1. Introduction

A solar collector has great importance in various industrial applications. Due to its simple design, low maintenance cost, and economic feasibility, a solar air heater is more widely used compared to other solar systems [

1]. A common type of solar air heaters is the flat-plate solar air heater that utilizes solar energy to heat air [

2]. In general, these types of solar air heaters are used for drying or curing concrete and clay in the construction industry [

3,

4], or drying fruits and vegetables within the food industry [

5]. The conventional solar air heaters consist of an absorber plate and a glass cover on top of it that forms a narrow channel wherein the air stream is heated in and directed through it [

6]. Since different factors, such as mass flow rate, plate sheet material, cover type, collector dimensions, etc., affect the solar air heater performance, researchers have adopted different techniques to increase the performance of solar collectors by changing the configuration of the system [

7,

8,

9]. However, the optimization of the thermal performance of solar air heaters is still a major challenge. Some researchers have proposed the use of porous materials instead of a metal sheet for the latter mentioned aim [

10]. In another study, a perforated Plexiglas was used instead of a normal cover to improve the cooling process of the cover and to enhance the performance of the collector [

2]. Yang et al. designed a solar air heater including offset trip fins and developed a numerical model to optimize the system [

11]. A similar study was performed by El-Khawajah et al. [

12]. A combination of artificial neural networks and genetic algorithms were applied to maximize the economic feasibility of the system in [

13,

14]. In another research, the thermal performance of a flat-plate solar air heater was optimized by taking advantage of the genetic algorithm and considering different operating parameters [

6].

Reviewing numerous literature shows that various optimization techniques were proposed for finding the optimal or semi-optimal configurations of solar air heaters. The current study aims to find the optimal configuration of a solar air heater under certain conditions. Single- and double-pass configurations of a solar air heater possessing four different pierced Plexiglas covers were examined at two different air mass flow rates by employing the Grey–Taguchi method. The goal was to find the optimal setup and to carry out a robust statistical analysis. Two criteria, temperature difference (∆T) and system performance, were taken into consideration and three factors affecting these criteria, i.e., solar collector type, mass flow rate, and cover type were also investigated. To the best of the authors’ knowledge, this issue has not been previously studied and it is obvious that the optimal condition leads to the maximum thermal performance of the system.

2. Performed Experimental Research

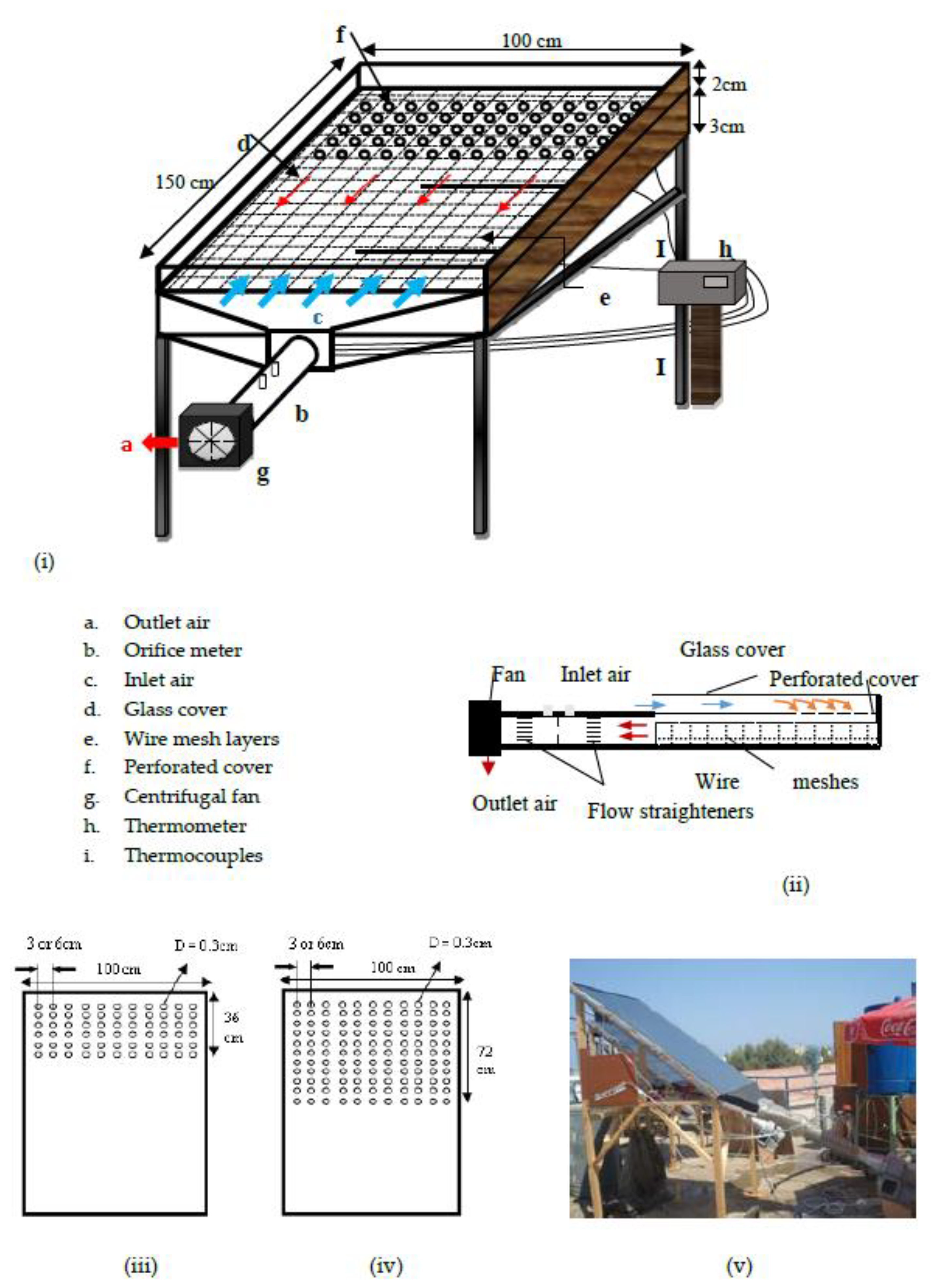

The experiment was conducted at Famagusta City in North Cyprus. The schematic and pictorial views of the manufactured solar air heater and the pierced covers are shown in

Figure 1. Different perforated Plexiglas covers with a thickness of 4 mm were used as the cover of the collector (length: 1500 mm and width: 1000 mm). Plywood with a thickness of 18 mm was used to make the frame of the solar collector. The frame was painted in a black color and was insulated with 30 mm thick Styrofoam to decrease heat loss from the system. The collector bed height was 30 mm and the distance between the first and second cover was 20 mm in the counter flow collector.

Inside the collector duct, 14 wire mesh layers were used instead of an absorber sheet and they were fixed in three separate sets with a distance of 5 mm between each set. Each mesh layer was painted in a black color to increase absorptivity. The wire meshes used in this collector were similar to the ones used by other researchers [

12,

15,

16].

The construction cost of the solar air collector was reduced because the mesh layers were much cheaper than an absorber plate. Moreover, by using wire mesh layers the pressure drop was decreased through the collector. As it is mentioned in the literature, the major heat loss is through the cover of the air heaters. In this experimental research, pierced transparent Plexiglas was used as cover instead of a normal glass cover to minimize the heat loss through the cover. Four types of pierced Plexiglas were employed. To determine the effect of the pierced cover on the performance of the solar air heater, the number of holes and the distance between their centers were different on various covers. The types of pierced Plexiglas covers were as follows:

- I.

One-fourth pierced Plexiglas cover: holes at the upper side of the cover in an area of 1000 × 360 mm2, holes center to center distance: 30 mm;

- II.

One-fourth pierced Plexiglas cover: holes at the upper side of the cover in an area of 1000 × 360 mm2, holes center to center distance: 60 mm;

- III.

One-half pierced Plexiglas cover: holes at the upper side of the cover in an area of 1000 × 720 mm2, holes center to center distance: 30 mm;

- IV.

One-half pierced Plexiglas cover: holes at the upper side of the cover in an area of 1000 × 720 mm2, holes center to center distance: 60 mm.

The diameter of the holes in all four types of covers was 3 mm. In order to create uniform airflow through the galvanized pipe, flow straighteners were fixed before and after the orifice meter.

For comparison purposes, the same solar collector was tested with a normal Plexiglas as its glazing. The opening area was 100 cm2.

The fan used in the system was a OBR 200 M-2K type. An inclined tube manometer was used to measure the pressure difference through the orifice and collector. The speed controller was connected to the fan to allow the user to adjust the speed.

The air temperature at different places was measured by T-type thermocouples. The temperature readings were recorded by a digital thermometer (±0.5 °C accuracy). The solar intensity was measured with a Pyranometer (resolution of ±0.5%). The solar collector was faced toward the south and its tilt angle was 39.5°. The experiments started at 8:00 and finished at 17:00 each day.

3. Grey–Taguchi Design

To set the experimental procedure to design the solar air heater, a combination of two methods, the Taguchi method and Grey Rational Analysis (GRA) are used in this study.

The Taguchi method [

17,

18,

19,

20] is a useful method in the design of experiments, which decreases the number of required experiments based on the given control factors. Each experiment is composed of a level of each control factor. The combination of the levels of control factors for each experiment is obtained by the predetermined orthogonal arrays. Then, each experiment is performed for several replications and an outcome is introduced by any replication which is named process response. The responses obtained from each experiment are converted to a signal-to-noise (

S/

N) ratio in order to be comparable. The experiment with the highest

S/

N value introduces the best level of control factors [

21,

22,

23].

As mentioned earlier, the solar air heater has the following control factors, and the levels of each factor that are considered to be optimized in the design of the solar air heater are mentioned in

Table 1.

Based on the explanations in

Section 2, the following process responses are considered for the solar air heater:

(the higher the ∆T, the better the characteristic);

Performance (the higher the performance, the better the characteristic).

∆

T defines the temperature difference between the air entering the collector and the outlet air temperature (∆

T = Outlet air temperature − inlet air temperature). T-type thermocouples located at the inlet and outlet of the collector were used to measure the air temperatures during the experiment (see

Figure 1). The recorded temperatures were then used to calculate the thermal efficiency (Performance) of the system. The following equation is applied to calculate the thermal performance (η

th) of the solar air heater at each experiment,

where

is the air mass flow rate (kg/s),

cp is the air specific heat (J/kg K), ∆

T is the temperature difference,

I is the solar radiation (W/m

2) and

A is the absorber area (m

2). A Pyranometer is used to measure the incident solar radiation at each hour of the experiment. For each system configuration, the performance is calculated and these data are used in the Grey–Taguchi design.

As two control factors have two levels and one control factor has five levels, one degree of freedom is considered for each level control factor and four degrees of freedom are considered for the factor with five levels. The total degree of freedom for the Taguchi method is calculated as

. Therefore, the orthogonal array of the Taguchi design of the solar air heater must have at least nine rows (experiments). Therefore, an L12 orthogonal array is suited for this Taguchi design which contains 12 experiments. The experiments of the Taguchi design obtained from the levels of control factors of

Table 1 are shown in

Table 2. For instance, the first experiment was performed with a single-pass solar collector, a mass flow rate of 0.011 kg/s, and a normal Plexiglas cover.

All the experiments were carried out in almost the same environmental conditions. For each experiment, the outcomes (

and performance) are reported and used as the process responses of the Taguchi design. Then, for each experiment, the following formula was used to calculate the

S/

N values:

where

n is the number of replications in each experiment and

is the value of process response

k at replication

i. In the Taguchi design of the solar air heater, the number of replications in all the experiments was set to be 1. The results of the process response values and related

S/

N ratios are reported in

Table 3.

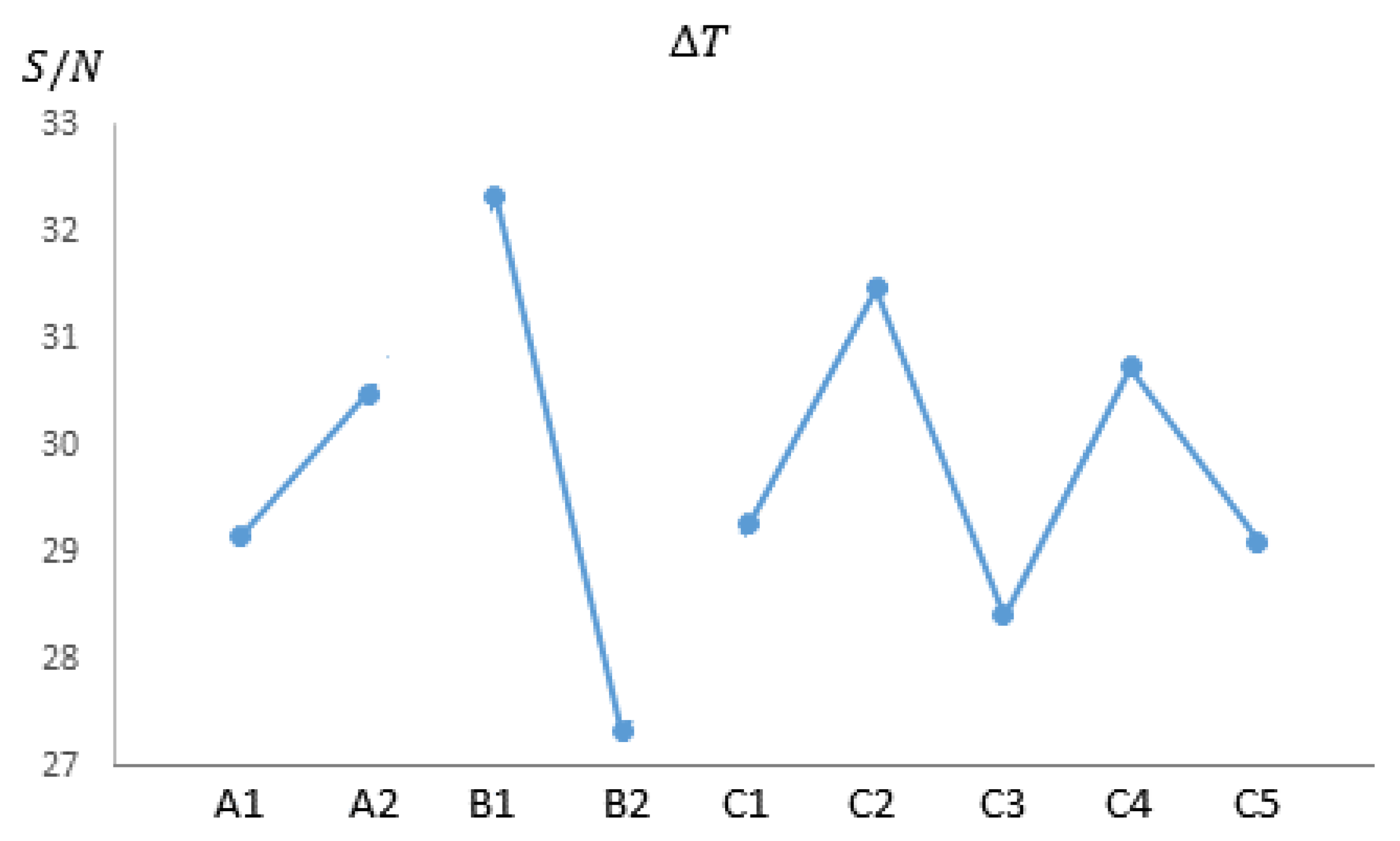

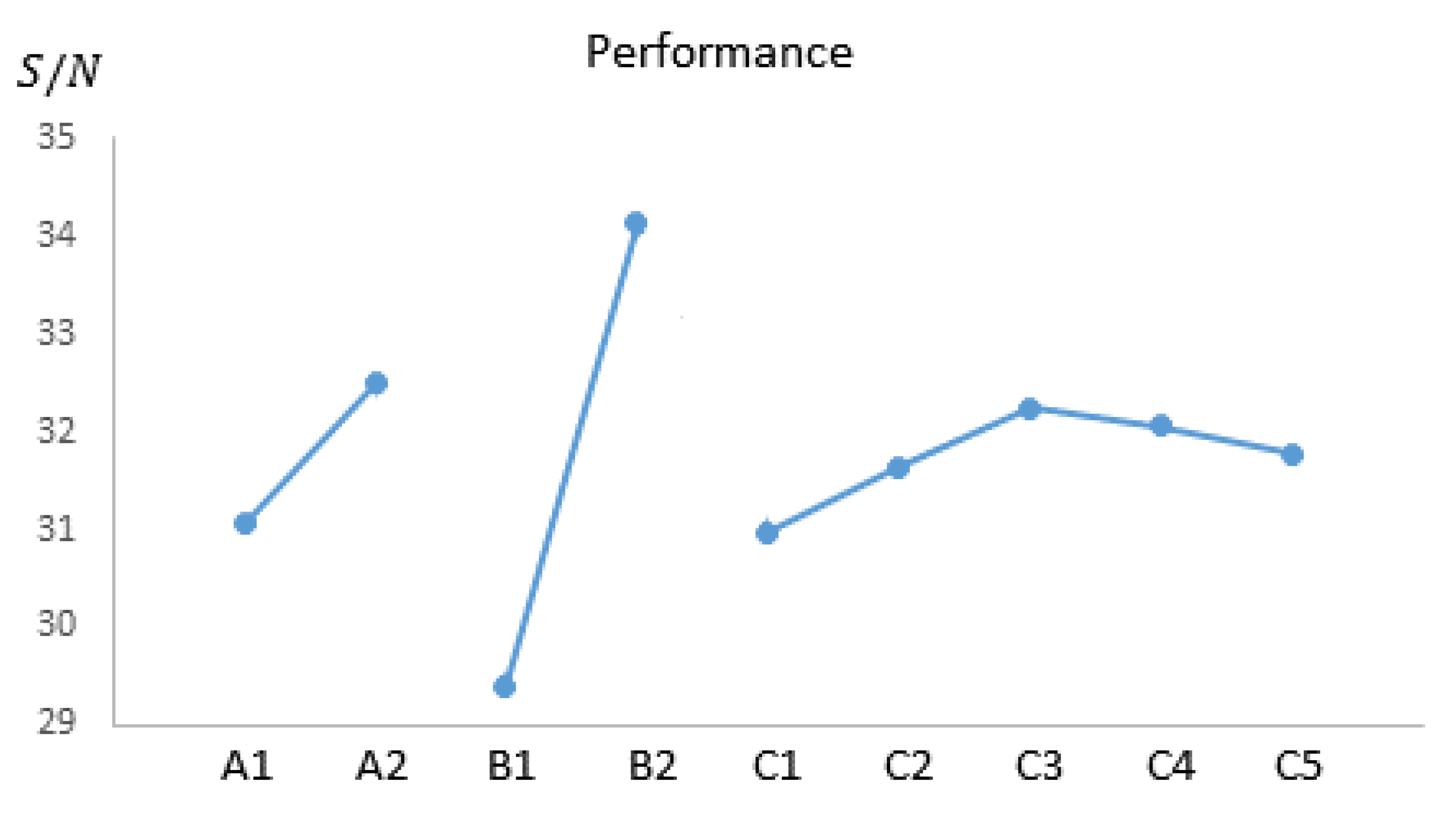

Then, the marginal average of

S/

N ratios of each level of the control factors for each process response value was calculated and is shown in

Table 4.

In

Section 4, the results presented in

Table 3 and

Table 4 are utilized to design the solar air heater using the best level of control parameters.

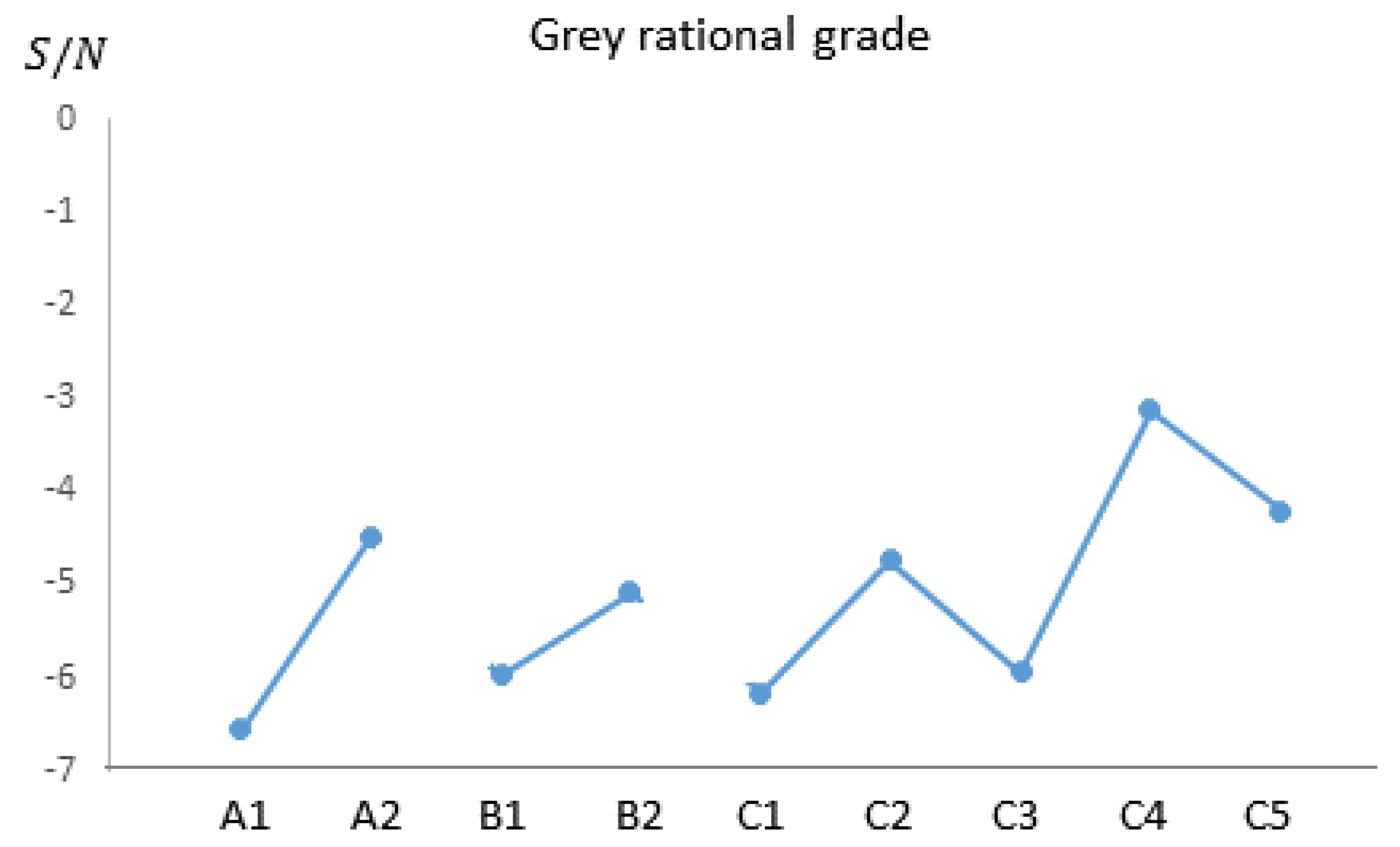

As in the design of the solar air heater, more than one process response (e.g., and performance) is to be maximized. Grey Rational Analysis (GRA) can provide good results in finding the most important levels of the control factors. GRA combines the observations of the process responses obtained by the experiments to a single value named grey rational grade. Then, the experiment having the highest grey rational grade introduces the best levels of the control factors.

Here, the GRA was hybridized by the Taguchi method to obtain a more economic experimental design compared with classic GRA. To reduce the number of experiments in GRA, the orthogonal array used for the Taguchi design was used. Based on the selected experiments obtained by the orthogonal array, the grey rational grades were computed. Then, the grey rational grades were converted to a S/N ratio for the comparison of the experiments. The process of the Grey–Taguchi method is explained in the following steps.

Step 1: The value of each process response is normalized by the following equations:

Step 2: Grey rational coefficient (

) of each response factor is calculated by the following formula:

where

(absolute value) and

is a reference value which is defined as the best-normalized value of process response

k among all its experiments, meaning that

.

and

are calculated as

and

, respectively. Finally,

is a distinguishing coefficient selected from the interval of zero and one. It controls the effect of

when its value is too large. In this study, the value

is set to be 0.5.

Step 3: Grey rational grade of each experiment is found by the following formula:

where

is the grey rational grade of experiment

i.

Step 4: Same as the Taguchi method, for each experiment an

S/

N ratio is calculated from its grey rational grade using Equation (3). Consequently, the average of

S/

N ratios of each level of the control factors from the

S/

N ratios of the grey rational grades is computed. All the results obtained from Steps 1 to 4 for the Grey–Taguchi design of the solar air heater are summarized in

Table 5.

Table 6 shows a marginal average of

S/

N ratios for different levels of each control factor. Analysis of the results and selection of the best level of each control factor are discussed in

Section 4.

5. Conclusions

Different configurations of the solar air heater were investigated by the Grey–Taguchi method to find the optimal configuration. The two criteria which were taken into consideration were temperature differences () and system performance. The three factors that affect these criteria were solar collector type, mass flow rate, and cover types. Any combination of these factors can be effective to increase or decrease the temperature difference and performance of the solar air heater.

The Grey–Taguchi method decreased the number of required combinations to a possible minimum value to make a robust statistical analysis. The experiment was performed with two types of solar collectors which were single-pass and double-pass systems, and at two different mass flow rates (0.011 kg/s and 0.032 kg/s). Four different pierced Plexiglas covers were used in the tests and this has made this experiment unique compared with other similar studies. The obtained results from both theoretical and experimental studies, as the temperature difference is considered, show that the optimal configuration is a double-pass solar collector with a one-fourth pierced Plexiglas cover that has a 60 mm distance between the centers of the holes, and a mass flow rate of 0.011 kg/s. As performance is considered, the optimal configuration is a double-pass solar collector with a one-half pierced Plexiglas cover that has a 60 mm distance between the centers of the holes, and a mass flow rate of 0.032 kg/s. Finally, when both factors are considered, the optimal configuration suggested by the method is a double-pass solar collector with a one-quarter pierced Plexiglas cover that has a 30 mm distance between the centers of the holes, and a mass flow rate of 0.032 kg/s.