Optimal Operation of Combined Cooling, Heating, and Power Systems with High-Penetration Renewables: A State-of-the-Art Review

Abstract

1. Introduction

1.1. Evolution of CCHP Operation Optimization Paradigms

- (1)

- Phase 1: Thermodynamics-Driven Strategies (2000–2010)

- (2)

- Phase 2: Single/Multi-Objective Optimization (2010–2020)

- (3)

- Phase 3: Uncertainty-Resilient Coordination (2021–Present)

1.2. Scope and Novelty of This Review

- (1)

- It establishes a multi-dimensional uncertainty analysis framework tailored to high-penetration renewable CCHP systems, systematically quantifying the interactions between renewable intermittency, demand volatility, and market dynamics. Unlike fragmented uncertainty discussions in prior studies, this framework maps uncertainty propagation across energy vectors and identifies critical coupling points where volatility amplifies, providing a holistic basis for targeted mitigation;

- (2)

- It summarizes the advantages of generalized energy storage (GES) in CCHP optimal operation, particularly in high-penetration renewable scenarios. By systematically integrating physical energy storage (PES) and virtual energy storage (VES) into a cohesive flexibility portfolio, GES demonstrates remarkable performance in addressing the core challenges of high renewable penetration;

- (3)

- It synthesizes modern uncertainty-aware optimization strategies into a structured decision matrix, enabling algorithm selection based on uncertainty characteristics, time scales, and risk preferences;

- (4)

- It develops a real-world application pathway for optimization algorithms, linking theoretical strategies to operational scenarios.

2. CCHP Systems with High-Penetration Renewables: Framework and Challenges

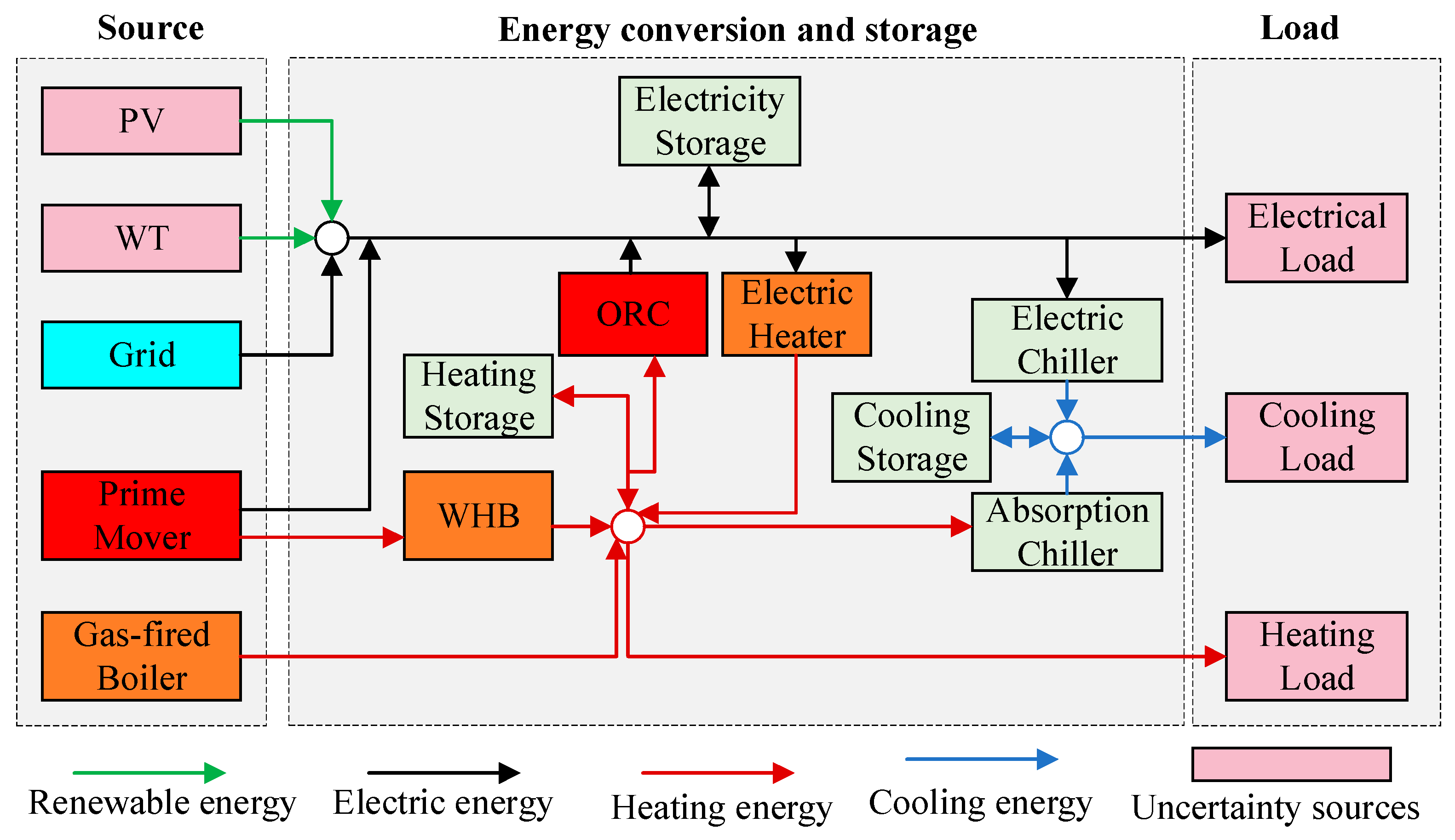

2.1. System Architecture

2.2. The Core Challenge: Uncertainty and Variability

- (1)

- China’s Electricity Market Reform: In Guangdong’s spot market pilot, intraday price volatility reached 25% [29], forcing CCHP operators to develop more dynamic bidding strategies to maintain profitability;

- (2)

- EU Carbon Pricing Mechanisms: The EU Carbon Border Adjustment Mechanism, fully effective in 2026, aligns with EU ETS prices (projected at EUR 85/ton CO2 in 2025) [30]. While not directly regulating CCHP systems, it significantly impacts the economics of gas-fired generation supporting covered industrial exports;

- (3)

- California Renewable Integration Challenges: The state’s “duck curve” phenomenon, driven by high solar penetration, creates late-afternoon net load ramps with historical price spikes reaching USD 200/MWh [31]. This requires CCHP systems to optimize storage dispatch and generation schedules around these predictable volatility patterns.

3. Flexibility-Enabled Operation for High-RE CCHP Systems

3.1. Storage-Driven Uncertainty Buffering

3.1.1. Physical Energy Storage (PES)

3.1.2. Virtual Energy Storage (VES)

3.1.3. Synergistic Integration: Generalized Energy Storage

3.2. Demand-Side Flexibility Activation

3.2.1. Electrical Flexible Loads: Interruptible and Shiftable Resources

3.2.2. Gas and Thermal Flexible Loads: Convertible and Transferable Resources

3.2.3. Sector-Specific Flexible Loads: Data Centers, Industrial Parks, and Buildings

3.2.4. Hydrogen-Integrated Flexible Resources

3.3. Multi-Energy Conversion Synergy

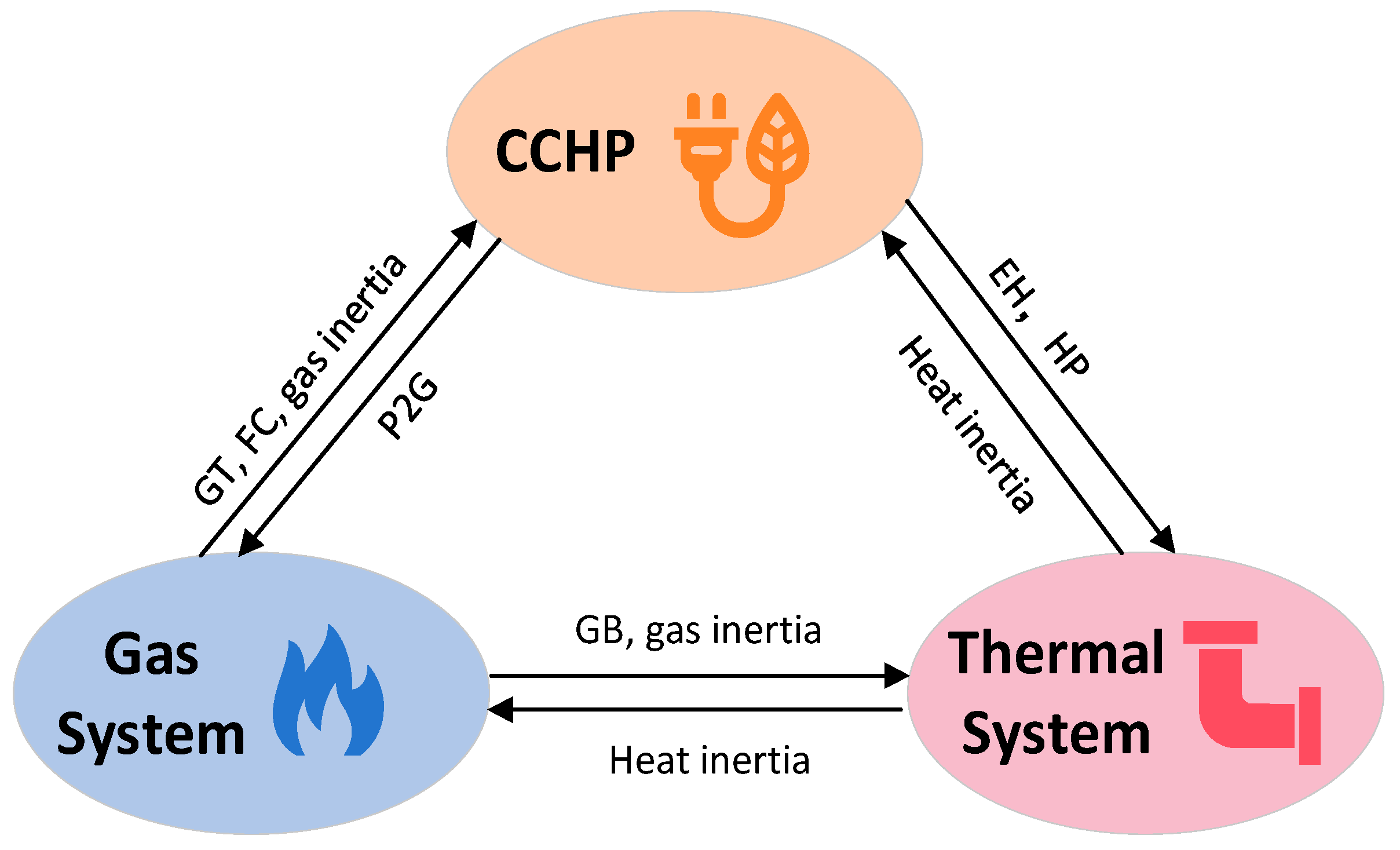

- (1)

- CCHP–Gas System Interaction: The CCHP unit connects to the gas system via gas turbines, fuel cells, and power-to-gas technology. GTs and FCs leverage gas inertia to enable dynamic response, while P2G converts surplus electricity into gas for storage, creating a bidirectional energy flow;

- (2)

- CCHP–Thermal System Interaction: Heat pumps, electric heaters, and thermal inertia support bidirectional heat-power adjustment. This allows the CCHP unit to reallocate its output priority between heat and electricity based on real-time renewable energy availability;

- (3)

- Gas–Thermal System Interaction: Gas boilers utilize gas inertia to supply heat, while heat inertia buffers temperature fluctuations. This cross-system coupling further enhances the system’s ability to balance supply and demand.

- (1)

- Interaction between the CCHP unit and natural gas system

- (2)

- Interaction between the CCHP unit and thermal system

- (3)

- Interaction between the thermal system and natural gas system

3.3.1. Gas–Electricity Synergy

3.3.2. Heat–Electricity Synergy

3.3.3. Electricity–Transportation and Electricity–Hydrogen Synergy

4. Optimization Strategies for Uncertain Scenarios

4.1. Robust Optimization (RO) Paradigms

4.1.1. Classic RO

4.1.2. Distributionally RO

4.1.3. Adaptive RO

- (1)

- Benders decomposition [87]

- (2)

- Cut-and-column generation (C&CG) [88]

4.2. Stochastic Optimization (SO) Paradigms

- (1)

- First-stage (here-and-now) decisions: These are made before uncertainties are observed, including day-ahead commitments that form the foundational operational framework. The core formulation is as follows:

- (2)

- Second-stage (wait-and-see) recourse actions: These are adjusted after observing specific uncertainty realizations, such as modifying battery discharge rates or grid import/export volumes to maintain balance. The core formulation is as follows:

4.3. Information Gap Decision Theory

4.4. Deep Reinforcement Learning

- (1)

- Definition of Markov Decision Process

- (2)

- Policies and value functions

4.5. Chance-Constrained Programming

4.6. Algorithm Comparison and Selection

4.6.1. Algorithm Comparison

4.6.2. Algorithm Selection

- (1)

- Select by Uncertainty Information

- If uncertainty has clear bounds, choose RO;

- If probability distribution is known, choose SO;

- If distribution is unknown, but historical data exist, choose DRO;

- If probabilistic constraints need to be satisfied, choose CCP;

- If uncertainty bounds are unknown, and both robustness and opportuneness matter, choose IGDT;

- If the system is complex, and online learning is needed, choose DRL.

- (2)

- Select by Time Scale

- For long-term planning, choose IGDT or SO;

- For day-ahead scheduling, choose RO, DRO, or SO;

- For intraday scheduling, choose SO or CCP;

- For multi-time scale dispatch (hours–days), choose adaptive RO;

- For real-time control, choose DRL or CCP.

- (3)

- Select by Risk Preference

- If risk-averse (avoid worst-case scenarios), choose RO;

- If risk-neutral (optimize expected value), choose SO;

- For probabilistic risk control (allow small-probability violations), choose CCP;

- If there is distributionally robust risk, choose DRO;

- If risk handling requires recourse adjustment across stages, choose adaptive RO.

- SO + CCP: Embed chance constraints in stochastic optimization to balance economy and safety;

- RO + DRL: Use RO to generate initial strategies, with DRL for online fine-tuning, as this is suitable for high-volatility scenarios;

- DRO + CCP: Add probabilistic constraints to the distributionally robust framework to address safety requirements under ambiguous distributions.

4.7. Constraint Handling in Uncertainty-Aware Optimization

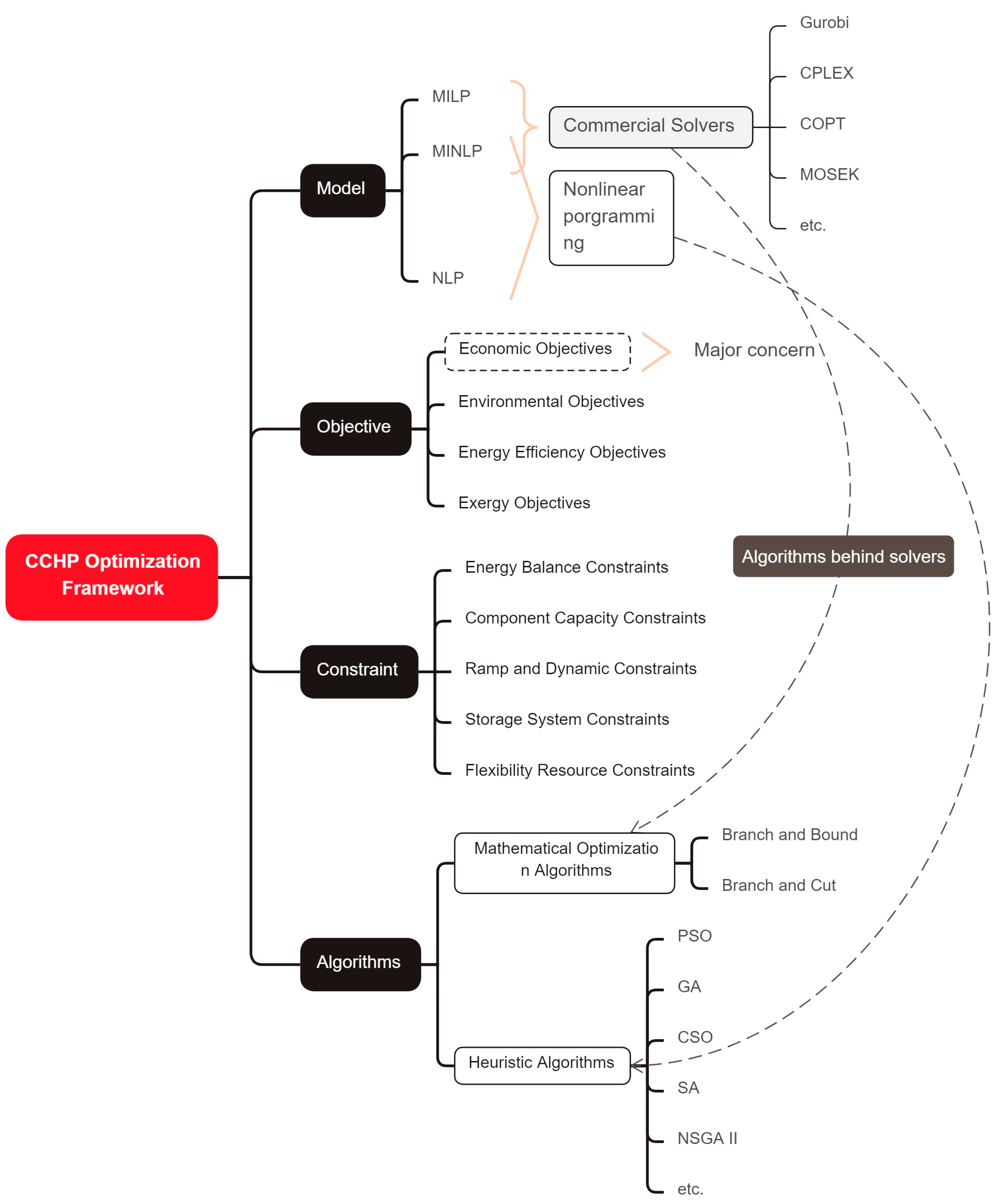

5. Modeling and Solution Techniques

5.1. Optimization Model Formulation

5.1.1. Objective Functions

- (1)

- Economic Objectives

- (2)

- Environmental Objectives

- (3)

- Energy Efficiency Objectives

- (4)

- Exergy Objectives

- (5)

- Multi-Objective Trade-offs

5.1.2. Key Constraints

- (1)

- Energy Balance Constraints

- (2)

- Component Capacity Constraints

- (3)

- Ramp and Dynamic Constraints

- (4)

- Storage System Constraints

- (5)

- Flexibility Resource Constraints

5.2. Solution Algorithms

5.2.1. Mathematical Programming

- (1)

- Linear/Quadratic Programming (LP/QP)

- (2)

- Mixed-Integer Linear/Nonlinear Programming (MILP/MINLP)

- (3)

- Decomposition Methods

5.2.2. Heuristic and Metaheuristic Algorithms

5.3. Real-World Implementation Framework

5.3.1. From Theoretical Innovations to Deployable Solutions

5.3.2. Phase-Driven Deployment Roadmap

- (1)

- Phase 1: Technology Validation in Campus Microgrids

- (2)

- Phase 2: Industrial Scaling with Hybrid Optimization

- (3)

- Phase 3: Urban Energy Hub Integration

6. Conclusions

6.1. Decisive Findings

- (1)

- Decision-Making Taxonomy for Uncertain Environments

- (2)

- Cross-Sectoral Flexibility Mechanisms

- (3)

- Systemic Integration of Generalized Energy Storage

6.2. Persistent Challenges

- (1)

- Improving computational efficiency for high-dimensional uncertainty in multi-stakeholder coordination;

- (2)

- Refining uncertainty modeling to capture extreme weather or market dynamics;

- (3)

- Addressing equitable benefit distribution in VPP-integrated CCHP clusters;

- (4)

- Enhancing AI techniques’ generalization for scalable real-world applications.

6.3. Future Research Trajectories

- (1)

- Hybrid Physics–AI Uncertainty Quantification

- (2)

- Privacy-Preserving Multi-CCHP Coordination

- (3)

- Long-Duration Energy Storage for Seasonal Balancing

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 4E | Energy, exergy, environment, economy |

| AHP | Analytic hierarchy process |

| ARO | Adaptive robust optimization |

| CAPEX | Capital expenditure |

| CCP | Chance-constrained programming |

| CCHP | Combined cooling, heating, and power |

| COP | Coefficient of Performance |

| DRO | Distributionally robust optimization |

| DRL | Deep reinforcement learning |

| EV | Electric vehicle |

| FC | Fuel cell |

| FEL | Following electrical load |

| FHL | Following hybrid load |

| FTL | Following thermal load |

| GA | Genetic algorithm |

| GT | Gas turbine |

| HVAC | Heating, ventilation, and air conditioning |

| IGDT | Information gap decision theory |

| LP/QP | Linear/quadratic programming |

| MDP | Markov decision process |

| MILP | Mixed-integer linear programming |

| MINLP | Mixed-integer nonlinear programming |

| ORC | Organic Rankine cycle |

| P2G | Power-to-gas |

| P2H | Thermal energy storage |

| PES | Physical energy storage |

| PM | Prime mover |

| PSO | Particle swarm optimization |

| RE | Renewable energy |

| RMSE | Root mean square error |

| RO | Robust optimization |

| SA | Simulated annealing |

| SOC | State of charge |

| TCL | Temperature-controlled load |

| TES | Thermal energy storage |

| TOPSIS | Technique for order preference by similarity to ideal solution |

| V2G | Vehicle-to-grid |

| VES | Virtual energy storage |

| VRE | Variable renewable energy |

| VSOC | Virtual state of charge |

| WHB | Waste heat boiler |

References

- Ahmed, I.; Habiba, U.-e.; Hossain, M.A.; Khalid, M. Assessment of smart district heating–cooling networks considering renewable and zero-carbon strategies. Renew. Sustain. Energy Rev. 2025, 224, 116037. [Google Scholar] [CrossRef]

- Qin, B.; Wang, H.; Liao, Y.; Li, H.; Ding, T.; Wang, Z.; Li, F.; Liu, D. Challenges and opportunities for long-distance renewable energy transmission in China. Sustain. Energy Technol. Assess. 2024, 69, 103925. [Google Scholar] [CrossRef]

- Yuan, M.; Mathiesen, B.V.; Schneider, N.; Xia, J.; Zheng, W.; Sorknæs, P.; Lund, H.; Zhang, L. Renewable energy and waste heat recovery in district heating systems in China: A systematic review. Energy 2024, 294, 130788. [Google Scholar] [CrossRef]

- Wu, D.W.; Wang, R.Z. Combined cooling, heating and power: A review. Progress. Energy Combust. Sci. 2006, 32, 459–495. [Google Scholar] [CrossRef]

- Gong, X.; Liu, J. Multi-Objective Energy-Saving Optimization and Analysis of a Combined Cooling, Heating, and Power (CCHP) System Driven by Geothermal Energy and LNG Cold Energy. Processes 2025, 13, 2135. [Google Scholar] [CrossRef]

- Al Moussawi, H.; Fardoun, F.; Louahlia-Gualous, H. Review of tri-generation technologies: Design evaluation, optimization, decision-making, and selection approach. Energy Convers. Manag. 2016, 120, 157–196. [Google Scholar] [CrossRef]

- Mago, P.J.; Hueffed, A.K. Evaluation of a turbine driven CCHP system for large office buildings under different operating strategies. Energy Build. 2010, 42, 1628–1636. [Google Scholar] [CrossRef]

- Mago, P.J.; Chamra, L.M.; Ramsay, J. Micro-combined cooling, heating and power systems hybrid electric-thermal load following operation. Appl. Therm. Eng. 2010, 30, 800–806. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A.; Chaer, I.; Suguartha, N. Performance evaluation of a tri-generation system with simulation and experiment. Appl. Energy 2009, 86, 2317–2326. [Google Scholar] [CrossRef]

- Kong, X.Q.; Wang, R.Z.; Li, Y.; Huang, X.H. Optimal operation of a micro-combined cooling, heating and power system driven by a gas engine. Energy Convers. Manag. 2009, 50, 530–538. [Google Scholar] [CrossRef]

- Gao, L.; Hwang, Y.; Cao, T. An overview of optimization technologies applied in combined cooling, heating and power systems. Renew. Sustain. Energy Rev. 2019, 114, 109344. [Google Scholar] [CrossRef]

- Moghimi, M.; Emadi, M.; Ahmadi, P.; Moghadasi, H. 4E analysis and multi-objective optimization of a CCHP cycle based on gas turbine and ejector refrigeration. Appl. Therm. Eng. 2018, 141, 516–530. [Google Scholar] [CrossRef]

- Wang, J.; Lu, Z.; Li, M.; Lior, N.; Li, W. Energy, exergy, exergoeconomic and environmental (4E) analysis of a distributed generation solar-assisted CCHP (combined cooling, heating and power) gas turbine system. Energy 2019, 175, 1246–1258. [Google Scholar] [CrossRef]

- Abbasi, M.H.; Sayyaadi, H.; Tahmasbzadebaie, M. A methodology to obtain the foremost type and optimal size of the prime mover of a CCHP system for a large-scale residential application. Appl. Therm. Eng. 2018, 135, 389–405. [Google Scholar] [CrossRef]

- Yousefi, H.; Ghodusinejad, M.H.; Noorollahi, Y. GA/AHP-based optimal design of a hybrid CCHP system considering economy, energy and emission. Energy Build. 2017, 138, 309–317. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Q.; Du, J.; Nojavan, S.; Jermsittiparsert, K.; Ghadimi, N. Optimal operation of CCHP and renewable generation-based energy hub considering environmental perspective: An epsilon constraint and fuzzy methods. Sustain. Energy Grids Netw. 2019, 20, 100274. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhou, Y.; Wei, C.; Guan, Z.; Chen, H. Multi-dimension day-ahead scheduling optimization of a community-scale solar-driven CCHP system with demand-side management. Renew. Sustain. Energy Rev. 2023, 185, 113654. [Google Scholar] [CrossRef]

- Feng, L.; Dai, X.; Mo, J.; Ma, Y.; Shi, L. Analysis of energy matching performance between CCHP systems and users based on different operation strategies. Energy Convers. Manag. 2019, 182, 60–71. [Google Scholar] [CrossRef]

- Das, B.K.; Al-Abdeli, Y.M.; Kothapalli, G. Effect of load following strategies, hardware, and thermal load distribution on stand-alone hybrid CCHP systems. Appl. Energy 2018, 220, 735–753. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Wang, P.; Gu, J.; Zheng, W.; Dong, Y. Bi-stage stochastic model for optimal capacity and electric cooling ratio of CCHPs-a case study for a hotel. Energy Build. 2019, 194, 113–122. [Google Scholar] [CrossRef]

- Zheng, C.Y.; Wu, J.Y.; Zhai, X.Q. A novel operation strategy for CCHP systems based on minimum distance. Appl. Energy 2014, 128, 325–335. [Google Scholar] [CrossRef]

- Saxena, V.; Manna, S.; Rajput, S.K.; Sharma, B.; Kumar, P.; Diwania, S.; Gupta, V.; Alsharif, M.H.; Kim, M.-K. Evolutionary computing in energy systems integration: Techniques and applications. Energy Rep. 2025, 13, 6450–6478. [Google Scholar] [CrossRef]

- Bataineh, K. Hybrid fuel-assisted solar-powered stirling engine for combined cooling, heating, and power systems: A review. Energy 2024, 300, 131506. [Google Scholar] [CrossRef]

- Mao, Y.; Wu, J.; Zhang, W. An Effective Operation Strategy for CCHP System Integrated with Photovoltaic/Thermal Panels and Thermal Energy Storage. Energies 2020, 13, 6418. [Google Scholar] [CrossRef]

- Liu, W.; Dou, Z.; Yan, Y.; Zhou, T.; Chen, J. Research on Optimal Scheduling of the Combined Cooling, Heating, and Power Microgrid Based on Improved Gold Rush Optimization Algorithm. Electronics 2025, 14, 3135. [Google Scholar] [CrossRef]

- Salimi, M.; Hosseinpour, M.; Mansouri, S.; Borhani, T.N. Environmental Aspects of the Combined Cooling, Heating, and Power (CCHP) Systems: A Review. Processes 2022, 10, 711. [Google Scholar] [CrossRef]

- Dupuy, A.; Percembli, A.A.; Grosu, L.; Tran, K.-H.; Dobrovicescu, A. Trigeneration Systems: A State-of-the-Art Review. Energies 2025, 18, 2594. [Google Scholar] [CrossRef]

- Hervé, P.L.; Michael, T.T.; Salomon, N.P.; Joseph, K.; Raphael, M.K.; Jean, N. Energy and exergy analyses of CCHP (combined cooling, heating and power) system based on co-firing of biogas and syngas produced from biomass. Heliyon 2023, 9, e21753. [Google Scholar] [CrossRef]

- He, S.Q.; Hou, Y.R.; Dong, Z.F.; Zhang, J.; Wu, Y.; Liu, S.L. The evolution of China’s electricity market-oriented reform: Pathways to achieving marketization and decarbonization in response to climate policy. J. Environ. Manag. 2025, 389, 126103. [Google Scholar] [CrossRef]

- Dittmann, B.; Lauter, T.; Prokopczuk, M.; Sibbertsen, P. What determines the price of carbon? New evidence from phase III and IV of the EU ETS. J. Clim. Financ. 2025, 12, 100070. [Google Scholar] [CrossRef]

- Mohseni-Gharyehsafa, B.; Bampoulas, A.; Finn, D.; Pallonetto, F. Energy flexibility and management software in building clusters: A comprehensive review. Next Energy 2025, 8, 100250. [Google Scholar] [CrossRef]

- Tang, H.; Wang, S.; Li, H. Flexibility categorization, sources, capabilities and technologies for energy-flexible and grid-responsive buildings: State-of-the-art and future perspective. Energy 2021, 219, 119598. [Google Scholar] [CrossRef]

- Anvari, S.; Medina, A.; Merchán, R.P.; Calvo Hernández, A. Sustainable solar/biomass/energy storage hybridization for enhanced renewable energy integration in multi-generation systems: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 223, 115997. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, B.; Sun, Q.; Wennersten, R. Application of energy storage in integrated energy systems—A solution to fluctuation and uncertainty of renewable energy. J. Energy Storage 2022, 52, 104812. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, Z.; Tao, H.; Yang, D.; Tang, X.; Wang, Y. Planar micro-supercapacitors toward high performance energy storage devices: Design, application and prospects. Energy Adv. 2023, 2, 765–783. [Google Scholar] [CrossRef]

- Dezhdar, A.; Assareh, E.; Agarwal, N.; Baheri, A.; Ahmadinejad, M.; Zadsar, N.; Yeganeh Fard, G.; Bedakhanian, A.; Aghajari, M.; Ghodrat, M.; et al. Modeling, optimization, and economic analysis of a comprehensive CCHP system with fuel cells, reverse osmosis, batteries, and hydrogen storage subsystems Powered by renewable energy sources. Renew. Energy 2024, 220, 119695. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, Y. The novel operation strategy of CCHP-GSHP-PV system based on device complementary characteristic considering different storage electricity modes. Energy 2025, 327, 136295. [Google Scholar] [CrossRef]

- Zeng, J.; Yin, S.; Tong, L.; Liu, C.; Wang, L.; Wu, C.-Y. Design and evaluation of an integrated CCHP system based on solar thermal supplementary heating and off-peak electrical thermal storage heating. Energy 2025, 328, 136505. [Google Scholar] [CrossRef]

- Mo, J.; Dai, X.; Xu, S.; Shi, L.; Feng, L. Analysis of performance and suitable users of CCHP systems with active thermal energy storage. Appl. Therm. Eng. 2023, 229, 120574. [Google Scholar] [CrossRef]

- Luo, W.; Wu, J.; Cai, J.; Mao, Y.; Chen, S. Capacity Allocation Optimization Framework for Hydrogen Integrated Energy System Considering Hydrogen Trading and Long-Term Hydrogen Storage. IEEE Access 2023, 11, 15772–15787. [Google Scholar] [CrossRef]

- Pan, G.; Gu, W.; Lu, Y.; Qiu, H.; Lu, S.; Yao, S. Optimal Planning for Electricity-Hydrogen Integrated Energy System Considering Power to Hydrogen and Heat and Seasonal Storage. IEEE Trans. Sustain. Energy 2020, 11, 2662–2676. [Google Scholar] [CrossRef]

- Mao, Y.; Cai, Z.; Wan, K.; Long, D. Bargaining-based energy sharing framework for multiple CCHP systems with a shared energy storage provider. Energy Sci. Eng. 2024, 12, 1369–1388. [Google Scholar] [CrossRef]

- Song, X.; Wu, H.; Zhang, J.; Zhao, C.; Peña-Mora, F. Optimal operation of shared energy storage-assisted wind-solar-thermal power generation systems under the electricity-carbon markets. Energy 2025, 330, 136614. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Xiong, H.; Guo, C. Distributed shared energy storage scheduling based on optimal operating interval in generation-side. Sustain. Energy Grids Netw. 2023, 34, 101026. [Google Scholar] [CrossRef]

- Zhong, S.; Tang, H. Peer-to-peer energy-carbon trading strategy for MIES based on electric hydrogen production and shared energy storage mechanism. Int. J. Hydrogen Energy 2025, 138, 843–858. [Google Scholar] [CrossRef]

- Sun, G.; Chen, X.; Zhou, Y.; Chen, S.; Wei, Z. Decentralized distributionally robust energy and reserve co-optimization of smart building clusters with virtual energy storage capability. Energy Build. 2024, 309, 114040. [Google Scholar] [CrossRef]

- Yin, Z.; Tan, Z.; Zheng, H.; Ju, L.; Tan, C. Two-stage information-gap optimization decision model of electricity-hydrogen integrated virtual power plant with shared energy storage. J. Energy Storage 2024, 100, 113612. [Google Scholar] [CrossRef]

- Çelik, D.; Khan, M.A.; Khosravi, N.; Waseem, M.; Ahmed, H. A review of energy storage systems for facilitating large-scale EV charger integration in electric power grid. J. Energy Storage 2025, 112, 115496. [Google Scholar] [CrossRef]

- Fambri, G.; Marocco, P.; Badami, M.; Tsagkrasoulis, D. The flexibility of virtual energy storage based on the thermal inertia of buildings in renewable energy communities: A techno-economic analysis and comparison with the electric battery solution. J. Energy Storage 2023, 73, 109083. [Google Scholar] [CrossRef]

- Maślak, G.; Orłowski, P. Operational optimisation of a microgrid using non-stationary hybrid switched model predictive control with virtual storage-based demand management. Renew. Sustain. Energy Rev. 2024, 202, 114685. [Google Scholar] [CrossRef]

- Fan, P.; Wang, D.; Sun, Y.; Wang, W. A generalized flexibility potential quantification method of active thermal energy storage system for grid-interactive efficient buildings. J. Energy Storage 2025, 117, 116120. [Google Scholar] [CrossRef]

- Liu, Z.-F.; Luo, X.-F.; Hou, X.-X.; Yu, J.-L.; Li, J.-X. Generalized energy pool-driven regional integrated energy system dispatch considering multi-time scale synergy carbon-storage game. Renew. Sustain. Energy Rev. 2025, 217, 115752. [Google Scholar] [CrossRef]

- Günther, S.; Bensmann, A.; Hanke-Rauschenbach, R. Representative energy management strategies for hybrid energy storage systems derived from a meta-review. Renew. Sustain. Energy Rev. 2025, 216, 115610. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Y.; Ma, T.; Tian, H.; Liu, J.; Zhou, M.; Wang, W. Multi-type energy storage expansion planning: A review for high-penetration renewable energy integration. Renew. Sustain. Energy Rev. 2025, 219, 115853. [Google Scholar] [CrossRef]

- Mao, Y.; Cai, Z.; Jiao, X.; Lond, D. Multi-timescale optimization scheduling of integrated energy systems oriented towards generalized energy storage services. Sci. Rep. 2025, 15, 8549. [Google Scholar] [CrossRef]

- Fang, Z.; Shek, J.K.H.; Sun, W. A review of grid-connected hybrid energy storage systems: Sizing configurations, control strategies, and future directions. J. Energy Storage 2025, 118, 116226. [Google Scholar] [CrossRef]

- Lingmin, C.; Jiekang, W.; Fan, W.; Huiling, T.; Changjie, L.; Yan, X. Energy flow optimization method for multi-energy system oriented to combined cooling, heating and power. Energy 2020, 211, 118536. [Google Scholar] [CrossRef]

- Wu, J.K.; Wu, Z.J.; Wu, F.; Tang, H.L.; Mao, X.M. CVaR risk-based optimization framework for renewable energy management in distribution systems with DGs and EVs. Energy 2018, 143, 323–336. [Google Scholar] [CrossRef]

- Mao, Y.S.; Wu, J.K.; Wang, R.D.; Cai, Z.H.; Zhang, R.; Chen, L.M. A Collaborative Demand-Controlled Operation Strategy for a Multi-Energy System. IEEE Access 2021, 9, 80571–80581. [Google Scholar] [CrossRef]

- Jiao, X.; Wu, J.; Mao, Y.; Yan, M. Carbon efficiency evaluation method for urban energy system with multiple energy complementary. Glob. Energy Interconnect. 2024, 7, 142–154. [Google Scholar] [CrossRef]

- Chen, L.; Tang, H.; Wu, J.; Li, C.; Wang, Y. A robust optimization framework for energy management of CCHP users with integrated demand response in electricity market. Int. J. Electr. Power Energy Syst. 2022, 141, 108181. [Google Scholar] [CrossRef]

- Saberi-Beglar, K.; Zare, K.; Seyedi, H.; Marzband, M.; Nojavan, S. Risk-embedded scheduling of a CCHP integrated with electric vehicle parking lot in a residential energy hub considering flexible thermal and electrical loads. Appl. Energy 2023, 329, 120265. [Google Scholar] [CrossRef]

- Zhang, L.; Jin, Q.; Zhang, W.; Chen, L.; Yang, N.; Chen, B. Risk-involved dominant optimization of multi-energy CCHP-P2G-based microgrids integrated with a variety of storage technologies. J. Energy Storage 2024, 80, 110260. [Google Scholar] [CrossRef]

- Yang, B.; Ge, S.; Liu, H.; Zhang, X.; Xu, Z.; Wang, S.; Huang, X. Regional integrated energy system reliability and low carbon joint planning considering multiple uncertainties. Sustain. Energy Grids Netw. 2023, 35, 101123. [Google Scholar] [CrossRef]

- Mao, Y.; Yuan, J.; Long, D.; Lin, H. Robust Optimization of Data Center Microgrid Capacity Configuration Considering Load Characteristics. In Proceedings of the 2024 8th International Conference on Automation, Control and Robots (ICACR), Xiangyang, China, 1–3 November 2024; pp. 122–125. [Google Scholar] [CrossRef]

- Fan, J.; Yan, R.; He, Y.; Zhang, J.; Zhao, W.; Liu, M.; An, S.; Ma, Q. Stochastic optimization of combined energy and computation task scheduling strategies of hybrid system with multi-energy storage system and data center. Renew. Energy 2025, 242, 122466. [Google Scholar] [CrossRef]

- Guo, Q.; Nojavan, S.; Lei, S.; Liang, X. Economic-environmental evaluation of industrial energy parks integrated with CCHP units under a hybrid IGDT-stochastic optimization approach. J. Clean. Prod. 2021, 317, 128364. [Google Scholar] [CrossRef]

- Saladi, J.K.; Suresh, R.; Datta, S.P. Performance analysis of solar-integrated ejector-based CCHP system for a commercial building. Sustain. Chem. Clim. Action 2025, 6, 100059. [Google Scholar] [CrossRef]

- Keskin, I.; Soykan, G. Distribution grid electrical performance and emission analysis of combined cooling, heating and power (CCHP)-photovoltaic (PV)-based data center and residential customers. J. Clean. Prod. 2023, 414, 137448. [Google Scholar] [CrossRef]

- Wang, Y.; Song, M.; Jia, M.; Li, B.; Fei, H.; Zhang, Y.; Wang, X. Multi-objective distributionally robust optimization for hydrogen-involved total renewable energy CCHP planning under source-load uncertainties. Appl. Energy 2023, 342, 121212. [Google Scholar] [CrossRef]

- Strobel, M.; Erguvan, M.; Da Silva, R.P.P.; Amini, S. Techno-economic analysis of an integrated green hydrogen production into a combined cooling, heating, and power (CCHP) system for a university campus. Appl. Therm. Eng. 2025, 277, 126997. [Google Scholar] [CrossRef]

- Du, J.; Guo, J. Analysis of Multi-Cascade CCHP System with Gas Turbine Bypass Extraction Air Energy Storage. Appl. Thermal Eng. 2023, 232, 121021. [Google Scholar] [CrossRef]

- Song, Z. A control strategy study of a renewable CCHP energy system integrated hydrogen production unit—A Case Study of an Industrial Park in Jiangsu Province. Energy Rep. 2023, 10, 1629–1651. [Google Scholar] [CrossRef]

- Lv, C.; Liang, R.; Jin, W.; Chai, Y.; Yang, T. Multi-stage resilience scheduling of electricity-gas integrated energy system with multi-level decentralized reserve. Appl. Energy 2022, 317, 119165. [Google Scholar] [CrossRef]

- Yang, J.; Lei, L.; Liu, D.; Luo, W. A distributed dispatch approach for district-level electric-heat-gas integrated energy systems considering carbon emission and green certificate trading. Electr. Power Syst. Res. 2025, 244, 111541. [Google Scholar] [CrossRef]

- Sheykhi, M.; Chahartaghi, M.; Safaei Pirooz, A.A.; Flay, R.G.J. Investigation of the effects of operating parameters of an internal combustion engine on the performance and fuel consumption of a CCHP system. Energy 2020, 211, 119041. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Yan, Z.; Cao, H.; Shi, H.; Jia, Y. Optimization of energy output in multimodal and multi-load CCHP systems with integrated electric energy storage. Energy Rep. 2025, 13, 4734–4748. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Z.; Li, Y.; Chen, Z.; Yap, P.-S.; Li, L. Two-stage design model of SE-GSHP-CCHP system for coupled thermal energy storage considering optimal configuration and scheduling. J. Energy Storage 2025, 115, 115926. [Google Scholar] [CrossRef]

- Zheng, C.Y.; Wu, J.Y.; Zhai, X.Q.; Wang, R.Z. A Novel Thermal Storage Strategy for CCHP System Based on Energy Demands and State of Storage Tank. Int. J. Electr. Power Energy Syst. 2017, 85, 117–129. [Google Scholar] [CrossRef]

- Wang, H.N.; Xue, X.J.; Zhao, C.Y. Performance analysis on combined energy supply system based on Carnot battery with packed-bed thermal energy storage. Renew. Energy 2024, 228, 120702. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Zhang, Y.; Yu, H.; Wang, Z.; Li, L.; Wang, N.; Yang, Z.; Maréchal, F.; Yang, Y. A multi-objective planning method for multi-energy complementary distributed energy system: Tackling thermal integration and process synergy. J. Clean. Prod. 2023, 390, 135905. [Google Scholar] [CrossRef]

- Ouyang, T.; Tan, X.; Tuo, X.; Qin, P.; Mo, C. Performance analysis and multi-objective optimization of a novel CCHP system integrated energy storage in large seagoing vessel. Renew. Energy 2024, 224, 120185. [Google Scholar] [CrossRef]

- Huang, Z.; You, H.; Chen, D.; Hu, B.; Liu, C.; Xiao, Y.; Prokazov, A.; Lysyakov, A. Thermodynamic, economic, and environmental analyses and multi-objective optimization of a CCHP system based on solid oxide fuel cell and gas turbine hybrid power cycle. Fuel 2024, 368, 131649. [Google Scholar] [CrossRef]

- Omidi Kashani, B.; Khoshbakhti Saray, R.; Kheiri, R. Comparative analysis of a CCHP system based on municipal solid waste (MSW) gasification using micro gas turbine and internal combustion engine: Energy, exergy, economic, and environmental (4E) perspectives. Energy 2025, 326, 136004. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, Y.; Bucknall, R. Optimised MOPSO with the grey relationship analysis for the multi-criteria objective energy dispatch of a novel SOFC-solar hybrid CCHP residential system in the UK. Energy Convers. Manag. 2021, 243, 114406. [Google Scholar] [CrossRef]

- Nondy, J. 4E analyses of a micro-CCHP system with a polymer exchange membrane fuel cell and an absorption cooling system in summer and winter modes. Int. J. Hydrogen Energy 2024, 52, 886–904. [Google Scholar] [CrossRef]

- Bertsimas, D.; Sim, M. The Price of Robustness. Oper. Res. 2004, 52, 35–53. [Google Scholar] [CrossRef]

- Zeng, B.; Zhao, L. Solving two-stage robust optimization problems using a column-and-constraint generation method. Oper. Res. Lett. 2013, 41, 457–461. [Google Scholar] [CrossRef]

- Ruan, Y.J.; Liang, Z.Y.; Qian, F.Y.; Meng, H.; Gao, Y. Operation strategy optimization of combined cooling, heating, and power systems with energy storage and renewable energy based on deep reinforcement learning. J. Build. Eng. 2023, 65, 105682. [Google Scholar] [CrossRef]

- Aguilar, D.; Quinones, J.J.; Pineda, L.R.; Ostanek, J.; Castillo, L. Optimal scheduling of renewable energy microgrids: A robust multi-objective approach with machine learning-based probabilistic forecasting. Appl. Energy 2024, 369, 123548. [Google Scholar] [CrossRef]

- Elabbassi, I.; Khala, M.; El yanboiy, N.; Eloutassi, O.; El hassouani, Y. Evaluating and comparing machine learning approaches for effective decision making in renewable microgrid systems. Results Eng. 2024, 21, 101888. [Google Scholar] [CrossRef]

| Phase and Timeframe | Core Paradigm | Key Developments | Critical Limitations |

|---|---|---|---|

| Phase 1: 2000–2010 Thermodynamics-Driven | Component-centric efficiency |

|

|

| Phase 2: 2010–2020 Single/Multi-Objective Optimization | 4E tradeoffs |

|

|

| Phase 3: 2021–Present Uncertainty-Resilient Coordination | AI-enabled adaptive control |

|

|

| Flexibility Resource | Subcategories | Primary Function | Typical Performance Metrics |

|---|---|---|---|

| Storage-Driven Buffering | Physical Energy Storage, Virtual Storage | Decouples energy supply–demand across timescales | Response time (seconds–days), capacity (kWh/m3), efficiency (%) |

| Demand-Side Adjustment | Electrical, Gas/Thermal, Sector-Specific | Alters consumption patterns to match RE availability | Load shift potential (MW), adjustable duration (h) |

| Multi-Energy Synergy | Gas–Electricity, Heat–Electricity, Hydrogen | Leverages coupling between energy vectors for dynamic rebalancing | RE utilization increase (%), cost reduction (%) |

| Feature | Physical Energy Storage | Virtual Energy Storage |

|---|---|---|

| Charge/Discharge Power | Rated power of storage device | Adjustable load deviation from baseline |

| Capacity Definition | Energy capacity | Equivalent energy-adjustment range |

| Power Dynamics | Fixed charge/discharge power limits | Time-dependent adjustable power deviation |

| State of Charge (SOC) | Remaining energy/rated capacity | VSOC: Normalized flexibility potential |

| Response Time | Seconds (batteries) to hours (TES) | Ultra-fast (seconds for TCLs/EVs) |

| Scalability | Limited by capital expenditures and space | Highly scalable through aggregation |

| Primary Role in CCHP | Bulk energy shifting (hours–days) | Real-time imbalance correction |

| Storage Type | Medium | Function | Performance Metrics | Limitations |

|---|---|---|---|---|

| Thermal | Water/ice/PCMs/molten salt | Decouples thermal/cooling production from demand |

|

|

| Electrochemical (Batteries) | Li-ion/flow batteries | Buffers short-term RE fluctuations |

|

|

| Shared Storage | Aggregated batteries/thermal tanks | Pools distributed resources for cost efficiency |

|

|

| Mobile Storage | EVs/mobile H2 tanks/thermal carriers | Enables cross-regional energy transfer |

|

|

| Chemical (Power-to-Gas/H2) | Hydrogen/methane via electrolysis | Converts surplus RE to storable fuels |

|

|

| VES Type | Regulation Mechanism | Efficiency | Performance in CCHP |

|---|---|---|---|

| Temperature-Control Loads | Thermal inertia | 70–80% (heat loss over 2–4 h) | Reduces chiller startup frequency by 30–40% |

| Electric Vehicles (V2G) | Smart charging/discharging | 80–90% (round-trip efficiency) | Shifts 30% of charging load to solar peaks |

| Heating Network | Pipeline thermal storage | 85–95% (heat retention over 8 h) | Decouples heat-power ratio by 4–8 h |

| Feature | PES | VES | GES | Integration Pathways |

|---|---|---|---|---|

| Primary Role | Deterministic energy buffering via tangible media | Flexibility provision through load/process adjustment | Unified framework synergizing PES and VES | Systemic coordination of multi-energy vectors |

| Key Benefits |

|

|

| Cross-domain flexibility transfer via multi-energy coupling |

| Major Limitations |

|

|

| Dependent on communication infrastructure and market mechanism |

| CCHP Integration | Centralized/decentralized hardware deployment | Demand response programs and aggregator coordination | AI-driven dynamic resource allocation | Hierarchical control: Device-level → Cluster-level → System-level optimization |

| Methods | Characteristics | Uncertainty Handling Mechanism |

|---|---|---|

| Robust optimization | Uncertain parameter sets are known | Worst-case immunization within uncertainty set |

| Stochastic programming | Probability distributions of uncertain parameters are known | Expected value optimization via scenario trees |

| Distributionally robust optimization | Unknown true distribution but belongs to ambiguity set | Min-max expected cost over ambiguity set |

| Information gap decision theory | Severe uncertainty about uncertainty bounds | Dual objective: robustness and opportunity |

| Deep reinforcement learning | Model-free learning from environment interactions | Q-learning/policy gradients with function approximation |

| Chance-constrained programming | Constraint violation probabilities specified | Probabilistic feasibility guarantees |

| Adaptive robust optimization (ARO) | Multi-stage decisions with recourse actions | Here-and-now + wait-and-see adaptive decisions |

| Criterion | SO | RO | DRO | Adaptive RO | DRL | CCP |

|---|---|---|---|---|---|---|

| Uncertainty type | Probabilistic | Bounded | Ambiguous set | Multi-stage bounded | Model-free | Probabilistic |

| Time scale | Hours–days | Days | Hours | Hours–days | Seconds–minutes | Minutes–hours |

| Risk handling | Expected value | Absolute | Distributional | Recourse-adjusted | Learned | Explicit probabilistic |

| Computation | High (O(Sn)) | Medium (O(2m)) | High (O(N1.5)) | Very H = high (O(T·2m)) | Low (online) | Medium (O(n3.5)) |

| Key feature | Scenario-based | Worst-case | Data-driven | Dynamic adjustment | AI-driven | Safety margins |

| CCHP fit | Day-ahead | Extreme events | Market volatility | Multi-time dispatch | Real-time control | Critical constraints |

| Hybrid Strategy | Best-Suited Scenario | Key Advantages | Simulation Results |

|---|---|---|---|

| RO + DRL [57] | Forecast uncertainty | Balances robustness and online adaptation | Cost ↓ 18–22%, robustness ↑ 30–40% |

| SO + CCP [61] | Gaussian-distributed | Cost-optimal with safety guarantees | Expected cost ↓ 15%, violation probability < 5% |

| DRO + CCP [59] | Ambiguous distributions + safety | Handles distributional ambiguity + risk | Worst-case cost ↓ 12%, CVaR ↓ 25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Yuan, J.; Jiao, X. Optimal Operation of Combined Cooling, Heating, and Power Systems with High-Penetration Renewables: A State-of-the-Art Review. Processes 2025, 13, 2595. https://doi.org/10.3390/pr13082595

Mao Y, Yuan J, Jiao X. Optimal Operation of Combined Cooling, Heating, and Power Systems with High-Penetration Renewables: A State-of-the-Art Review. Processes. 2025; 13(8):2595. https://doi.org/10.3390/pr13082595

Chicago/Turabian StyleMao, Yunshou, Jingheng Yuan, and Xianan Jiao. 2025. "Optimal Operation of Combined Cooling, Heating, and Power Systems with High-Penetration Renewables: A State-of-the-Art Review" Processes 13, no. 8: 2595. https://doi.org/10.3390/pr13082595

APA StyleMao, Y., Yuan, J., & Jiao, X. (2025). Optimal Operation of Combined Cooling, Heating, and Power Systems with High-Penetration Renewables: A State-of-the-Art Review. Processes, 13(8), 2595. https://doi.org/10.3390/pr13082595