Optimization of Enzyme-Assisted Extraction of Flavonoids from Corn Husks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Plant Material

2.2. Determination of Total Flavonoid Content

2.3. Enzyme-Assisted Extraction

2.4. Experimental Design

2.5. Heat-Reflux Extraction

3. Results

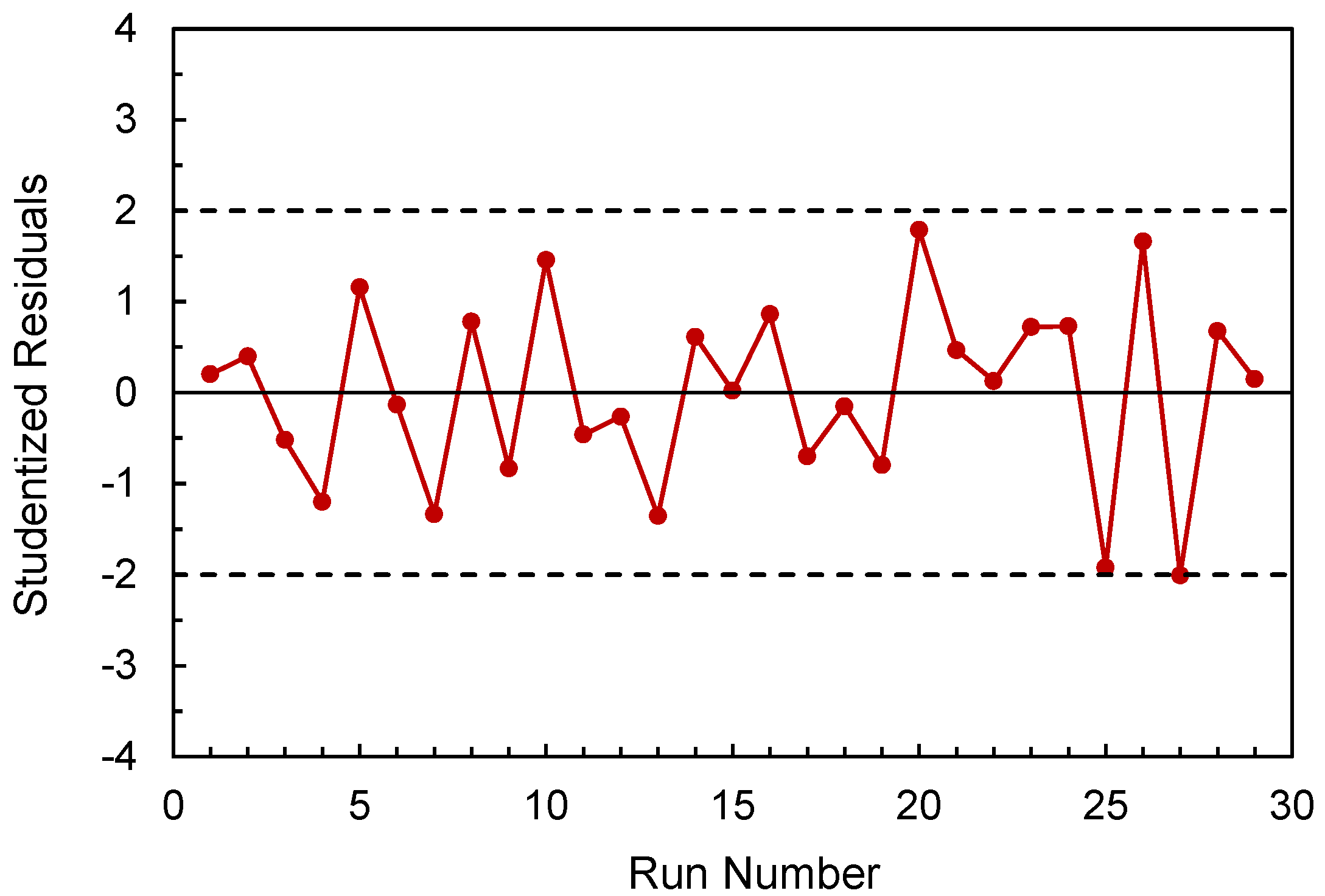

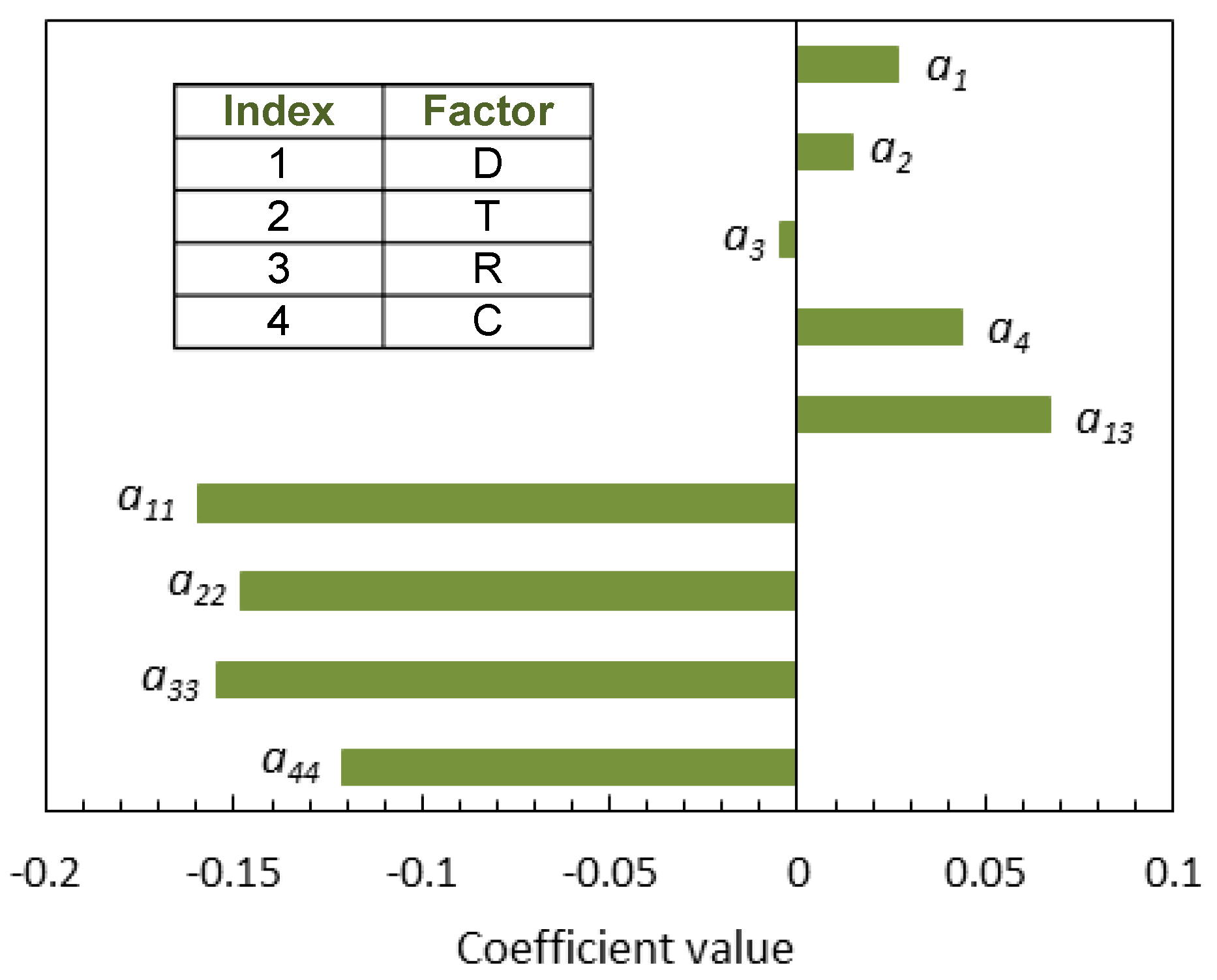

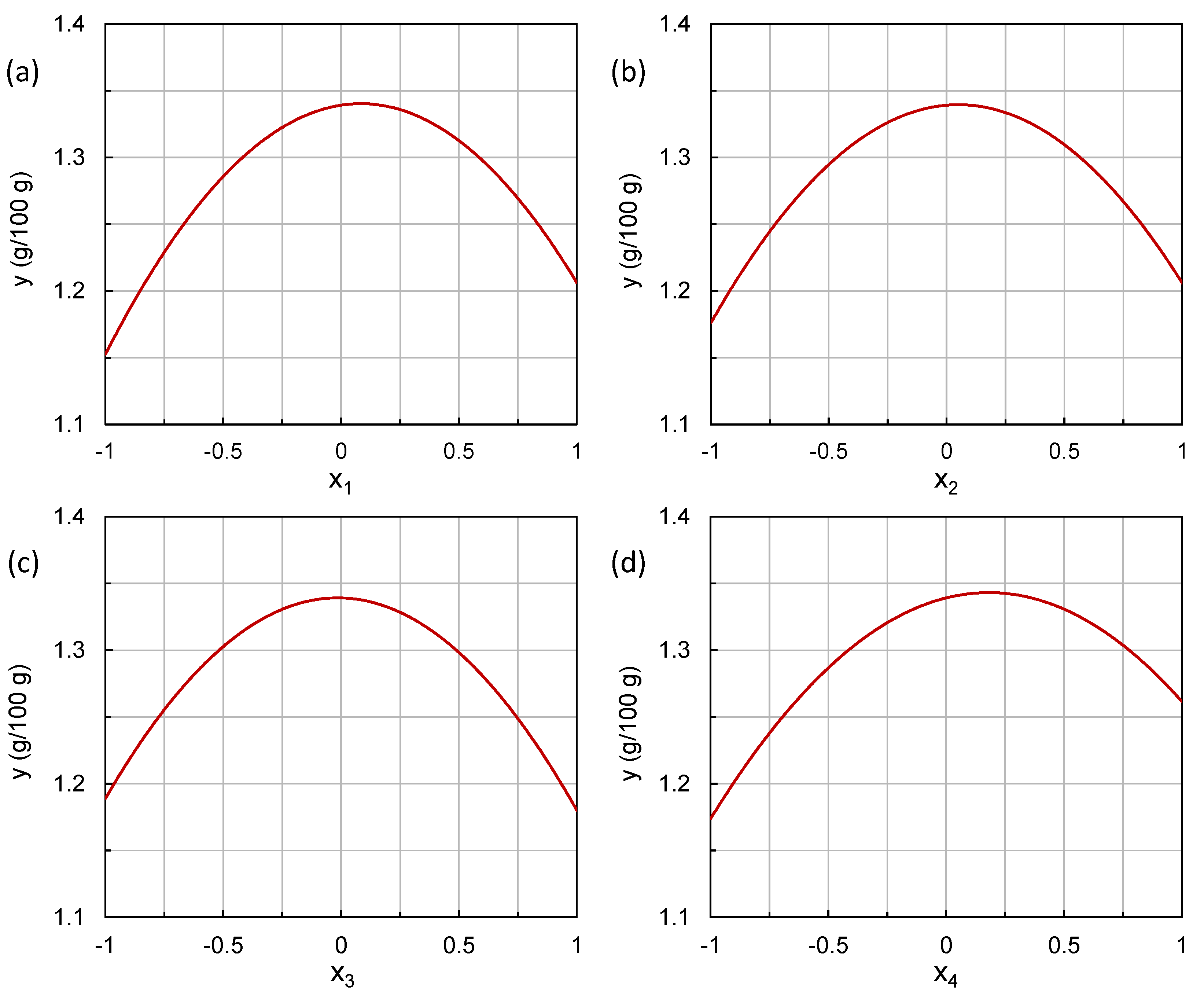

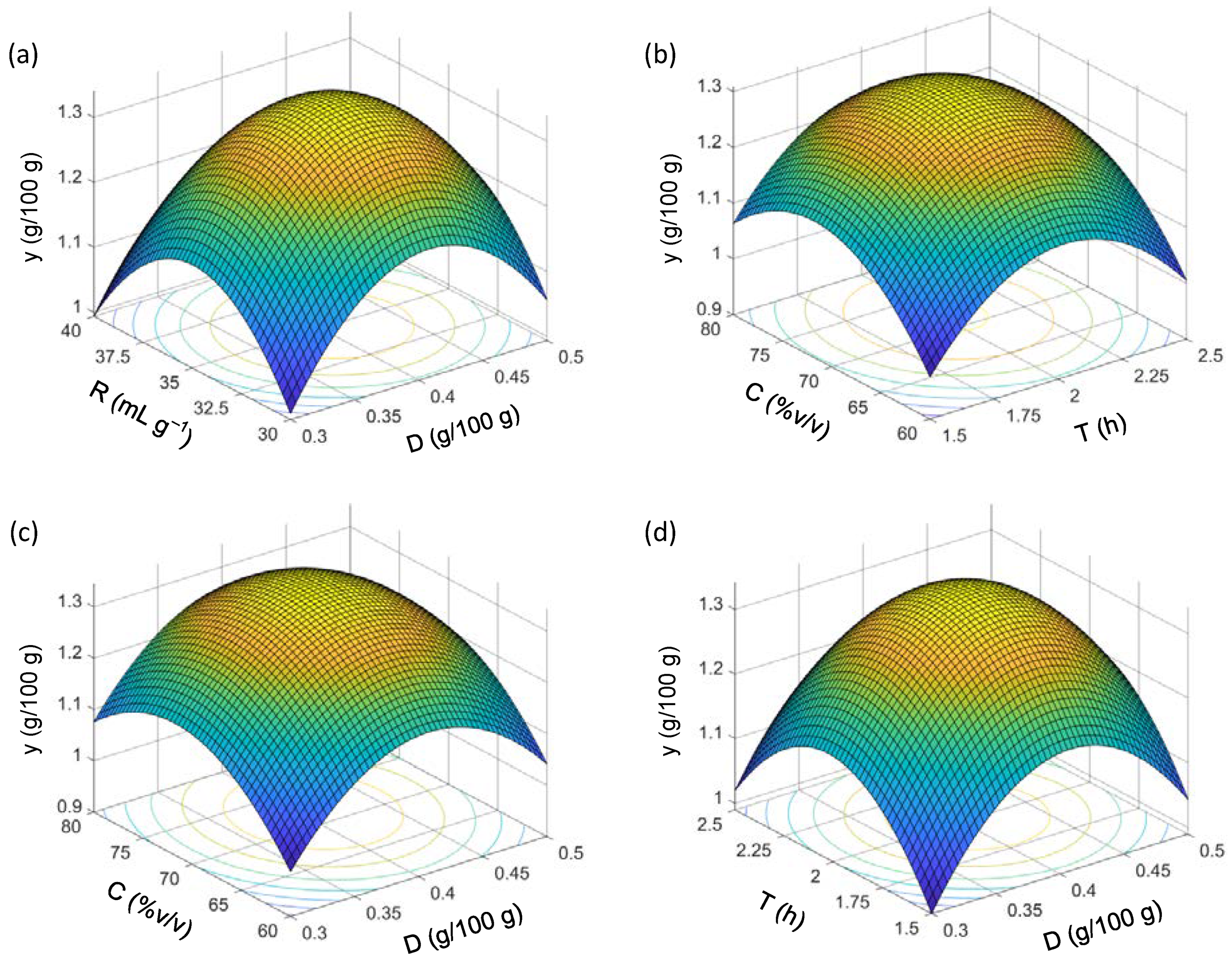

3.1. Model Fitting and Analysis of Response Surface

- (a)

- All of the four investigated factors affected the flavonoid extraction yield through both a linear and a quadratic term;

- (b)

- Concerning the linear terms, the R factor had only a marginal effect on the response variable, while the remaining factors provided a significant and positive contribution, increasing in the order: T < D < C;

- (c)

- There was a positive interaction between D and R, suggesting that the enzyme dosage had a more pronounced effect on flavonoid recovery at higher liquid-to-solid ratios.

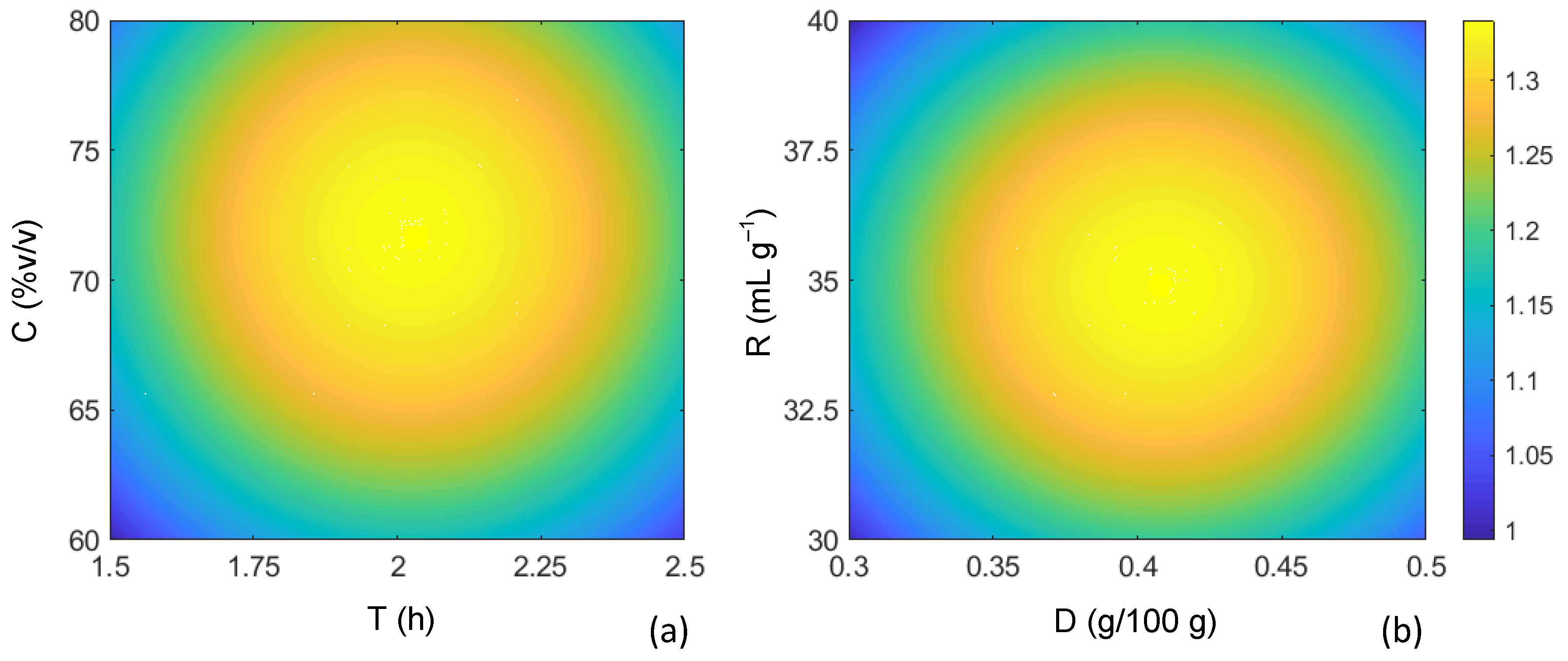

3.2. Optimizazion of Enzyme-Assisted Extraction

3.3. Comparison of Enzyme-Assisted Extraction and Heat-Reflux Extraction

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shiferaw, B.; Prasanna, B.M.; Hellin, J.; Bänziger, M. Crops that feed the world 6: Past successes and future challenges to the role played by maize in global food security. Food Secur. 2011, 3, 307. [Google Scholar] [CrossRef]

- Lopez-Martinez, L.X.; Oliart-Ros, R.M.; Valerio-Alfaro, G.; Lee, C.H.; Parkin, K.L.; Garcia, H.S. Antioxidant activity, phenolic compounds and anthocyanins content of eighteen strains of Mexican maize. Food Sci. Technol. 2009, 42, 1187–1192. [Google Scholar] [CrossRef]

- Ramos-Escudero, F.; Muñoz, M.A.; Alvarado-Ortíz, C.; Alvarado, A.; Yáñe, J.A. Purple corn (Zea mays L.) phenolic compounds profile and its assessment as an agent against oxidative stress in isolated mouse organs. J. Med. Food 2012, 15, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Hasanudin, K.; Hashim, P.; Mustafa, S. Corn silk (Stigma maydis) in healthcare: A phytochemical and pharmacological review. Molecules 2012, 17, 9697–9715. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, C.; Wang, Z.; Zhang, C.; Lu, S.; Liu, J. The antioxidant and free-radical scavenging activities of extract and fractions from corn silk (Zea mays L.) and related flavone glycosides. Food Chem. 2011, 126, 261–269. [Google Scholar] [CrossRef]

- Sarepoua, E.; Tangwongchai, T.; Suriharn, B.; Lertrat, K. Relationships between phytochemicals and antioxidant activity in corn silk. Int. Food Res. J. 2013, 20, 2073–2079. [Google Scholar]

- Reddy, N.; Yang, Y. Properties and potential applications of natural cellulose fibers from cornhusks. Green Chem. 2005, 7, 190–195. [Google Scholar] [CrossRef]

- Barl, B.; Biliaderis, C.G.; Murray, E.D.; Macgregor, A.W. Combined chemical and enzymic treatments of corn husk lignocellulosics. J. Sci. Food Agric. 1991, 56, 195–214. [Google Scholar] [CrossRef]

- Yoon, K.Y.; Woodams, E.E.; Hang, Y.D. Enzymatic production of pentoses from the hemicellulose fraction of corn residues. LWT Food Sci. Technol. 2006, 39, 388–392. [Google Scholar] [CrossRef]

- Hang, Y.D.; Woodams, E.E. Corn husks: A potential substrate for production of citric acid by Aspergillus niger. LWT Food Sci. Technol. 2000, 33, 520–521. [Google Scholar] [CrossRef]

- Mahalaxmi, Y.; Sathish, T.; Chaganti, S.R.; Prakasham, R.S. Corn husk as a novel substrate for the production of rifamycin B by isolated Amycolatopsis sp. RSP 3 under SSF. Process. Biochem. 2010, 45, 47–53. [Google Scholar] [CrossRef]

- Huda, S.; Yang, Y. Chemically extracted cornhusk fibers as reinforcement in light-weight poly(propylene) composites. Macromol. Mater. Eng. 2008, 293, 235–243. [Google Scholar] [CrossRef]

- Xiao, S.; Gao, R.; Gao, L.; Li, J. Poly(vinyl alcohol) films reinforced with nanofibrillated cellulose (NFC) isolated from corn husk by high intensity ultrasonication. Carbohydr. Polym. 2015, 136, 1027–1034. [Google Scholar] [CrossRef] [PubMed]

- Li, C.Y.; Kim, H.W.; Won, S.R.; Min, H.K.; Park, K.J.; Park, J.Y.; Ahn, M.S.; Rhee, H.I. Corn husk as a potential source of anthocyanins. J. Agric. Food Chem. 2008, 56, 11413–11416. [Google Scholar] [CrossRef]

- Khamphasan, P.; Lomthaisong, K.; Harakotr, B.; Ketthaisong, D.; Scott, M.P.; Lertrat, K.; Suriharn, B. Genotypic variation in anthocyanins, phenolic compounds, and antioxidant activity in cob and husk of purple field corn. Agronomy 2018, 8, 271. [Google Scholar] [CrossRef]

- Vijayalaxmi, S.; Jayalakshmi, S.K.; Sreeramulu, K. Polyphenols from different agricultural residues: Extraction, identification and their antioxidant properties. J. Food Sci. Technol. 2015, 52, 2761–2769. [Google Scholar] [CrossRef]

- Kupski, L.; Telles, A.C.; Gonçalves, L.M.; Nora, N.S.; Furlong, E.B. Recovery of functional compounds from lignocellulosic material: An innovative enzymatic approach. Food Biosci. 2018, 22, 26–31. [Google Scholar] [CrossRef]

- Khalid, M.; Saeed-ur-Rahman; Bilal, M.; Huang, D.-F. Role of flavonoids in plant interactions with the environment and against human pathogens—A review. J. Integr. Agric. 2019, 18, 211–230. [Google Scholar] [CrossRef]

- Shashirekha, M.N.; Mallikarjuna, S.E.; Rajarathnam, S. Status of bioactive compounds in foods, with focus on fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2015, 55, 1324–1339. [Google Scholar] [CrossRef]

- Leong, H.Y.; Show, P.L.; Lim, M.H.; Ooi, C.W.; Ling, T.C. Natural red pigments from plants and their health benefits: A review. Food Rev. Int. 2018, 34, 463–482. [Google Scholar] [CrossRef]

- Mojzer, E.B.; Hrnčič, M.K.; Škerget, M.; Knez, Ž.; Bren, U. Polyphenols: Extraction methods, antioxidative action, bioavailability and anticarcinogenic effects. Molecules 2016, 21, 901. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-García, C.; Sánchez-Quesada, C.; Gaforio, J.J. Dietary flavonoids as cancer chemopreventive agents: An updated review of human studies. Antioxidants 2019, 8, 137. [Google Scholar] [CrossRef] [PubMed]

- Hrnčič, M.K.; Španinger, E.; Košir, I.J.; Knez, Ž.; Bren, U. Hop compounds: Extraction techniques, chemical analyses, antioxidative, antimicrobial, and anticarcinogenic effects. Nutrients 2019, 11, 257. [Google Scholar] [CrossRef] [PubMed]

- Lavecchia, R.; Medici, F.; Piga, L.; Zuorro, A. Factorial design analysis of the recovery of flavonoids from bilberry fruit by-products. Int. J. Appl. Eng. Res. 2015, 23, 43555–43559. [Google Scholar]

- Lavecchia, R.; Zuorro, A. Recovery of flavonoids from three-phase olive pomace by aqueous ethanol extraction. ARPN J. Eng. Appl. Sci. 2016, 11, 13802–13809. [Google Scholar]

- Ko, M.-J.; Kwon, H.-L.; Chung, M.-S. Pilot-scale subcritical water extraction of flavonoids from satsuma mandarin (Citrus unshiu Markovich) peel. Innov. Food Sci. Emerg. Technol. 2016, 38, 175–181. [Google Scholar] [CrossRef]

- Liau, B.-C.; Ponnusamy, V.K.; Lee, M.-R.; Jong, T.-T.; Chen, J.-H. Development of pressurized hot water extraction for five flavonoid glycosides from defatted Camellia oleifera seeds (byproducts). Ind. Crop. Prod. 2017, 95, 296–304. [Google Scholar] [CrossRef]

- Sharma, K.; Mahato, N.; Lee, Y.R. Extraction, characterization and biological activity of citrus flavonoids. Rev. Chem. Eng. 2019, 35, 265–284. [Google Scholar] [CrossRef]

- Puri, M.; Sharma, D.; Barrow, C.J. Enzyme-assisted extraction of bioactives from plants. Trends Biotechnol. 2012, 30, 37–44. [Google Scholar] [CrossRef]

- Khorasani, E.A.; Mat, T.R.; Mohajer, S.; Banisalam, B. Antioxidant activity and total phenolic and flavonoid content of various solvent extracts from in vivo and in vitro grown Trifolium pratense L. (Red Clover). Biomed. Res. Int. 2015, 2015, 643285. [Google Scholar] [CrossRef]

- Agati, G.; Azzarello, E.; Pollastri, S.; Tattini, M. Flavonoids as antioxidants in plants: Location and functional significance. Plant. Sci. 2012, 196, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Baik, O.D.; Choi, Y.J.; Kim, S.M. Pretreatments for the efficient extraction of bioactive compounds from plant-based biomaterials. Crit. Rev. Food Sci. Nutr. 2014, 54, 1283–1297. [Google Scholar] [CrossRef] [PubMed]

- Baiano, A. Recovery of biomolecules from food wastes—A review. Molecules 2014, 19, 14821–14842. [Google Scholar] [CrossRef] [PubMed]

- Gligor, O.; Mocan, A.; Moldovan, C.; Locatelli, M.; Crișan, G.; Ferreira, I.C.F.R. Enzyme-assisted extractions of polyphenols—A comprehensive review. Trends Food Sci. Technol. 2019, 88, 302–315. [Google Scholar] [CrossRef]

- Doblin, M.S.; Pettolino, F.; Bacic, A. Plant cell walls: The skeleton of the plant world. Funct. Plant. Biol. 2010, 37, 357–381. [Google Scholar] [CrossRef]

- Scheller, H.V.; Ulvskov, P. Hemicelluloses. Annu. Rev. Plant. Biol. 2008, 61, 263–289. [Google Scholar] [CrossRef]

- Kuhad, R.C.; Gupta, R.; Singh, A. Microbial cellulases and their industrial applications. Enzyme Res. 2011, 1, 280696. [Google Scholar] [CrossRef]

- Lavecchia, R.; Zuorro, A. Cellulase Applications in Pigment and Bioactive Compound Extraction. In New and Future Developments in Microbial Biotechnology and Bioengineering; Gupta, V.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 209–222. [Google Scholar]

- Meini, M.-R.; Cabezudo, I.; Boschetti, C.E.; Romanini, D. Recovery of phenolic antioxidants from Syrah grape pomace through the optimization of an enzymatic extraction process. Food Chem. 2019, 283, 257–264. [Google Scholar] [CrossRef]

- Chen, S.; Xing, X.H.; Huang, J.J.; Xu, M.S. Enzyme-assisted extraction of flavonoids from Ginkgo biloba leaves: Improvement effect of flavonol transglycosylation catalyzed by Penicillium decumbens cellulase. Enzyme Microb. Technol. 2011, 48, 100–105. [Google Scholar] [CrossRef]

- Wang, Y.; Zu, Y.; Long, J.; Fu, Y.; Li, S.; Zhang, D.; Li, J.; Wink, M.; Efferth, T. Enzymatic water extraction of taxifolin from wood sawdust of Larix gmelini (Rupr.) Rupr. and evaluation of its antioxidant activity. Food Chem. 2011, 126, 1178–1185. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, X.; Si, J.; Gong, X.; Wang, S. Studies on cellulase-ultrasonic assisted extraction technology for flavonoids from Illicium verum residues. Chem. Cent. J. 2016, 10, 56. [Google Scholar] [CrossRef] [PubMed]

- Nema, N.; Alamir, L.; Mohammad, M. Production of cellulase from Bacillus cereus by submerged fermentation using corn husks as substrates. Int. Food Res. J. 2015, 22, 1831–1836. [Google Scholar]

- Yilmaz, N.D.; Sulak, M.; Yilmaz, K.; Kalin, F. Physical and chemical properties of water-retted fibers extracted from different locations in corn husks. J. Nat. Fibers 2016, 13, 397–409. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R.; Medici, F.; Piga, L. Use of cell wall degrading enzymes for the production of high-quality functional products from tomato processing waste. Chem. Eng. Trans. 2014, 38, 355–360. [Google Scholar]

- Zuorro, A.; Maffei, G.; Lavecchia, R. Optimization of enzyme-assisted lipid extraction from Nannochloropsis microalgae. J. Taiwan Inst. Chem. Eng. 2016, 67, 106–114. [Google Scholar] [CrossRef]

- Donohoe, B.S.; Resch, M.G. Mechanisms employed by cellulase systems to gain access through the complex architecture of lignocellulosic substrates. Curr. Opin. Chem. Biol. 2015, 29, 100–107. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Zheng, X.; Li, X.; Zhao, J. Adsorption and mechanism of cellulase enzymes onto lignin isolated from corn stover pretreated with liquid hot water. Biotechnol. Biofuels 2016, 9, 118. [Google Scholar] [CrossRef] [Green Version]

- Siqueira, G.; Arantes, V.; Saddler, J.N.; Ferraz, A.; Milagres, A.M.F. Limitation of cellulose accessibility and unproductive binding of cellulases by pretreated sugarcane bagasse lignin. Biotechnol. Biofuels 2017, 10, 176. [Google Scholar] [CrossRef]

- Vermaas, J.V.; Petridis, L.; Qi, X.; Schulz, R.; Lindner, B.; Smith, J.C. Mechanism of lignin inhibition of enzymatic biomass deconstruction. Biotechnol. Biofuels 2015, 8, 217. [Google Scholar] [CrossRef]

- Rahikainen, J.; Mikander, S.; Marjamaa, K.; Tamminen, T.; Lappas, A.; Viikari, L.; Kruus, K. Inhibition of enzymatic hydrolysis by residual lignins from softwood-study of enzyme binding and inactivation on lignin-rich surface. Biotechnol. Bioeng. 2011, 108, 2823–2834. [Google Scholar] [CrossRef]

- Dos Santos, A.C.; Ximenes, E.; Kim, Y.; Ladisch, M.R. Lignin–enzyme interactions in the hydrolysis of lignocellulosic biomass. Trends Biotechnol. 2019, 37, 518–531. [Google Scholar] [CrossRef] [PubMed]

- Rahikainen, J.L.; Evans, J.D.; Mikander, S.; Kalliola, A.; Puranen, T.; Tamminen, T.; Marjamaa, K.; Kruus, K. Cellulase-lignin interactions—The role of carbohydrate-binding module and pH in non-productive binding. Enzyme Microb. Technol. 2013, 53, 315–321. [Google Scholar] [CrossRef] [PubMed]

- Zuorro, A.; Lavecchia, R. Polyphenols and energy recovery from spent coffee grounds. Chem. Eng. Trans. 2011, 25, 285–290. [Google Scholar]

- Dorta, E.; Lobo, M.G.; Gonzalez, M. Reutilization of mango byproducts: Study of the effect of extraction solvent and temperature on their antioxidant properties. J. Food Sci. 2012, 77, C80–C88. [Google Scholar] [CrossRef] [PubMed]

- Zuorro, A.; Iannone, A.; Lavecchia, R. Water–organic solvent extraction of phenolic antioxidants from brewers’ spent grain. Processes 2019, 7, 126. [Google Scholar] [CrossRef]

- Fidaleo, M.; Lavecchia, R.; Zuorro, A. Extraction of bioactive polyphenols with high antioxidant activity from bilberry (Vaccinium myrtillus L.) processing waste. Orient. J. Chem. 2016, 32, 759–767. [Google Scholar] [CrossRef]

- Zuorro, A.; Maffei, G.; Lavecchia, R. Reuse potential of artichoke (Cynara scolimus L.) waste for the recovery of phenolic compounds and bioenergy. J. Clean. Prod. 2016, 111, 279–284. [Google Scholar] [CrossRef]

- Sun, R.C.; Sun, X.F.; Wang, S.Q.; Zhu, W.; Wang, X.Y. Ester and ether linkages between hydroxycinnamic acids and lignin from wheat, rice rye, and barley straws, maize stems, and fast-growing poplar wood. Ind. Crop. Prod. 2002, 15, 179–188. [Google Scholar] [CrossRef]

- Damoderan, S. Protein: Danaturation. In Handbook of Food Science, Technology and Engineering; Hui, Y.K., Ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Obataya, E.; Gril, J. Swelling of acetylated wood I: Swelling in organic liquids. J. Wood Sci. 2005, 51, 124–129. [Google Scholar] [CrossRef]

- El Seoud, O.A. Understanding solvation. Pure Appl. Chem. 2009, 81, 697–707. [Google Scholar] [CrossRef]

- Fidale, L.C.; Ruiz, N.; Heinze, T.; El Seoud, O.A. Cellulose swelling by aprotic and protic solvents: What are the similarities and differences? Macromol. Chem. Phys. 2008, 209, 1240–1254. [Google Scholar] [CrossRef]

- Kachrimanidou, V.; Kopsahelis, N.; Chatzifragkou, A.; Papanikolaou, S.; Yanniotis, S.; Kookos, I.; Koutinas, A.A. Utilisation of by-products from sunflower-based biodiesel production processes for the production of fermentation feedstock. Waste Biomass Valoriz. 2013, 4, 529–537. [Google Scholar] [CrossRef]

- Papadaki, A.; Androutsopoulos, N.; Patsalou, M.; Koutinas, M.; Kopsahelis, N.; de Castro, A.M.; Papanikolaou, S.; Koutinas, A.A. Biotechnological production of fumaric acid: The effect of morphology of Rhizopus arrhizus NRRL 2582. Fermentation 2017, 3, 33. [Google Scholar] [CrossRef]

- Kachrimanidou, V.; Kopsahelis, N.; Vlysidis, A.; Papanikolaou, S.; Kookos, I.K.; Monje Martínez, B.; Escrig Rondán, M.C.; Koutinas, A.A. Downstream separation of poly(hydroxyalkanoates) using crude enzyme consortia produced via solid state fermentation integrated in a biorefinery concept. Food Bioprod. Process. 2016, 100, 323–334. [Google Scholar] [CrossRef]

- Papadaki, A.; Kachrimanidou, V.; Papanikolaou, S.; Philippoussis, A.; Diamantopoulou, P. Upgrading grape pomace through Pleurotus spp. cultivation for the production of enzymes and fruiting bodies. Microorganisms 2019, 7, 207. [Google Scholar] [CrossRef] [PubMed]

- Papadaki, A.; Kopsahelis, N.; Mallouchos, A.; Mandala, I.; Koutinas, A.A. Bioprocess development for the production of novel oleogels from soybean and microbial oils. Food Res. Int. 2019, 126, 108684. [Google Scholar] [CrossRef]

| Factor | Factor Level | Unit | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| Enzyme dosage (D) | 0.3 | 0.4 | 0.5 | g/100 g |

| Incubation time (T) | 1.5 | 2.0 | 2.5 | h |

| Liquid-to-solid ratio (R) | 30 | 35 | 40 | mL g−1 |

| Ethanol concentration (C) | 60 | 70 | 80 | % v/v |

| SO | RO | Factor Level | y (g/100 g) | |||

|---|---|---|---|---|---|---|

| x1 | x2 | x3 | x4 | |||

| 1 | 2 | −1 | −1 | 0 | 0 | 1.047 |

| 2 | 3 | 1 | −1 | 0 | 0 | 1.018 |

| 3 | 27 | −1 | 1 | 0 | 0 | 0.890 |

| 4 | 4 | 1 | 1 | 0 | 0 | 1.070 |

| 5 | 9 | 0 | 0 | −1 | −1 | 1.022 |

| 6 | 8 | 0 | 0 | 1 | −1 | 1.037 |

| 7 | 13 | 0 | 0 | −1 | 1 | 1.103 |

| 8 | 25 | 0 | 0 | 1 | 1 | 0.990 |

| 9 | 17 | −1 | 0 | 0 | −1 | 0.991 |

| 10 | 15 | 1 | 0 | 0 | −1 | 1.092 |

| 11 | 26 | −1 | 0 | 0 | 1 | 1.131 |

| 12 | 20 | 1 | 0 | 0 | 1 | 1.215 |

| 13 | 22 | 0 | −1 | −1 | 0 | 1.093 |

| 14 | 10 | 0 | 1 | −1 | 0 | 1.120 |

| 15 | 21 | 0 | −1 | 1 | 0 | 0.992 |

| 16 | 23 | 0 | 1 | 1 | 0 | 1.138 |

| 17 | 14 | −1 | 0 | −1 | 0 | 1.040 |

| 18 | 29 | 1 | 0 | –1 | 0 | 0.898 |

| 19 | 1 | −1 | 0 | 1 | 0 | 0.969 |

| 29 | 12 | 1 | 0 | 1 | 0 | 1.096 |

| 21 | 16 | 0 | −1 | 0 | −1 | 0.966 |

| 22 | 6 | 0 | 1 | 0 | −1 | 1.010 |

| 23 | 7 | 0 | −1 | 0 | 1 | 1.070 |

| 24 | 5 | 0 | 1 | 0 | 1 | 1.136 |

| 25 | 18 | 0 | 0 | 0 | 0 | 1.387 |

| 26 | 19 | 0 | 0 | 0 | 0 | 1.260 |

| 27 | 11 | 0 | 0 | 0 | 0 | 1.334 |

| 28 | 24 | 0 | 0 | 0 | 0 | 1.311 |

| 29 | 28 | 0 | 0 | 0 | 0 | 1.404 |

| Coefficient | Term | Value | SE | Low CI | High CI |

|---|---|---|---|---|---|

| a0 | intercept | 1.339 | 0.031 | 1.274 | 1.405 |

| a1 | D | 0.027 | 0.020 | −0.016 | 0.069 |

| a2 | T | 0.015 | 0.020 | −0.028 | 0.057 |

| a3 | R | −0.005 | 0.020 | −0.047 | 0.038 |

| a4 | C | 0.044 | 0.020 | 0.002 | 0.086 |

| a13 | D × R | 0.067 | 0.035 | −0.006 | 0.141 |

| a11 | D × D | −0.160 | 0.028 | −0.217 | −0.102 |

| a22 | T × T | −0.148 | 0.028 | −0.206 | −0.090 |

| a33 | R × R | −0.155 | 0.028 | −0.212 | −0.097 |

| a44 | C × C | −0.121 | 0.028 | −0.179 | −0.064 |

| Source | DF | SS | MS | F | p |

|---|---|---|---|---|---|

| Regression | 9 | 0.410 | 4.60 × 10−2 | 9.32 | <0.0001 |

| Residual error | 19 | 0.093 | 4.91 × 10−3 | ||

| Lack-of-fit | 15 | 0.080 | 5.32 × 10−3 | 1.57 | 0.3567 |

| Pure error | 4 | 0.014 | 3.39 × 10−3 | ||

| Total | 28 | 0.510 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuorro, A.; Lavecchia, R.; González-Delgado, Á.D.; García-Martinez, J.B.; L’Abbate, P. Optimization of Enzyme-Assisted Extraction of Flavonoids from Corn Husks. Processes 2019, 7, 804. https://doi.org/10.3390/pr7110804

Zuorro A, Lavecchia R, González-Delgado ÁD, García-Martinez JB, L’Abbate P. Optimization of Enzyme-Assisted Extraction of Flavonoids from Corn Husks. Processes. 2019; 7(11):804. https://doi.org/10.3390/pr7110804

Chicago/Turabian StyleZuorro, Antonio, Roberto Lavecchia, Ángel Darío González-Delgado, Janet Bibiana García-Martinez, and Pasqua L’Abbate. 2019. "Optimization of Enzyme-Assisted Extraction of Flavonoids from Corn Husks" Processes 7, no. 11: 804. https://doi.org/10.3390/pr7110804

APA StyleZuorro, A., Lavecchia, R., González-Delgado, Á. D., García-Martinez, J. B., & L’Abbate, P. (2019). Optimization of Enzyme-Assisted Extraction of Flavonoids from Corn Husks. Processes, 7(11), 804. https://doi.org/10.3390/pr7110804