Laboratory Investigation of Miscible CO2-Induced Enhanced Oil Recovery from the East-Southern Pre-Caspian Region

Abstract

1. Introduction

2. Materials and Methods

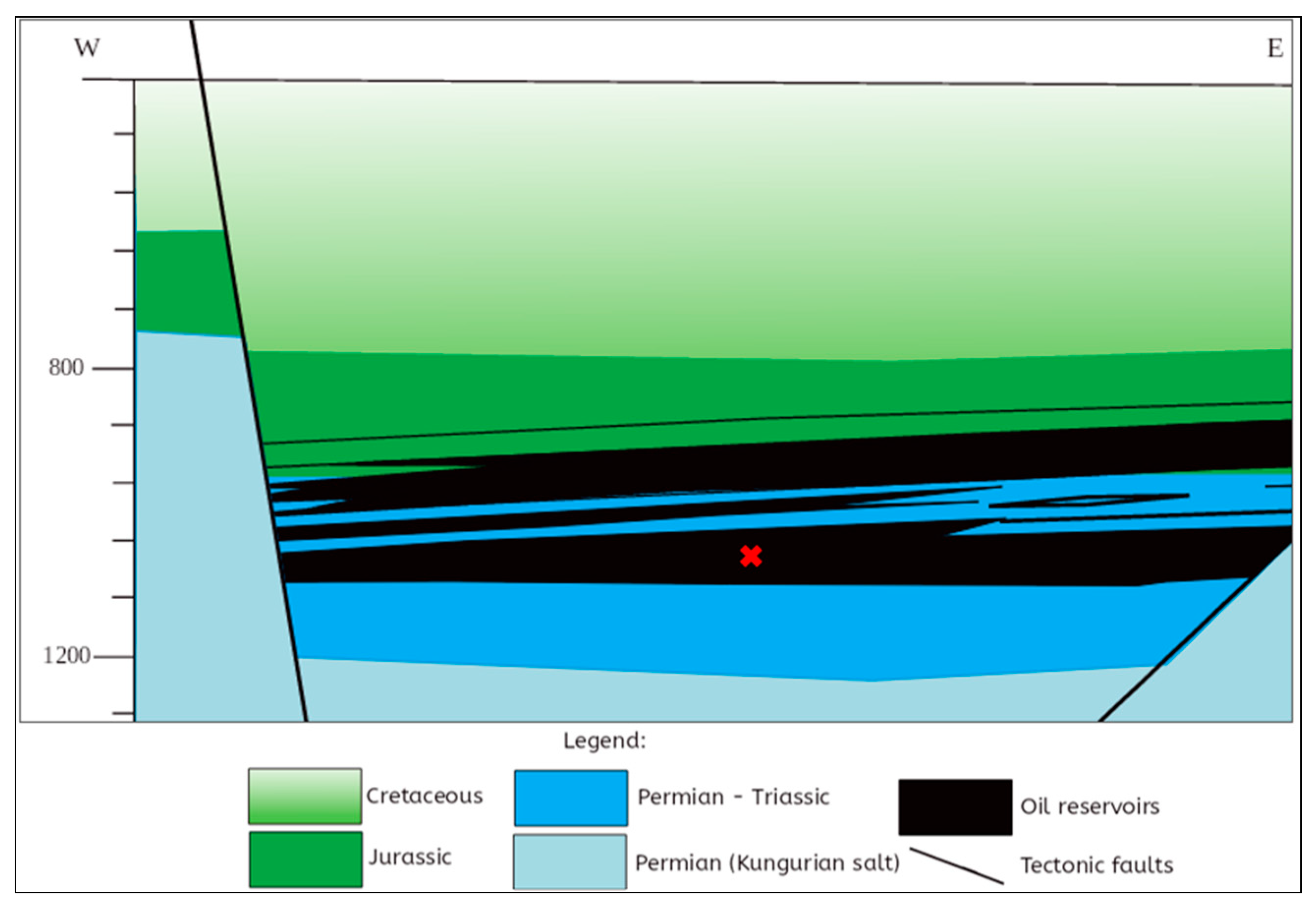

2.1. Geological Settings

2.2. Oil and Brine Used in Core Flooding

2.3. Minimum Miscible Pressure Estimation

2.4. Experimental Procedure

- ˗

- Core samples were saturated with model reservoir brine under controlled pressure and temperature conditions, with injection rates and fluid volumes carefully recorded.

- ˗

- Oil was subsequently injected until all brine was displaced, followed by a stabilization period of 24 h to ensure equilibrium.

- ˗

- CO2 was injected at a constant rate, and the produced fluid mixture (oil, water, and CO2) was separated and measured using a dedicated separator.

- ˗

- To assess the impact of CO2 injection, porosity and permeability were measured both before and after the experiment using the same core plug. These measurements were conducted under identical pressure and temperature conditions (13 MPa, 42 °C) using a single core sample, allowing reliable comparison of the property alterations.

- ˗

- SEM and XRD analyses were performed on the post-experiment samples to evaluate mineralogical and structural transformations. These methods provided a comprehensive understanding of the dynamic processes occurring within the reservoir rock during CO2 injection, offering valuable insights into optimizing EOR operations.

- The setup includes multiple high-pressure core holders made from corrosion-resistant stainless steel, ensuring uniform pressure distribution for accurate fluid displacement experiments.

- An integrated network of pipes and valves controls fluid injection and extraction, enabling smooth phase transitions between brine, oil, and gas. High-precision valves ensure leakage-free operation.

- A transparent fluid storage bottle and collection unit facilitate real-time monitoring of displaced fluids. Pressure and flow sensors connected to control units provide continuous feedback for precise experimental control and data acquisition.

- The core holders and fluid management system are mounted on a modular, mobile aluminum frame, enhancing adaptability and integration with other experimental setups. An auxiliary power distribution strip ensures reliable operation, minimizing electrical interference.

- ˗

- CO2 Cylinder: A high-capacity (up to 50 L) CO2 storage unit equipped with a pressure regulator to maintain a stable and controlled gas supply, ensuring consistent injection conditions.

- ˗

- Pressure Regulator: A precision regulator that modulates CO2 flow to maintain the required pressure for experimental stability.

- ˗

- Stabilization Tank: A dedicated buffer unit designed to collect displaced fluids during CO2 injection or regulate fluid flow to prevent system fluctuations.

- ˗

- High-Pressure Tubing: A network of reinforced stainless-steel pipelines and hoses ensuring secure, high-pressure transport of CO2 and fluids between components, minimizing leakage risks and enhancing operational safety.

- ˗

- Monitoring Instruments (Pressure Gauges, Flow Meters): Integrated high-precision monitoring devices calibrated for real-time measurement and regulation of CO2 and fluid flow parameters.

2.5. Core Flooding Experimental Conditions

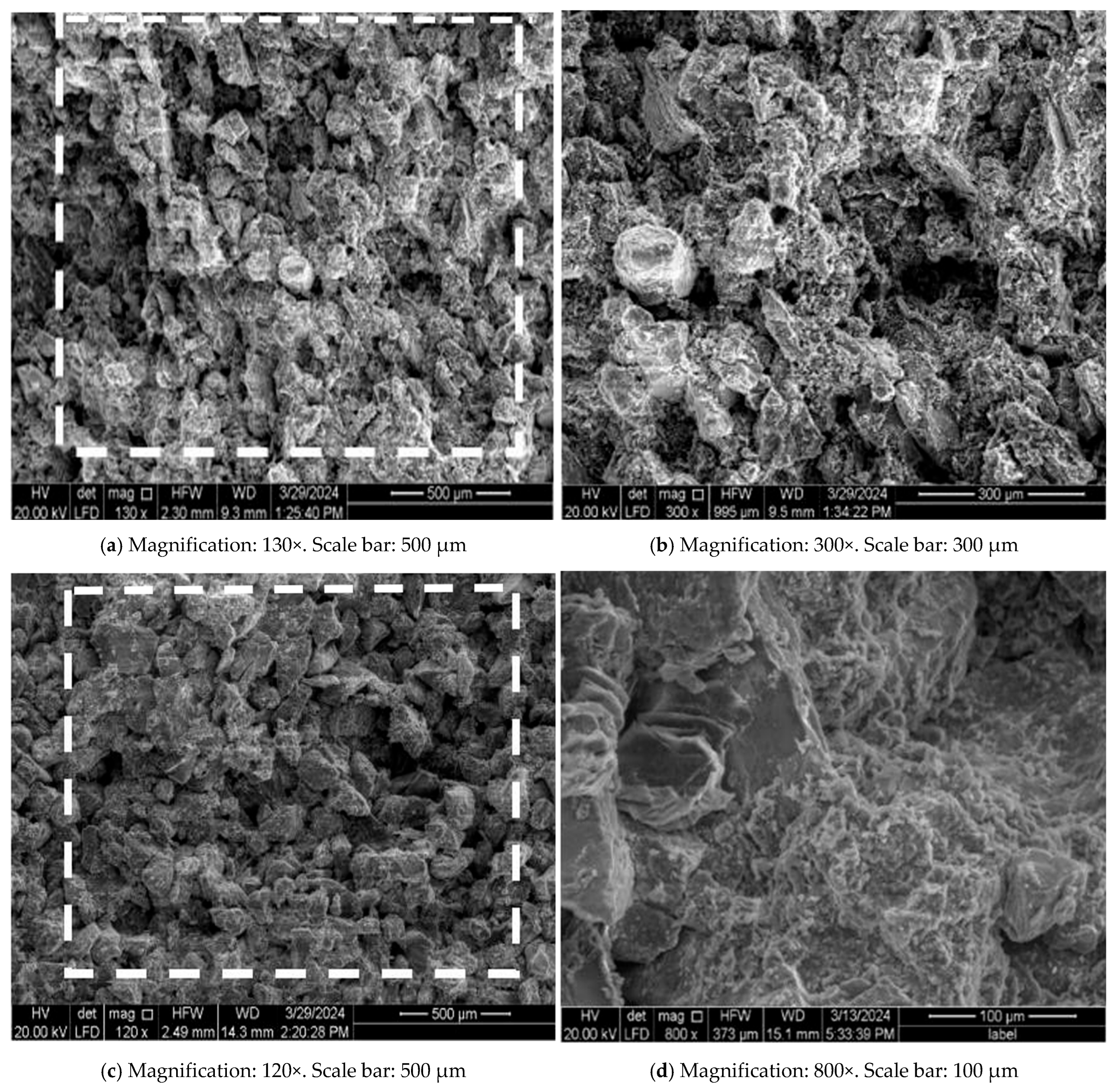

2.6. Scanning Electron Microscopy (SEM)

2.7. X-Ray Diffraction Analysis (XRD)

3. Results

Core Samples’ Characterization

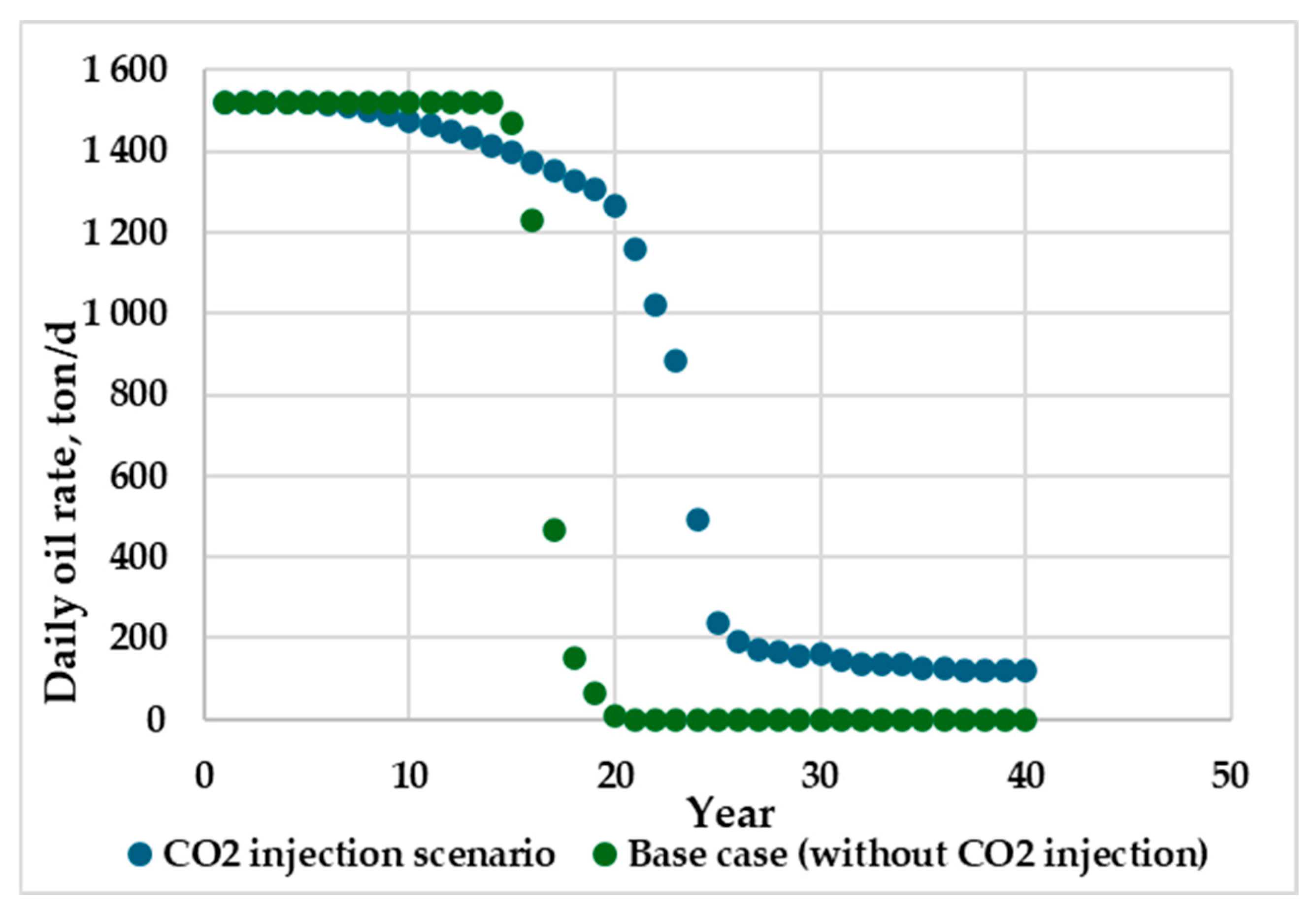

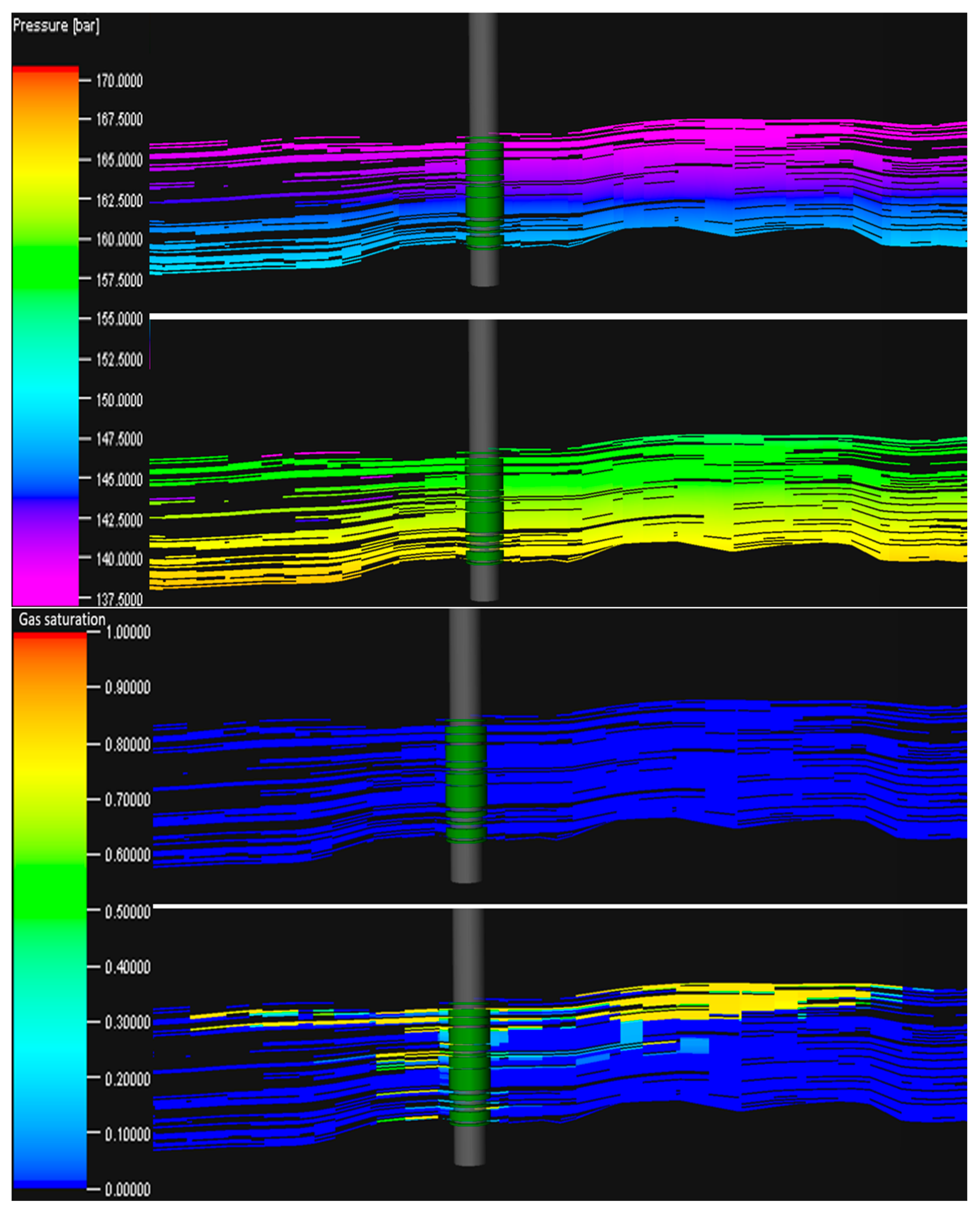

4. Simulation Study

- ✓

- Baseline reservoir conditions were established through initialization, ensuring accurate starting points for CO2 injection scenarios.

- ✓

- Laboratory measurements were used to calibrate model parameters. This step ensured alignment between simulated outputs and actual reservoir behavior.

- ✓

- Laboratory-derived fluid properties, core analysis, and PVT data were incorporated into the model to reflect realistic reservoir conditions and fluid responses to CO2 injection.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Massarweh, O.; Abushaikha, A.S. A Review of Recent Developments in CO2 Mobility Control in Enhanced Oil Recovery. Petroleum 2021, 8, 291–317. [Google Scholar] [CrossRef]

- Bealessio, B.A.; Alonso, N.A.B.; Mendes, N.J.; Sande, A.V.; Hascakir, B. A Review of Enhanced Oil Recovery (EOR) Methods Applied in Kazakhstan. Petroleum 2021, 7, 1–9. [Google Scholar] [CrossRef]

- Zhong, H.; Shi, B.; Bi, Y.; Cao, X.; Zhang, H.; Yu, C.; Tang, H. Interaction of Elasticity and Wettability on Enhanced Oil Recovery in Viscoelastic Polymer Flooding: A Case Study on Oil Droplet. Geoenergy Sci. Eng. 2025, 250, 213827. [Google Scholar] [CrossRef]

- Shabdirova, A.; Kozhagulova, A.; Samenov, Y.; Merbayev, R.; Niyazbayeva, A.; Shabdirov, D. Core Flooding Experiments on the Impact of CO2-EOR on the Petrophysical Properties and Oil Recovery Parameters of Reservoir Sandstones in Kazakhstan. Geosciences 2024, 14, 185. [Google Scholar] [CrossRef]

- Izgec, O.; Demiral, B.; Bertin, H.; Trefle, L.; Akin, S. CO2 Injection in Carbonates. In Proceedings of the SPE Western Regional Meeting, Irvine, CA, USA, 30 March–1 April 2005. [Google Scholar]

- Bachu, S. Identification of Oil Reservoirs Suitable for CO2-EOR and CO2 Storage (CCUS) Using Reserves Databases, with Application to Alberta, Canada. Int. J. Greenh. Gas Control. 2016, 44, 152–165. [Google Scholar] [CrossRef]

- Abuov, Y.; Serik, G.; Lee, W. Techno-Economic Assessment and Life Cycle Assessment of CO2-EOR. Environ. Sci. Technol. 2022, 56, 8571–8580. [Google Scholar] [CrossRef]

- Fath, A.H.; Pouranfard, A.-R. Evaluation of Miscible and Immiscible CO2 Injection in One of the Iranian Oil Fields. Egypt. J. Pet. 2014, 23, 255–270. [Google Scholar] [CrossRef]

- Gozalpour, F.; Ren, S.R.; Tohidi, B. CO2 EOR and Storage in Oil Reservoirs. Oil Gas Sci. Technol. Rev. IFP 2005, 60, 537–546. [Google Scholar] [CrossRef]

- Rufford, T.E.; Smart, S.; Watson, G.C.Y.; Graham, B.F.; Boxall, J.; Diniz da Costa, J.C.; May, E.F. The Removal of CO2 and N2 from Natural Gas: A Review of Conventional and Emerging Process Technologies. J. Pet. Sci. Eng. 2012, 94–95, 123–154. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, M.; Li, W.; Wen, F.; Dong, G.; Zou, L.; Zhang, Y. Development of a Predictive Model for Carbon Dioxide Corrosion Rate and Severity Based on Machine Learning Algorithms. Materials 2024, 17, 4046. [Google Scholar] [CrossRef]

- Rezaee, R.; Saeedi, A.; Iglauer, S.; Evans, B. Shale Alteration after Exposure to Supercritical CO2. Int. J. Greenh. Gas Control. 2017, 62, 91–99. [Google Scholar] [CrossRef]

- Khather, M.; Saeedi, A.; Myers, M.B.; Verrall, M. An Experimental Study for Carbonate Reservoirs on the Impact of CO2-EOR on Petrophysics and Oil Recovery. Fuel 2019, 235, 1019–1038. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Enhanced Oil Recovery: An Update Review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Krevor, S.; Pini, R.; Benson, S.M. Measurement of the Multiphase Flow Properties of the CO2/Brine System for Carbon Sequestration. Energy Procedia 2013, 37, 4499–4503. [Google Scholar] [CrossRef]

- He, H.; Ma, X.; Lei, F.; Liu, X.; Jiang, M.; Li, Y.; Mou, J. An Experimental Investigation of Interaction between CO2 Solution and Rock under Reservoir Conditions in the Jimsar Shale Oil Formation. Processes 2024, 12, 673. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Xu, N.; Wang, Y.; Bai, B. Settling Behavior and Mechanism Analysis of Kaolinite as a Fracture Proppant of Hydrocarbon Reservoirs in CO2 Fracturing Fluid. Colloids Surf. A Physicochem. Eng. Asp. 2025, 724, 137463. [Google Scholar] [CrossRef]

- Qingchao, L.; Jingjuan, W.; Qiang, L.; Fuling, W.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar] [CrossRef]

- Bulekbayev, Z.E.; Iskuzhiyev, B.A.; Kamalov, S.M. Oil and Gas Fields of Kazakhstan: A Catalogue, 3rd ed.; Kazhegeldin, A.M., Ed.; Kazakhstan Mineral Resources: Almaty, Kazakhstan, 2016. [Google Scholar]

- Cronquist, C. Carbon Dioxide Dynamic Miscibility with Light Reservoir Oils. In Proceedings of the 4th Annual U.S. DOE Symposium, Tulsa, OK, USA, 29–31 August 1978. [Google Scholar]

- Li, H.; Qin, J.; Yang, D. An Improved CO2-Oil Minimum Miscibility Pressure Correlation for Live and Dead Crude Oils. Ind. Eng. Chem. Res. 2012, 51, 3516–3523. [Google Scholar] [CrossRef]

- Orr, F.M., Jr.; Jensen, C.M. Interpretation of Pressure-Composition Phase Diagrams for CO2/Crude-Oil Systems. Soc. Pet. Eng. J. 1984, 24, 485–497. [Google Scholar] [CrossRef]

- Bondarenko, A.V.; Islamov, S.R.; Ignatyev, K.V.; Mardashov, D.V. Laboratory Studies of Polymer Compositions for Well-Kill under Increased Fracturing. Perm J. Pet. Min. Eng. 2020, 20, 37–48. [Google Scholar] [CrossRef]

- Speight, J.G. CHAPTER 5—Exploration and General Methods for Oil Recovery. In Enhanced Recovery Methods for Heavy Oil and Tar Sands; Speight, J.G., Ed.; Gulf Publishing Company: Houston, TX, USA, 2009; pp. 133–184. ISBN 978-1-933762-25-8. [Google Scholar]

- Martín, D.; Aparicio, P.; García, S.; Maroto-Valer, M.M. Mixed-Layer Illite-Smectite Illitization under Supercritical CO2 Conditions. Appl. Sci. 2022, 12, 11477. [Google Scholar] [CrossRef]

- Zholdybayeva, A.; Syzdykov, A.; Pourafshary, P.; Ismailova, J.; Delikesheva, D. Importance of Clay Swelling on the Efficacy of Cyclic Steam Stimulation in the East Moldabek Formation in Kazakhstan. Energies 2024, 17, 5078. [Google Scholar] [CrossRef]

| Retrieval Depth, Meters | Porosity, % | Permeability, mD | Reservoir Pressure, MPa | Viscosity of Oil, mPa·s | Reservoir Temperature, °C |

|---|---|---|---|---|---|

| 1057.47 | 30.3 | 144.5 | 10.5 | 18.5 | 42 |

| Component | NaHCO3 | Na2SO4 | MgCl2·6H2O | CaCl2 | NaCl |

|---|---|---|---|---|---|

| Content, g/L | 0.289 | 1.065 | 15.475 | 14.898 | 196.953 |

| Parameters | Before | After |

|---|---|---|

| Porosity after the Experiment, % | 30.3 | 22.2 |

| Permeability after the Experiment, mD | 144.5 | 116.6 |

| Oil Recovery Coefficient (CO2 Flooding), % | - | 54 |

| Element | O | Si | Cl | Fe | Na | Al | K | Mg | Total |

|---|---|---|---|---|---|---|---|---|---|

| Content, % | 44.71 | 16.25 | 12.31 | 8.86 | 7.35 | 5.18 | 4.64 | 0.69 | 100 |

| Element | O | Si | Al | K | Total |

|---|---|---|---|---|---|

| Content, % | 56.8 | 23.2 | 12.6 | 7.5 | 100 |

| Parameter | Model |

|---|---|

| Size | 93 × 88 × 78 |

| Total Cells | 638,352 |

| Active Cells | 194,413 |

| Cell Size, m | 100 × 100 × 1 |

| Type | E300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niyazbayeva, A.B.; Merbayev, R.B.; Samenov, Y.R.; Zholdybayeva, A.T.; Kozhagulova, A.A.; Shabdirova, A.D. Laboratory Investigation of Miscible CO2-Induced Enhanced Oil Recovery from the East-Southern Pre-Caspian Region. Processes 2025, 13, 2566. https://doi.org/10.3390/pr13082566

Niyazbayeva AB, Merbayev RB, Samenov YR, Zholdybayeva AT, Kozhagulova AA, Shabdirova AD. Laboratory Investigation of Miscible CO2-Induced Enhanced Oil Recovery from the East-Southern Pre-Caspian Region. Processes. 2025; 13(8):2566. https://doi.org/10.3390/pr13082566

Chicago/Turabian StyleNiyazbayeva, Ainur B., Rinat B. Merbayev, Yernazar R. Samenov, Assel T. Zholdybayeva, Ashirgul A. Kozhagulova, and Ainash D. Shabdirova. 2025. "Laboratory Investigation of Miscible CO2-Induced Enhanced Oil Recovery from the East-Southern Pre-Caspian Region" Processes 13, no. 8: 2566. https://doi.org/10.3390/pr13082566

APA StyleNiyazbayeva, A. B., Merbayev, R. B., Samenov, Y. R., Zholdybayeva, A. T., Kozhagulova, A. A., & Shabdirova, A. D. (2025). Laboratory Investigation of Miscible CO2-Induced Enhanced Oil Recovery from the East-Southern Pre-Caspian Region. Processes, 13(8), 2566. https://doi.org/10.3390/pr13082566