Physico-Chemical Changes, Microbiological Properties, and Storage Shelf Life of Cow and Goat Milk from Industrial High-Pressure Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Milk Sampling and Treatment

2.2. Physico-Chemical Analysis

2.3. Microbiological Analysis

2.4. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Effects of HPP on Physico-Chemical Properties

3.2. Effects of HPP on Microbiological Properties

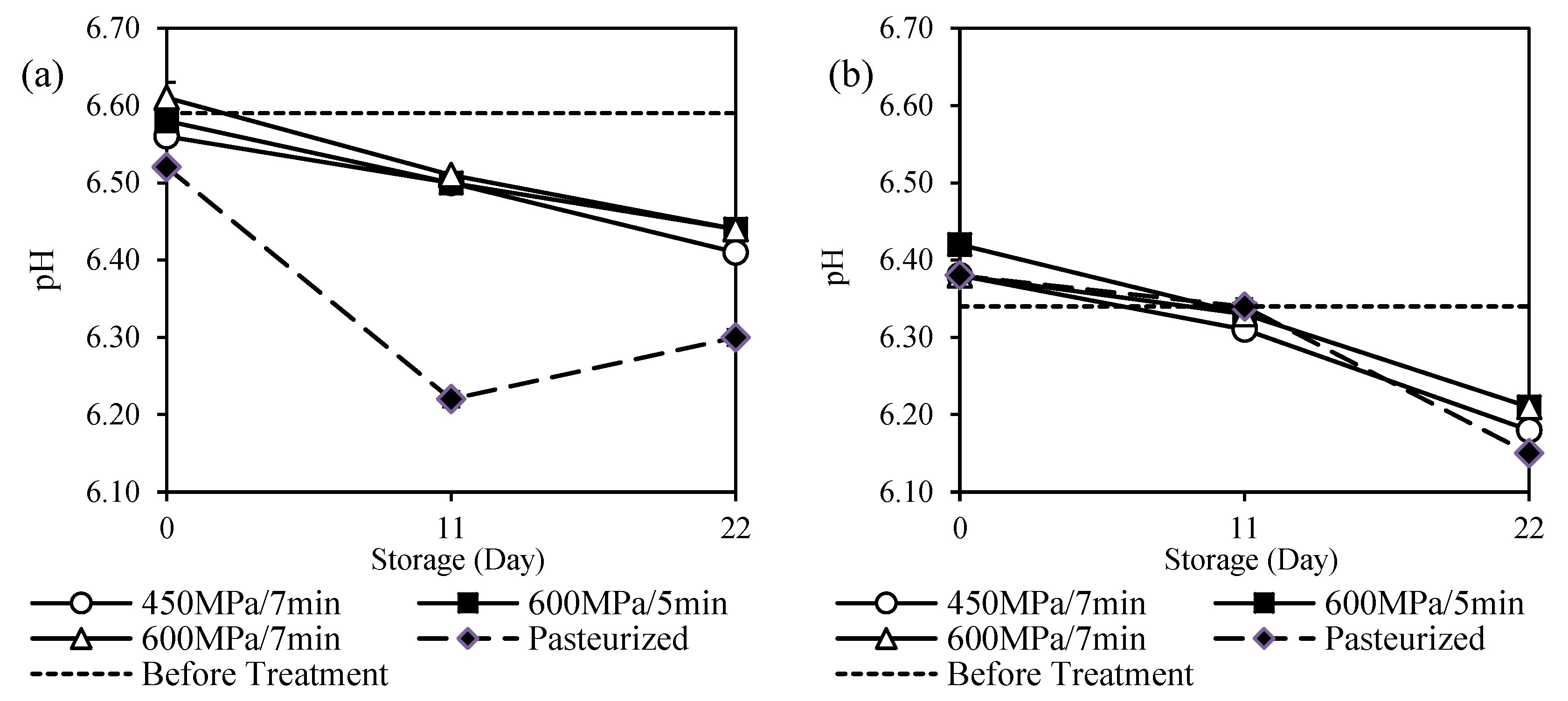

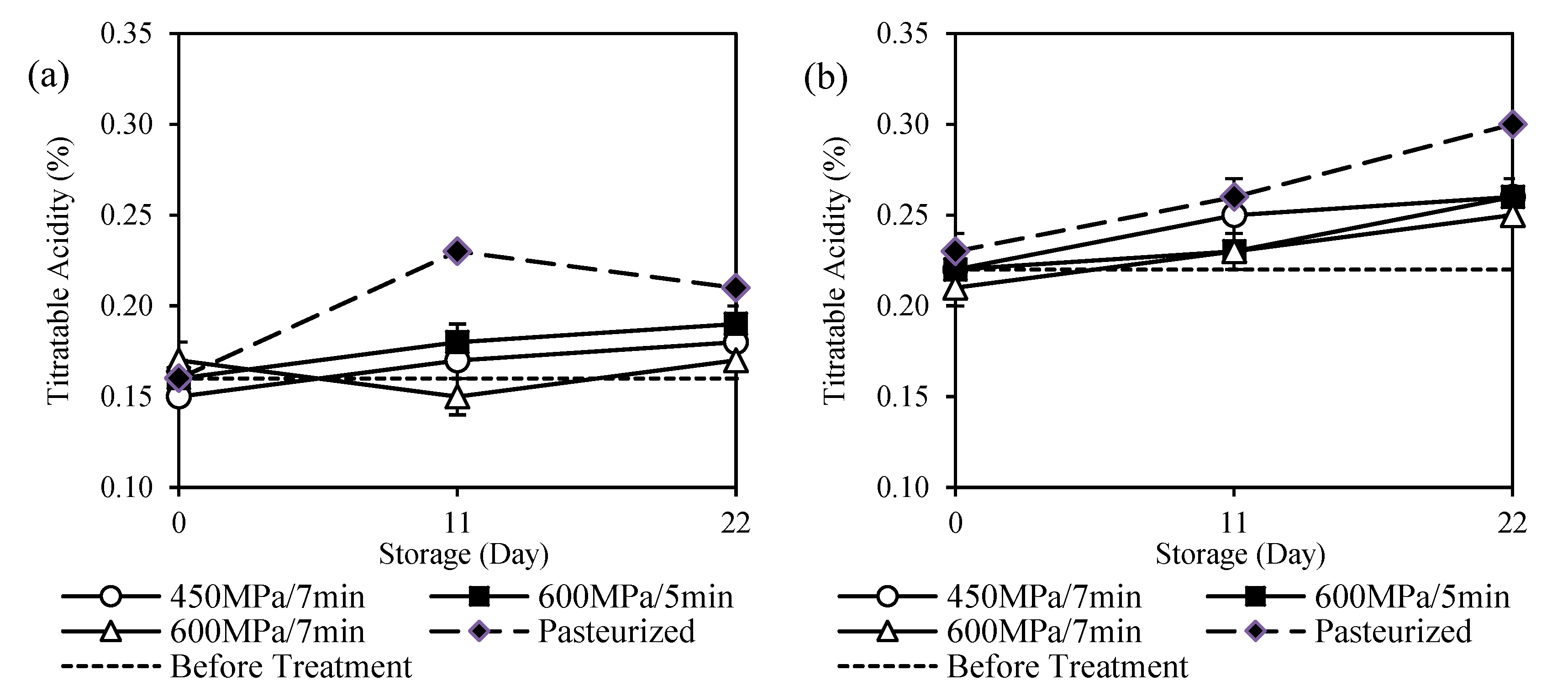

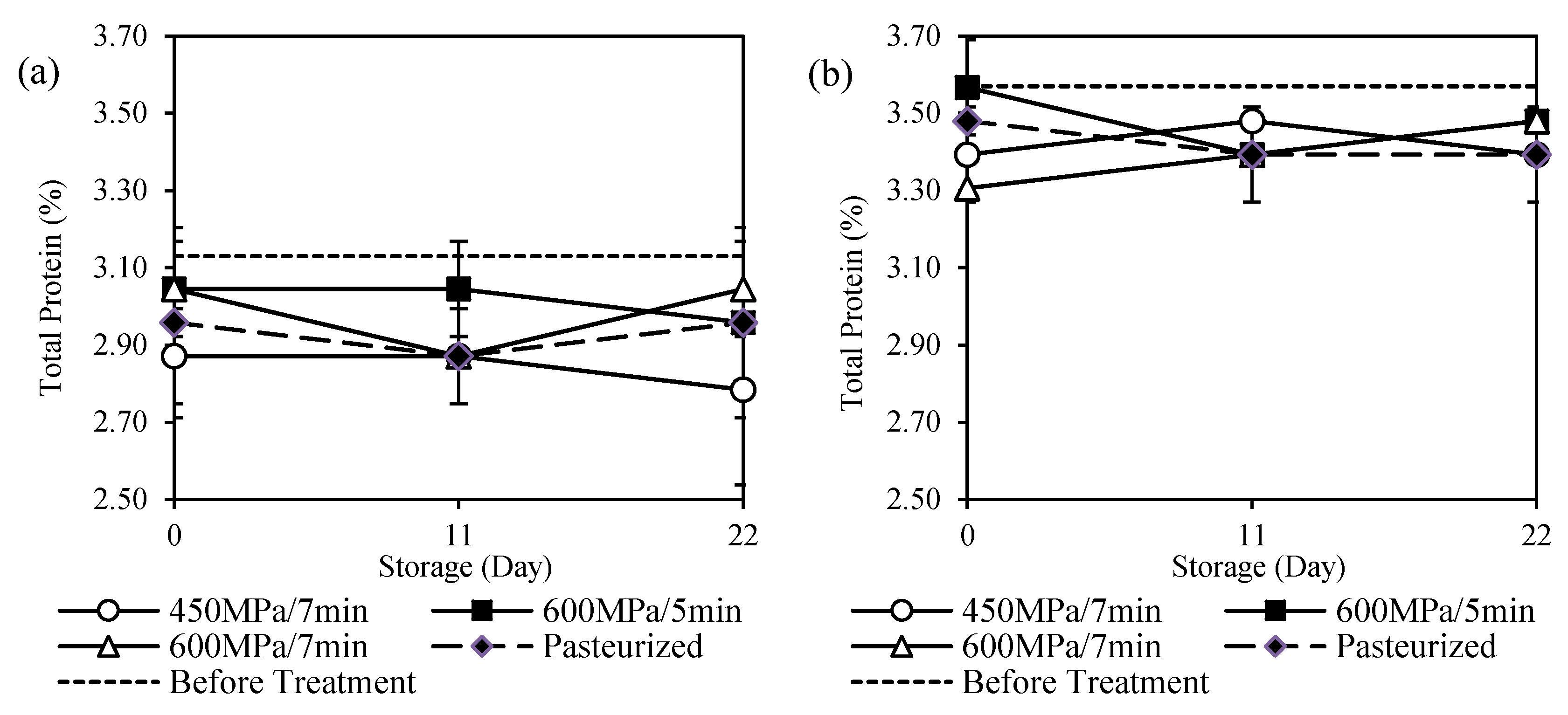

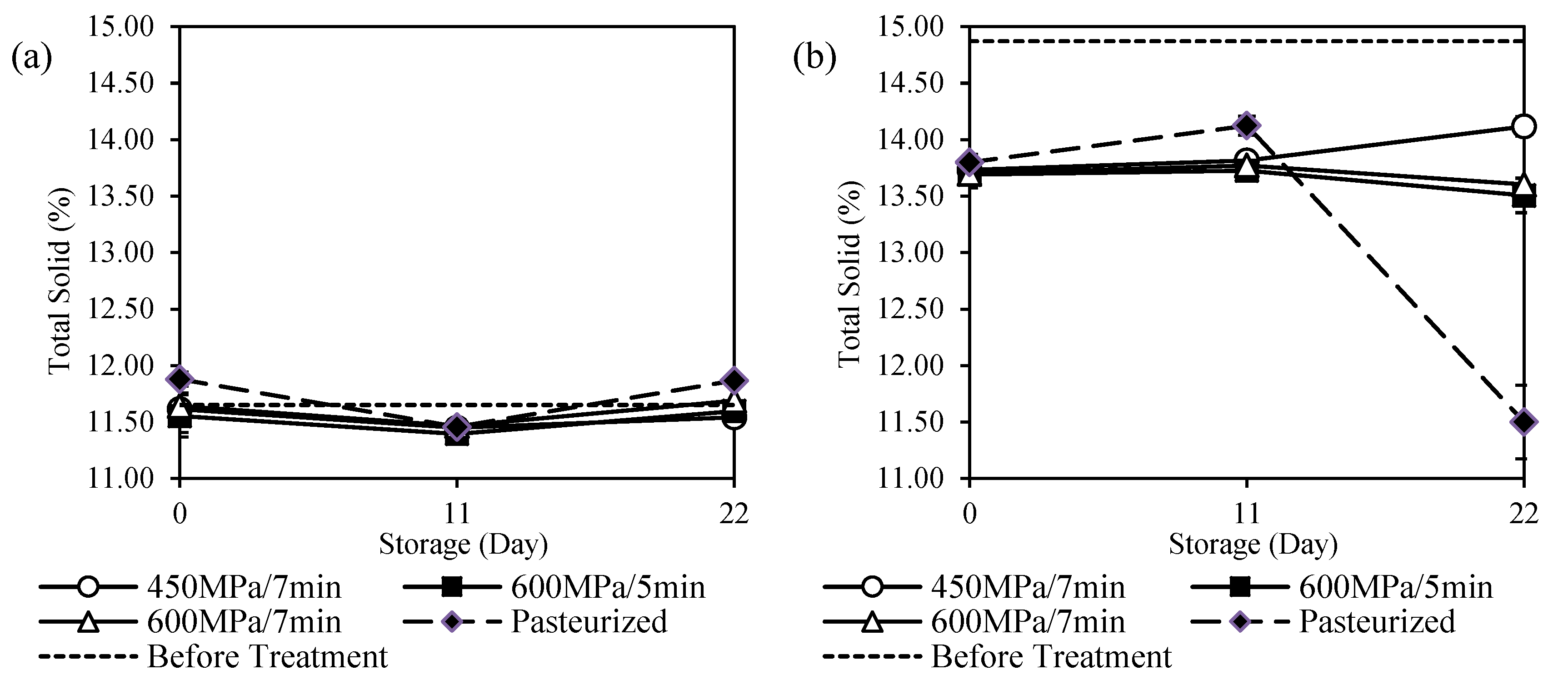

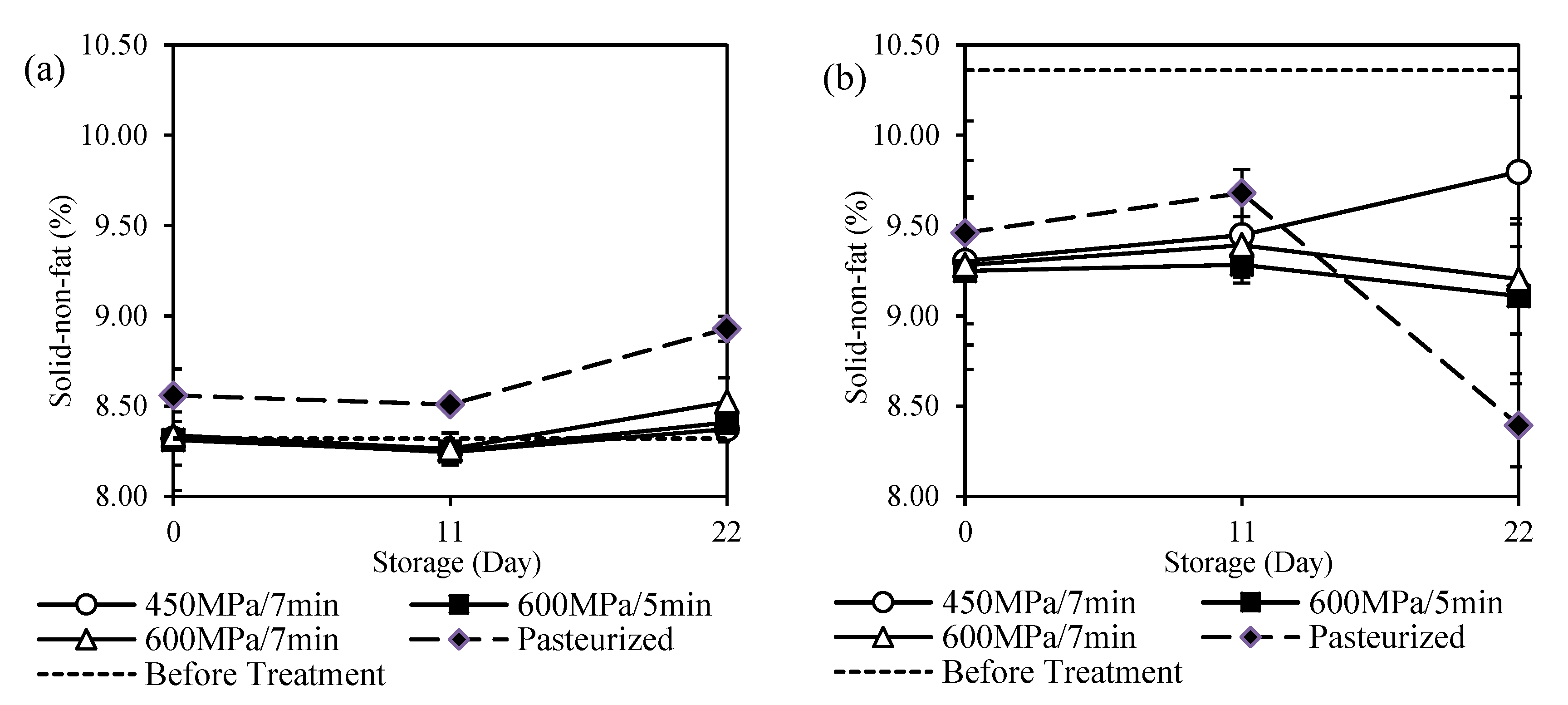

3.3. Changes in Physico-Chemical Properties in Milk during Storage

3.4. Changes in Microbiological Properties in Milk during Storage

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weaver, C.; Bettoni, R.W.; McMahon, D.; Spence, L. Milk and dairy products as part of the diet. In Milk and Dairy Products in Human Nutrition; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; pp. 103–183. ISBN 9789251078631. [Google Scholar]

- Clark, S.; Garcia, M.B.M. Introduction. A 100-Year Review: Advances in goat milk research. J. Dairy Sci. 2017, 100, 100026–100044. [Google Scholar] [CrossRef] [PubMed]

- Ulusoy, B.H. Nutritional and health aspects of goat milk consumption. Akad. Gida 2015, 13, 56–60. [Google Scholar]

- Woldemariam, H.W.; Asres, A.M. Microbial and physicochemical qualities of pasteurized milk. J. Food Process. Technol. 2017, 08, 1–5. [Google Scholar]

- Barraquio, V.L. Which milk is fresh. Int. J. Dairy Process. Res. 2014, 1, 1–6. [Google Scholar] [CrossRef]

- Holsinger, V.H.; Rajkowski, K.T.; Stabel, J.R. Milk pasteurization and safety: A brief history and update. Rev. Sci. Technol. 1997, 16, 441–451. [Google Scholar] [CrossRef]

- Ziarno, M.; Molska, I.; Gronczynska, M. Quality and shelf life of milk pasteurized at 84 °C/19-22 sec and free from post pasteurization contamination. Med. Weter. 2005, 61, 1165–1168. [Google Scholar]

- Nagla, B.A.H.; Mohamed, O.M.A.; Abdel, A.M.N. Microbial quality of heat-treated milk during storage. Pak. J. Nutr. 2009, 8, 1845–1848. [Google Scholar]

- Incecco, P.D.; Rosi, V.; Cabassi, G.; Hogenboom, J.A.; Pellegrino, L. Microfiltration and ultra-high-pressure homogenization for extending the shelf-storage stability of UHT milk. Food Res. Int. 2018, 107, 477–485. [Google Scholar] [CrossRef]

- Tamime, A.Y. Milk Processing and Quality Management; Wiley-Blackwell: West Sussex, UK, 2014; ISBN 9781444301649. [Google Scholar]

- Bogahawaththa, D.; Buckow, R.; Chandrapala, J.; Vasiljevic, T. Comparison between thermal pasteurization and high pressure processing of bovine skim milk in relation to denaturation and immunogenicity of native milk proteins. Innov. Food Sci. Emerg. Technol. 2018, 47, 301–308. [Google Scholar] [CrossRef]

- Considine, K.M.; Kelly, A.L.; Fitzgerald, G.F.; Hill, C.; Sleator, R.D. High-pressure processing - effects on microbial food safety and food quality. Fed. Eur. Microbiol. Soc. 2008, 1–9. [Google Scholar] [CrossRef]

- Wang, C.; Huang, H.; Hsu, C.; Yang, B.B. Recent Advances in food processing using high hydrostatic pressure recent advances in food processing using high hydrostatic pressure technology. Food Sci. Nutr. 2015, 56, 527–540. [Google Scholar]

- Alexandros, C.S.; Elena, S.I.; Mark, L.; Joan, T.; Liam, M.; Nicolae, C.; Anastasios, K.; Brijesh, K.T. Effect of high pressure processing on the safety, shelf life and quality of raw milk. Innov. Food Sci. Emerg. Technol. 2019, 52, 325–333. [Google Scholar]

- Chawla, R.; Patil, G.R.; Singh, A.K. High hydrostatic pressure technology in dairy processing: A review. J. Food Sci. Technol. 2011, 48, 260–268. [Google Scholar] [CrossRef] [PubMed]

- Elamin, W.M.; Endan, J.B.; Yusof, Y.A.; Shamsudin, R.; Ahmedov, A. High pressure processing technology and equipment evolution: A Review. J. Eng. Sci. Technol. Rev. 2015, 8, 75–83. [Google Scholar] [CrossRef]

- Pereda, J.; Ferragut, V.; Quevedo, J.M.; Guamis, B.; Trujillo, A.J. Effects of ultra-high pressure homogenization on microbial and physicochemical shelf life of milk. J. Dairy Sci. 2007, 90, 1081–1093. [Google Scholar] [CrossRef]

- Mussa, D.M.; Ramaswamy, H.S. Ultra high pressure pasteurization of milk: Kinetics of microbial destruction and changes in physico-chemical characteristics. Food. Sci. Technol. 1997, 30, 551–557. [Google Scholar] [CrossRef]

- Rademacher, B.; Kessler, H.G. High pressure inactivation of microorganisms and enzymes in milk and milk products. In High Pressure Bio-Science and Biotechnology; Elsevier: Amsterdam, The Netherlands, 1997; pp. 291–293. [Google Scholar]

- Sharabi, S.; Okun, Z.; Shpigelman, A. Changes in the shelf life stability of ribo fl avin, vitamin C and antioxidant properties of milk after (ultra) high pressure homogenization: Direct and indirect e ff ects. Innov. Food Sci. Emerg. Technol. 2018, 47, 161–169. [Google Scholar] [CrossRef]

- Amador-espejo, G.G.; Gallardo-chacon, J.J.; Nykänen, H.; Juan, B.; Trujillo, A.J. Effect of ultra high-pressure homogenization on hydro- and liposoluble milk vitamins. FRIN 2015, 77, 49–54. [Google Scholar] [CrossRef]

- Yang, B.; Shi, Y.; Xia, X.; Xi, M.; Wang, X.; Ji, B.; Meng, J. Inactivation of foodborne pathogens in raw milk using high hydrostatic pressure. Food Control 2012, 28, 273–278. [Google Scholar] [CrossRef]

- Pyne, G.T. The determination of milk-proteins by formaldehyde titration. Biochem. J. 1932, 26, 1006. [Google Scholar] [CrossRef]

- Gomaa, M.S.; Abdel-Aziz, M.E.; Hafez, E.H.; Salama, S.I. New method for determination of protein content of goat’s milk and compared with different methods. J. Food Dairy Sci. Mansoura Univ. 2014, 5, 95–101. [Google Scholar] [CrossRef]

- Ma, Y.; Barbano, D.M. Milk pH as a Function of CO2 concentration, temperature, and pressure in a heat exchanger. J. Dairy Sci. 2003, 86, 3822–3830. [Google Scholar] [CrossRef]

- José, M.P.; Adriano, G.; Bruna, W.M.; Daniel, N.L.; Claucia, F.V. Effects of pasteurization and ultra-high temperature processes on proximate composition and fatty acid profile in bovine milk. Am. J. Food Technol. 2015, 10, 265–272. [Google Scholar]

- Chopde, S.S.; Deshmukh, M.A.; Kalyankar, S.D.; Changade, S.P. Applications of high pressure technology for milk processing. Res. J. Anim. Husb. Dairy Sci. 2014, 5, 143–147. [Google Scholar] [CrossRef]

- Liepa, M.; Zagorska, J.; Galoburda, R. Effect of high pressure processing on milk coagulation properties. Res. Rural Dev. 2017, 1, 223–229. [Google Scholar]

- Zobrist, M.R.; Huppertz, T.; Uniacke, T.; Fox, P.F.; Kelly, A.L. High-pressure-induced changes in the rennet coagulation properties of bovine milk. Int. Dairy J. 2005, 15, 655–662. [Google Scholar] [CrossRef]

- Samaržija, D.; Zamberlin, Š.; Pogačić, T. Psychrotrophic bacteria and their negative effects on milk and dairy products quality psychrotrophic bacteria and milk and dairy products quality. Mijekarstvo 2012, 62, 75–95. [Google Scholar]

- Kent, D.J.; Chauhan, K.; Boor, K.J.; Wiedmann, M.; Martin, N.H. Spore test parameters matter: Mesophilic and thermophilic spore counts detected in raw milk and dairy powders differ significantly by test method. J. Dairy Sci. 2016, 99, 5180–5191. [Google Scholar] [CrossRef]

- McGuiggan, J.T.M.; McCleery, D.R.; Hannan, A.; Gilmour, A. Aerobic spore-forming bacteria in bulk raw milk: Factors influencing the numbers of psychrotrophic, mesophilic and thermophilic Bacillus spores. Int. J. Dairy Technol. 2002, 55, 100–107. [Google Scholar] [CrossRef]

- Wanjala, W.N.; Nduko, J.M.; Mwende, M.C. Coliforms Contamination and hygienic status of milk chain in emerging economies. J. Food Qual. Hazards Conrol 2018, 5, 3–10. [Google Scholar] [CrossRef]

- Evrendilek, G. Non-thermal processing of milk and milk products for microbial safety. In Dairy Microbiology and Biochemistry: Recent Developments; CRC Press: Boca Raton, FL, USA, 2017; pp. 322–355. [Google Scholar]

- McClements, J.M.; Patterson, M.F.; Linton, M. The effect of growth stage and growth temperature on high hydrostatic pressure inactivation of some psychrotrophic bacteria in milk. J. Food Prot. 2001, 64, 514–522. [Google Scholar] [CrossRef] [PubMed]

- Chmielewski, R.A.N.; Frank, J.F. Biofilm formation and control in food processing facilities. Compr. Rev. Food Sci. F 2006, 2, 22–32. [Google Scholar] [CrossRef]

- Christiansson, A.; Bertilsson, J.; Svensson, B. Bacillus cereus spores in raw milk: Factors affecting the contamination of milk during the grazing period. J. Dairy Sci. 1999, 82, 305–314. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Shukla, S. Occurance of Clostridium species in different dairy products and its associated health risk. Int. J. Recent Sci. Res. 2015, 6, 2827–2829. [Google Scholar]

- Mohamed, A.F.; Somda, M.K.; Fourreh, A.E.; Okieh, A.A.; Said, C.N.; Merito, A.; Yagi, S. Evaluation of microbiological quality of raw milk from farmers and dairy producers in six districts of Djibouti. J. Food Microbiol. Saf. Hyg. 2017, 02. [Google Scholar]

- Chye, F.Y.; Abdullah, A.; Ayob, M.K. Bacteriological quality and safety of raw milk in Malaysia. Food Microbiol. 2004, 21, 535–541. [Google Scholar] [CrossRef]

- Siddique, F.; Riffat, S.; Arshad, M.; Farooq, U.; Iftikhar, K.; Kharal, S. Effect of storage temperature on the physiochemical properties of UHT milk. Int. J. Food Allied Sci. 2016, 2, 52. [Google Scholar] [CrossRef]

- Brodziak, A.; Krol, J.; Litwinczuk, Z.; Zaborska, A.; Czernecki, T. Effect of storage time under home refrigeration conditions on the quality of opened drinking milk. Mljekarstvo 2017, 67, 283–296. [Google Scholar] [CrossRef][Green Version]

- Zajác, P.; Čapla, J.; Vietoris, V.; Zubrická, S.; Čurlej, J. Effects of storage on the major constituents of raw milk. Potravin. Sci. J. Food Ind. 2015, 9, 375–381. [Google Scholar] [CrossRef]

- Mahmood, A.; Usman, S. A comparative study on the physicochemical parameters of milk samples collected from buffalo, cow, goat and sheep of Gujrat, Pakistan. Pak. J. Nutr. 2010, 9, 1192–1197. [Google Scholar] [CrossRef][Green Version]

- Rawat, S. Food Spoilage: Microorganisms and their prevention. Pelagia Res. Libr. Asian J. Plant Sci. Res. 2015, 5, 47–56. [Google Scholar]

- Aldubhany, T.A.W.; Gouda, E.; Khattab, A.; Dabour, N. Effects of storage on some physico-chemical characteristics of uht milk stored at different temperature. Alexandria Sci. Exch. J. 2014, 35, 107–114. [Google Scholar]

- Ahmad, T.; Bilal, M.Q.; Ullah, S.; Muhammad, G. Effect of severity of mastitis on pH and specific gravity of buffalo milk. Pak. J. Agri. Sci. 2005, 42, 64–67. [Google Scholar]

- Huppertz, T.; Kelly, A.L.; Fox, P.F. Effects of high pressure on constituents and properties of milk. Int. Dairy J. 2002, 12, 561–572. [Google Scholar] [CrossRef]

- Janstová, B.; Lukasová, J.; Dracková, M.; Vorlová, L. Influence of Bacillus spp. enzymes on ultra high temperature-treated milk proteins. Acta Vet. Brno 2004, 73, 393–400. [Google Scholar]

- Omer, R.H.; Eltinay, A.H. Changes in chemical composition of camel raw milk during storage. Pak. J. Nutr. 2009, 8, 607–610. [Google Scholar]

- Doll, E.V.; Scherer, S.; Wenning, M. Spoilage of Microfiltered and pasteurized extended shelf life milk is mainly induced by psychrotolerant spore-forming bacteria that often originate from recontamination. Front. Microbiol. 2017, 8, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Risco, M.R.; Cortes, E.; Carrascosa, A.V.; Lopez-Fandino, R. Microbiological and chemical changes in high-pressure- treated milk during refrigerated storage. J. Food Prot. 1998, 61, 735–737. [Google Scholar] [CrossRef] [PubMed]

| Analysis | Before Treatment | 450 MPa/7 min | 600 MPa/5 min | 600 MPa/7 min | Pasteurized |

|---|---|---|---|---|---|

| Cow Milk | |||||

| pH | 6.59 ± 0.01 a | 6.56 ± 0.01 a | 6.58 ± 0.00 a | 6.61 ± 0.02 a | 6.52 ± 0.00 b |

| Titratable acidity | 0.16 ± 0.01 a | 0.15 ± 0.00 a | 0.16 ± 0.01 a | 0.17 ± 0.01 a | 0.16 ± 0.01 a |

| Specific gravity | 1.03 ± 0.00 a | 1.03 ± 0.00 a | 1.02 ± 0.00 a | 1.03 ± 0.00 a | 1.03 ± 0.00 a |

| Total protein | 3.13 ± 0.00 a | 2.87 ± 0.12 a | 3.04 ± 0.12 a | 3.04 ± 0.12 a | 2.96 ± 0.25 a |

| Total fat | 3.33 ± 0.08 a | 3.29 ± 0.06 a | 3.24 ± 0.09 a | 3.30 ± 0.14 a | 3.32 ± 0.08 a |

| Total solid | 11.65 ± 0.01 a | 11.61 ± 0.21 a | 11.55 ± 0.19 a | 11.64 ± 0.11 a | 11.88 ± 0.06 a |

| Solid-non-fat | 8.32 ± 0.09 a | 8.32 ± 0.15 a | 8.31 ± 0.28 a | 8.34 ± 0.03 a | 8.56 ± 0.14 a |

| Goat Milk | |||||

| pH | 6.34 ± 0.00 c | 6.38 ± 0.00 b | 6.42 ± 0.01 a | 6.38 ± 0.01 b | 6.38 ± 0.01 b |

| Titratable acidity | 0.22 ± 0.01 a | 0.22 ± 0.01 a | 0.22 ± 0.01 a | 0.21 ± 0.01 a | 0.23 ± 0.01 a |

| Specific gravity | 1.03 ± 0.00 a | 1.03 ± 0.00 a | 1.03 ± 0.00 a | 1.03 ± 0.00 a | 1.03 ± 0.00 a |

| Total protein | 3.57 ± 0.12 a | 3.39 ± 0.12 a | 3.57 ± 0.12 a | 3.31 ± 0.00 a | 3.48 ± 0.00 a |

| Total fat | 4.51 ± 0.05 a | 4.43 ± 0.49 a | 4.44 ± 0.41 a | 4.42 ± 0.45 a | 4.34 ± 0.61 a |

| Total solid | 13.88 ± 0.06 a | 13.73 ± 0.14 a | 13.69 ± 0.00 a | 13.70 ± 0.13 a | 13.08 ± 1.42 a |

| Solid-non-fat | 9.37 ± 0.10 a | 9.30 ± 0.35 a | 9.35 ± 0.41 a | 9.28 ± 0.58 a | 8.74 ± 2.03 a |

| Bacteria Count | Before Treatment | 450 MPa/7 min | 600 MPa/5 min | 600 MPa/7 min | Pasteurized |

|---|---|---|---|---|---|

| Cow Milk | |||||

| Total plate count (CFU/mL) | 1.5 × 105 | 6 × 103 | 2.6 × 101 | 2.5 × 102 | 1.5 × 102 |

| Psychrotrophic bacteria count (CFU/mL) | 9.2 × 104 | 8.3 × 102 | 1 | <1 | 5.4 × 101 |

| Mesophilic aerobic spore count (CFU/mL) | 7.0 × 101 | <1 | <1 | <1 | 2.0 × 101 |

| Total coliform count (CFU/mL) | 3.7 × 101 | <1 | <1 | <1 | <1 |

| Total yeast and mold count (CFU/mL) | 6.0 × 101 | <1 | <1 | <1 | <1 |

| Bacillus cereus (CFU/mL) | <1 | 2.0 × 101 | 6 | 4 | 8 |

| Clostridium perfringens (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Staphylococcus aureus (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Total E. coli count (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Thermophilic aerobic spore count (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Listeria monocytogenes per 25 g | Absent | Absent | Absent | Absent | Absent |

| Salmonella spp. per 25 g | Absent | Absent | Absent | Absent | Absent |

| Goat Milk | |||||

| Total plate count (CFU/mL) | 6.9 × 106 | 6.4 × 102 | 6 | 4.0 × 101 | 8.0 × 102 |

| Psychrotrophic bacteria count (CFU/mL) | 8.0 × 105 | <1 | <1 | <1 | 3.6 × 10 |

| Mesophilic aerobic spore count (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Total coliform count (CFU/mL) | 2.1 × 105 | <1 | <1 | <1 | 2.6 × 101 |

| Total yeast and mold count (CFU/mL) | 8.0 × 101 | <1 | <1 | <1 | <1 |

| Bacillus cereus (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Clostridium perfringens (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Staphylococcus aureus (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Total E. coli count (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Thermophilic aerobic spore count (CFU/mL) | <1 | <1 | <1 | <1 | <1 |

| Listeria monocytogenes per 25 g | Absent | Absent | Absent | Absent | Absent |

| Salmonella spp. per 25 g | Absent | Absent | Absent | Absent | Absent |

| Treatment | Cow Milk | Goat Milk | ||||

|---|---|---|---|---|---|---|

| Day 0 | Day 11 | Day 22 | Day 0 | Day 11 | Day 22 | |

| Psychrotrophic Bacteria Count | ||||||

| 450 MPa/7 min | 8.3 × 102 | 9.0 × 103 | 3.0 × 103 | <1 | 1.0 × 104 | 6.8 × 101 |

| 600 MPa/5 min | 1 | 1.2 × 104 | 4.6 × 102 | <1 | 1.8 × 102 | 2.2 × 101 |

| 600 MPa/7 min | <1 | 6.4 × 104 | 1.9 × 102 | <1 | 3 | <1 |

| Pasteurized | 5.4 × 101 | 1.2 × 104 | 2.0 × 103 | 3.6 × 10 | 9.0 × 105 | 9.0 × 108 |

| Total Plate Count | ||||||

| 450 MPa/7 min | 6.0 × 103 | 2.5 × 103 | 8.0 × 103 | 6.4 × 102 | 2.0 × 103 | 7.6 × 102 |

| 600 MPa/5 min | 2.6 × 101 | 6.0 × 103 | 3.7 × 102 | 6 | 8.8 × 102 | 3.6 × 104 |

| 600 MPa/7 min | 2.5 × 102 | 7.5 × 104 | 2.8 × 101 | 4.0 × 101 | 9.4 × 101 | 8.8 × 101 |

| Pasteurized | 1.5 × 102 | 1.1 × 104 | 3.0 × 103 | 8.0 × 102 | 6.0 × 105 | 3.5 × 108 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.F.; Chin, N.L.; Tee, T.P.; Chooi, S.K. Physico-Chemical Changes, Microbiological Properties, and Storage Shelf Life of Cow and Goat Milk from Industrial High-Pressure Processing. Processes 2020, 8, 697. https://doi.org/10.3390/pr8060697

Tan SF, Chin NL, Tee TP, Chooi SK. Physico-Chemical Changes, Microbiological Properties, and Storage Shelf Life of Cow and Goat Milk from Industrial High-Pressure Processing. Processes. 2020; 8(6):697. https://doi.org/10.3390/pr8060697

Chicago/Turabian StyleTan, Sok Fern, Nyuk Ling Chin, Tuan Poy Tee, and Sook Kuan Chooi. 2020. "Physico-Chemical Changes, Microbiological Properties, and Storage Shelf Life of Cow and Goat Milk from Industrial High-Pressure Processing" Processes 8, no. 6: 697. https://doi.org/10.3390/pr8060697

APA StyleTan, S. F., Chin, N. L., Tee, T. P., & Chooi, S. K. (2020). Physico-Chemical Changes, Microbiological Properties, and Storage Shelf Life of Cow and Goat Milk from Industrial High-Pressure Processing. Processes, 8(6), 697. https://doi.org/10.3390/pr8060697