Atmospheric Plasma Etching-Assisted Chemical Mechanical Polishing for 4H-SiC: Parameter Optimization and Surface Mechanism Analysis

Abstract

1. Introduction

2. Experimental Design and Methodology

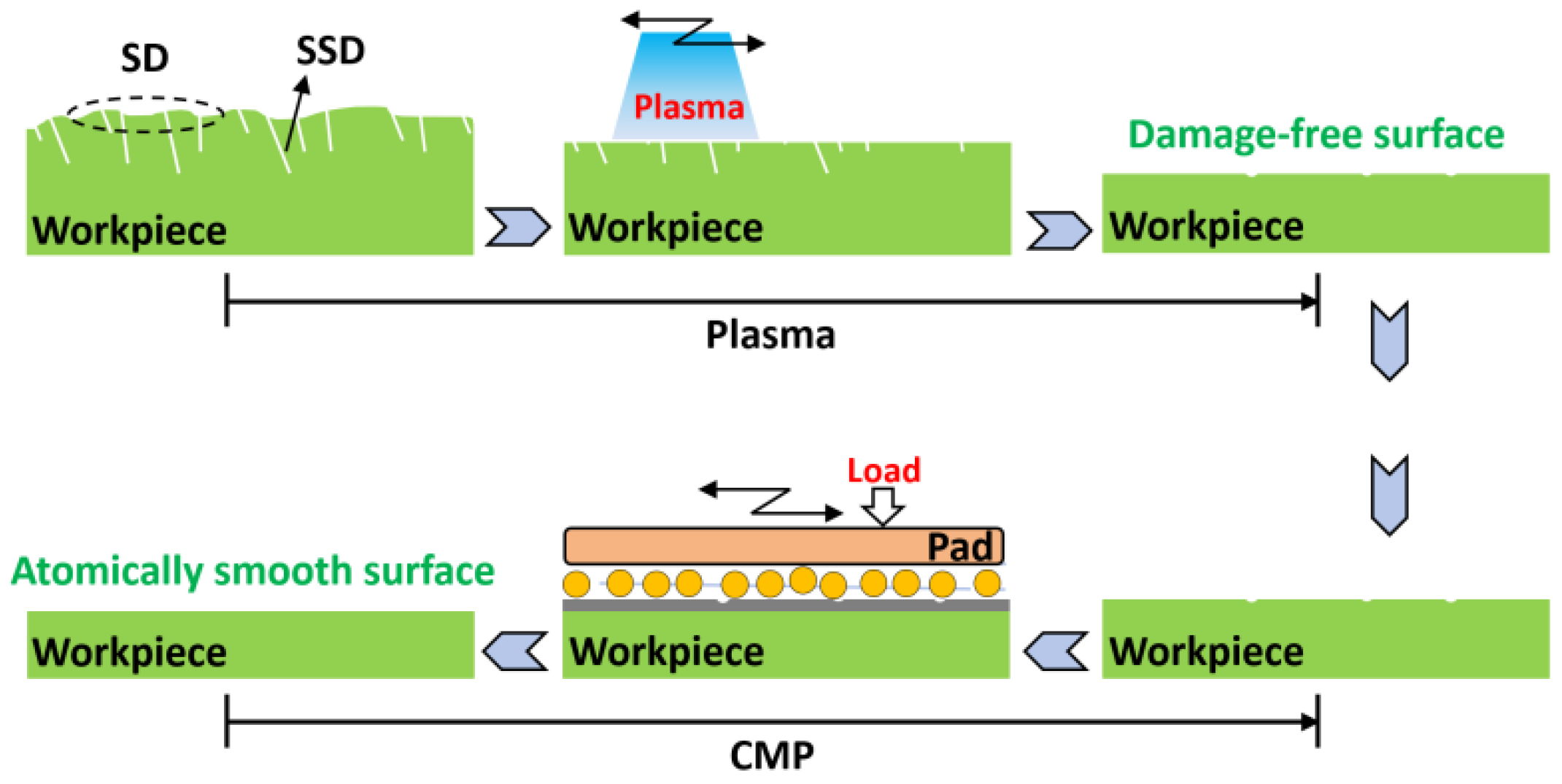

2.1. Plasma Etching Assisted CMP Model

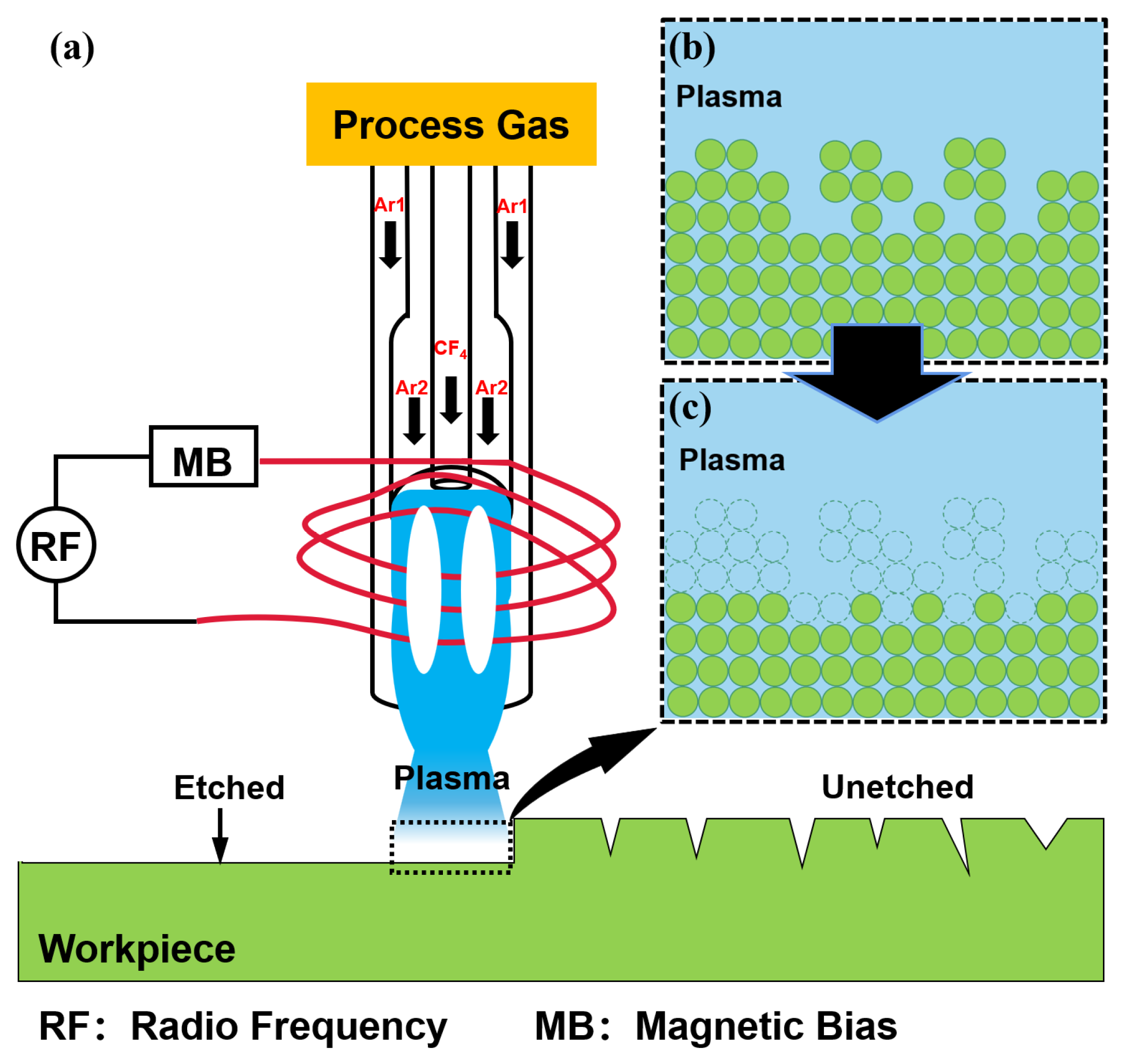

2.2. Plasma Etching Principle

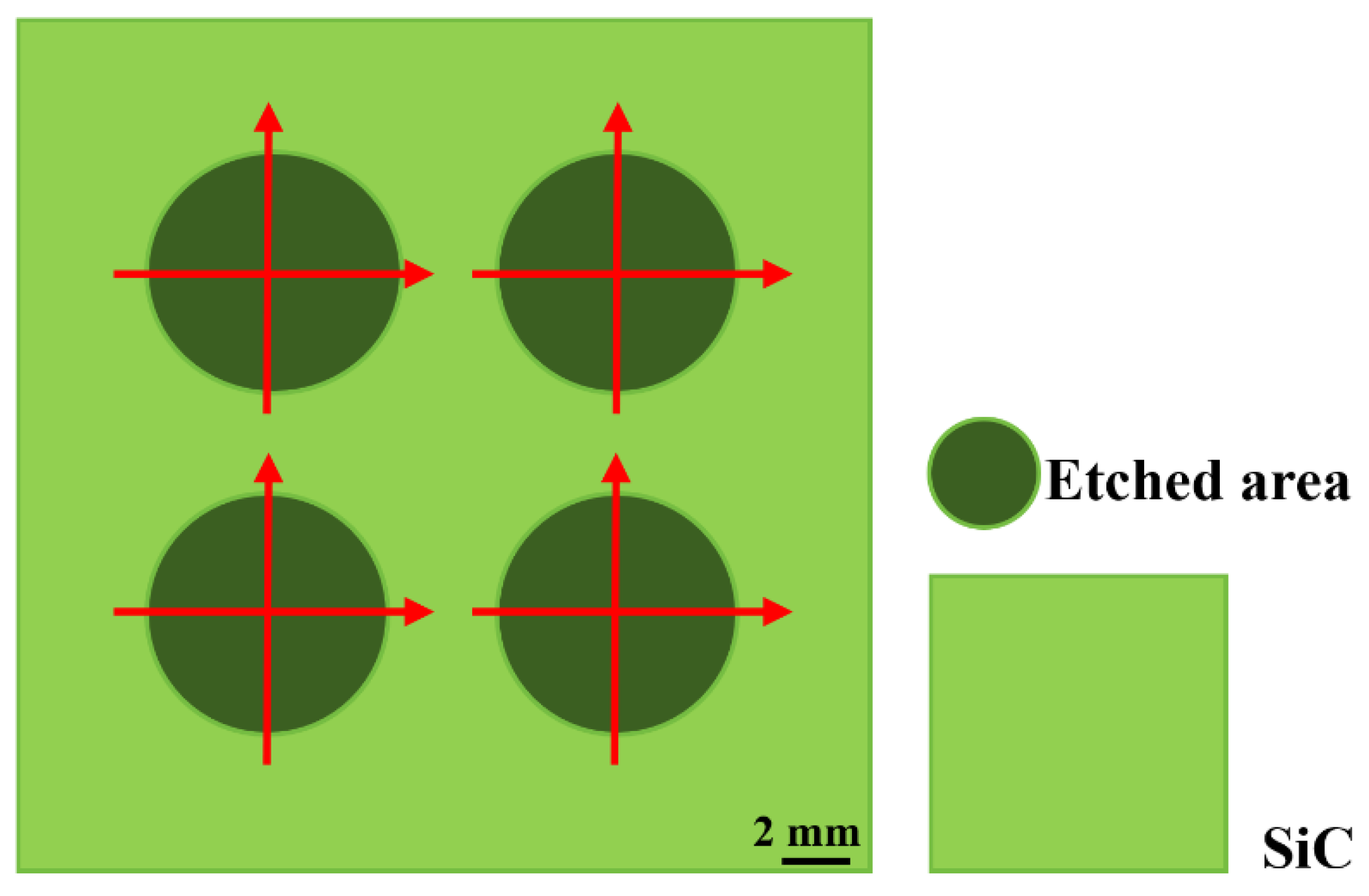

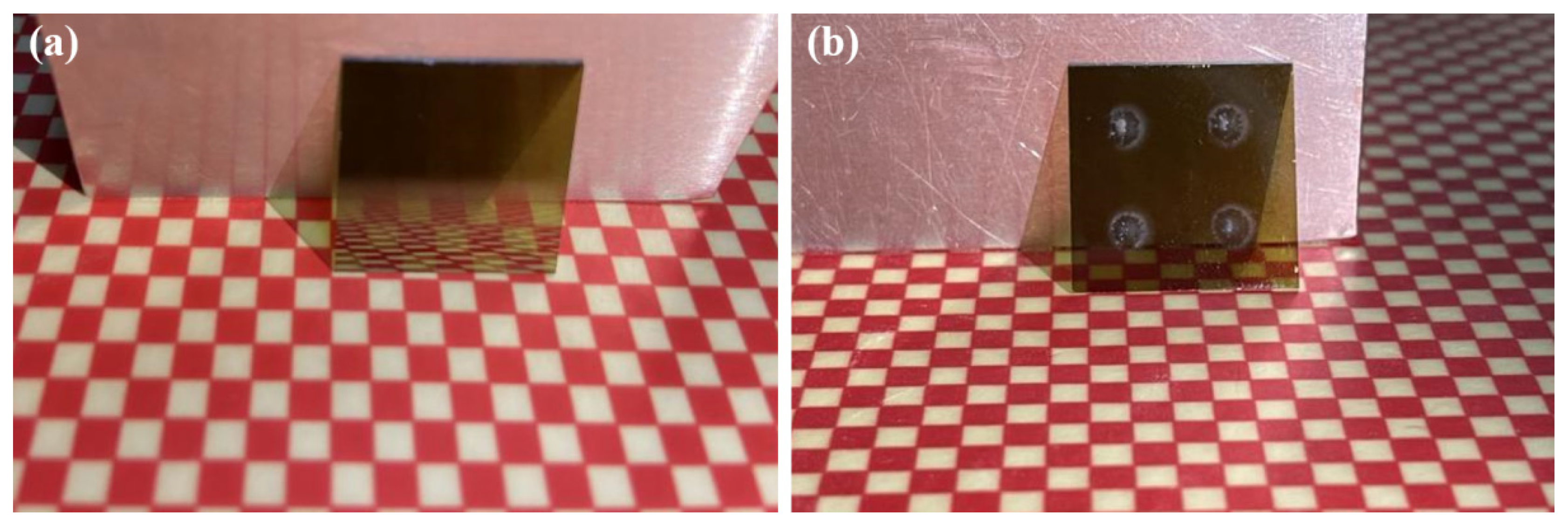

2.3. Experimental Process and Conditions

2.4. Characterization and Testing

3. Results and Discussion

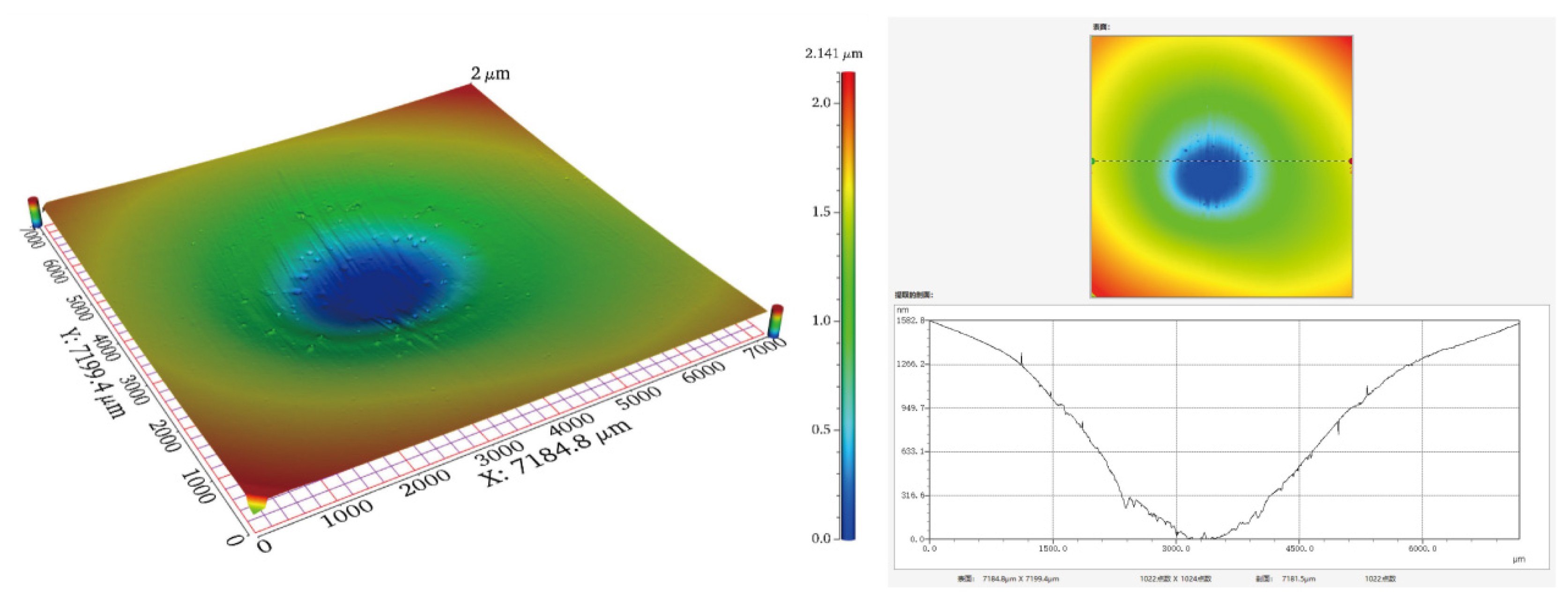

3.1. Effect of Etching Parameters on Etching Rate

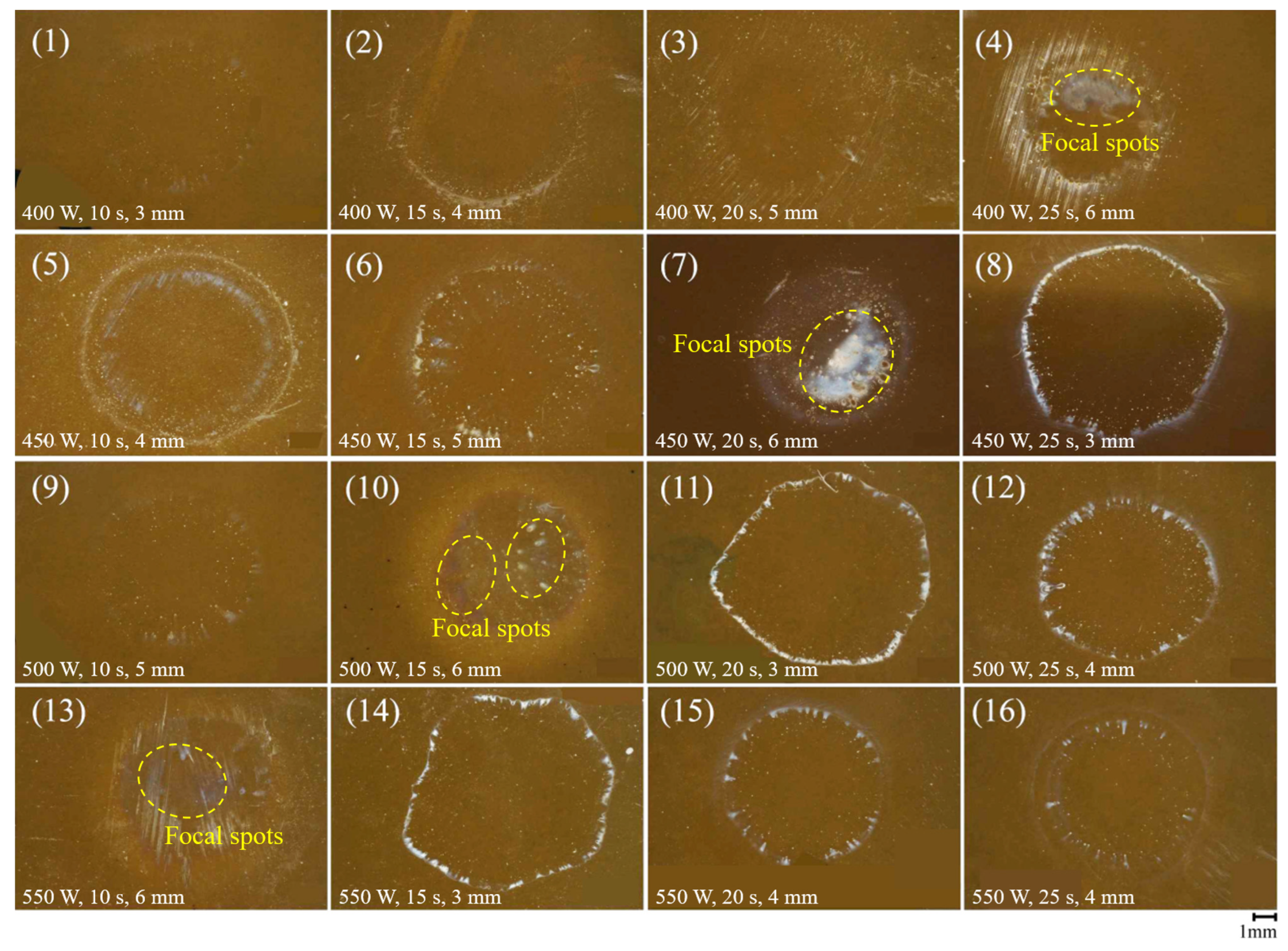

3.2. Effect of Etching Parameters on Surface Quality

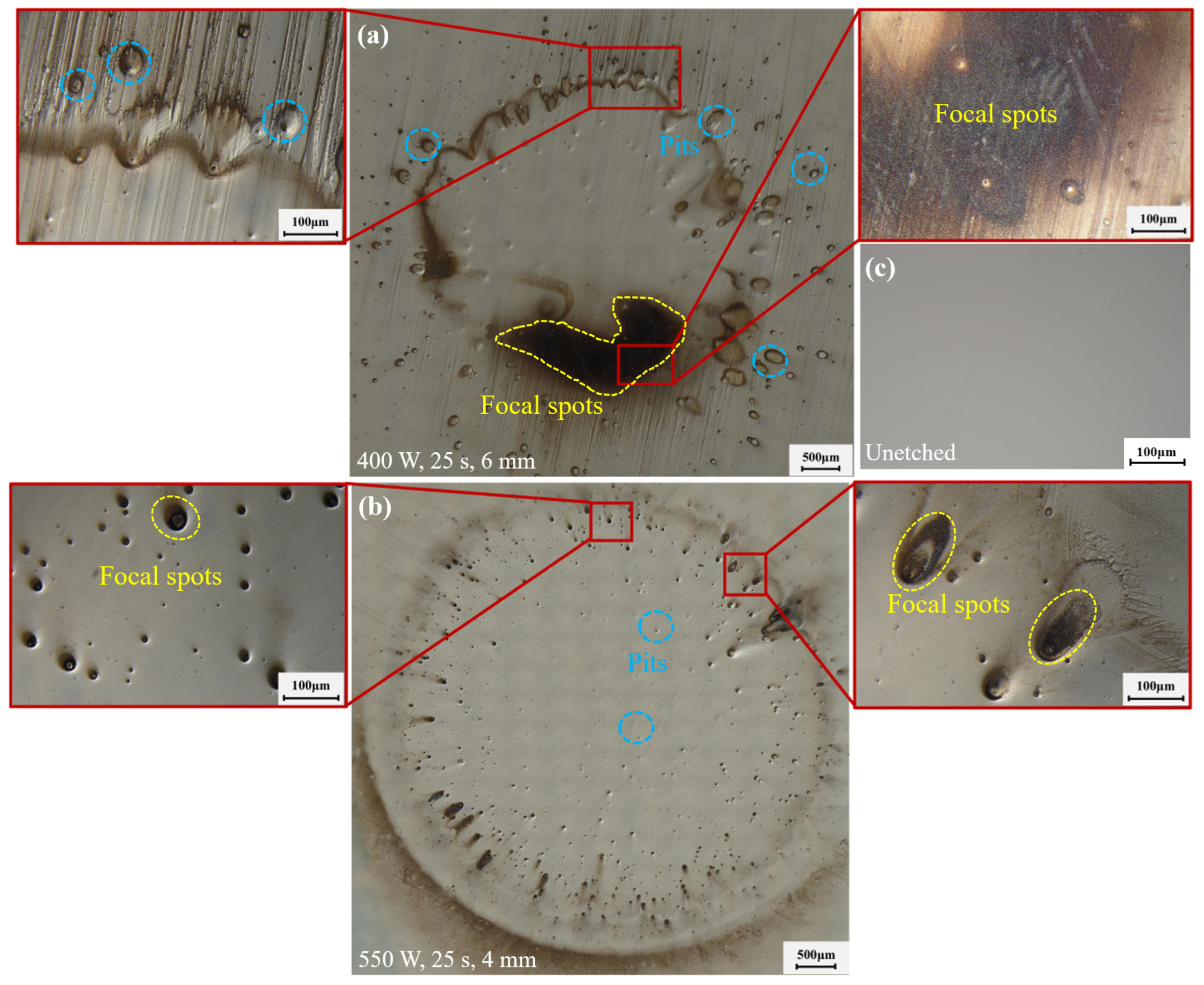

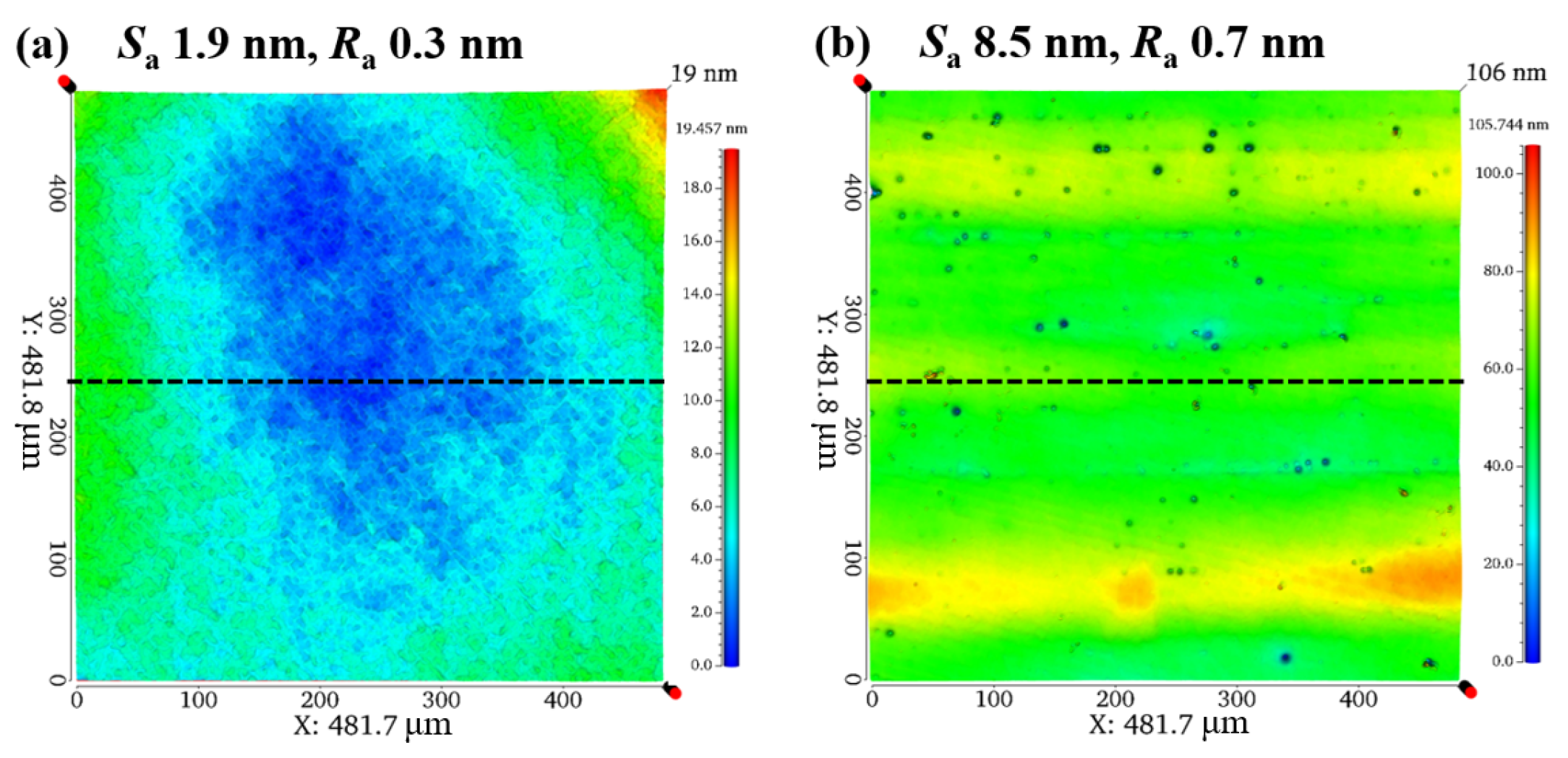

3.2.1. Effect of Distance

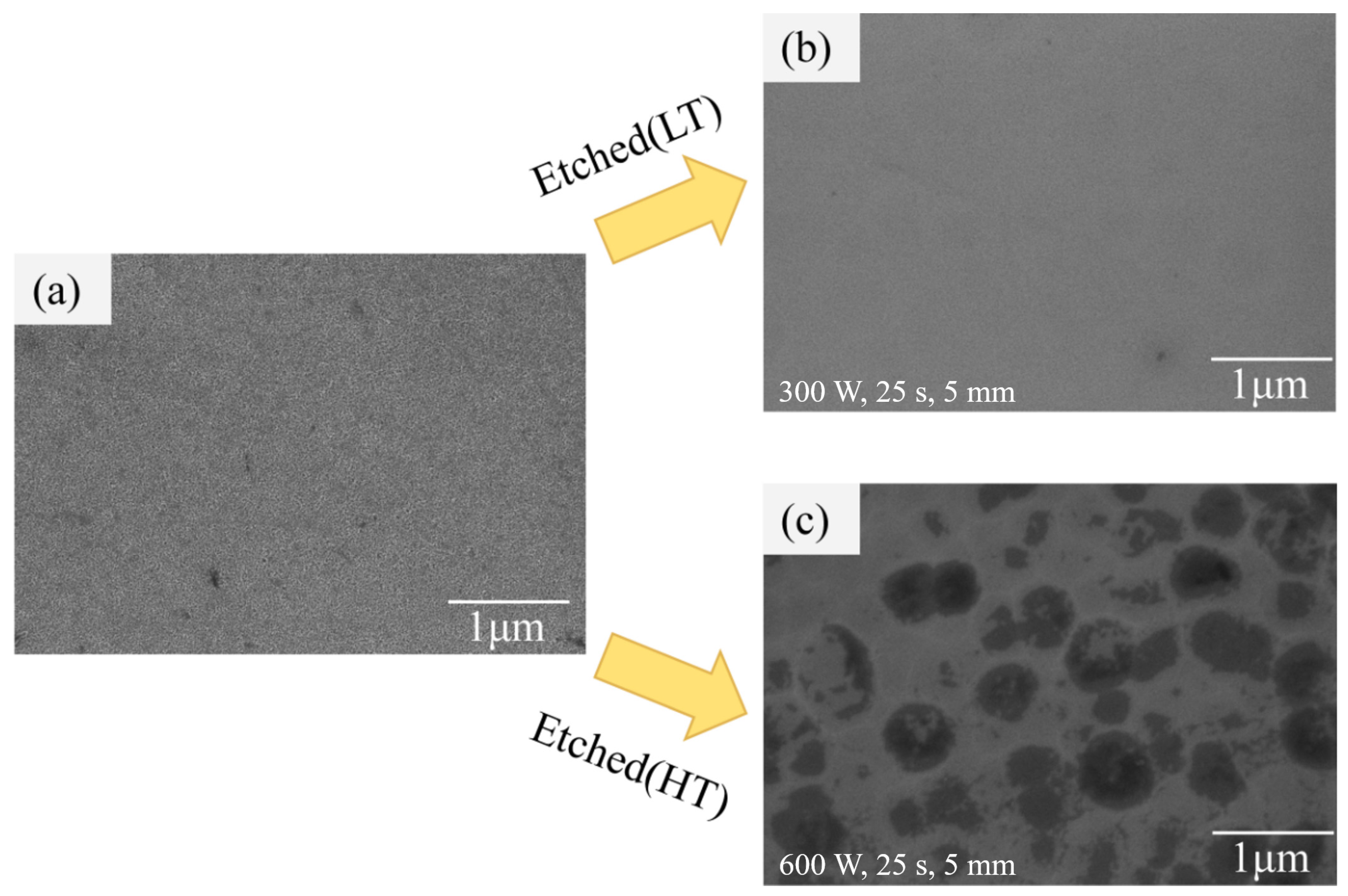

3.2.2. Effect of Temperature

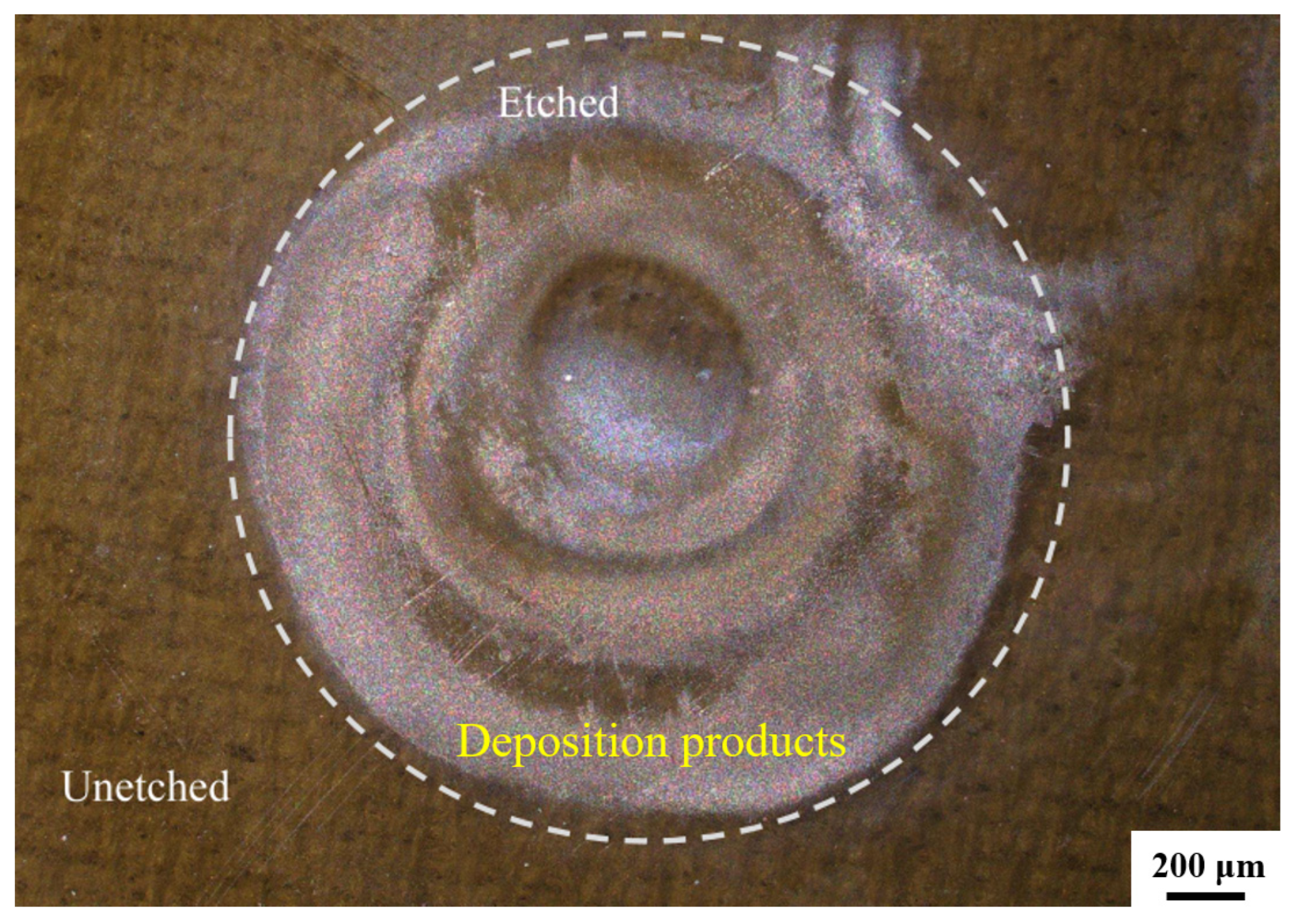

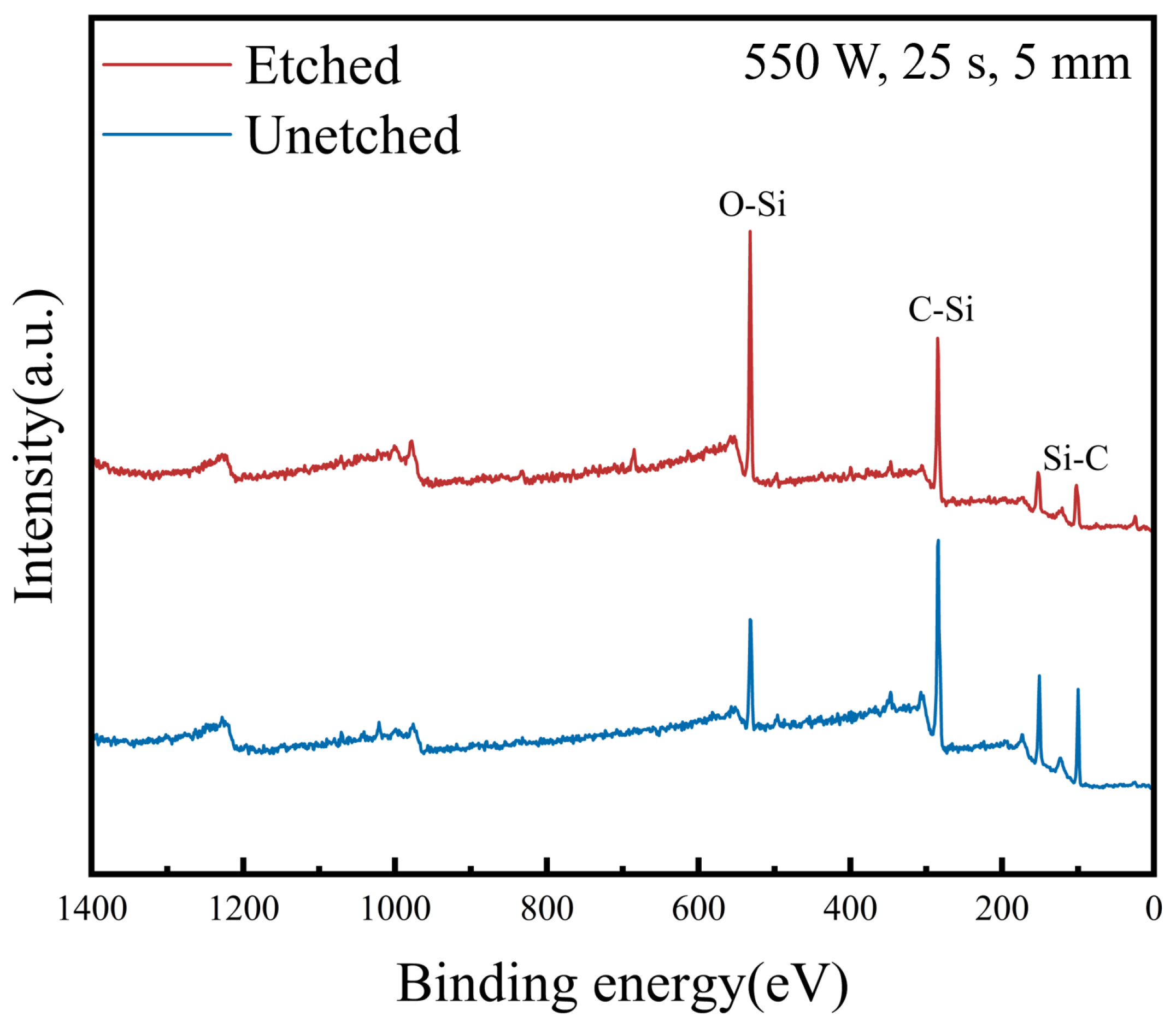

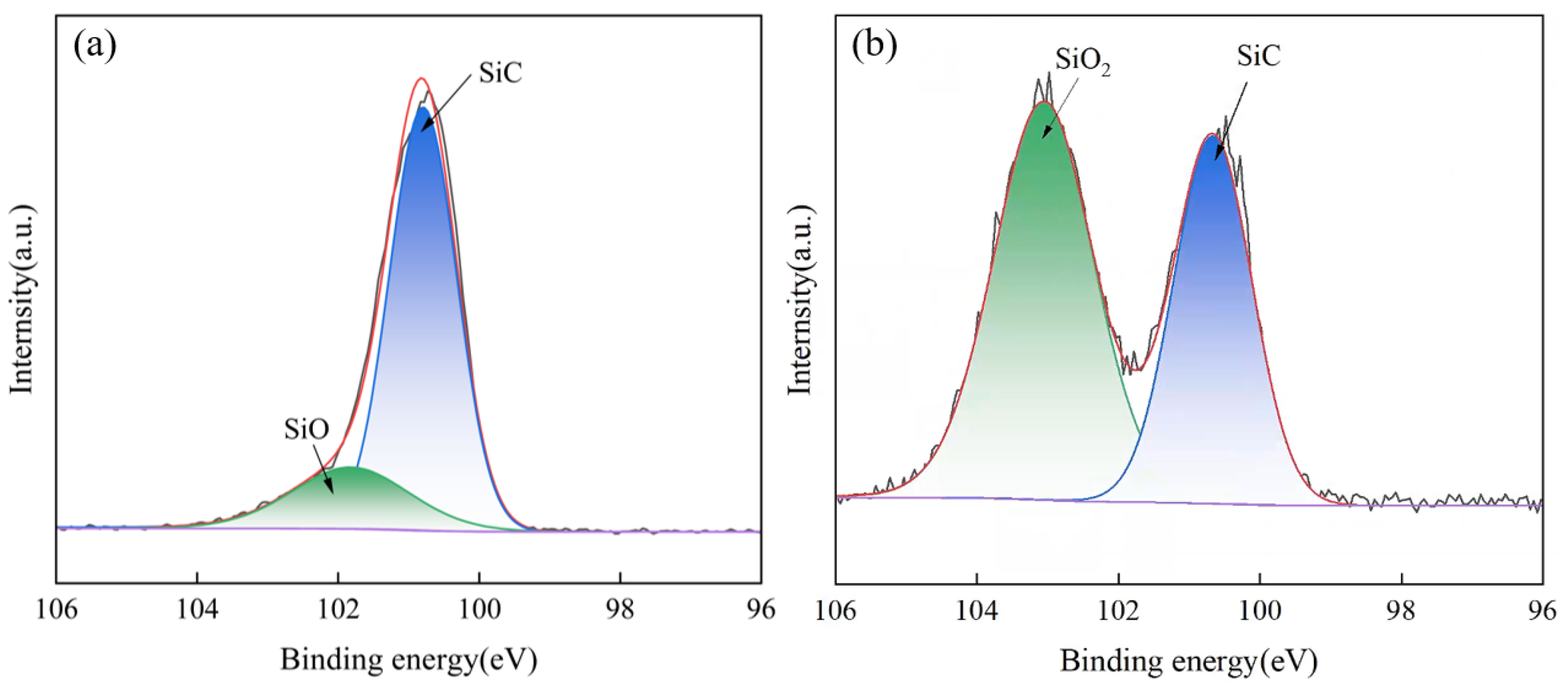

3.2.3. Analysis of XPS Test Results

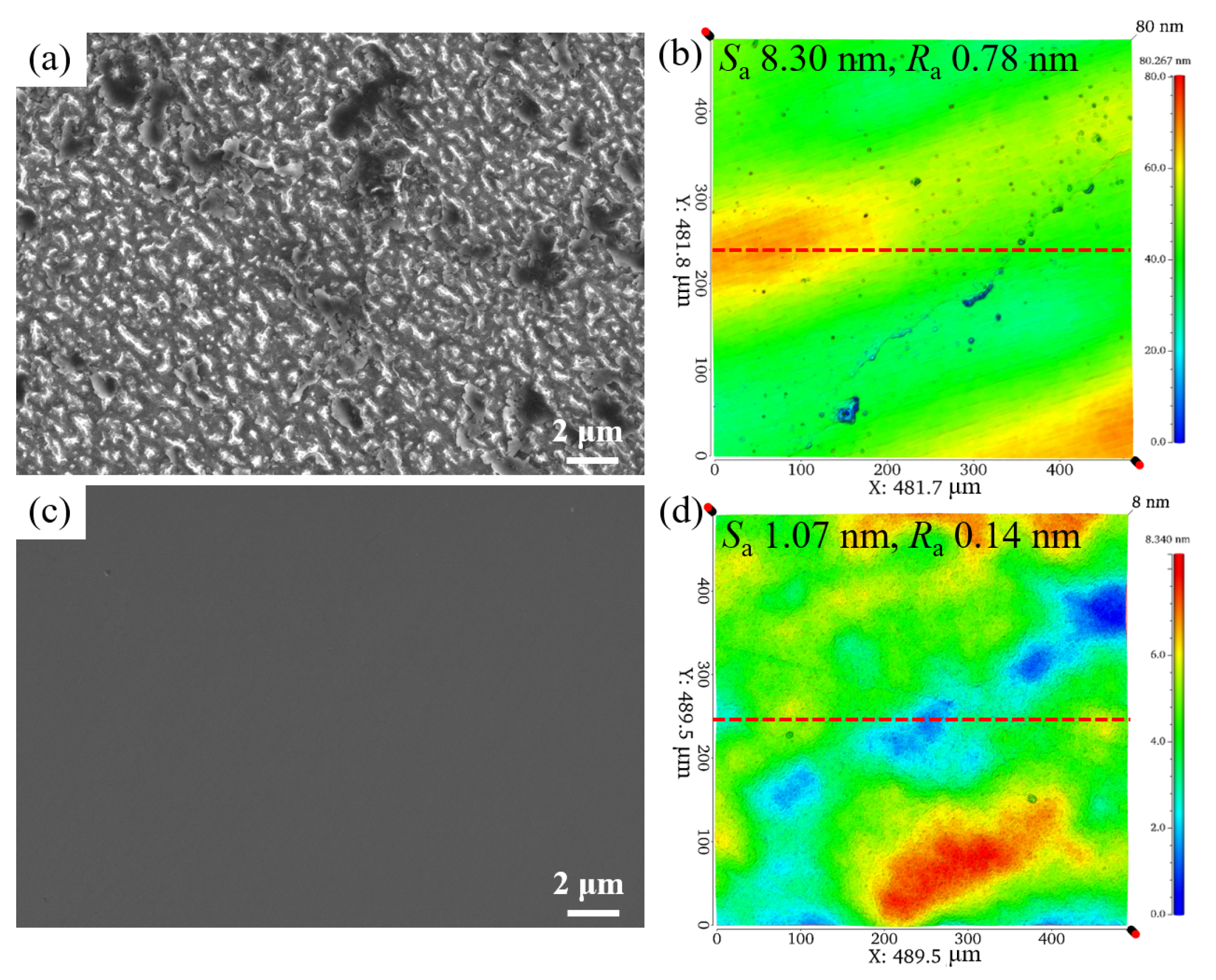

3.3. CMP Surface Quality Verification

4. Conclusions

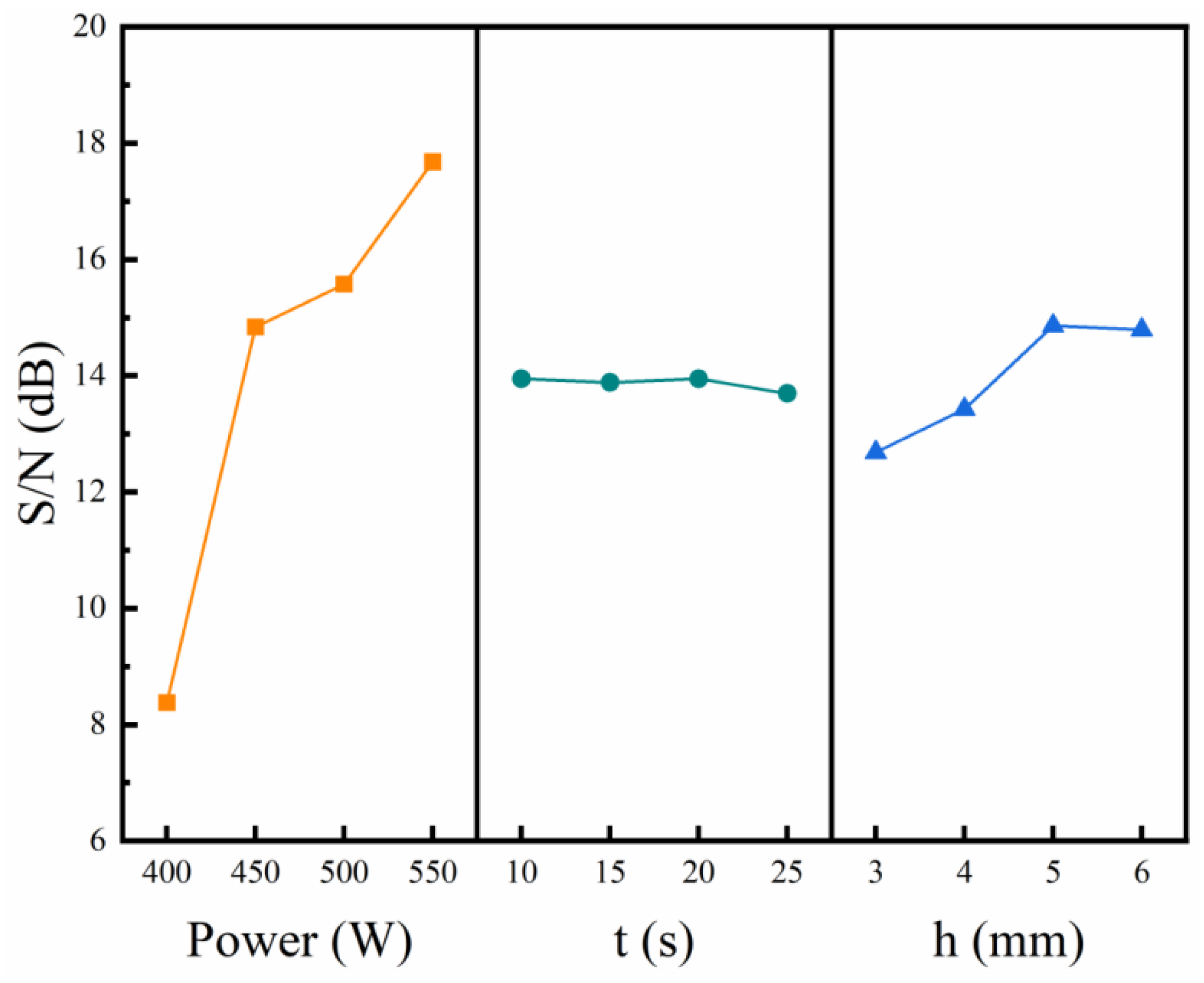

- This study reveals the influence of processing parameters on plasma etching technology: the applied power provides energy for plasma ionization and affects the surface quality after etching by influencing the temperature, while the distance between the nozzle and the substrate determines the uniformity of oxidation.

- The optimal etching process was determined through Taguchi experiments, and under optimal process conditions (550 W, 6 mm), atmospheric pressure plasma achieved the highest etching rate (5.99 μm/min) on SiC.

- XPS analysis indicated that the products of the etching reaction were SiO2. The current process cannot completely suppress defects such as deposition and etching pits. Future research will focus on suppressing the formation of deposition and etching pits to achieve smooth surface etching technology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shen, M.; Wu, L.; Wei, M.; Chen, H.; Yuan, J.; Lyu, B.; Deng, H.; To, S.; Beri, T.H.; Hang, W. High-efficiency free-damage electrochemical shear-thickening polishing of single-crystal silicon carbide. J. Manuf. Process. 2024, 132, 532–543. [Google Scholar] [CrossRef]

- Shen, M.; Wei, M.; Wu, L.; Han, Y.; Hong, B.; Lyu, B.; Chen, H.; Hang, W. Dominant parameters and mechanisms influencing the electrochemical shear-thickening polishing of 4H-SiC. Ceram. Int. 2024, 51, 10351–10364. [Google Scholar] [CrossRef]

- Lebedev, A.A. Development and Investigation of SiC and SiC-Based Devices. Crystals 2020, 10, 1127. [Google Scholar] [CrossRef]

- Chen, X.; Yang, X.; Xie, X.; Peng, Y.; Xiao, L.; Shao, C.; Li, H.; Hu, X.; Xu, X. Research progress of large size SiC single crystal materials and devices. Light-Sci. Appl. 2023, 12, 28. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, Y. Investigation into electrochemical oxidation behavior of 4H-SiC with varying anodizing conditions. Electrochem. Commun. 2019, 109, 106608. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Z.; Hong, B.; Hang, W.; Zhang, P.; Cao, X.; Xu, Q.; Chen, P.; Chen, H.; Yuan, J.; et al. Study on the affecting factors of material removal mechanism and damage behavior of shear rheological polishing of single crystal silicon carbide. J. Manuf. Process. 2024, 112, 225–237. [Google Scholar] [CrossRef]

- Li, G.F.; Hang, W.; Chen, H.Y.; Wang, R.; Pi, X.; Yang, D.; Yuan, J. Effect of subsurface damages in seed crystals on the crystal quality of 4H-SiC single crystals grown by the PVT technology. Crystengcomm 2024, 26, 875–880. [Google Scholar] [CrossRef]

- Shen, M.; Wei, M.; Wu, L.; Hong, B.; Ye, J.; Chen, H.; Yuan, J.; Lyu, B.; Wang, C.; Deng, H.; et al. Microwave plasma modification-assisted shear-thickening polishing of single-crystal silicon carbide. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2025, 94, 13–25. [Google Scholar] [CrossRef]

- Chen, H.; Wan, H.; Hong, B.; Hang, W.; Zhu, T.; Zhang, P.; Cao, X.; Xu, Q.; Wang, R.; Han, X.; et al. A novel liquid film shearing polishing technique for silicon carbide and its processing damage mechanisms. Appl. Surf. Sci. 2025, 688, 162317. [Google Scholar] [CrossRef]

- Deng, J.; Lu, J.; Yan, Q.; Pan, J. Enhancement mechanism of chemical mechanical polishing for single-crystal 6H-SiC based on Electro-Fenton reaction. Diam. Relat. Mat. 2021, 111, 108147. [Google Scholar] [CrossRef]

- Pang, L.F.; Li, X.B.; Li, T.T.; Jia, J.P. Ultra Precision Chemical Mechanical Polishing Technology for SiC Wafer. Micronano-Electron. Technol. 2021, 58, 1035–1040. [Google Scholar] [CrossRef]

- Lee, H.; Kim, H.; Jeong, H. Approaches to Sustainability in Chemical Mechanical Polishing (CMP): A Review. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 349–367. [Google Scholar] [CrossRef]

- Hang, W.; Shen, M.; Wei, M.; Wu, L.; Wang, Y.; Chen, H.; Lyu, B.; Zhao, J. Electrochemical shear-thickening polishing of 4H-SiC (000–1): Factors influencing the anodization process. Ceram. Int. 2025; in press. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, X.; Li, W.; Hang, W. Material removal modes and processing mechanism in microultrasonic machining of ball ceramic tool. Ceram. Int. 2024, 50, 28844–28856. [Google Scholar] [CrossRef]

- Xu, H.; Wang, J.; Li, Q.; Pan, F. Research progress of chemical mechanical polishing technology of silicon carbide wafer. Mod. Manuf. Eng. 2022, 501, 153–161+116. [Google Scholar] [CrossRef]

- Lei, H.; Luo, J.; Ma, J. Advances and Problems on Chemical Mechanical Polishing. Lubr. Eng. 2002, 27, 73–76. [Google Scholar]

- Deng, J.; Pan, J.; Zhang, Q.; Guo, X.; Yan, Q. Research progress in chemical mechanical polishing of single crystal SiC substrates. Diam. Abras. Eng. 2020, 40, 79–91. [Google Scholar] [CrossRef]

- Deng, H.; Hosoya, K.; Imanishi, Y.; Endo, K.; Yamamura, K. Electro-chemical mechanical polishing of single-crystal SiC using CeO2 slurry. Electrochem. Commun. 2015, 52, 5–8. [Google Scholar] [CrossRef]

- Yang, X.; Yang, X.; Kawai, K.; Arima, K.; Yamamura, K. Highly efficient planarization of sliced 4H–SiC (0001) wafer by slurryless electrochemical mechanical polishing. Int. J. Mach. Tools Manuf. 2019, 144, 103431. [Google Scholar] [CrossRef]

- Yang, X.; Yang, X.; Kawai, K.; Arima, K.; Yamamura, K. Dominant factors and their action mechanisms on material removal rate in electrochemical mechanical polishing of 4H-SiC (0001) surface. Appl. Surf. Sci. 2021, 562, 150130. [Google Scholar] [CrossRef]

- Yamamura, K.; Takiguchi, T.; Ueda, M.; Deng, H.; Hattori, A.; Zettsu, N. Plasma assisted polishing of single crystal SiC for obtaining atomically flat strain-free surface. CIRP Ann.-Manuf. Technol. 2011, 60, 571–574. [Google Scholar] [CrossRef]

- Yamamura, K.; Takiguchi, T.; Ueda, M.; Hattori, A.N.; Zettsu, N. High-Integrity Finishing of 4H-SiC (0001) by Plasma-Assisted Polishing. Adv. Mater. Res. 2010, 126–128, 423–428. [Google Scholar] [CrossRef]

- Deng, H.; Endo, K.; Yamamura, K. Damage-free finishing of CVD-SiC by a combination of dry plasma etching and plasma-assisted polishing. Int. J. Mach. Tools Manuf. 2017, 115, 38–46. [Google Scholar] [CrossRef]

- Deng, H.; Yamamura, K. Atomic-scale flattening mechanism of 4H-SiC (0 0 0 1) in plasma assisted polishing. CIRP Ann.-Manuf. Technol. 2013, 62, 575–578. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Chen, K.; Liu, D.; Lu, D.; Deng, H. Rapid subsurface damage detection of SiC using inductivity coupled plasma. Int. J. Extreme Manuf. 2021, 3, 035202. [Google Scholar] [CrossRef]

- Deng, H.; Endo, K.; Yamamura, K. Comparison of thermal oxidation and plasma oxidation of 4H-SiC (0001) for surface flattening. Appl. Phys. Lett. 2014, 104, 101608. [Google Scholar] [CrossRef]

- Zhang, J.F.; Wang, B.; Dong, S. Analysis of factors impacting atmospheric pressure plasma polishing. Int. J. Precis. Eng. Manuf. 2008, 9, 39–43. [Google Scholar]

- Wang, B.; Zhang, J.F.; Dong, S. New development of atmospheric pressure plasma polishing. Chin. Opt. Lett. 2009, 7, 537–538. [Google Scholar] [CrossRef]

- Yamamura, K.; Shimada, S.; Mori, Y. Damage-free improvement of thickness uniformity of quartz crystal wafer by plasma chemical vaporization machining. CIRP Ann.-Manuf. Technol. 2008, 57, 567–570. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density (g · cm3) | 3.2 |

| melting point (°C) | 2700.0 |

| Mohs Hardness | 9.5 |

| Poisson ratio ν | 0.14 |

| Parameter | Value |

|---|---|

| Ar1 (slm) | 17 |

| Ar2 (slm) | 2 |

| CF4 (sccm) | 30 |

| Power (W) | 400, 450, 500, 550 |

| Time (s) | 10, 15, 20, 25 |

| Distance (mm) | 3, 4, 5, 6 |

| Level | Factor | ||

|---|---|---|---|

| A | B | C | |

| P/W | t/s | h/mm | |

| 1 | 400 | 10 | 3 |

| 2 | 450 | 15 | 4 |

| 3 | 500 | 20 | 5 |

| 4 | 550 | 25 | 6 |

| No. | A | B | C | Depth /μm | Standard Deviation /σ | Etching Rate /(μm/min) | No. | A | B | C | Depth /μm | Standard Deviation /σ | Etching Rate /(μm/min) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power /W | t/s | h/mm | Power /W | t/s | h/mm | ||||||||

| 1 | 400 | 10 | 3 | 0.2584 | 0.0389 | 1.5501 | 9 | 500 | 10 | 5 | 1.0727 | 0.0998 | 6.4364 |

| 2 | 400 | 15 | 4 | 0.4690 | 0.0730 | 1.8758 | 10 | 500 | 15 | 6 | 1.4510 | 0.1674 | 5.8040 |

| 3 | 400 | 20 | 5 | 1.3310 | 0.1603 | 3.9929 | 11 | 500 | 20 | 3 | 1.9477 | 0.2303 | 5.8432 |

| 4 | 400 | 25 | 6 | 1.7081 | 0.2081 | 4.0995 | 12 | 500 | 25 | 4 | 2.5646 | 0.2980 | 6.1549 |

| 5 | 450 | 10 | 4 | 1.1714 | 0.1547 | 7.0284 | 13 | 550 | 10 | 6 | 1.4776 | 0.1633 | 8.8658 |

| 6 | 450 | 15 | 5 | 1.6498 | 0.1922 | 6.5991 | 14 | 550 | 15 | 3 | 2.1180 | 0.2079 | 8.4721 |

| 7 | 450 | 20 | 6 | 1.4567 | 0.1109 | 4.3700 | 15 | 550 | 20 | 4 | 2.0296 | 0.1141 | 6.0887 |

| 8 | 450 | 25 | 3 | 1.9133 | 0.2230 | 4.5918 | 16 | 550 | 25 | 5 | 3.3809 | 0.3210 | 8.1142 |

| Level | Average Etching Rate/(μm/min) | ||

|---|---|---|---|

| Power/W | t/s | h/mm | |

| 1 | 8.376 | 13.949 | 12.684 |

| 2 | 14.838 | 13.882 | 13.425 |

| 3 | 15.575 | 13.947 | 14.86 |

| 4 | 17.678 | 13.693 | 14.794 |

| Delta | 9.302 | 0.256 | 2.176 |

| Rank | 1 | 3 | 2 |

| Element | Not Etched (%) | Etched (%) |

|---|---|---|

| C | 55.02 | 42.21 |

| O | 14.21 | 30.35 |

| Si | 30.26 | 24.26 |

| F | 0.51 | 3.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, M.; Wei, M.; Li, X.; Yuan, J.; Hang, W.; Han, Y. Atmospheric Plasma Etching-Assisted Chemical Mechanical Polishing for 4H-SiC: Parameter Optimization and Surface Mechanism Analysis. Processes 2025, 13, 2550. https://doi.org/10.3390/pr13082550

Shen M, Wei M, Li X, Yuan J, Hang W, Han Y. Atmospheric Plasma Etching-Assisted Chemical Mechanical Polishing for 4H-SiC: Parameter Optimization and Surface Mechanism Analysis. Processes. 2025; 13(8):2550. https://doi.org/10.3390/pr13082550

Chicago/Turabian StyleShen, Mengmeng, Min Wei, Xuelai Li, Julong Yuan, Wei Hang, and Yunxiao Han. 2025. "Atmospheric Plasma Etching-Assisted Chemical Mechanical Polishing for 4H-SiC: Parameter Optimization and Surface Mechanism Analysis" Processes 13, no. 8: 2550. https://doi.org/10.3390/pr13082550

APA StyleShen, M., Wei, M., Li, X., Yuan, J., Hang, W., & Han, Y. (2025). Atmospheric Plasma Etching-Assisted Chemical Mechanical Polishing for 4H-SiC: Parameter Optimization and Surface Mechanism Analysis. Processes, 13(8), 2550. https://doi.org/10.3390/pr13082550