Comprehensive Strategy for Effective Exploitation of Offshore Extra-Heavy Oilfields with Cyclic Steam Stimulation

Abstract

1. Introduction

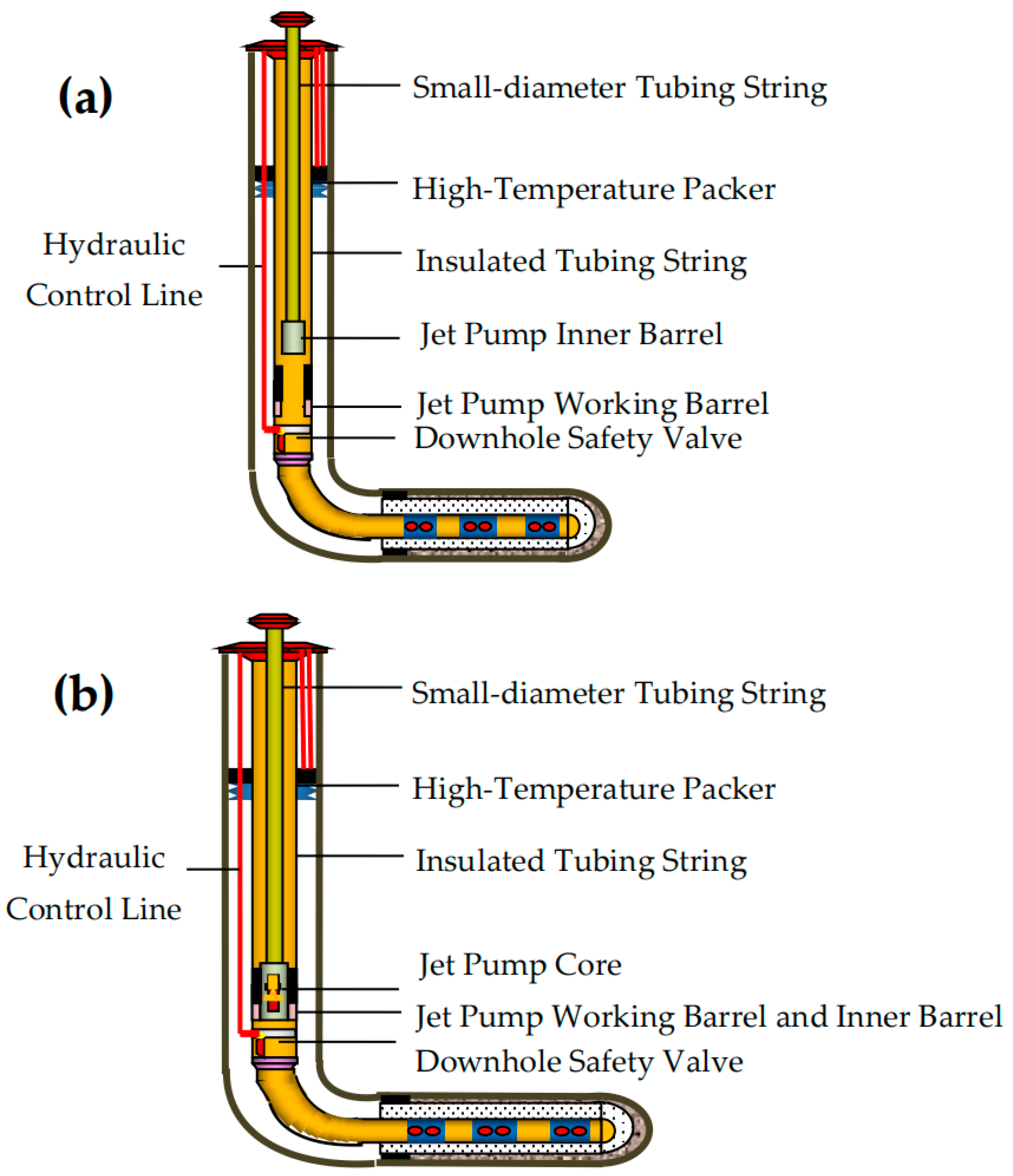

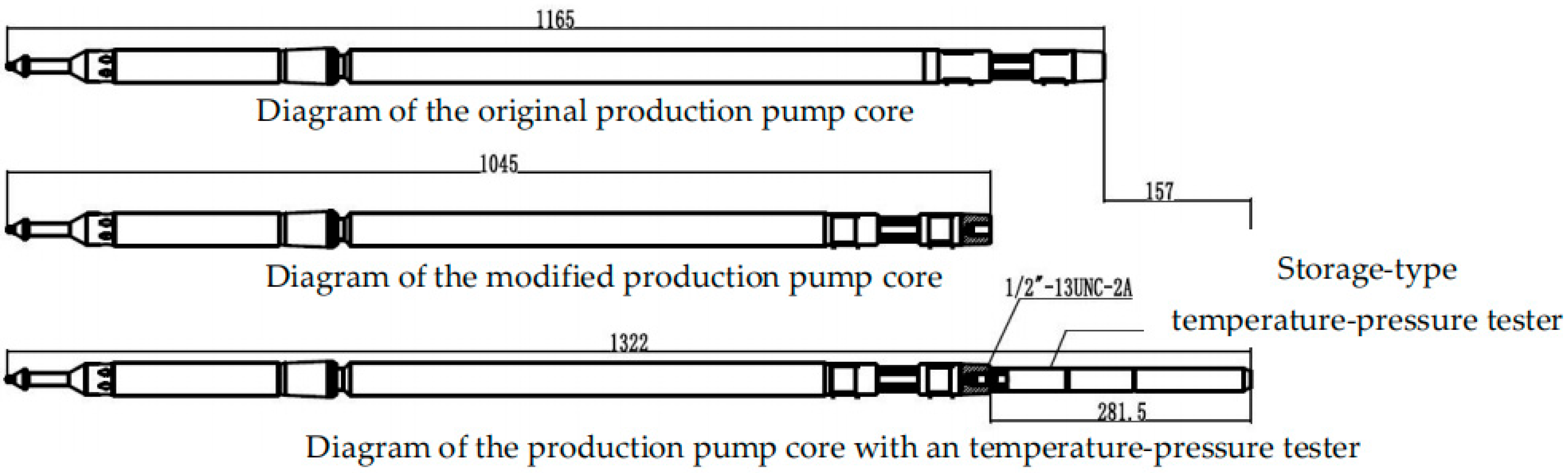

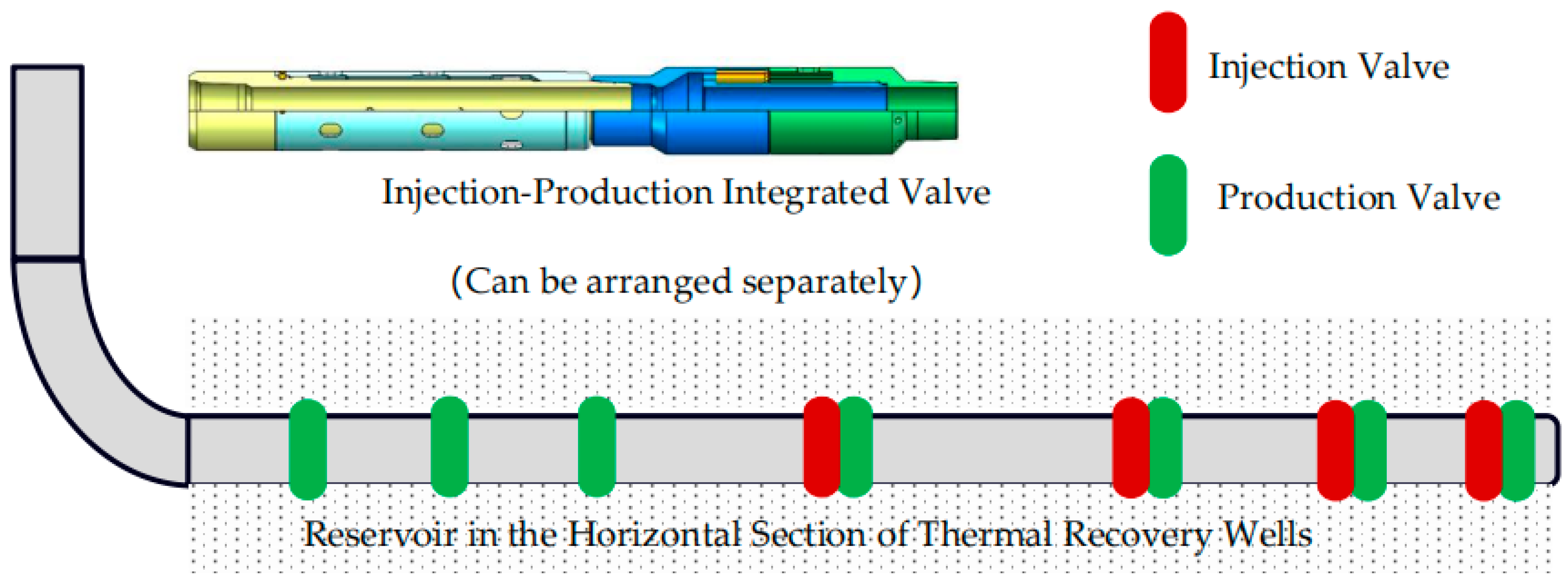

2. Jet Pump-Based Integrated Injection-Production for Extra-Heavy Oil Lift

2.1. Design Strategy

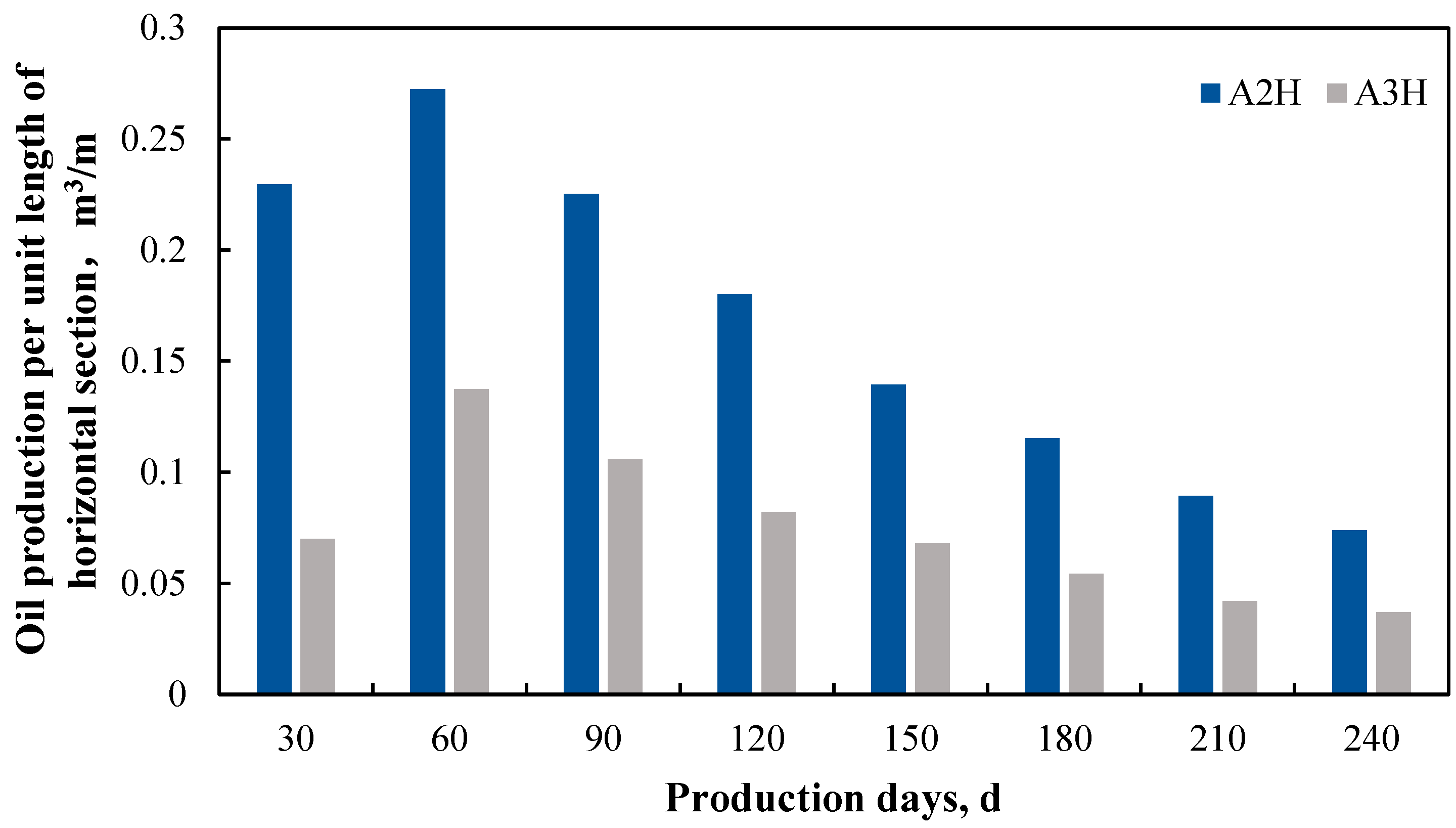

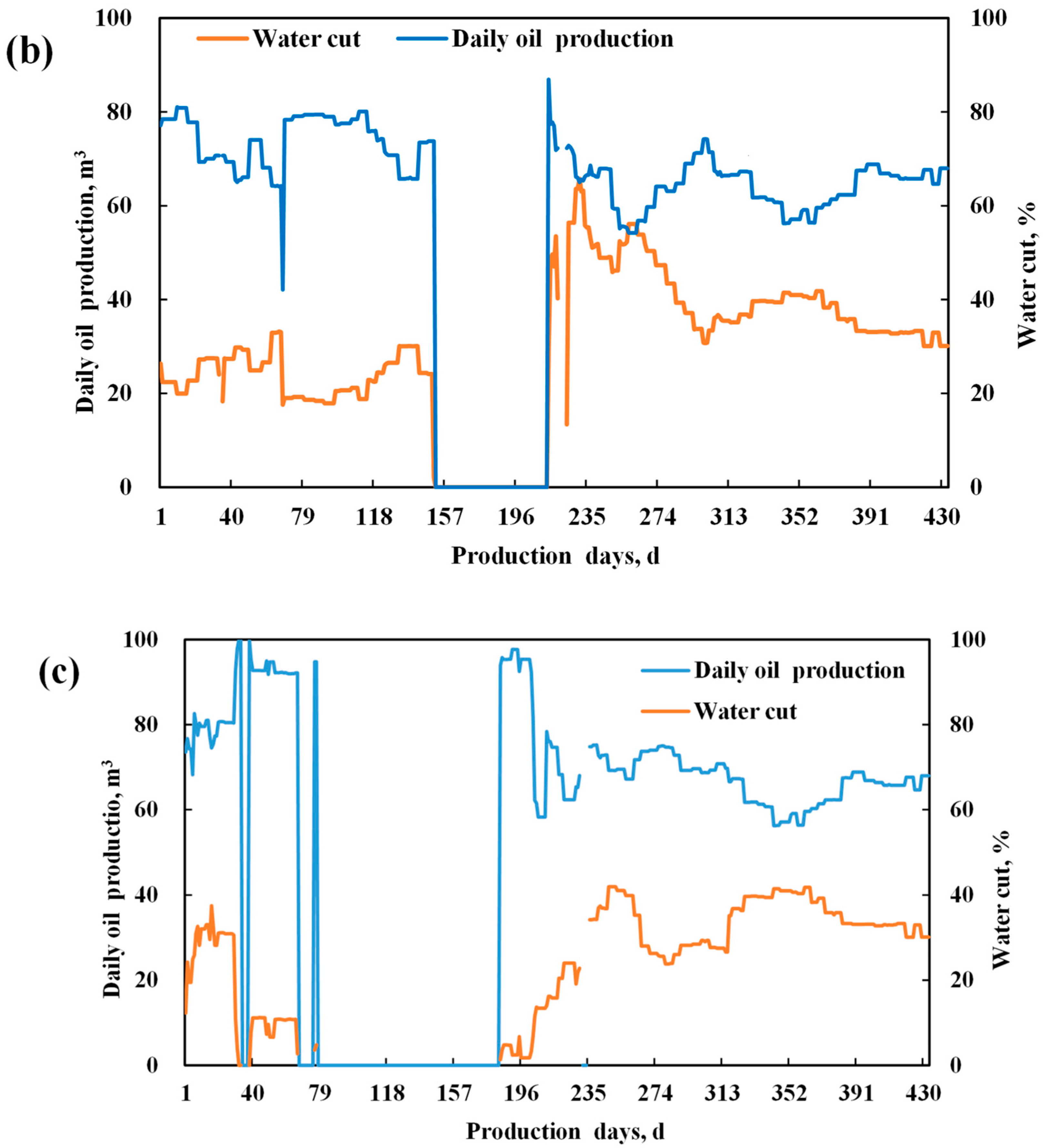

2.2. Application Effect

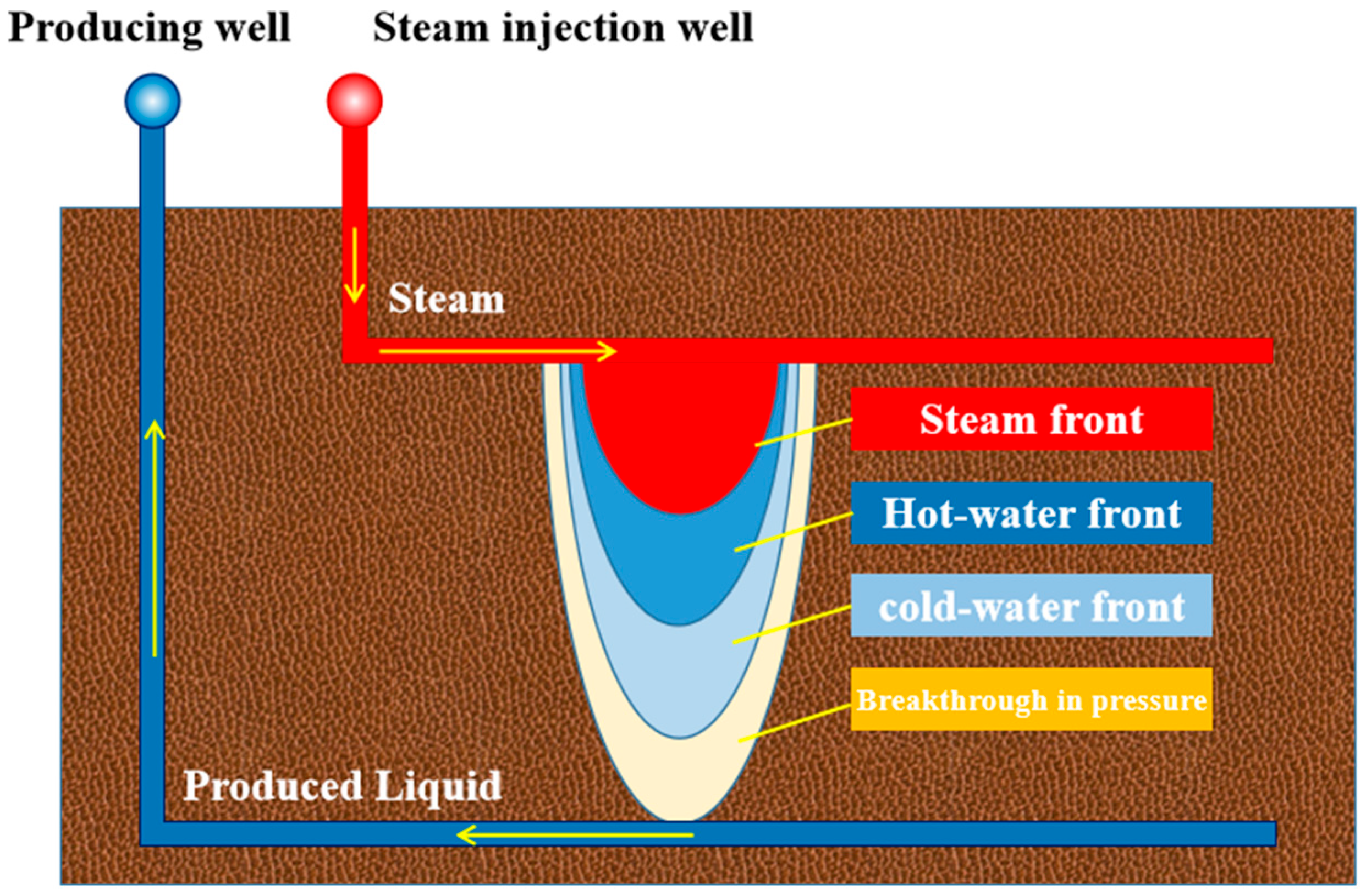

3. Causes Analysis and Control Technologies of Steam Channeling

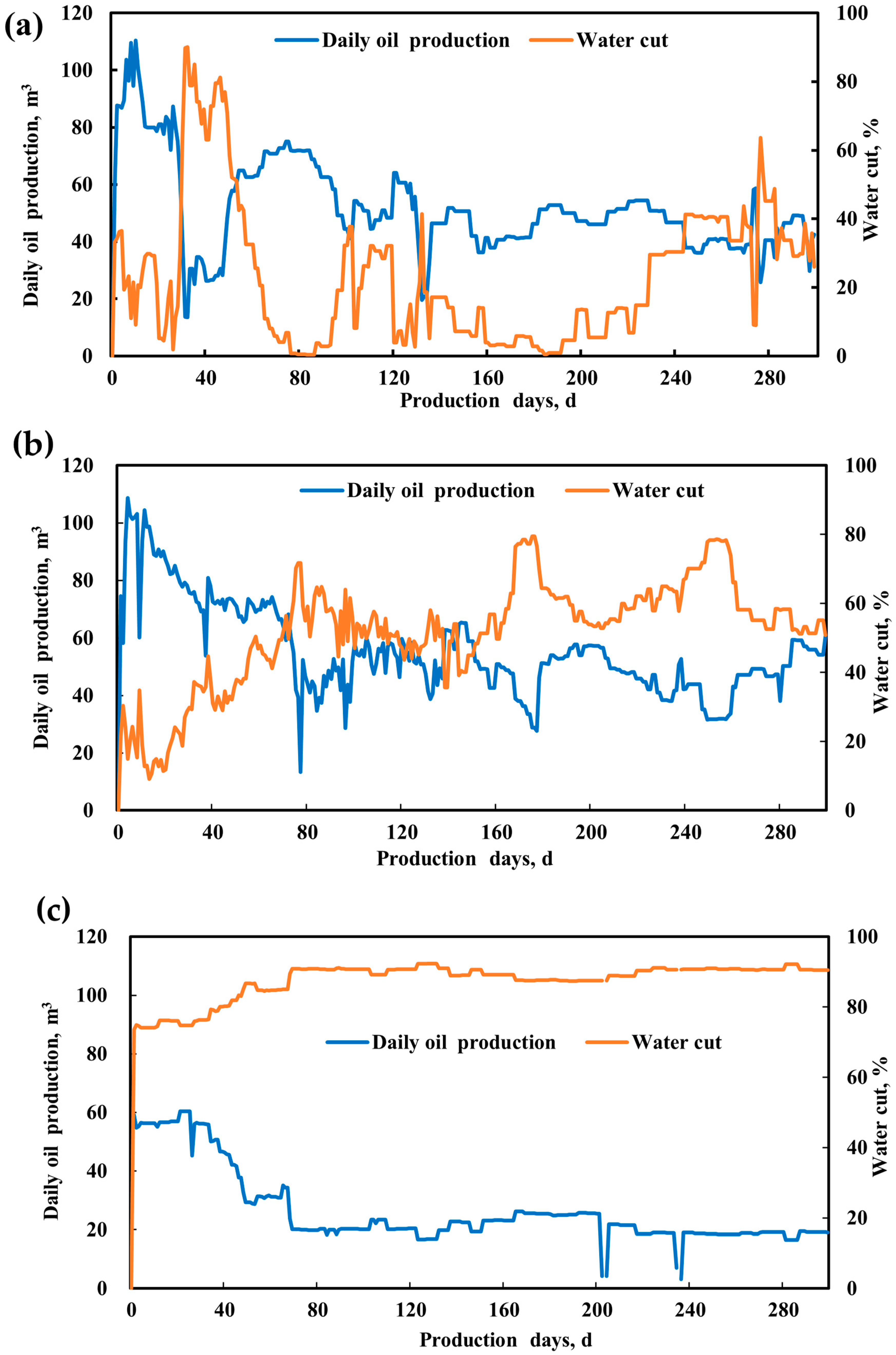

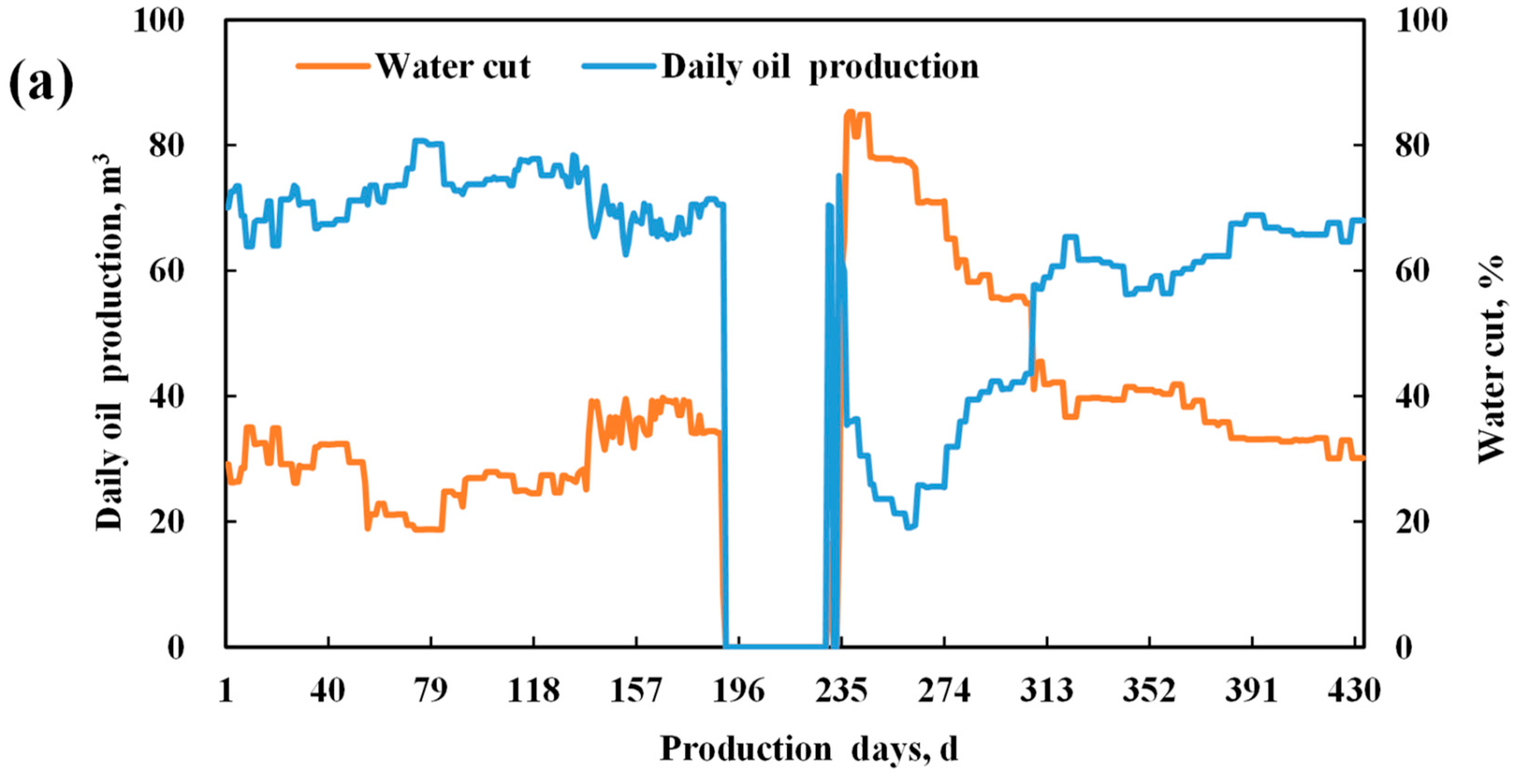

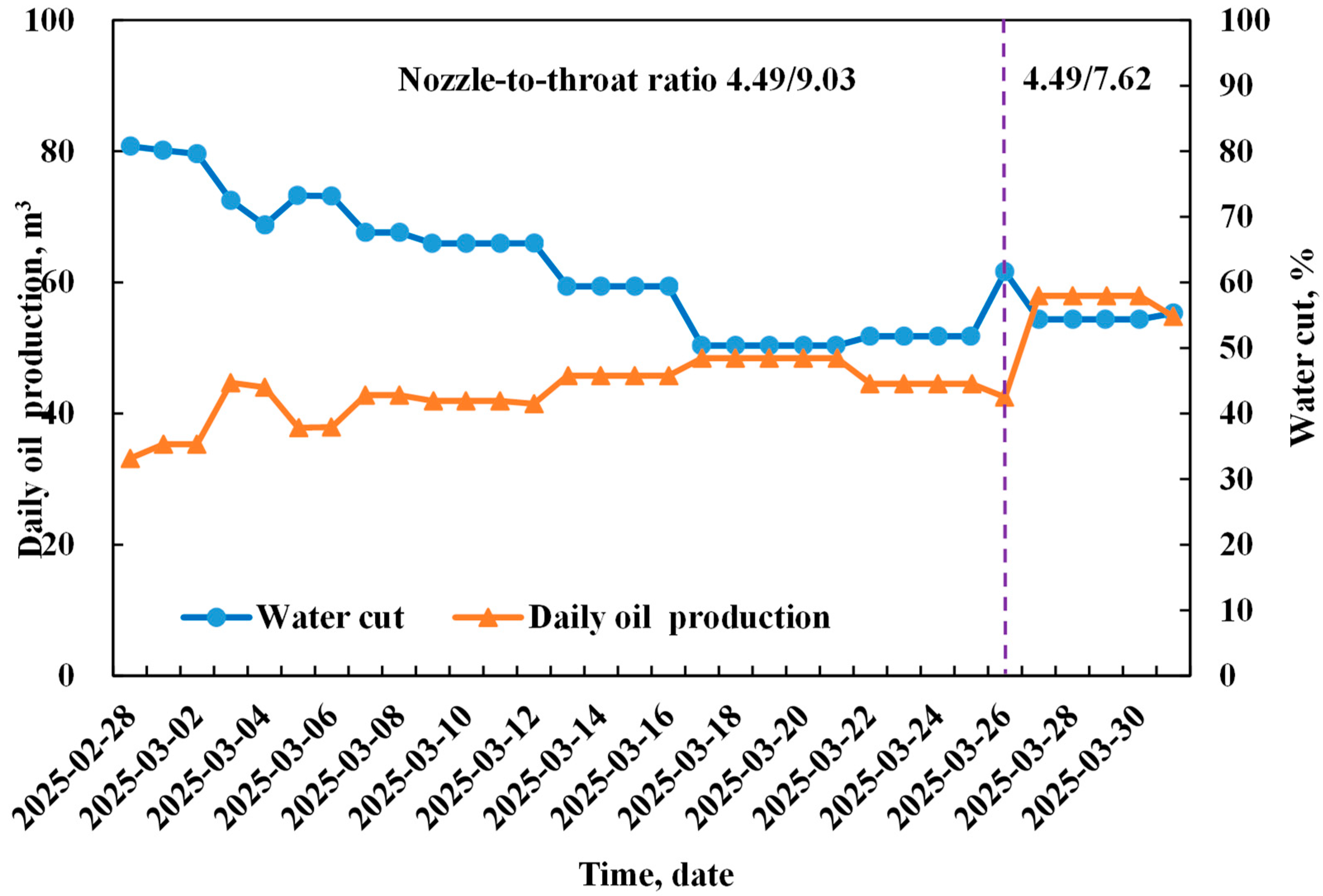

3.1. Analysis of Steam Channeling Situation

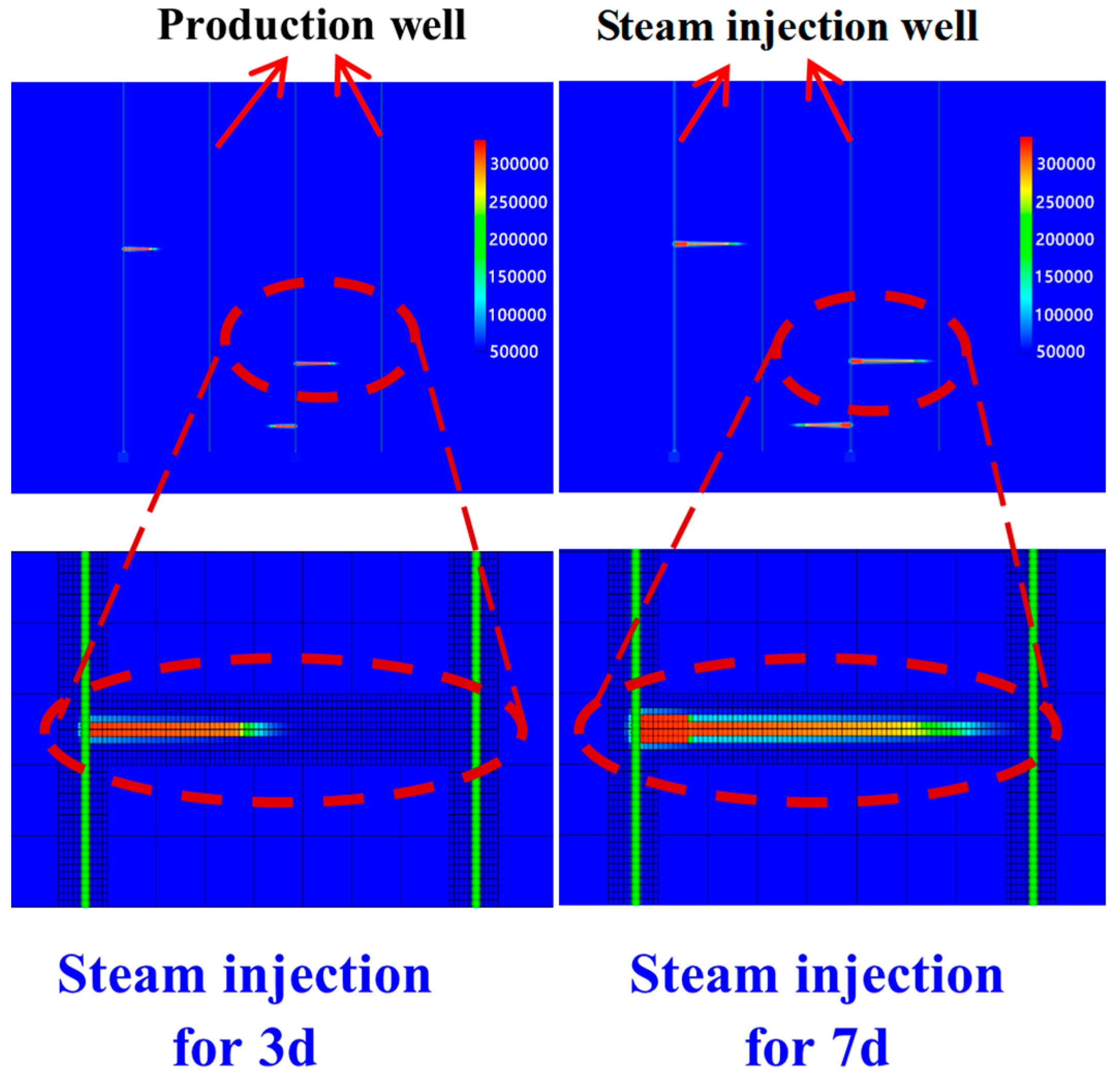

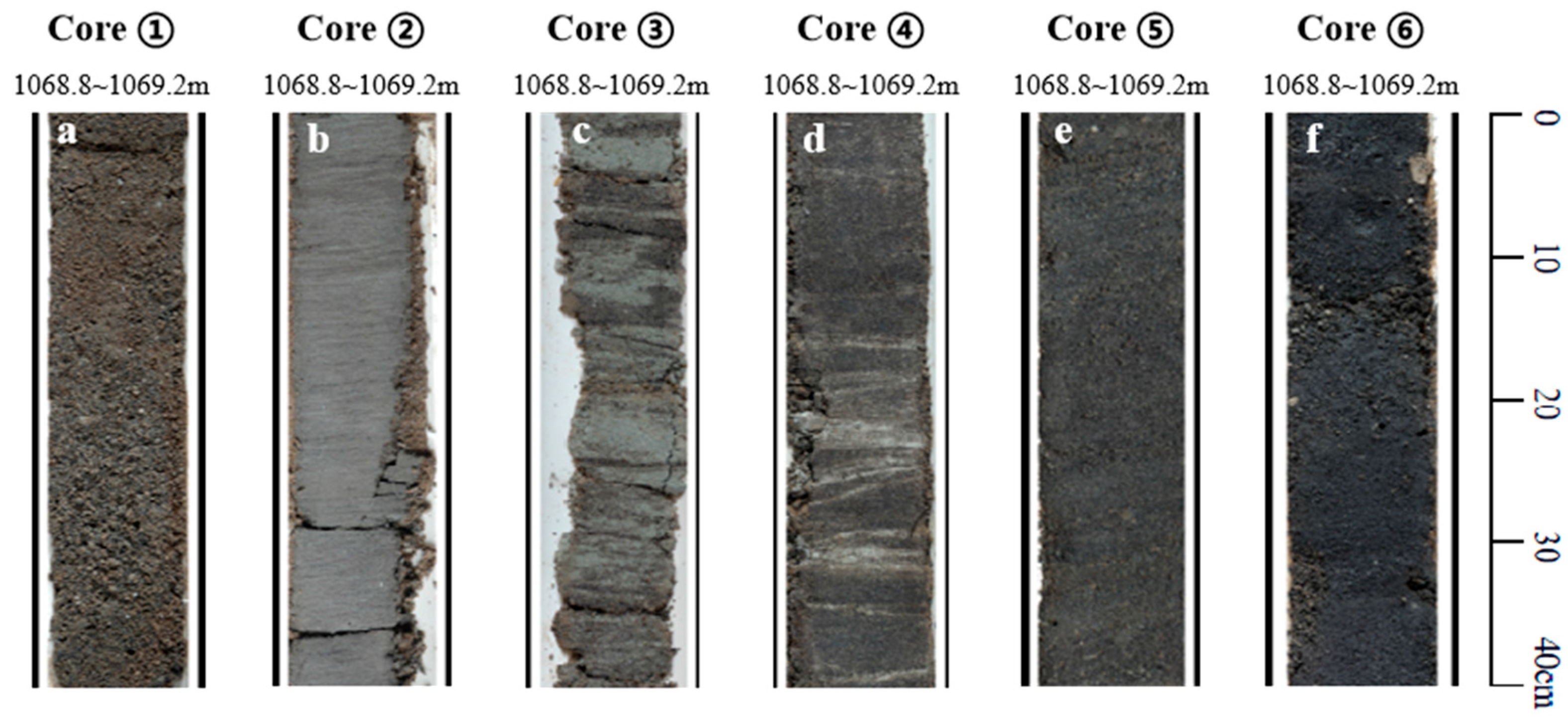

3.2. Reasons for Steam Channeling

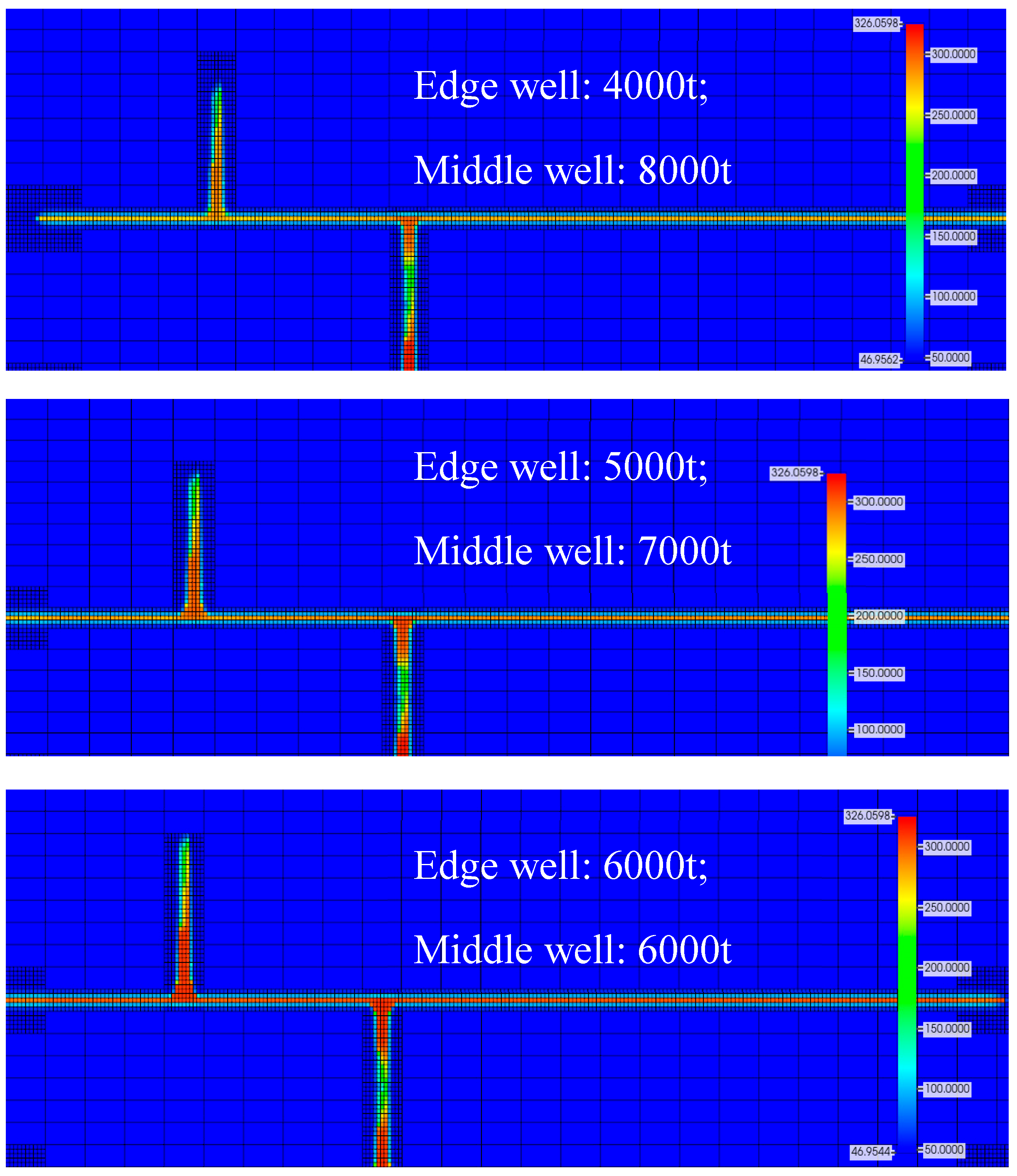

3.3. Steam Channeling Control Technologies

4. Causes Analysis and Control Technologies of Steam Channeling and High Water Cut

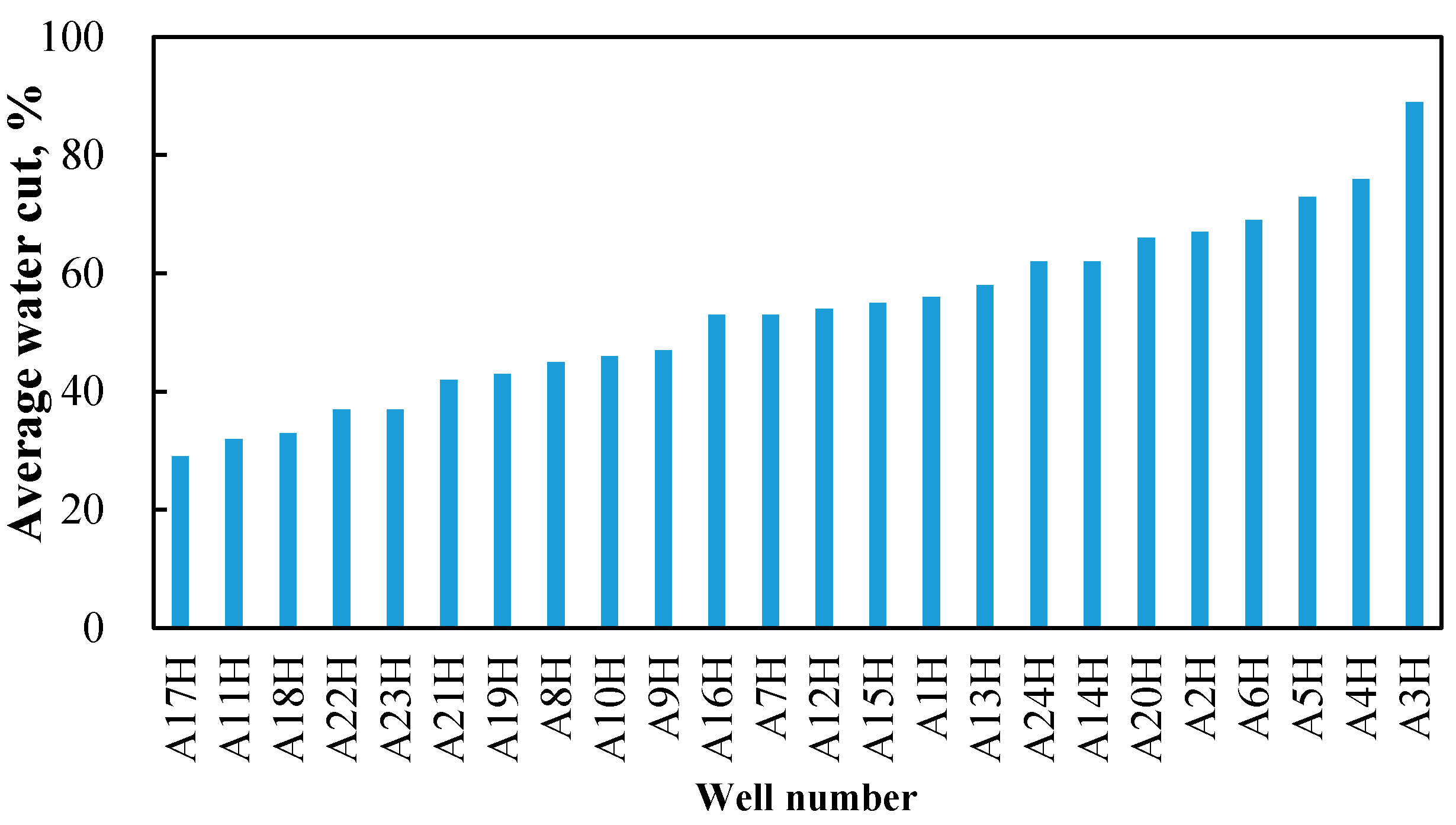

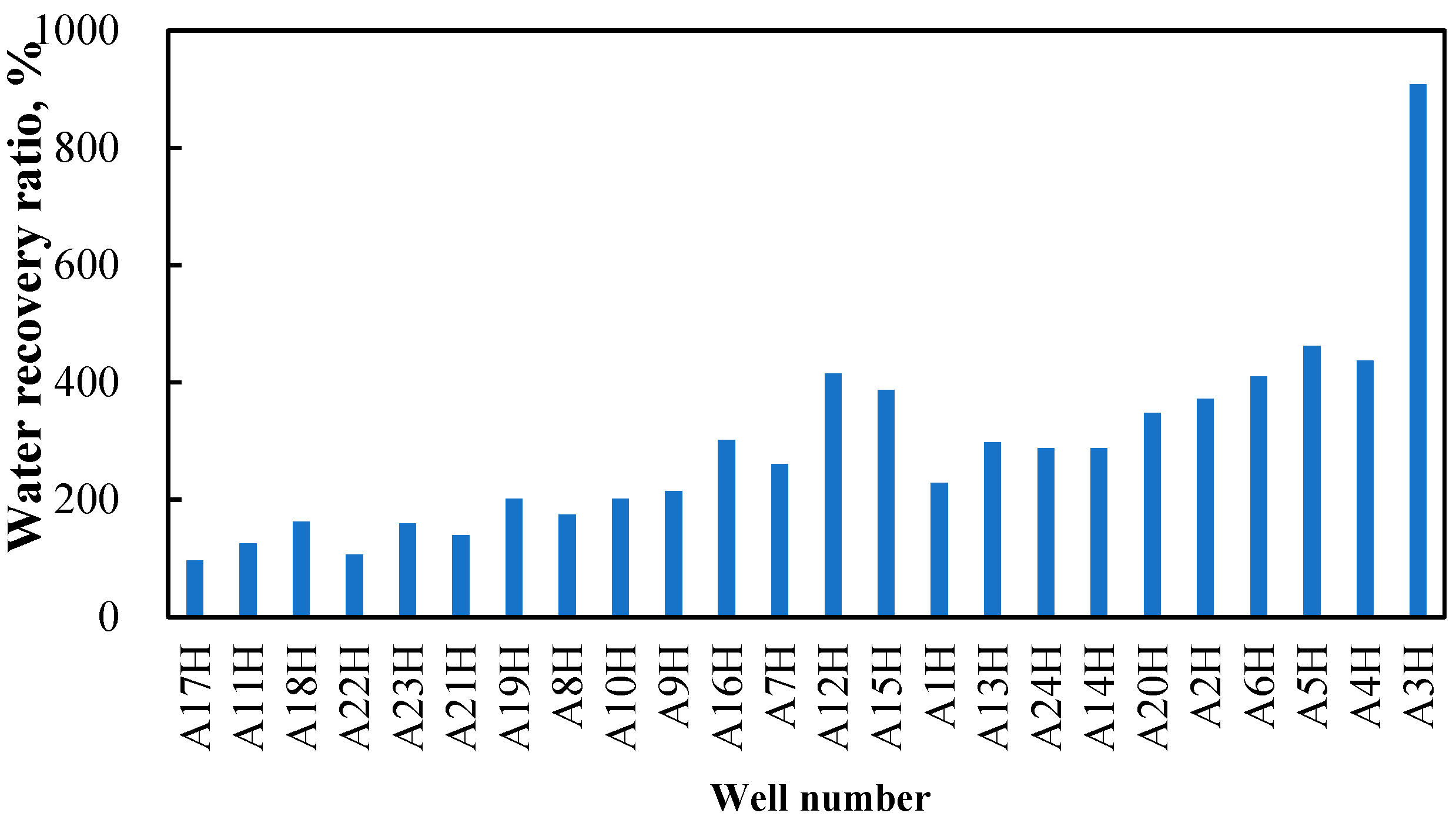

4.1. Analysis of High Water Cut Situation

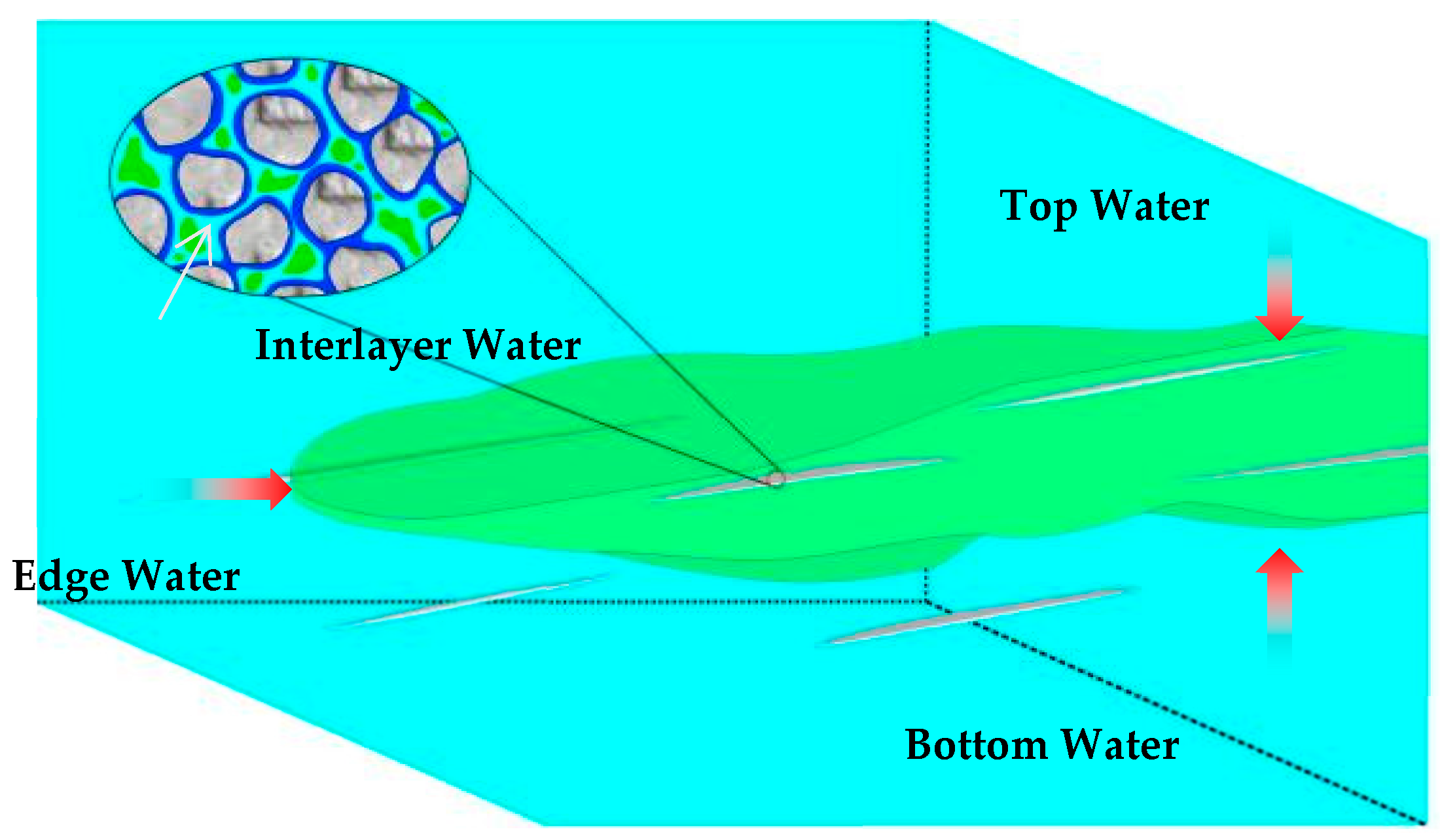

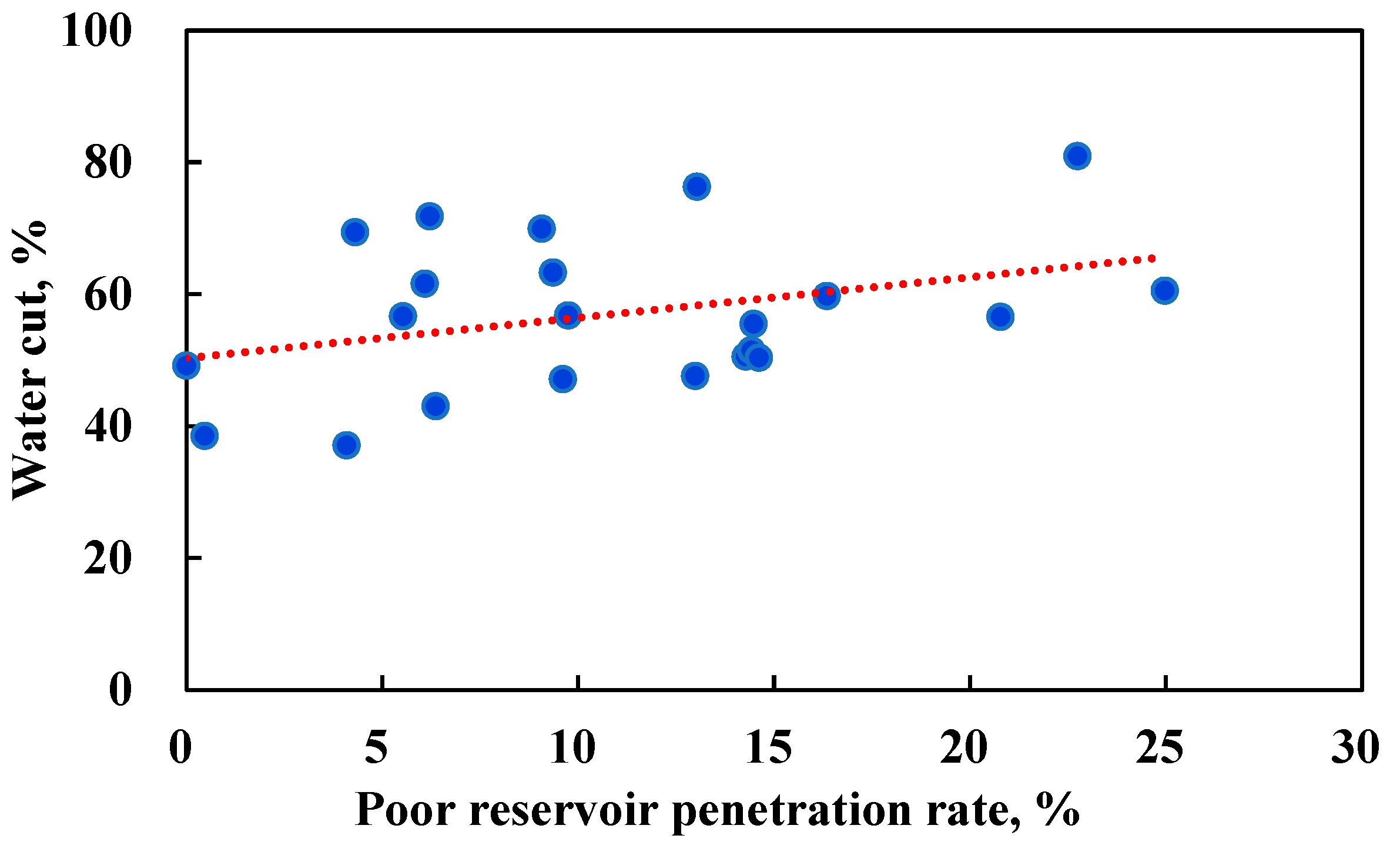

4.2. Reasons for High Water Cut

4.3. High Water Cut Treatment Technology

4.4. Production Strategy Adjustment

5. Overall Development Status of the Oilfield

6. Conclusions

- (1)

- To tackle the challenges of inter-well steam channeling, high water cut, and a high water recovery ratio encountered during the first cycle of steam stimulation in the N extra-heavy oil field, a detailed reservoir characterization was carried out. This comprehensive analysis confirmed that low-quality reservoirs are the main flow paths for steam and water channeling.

- (2)

- To address the above challenges, an integrated efficiency-improving technology system was developed based on three technical pillars: regional steam injection for channeling control, graded water control and plugging, and production system optimization. Based on reservoir penetration rate and aquifer influence degree, three differentiated chemical plugging strategies were developed: high-temperature N2 foam profile control for wells with reservoir penetration rate > 95% and weak water invasion; high-temperature degradable gel water control for wells with reservoir penetration rate 80–95% and near-edge water; and ultrafine cement plugging for wells with reservoir penetration rate < 80% and severe water invasion (water cut > 100%), realizing precise governance of wells with different water invasion types. The deployment of dynamic tubing strings in offshore thermal recovery wells entails relatively high costs. Therefore, chemical agents are typically injected through the original well tubing during the plugging and profile control operations of oil wells. These agents primarily rely on natural selectivity to penetrate the high-water-cut preferential channels; however, the injection accuracy of chemical agents into high-water-cut reservoir zones requires further enhancement, for instance, by adopting fixed-point injection tubing strings.

- (3)

- Field applications included regional steam injection in 10 well groups, water control operations in 12 wells, and production optimization in 5 wells. Post-treatment, the average water cut per well was reduced by 10%. This study offers essential technical guidance for advancing the large-scale and high-efficiency development of extra-heavy oil reservoirs in the Bohai Oilfield.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, W. Current Status of Heavy Oil Development Technologies in Canada and Application Considerations for New Technologies in Bohai Sea, China. China Offshore Oil Gas (Eng.) 2006, 18, 123–125. [Google Scholar] [CrossRef]

- Rosa, M.B.; Cavalcante, J.S.A.; Miyakawa, T.M.; de Freitas, L.C.S. The Giant Lula Field: World’s Largest Oil Production in Ultra-Deep Water Under a Fast-Track Development. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar] [CrossRef]

- Sun, H.; Wang, H.; Cao, X.; Shu, Q.; Fan, Z.; Wu, G.; Yang, Y.; Wu, Y. Innovations and Applications of the Thermal Recovery Techniques for Heavy Oil. Energy Geosci. 2024, 5, 100332. [Google Scholar] [CrossRef]

- Cai, H.; Zou, J. Technical challenges, current situation, and prospects of thermal recovery of heavy oil in Bohai Oilfield. China Offshore Oil Gas 2024, 36, 157–169. [Google Scholar]

- Zhu, G.; Wang, X. Horizontal steam flooding pilot test for thin shallow super heavy oil of Chunfeng Oilfield in Junggar basin, Junggar Basin. Sci. Technol. Rev. 2014, 32, 55–60. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Y.; Shen, D.; Nie, L.; Li, X. Physical modeling experiments on steam nitrogen foam flooding for a vertical and horizontal well combination. Acta Pet. Sin. 2012, 33, 90–95. [Google Scholar] [CrossRef]

- Zhang, J.; Song, H.; Zhang, W.; Rong, K.; Li, Y.; Pan, Y. Profile control technique for steam channeling challenge in small well spacing huff-and-puff in offshore ultra heavy oil reservoirs. Oil Drill. Prod. Technol. 2024, 46, 199–266. [Google Scholar] [CrossRef]

- Ma, L.; Peng, Y.; Wang, J.; Gao, Y.; Pu, C.; Wen, L. Characterization and treatment of steam channeling after multiple cycles of huff and puff in heavy oil L reservoir. Pet. Geol. Eng. 2024, 38, 53–63. [Google Scholar] [CrossRef]

- Lin, S.; Sun, Y.; Zhang, W.; Mei, W.; Ji, H.; Tong, C.; Liu, C. Theoretical research and application of staged steam injection for horizontal wells in offshore oilfields. Petrochem. Ind. Appl. 2023, 42, 47–50. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, W.; Han, X.; Zhao, Y.; Wang, Q.; Wang, Z. Research and application of enhanced nitrogen foam water control technology for offshore super heavy oil thermal recovery. Spec. Petrochem. 2025, 42, 31–34. [Google Scholar] [CrossRef]

- Qin, H. Exploration and practice in fine development of ultra heavy oil reservoir. Adv. Fine Petrochem. 2025, 26, 12–16. [Google Scholar] [CrossRef]

- Mohammadi, S.; Berg, C.F.; Schümann, H. The Potential of Subsea Water Separation and Treatment for Efficient Offshore Operations. Energy Fuels 2025, 39, 20104–20128. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, H.; Xu, Z.; Zhang, X.; Wang, T.; Liu, H.; Ma, X.; Zhu, J.; Zhang, X.; Kang, W. Development and evaluation of organic/metal ion double crosslinking polymer gel for anti-CO2 gas channeling in high temperature and low permeability reservoirs. Pet. Sci. 2025, 22, 724–738. [Google Scholar] [CrossRef]

- Gu, Z.; Zhang, C.; Li, P.; Li, Z.; Wang, M.; Li, Z. CO2-induced in-situ targeted precipitation of asphaltene in heavy oil reservoirs: Balancing Formation Gas Channeling Regulation and Wellbore Asphaltene Blockage Prevention. SPE J. 2024, 29, 6138–6154. [Google Scholar] [CrossRef]

- Xu, W.; Yang, H.; Xie, C.; Zhang, H.; Xu, Y.; Zhang, J. Development technology and application of heavy oil thermal recovery in Bohai oilfield. Petrochem. Ind. Appl. 2024, 43, 34–53. [Google Scholar] [CrossRef]

- Sun, Q.; Li, Z.; Li, S.; Jiang, L.; Wang, J.; Wang, P. Utilization of surfactant-stabilized foam for enhanced oil recovery by adding nanoparticles. Energy Fuels 2014, 28, 2384–2394. [Google Scholar] [CrossRef]

- White, A.J.; Hounslow, M.J. Modelling droplet size distributions in polydispersed wet-steam flows. Int. J. Heat Mass Transf. 2000, 43, 1873–1884. [Google Scholar] [CrossRef]

- Gu, Z.H.; Zhang, C.; Lu, T.; Wang, H.Y.; Li, Z.M.; Wang, H.T. Experimental analysis of the stimulation mechanism of CO2-assisted steam flooding in ultra-heavy oil reservoirs and its significance in carbon sequestration. Fuel 2023, 345, 128188. [Google Scholar] [CrossRef]

- Bera, A.; Babadagli, T. Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: A review. Appl. Energy 2015, 151, 206–226. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, D.; Zhang, Z.; Wang, S.; Wang, Q.; Xia, D. Steam channeling control in the steam flooding of super heavy oil reservoirs, Shengli Oilfield. Pet. Explor. Dev. 2012, 39, 785–790. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.F.; Lun, Z.M.; Gu, Z.H.; Li, Z.M. Unveiling the beneficial effects of N2 as a CO2 impurity on fluid-rock reactions during carbon sequestration in carbonate reservoir aquifers: Challenging the notion of purer is always better. Environ. Sci. Technol. 2024, 58, 22980–22991. [Google Scholar] [CrossRef]

- Chai, M.J.; Nourozieh, H.; Chen, Z.X.; Yang, M. A technical, economic, and environmental assessment on dimethyl ether (DME) as a renewable solvent from carbon dioxide utilization for heavy oil recovery. Chem. Eng. J. 2024, 482, 148936. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–11211. [Google Scholar] [CrossRef]

- Jamshid-Nezhad, M. Steam alternating non-condensable gas injection for more heavy oil recovery. Energy 2022, 240, 122476. [Google Scholar] [CrossRef]

- Zhou, W.; Xin, C.; Chen, S.; Yu, Q.; Wang, K. Polymer-Enhanced Foam Flooding for Improving Heavy Oil Recovery in Thin Reservoirs. Energy Fuels 2020, 34, 4116–4128. [Google Scholar] [CrossRef]

- Yang, Y.; Lyu, C.; Shi, L.; Hu, C.; Zhu, Y.; Hou, J.; Yu, H.; Zhang, Y. A Mini-Review of the Solvent Steam Co-Injection Process: Solvent Selection Criterion and Phase Behavior. Energy Fuels 2025, 39, 8391–8406. [Google Scholar] [CrossRef]

- Nishi, Y.; Iwashita, N.; Sawada, Y.; Inagaki, M. Sorption kinetics of heavy oil into porous carbons. Water Res. 2002, 36, 5029–5036. [Google Scholar] [CrossRef] [PubMed]

- Pang, Z.X.; Wang, L.T.; Yin, F.H.; Lyu, X.C. Steam chamber expanding processes and bottom water invading characteristics during steam flooding in heavy oil reservoirs. Energy 2021, 234, 121214. [Google Scholar] [CrossRef]

- Dong, X.H.; Jiang, X.C.; Zheng, W.; Liu, H.Q.; Liu, R.J.; Wang, W.C.; Zeng, D.S.; Wang, T.C. Discussion on the sweep efficiency of hybrid steam−chemical process in heavy oil reservoirs: An experimental study. Pet. Sci. 2022, 19, 2905–2921. [Google Scholar] [CrossRef]

- Gu, Z.; Li, Z.; Xu, Z.; Lu, C.; Liu, C.; Jiang, Y.; Lu, T. Experimental investigation on microscopic force measurement of foam and heavy oil. Langmuir 2021, 36, 14748–14762. [Google Scholar] [CrossRef]

- Sun, X.; Hou, L.; Tang, S.; Wang, M.; Xiong, Y.; Zhu, Z. Removal mechanism of adhering heavy oil from pipeline wall in low-temperature flow. Energy 2024, 296, 131118. [Google Scholar] [CrossRef]

- Xi, C.; Qi, Z.; Zhang, Y.; Liu, T.; Shen, D.; Mu, H.; Dong, H.; Li, X.; Jiang, Y.; Wang, H. CO2 assisted steam flooding in late steam flooding in heavy oil reservoirs. Pet. Explor. Dev. 2019, 46, 1242–1250. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.; Rui, Z.; Wang, H.; Feng, J.; Zhang, L.; Zeng, F. Feasibility study of CO2 huff ‘n’ puff process to enhance heavy oil recovery via long core experiments. Appl. Energy 2019, 236, 526–539. [Google Scholar] [CrossRef]

- Zhang, J. Performance of high temperature steam injection in horizontal wells of heavy oil reservoirs. Energy 2023, 282, 128863. [Google Scholar] [CrossRef]

- Sun, X.; Jia, Z.; Zhao, Y.; Sun, X.; Yu, G. CO2 mass transfer in SiO2 nanoparticle-enhanced carbonated water/heavy oil systems under reservoir conditions. Chem. Eng. J. 2025, 521, 166838. [Google Scholar] [CrossRef]

- Gu, Z.; Li, Z.; Xu, Z.; Zhang, C. Microscopic mechanical model analysis and visualization investigation of SiO2 nanoparticle/HPAM polymer foam liquid film displacing heavy oil. Langmuir 2022, 38, 9166–9185. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Li, Y.; Liu, Y.; Li, A.; Chen, D.; Chen, L. A numerical simulation method for cyclic steam stimulation development of heavy oil reservoirs with multi-layer radial horizontal wells. Processes 2025, 13, 3694. [Google Scholar] [CrossRef]

- García-Maza, S.; Rojas-Flores, S.; González-Delgado, A.D. Impact of mass integration on the technoeconomic performance of the gas oil hydrocracking process in Latin America. Processes 2025, 13, 3681. [Google Scholar] [CrossRef]

- Hu, J.; Yang, J.; Wang, P.; Gu, X.; Chen, G. Improvement of the fluidity of heavy oil using a composite viscosity reducer. Processes 2025, 13, 3547. [Google Scholar] [CrossRef]

- Zuo, M.; Chen, H.; Qi, X.; Liu, X.; Xu, C.; Yu, H.; Brahim, M.S.; Wu, Y.; Liu, H. Effects of CO2 injection volume and formation of in-situ new phase on oil phase behavior during CO2 injection for enhanced oil recovery in tight oil reservoirs. Chem. Eng. J. 2022, 452, 139454. [Google Scholar] [CrossRef]

- Liu, Y.L.; Zhang, C.; Li, S.Y.; Li, Z.M. Study of Steam Heat Transfer Enhanced by CO2 and Chemical Agents: In Heavy Oil Production. Pet. Sci. 2023, 20, 1030–1043. [Google Scholar] [CrossRef]

- Li, B.; Li, B.; Zang, Y.; Zhu, D.; Li, Z.; Ruan, L. Experimental Study of the Distillation Mechanism during Coinjection of Flue Gas and Steam for Heavy Oil Development. Sep. Purif. Technol. 2023, 324, 124553. [Google Scholar] [CrossRef]

- Kasala, E.E.; Wang, J.; Majid, A.; Nadege, M.N.; Nyakilla, E.E. Advancement Perspectives in Enhancing Heavy Oil Recovery Using N2- and CO2-Assisted Steam Injection: Exploring Molecular Interactions to Field Applications. Energy Fuels 2025, 39, 10200–10244. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Y.; Gu, Z.; Li, P.; Li, Z.; Zhang, K. Chemicals-CO2 Mechanisms of Inhibiting Steam Heat Transfer and Enhancing Oil Film Strip: Steam Flow through the Wall-Adhering Oil Film Surface in Porous Medium. Fuel 2024, 356, 129572. [Google Scholar] [CrossRef]

| Order | Oil Well (Injection Well→Production Well) | Temperature Variation Impact Duration (d) | Water Cut Variation Impact Duration (d) | Daily Oil Production (t·d−1) | |

|---|---|---|---|---|---|

| Before Steam Channeling | During Steam Channeling | ||||

| 1 | A18H→A19H | 23 | 36 | 100 | 8 |

| 2 | A22H→A23H | 45 | 42 | 70 | 17 |

| 3 | A26H→A17H | 59 | 51 | 82 | 26 |

| 4 | A13H→A12H | 43 | 38 | 51 | 28 |

| 5 | A11H→A12H | 60 | 37 | 44 | 32 |

| 6 | A10H→A9H | 23 | 23 | 91 | 84 |

| 7 | A10H→A11H | 26 | 31 | 71 | 47 |

| 8 | A3H→A4H | 21 | 24 | 50 | 33 |

| 9 | A11H→A10H | 80 | 70 | 55 | 31 |

| 10 | A4H→A5H | 75 | 81 | 37 | 53 |

| 11 | A16H→A45H | 21 | 38 | 39 | 49 |

| Classification | Target Formation | Water Production Mechanism | Thermal Injection Optimization | Production Regime Adjustment | Chemical Control Method |

|---|---|---|---|---|---|

| Type I | Guantao formation | Condensate and inferior-zone water | Adhere to the ODP-based steam injection scheme, progressively increasing the steam volume by 10% per cycle | Moderate liquid rate increase | Multi-stage slug injection of high-temperature N2 foam for profile control |

| Type II | Guantao formation (Type II-a) | Condensate and inferior-zone water (with significant contribution from the latter) | Explore an appropriately elevated steam injection intensity, with a 20% incremental rate per cycle | Feasibility of aggressively increasing | High-temperature resistant, high-strength gel for water control |

| Mingxia formation (Type II-b) | Condensate and inferior-zone water (with potential hydraulic connection to the aquifer) | Investigate a “Less Steam, More Cycles” pattern to delay communication with edge water | Moderate liquid rate control | ||

| Type III | Mingxia formation | Botto and edge water breakthrough | Cement Plugging |

| Target Well | Plugging Agent Type | Injection Parameters | Testing Method |

|---|---|---|---|

| Type I | Nitrogen Foam | Injection rate: 10 t/h; surface foaming; gas–liquid ratio: 1:1; average injection volume: 500 m3; concentration: 5% | Compare key parameters (e.g., cumulative oil production in the same period and cyclic oil/steam ratio) of the oil well before and after plugging |

| Type II | Inorganic Gel | Injection rate: 6 t/h; concentration: 20%; injection volume: 300 m3 | Compare key indicators (e.g., steam injection pressure and steam injection rate) of the oil well before and after plugging |

| Type III | Ultrafine Cement | Injection rate: 6 t/h; plugging radius: 0.1 m; plugging dosage: designed based on plugging length | Compare key parameters (e.g., water cut) of the oil well before and after plugging |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhang, C.; Bai, J.; Zheng, X.; Zhang, W.; Zhang, C. Comprehensive Strategy for Effective Exploitation of Offshore Extra-Heavy Oilfields with Cyclic Steam Stimulation. Processes 2026, 14, 359. https://doi.org/10.3390/pr14020359

Zhang C, Bai J, Zheng X, Zhang W, Zhang C. Comprehensive Strategy for Effective Exploitation of Offshore Extra-Heavy Oilfields with Cyclic Steam Stimulation. Processes. 2026; 14(2):359. https://doi.org/10.3390/pr14020359

Chicago/Turabian StyleZhang, Chunsheng, Jianhua Bai, Xu Zheng, Wei Zhang, and Chao Zhang. 2026. "Comprehensive Strategy for Effective Exploitation of Offshore Extra-Heavy Oilfields with Cyclic Steam Stimulation" Processes 14, no. 2: 359. https://doi.org/10.3390/pr14020359

APA StyleZhang, C., Bai, J., Zheng, X., Zhang, W., & Zhang, C. (2026). Comprehensive Strategy for Effective Exploitation of Offshore Extra-Heavy Oilfields with Cyclic Steam Stimulation. Processes, 14(2), 359. https://doi.org/10.3390/pr14020359