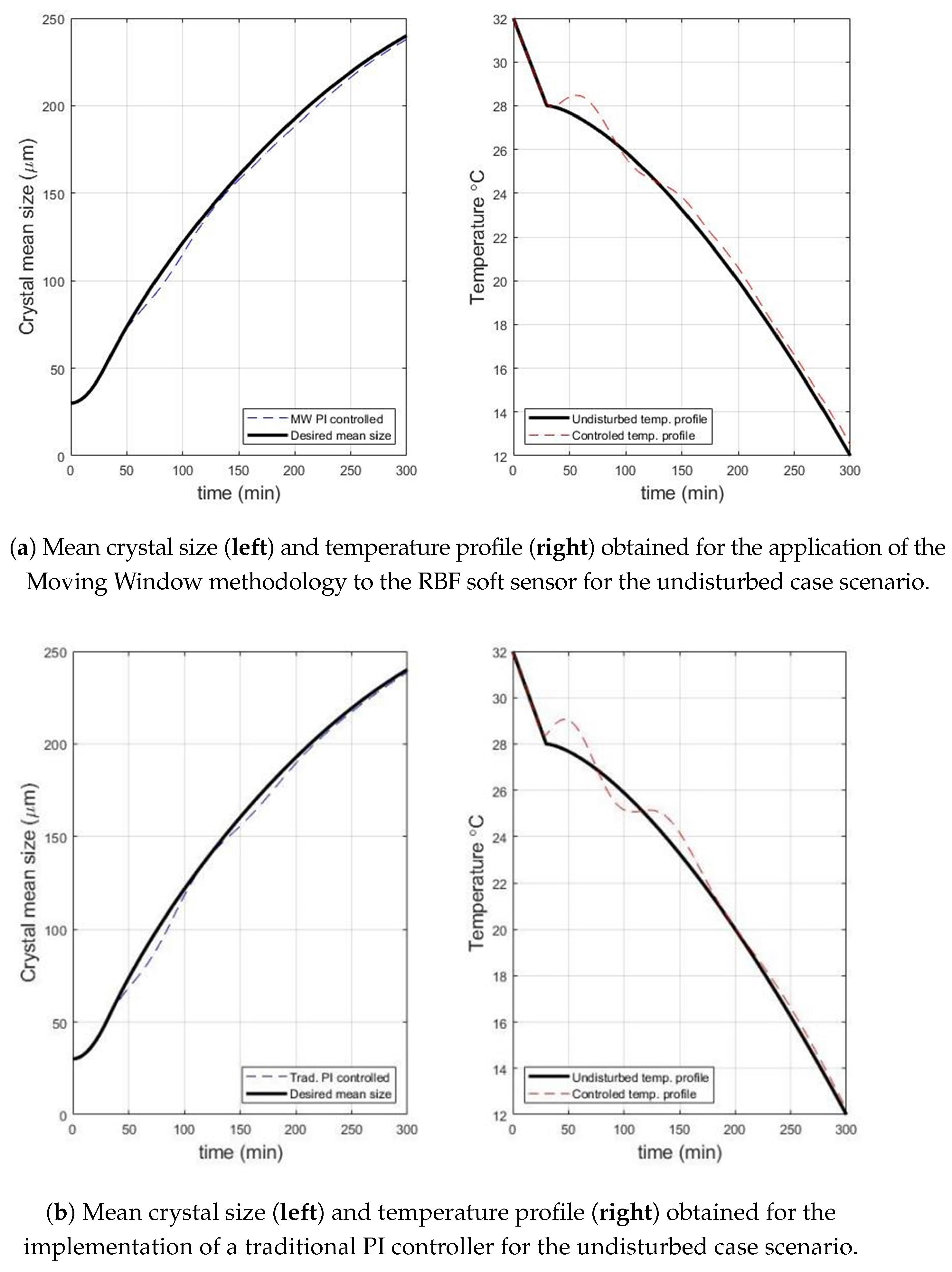

3.2.1. Moving Window Soft Sensor Application

- The sudden drops in temperature (Figure 5) pushed the system to the secondary nucleation regime, creating a surge of new and small crystals that reduced the overall mean particle size. This increment of the number of small crystals also reduced the potential of achieving the target size, as it can be compared to the impact of having increased number of seed crystals in the system (however, this time they appeared during process operation, instead of being present from the beginning);

- Increments in the temperature above the predefined setpoint can create conditions for the system to become undersaturated, reducing the overall mean size. However, small crystals will be dissolved due to dissolution mechanics, and the overall solute concentration increases. Therefore, with fewer particles within the system and more solute, the overall dynamics of the system have changed, and the RBF required more time to adapt, leading to wrong predictions.

3.2.2. Growing Window Soft Sensor Application

3.2.3. Golden Batch Soft Sensor Application

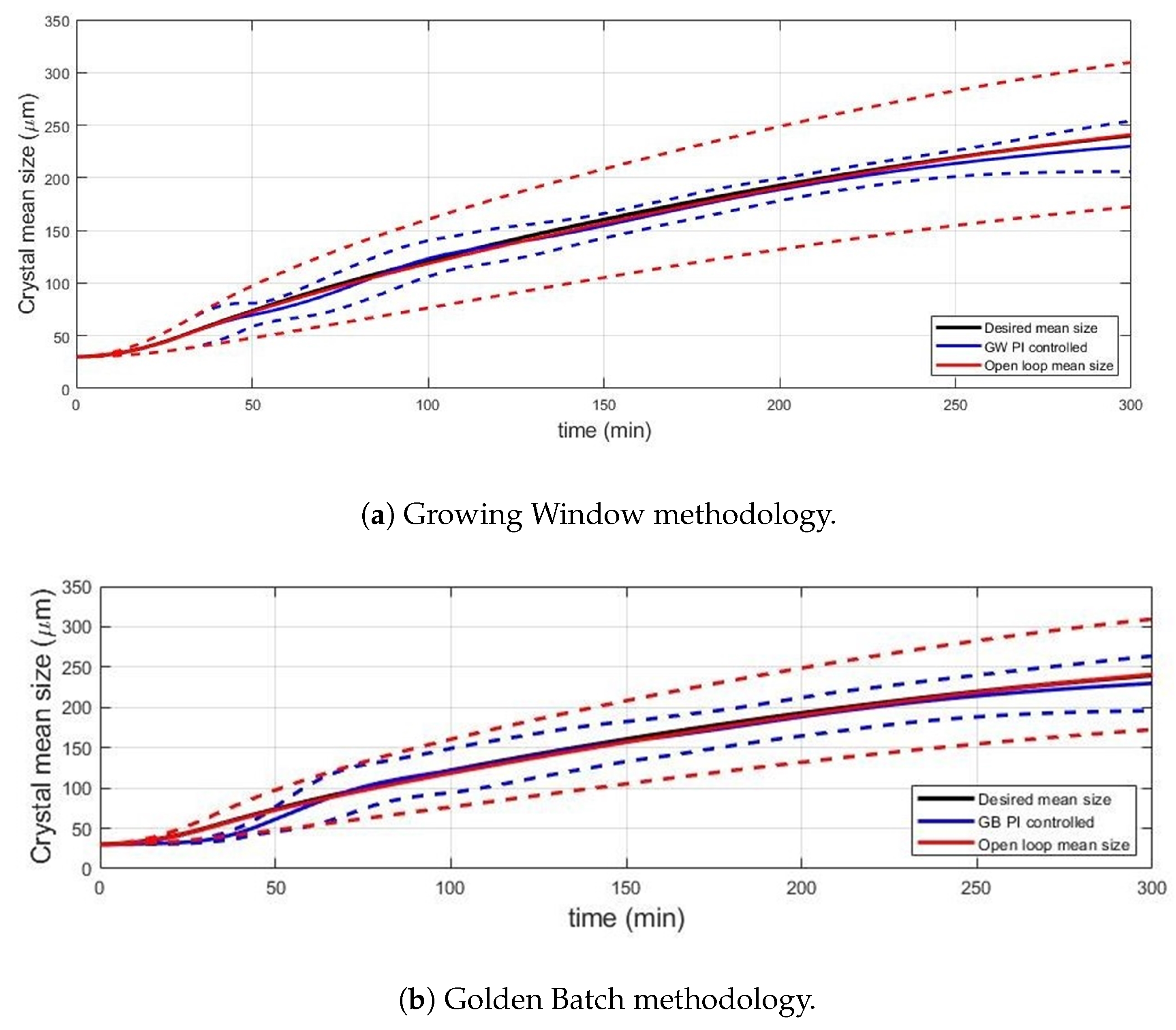

3.2.4. Control Performance Evaluation for RBF Soft Sensor Methodologies

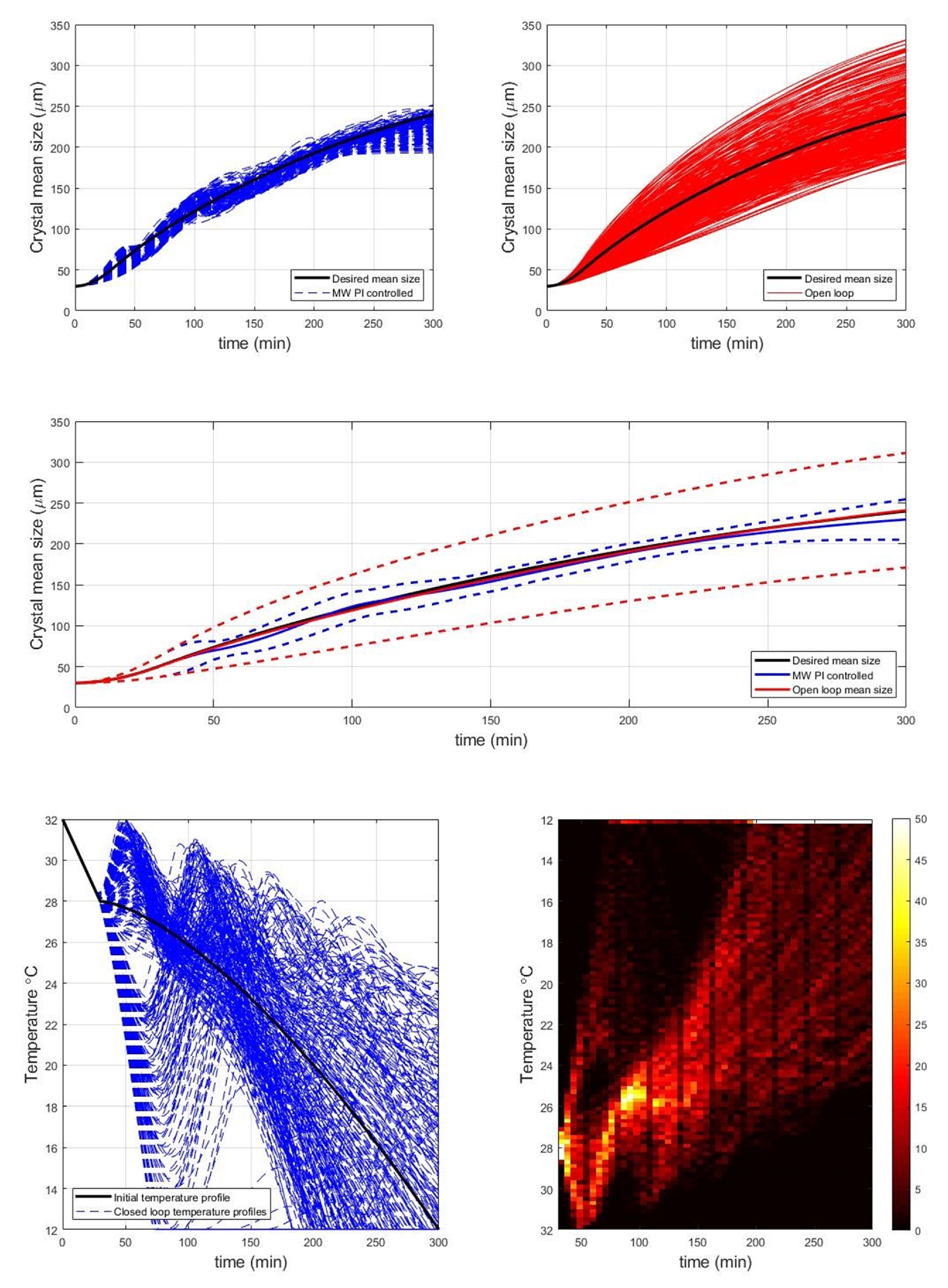

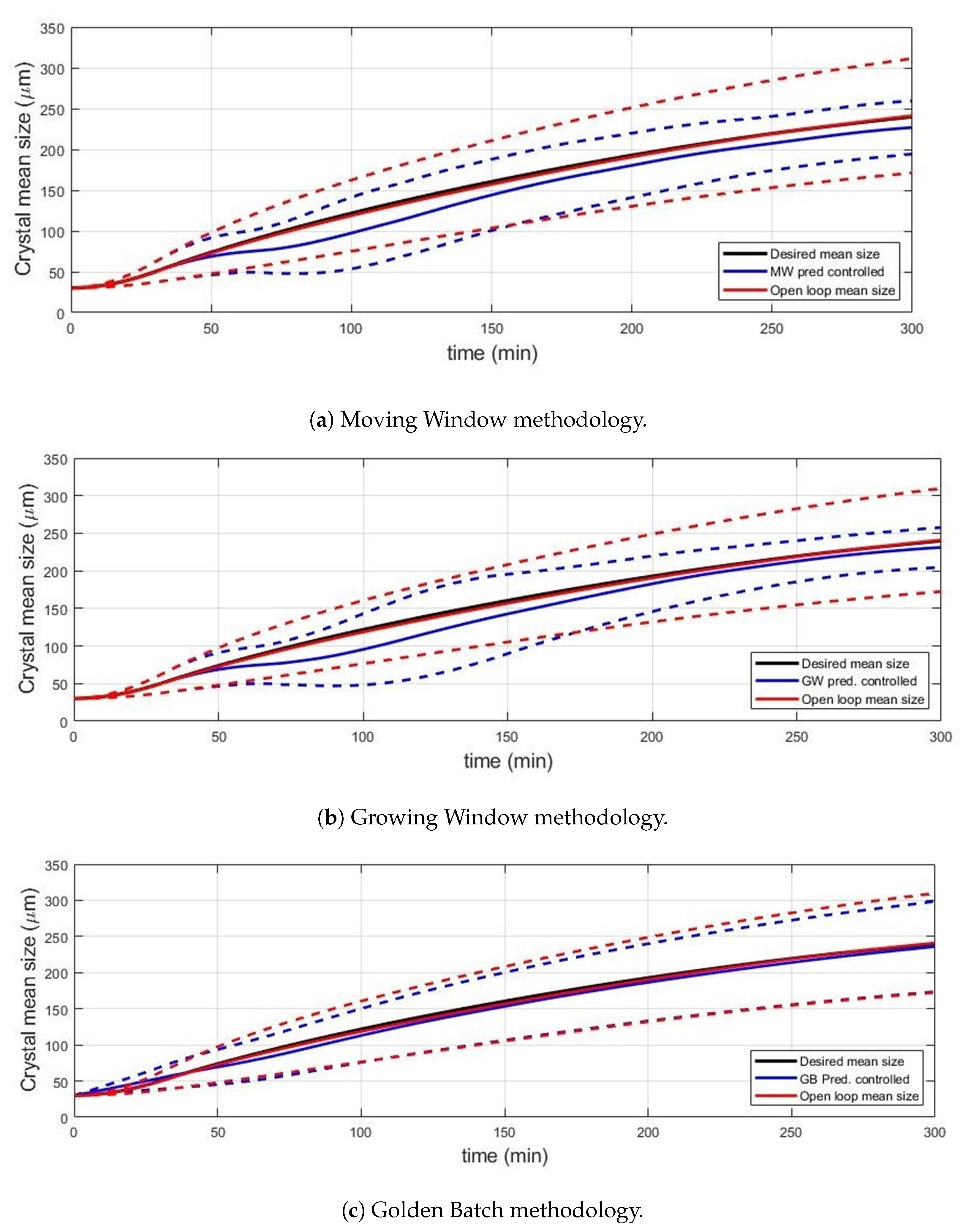

3.3. RBF Predictive Control

- In order to provide the RBF with enough significant training data, the predictive control only took control after 1 h. Following the linear decrease of temperature from 32 C to 28 C, there was a linear increase of the temperature from 28 C to 30 C. This provided more training data regarding the effect of heating on the crystallization, and if the correct conditions were met, the RBF could adapt to dissolution occurrences. RBF predictive control using Golden Batch did not follow this pattern and instead took control over the cooling system from the very beginning of the simulation.

3.3.1. Moving Window Predictive Control

3.3.2. Growing Window Predictive Control

3.3.3. Golden Batch Predictive Control

- For early process times, the Golden Batch was unstable, not being able to find a smooth pattern to follow. This causes an off-set between the desired and the current mean crystal size.

- Once the unstable period has passed, the future predictions tend towards the initial training data temperature at the respective time. This indicated that the initial set of data (the Golden Batch data) was overruling the weight of the newly incorporated measurements. As there was no disturbance included, the final mean size shows almost no deviation.

3.4. Control Performance Evaluation for Predictive RBF Methodologies

4. Conclusions

- The data availability is of utmost importance for the choice of a Golden Batch methodology. Not only the availability of data is required, but the reliability of its annals is demanded. If only a segment of a certain process is used for the initial training data of a Golden Batch RBF is used, the predictions for the non-included process behavior should not be trusted. This was verified for the predictive control using the Golden Batch methodology, where there was not sufficient information to decide on which action to take, even when knowing that there would be a deviation. The reason why the PI soft sensor accomplished good results for the same methodology, is because the controller action was not entitled to the RBF itself, but to the PI controller. Regarding quality, for all the methodologies, the RBF is being trained with the data it is provided with. If accurate data is not given to the model, the learning process is hampered, and the predictions of this referred model cannot be trusted.

- The expected deviations to the system refer to known deviations, expected deviations or lack of knowledge of the system dynamics/behavior. To start with the implementation of a Golden Batch is a risk, if deviations are expected, and if not enough knowledge of the process is held. Depending on the knowledge of the expected/measured disturbances, a smoother RBF can be implemented (Moving Window), or a more effective methodology should be applied if the range and magnitude of such disturbances are unknown. The choice regarding using RBF as a soft sensor or as a predictive model relies mostly on the time required to obtain the measurements.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- U.S. Food and Drug Administration. PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance; U.S. Food and Drug Administration: Rockville, MD, USA, 2004.

- U.S. Food and Drug Administration. Innovation, Stagnation: Challenges and Opportunity on the Critical Path to New Medical Products; U.S. Food and Drug Administration: Rockville, MD, USA, 2004.

- Wu, H.; Khan, M.R.A.; Hussain, A.S. Process control perspective for process analytical technology: Integration of chemical engineering practice into semiconductor and pharmaceutical industries. Chem. Eng. Commum. 2007, 194, 760–779. [Google Scholar] [CrossRef]

- Simon, L.L.; Pataki, H.; Marosi, G.; Meemken, F.; Hungerbühler, K.; Baiker, A.; Tummala, S.; Glennon, B.; Kuentz, M.; Steele, G.; et al. Assessment of recent process analytical (PAT) trends: A multiauthor review. Oranic Process. Res. Dev. 2015, 19, 3–62. [Google Scholar] [CrossRef]

- D’Amato, R.J.; Loughnan, M.S.; Flynn, E.; Folkman, J. Thalidomide is an inhibitor of angiogenesis. Proc. Natl. Acad. Sci. USA 1994, 91, 4082–4085. [Google Scholar] [CrossRef]

- Wnendt, S.; Finkam, M.; Winter, W.; Ossig, J.; Raabe, G.; Zwingenberger, K. Enantioselective inhibition of TBF-α release by thalidomide and thalidomide-analogues. Chirality 1996, 8, 390–396. [Google Scholar] [CrossRef]

- Bauer, J.; Spanton, S.; Henry, R.; Quick, J.; Dziki, W.; Porter, W.; Morris, J. Rironavir: An extraordinary example of conformational polymorphism. Pharm. Res. 2001, 18, 859–866. [Google Scholar] [CrossRef] [PubMed]

- Bakar, M.R.A.; Nagy, Z.K.; Saleemi, A.N.; Rielly, C.D. The impact of direct nucleation control on crystal size distribution in pharmaceutical crystallization processes. Cryst. Growth Des. 2009, 9, 1378–1384. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Nagy, Z.K. Automated direct nucleation control in continuous mixed suspension mixed product removal cooling crystallization. Cryst. Growth Des. 2015, 15, 5839–5848. [Google Scholar] [CrossRef]

- Mesbah, A.; Landlust, J.; Huesman, A.E.M.; Kramer, H.J.M.; Jansens, P.J.; Van den Hof, P.M.J. A model-based control framework for industrial batch crystallization processes Author links open overlay panel. Chem. Eng. Res. Des. 2010, 88, 1223–1233. [Google Scholar] [CrossRef]

- Aamir, E.; Rielly, C.D.; Nagy, Z.K. Experimental evaluation of the targeted direct design of temperature trajectories for growth-dominated crystallization processes using an analytical crystal size distribution estimator. Ind. Eng. Chem. Res. 2012, 51, 16677–16687. [Google Scholar] [CrossRef]

- Nagy, Z.K. Model based robust control approach for batch crystallization product design. Comput. Chem. Eng. 2009, 33, 1685–1691. [Google Scholar] [CrossRef]

- Trifkovic, M.; Sheikhzadeh, M.; Rohani, S. Kinetics estimation and single and multiobjective optimization of a seeded, anti-solvent, isothermal batch crystallizer. Ind. Eng. Chem. Res. 2008, 47, 1586–1595. [Google Scholar] [CrossRef]

- Suárez, L.A.P.; Georgieva, P.; de Azevedo, S.F. Neural Network Model Predictive Control Applied to a Fed-Batch Sugar Crystallization. In Proceedings of the 8th Portuguese conference on Automatic Control, Vila Real, Portugal, 21–23 July 2008; pp. 142–148. [Google Scholar]

- Daosud, W.; Thampasato, J.; Kittisupakom, P. Neural Network based Modeling and Control for a Batch heating/Cooling Evaporative Crystallization Process. Eng. J. 2016, 21, 127–143. [Google Scholar] [CrossRef]

- Seborg, D.E.; Mellichamp, D.A.; Edgar, T.F.; Doyle, F.J., III. Process Dynamics and Control; John Wiley & Sons. Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Ramchadran, S.; Rhinehart, R.R. Do Neural Networks Offer Something For You. InTech 1995, 42, 59–64. [Google Scholar]

- Broomhead, D.S.; Lowe, D. Multivariate functional interpolation and adaptive networks. Complex Systems 1988, 2, 321–355. [Google Scholar]

- Fang, H.; Horstemeyer, M.F. Global response approximation with radial basis functions. Eng. Optim. 2006, 237, 407–424. [Google Scholar] [CrossRef]

- Gernaey, K.V.; Glassey, J.; Skogestad, S.; Krämer, S.; Weiß, A.; Engell, S.; Pistikopoulos, E.N.; Cameron, D.B. Process Systems Engineering, 5. Process Dynamics, Control, Monitoring and Identification; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2013. [Google Scholar]

- Sanner, R.M.; Slotine, J.E. Gaussian network for adaptive control. IEEE Trans. Neural Netw. 1992, 3, 837–863. [Google Scholar] [CrossRef]

- Pottman, M.; Seborg, D.E. A nonlinear predictive control strategy based on radial basis functions. Comput. Chem. Eng. 1997, 21, 965–980. [Google Scholar] [CrossRef]

- Öner, M.; Montes, F.C.C.; Ståhlberg, T.; Stocks, S.M.; Bajtner, J.E.; Sin, G. Comprehensive evaluation of a data driven control strategy: Experimental application to a pharmaceutical crystallization process. Chem. Eng. Res. Des. 2020, 163, 248–261. [Google Scholar] [CrossRef]

- Costa, C.B.B.; da Costa, A.C.; Filho, R.M. Mathematical modeling and optimal control strategy development for an adipic acid crystallization process. Chem. Eng. Process. 2005, 44, 737–753. [Google Scholar] [CrossRef]

- Puel, F.; Févotte, G.; Klein, J.P. Simulation and analysis of industrial crystallization process through multidimensional population balance equations. Part 1: A resolution algorithm based on the method of classes. Chem. Eng. Sci. 2003, 58, 3715–3727. [Google Scholar] [CrossRef]

- Rashid, A.; White, E.T.; Howes, T.; Litster, J.D.; Marziano, I. Growth rates of ibuprofen crystals grown from ethanol and aqueous ethanol. Chem. Eng. Res. Des. 2012, 90, 158–161. [Google Scholar] [CrossRef]

- Rashid, A.; White, E.T.; Howes, T.; Marziano, I. Effect of solvent composition and temperature on the solubility of ibuprofen in aqueous ethanol. Chem. Eng. Data 2014, 59, 2699–2703. [Google Scholar] [CrossRef]

- Rashid, A.; White, E.T.; Howes, T.; Marziano, I. The Metastability and Nucleation Thresholds of Ibuprofen in Ethanol and Water Mixtures. Int. J. Chem. Eng. 2015, 2015. [Google Scholar] [CrossRef]

- Jin, R.; Chen, W.; Sudjianto, A. On sequential sampling for global metamodeling in engineering design. In Proceedings of the ASME Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASME, Montreal, QC, Canada, 29 September–2 October 2002; pp. 539–548. [Google Scholar]

- Mulgrew, B. Applying radial basis functions. IEEE Signal Process. Mag. 1996, 13, 50–65. [Google Scholar] [CrossRef]

- Acar, E.; Rais-Rohani, M. Ensemble of metamodels with optimized weight factors. Struct. Multidiscip. Optim. 2009, 37, 279–294. [Google Scholar] [CrossRef]

- Colaço, M.J.; Dulikravich, G.S.; Sahoo, D.A. A Comparison of Two Methods for Fitting High Dimensional Response Surfaces. In Proceedings of the Inverse Problems, Design and Optimization Symposium, Miami, FL, USA, 16–18 April 2007. [Google Scholar]

- Poggio, T.; Girosi, G. Networks for Approximation and Learning. Proc. IEEE 1990, 78, 1481–1497. [Google Scholar] [CrossRef]

- Orr, M.J.L. Introduction to Radial Basis Function Networks; Technical Report; University of Edinburgh: Edinburgh, Scotland, 1996. [Google Scholar]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Prentice Hall: Upper Saddle River, NJ, USA, 1994. [Google Scholar]

- Mann, I.; McLaughlin, S. Dynamical System Modelling using Radial Basis Functions. In Proceedings of the IEEE 2000 Adaptive Systems for Signal Processing, Communications, and Control Symposium (Cat. No.00EX373), Lake Louise, AB, Canada, 1–4 October 2000; pp. 461–465. [Google Scholar]

- Friedman, J.H. Multivariate Adaptive Regression Splines. Annu. Stat. 1991, 19, 1–67. [Google Scholar] [CrossRef]

- Jēkabsons, G. Radial Basis Function Interpolation. 2009. Available online: http://www.cs.rtu.lv/jekabsons/regression.html (accessed on 2 February 2019).

- Helton, J.C.; Davis, F.J. Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliab. Eng. Syst. Saf. 2003, 81, 23–69. [Google Scholar] [CrossRef]

| Parameter | Units | Mean Value | Uncertainty Range % |

|---|---|---|---|

| Solvent mass () | kg | 55 | 15 |

| Water concentration () | kg/kg | 0.1 | 90 |

| Linear cooling time () | min | 30 | 50 |

| [28] | #/min/kg | 5.3 | 65 |

| [26] | m/min/S | 1.78 × 10 | 60 |

| Initial seed mass () | kg/kg | 0.05 | 50 |

| RBF Methodologies | |||

|---|---|---|---|

| Moving Window | Growing Window | Golden Batch | |

| Soft sensor | |||

| Crystallization time | 5 h | 5 h | 5 h |

| 30 min | 30 min | from the start | |

| every min | every min | every min | |

| every 3 min | every 3 min | every 3 min | |

| 75 | unlimited | 301 | |

| Proportional gain (PI) | 0.03 | 0.03 | 0.03 |

| Integral gain (PI) | |||

| Time delay | 3 min | 3 min | 3 min |

| Predictive control | |||

| Crystallization time | 5 h | 5 h | 5 h |

| 60 min | 60 min | from the start | |

| every min | every min | every min | |

| every 3 min | every 3 min | every 3 min | |

| 75 | unlimited | 301 | |

| Time delay | 3 min | 3 min | 3 min |

| Max cooling/heating rate | 0.5 C/min | 0.5 C/min | 0.5 C/min |

| Max/Min temperature | 32 C /10 C | 32 C/10 C | 32 C/10 C |

| m) | m) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PI(30) | MW | GW | PI | GB | PI(30) | MW | GW | PI | GB | ||

| Soft sensor | |||||||||||

| Undisturbed | 1.80 | 1.45 | 1.60 | 5.63 | 4.98 | 2.85 | 3.48 | 4.09 | 5.19 | 5.90 | |

| 3.41 | 2.63 | 2.74 | 3.87 | 4.98 | 3.22 | 3.45 | 4.08 | 3.96 | 3.95 | ||

| 2.15 | 5.14 | 4.51 | 9.56 | 9.98 | 2.37 | 11.12 | 9.06 | 10.38 | 11.78 | ||

| 1.85 | 1.5 | 1.66 | 5.69 | 4.48 | 3.04 | 3.80 | 4.42 | 5.47 | 4.80 | ||

| 1.75 | 1.3 | 1.52 | 5.57 | 3.81 | 2.67 | 3.13 | 3.79 | 4.98 | 2.28 | ||

| 4.19 | 4.02 | 4.08 | 6.60 | 6.16 | 17.5 | 19.8 | 19.73 | 17.59 | 19.55 | ||

| 1.26 | 0.95 | 1.08 | 7.05 | 5.87 | 1.88 | 1.59 | 2.32 | 7.46 | 7.32 | ||

| 1.70 | 1.30 | 1.45 | 5.69 | 4.42 | 2.51 | 2.68 | 3.45 | 5.13 | 5.06 | ||

| 2.00 | 1.68 | 1.84 | 5.58 | 4.32 | 3.72 | 4.68 | 5.37 | 5.79 | 5.73 | ||

| 1.94 | 1.45 | 1.64 | 5.20 | 3.48 | 2.89 | 2.79 | 3.78 | 4.52 | 2.82 | ||

| 1.74 | 1.46 | 1.65 | 6.21 | 4.26 | 2.90 | 3.91 | 4.70 | 6.33 | 3.67 | ||

| Predictive control | |||||||||||

| Undisturbed | 16.91 | 16.73 | 2.25 | 19.51 | 18.87 | 1.45 | |||||

| 3.15 | 3.27 | 5.72 | 3.49 | 4.02 | 6.07 | ||||||

| 37.35 | 47.23 | 6.32 | 44.76 | 94.50 | 23.49 | ||||||

| 16.44 | 16.47 | 3.50 | 18.90 | 18.61 | 273 | ||||||

| 15.81 | 8.56 | 3.91 | 18.63 | 13.24 | 2.69 | ||||||

| 13.79 | 17.01 | 21.57 | 17.56 | 35.98 | 108.60 | ||||||

| 9.10 | 16.54 | 2.62 | 14.87 | 38.92 | 4.46 | ||||||

| 16.78 | 8.45 | 3.73 | 20.55 | 8.28 | 10.98 | ||||||

| 9.56 | 9.20 | 4.94 | 9.63 | 9.27 | 13.84 | ||||||

| 9.16 | 6.19 | 1.94 | 10.06 | 5.95 | 1.08 | ||||||

| 19.29 | 13.03 | 3.55 | 23.56 | 15.86 | 3.96 | ||||||

| Units | OP | MW | GW | GB | |

|---|---|---|---|---|---|

| Soft sensor | |||||

| Average mean size | m | 241.0 | 229.9 | 230.0 | 229.9 |

| Upper bound () | m | 309.6 | 254.8 | 254.1 | 263.8 |

| Lower bound () | m | 172.5 | 205.1 | 205.8 | 195.9 |

| Pr(|mean size-240| < 10) | % | 18.4 | 63.2 | 63.4 | 62.8 |

| Pr(|mean size-240| < 20) | % | 37.5 | 76.3 | 77.6 | 76.3 |

| Predictive control | |||||

| Average mean size | m | 241.0 | 226.8 | 231.2 | 236.2 |

| Upper bound () | m | 309.6 | 259.3 | 257.6 | 298.7 |

| Lower bound () | m | 172.5 | 194.3 | 204.6 | 173.6 |

| Pr(|mean size-240| < 10) | % | 18.4 | 53.5 | 65.8 | 33.1 |

| Pr(|mean size-240| < 20) | % | 37.5 | 69.9 | 77.9 | 50.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montes, F.C.C.; Öner, M.; Gernaey, K.V.; Sin, G. Model-Based Evaluation of a Data-Driven Control Strategy: Application to Ibuprofen Crystallization. Processes 2021, 9, 653. https://doi.org/10.3390/pr9040653

Montes FCC, Öner M, Gernaey KV, Sin G. Model-Based Evaluation of a Data-Driven Control Strategy: Application to Ibuprofen Crystallization. Processes. 2021; 9(4):653. https://doi.org/10.3390/pr9040653

Chicago/Turabian StyleMontes, Frederico C. C., Merve Öner, Krist V. Gernaey, and Gürkan Sin. 2021. "Model-Based Evaluation of a Data-Driven Control Strategy: Application to Ibuprofen Crystallization" Processes 9, no. 4: 653. https://doi.org/10.3390/pr9040653

APA StyleMontes, F. C. C., Öner, M., Gernaey, K. V., & Sin, G. (2021). Model-Based Evaluation of a Data-Driven Control Strategy: Application to Ibuprofen Crystallization. Processes, 9(4), 653. https://doi.org/10.3390/pr9040653