Practical Approach for Formation Damage Control in CO2 Gas Flooding in Asphaltenic Crude Systems

Abstract

1. Background

Research Contribution and Novelty

2. Literature Review

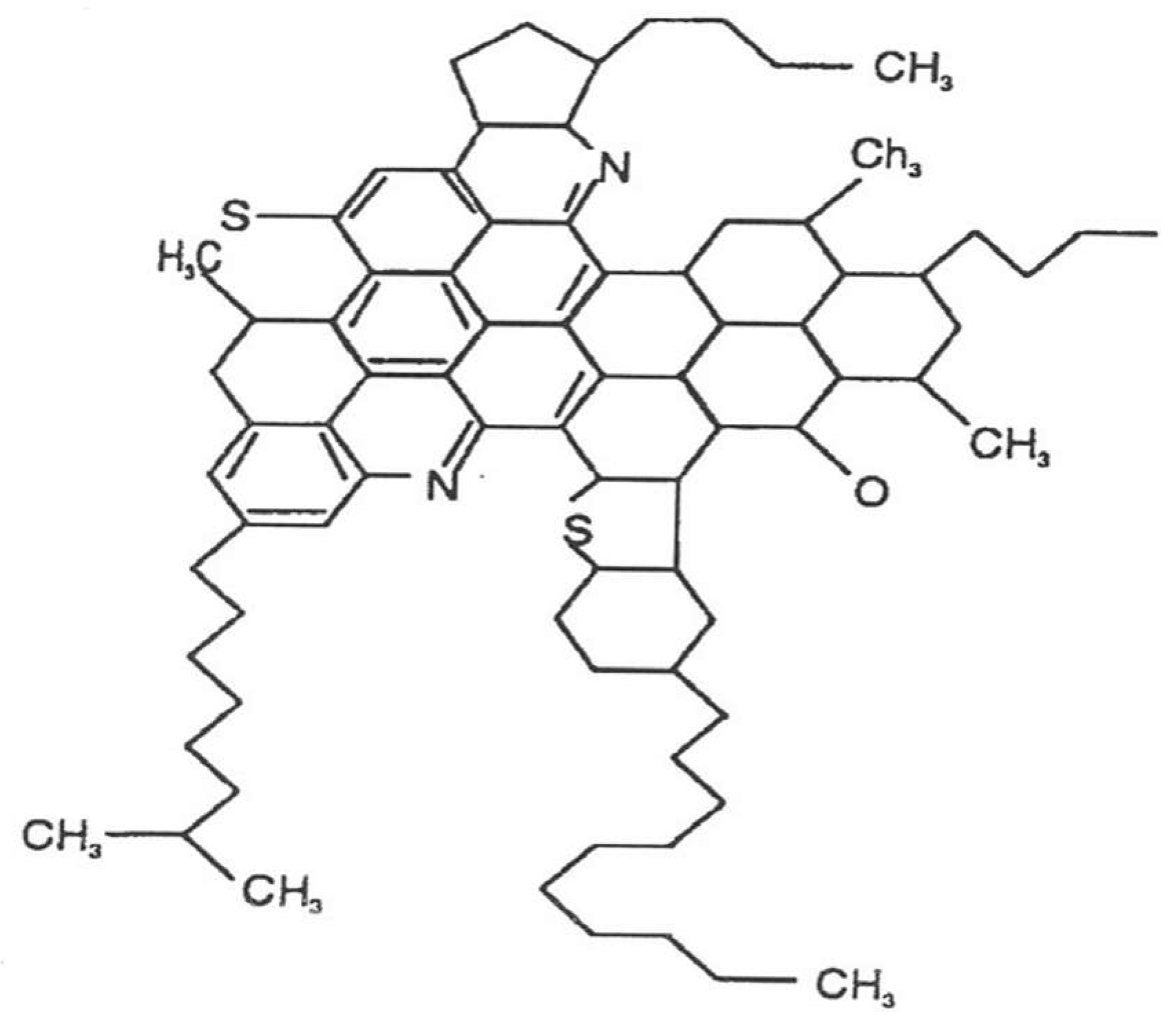

2.1. Asphaltene

2.2. Mechanisms of CO2 Miscible Flooding in Enhanced Oil Recovery

2.3. Multi-Contact Miscibility

3. Methodology

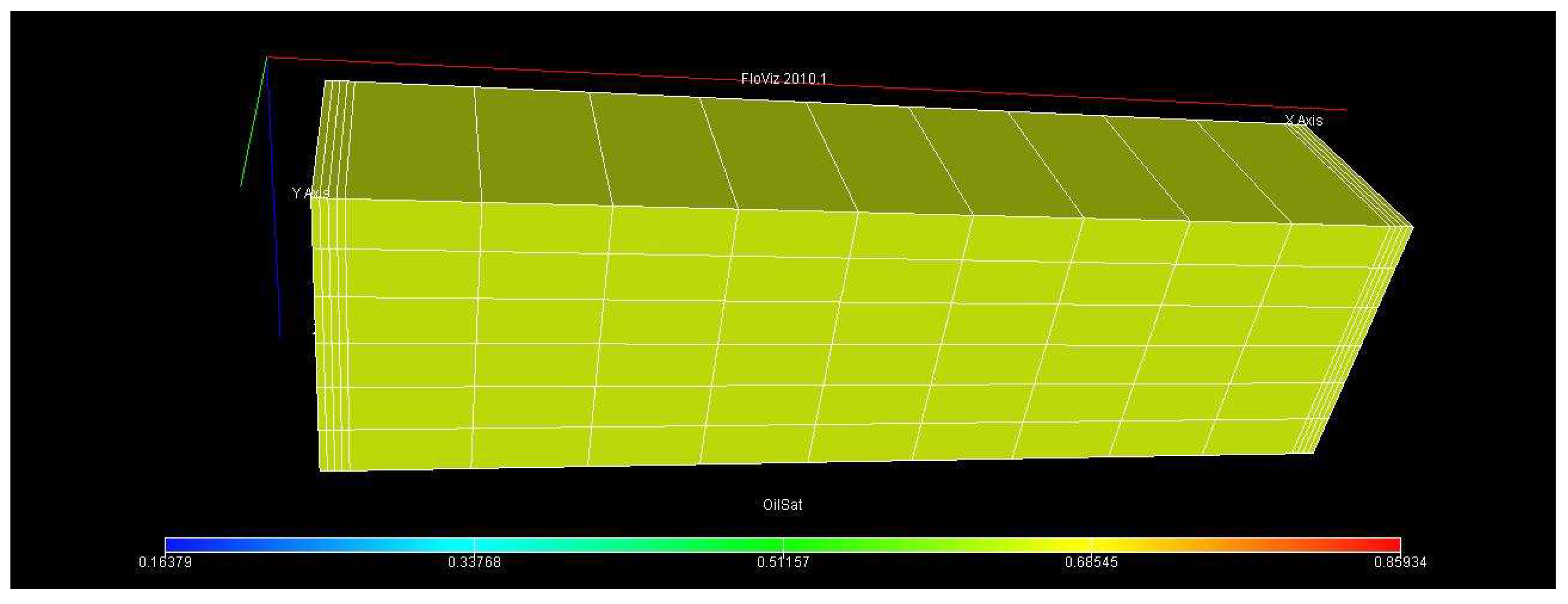

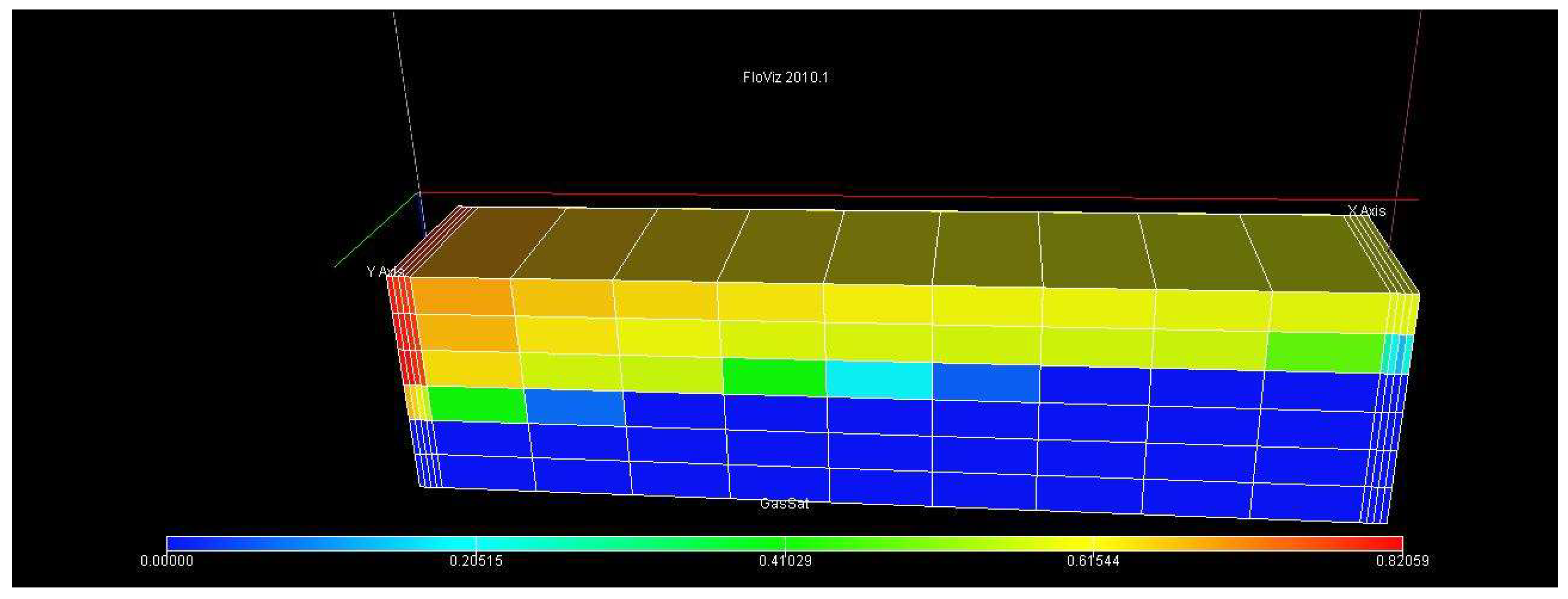

3.1. System Model and Simulation

3.1.1. Governing Equations and Model Assumptions

3.1.2. Application of the Generalized Einstein Model in Simulations

- -

- μ = apparent viscosity of the crude oil containing precipitated asphaltenes,

- -

- μ0 = viscosity of the clean base oil,

- -

- k = intrinsic viscosity factor (dimensionless, tuned during calibration),

- -

- φ = local volumetric fraction of precipitated asphaltenes in the pore space.

3.1.3. Model Calibration and Validation

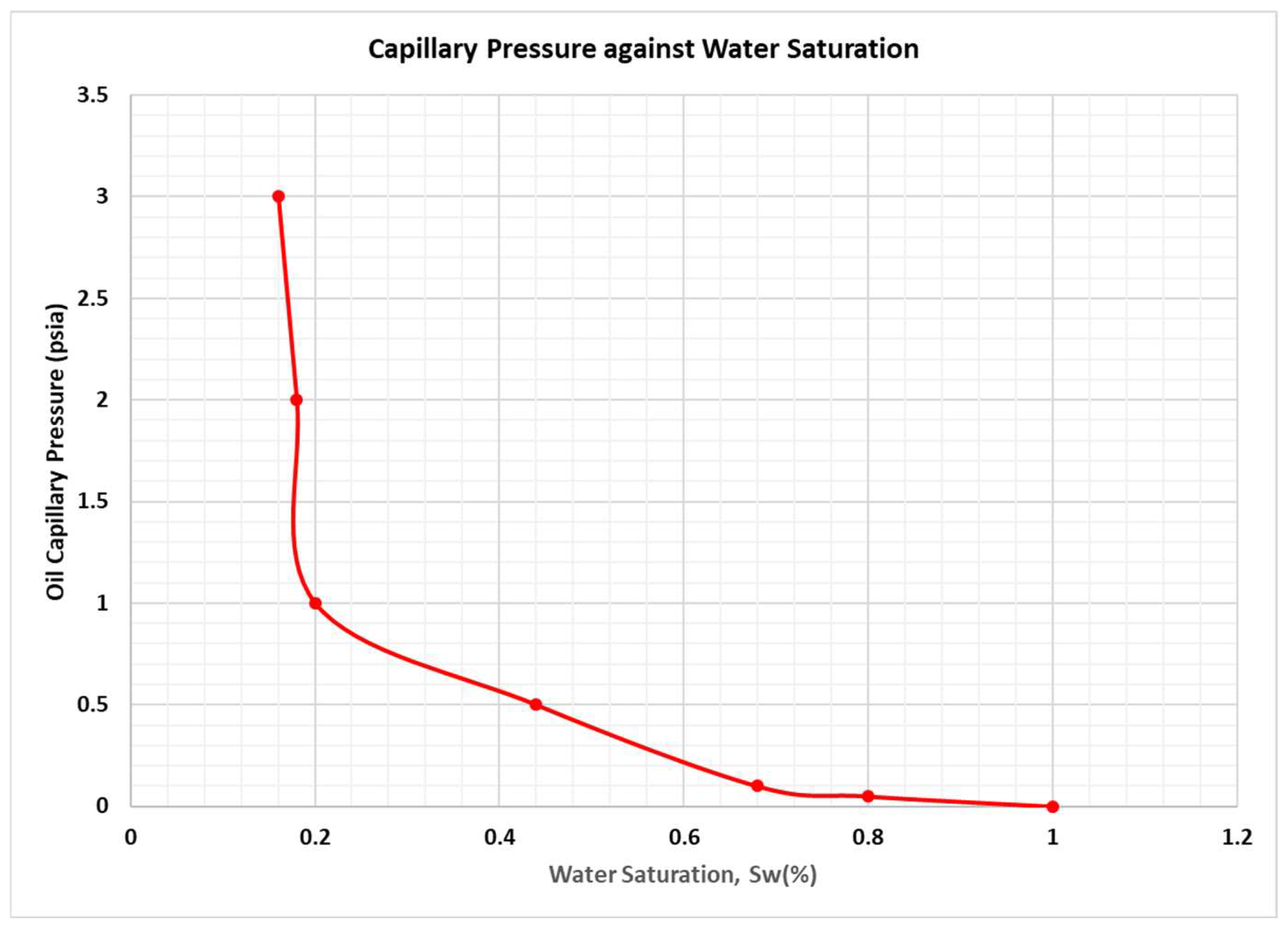

3.2. Reservoir Model

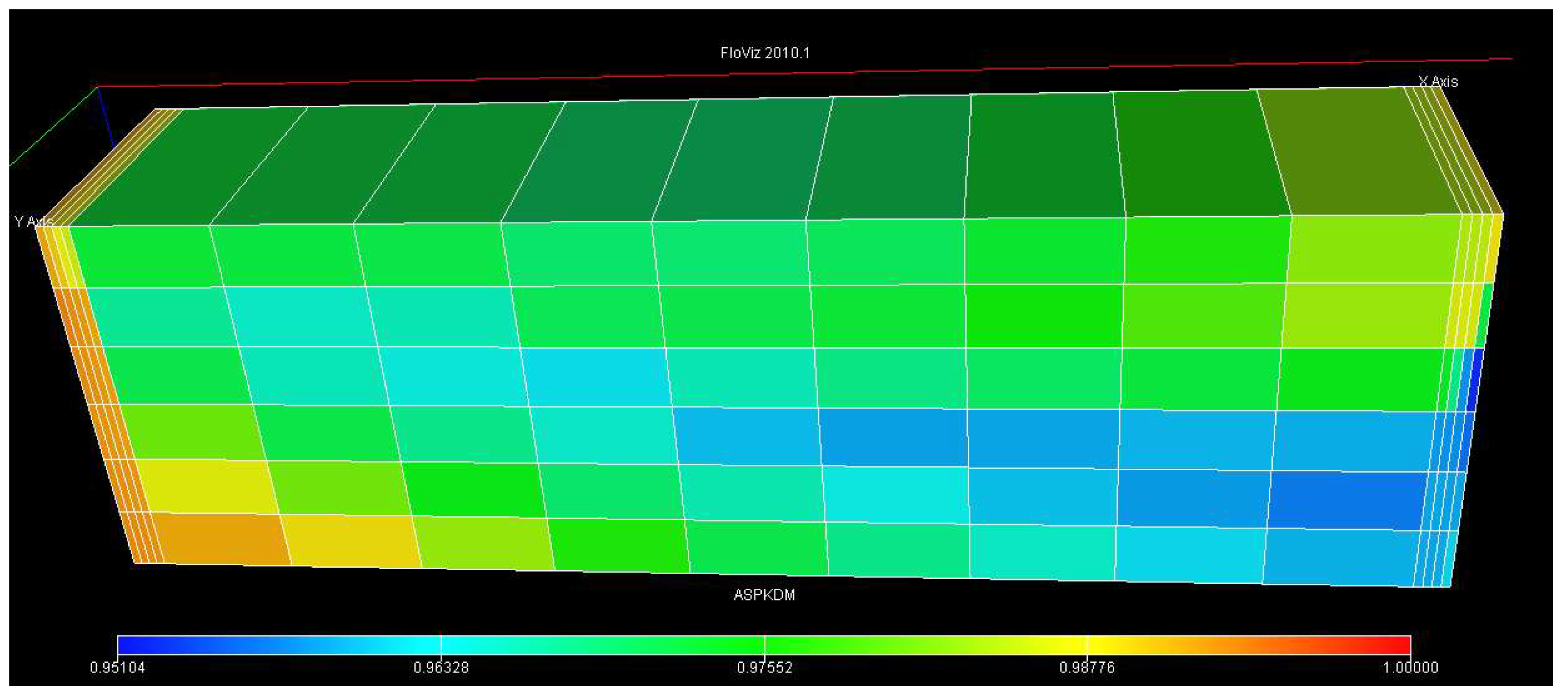

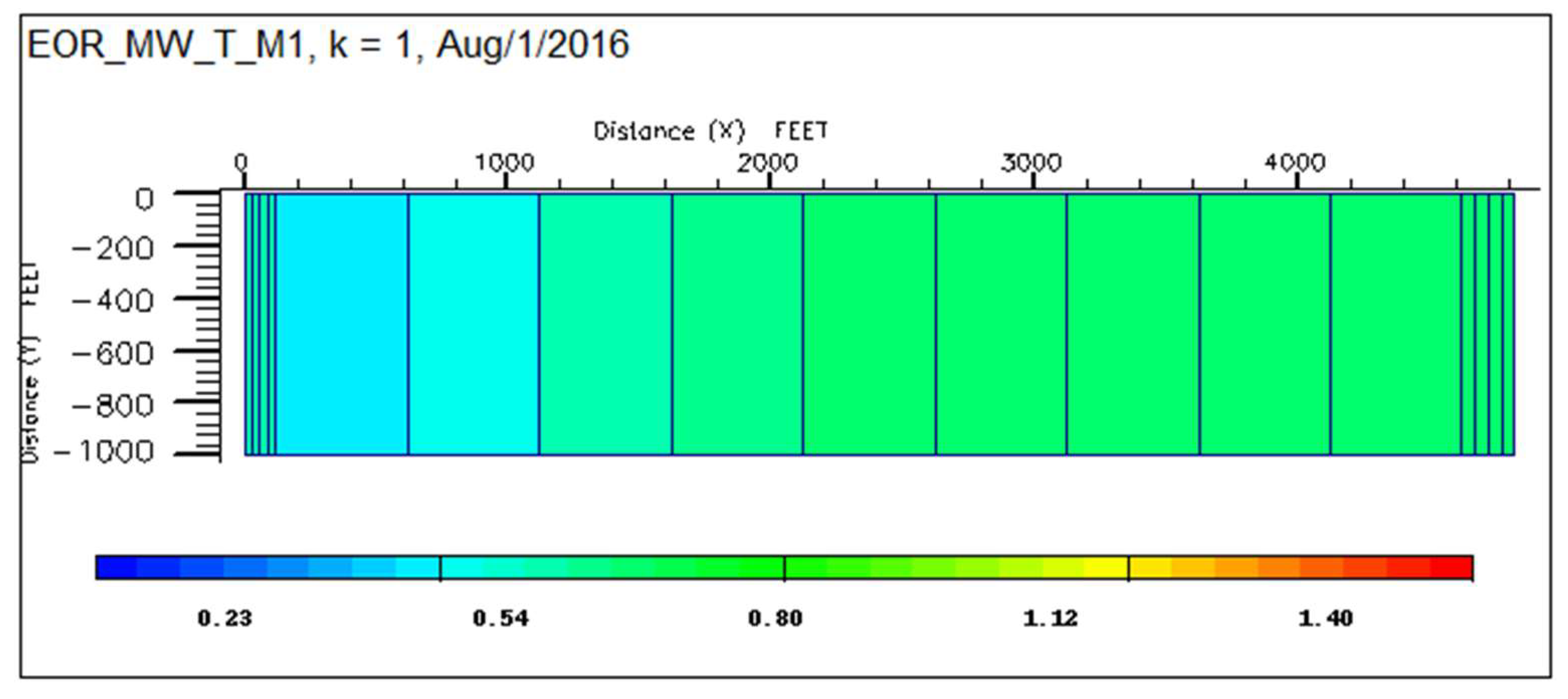

Reservoir Properties and Visualization Enhancements

3.3. Mesh Sensitivity Analysis

- Coarse Grid: 17 × 1 × 3 blocks.

- Medium Grid: 34 × 1 × 6 blocks (base case used in simulation).

- Fine Grid: 68 × 1 × 12 blocks.

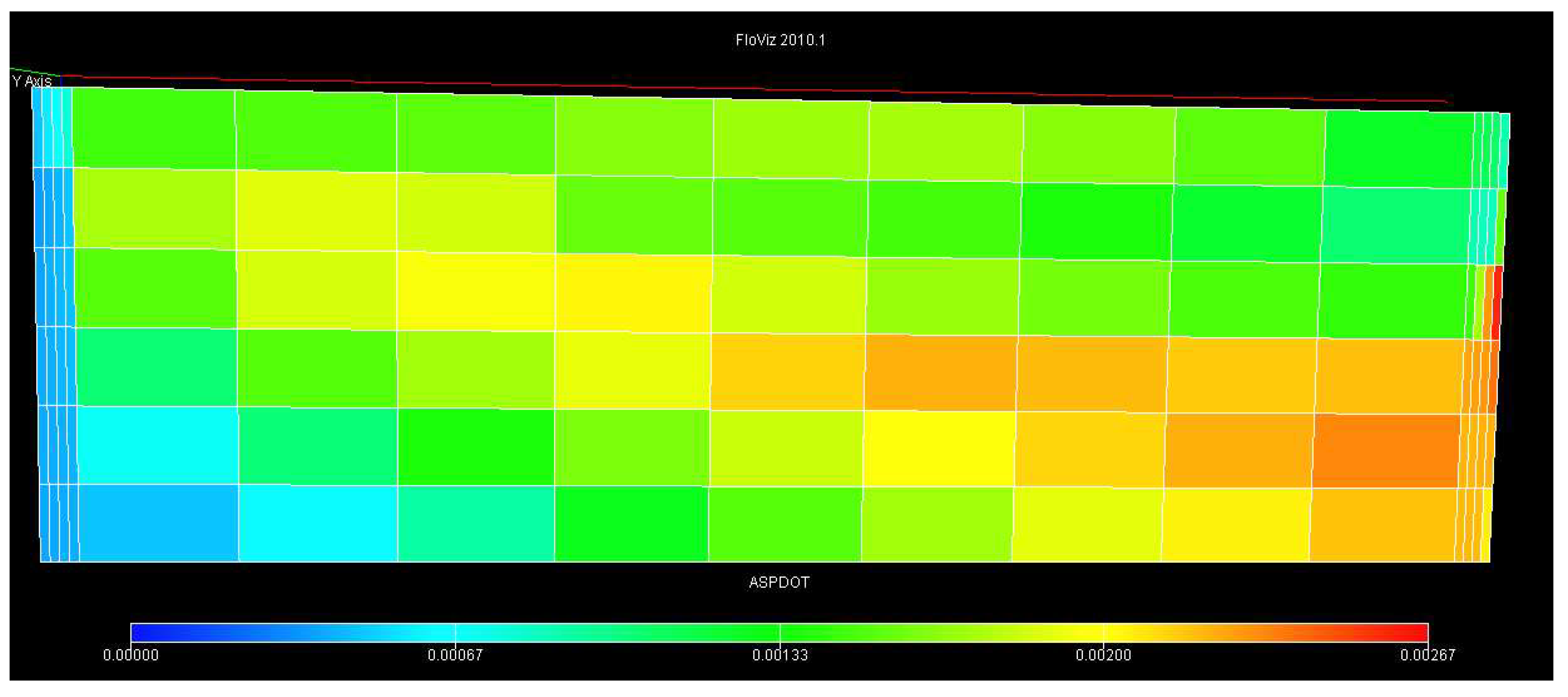

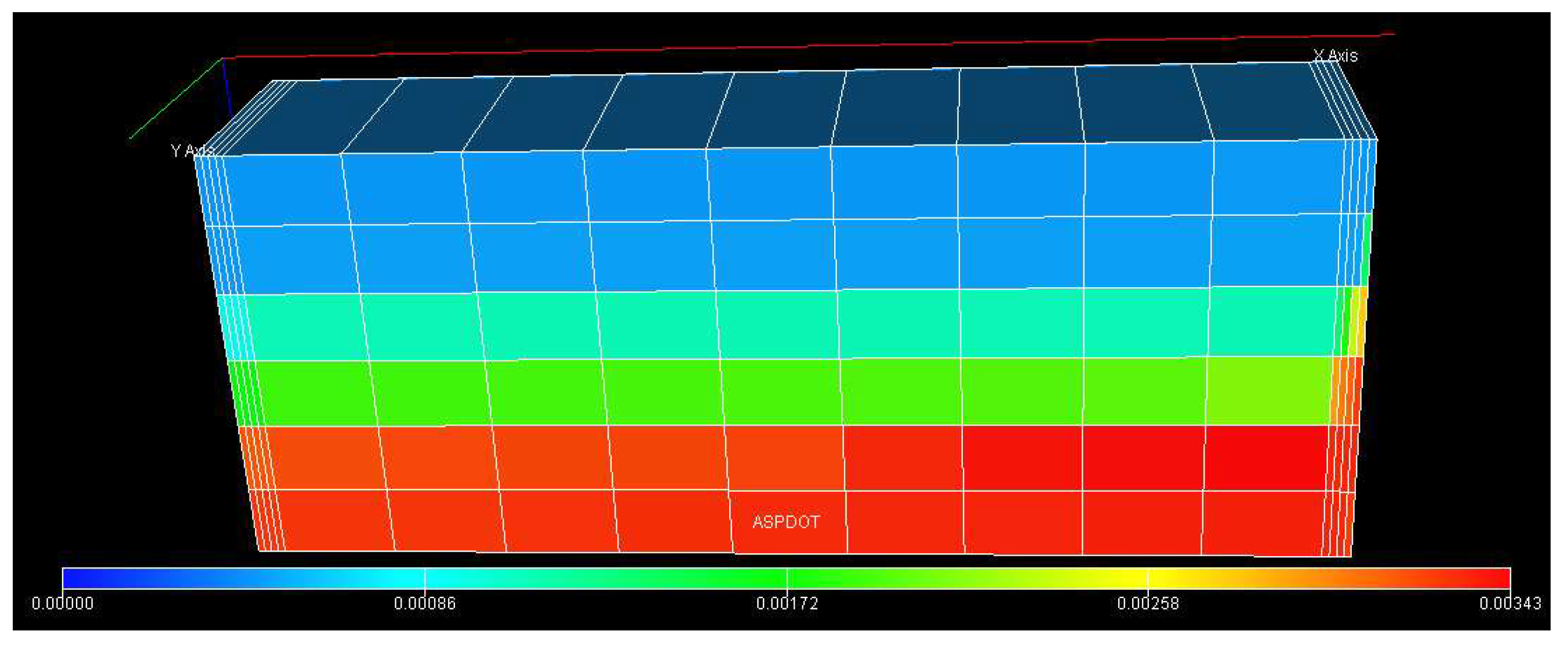

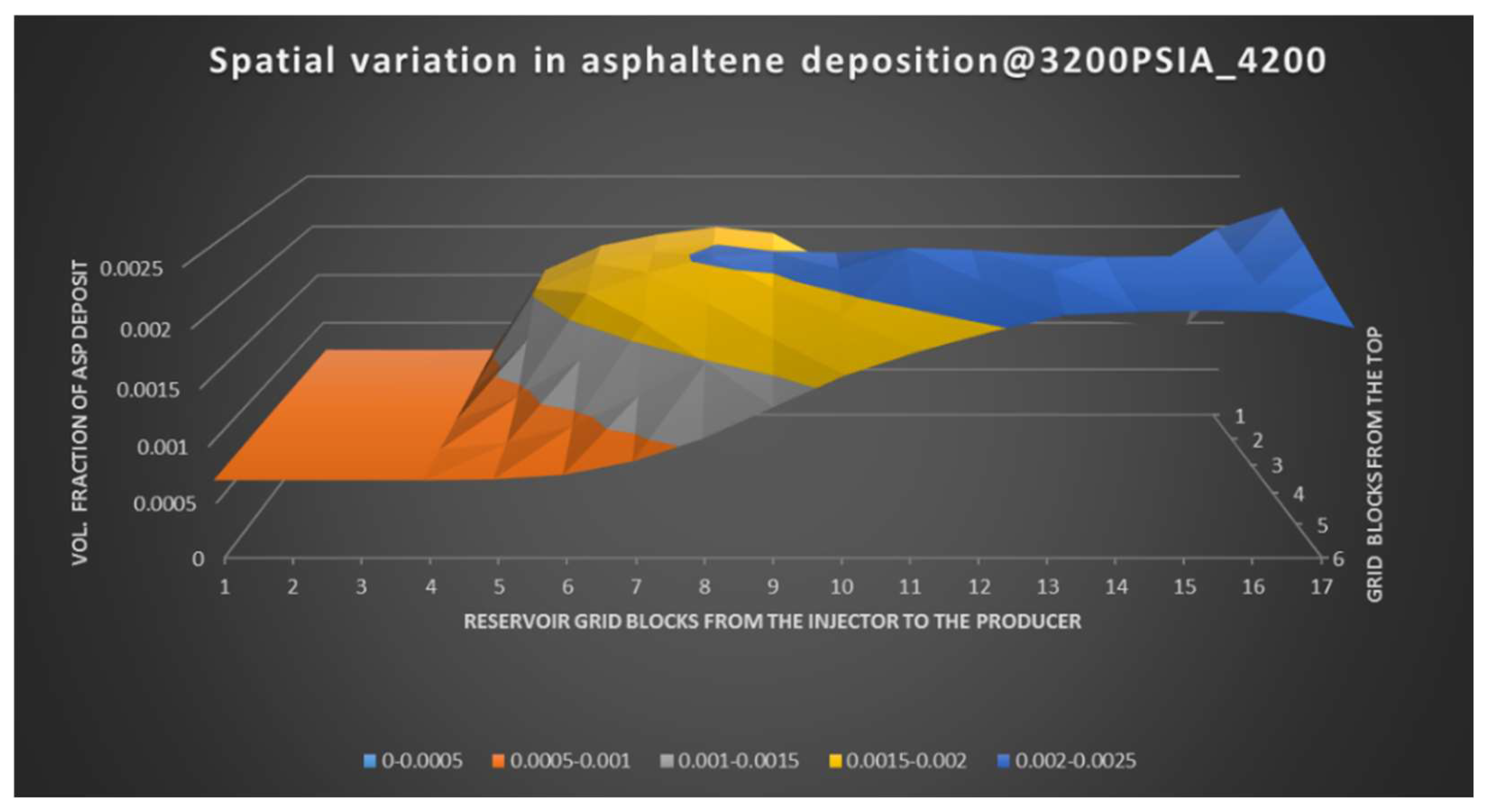

- Highest deposition near the production well due to low-pressure zones.

- Moderate deposition in the mid-reservoir due to gravitational segregation.

- Minimal deposition near the injection well due to higher shear stress.

4. Results and Discussion

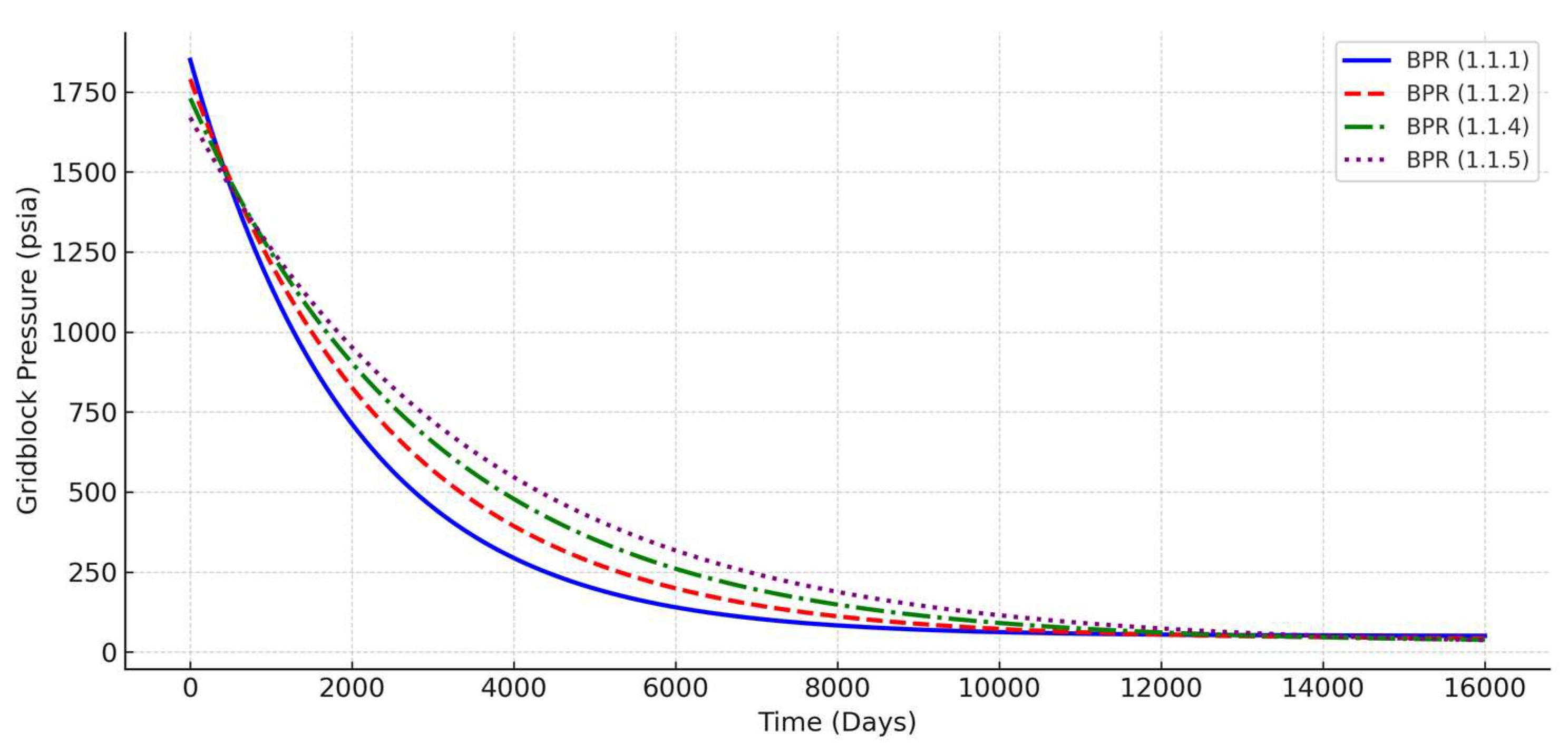

4.1. Simulation Results

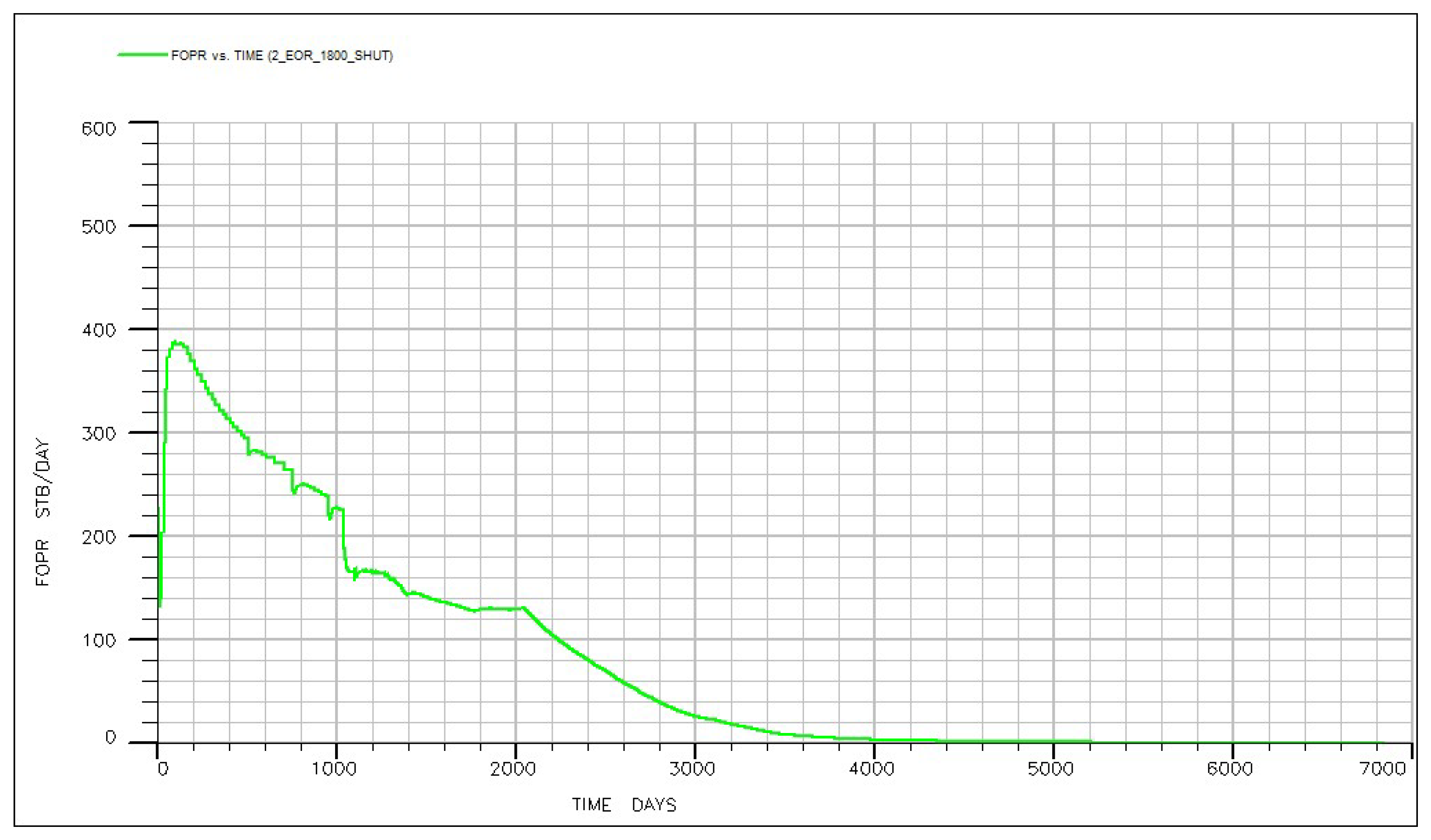

4.2. CO2 Injection at Pressure Below the MMP

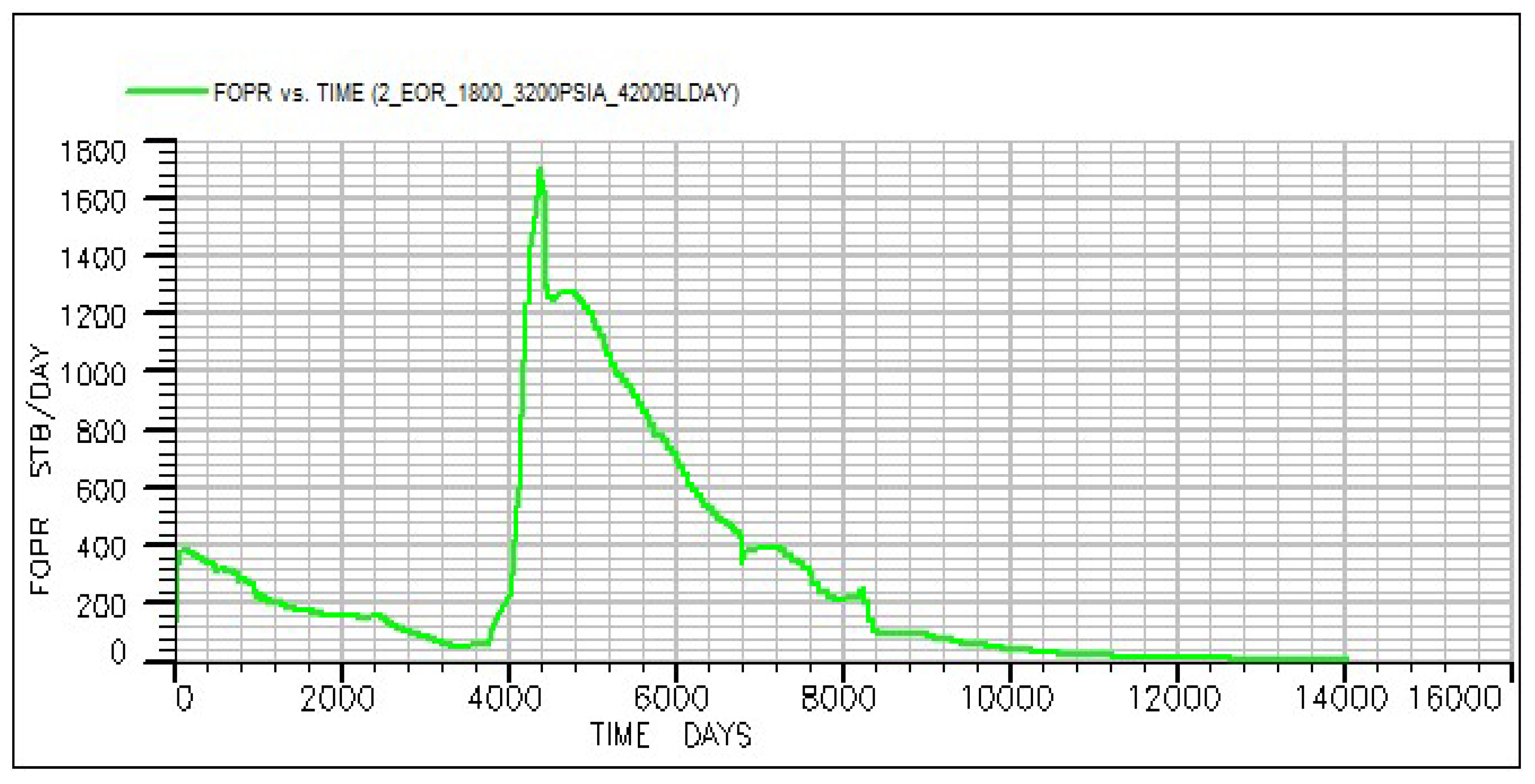

4.3. CO2 Injection at Pressure Above the Minimum Miscibility Pressure

4.4. Production Outputs for CO2 Injection

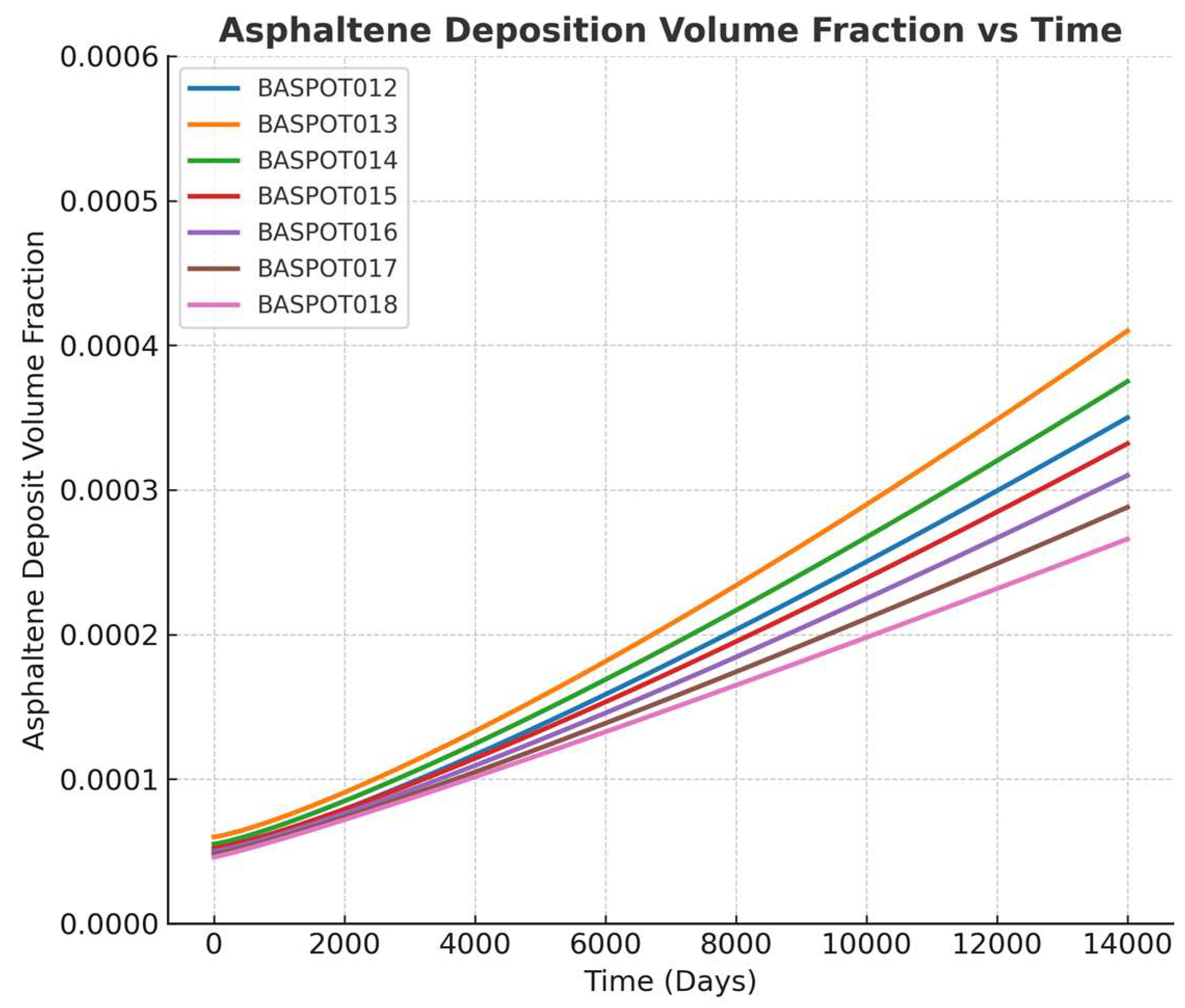

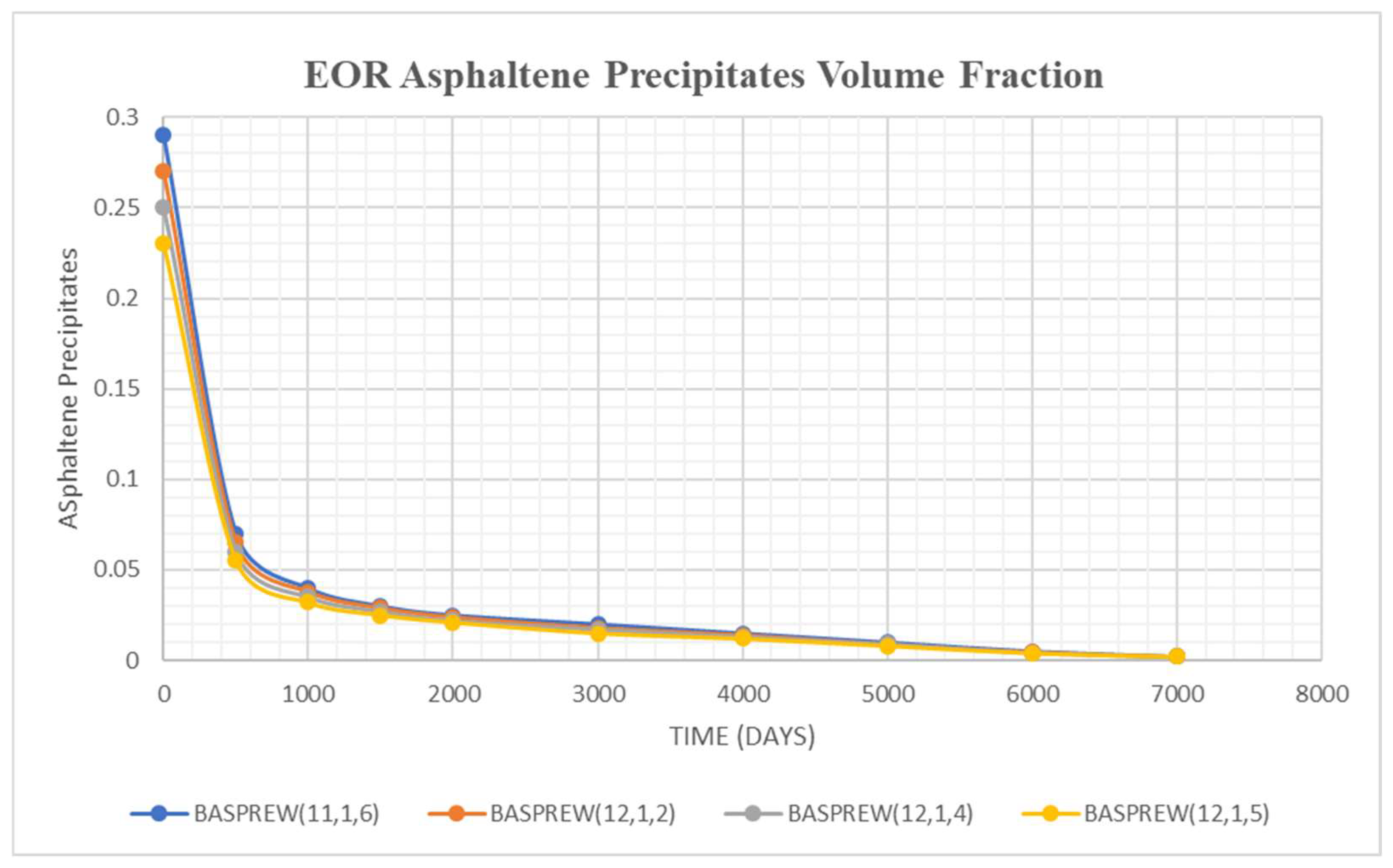

4.5. Asphaltene Behavior Under No Water Injection Conditions

4.6. Asphaltene Behavior Under Water Injection Conditions (Washout Effects)

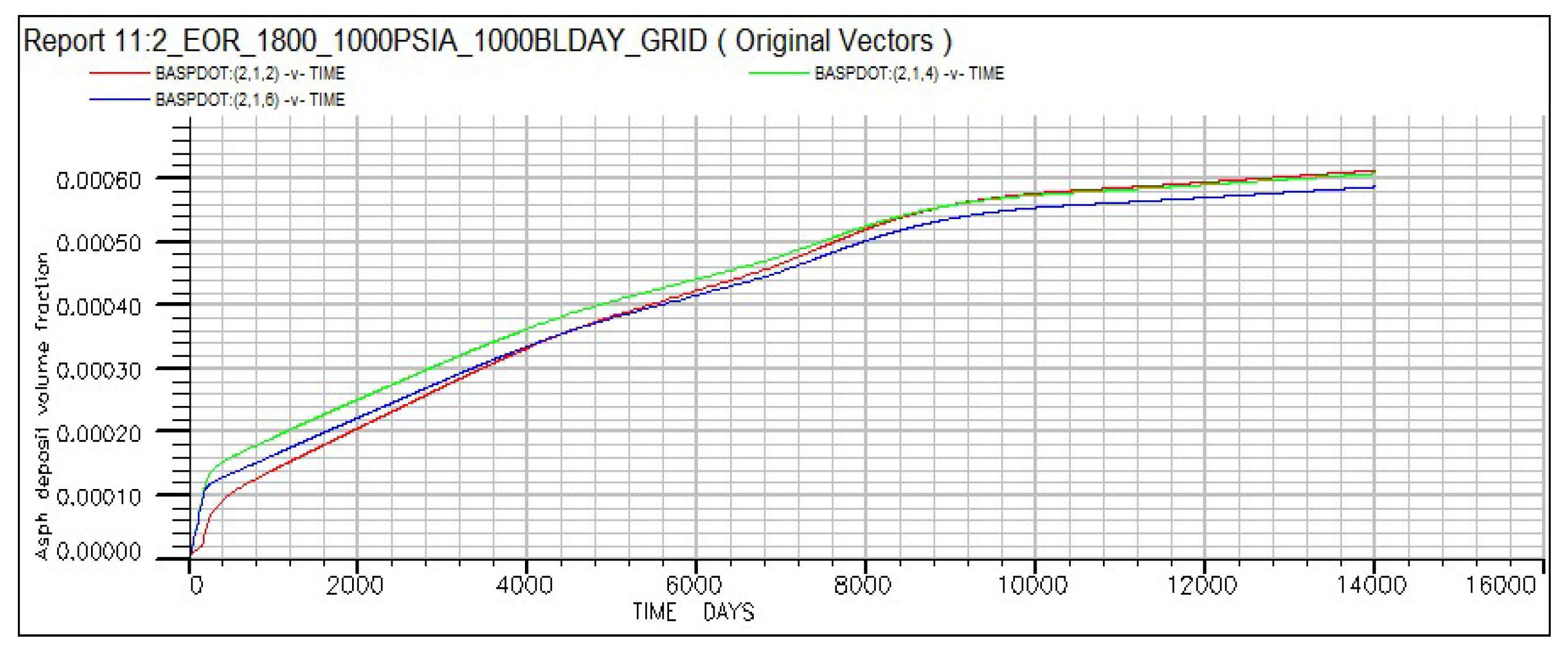

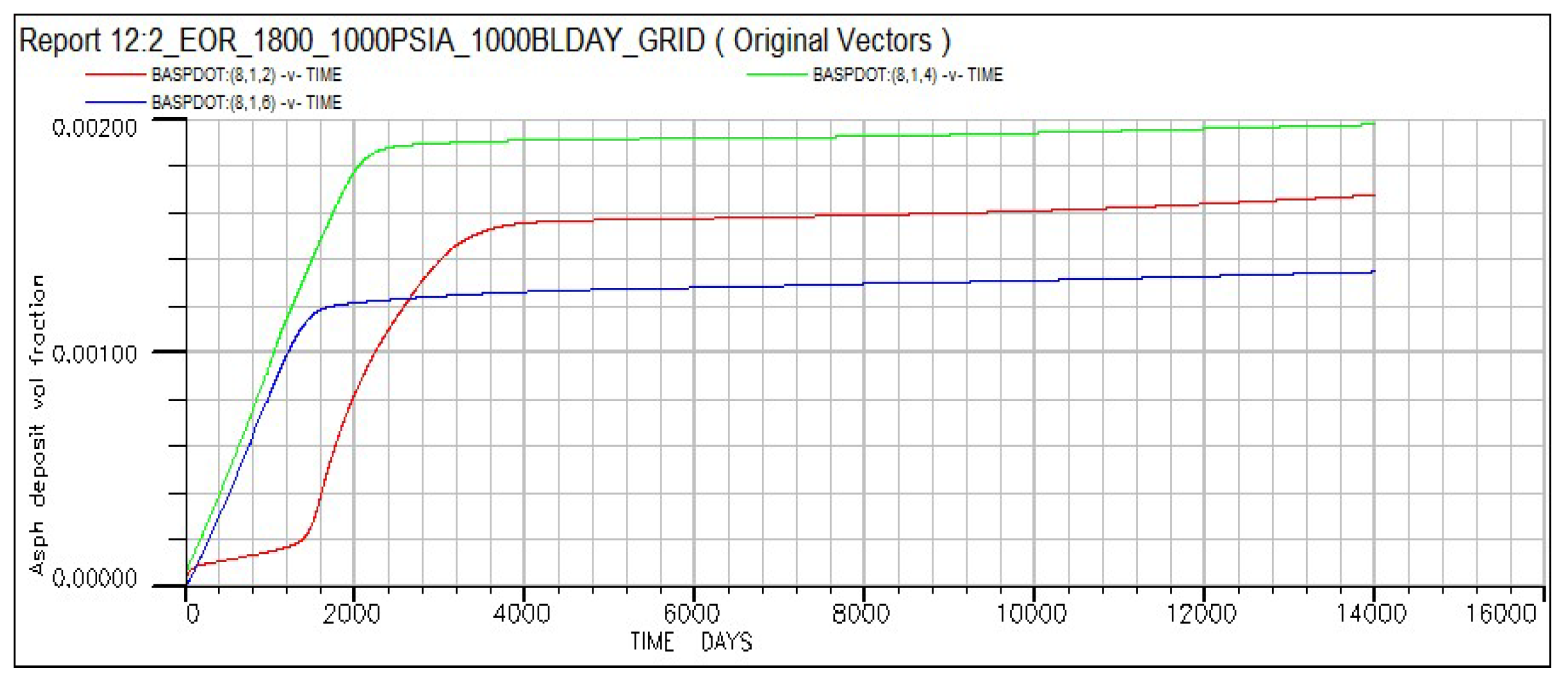

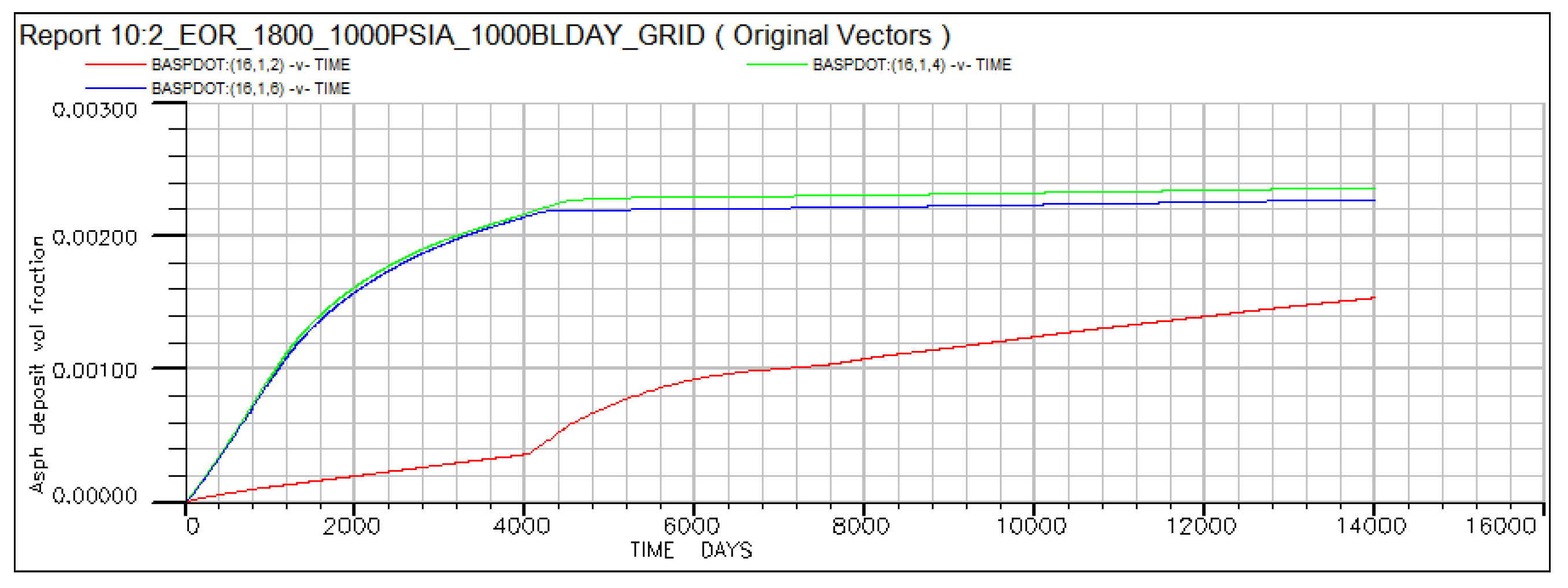

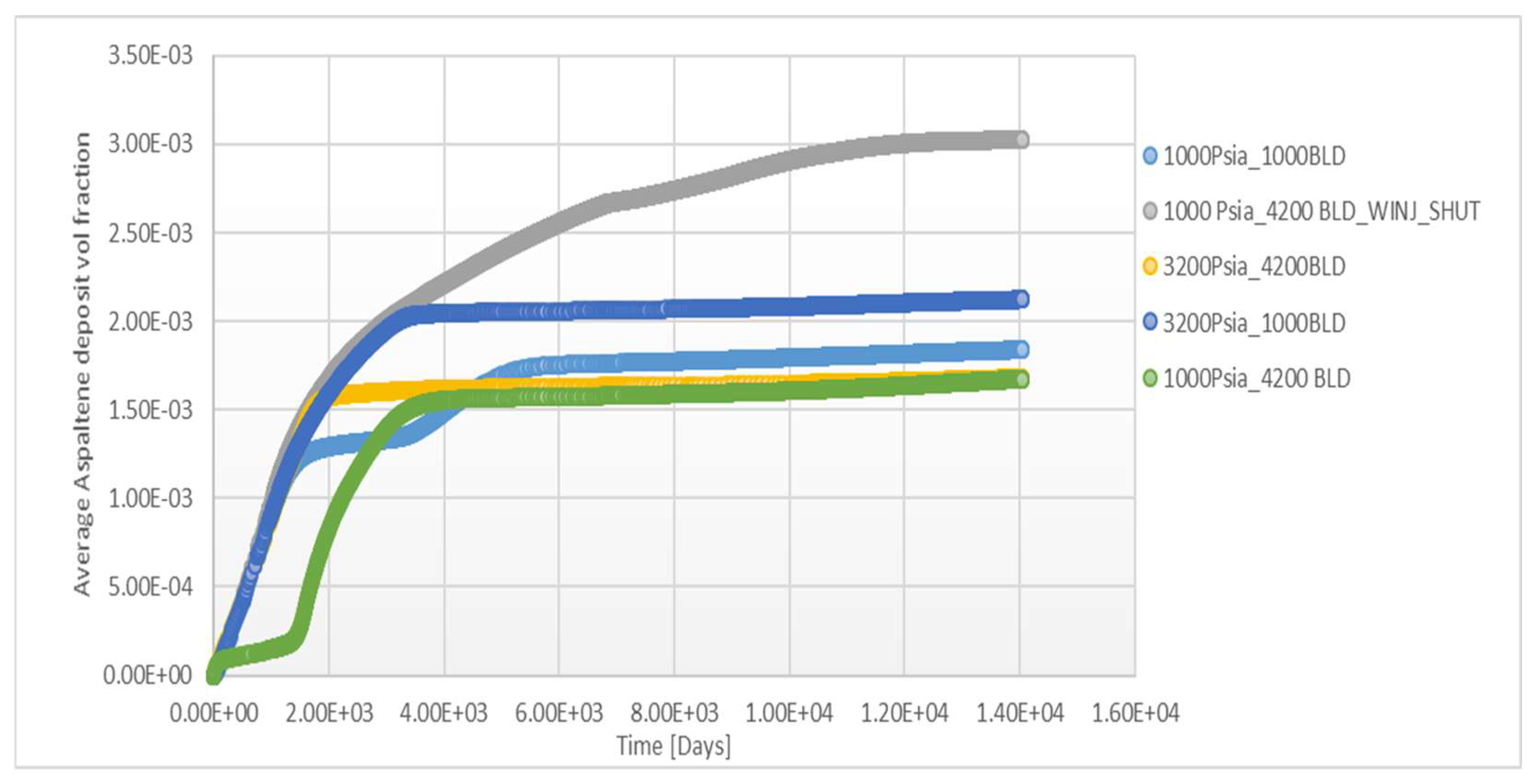

4.7. Asphaltene Behavior Under CO2 Injection Rate of 1000 bbl and Pressure of 1000 psia

4.8. Asphaltene Behavior Under CO2 Injection Rate of 2200 bbl and Pressure of 4200 psia

4.9. Asphaltene Behavior Under CO2 Injection Rate of 1000 bbl and Pressure of 3200 psia

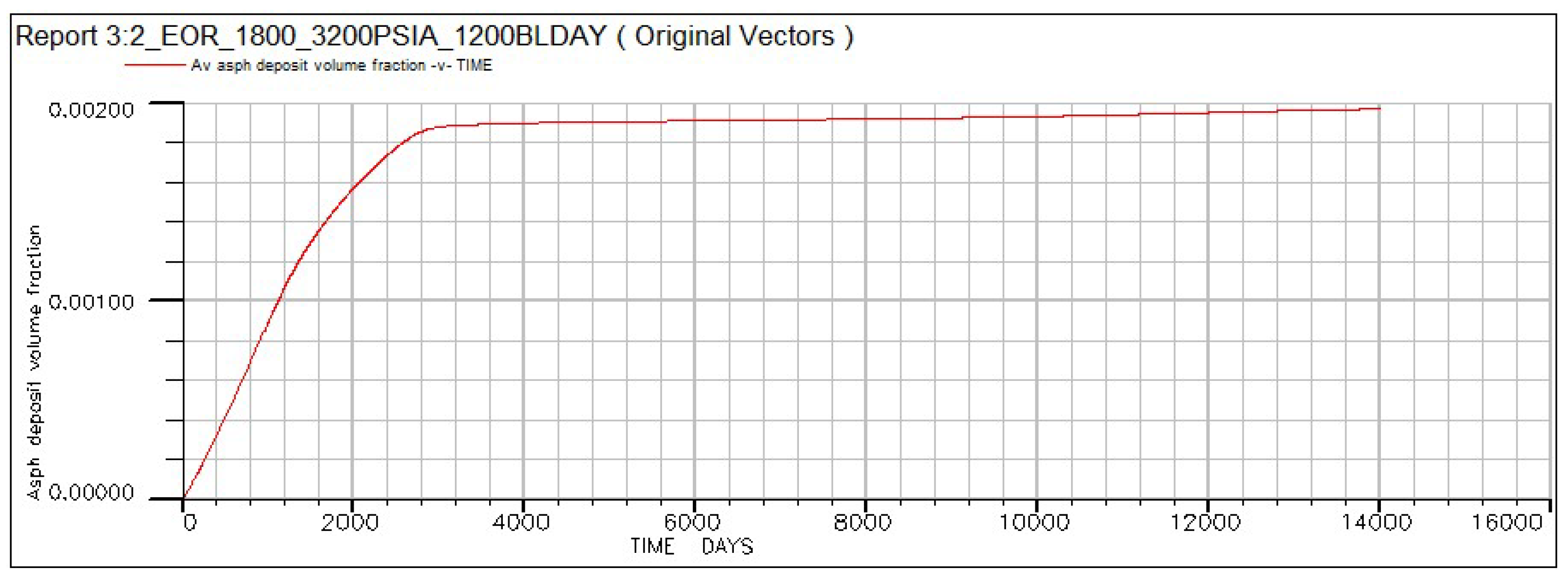

4.10. Asphaltene Behavior Under CO2 Injection Rate of 1200 bbl and Pressure of 3200 psia

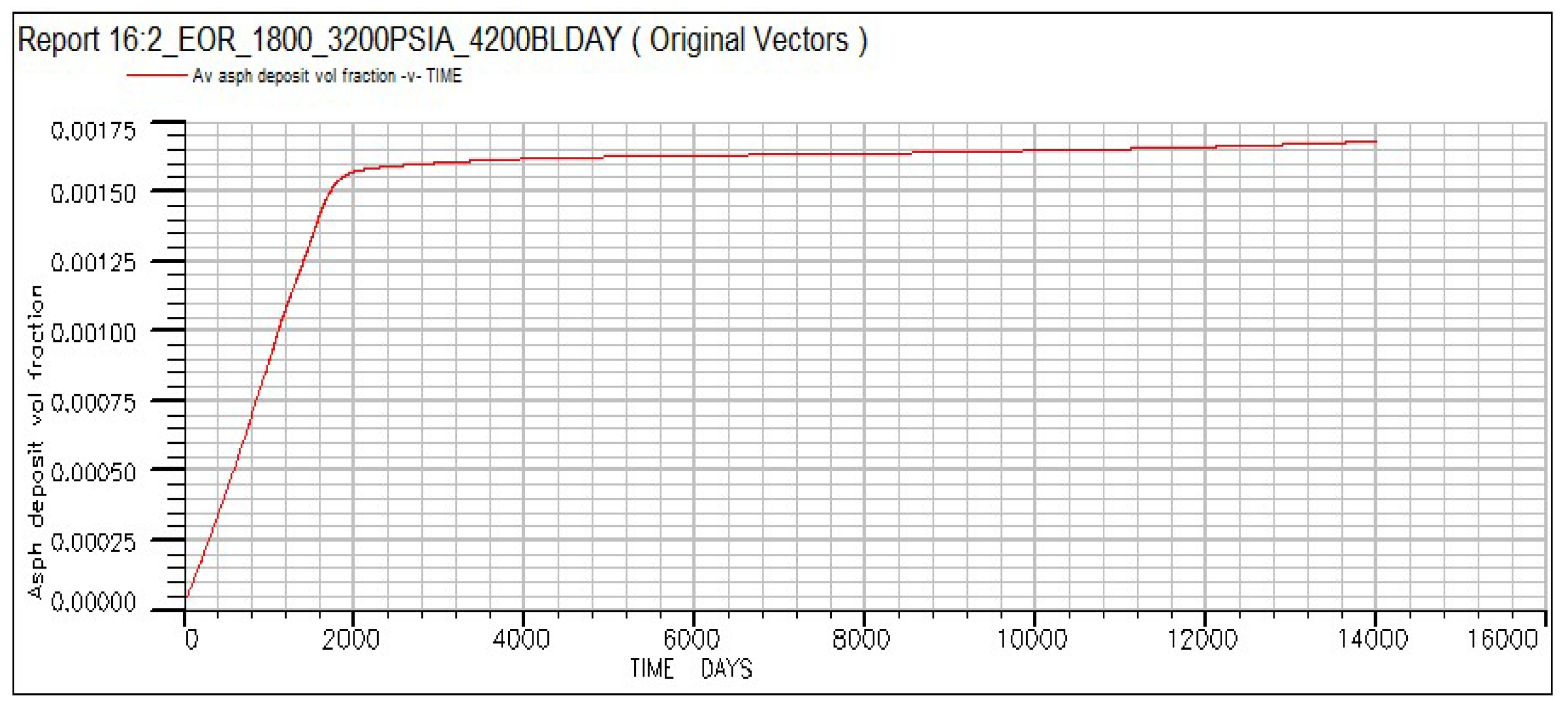

4.11. Asphaltene Behavior Under CO2 Injection Rate of 4200 bbl and Pressure of 3200 psia

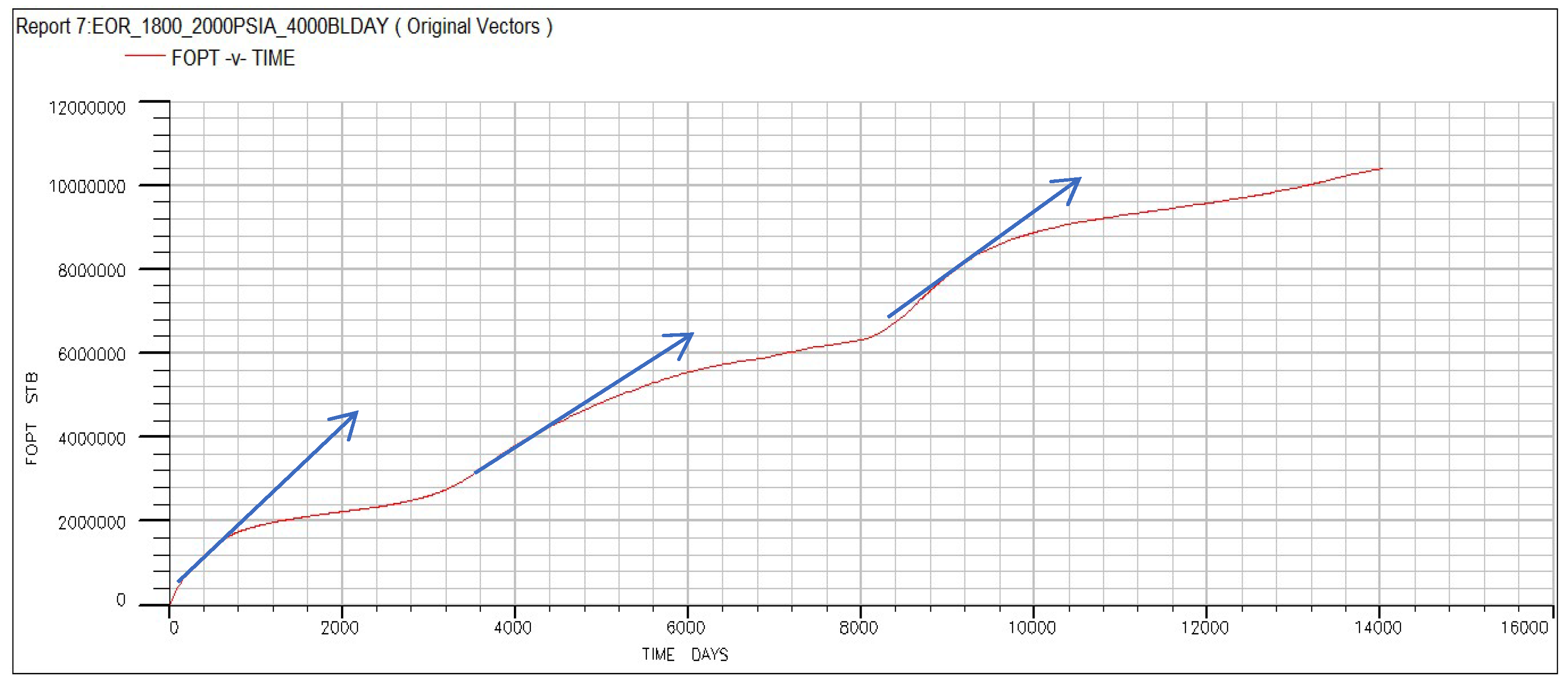

4.12. Oil Production

4.13. Alternative Asphaltene Deposition Control Methods

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| bbl | Barell |

| SCN | Single Carbon Number |

| CO2 | Carbon dioxide |

| EOR | Enhanced Oil Recovery |

| MMP | Minimum Miscibility Pressure |

References

- International Energy Agency (IEA). Global Energy Review 2025; IEA: Paris, France, 2025; Available online: https://www.iea.org/reports/global-energy-review-2025 (accessed on 18 August 2025).

- Kant, S.; Beintema, K.; Bell, M.; Al-Khulaifi, K. The Smarter Path to Energy Security and Profitability? Optimizing Production. Boston Consulting Group (BCG). Available online: https://www.bcg.com/publications/2025/optimizing-production-for-energy-profit-security (accessed on 18 August 2025).

- Mahdavi, S.; Jalilian, M.; Dolati, S. Review and perspectives on CO2 induced asphaltene instability: Fundamentals and implications for phase behaviour, flow assurance, and formation damage in oil reservoirs. Fuel 2024, 368, 131574. [Google Scholar] [CrossRef]

- Halim, M.C.; Hamidi, H.; Akisanya, A.R. Minimizing Formation Damage in Drilling Operations: A Critical Point for Optimizing Productivity in Sandstone Reservoirs Intercalated with Clay. Energies 2022, 15, 162. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Galedarzadeh, M.; Shadizadeh, S.R. Low parameter model to monitor bottom hole pressure in vertical multiphase flow in oil production wells. Petroleum 2015, 2, 258–266. [Google Scholar] [CrossRef]

- Lake, L.; Johns, R.T.; Rossen, W.R.; Pope, G.A. Fundamentals of Enhanced oil Recovery; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar] [CrossRef]

- Singh, A. Technology Focus: Formation Damage (March 2023). J. Pet. Technol. 2023, 75, 83–84. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Xu, N.; Wang, Y.; Bai, B. Settling Behavior and Mechanism Analysis of Kaolinite as a Fracture Proppant of Hydrocarbon Reservoirs in CO2 Fracturing Fluid. Colloids Surf. A 2025, 724, 137463. [Google Scholar] [CrossRef]

- Elrahmani, A.; Al-Raoush, R.I. Spatial Dependency of Clogged Throats in Porous Media: A Microscale Investigation. SPE J. 2025, 30, 712–728. [Google Scholar] [CrossRef]

- Yin, D.; Li, Q.; Zhao, D. Investigating Asphaltene Precipitation and Deposition in Ultra-Low Permeability Reservoirs during CO2-Enhanced Oil Recovery. Sustainability 2024, 16, 4303. [Google Scholar] [CrossRef]

- Sadeghtabaghi, Z.; Alhreez, M.; Wen, D. A Review on Asphaltenes Characterization by X-ray Diffraction: Fundamentals, Challenges, and Tips. J. Mol. Struct. 2021, 1238, 130425. [Google Scholar] [CrossRef]

- Ghadimi, M.; Ghaedi, M.; Malayeri, M.R.; Amani, M.J. A new approach to model asphaltene induced permeability damage with emphasis on pore blocking mechanism. J. Pet. Sci. Eng. 2020, 184, 106512. [Google Scholar] [CrossRef]

- Elkahky, S.; Lagat, C.; Sarmadivaleh, M.; Barifcani, A. A comparative study of density estimation of asphaltene structures using group contribution methods and molecular dynamic simulations for an Australian oil field. J. Pet. Explor. Prod. Technol. 2019, 9, 2699–2708. [Google Scholar] [CrossRef]

- Svalova, A.; Walshaw, D.; Lee, C.; Demyanov, V.; Parker, N.G.; Povey, M.J.; Abbott, G.D. Estimating the Asphaltene Critical Nano aggregation Concentration Region Using Ultrasonic Velocity Measurements. Sci. Rep. 2021, 11, 6698. [Google Scholar] [CrossRef] [PubMed]

- Fajardo-Rojas, F.; Alvarez Solano, O.A.; Samaniuk, J.R.; Pradilla, D. Deviation from Equilibrium Thermodynamics of an Asphaltene Model Compound during Compression–Expansion Experiments at Fluid–Fluid Interfaces. Langmuir 2021, 37, 1799–1810. [Google Scholar] [CrossRef]

- Mohammed, I.; Mahmoud, M.; Shehri, D.A.; El-Husseiny, A.; Alade, O. Asphaltene precipitation and deposition: A critical review. J. Pet. Sci. Eng. 2020, 197, 107956. [Google Scholar] [CrossRef]

- Yonebayashi, H.; Iwama, H.; Takabayashi, K.; Miyagawa, Y.; Watanabe, T. Uneven distribution of asphaltene deposits in CO2 flooding path: Interpretation by combining thermodynamic and Micro-CT 3D geological porous models. Energy Fuels 2020, 35, 329–340. [Google Scholar] [CrossRef]

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental aspects, mechanisms and emerging possibilities of CO2 miscible flooding in enhanced oil recovery: A review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

- Ebaid, H.; Gasser, M.; Yehia, T.; Okoroafor, E.R. Enhancing Oil Recovery in Heterogeneous Reservoirs with CO2 Flooding: A Simulation Study. In Proceedings of the SPE/AAPG/SEG Carbon, Capture, Utilization, and Storage Conference and Exhibition, Houston, TX, USA, 11–13 March 2024; Available online: https://onepetro.org/ccusce/proceedings-abstract/24JCUS/3-24JCUS/D031S017R001/543723 (accessed on 10 May 2025).

- Zhu, D.; Li, B.; Chen, L.; Zhang, C.; Zheng, L.; Chen, W.; Li, Z. Experimental investigation of CO2 foam flooding-enhanced oil recovery in fractured low-permeability reservoirs: Core-scale to pore-scale. Fuel 2024, 362, 130792. [Google Scholar] [CrossRef]

- Khalili, Y.; Ahmadi, M.; Amirkabir University of Technology. Reservoir Modeling & Simulation: Advancements, challenges, and future Perspectives. J. Chem. Pet. Eng. 2023, 57, 343–364. [Google Scholar] [CrossRef]

- Young, L.C. Compositional Reservoir simulation: A review. SPE J. 2022, 27, 2746–2792. [Google Scholar] [CrossRef]

- AlHammadi, A.A.; Abutaqiya, M.I.L. Predictive Modeling of Phase Behavior of Reservoir Fluids under Miscible Gas Injection Using the Peng–Robinson Equation of State and the Aromatic Ring Index. ACS Omega 2023, 8, 3270–3277. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Zhao, H.; Wang, B.; Nan, R.; An, C. Quantitative Evaluation of C7+ Splitting and EOS Tuning for SCN-Based Pseudo-Component Models in Reservoir Fluid Phase Behavior. Processes 2024, 12, 2066. [Google Scholar] [CrossRef]

- Nasiri, A.; Zhang, Y.; Zendehboudi, S.; Bahadori, A. Thermal effects on fluid flow and production performance in vertical oil wells. J. Pet. Sci. Eng. 2022, 213, 110620. [Google Scholar] [CrossRef]

- Alvarez, J.; Ayala, R.; Hascakir, B. Experimental evaluation of asphaltene precipitation, deposition, and mitigation in high-permeability sandstone cores. J. Pet. Sci. Eng. 2022, 210, 110112. [Google Scholar] [CrossRef]

- Smith, J.L.; Haskett, C.; Leontaritis, K. Advances in chemical inhibition of asphaltene deposition. In Proceedings of the SPE International Oilfield Scale Conference, Aberdeen, UK, 18–19 June 2018. [Google Scholar] [CrossRef]

- Zvereva, A.E.; Ershov, M.A.; Savelenko, V.D.; Lobashova, M.M.; Rogova, M.Y.; Makhova, U.A.; Tikhomirova, E.O.; Burov, N.O.; Aleksanyan, D.R.; Kapustin, V.M.; et al. Use of Asphaltene Stabilizers for the Production of Very Low-Sulfur Fuel Oil: Experimental Evaluation of Alkylphenol-Formaldehyde Resin Stabilizers. Energies 2023, 16, 7649. [Google Scholar] [CrossRef]

- Rahmani, O.; Dabir, B.; Jafari Behbahani, T. Experimental and modeling study of asphaltene deposition control by chemical inhibitors during CO2 flooding. Fuel 2021, 293, 120465. [Google Scholar] [CrossRef]

| Mesh Size | Cumulative Oil Produced (STB) | Peak Oil Rate (STB/Day) | Max Asphaltene Deposition (%) |

|---|---|---|---|

| Coarse (17 × 1 × 3) | 13,900 | 785 | 6.2 |

| Medium (34 × 1 × 6) | 14,380 | 770 | 5.4 |

| Fine (68 × 1 × 12) | 14,420 | 768 | 5.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sergio, D.; Oladele, D.A.; Nuetor, F.D.; Goswami, H.; Trabelsi, R.; Trabelsi, H.; Boukadi, F. Practical Approach for Formation Damage Control in CO2 Gas Flooding in Asphaltenic Crude Systems. Processes 2025, 13, 2740. https://doi.org/10.3390/pr13092740

Sergio D, Oladele DA, Nuetor FD, Goswami H, Trabelsi R, Trabelsi H, Boukadi F. Practical Approach for Formation Damage Control in CO2 Gas Flooding in Asphaltenic Crude Systems. Processes. 2025; 13(9):2740. https://doi.org/10.3390/pr13092740

Chicago/Turabian StyleSergio, David, Derrick Amoah Oladele, Francis Dela Nuetor, Himakshi Goswami, Racha Trabelsi, Haithem Trabelsi, and Fathi Boukadi. 2025. "Practical Approach for Formation Damage Control in CO2 Gas Flooding in Asphaltenic Crude Systems" Processes 13, no. 9: 2740. https://doi.org/10.3390/pr13092740

APA StyleSergio, D., Oladele, D. A., Nuetor, F. D., Goswami, H., Trabelsi, R., Trabelsi, H., & Boukadi, F. (2025). Practical Approach for Formation Damage Control in CO2 Gas Flooding in Asphaltenic Crude Systems. Processes, 13(9), 2740. https://doi.org/10.3390/pr13092740