1. Introduction

The increasing deployment of distributed generations (DGs), the advantage of renewable energy in reducing carbon emissions, the intermittency of renewable generations, the advent of advanced controllers and the need to have a more reliable and resilient power grid are some of major causes for the ongoing energy transition reforms globally [

1,

2,

3].

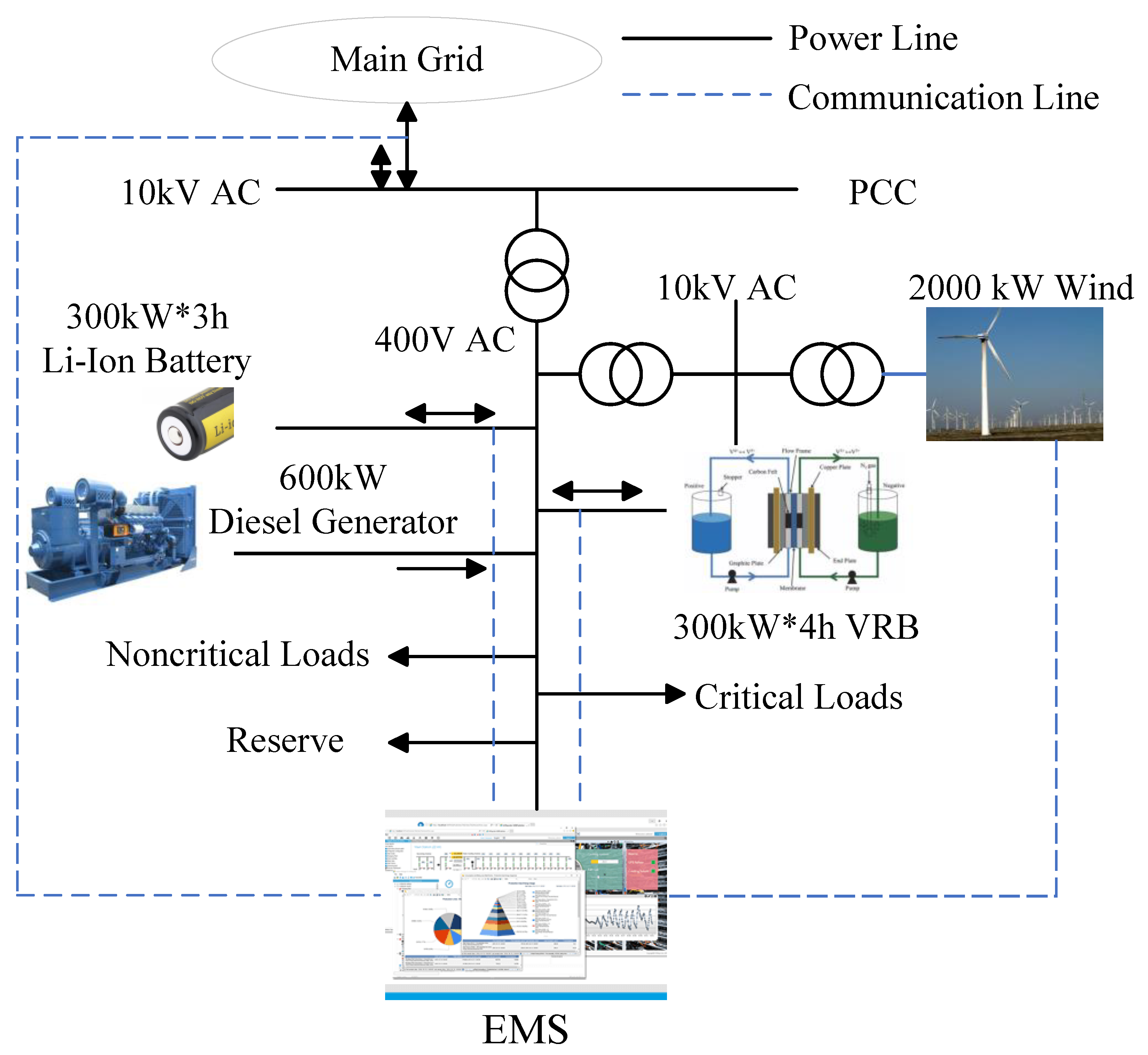

A microgrid (MG) is the assemblage of integrated electricity consumers, distributed generations (DGs) and distributed energy storages (DESs) at a distribution grid voltage level with clear electrical margins. The DGs can be the conventional or fuel-fired dispatchable power resources, such as a diesel generator, microturbine, fuel cell and other related energy sources [

4]. The DGs can also contain renewable energy resources (RESs)—for example, wind power generation, photovoltaic (PV) solar generation, biomass and other technologies. While the distributed sources (DSs) can include batteries, flywheels and super-capacitors. Microgrids have a black starting ability and can function either in island mode or in grid-coupled mode [

5]. They are not coupled with the upstream utility network when operating in the island mode. However, in the grid-coupled mode, MGs function in connection with the utility grid and exchange (buy or sell) power with the main grid.

Grid-coupled microgrids can export or import electrical energy to/from the larger electricity network. The power exchange with the upstream electricity network has generally been traded with a static, presettled price. Nevertheless, with the recent advent of smart sensor products and technology, it has become possible to precisely measure power generation and demands instantaneously or in real-time. This has created the opportunity for the change to time-of-use dynamic pricing schemes for electricity trading nowadays [

6]. Well-established control techniques that can integrate a number of generation resources and storage devices in a microgrid framework are developing to provide electricity users access to obtain sustainable and secure electric power nearby [

7,

8]. It also paves the way for selling energy during excess power production or at expensive-price hours and buying energy during production shortage or cheap-price hours.

An energy management system (EMS) is a fundamental component of MG control and operational supervision. It takes input information from the generation sources, energy storage devices, load demands and main grid to properly allocate the microgrid energy resources (or decide the amount and duration of energy utilization). If this EMS decision is performed by solving some desired objective function (it can be the minimization of cost or maximization of profit), it is called an optimal EMS. The power-trading advancement inspires microgrid aggregators to adjust their power-exchange engagements with the upstream grid based on time-of-use dynamic pricing schemes in order to reduce power generation costs (fuel expenses), guarantee the enhanced utilization of RESs and DSs and improve the energy-trading profit. To accomplish these objectives, robust and optimal EMS should be implemented and integrated in the microgrid control architecture [

6,

9,

10,

11].

There have been several research works, by various individuals and institutions, on microgrid EMS in the previous couple of years. These works on microgrid EMS have had different objectives, configurations, scenarios and contexts. Some of these works are presented below.

A sensitivity study that augmented EMS, considering the rating of the energy storage system (ESS) and the growing trend of electric loads, was proposed for a microgrid system in Taiwan [

12]. It aimed to search the optimal operation points of the microgrid energy resources for maximum profit. The EMS for optimal energy trading between two interconnected microgrid systems was presented in [

13]. The objective was to minimize the power generation and transportation costs. In this work, centralized versus decentralized control schemes were investigated, employing iterative approaches and convex optimization techniques.

The work proposed in [

14] developed an EMS to find the operating power set points of power sources in an MG. The work was based on an artificial neural network (ANN) and emphases to lower the total power generation expense of a MG that was involved in energy trading with the main electricity grid. Livengood [

15] proposed a power management device known as an energy box to manage the electricity consumption of residential communities in a real–time dynamic electricity pricing scenarios. In this work, a stochastic dynamic program was used to solve the EMS objective problem using predictions of the electricity demand, meteorological variables and electricity price. The EMS decisions were the charging/discharging power of the ESS and amount of main grid import/export power.

An EMS with a hierarchical optimization framework was implemented in [

16]. It focused on reducing the power generation spending and maximizing the power trading profit of a MG participating in a wholesale electricity-trading platform.

An optimal EMS model implemented employing a mixed-integer-linear-program (MILP) was formulated in [

17] for minimizing operation expenditures in community microgrids in a dynamic price electricity market. The microgrid consisted of heating/cooling demands, ESS and dispatchable demands. Malysz [

18] described an online power management technique to economically operate ESS devices of grid-coupled microgrids. The technique used a MILP described over a rolling scheduling period, employing forecasted electric loads and renewable power productions.

A genetic algorithm (GA)-based EMS [

4] and modified particle swarm optimization (MPSO)-based EMS [

5] were proposed for isolated microgrids containing multiple DGs and DSs. These EMS were targeted to reduce the operation costs of the MGs and effectively utilize the renewable and energy storage devices based on predictions of the electricity demand and renewables. References [

5,

7] proposed optimal EMS configurations depending on the prediction information of the electricity demands and renewable power productions for grid-connected microgrids in a variable electricity price environment. The proposed optimization problems were aimed to maximize profit and solved using the regrouping particle swarm optimization (RegPSO) technique.

Most of the aforementioned research works on microgrid energy management considered an ESS with one storage unit. The possible potential benefit of a microgrid ESS with more than one storage devices has not been investigated. Besides, the microgrids considered did not include multiple and integrated energy resources. Furthermore, the optimization techniques used to solve the EMS optimization problems did not ensure a global optimum solution, which, in turn, obstructed the exploitation of the maximum benefit of the microgrid in the power trading with the upper utility network.

In this paper, we propose an efficient power management technique for the 24 h-ahead optimal operation of mega-scale grid-coupled microgrids that consists of wind energy, a diesel generator, an energy storage system with several units and local (critical and noncritical) loads. The major target of the devised energy management methodology is to reduce the microgrid expenditure for fuel, operation and maintenance and main grid power import. It also targets maximizing the MG profit by exporting electricity to the upstream utility network. The optimization framework considers the stochastic ties of the wind power and electricity consumption in the MG, and pertinent predictions are employed to manage the stochastic ties. The optimization model is formulated for the 24 h-ahead scheduling period with a one-hour resolution, and it is solved using the ant colony optimization (ACO)-based meta-heuristic technique. Actual data and parameters obtained from an operating MG platform in Atlanta, GA, USA are employed to formulate and validate the proposed energy management approach. To assess and compare the efficacy of the devised method, another heuristic technique called a pattern search (PS) was also developed to obtain the EMS solution. The ACO was able to obtain the global best solution of the microgrid EMS problem. In addition, we chose ACO, as it has few parameters to update during the optimization process compared to other AI methods. The main contribution of the paper is the optimization formulation of microgrids considering the uncertainties of the renewable and load demands using integrated forecasting tools. From the optimization point to point, the contribution of the paper lays in implementing the ACO to solve such microgrid energy management optimization problems.

The arrangement of the other sections of the paper is described below.

Section 2 outlines the case study microgrid and the proposed EMS optimization model.

Section 3 describes the devised EMS framework and the working mechanism of the ACO. The simulation findings and comparative analysis are presented and discussed in

Section 4. The study is summarized in

Section 5.

4. Simulation Results and Discussions

Case Study

A large-scale grid-connected microgrid containing a 2000-kW wind generator, 600-kW diesel generator and 2100-kW·h ESS (300-kW·4-h VRB and 300-kW·3-h Li–Ion battery) is considered as a case study microgrid platform in this paper. It is a practical microgrid framework in Atlanta, GA, USA, which is designed to supply electricity to industrial park loads with a peak aggregate capacity of 3000 kW.

The lowest and peak SOC limits of the ESS devices are set as 20% and 100%, respectively. The initial SOCs (at 00:00 or 12:00 a.m.) of the ESS devices are assumed to be 20%. The maximum charging/discharging power of the ESS units is taken as 300 kW. The ideal charging and discharging efficiency (100%) is assumed. The diesel generator maximum generation is set as 600 kW, and its parameters are given in

Table 2. The maximum grid power exchange is set as 4000 kW, which equals the capacity of the grid-coupling transformer. SU is a fixed startup cost of the diesel generator. SD is a fixed shutdown cost of the diesel generator.

Several scenarios of the generation and load demands have been investigated to validate the proposed EMS optimization approach based on the information of the case study microgrid. However, for the purpose of illustration and summarizing the findings, the performance of the proposed approach will be discussed next based on a single-day scenario. The 24-ahead predictions of the wind power and electricity demand are depicted in

Figure 4 and

Figure 5, respectively.

The electricity price is shown in

Figure 6. The price data is the actual energy cost of industries and big institutions in Atlanta, GA, USA. It is shown that the power-selling bill to the upstream utility network is constant through the operating day, while the electricity purchasing bill from the upstream utility network is dynamic (time-of-use pricing scheme) within the day and has three step-prices within a day (low price period, moderate price period and peak price period).

Table 3 specifies the parameters associated with the O&M expenses for the various components of the microgrid.

Figure 7 depicts the ACO-based optimal solution for the formulated EMS objective function. The associated SOCs of the ESS devices are also illustrated in

Figure 8.

As clearly observed in

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8, during the time interval (00:00, 7:00) or (12 a.m., 7 a.m.) the produced wind power cannot deliver the full electricity consumption. However, the utility electricity bill is cheapest in this time interval, and therefore, the MG purchases power from the upstream utility network to support the wind generation to supply the load demand and charge the ESS. The diesel generator also supplies power to support the wind generation in this period. The ESS devices continuously charge and become full in this period.

In the period (7:00, 10:00) or (7 a.m., 10 a.m.), the wind power generation increases and becomes more than the load demand. The ESS units are at their full charge state in this time. Hence, the MG exports the excess energy from the wind power and ESS units in this period and earns profit. The diesel generator stops producing to lower the fuel expense, in this period, as there is excess renewable power production.

During the period (10:00, 15:00) or (10 a.m., 3 p.m.), which is the peak electricity price time interval, the microgrid still has more surplus electricity due to more production by the wind plant. Thus, the MG still keeps selling electricity to the upper utility network and charges the energy storage devices. The diesel generator does not produce power in this period, since there is still excess renewable power production in the MG.

During the period (15:00, 19:00) or (3 p.m., 7 p.m.), the wind power generation decreases and becomes lower than the load demand. The ESS units are at full in this period, and the electricity bill is medium. The microgrid supplies the load demand in this period using the generations from the ESS units and the dispatchable DG, in addition to the wind generation. The MG neither buys nor sells power from/to the utility network in this period.

The wind power generation increases again in the period (20:00, 23:00) and becomes greater than the microgrid electricity consumption. The microgrid exports the surplus generation to the main grid and charges the ESS devices in this period. The diesel generator power is zero in this period to lower the fuel expense, since there is plenty of renewable power production in the MG

Figure 9 shows the PS-based solution of the microgrid EMS optimization problem for the case study microgrid.

The hourly power production fuel cost comparison between the two EMS optimization approaches is shown in

Figure 10. It is shown that the ACO-based EMS optimization solution has resulted in lower fuel costs in most of the operating hours of the day.

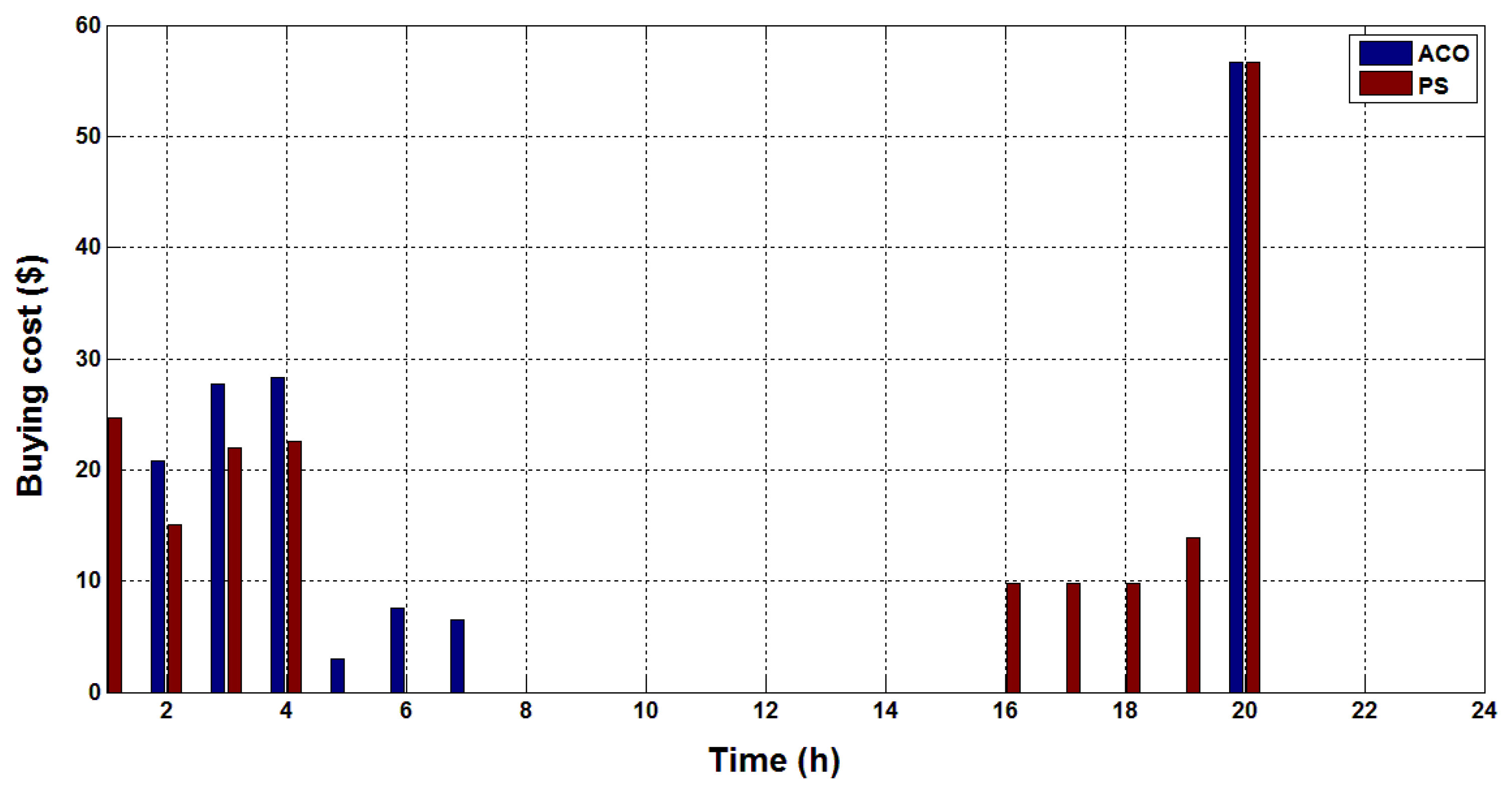

The hourly main grid power purchasing cost comparison between the two EMS optimization methods is shown in

Figure 11. It is observed that the ACO-based EMS optimization solution has given lower purchasing costs in most of the operating hours of the day.

As it is shown in

Figure 10 and

Figure 11 above, the fuel cost and power purchasing cost are almost zero, as the microgrid has sufficient renewable energy production from the wind during this period.

The comparison of the hourly income of exporting electricity to the upstream utility network between the two EMS optimization techniques is shown in

Figure 12. It is clearly shown that the ACO-based EMS optimization solution has achieved a higher income in several hours of the day.

Table 4 presents the daily power generation fuel cost, grid power purchasing cost and power-selling income by both EMS optimization solutions. It is observed in the table that the proposed ACO-based EMS solution has achieved a lower total fuel cost and grid power purchasing expense and higher total power selling income.

Table 5 presents the computational time elapsed by both methods to obtain their solutions using the MATLAB/Simulink software (MATLAB2016a, MathWorks.lnc, Natick, MA, USA) platform on a PC with an Intel core i7 CPU, 4.0 GHz processor and 8GB RAM. The ACO-based method has given the optimal solution within a shorter computation time.