Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review

Abstract

1. Introduction

2. Drying of Fruits

2.1. Convectional Hot Air Drying

2.2. Osmotic Drying

2.3. Microwave Drying

2.4. Freeze-Drying

3. Quality of Dried Fruits

3.1. Physical Quality

3.2. Chemical Quality

3.3. Nutritional Quality

3.4. Sensory Quality

3.5. Comparison of Drying Methods

4. Unconventional/Emerging Drying Intensification Technologies

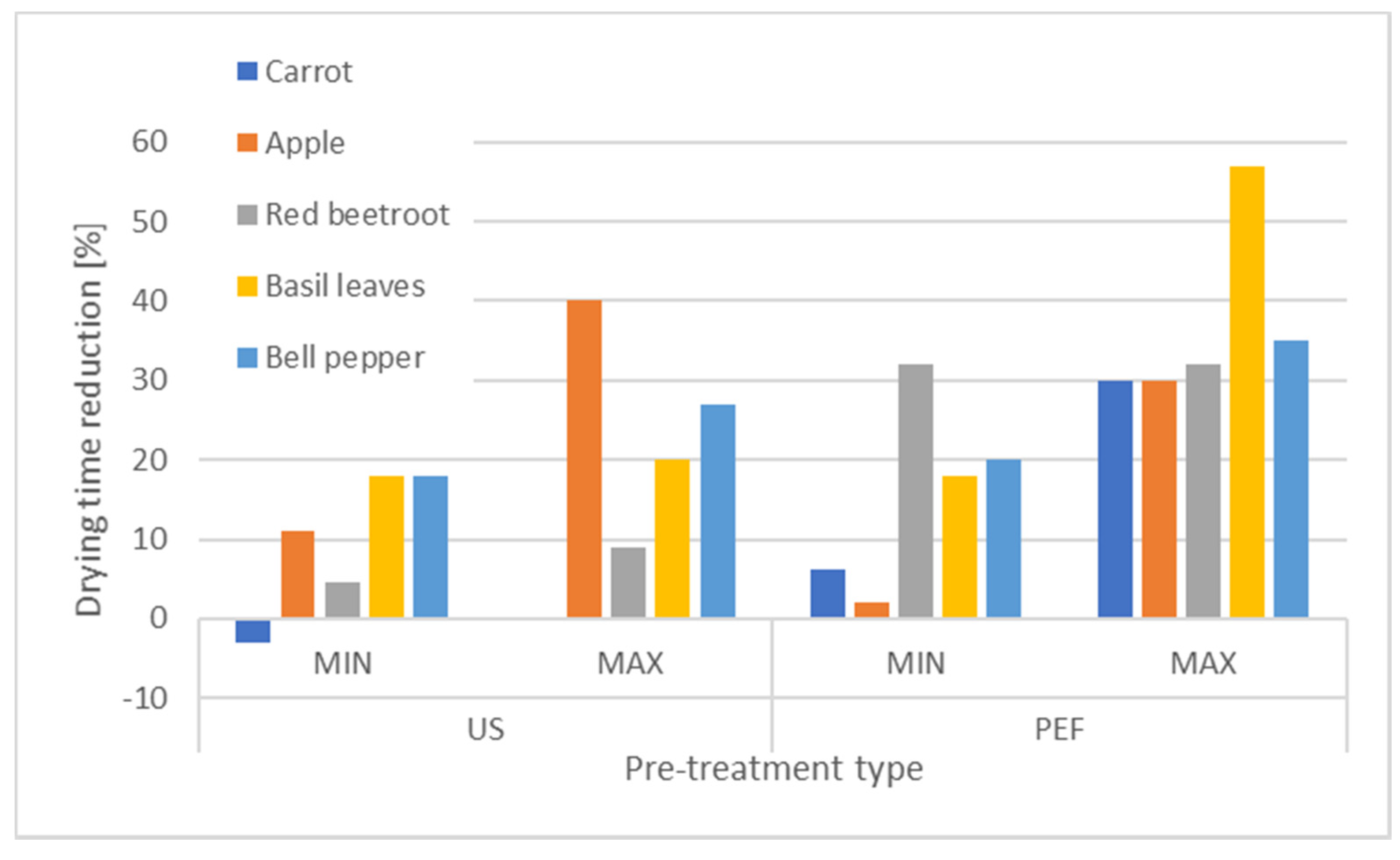

4.1. Ultrasound

4.2. Pulsed Electric Fields

4.3. High Hydrostatic Pressure

4.4. Cold Plasma

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Orsat, V.; Changrue, V.; Raghavan, G.S.V. Microwave drying of fruits and vegetables. Stewart Postharvest Rev. 2006, 2, 1–7. [Google Scholar] [CrossRef]

- Ratti, C. Advances in Food Dehydration. In Dehydration of Foods; Araya-Farias, M., Ratti, C., Eds.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Mercer, D.G. An Introduction to the Dehydration and Drying of Fruits and Vegetables; University of Guelph: Guelph, ON, Canada, 2014; p. 166. [Google Scholar]

- Chua, K.J.; Chou, S.K. Low-cost drying methods for developing countries. Trends Food Sci. Tech. 2003, 14, 519–528. [Google Scholar] [CrossRef]

- Çoklar, H.; Akbulut, M. Effect of sun, oven and freeze-drying on anthocyanins, phenolic compounds and antioxidant activity of black grape (Ekşikara) (Vitis vinifera L.). S. Afr. J. Enol. Vitic. 2017, 38, 264–272. [Google Scholar] [CrossRef]

- Sette, P.; Salvatori, D.; Schebor, C. Physical and mechanical properties of raspberries subjected to osmotic dehydration and further dehydration by air- and freeze-drying. Food Bioprod. Process. 2016, 100, 156–171. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B.; Saravacos, G.D. The effect of the method of drying on the colour of dehydrated products. Int. J. Food Sci. Tech. 2001, 36, 53–59. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. 2017, 59, 1408–1432. [Google Scholar] [CrossRef] [PubMed]

- Mujumdar, A.S.; Devahastin, S. Fundamental principles of drying. In Guide to Industrial Drying; Mujumdar, A.S., Ed.; Universiti Kebangsaan Malaysia: Hyderabad, India, 2008. [Google Scholar]

- Chen, X.D.; Mujumdar, A.S. Food Processing; Blackwell Publishing: West Sussex, UK, 2008. [Google Scholar]

- Nijhuis, H.H.; Torringa, H.M.; Muresan, S.; Yuksel, D.; Leguijt, C.; Kloek, W. Approaches to improving the quality of dried fruit and vegetables. Trends Food Sci. Tech. 1998, 9, 13–20. [Google Scholar] [CrossRef]

- Le Maguer, M. Osmotic Dehydration: Review and Future Directions; CERIA: Bruxelles, Belgium, 1998; pp. 283–309. [Google Scholar]

- Pavkov, I.; Stamenković, Z.; Radojčin, M.; Krstan, K.; Bursić, V.; Bikić, S.; Mitrevski, V. Osmotic and convective drying of strawberries: Effects of experimental parameters on the drying kinetics, color and rehidratation. PTEP J. Proces. Energy Agric. 2018, 22, 58–64. [Google Scholar] [CrossRef]

- Lazarides, H.N.; Katsanidis, E.; Nickolaidis, A. Mass transfer kinetics during osmotic preconcentration aiming at minimal solid uptake. J. Food Eng. 1995, 25, 151–166. [Google Scholar] [CrossRef]

- Mayor, L.; Moreira, R.; Chenlo, F.; Sereno, A.M. Kinetics of osmotic dehydration of pumpkin with sodium chloride solutions. J. Food Eng. 2006, 74, 253–262. [Google Scholar] [CrossRef]

- Rastogi, N.K.; Raghavarao, K.S.M.S. Kinetics of osmotic dehydration under vacuum. LWT Food Sci. Technol. 1996, 29, 669–672. [Google Scholar] [CrossRef]

- Sagar, V.R.; Kumar, P.S. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Lahsasni, S.; Kouhila, M.; Mahrouz, M.; Jaouhari, J.T. Drying kinetics of prickly pear fruit (Opuntia ficus indica). J. Food Eng. 2004, 61, 173–179. [Google Scholar] [CrossRef]

- Toğrul, İ.T.; Pehlivan, D. Mathematical modelling of solar drying of apricots in thin layers. J. Food Eng. 2002, 55, 209–216. [Google Scholar] [CrossRef]

- Garcia, R.; Leal, F.; Rolz, C. Drying of bananas using microwave and air ovens. Int. J. Food Sci. Technol. 2007, 23, 73–80. [Google Scholar] [CrossRef]

- Li, Z.; Raghavan, G.S.V.; Orsat, V. Optimal power control strategies in microwave drying. J. Food Eng. 2010, 99, 263–268. [Google Scholar] [CrossRef]

- Ezhilarasi, P.N.; Indrani, D.; Jena, B.S.; Anandharamakrishnan, C. Freeze drying technique for microencapsulation of Garcinia fruit extract and its effect on bread quality. J. Food Eng. 2013, 117, 513–520. [Google Scholar] [CrossRef]

- Ceballos, A.M.; Giraldo, G.I.; Orrego, C.E. Effect of freezing rate on quality parameters of freeze dried soursop fruit pulp. J. Food Eng. 2012, 111, 360–365. [Google Scholar] [CrossRef]

- Topić, R.M.; Topić, G.R.; Aćimović, D. Justify using of sublimation drying with aspect of characteristics and energy demand value. PTEP J Proces. Energy Agric. 2010, 5, 81–84. [Google Scholar]

- Kalra, S.K.; Bhardway, K.C. Use of simple solar dehydrator for drying fruits and vegetable products. J. Food Sci. Technol. 1981, 8, 23–26. [Google Scholar]

- Stamenković, Z.; Pavkov, I.; Radojčin, M.; Tepić Horecki, A.; Kešelj, K.; Kovačević, D.B.; Putnik, P. Convective drying of fresh and frozen raspberries and change of their physical and nutritive properties. Foods 2019, 8, 251. [Google Scholar] [CrossRef] [PubMed]

- Cavusoglu, C. Investigations into the High-Temperature Air Drying of Tomato Pieces; Universität Bonn, Rheinische Friedrich-Wilhelms-Universität: Bonn, Germany, 2008. [Google Scholar]

- Giangiacomo, R.; Torreggiani, D.; Abbo, E. Osmotic dehydration of fruit: Part 1. Sugars exchange between fruit and extracting syrups. J. Food Process. Preserv. 1987, 11, 183–195. [Google Scholar] [CrossRef]

- Tregunno, N.B.; Goff, H.D. Osmodehydrofreezing of apples: Structural and textural effects. Food Res. Int. 1996, 29, 471–479. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Mujumdar, A.S. Effect of osmotic treatment with concentrated sugar and salt solutions on kinetics and color in vacuum contact drying. J. Food Process. Preserv. 2007, 31, 671–687. [Google Scholar] [CrossRef]

- Islam, M.N.; Flink, J.N. Dehydration of potato. Int. J. Food Sci. Technol. 2007, 17, 387–403. [Google Scholar] [CrossRef]

- Kowalska, H.; Belka, M.; Lenart, A. Influence of microwave heating on mass transfer during osmotic dehydration of apples. Pol. J. Food Nutr. Sci. 2007, 57, 317–323. [Google Scholar]

- Bolin, H.R.; Huxsoll, C.C.; Jackson, R.; Ng, K.C. Effect of osmotic agents and concentration on fruit quality. J. Food Sci. 1983, 48, 202–205. [Google Scholar] [CrossRef]

- Radojčin, M.; Babić, M.; Babić, L.; Pavkov, I.; Bukurov, M.; Bikić, S.; Mitrevski, V. Effects of osmotic pretreatment on quality and physical properties of dried quinces (Cydonia oblonga). J. Food Nutr. Res. 2015, 54, 142–154. [Google Scholar]

- Babić, M.; Babić, L.; Pavkov, I.; Radojčin, M. Changes in physical properties throught osmotic drying of quince (Cydonia oblonga mill.). PTEP J. Proces. Energy Agric. 2008, 12, 101–107. [Google Scholar]

- Raoult-Wack, A.L. Recent advances in the osmotic dehydration of foods. Trends Food Sci. Tech. 1994, 5, 255–260. [Google Scholar] [CrossRef]

- Taiwo, K.A.; Angersbach, A.; Ade-Omowaye, B.I.O.; Knorr, D. Effects of pretreatments on the diffusion kinetics and some quality parameters of osmotically dehydrated apple slices. J. Agric. Food Chem. 2001, 49, 2804–2811. [Google Scholar] [CrossRef] [PubMed]

- Ade-Omowaye, B.I.O.; Rastogi, N.K.; Angersbach, A.; Knorr, D. Effects of high hydrostatic pressure or high intensity electrical field pulse pre-treatment on dehydration characteristics of red paprika. Innov. Food Sci. Emerg. 2001, 2, 1–7. [Google Scholar] [CrossRef]

- Cárcel, J.A.; Benedito, J.; Rosselló, C.; Mulet, A. Influence of ultrasound intensity on mass transfer in apple immersed in a sucrose solution. J. Food Eng. 2007, 78, 472–479. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, M.; Li, X.; Mujumdar, A.S. Ultrasonically enhanced osmotic pretreatment of sea cucumber prior to microwave freeze drying. Dry. Technol. 2008, 26, 420–426. [Google Scholar] [CrossRef]

- Radojčin, M.; Babić, M.; Babić, L.; Pavkov, I.; Stamenković, Z. Influence of different pretreatments on the colour of dried pears. PTEP J. Proces. Energy Agric. 2013, 17, 176–179. [Google Scholar]

- Rahman, M.S.; Perera, C. Drying and food preservation. In Hand-Book of Food Preservation; Rahman, M.S., Ed.; Marcel Dekker: New York, NY, USA, 1999; pp. 173–216. [Google Scholar]

- Azarpazhooh, E.; Ramaswamy, H.S. Microwave-osmotic dehydration of apples under continuous flow medium spray conditions: Comparison with other methods. Dry. Technol. 2009, 28, 49–56. [Google Scholar] [CrossRef]

- Laguerre, J.-C.; Hamoud-Agha, M.M. Microwave heating for food preservation. In Food Preservation and Waste Exploitation; Socaci, S.A., Fărcaş, A.C., Aussenac, T., Laguerre, J.C., Eds.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Cohen, J.S.; Yang, T.C.S. Progress in food dehydration. Trends Food Sci. Tech. 1995, 6, 20–25. [Google Scholar] [CrossRef]

- Schiffmann, R.F. Microwave processes for the food industry. In Handbook of Microwave Technology for Food Applications; Datta, A.K., Anantheswaran, R.C., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 229–338. [Google Scholar]

- Onwude, D.I.; Hashim, N.; Chen, G. Recent advances of novel thermal combined hot air drying of agricultural crops. Trends Food Sci. Tech. 2016, 57, 132–145. [Google Scholar] [CrossRef]

- Morais, R.M.S.C.; Morais, A.M.M.B.; Dammak, I.; Bonilla, J.; Sobral, P.J.A.; Laguerre, J.C.; Afonso, M.J.; Ramalhosa, E.C.D. Functional dehydrated foods for health preservation. J. Food Qual. 2018, 2018, 1–29. [Google Scholar] [CrossRef]

- Nowak, D.; Jakubczyk, E. The freeze-drying of foods-The characteristic of the process course and the effect of its parameters on the physical properties of food materials. Foods 2020, 9, 1488. [Google Scholar] [CrossRef]

- Hammami, C.; René, F. Determination of freeze-drying process variables for strawberries. J. Food Eng. 1997, 32, 133–154. [Google Scholar] [CrossRef]

- Lachowicz, S.; Michalska, A.; Lech, K.; Majerska, J.; Oszmiański, J.; Figiel, A. Comparison of the effect of four drying methods on polyphenols in saskatoon berry. LWT Food Sci. Technol. 2019, 111, 727–736. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Mykhailyk, V.; Wiktor, A.; Toepfl, S.; Nowacka, M.; Bialik, M.; Czyżewski, J.; Witrowa-Rajchert, D.; Parniakov, O. Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innov. Food Sci. Emerg. 2019, 57, 57. [Google Scholar] [CrossRef]

- Shishehgarha, F.; Makhlouf, J.; Ratti, C. Freeze-drying characteristics of strawberries. Dry. Technol. 2002, 20, 131–145. [Google Scholar] [CrossRef]

- Krokida, M.K.; Karathanos, V.T.; Maroulis, Z.B. Effect of freeze-drying conditions on shrinkage and porosity of dehydrated agricultural products. J. Food Eng. 1998, 35, 369–380. [Google Scholar] [CrossRef]

- Domin, M.; Dziki, D.; Kłapsia, S.; Blicharz-Kania, A.; Biernacka, B.; Krzykowski, A. Influence of the freeze-drying conditions on the physicochemical properties and grinding characteristics of kiwi. Int. J. Food Eng. 2020, 16(1–2), 20180315. [Google Scholar] [CrossRef]

- Franceschinis, L.; Salvatori, D.M.; Sosa, N.; Schebor, C. Physical and functional properties of blackberry freeze- and spray-dried powders. Dry. Technol. 2013, 32, 197–207. [Google Scholar] [CrossRef]

- Munzenmayer, P.; Ulloa, J.; Pinto, M.; Ramirez, C.; Valencia, P.; Simpson, R.; Almonacid, S. Freeze-drying of blueberries: Effects of carbon dioxide (CO2) laser perforation as skin pretreatment to improve mass transfer, primary drying time, and quality. Foods 2020, 9, 211. [Google Scholar] [CrossRef]

- Ong, S.P.; Law, C.L. Hygrothermal properties of various foods, vegetables and fruits. In Drying of Foods, Vegetables and Fruits-Vol. 1; Jangam, S.V., Law, C.L., Mujumdar, A.S., Eds.; University of Singapore: Singapore, 2012; pp. 31–58. [Google Scholar]

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Cárcel, J.A.; García-Pérez, J.V.; Sanjuán, N.; Mulet, A. Influence of pre-treatment and storage temperature on the evolution of the colour of dried persimmon. LWT Food Sci. Technol. 2010, 43, 1191–1196. [Google Scholar] [CrossRef]

- Rodrigues, A.C.C.; Cunha, R.L.; Hubinger, M.D. Rheological properties and colour evaluation of papaya during osmotic dehydration processing. J. Food Eng. 2003, 59, 129–135. [Google Scholar] [CrossRef]

- Bustos, M.C.; Rocha-Parra, D.; Sampedro, I.; de Pascual-Teresa, S.; León, A.E. The influence of different air-drying conditions on bioactive compounds and antioxidant activity of berries. J. Agric. Food Chem. 2018, 66, 2714–2723. [Google Scholar] [CrossRef] [PubMed]

- Omolola, A.O.; Jideani, A.I.O.; Kapila, P.F. Quality properties of fruits as affected by drying operation. Crit. Rev. Food Sci. 2015, 57, 95–108. [Google Scholar] [CrossRef] [PubMed]

- Pavkov, I.; Stamenković, Z.; Radojčin, M.; Babić, M.; Bikić, S.; Mitrevski, V.; Lutovska, M. Convective andfreeze drying of raspberry: Effect of experimental parameters on drying kinetics, physical properties andrehydration capacity. In Proceedings of the INOPTEP 5th International Conference Sustainable Postharvestand Food Technologies, Vršac, Serbia, 23–28 April 2017; pp. 261–266. [Google Scholar]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B. Effect of drying method on shrinkage and porosity. Dry. Technol. 1997, 15, 2441–2458. [Google Scholar] [CrossRef]

- Lozano, J.E.; Rotstein, E.; Urbicain, M.J. Shrinkage, porosity and bulk density of foodstuffs at changing moisture contents. J. Food Sci. 1983, 48, 1497–1502. [Google Scholar] [CrossRef]

- Rahman, M.S.; Potluri, P.L. Shrinkage and density of squid flesh during air drying. J. Food Eng. 1990, 12, 133–143. [Google Scholar] [CrossRef]

- Rahman, M.S.; Perera, C.O.; Chen, X.D.; Driscoll, R.H.; Potluri, P.L. Density, shrinkage and porosity of calamari mantle meat during air drying in a cabinet dryer as a function of water content. J. Food Eng. 1996, 30, 135–145. [Google Scholar] [CrossRef]

- Wang, N.; Brennan, J.G. Changes in structure, density and porosity of potato during dehydration. J. Food Eng. 1995, 24, 61–76. [Google Scholar] [CrossRef]

- Sablani, S.S.; Rahman, M.S. Pore formation in selected foods as a function of shelf temperature during freeze drying. Dry. Technol. 2007, 20, 1379–1391. [Google Scholar] [CrossRef]

- Meda, L.; Ratti, C. Rehydration of freeze-dried strawberries at varying temperatures. J. Food Process. Eng. 2005, 28, 233–246. [Google Scholar] [CrossRef]

- Kowalska, H.; Marzec, A.; Kowalska, J.; Ciurzyńska, A.; Samborska, K.; Bialik, M.; Lenart, A. Rehydration properties of hybrid method dried fruit enriched by natural components. Int. Agrophys. 2018, 32, 175–182. [Google Scholar] [CrossRef]

- Zhang, L.; Qiao, Y.; Wang, C.; Liao, L.; Liu, L.; Shi, D.; An, K.; Hu, J.; Xu, Q. Effects of freeze vacuum drying combined with hot air drying on the sensory quality, active components, moisture mobility, odors, and microstructure of kiwifruits. J. Food Qual. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Wiktor, A.; Iwaniuk, M.; Śledź, M.; Nowacka, M.; Chudoba, T.; Witrowa-Rajchert, D. Drying kinetics of apple tissue treated by pulsed electric field. Dry. Technol. 2013, 31, 112–119. [Google Scholar] [CrossRef]

- Wiktor, A.; Nowacka, M.; Dadan, M.; Rybak, K.; Lojkowski, W.; Chudoba, T.; Witrowa-Rajchert, D. The effect of pulsed electric field on drying kinetics, color, and microstructure of carrot. Dry. Technol. 2015, 34, 1286–1296. [Google Scholar] [CrossRef]

- Ammar, J.B.; Lanoisellé, J.-L.; Lebovka, N.I.; Van Hecke, E.; Vorobiev, E. Effect of a pulsed electric field and osmotic treatment on freezing of potato tissue. Food Biophys. 2010, 5, 247–254. [Google Scholar] [CrossRef]

- Kamiloglu, S.; Toydemir, G.; Boyacioglu, D.; Beekwilder, J.; Hall, R.D.; Capanoglu, E. A review on the effect of drying on antioxidant potential of fruits and vegetables. Crit. Rev. Food Sci. 2015, 56, S110–S129. [Google Scholar] [CrossRef]

- Mohammed, S.; Edna, M.; Siraj, K. The effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of fruits: A case of mangoes and pineapples. Heliyon 2020, 6, e04163. [Google Scholar] [CrossRef]

- Suna, S.; Tamer, C.E.; Inceday, B.; Sinir, G.Ö.; Çopur, Ö.U. Impact of drying methods on physicochemical and sensory properties of apricot pestil. Indian J. Tradit. Knowl. 2014, 13, 47–55. [Google Scholar]

- Nemzer, B.; Vargas, L.; Xia, X.; Sintara, M.; Feng, H. Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem. 2018, 262, 242–250. [Google Scholar] [CrossRef]

- Adak, N.; Heybeli, N.; Ertekin, C. Infrared drying of strawberry. Food Chem. 2017, 219, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Zielinska, M.; Zielinska, D.; Markowski, M. The effect of microwave-vacuum pretreatment on the drying kinetics, color and the content of bioactive compounds in osmo-microwave-vacuum dried cranberries (Vaccinium macrocarpon). Food Bioprocess. Tech. 2017, 11, 585–602. [Google Scholar] [CrossRef]

- Cao, X.; Islam, M.N.; Xu, W.; Chen, J.; Chitrakar, B.; Jia, X.; Liu, X.; Zhong, S. Energy consumption, colour, texture, antioxidants, odours, and taste qualities of litchi fruit dried by intermittent ohmic heating. Foods 2020, 9, 425. [Google Scholar] [CrossRef] [PubMed]

- Verbeyst, L.; Bogaerts, R.; Van der Plancken, I.; Hendrickx, M.; Van Loey, A. Modelling of vitamin C degradation during thermal and high-pressure treatments of red fruit. Food Bioprocess. Tech. 2012, 6, 1015–1023. [Google Scholar] [CrossRef]

- Nguyen, T.V.L.; Nguyen, Q.D.; Nguyen, P.B.D.; Tran, B.L.; Huynh, P.T. Effects of drying conditions in low-temperature microwave-assisted drying on bioactive compounds and antioxidant activity of dehydrated bitter melon (Momordica harantian L.). Food Sci. Nutr. 2020, 8, 3826–3834. [Google Scholar] [CrossRef]

- Bennett, L.E.; Jegasothy, H.; Konczak, I.; Frank, D.; Sudharmarajan, S.; Clingeleffer, P.R. Total polyphenolics and anti-oxidant properties of selected dried fruits and relationships to drying conditions. J Funct. Foods 2011, 3, 115–124. [Google Scholar] [CrossRef]

- Ouaabou, R.; Nabil, B.; Ouhammou, M.; Idlimam, A.; Lamharrar, A.; Ennahli, S.; Hanine, H.; Mahrouz, M. Impact of solar drying process on drying kinetics, and on bioactive profile of Moroccan sweet cherry. Renew. Energy 2020, 151, 908–918. [Google Scholar] [CrossRef]

- ISO. Sensory analysis -Identification and selection of descriptors for establishing a sensory profile by a multidimensional approach. In ISO 11035; ISO: Switzerland, 1994; Volume 67, pp. 1–26. [Google Scholar]

- ISO. Sensory analysis-Methodology, General guidance for establishing a sensory profile. In ISO 13299; ISO: Switzerland, 2003; Volume 67, pp. 1–24. [Google Scholar]

- ISO. Sensory analysis -General guidelines for the selection, training and monitoring of selected assessors. In ISO 8586:2012; ISO: Switzerland, 2012; Volume 67, pp. 1–28. [Google Scholar]

- Naes, T.; Brockhoff, P.B.; Tomic, O. Statistics for Sensory and Consumer Science; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Pawłowski, A.; Szadzińska, J.; Łechtańska, J.; Stasiak, M. High power airborne ultrasound assist in combined drying of raspberries. Innov. Food Sci. Emerg. 2016, 34, 225–233. [Google Scholar] [CrossRef]

- Szychowski, P.J.; Lech, K.; Sendra-Nadal, E.; Hernández, F.; Figiel, A.; Wojdyło, A.; Carbonell-Barrachina, Á.A. Kinetics, biocompounds, antioxidant activity, and sensory attributes of quinces as affected by drying method. Food Chem. 2018, 255, 157–164. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Legua, P.; Lech, K.; Carbonell-Barrachina, Á.A.; Hernández, F. Chemical composition, antioxidant capacity, and sensory quality of dried jujube fruits as affected by cultivar and drying method. Food Chem. 2016, 207, 170–179. [Google Scholar] [CrossRef]

- Leite, J.B.; Mancini, M.C.; Borges, S.V. Effect of drying temperature on the quality of dried bananas cv. prata and d’água. LWT Food Sci. Technol. 2007, 40, 319–323. [Google Scholar] [CrossRef]

- Sunjka, P.S.; Rennie, T.J.; Beaudry, C.; Raghavan, G.S.V. Microwave-convective and microwave-vacuum drying of cranberries: A comparative study. Dry. Technol. 2004, 22, 1217–1231. [Google Scholar] [CrossRef]

- Krulis, M.; Kühnert, S.; Leiker, M.; Rohm, H. Influence of energy input and initial moisture on physical properties of microwave-vacuum dried strawberries. Eur. Food Res. Technol. 2005, 221, 803–808. [Google Scholar] [CrossRef]

- Hawlader, M.N.A.; Perera, C.O.; Tian, M. Properties of modified atmosphere heat pump dried foods. J. Food Eng. 2006, 74, 392–401. [Google Scholar] [CrossRef]

- Hendriks, M.M.W.B.; de Boer, J.H.; Smilde, A.K.; Doornbos, D.A. Multicriteria decision making. Chemom. Intell. Lab. Syst. 1992, 16, 175–191. [Google Scholar] [CrossRef]

- Héberger, K. Sum of ranking differences compares methods or models fairly. TrAC Trend Anal. Chem. 2010, 29, 101–109. [Google Scholar] [CrossRef]

- Sipos, L.; Bernhardt, B.; Gere, A.; Komáromi, B.; Orbán, C.; Bernáth, J.; Szabó, K. Multicriteria optimization to evaluate the performance of Ocimum basilicum L. varieties. Ind. Crop. Prod. 2016, 94, 514–519. [Google Scholar] [CrossRef]

- Gere, A.; Sipos, L.; Kovács, S.; Kókai, Z.; Héberger, K. Which just-about-right feature should be changed if evaluations deviate? A case study using sum of ranking differences. Chemom. Intell. Lab. Syst. 2017, 161, 130–135. [Google Scholar] [CrossRef]

- Rácz, A.; Bajusz, D.; Fodor, M.; Héberger, K. Comparison of classification methods with “n-class” receiver operating characteristic curves: A case study of energy drinks. Chemom. Intell. Lab. Syst. 2016, 151, 34–43. [Google Scholar] [CrossRef][Green Version]

- Gere, A.; Radványi, D.; Héberger, K. Which insect species can best be proposed for human consumption? Innov. Food Sci. Emerg. 2019, 52, 358–367. [Google Scholar] [CrossRef]

- Stamenković, Z.; Radojčin, M.; Pavkov, I.; Bikić, S.; Ponjičan, O.; Bugarin, R.; Kovács, S.; Gere, A. Ranking and multicriteria decision making in optimization of raspberry convective drying processes. J. Chemom. 2020, 34, e3224. [Google Scholar] [CrossRef]

- Bajusz, D.; Rácz, A.; Héberger, K. Why is Tanimoto index an appropriate choice for fingerprint-based similarity calculations? J. Cheminform. 2015, 7, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Sobukola, O.P.; Dairo, O.U.; Odunewu, A.V. Convective hot air drying of blanched yam slices. Int. J. Food Sci. Technol. 2008, 43, 1233–1238. [Google Scholar] [CrossRef]

- Doymaz, İ. Influence of blanching and slice thickness on drying characteristics of leek slices. Chem. Eng. Process. 2008, 47, 41–47. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Wiktor, A.; Sledz, M.; Nowacka, M. Selected emerging technologies to enhance the drying process: A review. Dry. Technol. 2014, 32, 1386–1396. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.-W. Enhancement of food processes by ultrasound: A review. Crit. Rev. Food Sci. 2014, 55, 570–594. [Google Scholar] [CrossRef]

- Ashokkumar, M. Applications of ultrasound in food and bioprocessing. Ultrason. Sonochem. 2015, 25, 17–23. [Google Scholar] [CrossRef]

- Wu, J.; Nyborg, W.L. Ultrasound, cavitation bubbles and their interaction with cells. Adv. Drug Deliv. Rev. 2008, 60, 1103–1116. [Google Scholar] [CrossRef]

- de la Fuente-Blanco, S.; de Sarabia, E.R.-F.; Acosta-Aparicio, V.M.; Blanco-Blanco, A.; Gallego-Juárez, J.A. Food drying process by power ultrasound. Ultrasonics 2006, 44, e523–e527. [Google Scholar] [CrossRef]

- Miano, A.C.; Ibarz, A.; Augusto, P.E.D. Mechanisms for improving mass transfer in food with ultrasound technology: Describing the phenomena in two model cases. Ultrason. Sonochem. 2016, 29, 413–419. [Google Scholar] [CrossRef]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound–A review. Trends Food Sci. Tech. 2016, 56, 126–141. [Google Scholar] [CrossRef]

- Magalhães, M.L.; Cartaxo, S.J.M.; Gallão, M.I.; García-Pérez, J.V.; Cárcel, J.A.; Rodrigues, S.; Fernandes, F.A.N. Drying intensification combining ultrasound pre-treatment and ultrasound-assisted air drying. J. Food Eng. 2017, 215, 72–77. [Google Scholar] [CrossRef]

- Nowacka, M.; Wiktor, A.; Śledź, M.; Jurek, N.; Witrowa-Rajchert, D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012, 113, 427–433. [Google Scholar] [CrossRef]

- Nowacka, M.; Wedzik, M. Effect of ultrasound treatment on microstructure, colour and carotenoid content in fresh and dried carrot tissue. Appl. Acoust. 2016, 103, 163–171. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Linhares, F.E.; Rodrigues, S. Ultrasound as pre-treatment for drying of pineapple. Ultrason. Sonochem. 2008, 15, 1049–1054. [Google Scholar] [CrossRef]

- Śledź, M.; Nowak, P.; Witrowa-Rajchert, D. Drying of parsley leaves pre-treated by ultrasound. ZPPNR 2014, 579, 91–99. [Google Scholar]

- Szadzińska, J.; Łechtańska, J.; Pashminehazar, R.; Kharaghani, A.; Tsotsas, E. Microwave- and ultrasound-assisted convective drying of raspberries: Drying kinetics and microstructural changes. Dry. Technol. 2018, 37, 1–12. [Google Scholar] [CrossRef]

- da Silva, E.S.; Brandão, S.C.R.; da Silva, A.L.; da Silva, J.H.F.; Coêlho, A.C.D.; Azoubel, P.M. Ultrasound-assisted vacuum drying of nectarine. J. Food Eng. 2019, 246, 119–124. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Yu, H.; Yin, Y.; Li, X.; Duan, X. Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry. Technol. 2016, 35, 564–576. [Google Scholar] [CrossRef]

- Timmermans, R.A.H.; Mastwijk, H.C.; Berendsen, L.B.J.M.; Nederhoff, A.L.; Matser, A.M.; Van Boekel, M.A.J.S.; Groot, M.N. Moderate intensity Pulsed Electric Fields (PEF) as alternative mild preservation technology for fruit juice. Int. J Food Microbiol. 2019, 298, 63–73. [Google Scholar] [CrossRef]

- Kayalvizhi, V.; Pushpa, A.J.S.; Sangeetha, G.; Antony, U. Effect of pulsed electric field (PEF) treatment on sugarcane juice. J. Food Sci. Technol. 2016, 53, 1371–1379. [Google Scholar] [CrossRef] [PubMed]

- Weaver, J.C.; Chizmadzhev, Y.A. Theory of electroporation: A review. Bioelectrochem. Bioenerg. 1996, 41, 135–160. [Google Scholar] [CrossRef]

- Kotnik, T.; Frey, W.; Sack, M.; Meglič, S.H.; Peterka, M.; Miklavčič, D. Electroporation-based applications in biotechnology. Trends Biotechnol. 2015, 33, 480–488. [Google Scholar] [CrossRef]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Thamkaew, G.; Galindo, F.G. Influence of pulsed and moderate electric field protocols on the reversible permeabilization and drying of Thai basil leaves. Innov. Food Sci. Emerg. 2020, 64, 102430. [Google Scholar] [CrossRef]

- Maza, M.; Álvarez, I.; Raso, J. Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages 2019, 5, 47. [Google Scholar] [CrossRef]

- Min, S.; Jin, Z.T.; Zhang, Q.H. Commercial scale pulsed electric field processing of tomato juice. J. Agric. Food Chem. 2003, 51, 3338–3344. [Google Scholar] [CrossRef]

- Fauster, T.; Schlossnikl, D.; Rath, F.; Ostermeier, R.; Teufel, F.; Toepfl, S.; Jaeger, H. Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. J. Food Eng. 2018, 235, 16–22. [Google Scholar] [CrossRef]

- Wiktor, A.; Singh, A.P.; Parniakov, O.; Mykhailyk, V.; Mandal, R.; Witrowa-Rajchert, D. PEF as an alternative tool to prevent thermolabile compound degradation during dehydration processes. In Pulsed Electric Fields to Obtain Healthier and Sustainable Food for Tomorrow; Barba, F., Parniakov, O., Wiktor, A., Eds.; Academic Press: London, UK, 2020; pp. 155–202. [Google Scholar]

- Ostermeier, R.; Parniakov, O.; Töpfl, S.; Jäger, H. Applicability of pulsed electric field (PEF) pre-treatment for a convective two-step drying process. Foods 2020, 9, 512. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, Y.; Zhang, D. Study of the effect of high-pulsed electric field treatment on vacuum freeze-drying of apples. Dry. Technol. 2011, 29, 1714–1720. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Wiktor, A.; Siemer, C.; Toepfl, S.; Mykhailyk, V.; Gondek, E.; Rybak, K.; Witrowa-Rajchert, D.; Parniakov, O. The effects of pulsed electric fields on the quality parameters of freeze-dried apples. J. Food Eng. 2019, 252, 36–43. [Google Scholar] [CrossRef]

- Fauster, T.; Giancaterino, M.; Pittia, P.; Jaeger, H. Effect of pulsed electric field pretreatment on shrinkage, rehydration capacity and texture of freeze-dried plant materials. LWT 2020, 121, 108937. [Google Scholar] [CrossRef]

- Liu, C.; Pirozzi, A.; Ferrari, G.; Vorobiev, E.; Grimi, N. Effects of pulsed electric fields on vacuum drying and quality characteristics of dried carrot. Food Bioprocess. Tech. 2019, 13, 45–52. [Google Scholar] [CrossRef]

- Huang, H.-W.; Wu, S.-J.; Lu, J.-K.; Shyu, Y.-T.; Wang, C.-Y. Current status and future trends of high-pressure processing in food industry. Food Control. 2017, 72, 1–8. [Google Scholar] [CrossRef]

- Rastogi, N.K.; Angersbach, A.; Knorr, D. Synergistic effect of high hydrostatic pressure pretreatment and osmotic stress on mass transfer during osmotic dehydration. J. Food Eng. 2000, 45, 25–31. [Google Scholar] [CrossRef]

- Eshtiaghi, M.N.; Stute, R.; Knorr, D. High-pressure and freezing pretreatment effects on drying, rehydration, texture and color of green beans, carrots and potatoes. J. Food Sci. 1994, 59, 1168–1170. [Google Scholar] [CrossRef]

- Janowicz, M.; Lenart, A. The impact of high pressure and drying processing on internal structure and quality of fruit. Eur. Food Res. Technol. 2018, 244, 1329–1340. [Google Scholar] [CrossRef]

- Yucel, U.; Alpas, H.; Bayindirli, A. Evaluation of high pressure pretreatment for enhancing the drying rates of carrot, apple, and green bean. J. Food Eng. 2010, 98, 266–272. [Google Scholar] [CrossRef]

- Kingsly, A.R.P.; Balasubramaniam, V.M.; Rastogi, N.K. Effect of high-pressure processing on texture and drying behavior of pineapple. J. Food Process. Eng. 2009, 32, 369–381. [Google Scholar] [CrossRef]

- George, J.M.; Sowbhagya, H.B.; Rastogi, N.K. Effect of high pressure pretreatment on drying kinetics and oleoresin extraction from ginger. Dry. Technol. 2017, 36, 1107–1116. [Google Scholar] [CrossRef]

- Núñez-Mancilla, Y.; Vega-Gálvez, A.; Pérez-Won, M.; Zura, L.; García-Segovia, P.; Di Scala, K. Effect of osmotic dehydration under high hydrostatic pressure on microstructure, functional properties and bioactive compounds of strawberry (Fragaria Vesca). Food Bioprocess. Tech. 2013, 7, 516–524. [Google Scholar] [CrossRef]

- Kim, K.W.; Kim, Y.-T.; Kim, M.; Noh, B.-S.; Choi, W.-S. Effect of high hydrostatic pressure (HHP) treatment on flavor, physicochemical properties and biological functionalities of garlic. LWT Food Sci. Technol. 2014, 55, 347–354. [Google Scholar] [CrossRef]

- Sampedro, F.; McAloon, A.; Yee, W.; Fan, X.; Geveke, D.J. Cost analysis and environmental impact of pulsed electric fields and high pressure processing in comparison with thermal pasteurization. Food Bioprocess. Tech. 2014, 7, 1928–1937. [Google Scholar] [CrossRef]

- Pankaj, S.K.; Bueno-Ferrer, C.; Misra, N.N.; Milosavljević, V.; O’Donnell, C.P.; Bourke, P.; Keener, K.M.; Cullen, P.J. Applications of cold plasma technology in food packaging. Trends Food Sci. Tech. 2014, 35, 5–17. [Google Scholar] [CrossRef]

- Niemira, B.A. Cold plasma decontamination of foods. Annu. Rev. Food Sci. Technol. 2012, 3, 125–142. [Google Scholar] [CrossRef]

- Encinas, N.; Abenojar, J.; Martínez, M.A. Development of improved polypropylene adhesive bonding by abrasion and atmospheric plasma surface modifications. Int. J. Adhes. Adhes. 2012, 33, 1–6. [Google Scholar] [CrossRef]

- Wiktor, A.; Hrycak, B.; Jasiński, M.; Rybak, K.; Kieliszek, M.; Kraśniewska, K.; Witrowa-Rajchert, D. Impact of atmospheric pressure microwave plasma treatment on quality of selected spices. Appl. Sci. 2020, 10, 6815. [Google Scholar] [CrossRef]

- Bao, T.; Hao, X.; Shishir, M.R.I.; Karim, N.; Chen, W. Cold plasma: An emerging pretreatment technology for the drying of jujube slices. Food Chem. 2021, 337, 127783. [Google Scholar] [CrossRef]

- Zhou, Y.-H.; Vidyarthi, S.K.; Zhong, C.-S.; Zheng, Z.-A.; An, Y.; Wang, J.; Wei, Q.; Xiao, H.-W. Cold plasma enhances drying and color, rehydration ratio and polyphenols of wolfberry via microstructure and ultrastructure alteration. LWT 2020, 134, 110173. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Karim, N.; Bao, T.; Gowd, V.; Ding, T.; Sun, C.; Chen, W. Cold plasma pretreatment–A novel approach to improve the hot air drying characteristics, kinetic parameters, and nutritional attributes of shiitake mushroom. Dry. Technol. 2019, 38, 2134–2150. [Google Scholar] [CrossRef]

- Li, S.; Chen, S.; Han, F.; Xv, Y.; Sun, H.; Ma, Z.; Chen, J.; Wu, W. Development and optimization of cold plasma pretreatment for drying on corn kernels. J. Food Sci. 2019, 84, 2181–2189. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-L.; Zhong, C.-S.; Mujumdar, A.S.; Yang, X.-H.; Deng, L.-Z.; Wang, J.; Xiao, H.-W. Cold plasma pretreatment enhances drying kinetics and quality attributes of chili pepper (Capsicum annuum L.). J. Food Eng. 2019, 241, 51–57. [Google Scholar] [CrossRef]

| Dried Material | Shape and Form | Freezing Temperature | Pressure of the Chamber | Drying Time | Monitored Properties | Ref. |

|---|---|---|---|---|---|---|

| Raspberry | Whole | −20 ℃ | 1 Pa | 48 h | Bioactive compounds, shrinkage, color change | [26] |

| Strawberries | Pieces—3.5 cm high layer | −20 ℃ and −80 ℃ | 15–200 Pa | 60–65 h | Moisture, rehydration ratio, appearance, shape, color, texture | [50] |

| Saskatoon berry | Whole | n/a | n/a | 24 h | Moisture, water activity, color, polyphenolic compounds | [51] |

| Raspberry | Whole | Frozen with liquid nitrogen | 4 Pa | 48 h | Water sorption, glass transition temperature (Tg), molecular mobility, texture and rehydration properties | [6] |

| Apple | Slices of a thickness of 6 ± 0.5mm, average diameter 72 ± 3 mm | Samples were not frozen | 100 Pa | Needed to achieve MR = 0.004 840 ± 21 and 368 ± 10min, for the untreated and the pulsed electric field (PEF) treated | Moisture, rehydration, hygroscopic properties, water activity | [52] |

| Strawberries | 5 and 10 mm slices and wholes | −40 ℃ | 50 Pa | 12 and 24 for slices 48 for whole fruit | Moisture, color, volume, | [53] |

| Carrot | Cylinders with a diameter of 20 mm and 8 mm height | −35 ℃ for 48 h, 1 h in liquid N2 | 3–300 Pa | 24 h | Volume, bulk density, glass transition temperature, porosity | [54] |

| Kiwi | Whole fruit (without peel) | −40 ℃ | 12, 20, 42, 85, and 103 Pa | n/a | Color, texture, rehydration, total phenolic content, antioxidant properties and sensory analysis | [55] |

| Banana | Cylinders with a diameter of 20 mm, height 8 mm | −35 ℃ for 48 h, 1 h in liquid N2 | 3–300 Pa | 24 h | Volume, bulk density, glass transition temperature, porosity | [54] |

| Blackberries | Juice with carrier agents | n/a | 0.0004 Pa | 48 h | Moisture, thermal property, density, morphology, antiradical activity | [56] |

| Blueberries | Whole fruit | −35 ℃ | 13 Pa | n/a | Mass transfer, drying time, berry-busting, skin perforation | [57] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radojčin, M.; Pavkov, I.; Bursać Kovačević, D.; Putnik, P.; Wiktor, A.; Stamenković, Z.; Kešelj, K.; Gere, A. Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes 2021, 9, 132. https://doi.org/10.3390/pr9010132

Radojčin M, Pavkov I, Bursać Kovačević D, Putnik P, Wiktor A, Stamenković Z, Kešelj K, Gere A. Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes. 2021; 9(1):132. https://doi.org/10.3390/pr9010132

Chicago/Turabian StyleRadojčin, Milivoj, Ivan Pavkov, Danijela Bursać Kovačević, Predrag Putnik, Artur Wiktor, Zoran Stamenković, Krstan Kešelj, and Attila Gere. 2021. "Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review" Processes 9, no. 1: 132. https://doi.org/10.3390/pr9010132

APA StyleRadojčin, M., Pavkov, I., Bursać Kovačević, D., Putnik, P., Wiktor, A., Stamenković, Z., Kešelj, K., & Gere, A. (2021). Effect of Selected Drying Methods and Emerging Drying Intensification Technologies on the Quality of Dried Fruit: A Review. Processes, 9(1), 132. https://doi.org/10.3390/pr9010132