Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing

Abstract

1. Introduction

2. Principles of Hydrodynamic Cavitation

3. Emulsification

4. Extraction

5. Food Processing

6. Biofuel

7. Remediation

7.1. Pharmaceuticals

7.2. Dyes

7.3. Pesticides and Insecticides

7.4. Other Organic Compounds

7.5. Bacteria and Aquatic Organisms

7.6. Industrial Effluent

8. Summary

- The important cavitation factors that affect the emulsification process are attributed to the (a) intensity of turbulence in oil/aqueous phase; (b) viscosity and density of the solution; (c) constriction type, the pressure, and Cv; (d) the number of cavitation passes and concentration of surfactant;

- Enhanced extraction and better pretreatment via HC is dedicated to (a) enhanced diffusion, mass transfer rate, and solvent penetration into cells following the implosion of cavitating bubbles, which generates high pressure as well as temperature in the solution; (b) the generation of active radicals, shock waves, and microjets during the bubble collapse to assist cell disruption and the associated enlargement of pores;

- The efficiency of HC-based treatment depends on several operating parameters, such as solution pH and temperature, HC inlet pressure and type of constriction, the concentration of pollutants, and catalysts;

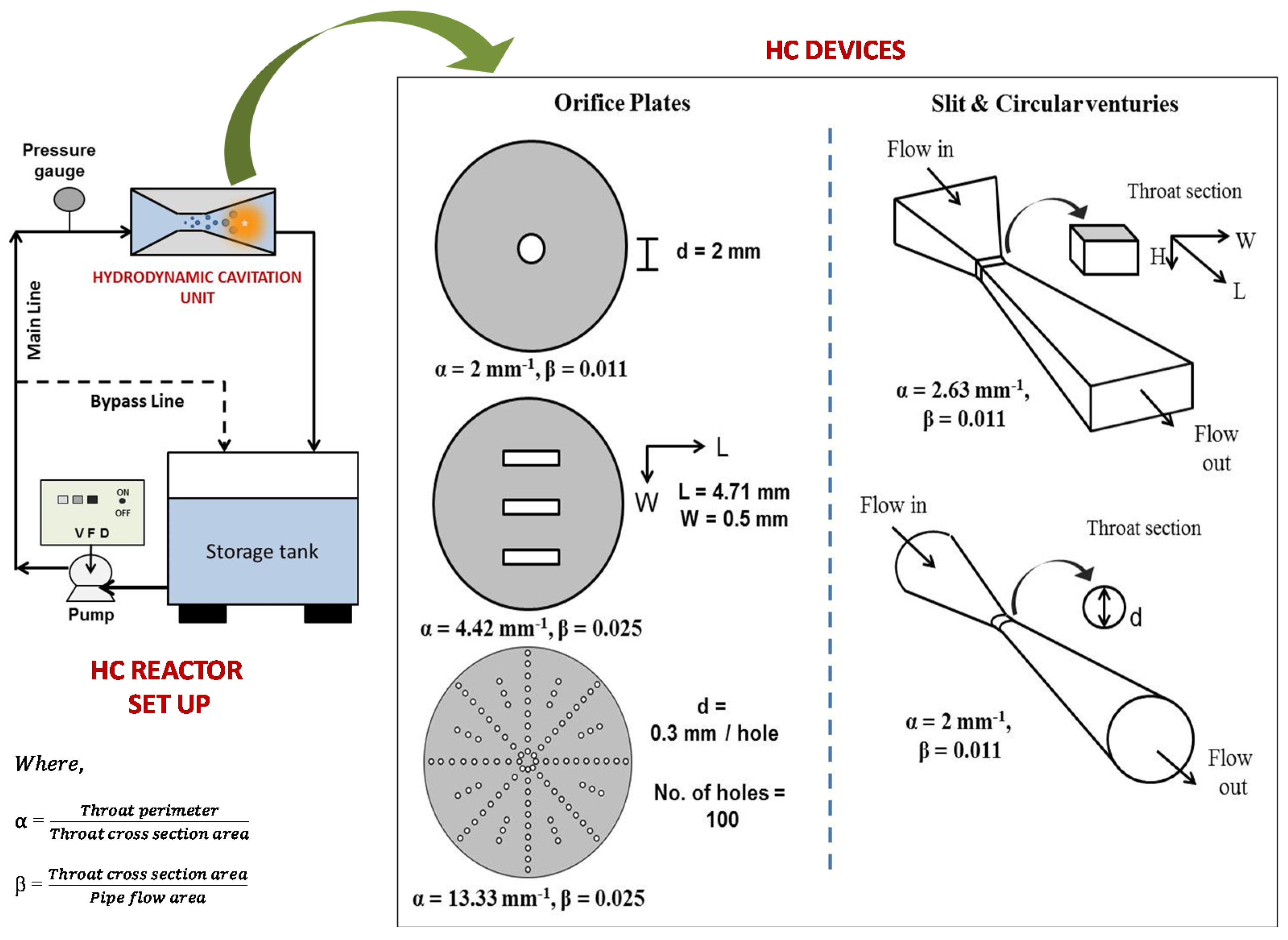

- Among the various devices reported in the literature, venturies give better degradation efficiency than orifice plates and for the given throat area it is always better to have a device of higher throat perimeter, which can be achieved either by changing the shape of the throat or by making orifice plates of multiple holes of smaller diameter.

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chuah, L.F.; Klemes, J.J.; Yusup, S.; Bokhari, A.; Akbar, M.M. A review of cleaner intensification technologies in biodiesel production. J. Clean. Prod. 2017, 146, 181–193. [Google Scholar] [CrossRef]

- Asaithambi, N.; Singha, P.; Dwivedi, M.; Singh, S.K. Hydrodynamic cavitation and its application in food and beverage industry: A review. J. Food Process Eng. 2019, 42, e13144. [Google Scholar] [CrossRef]

- Bandala, E.R.; Rodriguez-Narvaez, O.M. On the Nature of Hydrodynamic Cavitation Process and Its Application for the Removal of Water Pollutants. Air Soil Water Res. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Zupanc, M.; Pandur, Ž.; Stepišnik, P.T.; Stopar, D.; Petkovšek, M.; Dular, M. Effects of cavitation on different microorganisms: The current understanding of the mechanisms taking place behind the phenomenon. A review and proposals for further research. Ultrason. Sonochem. 2019, 57, 147–165. [Google Scholar] [CrossRef] [PubMed]

- Panda, D.; Manickam, S. Hydrodynamic cavitation assisted degradation of persistent endocrine-disrupting organochlorine pesticide Dicofol: Optimization of operating parameters and investigations on the mechanism of intensification. Ultrason. Sonochem. 2019, 51, 526–532. [Google Scholar] [CrossRef] [PubMed]

- Panda, D.; Manickam, S. Sonochemical degradation of endocrine-disrupting organochlorine pesticide Dicofol: Investigations on the transformation pathways of dechlorination and the influencing operating parameters. Chemosphere 2018, 204, 101–108. [Google Scholar]

- Saharan, V.K.; Badve, M.P.; Pandit, A.B. Degradation of reactive red 120 dye using hydrodynamic cavitation. Chem. Eng. J. 2011, 178, 100–107. [Google Scholar] [CrossRef]

- Carpenter, J.; George, S.; Saharan, V.K. Low pressure hydrodynamic cavitating device for producing highly stable oil in water emulsion: Effect of geometry and cavitation number. Chem. Eng. Process. Process Intensif. 2017, 116, 97–104. [Google Scholar] [CrossRef]

- Bargole, S.; George, S.; Saharan, V.K. Improved rate of transesterification reaction in biodiesel synthesis using hydrodynamic cavitating devices of high throat perimeter to flow area ratios. Chem. Eng. Process. Process Intensif. 2019, 139, 1–13. [Google Scholar] [CrossRef]

- Ramisetty, K.A.; Pandit, A.B.; Gogate, P.R. Novel Approach of Producing Oil in Water Emulsion Using Hydrodynamic Cavitation Reactor. Ind. Eng. Chem. Res. 2014, 53, 16508–16515. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, G.; Nie, Y.; Ji, J. Hydrodynamic cavitation as an efficient method for the formation of sub-100 nm O/W emulsions with high stability. Chin. J. Chem. Eng. 2016, 24, 1477–1480. [Google Scholar] [CrossRef]

- Patil, L.; Gogate, P.R. Large scale emulsification of turmeric oil in skimmed milk using different cavitational reactors: A comparative analysis. Chem. Eng. Process. Process Intensif. 2018, 126, 90–99. [Google Scholar] [CrossRef]

- Yang, F.; Liu, X.; Ren, X.; Huang, Y.; Huang, C.; Zhang, K. Swirling cavitation improves the emulsifying properties of commercial soy protein isolate. Ultrason. Sonochem. 2018, 42, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Parthasarathy, S.; Ying, T.S.; Manickam, S. Generation and optimization of palm oil-based oil-in-water (O/W) submicron-emulsions and encapsulation of curcumin using a liquid whistle hydrodynamic cavitation reactor (LWHCR). Ind. Eng. Chem. Res. 2013, 52, 11829–11837. [Google Scholar] [CrossRef]

- Tang, S.Y.; Sivakumar, M. A novel and facile liquid whistle hydrodynamic cavitation reactor to produce submicron multiple emulsions. AIChEJ 2013, 59, 155–167. [Google Scholar] [CrossRef]

- Panda, D.; Manickam, S. Cavitation Technology—The Future of Greener Extraction Method: A Review on the Extraction of Natural Products and Process Intensification Mechanism and Perspectives. Appl. Sci. 2019, 9, 766. [Google Scholar] [CrossRef]

- Lee, I.; Han, J. Simultaneous treatment (cell disruption and lipid extraction) of wet microalgae using hydrodynamic cavitation for enhancing the lipid yield. Bioresour. Technol. 2015, 186, 246–251. [Google Scholar] [CrossRef]

- Lee, I.; Oh, Y.; Hanc, J. Design optimization of hydrodynamic cavitation for effectual lipid extraction from wet microalgae. J. Environ. Chem. Eng. 2019, 7, 102942. [Google Scholar] [CrossRef]

- Setyawan, M.; Budiman, A.; Mulyono, P. Optimum Extraction of Algae-oil from Microalgae using Hydrodynamic Cavitation. IJRER 2018, 8, 451–458. [Google Scholar]

- Preece, K.E.; Hooshyar, N.; Krijgsman, A.J.; Fryer, P.J.; Zuidam, N.J. Intensification of protein extraction from soybean processing materials using hydrodynamic cavitation. Innov. Food Sci. Emerg. Technol. 2017, 41, 47–55. [Google Scholar] [CrossRef]

- Grillo, G.; Boffa, L.; Binello, A.; Mantegna, S.; Cravotto, G.; Chemat, F.; Dizhbite, T.; Lauberte, L.; Telysheva, G. Cocoa bean shell waste valorisation; extraction from lab to pilot-scale cavitational reactors. Food Res. Int. 2019, 115, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Mevada, J.; Devi, S.; Pandit, A. Large scale microbial cell disruption using hydrodynamic cavitation: Energy saving options. Biochem. Eng. J. 2019, 143, 151–160. [Google Scholar] [CrossRef]

- Albanese, L.; Bonetti, A.; D’Acqui, L.P.; Meneguzzo, F.; Zabini, F. Affordable Production of Antioxidant Aqueous Solutions by Hydrodynamic Cavitation Processing of Silver Fir (Abies alba Mill.) Needles. Foods 2019, 8, 65. [Google Scholar] [CrossRef] [PubMed]

- Meneguzzo, F.; Brunetti, C.; Fidalgo, A.; Ciriminna, R.; Delisi, R.; Albanese, L.; Zabini, F.; Gori, A.; Nascimento, L.B.S.; Carlo, A.D.; et al. Real-Scale Integral Valorization of Waste Orange Peel via Hydrodynamic Cavitation. Processes 2019, 7, 581. [Google Scholar] [CrossRef]

- Amienyo, D.; Azapagic, A. Life cycle environmental impacts and costs of beer production and consumption in the UK. Int. J. Life Cycle Assess. 2016, 21, 492–509. [Google Scholar] [CrossRef]

- Hager, A.S.; Taylor, J.; Waters, D.M.; Arendt, E.K. Gluten free Beer—A Review. Trends Food Sci. Tech. 2014, 36, 44–54. [Google Scholar] [CrossRef]

- Harasym, J.; Podeszwa, T. Towards sustainable de-growth—Medical survey data as predictors for estimation of niche market value—Gluten-free beer market case. J. Clean. Prod. 2015, 108, 1232–1238. [Google Scholar] [CrossRef]

- Albanese, L.; Ciriminna, R.; Meneguzzo, F.; Pagliaro, M. Beer-brewing powered by controlled hydrodynamic cavitation: Theory and real-scale experiments. J. Cleaner Prod. 2017, 142, 1457–1470. [Google Scholar] [CrossRef]

- Albanese, L.; Ciriminna, R.; Meneguzzo, F.; Pagliaro, M. Gluten reduction in beer by hydrodynamic cavitation assisted brewing of barley malts. LWT 2017, 82, 342–353. [Google Scholar] [CrossRef]

- Ciriminna, R.; Albanese, L.; Stefano, V.D.; Delisi, R.; Avellone, G.; Meneguzzo, F.; Pagliaro, M. Beer produced via hydrodynamic cavitation retains higher amounts of xanthohumol and other hops prenylflavonoids. LWT 2018, 91, 160–167. [Google Scholar] [CrossRef]

- Li, K.; Woo, M.W.; Patel, H.; Metzger, L.; Selomulya, C. Improvement of rheological and functional properties of milk protein concentrate by hydrodynamic cavitation. J. Food Eng. 2018, 221, 106–113. [Google Scholar] [CrossRef]

- Pathania, S.; Ho, Q.T.; Hogan, S.A.; McCarthy, N.; Tobin, J.T. Applications of hydrodynamic cavitation for instant rehydration of high protein milk powders. J. Food Eng. 2018, 225, 18–25. [Google Scholar] [CrossRef]

- Shaikh, T.; Swamiappan, S. Pharmaceutical and pharmacological profile of guar gum an overview. Int. J. Pharm. Pharm. Sci. 2011, 3, 38–40. [Google Scholar]

- Prajapat, A.L.; Gogate, P.R. Intensification of depolymerization of aqueous guar gum using hydrodynamic cavitation. Chem. Eng. Process. Process Intensif. 2015, 93, 1–9. [Google Scholar] [CrossRef]

- Lohani, U.C.; Muthukumarappan, K.; Meletharayil, G.H. Application of hydrodynamic cavitation to improve antioxidant activity in sorghum flour and apple pomace. Food Bioprod. Process. 2016, 100, 335–343. [Google Scholar] [CrossRef]

- Hilares, R.T.; Santos, J.G.; Shiguematsu, N.B.; Ahmed, M.A.; Silva, S.S.; Santos, J.C. Low-pressure homogenization of tomato juice using hydrodynamic cavitation technology: Effects on physical properties and stability of bioactive compounds. Ultrason. Sonochem. 2019, 54, 192–197. [Google Scholar] [CrossRef]

- Maddikeri, G.L.; Gogate, P.R.; Pandit, A.B. Intensified synthesis of biodiesel using hydrodynamic cavitation reactors based on the interesterification of waste cooking oil. Fuel 2014, 137, 285–292. [Google Scholar] [CrossRef]

- Chuah, L.F.; Yusup, S.; Aziz, A.R.; Bokhari, A.; Abdullah, M.Z. Cleaner production of methyl ester using waste cooking oil derived from palm olein using a hydrodynamic cavitation reactor. J. Cleaner Prod. 2016, 112, 4505–4514. [Google Scholar] [CrossRef]

- Cheung, C.S.; Man, X.J.; Fong, K.W.; Tsang, O.K. Effect of Waste Cooking Oil Biodiesel on the Emissions of a Diesel Engine. Energy Procedia 2015, 66, 93–96. [Google Scholar] [CrossRef]

- Bokhari, A.; Chuah, L.F.; Yusup, S.; Klemes, J.J.; Akbar, M.M.; Kamil, R.M. Cleaner production of rubber seed oil methyl ester using a hydrodynamic cavitation: Optimisation and parametric study. J. Cleaner Prod. 2016, 136, 31–41. [Google Scholar] [CrossRef]

- Bokhari, A.; Yusup, S.; Chuah, L.F.; Klemeš, J.J.; Asif, S.; Ali, B.; Akbar, M.M.; Kamil, R.N. Pilot scale intensification of rubber seed (Hevea brasiliensis) oil via chemical interesterification using hydrodynamic cavitation technology. Bioresour. Technol. 2017, 242, 272–282. [Google Scholar] [CrossRef] [PubMed]

- Ghayal, D.; Pandit, A.B.; Rathod, V.K. Optimization of biodiesel production in a hydrodynamic cavitation reactor using used frying oil. Ultrason. Sonochem. 2013, 20, 322–328. [Google Scholar] [CrossRef] [PubMed]

- Crudo, D.; Bosco, V.; Cavaglià, G.; Grillo, G.; Mantegna, S.; Cravotto, G. Biodiesel production process intensification using a rotor-stator type generator of hydrodynamic cavitation. Ultrason. Sonochem. 2016, 33, 220–225. [Google Scholar] [CrossRef] [PubMed]

- Mohod, A.V.; Gogate, P.R.; Viel, G.; Firmino, P.; Giudici, R. Intensification of biodiesel production using hydrodynamic cavitation based on high speed homogenizer. Chem. Eng. J. 2017, 316, 751–757. [Google Scholar] [CrossRef]

- Chitsaz, H.; Omidkhah, M.; Ghobadian, B.; Ardjmand, M. Optimization of hydrodynamic cavitation process of biodiesel production by response surface methodology. J. Environ. Chem. Eng. 2018, 6, 2262–2268. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- Kim, I.; Lee, I.; Jeon, S.H.; Hwang, T.; Han, J. Hydrodynamic cavitation as a novel pretreatment approach for bioethanol production from reed. Bioresour. Technol. 2015, 192, 335–339. [Google Scholar] [CrossRef]

- Hilares, R.T.; Ienny, J.V.; Marcelino, P.F.; Ahmed, M.A.; Antunes, F.A.; Silva, S.S.; Santos, J.C. Ethanol production in a simultaneous saccharification and fermentation process with interconnected reactors employing hydrodynamic cavitation-pretreated sugarcane bagasse as raw material. Bioresour. Technol. 2017, 243, 652–659. [Google Scholar] [CrossRef]

- Madison, M.J.; Coward-Kelly, G.; Liang, C.; Karim, M.N.; Falls, M.; Holtzapple, M.T. Mechanical pretreatment of biomass—Part I: Acoustic and hydrodynamic cavitation. Biomass Bioenergy 2017, 98, 135–141. [Google Scholar] [CrossRef]

- Ramirez-Cadavid, D.A.; Kozyuk, O.; Lyle, P.; Michel, F.C., Jr. Effects of hydrodynamic cavitation on dry mill corn ethanol production. Process Biochem. 2016, 51, 500–508. [Google Scholar] [CrossRef]

- Patil, P.N.; Gogate, P.R.; Csoka, L.; Dregelyi-Kiss, A.; Horvath, M. Intensification of biogas production using pretreatment based on hydrodynamic cavitation. Ultrason. Sonochem. 2016, 30, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Garuti, M.; Langone, M.; Fabbri, C.; Piccinini, S. Monitoring of full-scale hydrodynamic cavitation pretreatment in agricultural biogas plant. Bioresour. Technol. 2018, 247, 599–609. [Google Scholar] [CrossRef] [PubMed]

- Habashi, N.; Mehrdadi, N.; Mennerich, A.; Alighardashi, A.; Torabian, A. Hydrodynamic cavitation as a novel approach for pretreatment of oily wastewater for anaerobic co-digestion with waste activated sludge. Ultrason. Sonochem. 2016, 31, 362–370. [Google Scholar] [CrossRef]

- Saxena, S.; Saharan, V.K.; George, S. Modeling & simulation studies on batch anaerobic digestion of hydrodynamically cavitated tannery waste effluent for higher biogas yield. Ultrason. Sonochem. 2019, 58, 104692. [Google Scholar]

- Lee, I.; Han, J. The effects of waste-activated sludge pretreatment using hydrodynamic cavitation for methane production. Ultrason. Sonochem. 2013, 20, 1450–1455. [Google Scholar] [CrossRef]

- Seo, Y.H.; Yun, Y.; Lee, H.; Han, J. Pretreatment of cheese whey for hydrogen production using a simple hydrodynamic cavitation system under alkaline condition. Fuel 2015, 150, 202–207. [Google Scholar] [CrossRef]

- Mostafalou, S.; Abdollahi, M. Pesticides and human chronic diseases: Evidences, mechanisms, and perspectives. Toxicol. Appl. Pharmacol. 2013, 268, 157–177. [Google Scholar] [CrossRef]

- Panda, D.; Sethu, V.; Manickam, S. Kinetics and mechanism of low-frequency ultrasound driven elimination of trace level aqueous perfluorooctanesulfonic acid and perfluorooctanoic acid. Chem. Eng. Process. Process Intensif. 2019, 142, 107542. [Google Scholar] [CrossRef]

- Panda, D.; Sethu, V.; Manickam, S. Removal of Hexabromocyclododecane using ultrasound-based advanced oxidation process: Kinetics, pathways and influencing factors. Environ. Technol. Innov. 2020, 17, 100605. [Google Scholar] [CrossRef]

- COM 876. Proposal for a Directive of the European Parliament and of the Council Amending Directives 2000/60/EC and 2008/105/EC as Regards Priority Substances in the Field of Water Policy; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Rzymski, P.; Drewek, A.; Klimaszyk, P. Pharmaceutical pollution of aquatic environment: An emerging and enormous challenge. Limnol. Rev. 2017, 17, 97–107. [Google Scholar] [CrossRef]

- Tijani, J.O.; Fatoba, O.O.; Babajide, O.O.; Petrik, L.F. Pharmaceuticals, endocrine disruptors, personal care products, nanomaterials and perfluorinated pollutants: A review. Environ. Chem. Lett. 2017, 14, 27–49. [Google Scholar] [CrossRef]

- Bagal, M.V.; Gogate, P.R. Degradation of diclofenac sodium using combined processes based on hydrodynamic cavitation and heterogeneous photocatalysis. Ultrason. Sonochem. 2014, 21, 1035–1043. [Google Scholar] [CrossRef]

- Thanekar, P.; Panda, M.; Gogate, P.R. Degradation of carbamazepine using hydrodynamic cavitation combined with advanced oxidation processes. Ultrason. Sonochem. 2018, 40, 567–576. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jia, J.; Wang, Y. Combination of photocatalysis with hydrodynamic cavitation for degradation of tetracycline. Chem. Eng. J. 2017, 315, 274–282. [Google Scholar] [CrossRef]

- Rajoriya, S.; Bargole, S.; George, S.; Saharan, V.K.; Gogate, P.R.; Pandit, A.B. Synthesis and characterization of samarium and nitrogen doped TiO2 photocatalysts for photo-degradation of 4-acetamidophenol in combination with hydrodynamic and acoustic cavitation. Sep. Pur. Technol. 2018, 209, 254–269. [Google Scholar] [CrossRef]

- Roy, K.; Moholkar, V.S. Sulfadiazine degradation using hybrid AOP of heterogeneous Fenton/persulfate system coupled with hydrodynamic cavitation. Chem. Eng. J. 2019, in press. [Google Scholar] [CrossRef]

- Zupanc, M.; Kosjek, T.; Petkovšek, M.; Dular, M.; Kompare, B.; Širok, B.; Strazar, M.; Heath, E. Shear-induced hydrodynamic cavitation as a tool for pharmaceutical micropollutants removal from urban wastewater. Ultrason. Sonochem. 2014, 21, 1213–1221. [Google Scholar] [CrossRef]

- Rajoriya, S.; Bargole, S.; Saharan, V.K. Degradation of a cationic dye (Rhodamine 6G) using hydrodynamic cavitation coupled with other oxidative agents: Reaction mechanism and pathway. Ultrason. Sonochem. 2017, 34, 183–194. [Google Scholar] [CrossRef]

- Rajoriya, S.; Bargole, S.; Saharan, V.K. Degradation of reactive blue 13 using hydrodynamic cavitation: Effect of geometrical parameters and different oxidizing additives. Ultrason. Sonochem. 2017, 37, 192–202. [Google Scholar] [CrossRef]

- Bethi, B.; Sonawane, S.H.; Rohit, G.S.; Holkar, C.R.; Pinjari, D.V.; Bhanvase, B.A.; Pandit, A.B. Investigation of TiO2 photocatalyst performance for decolorization in the presence of hydrodynamic cavitation as hybrid AOP. Ultrason. Sonochem. 2016, 28, 150–160. [Google Scholar] [CrossRef]

- Çalışkan, Y.; Yatmaz, H.C.; Bektaş, N. Photocatalytic oxidation of high concentrated dye solutions enhanced by hydrodynamic cavitation in a pilot reactor. Process Safety Environ. Protect. 2017, 111, 428–438. [Google Scholar] [CrossRef]

- Mishra, K.P.; Gogate, P.R. Intensification of degradation of Rhodamine B using hydrodynamic cavitation in the presence of additives. Sep. Purif. Technol. 2010, 75, 385–391. [Google Scholar] [CrossRef]

- Saharan, V.K.; Pandit, A.B.; Satish, P.S.; Anandan, S. Hydrodynamic cavitation as an advanced oxidation technique for the degradation of acid red 88 dye. Ind. Eng. Chem. Res. 2012, 51, 1981–1989. [Google Scholar] [CrossRef]

- Gogate, P.R.; Bhosale, G.S. Comparison of effectiveness of acoustic and hydrodynamic cavitation in combined treatment schemes for degradation of dye wastewaters. Chem. Eng. Process. Process Intensif. 2013, 71, 59–69. [Google Scholar] [CrossRef]

- Gore, M.M.; Saharan, V.K.; Pinjari, D.V.; Chavan, P.V.; Pandit, A.B. Degradation of reactive orange 4 dye using hydrodynamic cavitation based hybrid techniques. Ultrason. Sonochem. 2014, 21, 1075–1082. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.S.; Sonawane, S.H.; Pandit, A.B. Degradation of methylene blue dye in aqueous solution using hydrodynamic cavitation based hybrid advanced oxidation processes. Chem Eng Process. Process Intensif. 2017, 122, 288–295. [Google Scholar] [CrossRef]

- Raut-Jadhav, S.; Saharan, V.K.; Pinjari, D.; Sonawane, S.; Saini, D.; Pandit, A.B. Intensification of degradation of imidacloprid in aqueous solutions by combination of hydrodynamic cavitation with various advanced oxidation processes (AOPs). J. Environ. Chem. Eng. 2013, 1, 850–857. [Google Scholar] [CrossRef]

- Raut-Jadhav, S.; Saini, D.; Sonawane, S.; Pandit, A.B. Effect of process intensifying parameters on the hydrodynamic cavitation based degradation of commercial pesticide (methomyl) in the aqueous solution. Ultrason. Sonochem. 2016, 28, 283–293. [Google Scholar] [CrossRef]

- Barik, A.J.; Gogate, P.R. Hybrid treatment strategies for 2,4,6-trichlorophenol degradation based on combination of hydrodynamic cavitation and AOPs. Ultrason. Sonochem. 2018, 40, 383–394. [Google Scholar] [CrossRef]

- Gogate, P.R.; Patil, P.N. Combined treatment technology based on synergism between hydrodynamic cavitation and advanced oxidation processes. Ultrason. Sonochem. 2015, 25, 60–69. [Google Scholar] [CrossRef]

- Patil, P.N.; Bote, S.D.; Gogate, P.R. Degradation of imidacloprid using combined advanced oxidation processes based on hydrodynamic cavitation. Ultrason. Sonochem. 2014, 21, 1770–1777. [Google Scholar] [CrossRef]

- Joshi, R.K.; Gogate, P.R. Degradation of dichlorvos using hydrodynamic cavitation based treatment strategies. Ultrasonic. Sonochem. 2012, 19, 532–539. [Google Scholar] [CrossRef]

- Bagal, M.V.; Gogate, P.R. Degradation of 2,4-dinitrophenol using a combination of hydrodynamic cavitation, chemical and advanced oxidation processes. Ultrasonic. Sonochem. 2013, 20, 1226–1235. [Google Scholar] [CrossRef] [PubMed]

- Barik, A.J.; Gogate, P.R. Degradation of 4-chloro 2-aminophenol using a novel combined process based on hydrodynamic cavitation, UV photolysis and ozone. Ultrasonic. Sonochem. 2016, 30, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Jawale, R.H.; Gogate, P.R. Novel approaches based on hydrodynamic cavitation for treatment of wastewater containing potassium thiocyanate. Ultrasonic. Sonochem. 2019, 52, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Cui, M.; Lee, Y.; Kim, J.; Son, Y.; Khim, J. Hydrodynamic cavitation and activated persulfate oxidation for degradation of bisphenol A: Kinetics and mechanism. Chem. Eng. J. 2018, 338, 323–332. [Google Scholar] [CrossRef]

- Jain, P.; Bhandaria, V.M.; Balapure, K.; Jena, J.; Ranade, V.V.; Killedar, D.J. Hydrodynamic cavitation using vortex diode: An efficient approach for elimination of pathogenic bacteria from water. J. Environ. Manag. 2019, 242, 210–219. [Google Scholar] [CrossRef]

- Loraine, G.; Chahine, G.; Hsiao, C.T.; Choi, J.K.; Aley, P. Disinfection of gram-negative and gram-positive bacteria using DynaJets hydrodynamic cavitating jets. Ultrason. Sonochem. 2012, 19, 710–717. [Google Scholar] [CrossRef]

- Šarc, A.; Kosel, J.; Stopar, D.; Oder, M.; Dular, M. Removal of bacteria Legionella pneumophila, Escherichia coli, and Bacillus subtilis by (super) cavitation. Ultrason. Sonochem. 2018, 42, 228–236. [Google Scholar] [CrossRef]

- Mane, M.B.; Bhandari, V.M.; Balapure, K.; Ranade, V.V. A novel hybrid cavitation process for enhancing and altering rate of disinfection by use of natural oils derived from plants. Ultrason. Sonochem. 2020, 61, 104820. [Google Scholar] [CrossRef] [PubMed]

- Kosel, J.; Gutierrez-Aguirre, I.; Racki, N.; Dreo, T.; Ravnikar, M.; Dular, M. Efficient inactivation of MS-2 virus in water by hydrodynamic cavitation. Water Res. 2017, 124, 465–471. [Google Scholar] [CrossRef] [PubMed]

- Pantelić, D.; Svirčev, Z.; Simeunović, J.; Vidović, M.; Trajković, I. Cyanotoxins: Characteristics, production and degradation routes in drinking water treatment with reference to the situation in Serbia. Chemosphere 2013, 91, 421–441. [Google Scholar] [CrossRef] [PubMed]

- Chow, C.W.; Panglisch, S.; House, J.; Drikas, M.; Burch, M.D.; Gimbel, R. A study of membrane filtration for the removal of cyanobacterial cells. J. Water Supply Res. Technol. 1997, 46, 324–334. [Google Scholar]

- EPA. Cyanobacteria and Cyanotoxins: Information for Drinking Water Systems, United States Environ. Prot. Agency no. EPA-810F11001; EPA: Washington, DC, USA, 2012; pp. 1–9. [Google Scholar]

- Li, P.; Song, Y.; Yu, S.; Park, H. The effect of hydrodynamic cavitation on Microcystis aeruginosa: Physical and chemical factors. Chemosphere 2015, 136, 245–251. [Google Scholar] [CrossRef]

- Wu, Z.; Shen, H.; Ondruschka, B.; Zhang, Y.; Wang, W.; Bremner, D.H. Removal of blue-green algae using the hybrid method of hydrodynamic cavitation and ozonation. J. Hazard. Mater. 2012, 235–236, 152–158. [Google Scholar] [CrossRef]

- Kim, D.; Kim, E.K.; Koh, H.G.; Kim, K.; Han, J.; Chang, Y.K. Selective removal of rotifers in microalgae cultivation using hydrodynamic cavitation. Algal Res. 2017, 28, 24–29. [Google Scholar] [CrossRef]

- Cvetković, M.; Grego, M.; Turk, V. The efficiency of a new hydrodynamic cavitation pilot system on Artemia salina cysts and natural population of copepods and bacteria under controlled mesocosm conditions. Marine Pollut. Bulletin 2016, 105, 341–350. [Google Scholar] [CrossRef]

- Saxena, S.; Saharan, V.K.; George, S. Enhanced synergistic degradation efficiency using hybrid hydrodynamic cavitation for treatment of tannery waste effluent. J. Clean. Prod. 2018, 198, 1406–1421. [Google Scholar] [CrossRef]

- Saxena, S.; Rajoriya, S.; Saharan, V.K.; George, S. An advanced pretreatment strategy involving hydrodynamic and acoustic cavitation along with alum coagulation for the mineralization and biodegradability enhancement of tannery waste effluent. Ultrasonic. Sonochem. 2018, 44, 299–309. [Google Scholar] [CrossRef]

- Rajoriya, S.; Bargole, S.; George, S.; Saharan, V.K. Treatment of textile dyeing industry effluent using hydrodynamic cavitation in combination with advanced oxidation reagents. J. Hazard. Mater. 2018, 344, 1109–1115. [Google Scholar] [CrossRef]

- Boczkaj, G.; Gągol, M.; Klein, M.; Przyjazny, A. Effective method of treatment of effluents from production of bitumens under basic pH conditions using hydrodynamic cavitation aided by external oxidants. Ultrason. Sonochem. 2018, 40, 969–979. [Google Scholar] [CrossRef]

- Thanekar, P.; Gogate, P.R. Combined hydrodynamic cavitation based processes as an efficient treatment option for real industrial effluent. Ultrason. Sonochem. 2019, 53, 202–213. [Google Scholar] [CrossRef] [PubMed]

| Emulsion | HC Reactor | Parameters | Smallest Droplet Size (nm) | Ref. |

|---|---|---|---|---|

| O/W: Mustard/Water | Venturi (slit) | Surfactants (8% v/v): Tween 80, Span 80; Cv: 0.19 (10 bar); CP: 200; Time (min): 90 | 87 | [8] |

| O/W; Coconut oil in water | Venturi (circular and slit) | Surfactants (5.5% by volume): tween 80 and span 80; Inlet pressure (bar): 10; Time (min): 30 | 200 | [10] |

| O/W: Soybean/Heptane/Castor/Water | Orifice | Surfactants (1.25 wt%): SDS; Inlet pressure (psi): 120; CP: 6 | 27 | [11] |

| Turmeric oil in skimmed milk | Venturi (circular) | Surfactant: SDS; Inlet pressure: 5 bar; Time (min): 45 | 246.5 | [12] |

| Soy protein isolate | Swirling Jet | Pressure (MPa): 0.6; Time (min): 60 | - | [13] |

| Matrix: Extract | Reactor | Parameters | Yield | Ref. |

|---|---|---|---|---|

| Microalgae Nannochloropsis salina (wet): Lipids | Venturi | Cv: 1.17; ED (min): 25.05 | 99% | [17] |

| Microalgae Nannochloropsis salina (wet): Lipids | Orifice | Inlet pressure (bar): 4; T (°C): 60; ED (min): 20 | 46.0 ± 3.7% | [18] |

| Microalgae Nannochloropsis sp. (dry): Lipids | Venturi | Cv: 0.126; T (°C): 42; ED (h): 2 | 93% | [19] |

| Soybean: Protein | Venturi | Inlet pressure (MPa): 100 | 82% | [20] |

| Cocoa bean shell: Theobromine Caffeine Fatty acids | Rotor/stator | RPM: 3000; ED (min): 11 | 160.2 mg/g 8.9 mg/g 964 mg/g | [21] |

| Yeast: Enzyme | Orifice | Pressure: 6 bar; T (°C): 50 | 55.78 U/mL | [22] |

| Silver Fir: Phenolics Flavonoids | Venturi | RPM: 2900; ED (min): 60; T (°C): 67.5 | 100% | [23] |

| Waste orange peel: Pectin Polyphenols Terpenes | Venturi | RPM: 2900; ED (min): 10; T (°C): 20 | 60% 45% | [24] |

| Food type | Goal | Reactor | Outcome | Ref. |

|---|---|---|---|---|

| Beer | Overall brewing | Venturi | Speed up enzymatic Saccharification; 30% higher starch extraction; Reduction in processing time; 30% greater energy saving; Disinfection | [28] |

| Gluten reduction | Venturi | Gluten content reduced significantly (>270 mg/L to <20 mg/L) | [29] | |

| Hops bioactive compounds retention/generation | Venturi | Retained XN, DMX, and 6-GN | [30] | |

| Milk | Milk protein (MPC80) modification | Rotor-stator/sonolator | Reduction in viscosity; Increase in bulk, tapped density | [31] |

| Milk protein concentrate powders (MPC80) rehydration | Rotor-stator/sonolator | Significant reduction in the particle size of milk powder | [32] | |

| Guar gum | Depolymerization | Slit venturi | Viscosity reduced effectively | [33] |

| Sorghum flour; Apple pomace | Antioxidant activity enhancement | Rotor-stator/sonolator | 11.2% and 7.2% enhancement of TPC in AP and SF | [35] |

| Tomato juice | Homogenization, Bioactive compound stabilization | Orifice | Lycopene and phenolic compounds stability enhanced | [36] |

| Product | Feedstock | Reactor Type | Optimum Parameters | Yield (%) | Ref |

|---|---|---|---|---|---|

| Biodiesel | Waste cooking oil | Slit venturi | T (°C): 40; Inlet Pressure (bar): 3; O/Methyl acetate: 1:12; Catalyst: 1 wt% CH3OK | 90 | [37] |

| Waste cooking oil (palm Olein) | Orifice | T (°C): 60; Inlet Pressure (bar): 2; O/Methanol: 1:6; Catalyst: 1 wt% KOH | 98.1 | [38] | |

| Rubber seed oil | Orifice | T (°C): 55; Inlet Pressure (bar): 3; O/Methanol: 1:6; Catalyst: 1 wt% KOH | 96.5 | [40] | |

| Rubber seed oil | Orifice | T (°C): 50; Inlet Pressure (bar): 3; O/Methyl acetate: 1:14; Catalyst: 0.75 wt% CH3KO | 88 | [41] | |

| Used frying oil | Orifice | T (°C): 60; Inlet Pressure (bar): 3; O/Methanol: 1:6; Catalyst: 1 wt% KOH | 95 | [42] | |

| Palm oil | Rotor-stator | T (°C): 55; Methanol/O: 13% v/v; Catalyst: 3.67 g/L NaOH | 99 | [43] | |

| Waste and fresh cooking oil (sunflower) | Spinning tube | T (°C): 50; RPM: 1200-3500; O/Methanol: 1:12; Catalyst: 3 wt% KOH | 97; 92.3 | [44] | |

| Waste frying oil | Venturi | T (°C): 63; Inlet Pressure (bar): 3.27; O/Methanol: 1:6; Catalyst: 1.1 wt% NaOH | 97.56 | [45] | |

| Waste cooking oil | Orifice | T (°C): 35 ± 3; Inlet Pressure (bar): 7; O/Methanol: 1:6.8; Catalyst: 1 wt% NaOH | 99 | [9] | |

| Bioethanol | Reed | Orifice | T (°C): 77; Inlet Pressure (atm): 5; S/L: 11.8% wt/wt; Base: 3% NaOH | 90 | [47] |

| Sugarcane bagasse | Orifice | T (°C): 60; Inlet Pressure (bar): 3; S/L: 5; Base: 0.3 mol/L NaOH | 96 | [48] | |

| Biogas | Wheat straw | Rotor-stator | T (°C): 37; RPM: 2500; S/L: 1.5% wt/wt; Base: 0.3 M KOH | - | [51] |

| Agricultural biomass | Rotor-stator | Inlet Pressure (bar): 2 | - | [52] | |

| Oily wastewater | Orifice | T (°C): 37 ± 1 Inlet Pressure (bar): 10.25 | 84.35 | [53] | |

| Tannery waste effluent | Slit venturi | Inlet pressure (bar): 5; Seed dosages (wt%): 10 | - | [54] | |

| Waste-activated sludge | Orifice | T (°C): 150; Up/down-stream pressure: 0.7, 0.07 MPa; Catalyst: 5 N NaOH | 63.90 | [55] | |

| Hydrogen | Cheese whey | Orifice | Pressure (MPa): 0.7; Base: 5 M KOH | 3.30 mol H2/mol lactose | [56] |

| Category | Pollutant | HC Type | Parameters | Comment | Ref. |

|---|---|---|---|---|---|

| Pharmaceuticals | Diclofenac sodium | Slit venture (Flow area: 11.4 mm2, α: 1.38, β: 0.052, Half divergence angle: 5.5°, Throat height to length ratio: 1:1) | Inlet Pressure (bar): 3, CV: 0.28, Flow rate (LPH): 1075, Initial concentration (ppm): 20, Reaction volume (L): 5, Treatment time (min): 120, pH: 4, T (°C): 35, H2O2: 0.2 g/L, TiO2: 0.2 g/L | HC alone: 26.85% degradation HC+UV+TiO2: 94.78% degradation Synergetic coefficient: 2.5 | [63] |

| Carbamazepine (CBZ) | Slit venture (Flow area: 14.64 mm2, α: 1.30, β: 0.038, Half divergence angle: 5.5, Throat height to length ratio: 1:1) | Inlet pressure (bar): 4; Initial concentration (ppm): 10, Reaction volume (L): 4, Treatment time (min): 120, pH: 4, T (°C): 35, H2O2 (ppm): 50, O3 flow rate (g/h): 0.4 | HC alone: 38.7% degradation HC+H2O2+O3: 100% degradation Synergetic coefficient: 3.2 | [64] | |

| Tetracycline | Circular venturi (Throat diameter: 2 mm, α: 2.00, Half divergence angle: 10°) | Inlet pressure (bar): 3.4, CV: 0.59, Flow rate (LPH): 380.52, Initial concentration (ppm): 30, Reaction volume (L): 4, Treatment time (min): 90; pH: 4.2, T (°C): 30, UV (W): 9, TiO2 (ppm): 100 | HC alone: 12.2% degradation HC+UV+TiO2: 78.2% degradation Synergetic coefficient: 3.2 | [65] | |

| 4-acetamidophenol | Slit venturi: (Flow area: 3.14 mm2, α: 2.64, β: 0.011, Half divergence angle: 6.5 Throat height to length ratio: 1:1) | Inlet pressure (bar): 5, CV: 0.07, Initial concentration (ppm): 50, Reaction volume (L): 3, Treatment time (min): 180, pH: 6.8, T (°C): 20–25, UV (W): 3, TiO2: 2 g/L | HC alone: 8.3% degradation HC+UV+TiO2: 90.8% degradation Synergetic coefficient: 1.5 | [66] | |

| Sulfadiazine | Circular orifice: (Hole diameter: 4 mm, Flow area: 25.12 mm2, α: 1 mm2, β: 0.073) | Inlet pressure (atm): 10, CV: 0.25, Initial concentration (ppm): 20, Reaction volume (L): 5, pH: 4, Treatment time (min): 90, H2O2: 0.95 mL/L, α-Fe2O3 (ppm): 181.8, Na2S2O8: 348.5 mg/L | HC+Fenton+Persulfate: 81% degradation | [67] | |

| Clofibric acid; Ibuprofen; Naproxen; Ketoprofen; Carbamazepine; Diclofenac | Rotor-stator: (R1: rotor with 12 grooves, R2: rotor with 11 grooves) | Initial concentration: 1 μg/L; Reaction volume (L): 2.5; T (°C): 50; Treatment time (min): 15; H2O2: 1.7 g/L | HC+H2O2: 55%–93% removal | [68] | |

| Dyes | Rhodamine 6G (Rh6G) | Slit venturi: (Flow area: 3.14 mm2, α: 2.64, β: 0.011, Half divergence angle: 6.5 Throat height to length ratio: 1:1) | Inlet pressure (bar): 5, CV: 0.07, Flow rate (LPH): 1.64 × 10−4 m3/s, Initial concentration (ppm): 50, Reaction volume (L): 6, Treatment time (min): 120, pH: 10, T (°C): 30 ± 2, O3 flow rate (g/h): 3 | HC alone: 32% decolorization HC+H2O2: 53.72% decolorization HC+O3: 100% decolorization/73% mineralization Synergetic coefficient: 1.58 | [69] |

| Reactive blue 13 | Slit venturi: (Flow area: 3.14 mm2, α: 2.64, β: 0.011, Half divergence angle: 6.5, Throat height to length ratio: 1:1) | Inlet pressure (bar): 4, CV: 0.08, Initial concentration (ppm): 30, Reaction volume (L): 6, Treatment time (min): 120, pH: 2.0, O3 flow rate (g/h): 3 | HC alone: 47% decolorization HC+O3: 100% decolorization/72% mineralization Synergetic coefficient: 3.47 | [70] | |

| Crystal violet | Circular venturi: (Throat diameter: 2 mm, α: 2.00, β: 0.013 Half divergence angle: 6°) | Inlet pressure (bar): 5, CV: 0.15, Initial concentration (ppm): 50, Reaction volume (L): 5, Treatment time (min): 90, pH: 6.5, T (°C): 35, Fe-TiO2 (ppm): 600, UV (W): 125 | HC alone: 44.5% decolorization HC+UV+Fe-TiO2: 98% decolorization | [71] | |

| Reactive red 180 | Circular venturi: (Throat diameter: 7 mm, α: 0.57, β: 0.05, Half divergence angle: 6°) | Inlet pressure (bar): 5, CV: 0.177, Flow rate: 4.1 m3/h, Initial concentration (ppm): 100, Reaction volume (L): 16, Treatment time (min): 180, pH: 2, T (°C): 35, UV (W): 15 (6 lamps) | HC alone: 4.6% decolorization HC+UV+TiO2: 90.7% decolorization/45% COD/38.7% TOC removal HC+UV+ZnO: 99.7% decolorization/77% COD/66% TOC removal Synergetic coefficient: 1.8 | [72] | |

| Rhodamine-B | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.027, Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.091, Flow rate: 400 L/h, Initial concentration (ppm): 10, Reaction volume (L): 4, Treatment time (min): 120, pH: 2.5, T (°C): 40, FeSO4:H2O2: 1:5 | HC alone: 59.3% degradation/30% TOC removal HC+ Fenton: 99% degradation/57% TOC removal | [73] | |

| Acid Red 88 | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.013 Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.15, Flow rate (LPH): 410, Initial concentration (µM): 100, Reaction volume (L): 4, Treatment time (min): 120, pH: 2, T (°C): 35, Molar ratio (dye: H2O2): 1:60 | HC alone: 92% decolorization/35% TOC removal H2O2 alone: 4.6% decolorization HC+ H2O2: 99% decolorization/72% TOC removal | [74] | |

| Reactive red 120 | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.013, Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.15, Flow rate (LPH): 410, Initial concentration (ppm): 50, Reaction volume (L): 6, Treatment time (min): 180, pH: 2, T (°C): 35, Molar ratio (dye: H2O2): 1:60 | HC alone: 60% decolorization/28% TOC removal H2O2 alone: 13% decolorization HC+ H2O2: 100% decolorization & 60% TOC removal | [7] | |

| Orange acid-II (OA-II) | Circular orifice: (Throat diameter: 2 mm, α: 2, β: 0.0064) | Inlet pressure (bar): 5, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 120, pH: 3, T (°C): 20, H2O2 (ppm): 571.2 | HC alone: 34.2% decolorization/27.3% TOC reduction H2O2 alone: 11% decolorization HC+ H2O2: 96% decolorization | [75] | |

| Reactive orange 4 | Circular venturi: (Throat diameter: 2 mm, α: 2.00, β: 0.013, Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.15, Flow rate (LPH): 410, Initial concentration (ppm): 40, Reaction volume (L): 5, Treatment time (min): 120; pH: 2, Molar ratio: 1:30 (dye: H2O2), O3 flow rate (g/h): 3 | HC alone: 37.23% decolorization H2O2 alone: 4.65% decolorization HC+ H2O2+O3: 100% decolorization Synergetic coefficient: 3.87 | [76] | |

| Methylene blue | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.013, Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.15, Flow rate (LPH): 410, Initial concentration (ppm): 50, Reaction volume (L): 5, Treatment time (min): 120; pH: 2, T (°C): 35, UV (W): 125, Bismuth doped TiO2 (Bi-TiO2) (ppm): 200 | HC alone: 32.32% decolorization UV+Bi-TiO2: 26.52% decolorization HC+UV+Bi-TiO2: 64.5% decolorization Synergetic coefficient: 1.46 | [77] | |

| Pesticides | Imidacloprid | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.013, Half divergence angle: 6.4°) | Inlet pressure (bar): 15, CV: 0.067, Flow rate: 610 L/h, Initial concentration (ppm): 25, Reaction volume (L): 5, pH: 2.7, T (°C): 31, Molar ratio: 1:40 (pollutant: H2O2), UV (W): 250, Nb2O5 (ppm): 200 | HC alone: 26% degradation (120 min)/9.6% mineralization (180 min) HC+Fenton: 97.77% degradation (15 min) HC+UV+Nb2O5: 55% degradation in (120 min)/19% Mineralization (180 min) HC+photo-Fenton: 99.23% degradation (15 min) Synergetic coefficient: 2.912 | [78] |

| Methomyl | Circular venturi: (Throat diameter: 2 mm, α: 2.0, β: 0.013, Half divergence angle: 6.4°) | Inlet pressure (bar): 5, CV: 0.21, Flow rate: 375 L/h, Initial concentration (ppm): 25, Reaction volume (L): 5, pH: 2.5, Molar ratio (pollutant: H2O2): 1:30, Molar ratio (FeSO4: H2O2): 1:20, O3 flow rate (g/h): 0.75 | HC alone: 27.49% degradation (120 min) O3 alone: 6% mineralization (120 min) HC+ H2O2: 97.2% degradation (60 min)/15.4% TOC reduction (120 min) Fenton alone: 29% degradation (30 min)/9.5% TOC reduction (120 min) HC+ Fenton: 100% degradation (30 min)/35.8% TOC reduction (120 min) HC+O3: 100% degradation/70.8% TOC reduction (120 min) Synergetic coefficient: 47.6 | [79] | |

| 2,4,6- Trichlorophenol (2,4,6-TCP) | Slit venturi: (Flow area: 11.4 mm2, α: 1.38, β: 0.052, Half divergence angle: 5.5°, Throat height to length ratio: 1:1) | Inlet pressure (bar): 4, CV: 0.23, Initial concentration (ppm): 20, Reaction volume (L): 7, Treatment time (min): 120, pH: 7, T (°C): 30, Molar ratio: 1:5 (TCP: H2O2), O3 flow rate (g/h): 0.4 | HC alone: 32.13% degradation HC+ H2O2: 62% degradation HC+O3: 97.1% degradation Synergetic coefficient: 1.48 | [80] | |

| Triazophos | Circular orifice: (Throat diameter: 2 mm, α: 2.0, β: 0.0064) | Inlet pressure (bar): 5, CV: 0.29, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 120, pH: 3, O3 flow rate (g/h): 0.576, (FeSO4:H2O2): 2:2 | HC alone: 35.77% degradation HC+Fenton: 82.2% degradation Synergetic coefficient: 3.34 | [81] | |

| Imidacloprid | Slit venturi: (Throat dimensions: W: 7.67 mm, H: 1.91 mm, L: 1.91 mm, Half divergence angle: 5.5°) | Inlet pressure (bar): 4, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 60, pH: 3, T (°C): 34, (H2O2: Fe powder): 2:1 | HC alone: 27.93% degradation HC+Fenton: 100% degradation | [82] | |

| Dichlorvos | Circular orifice: (Throat diameter: 2 mm) | Inlet pressure (bar): 5, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 60, pH: 3, T (°C): 31, H2O2 (ppm): 16, FeSO4 (ppm): 48 | HC alone: 12.5% degradation HC+Fenton: 91.5% degradation | [83] | |

| Organic pollutants | 2,4-dinitrophenol | Circular orifice: (Throat diameter: 2 mm) | Inlet pressure (bar): 4, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 60, pH: 4, T (°C): 35, H2O2 (g/L): 0.3, FeSO4 (g/L): 0.6 | HC alone: 12.4% degradation HC+ Fenton: 100% degradation | [84] |

| 4-chloro 2-aminophenol | Circular orifice: (Throat diameter: 2 mm) | Inlet pressure (bar): 4, Initial concentration (ppm): 20, Reaction volume (L): 7, Treatment time (min): 120, pH: 6, T (°C): 30, UV (W): 8, O3 flow rate (mg/h): 400 | HC only: 21.89% degradation O3 only: 64.29% degradation UV only: 68.89% degradation HC+UV+O3: 96.85% degradation | [85] | |

| Potassium thiocyanate | Circular venturi: (Throat diameter: 2 mm) | Inlet pressure (bar): 4, CV: 0.205, Flow rate (LPH): 339, Initial concentration (ppm): 20, Reaction volume (L): 4, Treatment time (min): 120, pH: 2, T (°C): 37, H2O2 (ppm): 20, O3 flow rate (mg/h): 400, CuO (g/L): 0.15 | HC only: 52.8% degradation H2O2 only: 6.7% degradation O3 only: 5.6% degradation CuO only: 5.1% degradation HC+H2O2+O3+ CuO: 100% degradation | [86] | |

| Bisphenol A | Circular orifice: (Throat diameter: 2 mm) | Inlet pressure (MPa): 0.5, Initial concentration (ppm): 10, Reaction volume (L): 10, Treatment time (min): 120; pH: 6, T (°C): 50; PS: 4.17 mM | HC+ Persulfate (PS): 81.28% degradation | [87] | |

| Bacteria | Gram-negative: Escherichia coli; Gram-positive: Staphylococcus aureus | Vortex diode: (Chamber diameter: 66 mm) | Pressure drop (bar): 0.5, Reaction volume (L): 20 | 99% and 98% removal, respectively | [88] |

| Gram-negative: Escherichia coli; Klebsiella pneumoniae; Pseudomonas syringae; Pseudomonas aeruginosa; Gram-positive: Bacillus subtilis | DYNAJETS Nozzle | Nozle pressure (bar): 2.1, Reaction volume (L): 1.8–20 | Highly efficient overall inactivation | [89] | |

| Gram-negative: Legionella pneumophila; Escherichia coli; Gram-positive: Bacillus subtilis | Circular venturi: (Throat cross-section: 1 × 5 mm, Half divergence angle: 5°) | Inlet pressure (bar): 0.2, CV: 0.78, Flow rate (L/min): 0.2, Reaction volume (L): 4, Treatment time (min): 120 | Complete inactivation | [90] | |

| Gram-negative: Escherichia coli; Gram-positive: Staphylococcus aureus | Vortex diode: (Chamber diameter: 66 mm) | Pressure drop (bar): 2, Reaction volume (L): 20 | 100% disinfection | [91] | |

| Virus | Bacteriophage MS2 | Circular orifice: (Throat diameter: 2 mm) | Inlet pressure (bar): 7, Reaction volume (L): 1, Treatment time (min): 90, T (°C): <29 | Infectivity reduced to 4 logs (≥99.99%) | [92] |

| Cyanobacteria | Microcystis aeruginosa | Circular orifice | Inlet pressure (MPa): 0.4, Reaction volume (L): 5, Treatment time (min): 30, T (°C): 25, H2O2: 0.1 mmol/L | HC+ H2O2: 93% algal removal | [96] |

| Microcystis aeruginosa | Circular orifice: (Throat diameter: 5, 10, or 12 mm) | Initial concentration: 30 μg/L, Reaction volume (L): 1.75, Treatment time (min): 10, T (°C): 20, O3 flow rate (mg/min): 1.9 | HC alone: 15% algal removal O3 alone: 35% algal removal HC+O3: 99% algal removal | [97] | |

| Aquatic organisms | Rotifer: Brachionus rotundiformis | Circular orifice: (Throat diameter: 0.5 mm, 27 holes) | Initial concentration: 1000–8000 individuals/mL, Inlet pressure (bar): 3, Reaction volume (L): 20 | 99.9% removal | [98] |

| Multicellular: Copepod; Unicellular: Natural bacteria; Cyst: Artemia salina | Circular orifice | Inlet pressure (bar): 1.8–2.8, Reaction volume (L): 150, Treatment time (min): 60 | 100%, 86%, and 99.8% damage, respectively | [99] | |

| Industrial effluent | Tannery waste effluent (TWE) | Slit venturi: (Flow area: 3.14 mm2, α: 2.64, β: 0.011, Half divergence angle: 6.5, Throat height to length ratio: 1:1) | Inlet pressure (bar): 5, Initial COD (ppm): 8800–10,080, TOC (ppm): 2290–2583, BOD (ppm): 2800–3200, BI: 0.28–0.33 | HC: 14.46% COD & 12.60% TOC reduction, BI: 0.43 HC+ O3: 26.81% COD reduction at 7 g/h of ozone feed, BI: 0.42 HC+H2O2: 34.35% COD reduction at H2O2 feed rate of 14.27 g/L, BI: 0.41 HC+Fenton: 50.20% COD reduction at Fenton’s dose of 3.0 g/L and FeSO4.7H2O: H2O2 of 1:3, BI: 0.46, Synergetic coefficient: 2.68 | [100] |

| Tannery waste effluent organic content | Slit venturi: (Throat area: 3.14 mm2) | Inlet pressure (bar): 5, Treatment time (min): 120, Reaction volume (L): 20, pH: 4.5, T (°C): 30 ± 2; Alum dose: 0.5 g/100 mL, 2 g/100 mL | HC+Coagulant: 35.6% COD and 43.9% TOC reduction, BI increased from 0.14 to 0.57 | [101] | |

| Textile dyeing industry (TDI) | Slit venturi: (Flow area: 3.14 mm2, α: 2.64, β: 0.011, Half divergence angle: 6.5, Throat height to length ratio: 1:1) | Inlet pressure (bar): 5, COD (ppm): 2560–4640, TOC (ppm): 556–1184 | HC: 12% COD reduction, 17% TOC reduction HC+O3: 48% TOC, 22.72% COD reduction at ozone flow rate of 3g/h, Synergetic coefficient: 1.42 HC+Fenton: 48% TOC, 38% COD reduction at FeSO4.7H2O: H2O2 of 1:5, Synergetic coefficient: 1.42 | [102] | |

| Industrial effluent from bitumen production process industry | Circular venturi: (Throat diameter: 2 mm, α: 2.00, β: 0.013, Half divergence angle: 5.6°) | Inlet pressure (bar): 8, CV: 0.14, COD (ppm): 8000–12,000, pH: 10.5, T (°C): 40, O3 flow rate (g/h): 9.41 | HC: 12.5% COD reduction (360 min), BI: 0.39 O3: 20% COD reduction, BI: 0.32 HC+ H2O2: 20% COD reduction (360 min), BI: 0.26 HC+O3: 39.7% COD reduction (360 min), BI: 0.34 Synergetic coefficient: 1.2 | [103] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panda, D.; Saharan, V.K.; Manickam, S. Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing. Processes 2020, 8, 220. https://doi.org/10.3390/pr8020220

Panda D, Saharan VK, Manickam S. Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing. Processes. 2020; 8(2):220. https://doi.org/10.3390/pr8020220

Chicago/Turabian StylePanda, Debabrata, Virendra Kumar Saharan, and Sivakumar Manickam. 2020. "Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing" Processes 8, no. 2: 220. https://doi.org/10.3390/pr8020220

APA StylePanda, D., Saharan, V. K., & Manickam, S. (2020). Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing. Processes, 8(2), 220. https://doi.org/10.3390/pr8020220