Abstract

The study aims to improve the efficiency of oil field development at the Kalamkas field through the implementation of new methods for analyzing hydrodynamic survey data and monitoring well conditions. It is hypothesized that the use of integrated geophysical and hydrodynamic methods will enhance forecasting accuracy, optimize field operations, and increase the hydrocarbon recovery factor. An integrated approach combining pulsed neutron logging (PNL), acoustic cementometry (AC), inflow and injectivity profile evaluation methods, and specialized software for advanced data interpretation was applied, significantly improving the accuracy of well condition analysis. The analysis enabled the identification of oil and gas saturation intervals, zones of increased water cut, and cementing defects in casing, and allowed for a quantitative assessment of reservoir permeability dynamics. Hydraulic fracturing application resulted in a 10–15% increase in permeability in certain zones, with an average oil recovery factor increase of 5%. Analysis of PNL data demonstrated the transition of oil-saturated reservoirs to water saturation during development, confirmed by geophysical and pressure build-up survey results. The study identified the primary causes of increased water cut and key factors leading to production rate decline. Proposed measures for optimizing operating modes and well grid efficiency contribute to improving existing field management practices.

1. Introduction

In contemporary hydrocarbon production, the monitoring of reservoir development, well operation, and well equipment constitutes an integral component of effective field management. These activities are of paramount importance in increasing the hydrocarbon recovery factor and in preventing complications that may arise during well operation. In view of the ageing of equipment and the evolution of the geological characteristics of reservoirs, it becomes imperative to undertake regular assessments of the condition of wells and their equipment. This approach is intended to extend the service life of wells and enhance productivity.

The development of reservoirs and the operation of wells are aimed at achieving stable production levels. This is achieved by analysing current data, promptly identifying deviations in equipment performance, and making necessary adjustments. Contemporary monitoring methodologies encompass the utilisation of pressure and temperature sensors, in addition to the analysis of produced fluids and other parameters. These methodologies facilitate real-time tracking of alterations and expeditious responses to potential issues. Moreover, the integration of digital technologies, including process automation and artificial intelligence for data analysis, has been demonstrated to significantly enhance the accuracy of forecasting and the optimisation of well operation.

The economic efficiency of control measures is also a significant factor, as they assist in minimising repair costs, reducing operating expenses, and preventing premature equipment wear. The proper planning and execution of control activities has been demonstrated to contribute not only to improved production indicators but also to the overall profitability of the field. It is therefore vital to monitor the condition of reservoirs, wells, and well equipment in order to ensure sustainable and economically viable hydrocarbon production. This underscores the importance of this topic.

The development of an oil field and the operation of its facilities is a complex technological process that typically commences with a limited amount of initial data [1,2]. In the context of significant economic changes in the market, it becomes necessary to regularly assess the profitability of the entire oil and gas production complex—not only as a whole but also for individual divisions of enterprises, down to the level of each well. It is evident that wells located in close proximity to one another often exhibit significant differences, which necessitates individual monitoring of each production and injection well [2,3].

The development of a productive reservoir is a process that can be managed in such a way as to increase sweep efficiency and displacement coefficient. This, in turn, can contribute to an increase in the oil recovery factor. The dissemination of timely information pertaining to the status of reservoir development, in conjunction with the selection and implementation of optimal geological and technological measures from a technical and economic standpoint, facilitates the augmentation of hydrocarbon recovery [4,5,6].

A prime example of a comprehensive approach to field development is the Kalamkas field, which was put into pilot industrial operation in 1979. As of 1 January 2021, the number of drilled wells was 3507, including 41 horizontal wells and 45 with lateral horizontal sections. In accordance with the stipulated development plan [4], the drilling of 420 wells was scheduled between 2018 and 2023. This encompassed 320 production wells and 50 injection wells, utilising hydraulic fracturing (HF), simultaneous separate injection (SSI), and polymer injection technologies in the Yu-I, Yu-1S, and Yu-IV formations. Mature oil fields, such as Kalamkas, continue to exert a dominant influence on global production, accounting for up to 70% of total output. Concurrently, the advancement of these domains is encumbered by several challenges, including elevated water cut, declining pressure, and an uneven distribution of residual oil, in addition to challenges pertaining to injection and production. For instance, at the Daqing field, the range of residual reserves following extraction is from 38% to 42% at water cuts of 93% to 96%. The necessity for innovative technologies capable of mobilising dispersed residual oil and improving reservoir sweep by water flooding is emphasised by these features.

Recent scientific research has focused on the development of more accurate methods for analysing data obtained from hydrodynamic well surveys. A significant amount of attention has been dedicated to the problem of determining the pressure build-up curve during reservoir testing with constant porosity. In particular, this paper analyses non-stationary solutions of the Darcy equation and methods for approximating the asymptotic part of the pressure build-up curve. In this study, methodology for the calculation of hydrodynamic parameters is proposed, based on a comprehensive interpretation of the pressure build-up curve. A distinctive feature of this approach is the ability to adequately describe the entire pressure recovery process after well shut-in, which ensures a more accurate assessment of reservoir parameters [7,8].

A review of the literature indicates that significant attention has been devoted to non-stationary solutions of the deterministic Darcy equation for infinite reservoirs, as well as empirical and semi-automatic analysis methods, in the context of hydrodynamic surveys in reservoirs with constant porosity [3,4]. Methodologies for empirical modelling of static errors associated with the non-trivial approximation of the asymptotic part of the pressure build-up curve have also been employed [9,10].

Consequently, the subjects of reservoir development control, well operation, and the interpretation of hydrodynamic survey data continue to be of significant relevance from both scientific and practical standpoints. It is directly related to the challenges of enhancing oil recovery, optimising field development, and making rational use of residual hydrocarbon reserves.

Analysis of literature sources showed that to solve the problem of determining the pressure build-up curve for well testing of a reservoir with constant porosity, considerable attention was paid to nonstationary solutions of the deterministic Darcy equation for an unconfined reservoir, as well as methods of empirical and semi-automatic analysis. Methods of empirical modelling of static errors associated with non-trivial approximation of the asymptotic part of the pressure build-up curve were used.

In this study, a new method for calculating the hydrodynamic parameters of an oil reservoir was developed that takes into account all the information obtained from the pressure build-up curve. Unlike existing methods, the proposed model of pressure dependence on time allows for adequately describing the entire pressure build-up curve at well closure, which provides a more accurate assessment of the hydrodynamic parameters of the reservoir [7,8]. The aim of this work is to demonstrate effective methods for monitoring the development of a mature oil field, as well as to develop and apply a new method for calculating the reservoir’s hydrodynamic parameters based on the analysis of the pressure build-up curve.

2. Materials and Methods

Hydrodynamic studies (HDS) of oil wells have been utilised as the primary method for acquiring information regarding the filtration-capacity properties of reservoirs, inflow parameters, and the interaction of the well with the productive horizon. The HDS methodology comprises a series of techniques for the analysis of fluid flow dynamics within a porous medium. The primary objective of the HDS is to evaluate the current state of reservoirs and to predict their future development.

The primary objective of HDS in this study is to obtain data on the physico-geological parameters of the reservoir, including permeability, saturation, and reservoir pressure, as well as to identify heterogeneities in the reservoir structure. The findings obtained from this study enable the determination of optimal well operating modes, adjustment of the development grid, and the selection of the most effective technologies for enhanced oil recovery, including water, gas, and polymer injection [3,10,11].

Reference [12] presents an extensive review of previously published reserve management methods for the development of mature fields. Following the identification of mature fields and the provision of a general overview, the text goes on to describe various aspects of mature field development. The primary issue to be addressed is that of the evaluation of residual reserves, with a focus on ascertaining the quantity and geographical distribution of residual oil following primary and secondary recovery processes. This evaluation will be informed by field data, well logging, and core analysis. Following a residual oil assessment, the extraction methods are classified, including tertiary recovery, infill drilling, horizontal drilling, optimal waterflood design for mature fields, optimal well placement, and other reservoir management methods. The presentation encompasses both large fields operated by major companies and small fields run by independent companies, illustrating the breadth of the proposed or implemented field applications. As stated in References [11,13], a thorough review of the methods and strategies employed in the development of mature fields is provided, with particular emphasis on the efficiency and economic viability of various residual oil recovery methods.

In order to achieve the objectives of the study, the following methodologies were applied:

- -

- Classical methods of well testing under natural flow conditions, in which changes in pressure and temperature were recorded at various flow rates. The data were utilised to ascertain the inflow characteristics and to evaluate the degree of reservoir saturation.

- -

- The execution of hydrodynamic tests with inflow control at the wellhead facilitates the investigation of alterations in filtration parameters under varying reservoir loads. Furthermore, it enables the identification of hydrodynamic barriers and the phenomenon of water breakthrough.

- -

- The following paper sets out the interpretation methods for HDS results, which are based on the application of numerical modelling, machine learning algorithms, and artificial intelligence. This approach facilitated the acquisition of quantitative assessments of productive reservoir properties and the construction of predictive models of reservoir development based on actual data. All measurements were carried out in accordance with current regulatory documents and methodological guidelines, ensuring the reliability and reproducibility of the results obtained.

The following algorithm is employed for the interpretation of pressure build-up data:

- -

- The dataset under consideration incorporates information derived from pulsed neutron logging (PNL), acoustic cementometry (AC), and inflow and injectivity profile data.

- -

- In the initial stage of the data preprocessing procedure, the implementation of noise filtering and correction is undertaken with the objective of enhancing the accuracy of the subsequent data processing. This is a prerequisite for the accuracy of subsequent interpretation.

- -

- The algorithm incorporates the calculation of pressure within the productive formation, with consideration given to its dynamic fluctuations over time. The following formula is employed for this purpose:where P(t) is the pressure at time t; P0 is the initial pressure; Q is the fluid flow rate in the well; A is the cross-sectional area of the reservoir; and t0 is the measurement start time.

- -

- The assessment of interlayer flows is achieved through the utilisation of a numerical modelling method, incorporating hydrodynamic and geophysical data. This facilitates precise determination of pressure changes, contingent on the interactions between disparate reservoir layers.

- -

- Following the acquisition of the data, the algorithm employs specialised software for detailed analysis, facilitating precise identification of water-cut zones, saturation intervals, and the detection of cementing defects.

Hydrodynamic studies facilitate the acquisition of contemporary data concerning the status of the reservoir and wells. Moreover, they enable the exploration of a broad spectrum of subjects pertaining to the optimisation of field development. Decisions can be made regarding the adjustment of well operating modes, the implementation of enhanced oil recovery measures, and the reduction of operating costs, thereby significantly increasing project profitability. This assertion is supported by HDS data. Furthermore, HDS facilitates the evaluation of the efficacy of previously implemented measures, including hydraulic fracturing and waterflooding, thereby providing a foundation for the subsequent planning of additional interventions.

Notwithstanding the manifest advantages of HDS, their implementation may be accompanied by technical and economic challenges, such as the need for temporary production shutdowns, high equipment costs, and the complexity of interpreting the obtained data. Concurrently, advancements in digital technologies and the utilisation of big data are engendering novel opportunities for the more precise and efficient analysis of hydrodynamic parameters.

Consequently, hydrodynamic studies represent a pivotal instrument in the management of oil field development. It has been demonstrated that the implementation of this system facilitates the evaluation of the present condition of reservoirs and wells. Furthermore, it has been shown to enhance hydrocarbon production efficiency to a considerable degree, thereby ensuring a stable and profitable field operation process.

The objectives of hydrodynamic methods for monitoring and regulating development at the late stage of the Kalamkas field include the following.

In order to ensure the effective management of oil reservoir development, it is essential to obtain the necessary information regarding the status of reservoir development. This includes assessing and refining the productive and filtration characteristics of the reservoirs. Furthermore, evaluating the condition of the near-wellbore zones is crucial for determining the optimal operating mode for the well. The effectiveness of production enhancement measures must also be assessed in order to ensure the efficient functioning of the reservoir. Additionally, monitoring the energy state of the reservoir is necessary for maintaining a comprehensive understanding of reservoir dynamics. Finally, evaluating the hydrodynamic connection between wells and production facilities, as well as identifying any disruptions or reservoir compartmentalization, is essential for ensuring the safe and efficient operation of the reservoir.

In order to achieve these objectives, it is recommended that the following types of studies and measurements continue to be carried out:

The following elements constitute the framework for the investigation:

- -

- the determination of dynamic and static bottomhole pressures and temperatures;

- -

- the investigation of changes in static and dynamic pressures and temperatures along the wellbore;

- -

- studies using steady-state (SS) and pressure build-up (PBU/PBU) methods in wells;

- -

- the investigation of well interactions (hydroacoustic monitoring, tracer fluids).

The true extent of the hydrodynamic and field geophysical studies conducted at the Kalamkas field was established in response to the necessity for the acquisition of novel information, the implementation of a well operating method, and the assessment of economic viability.

The majority of the wells under scrutiny exhibit a negative skin effect, suggesting that the near-wellbore zone (NWZ) is in a satisfactory state or that a well-developed fracture system has been formed as a consequence of hydraulic fracturing (HF) that has been conducted at the field over the course of years of development.

The majority of the production well stock is operated using mechanized sucker-rod pumping (SRP). As stated in the project documentation, direct measurements of reservoir pressure in these wells are only provided during well shutdowns for maintenance operations and during periods of inactivity. In practice, for wells with mechanized operation, reservoir and bottomhole pressures are determined by calculation, using measurements of static and dynamic fluid levels during level surveys and pressure build-up (PBU) tests. Dynamic fluid levels are also determined during dynamometer surveys. Subsequently, reservoir pressure values are obtained by recalculating these data.

The objective of the field studies is twofold: firstly, to monitor the depletion of reserves, and secondly, to assess the current state of reservoirs. The traditional set of measurements taken includes those of bottomhole pressures and temperatures, in addition to the sampling of downhole fluids. Furthermore, hydrodynamic well tests are also conducted, such as the steady-state testing method (SST) and the pressure build-up method (PBU). These approaches have been extensively utilised in both operating and new wells, including for the evaluation of the technological effectiveness of reservoir stimulation measures (e.g., selective conformance control, SCC, and hydraulic fracturing, HF) [3,4,7,9].

A synthesis of literature sources and project materials has been undertaken to compile a table of the recommended set of studies. This table is intended to facilitate the most effective solutions to the tasks of reservoir monitoring and optimisation. Table 1 presents a list of recommended research activities that are used in field practice for well monitoring and for assessing the technological state of reservoirs. The systematization of these methods formed the basis for the methodology implemented in this study.

Table 1.

A set of recommended research works.

In the context of this study, the findings of hydrodynamic testing of wells at the Uzen field were analysed. The primary objective of the study was to analyse the pressure build-up curves (PBU) in order to ascertain the filtration capacity properties of the reservoir and evaluate the condition of the near-wellbore zone.

The analysis was conducted using data obtained from well shut-ins, with subsequent measurements of bottomhole pressure taken at various time intervals. The interpretation of the curves was conducted utilising semi-analytical models founded on solutions to the Darcy flow equation for a homogeneous reservoir with constant porosity and infinite boundaries, in accordance with the approaches delineated in [1].

Furthermore, methodologies for approximating the asymptotic section of the curve were employed, thereby enabling the consideration of static errors and the specific behaviour of pressure at late stages of recovery.

At the Kalamkas field, the monitoring of development is conducted through the implementation of a series of geophysical surveys, which are performed in both open-hole and cased wells.

3. Geophysical Surveys in an Open Borehole

Geophysical surveys in open-hole wells (well logging) encompass a broad array of methodologies employed to address geological and technical challenges, including stratigraphic and lithological division of sections, identification of reservoirs and their saturation, as well as monitoring the wellbore trajectory and the technical condition of wells. These methodologies encompass lateral logging, induction logging, acoustic surveys, radioactive logging, and a range of other specialised techniques. The primary objective of such surveys is to maximise the geological detail of the section and to assess the filtration-capacity parameters of the reservoir, a process that is vital for the design of field development and the operation of wells.

The advent of contemporary technologies for interpreting well logging results, including Interactive Petrophysics and Prime software, has engendered a paradigm shift in the realm of data analysis. These technologies facilitate enhanced accuracy through the utilisation of sophisticated processing algorithms. These tools take into account local geological conditions, reservoir type, fluid saturation, and section features, thereby improving the reliability of the interpretation. Furthermore, the adaptability of these software products, evidenced by their flexible settings and visualization capabilities, facilitates the customisation of processing methodologies to specific geological and technical support tasks for field development. These surveys are indispensable for increasing oil recovery factors, especially when developing complex reservoirs such as fractured or layered formations, as well as for monitoring the development of horizontal and deviated wells.

During the period under analysis (PYA), spanning from 1 January 2019 to 1 January 2021, a total of 161 vertical wells were drilled at the Kalamkas field, accompanied by the execution of a comprehensive suite of open-hole geophysical surveys (well logging). In 2020, geotechnical investigations (GTI) were conducted during the drilling of seven (8238, 8345, 8364, 8526, 8820, 9129, and 9367) production wells in the conductor interval (0–500 m) to study the causes of gas shows. Furthermore, during the 2019–2020 period, core samples were collected from four wells (8063, 9129, 8820, and 8238). As illustrated in Table 2, the coverage of core sampling and analyses for the aforementioned wells is presented.

Table 2.

Illumination of core sampling by wells.

The drilling of vertical wells in the productive section of the formation was performed with a 215.9 mm diameter bit, utilising polymer-based drilling fluids with a specific gravity of 1.28–1.42 g/cm3 and a specific electrical resistance (SER) of 0.2–0.8 mm. The suite of open-hole well logging was performed using the following methods: two-probe induction logging (ILD, ILS), dual laterolog (LLD, LLS), micro-laterolog (MLL), calliper logging (CALI), spontaneous potential method (SP), gamma ray logging (GR), acoustic logging (DT), and thermometry (TM). Geophysical surveys in the interval of productive deposits were complemented by density gamma-gamma logging (RHOB), photoelectric effect logging (PE), and neutron logging (NPHI). The standard set of well logging was performed along the wellbore and included the following methods: measurement of electrical resistance (ER) with roof and bottom gradient probes (A2M0.5N, N0.5M2A), spontaneous potential method (SP), calliper logging (CALI), radioactive logging (GR, NNL), induction logging (IL), thermometry (TM), and resistivity logging (RES).

The following detailed studies were included: laterolog (LL), micro-laterolog (MLL), multisonde induction logging (VIKIZ), acoustic logging for longitudinal wave velocity (AC), density (litho-density) gamma-gamma logging (GRD), and microprobes (MCL). Inclination surveys were performed to monitor the spatial position of the wellbore. The quality of casing cementation and the determination of cement top height were assessed by means of acoustic cementometry (AC + FCD).

The quality of primary well logging data processing was evaluated through reinterpretation of the logging materials. This approach enabled the comparison and correlation of interpretations provided by different service companies.

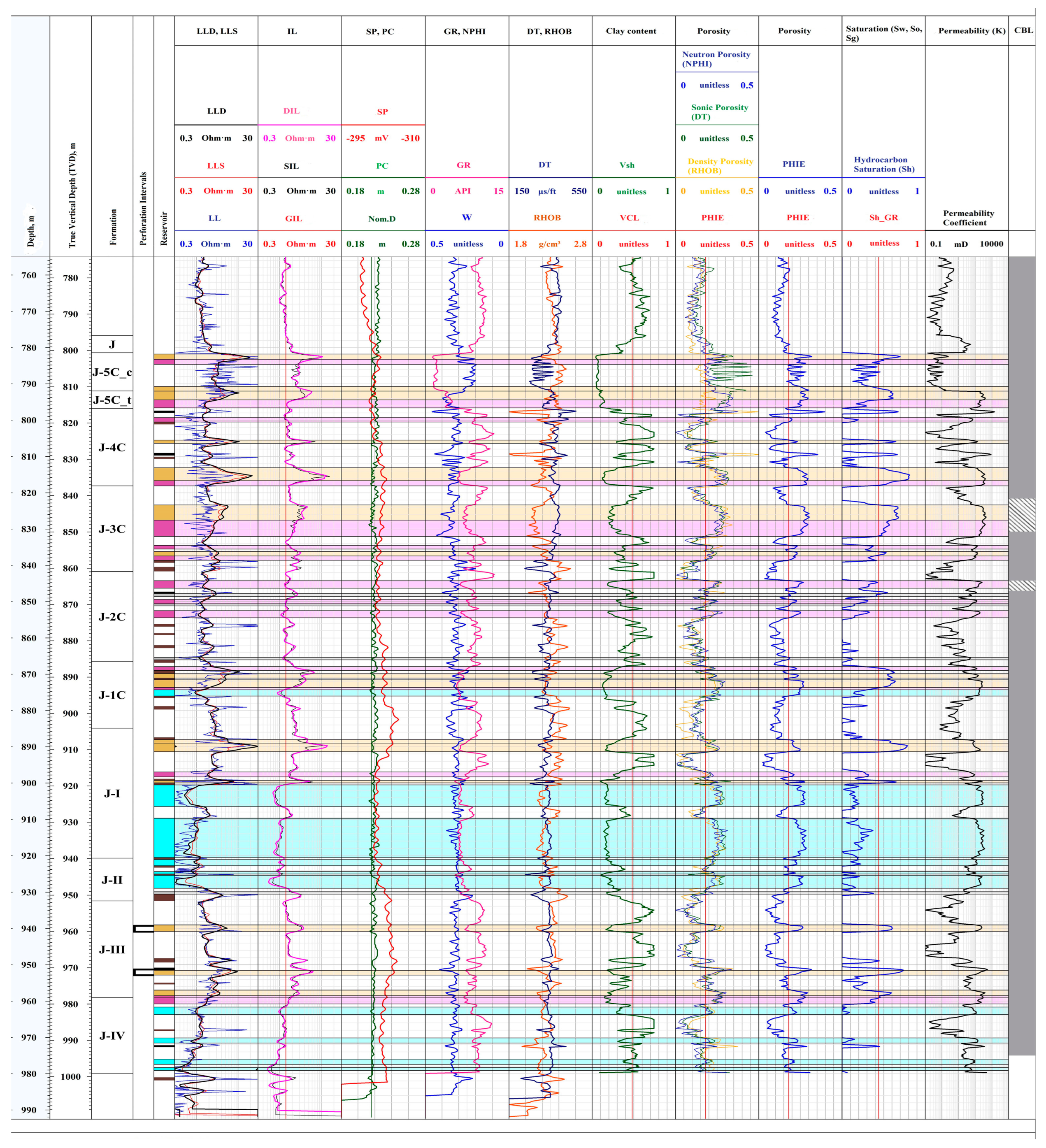

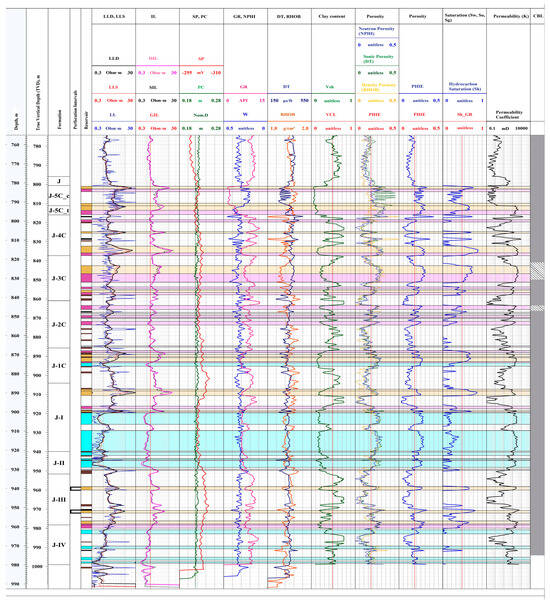

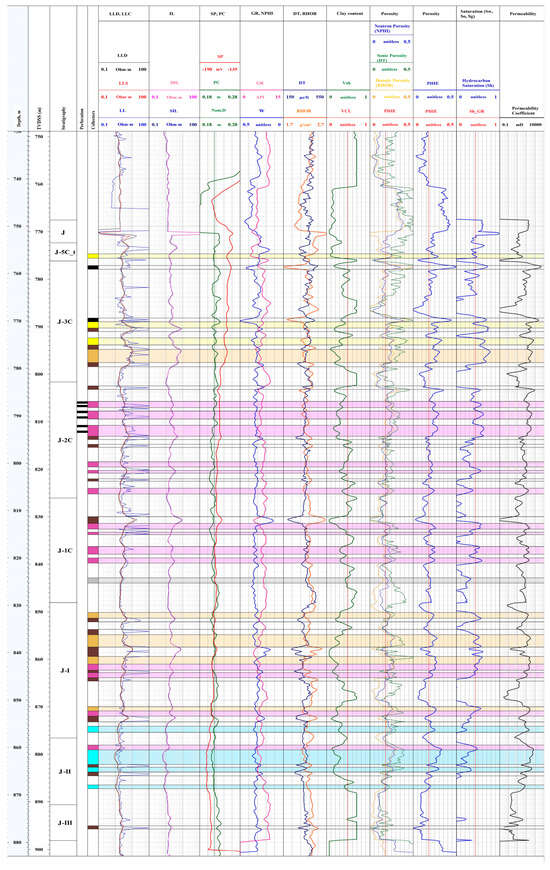

As the development of the Kalamkas field reaches its conclusion, a substantial degree of water saturation is becoming evident within the productive reservoirs. This assertion is substantiated by the findings of geophysical surveys conducted in well 8331 (see Figure 1). A thorough examination of the logging diagrams reveals that during the Yu2s and Yu3s formation intervals, water-saturated zones are predominant, along with oil–water and water–oil combinations. Such alterations are a direct consequence of long-term reservoir exploitation and interventions such as water injection to maintain reservoir pressure.

Figure 1.

Chart fragment for well 8331.

The interpretation is presented as a saturation profile of the reservoirs. The conventional symbols employed encompass water-bearing, oil-bearing, gas-bearing, combined saturation zones, and intervals that have undergone alteration during the developmental process. The logging data comprise gamma ray (GR), spontaneous potential (SP), acoustic (AC), resistivity gamma-gamma (RGG), resistivity, and porosity curves. These have been shown to reliably allow for the evaluation of reservoir saturation characteristics.

Analysis of the quality of processing of primary GPS materials was evaluated by re-interpreting the logging materials, which made it possible to compare and contrast the interpretation of service companies. The Kalamkas field is at a late stage of development. For this reason, reservoir watering is observed in many areas (Figure 1).

In the course of the analysis of the quality of primary well logging data processing, a problem was encountered in determining the nature of reservoir saturation. This was due to the fact that the full suite of geophysical surveys had not been carried out in accordance with the stipulations of the well construction project. The suite of geophysical methods was found to be incomplete, with the following techniques not included: induction logging (multi-probe, multi-depth VIKIZ), micro-profiling (MCL), and lateral logging (LL). The limited set of curves made it difficult to determine the saturation type of the reservoir rocks.

In the water-saturated reservoir, the IL and LL curves demonstrate “sinusoidal” variations in the intervals 823.3–835.4 m and 844.2–846.4 m (horizons Yu-3S, Yu-2S). A similar pattern is observed in instances where reservoir rocks become water-saturated due to development, or when the well is inadequately prepared for logging operations. However, in the absence of further data, the well has been reinterpreted, leading to the conclusion that the reservoir rocks are located against horizons Yu-3S and Yu-2S. These rocks have been assessed as water-saturated, indicating that they have been altered by development.

In the current Yu-3 horizon, the intervals 939–941 m and 951–953 m are perforated and operate with an oil flow rate of 5.6 t/day, a total fluid flow rate of 53 t/day, and a water cut of 88%.

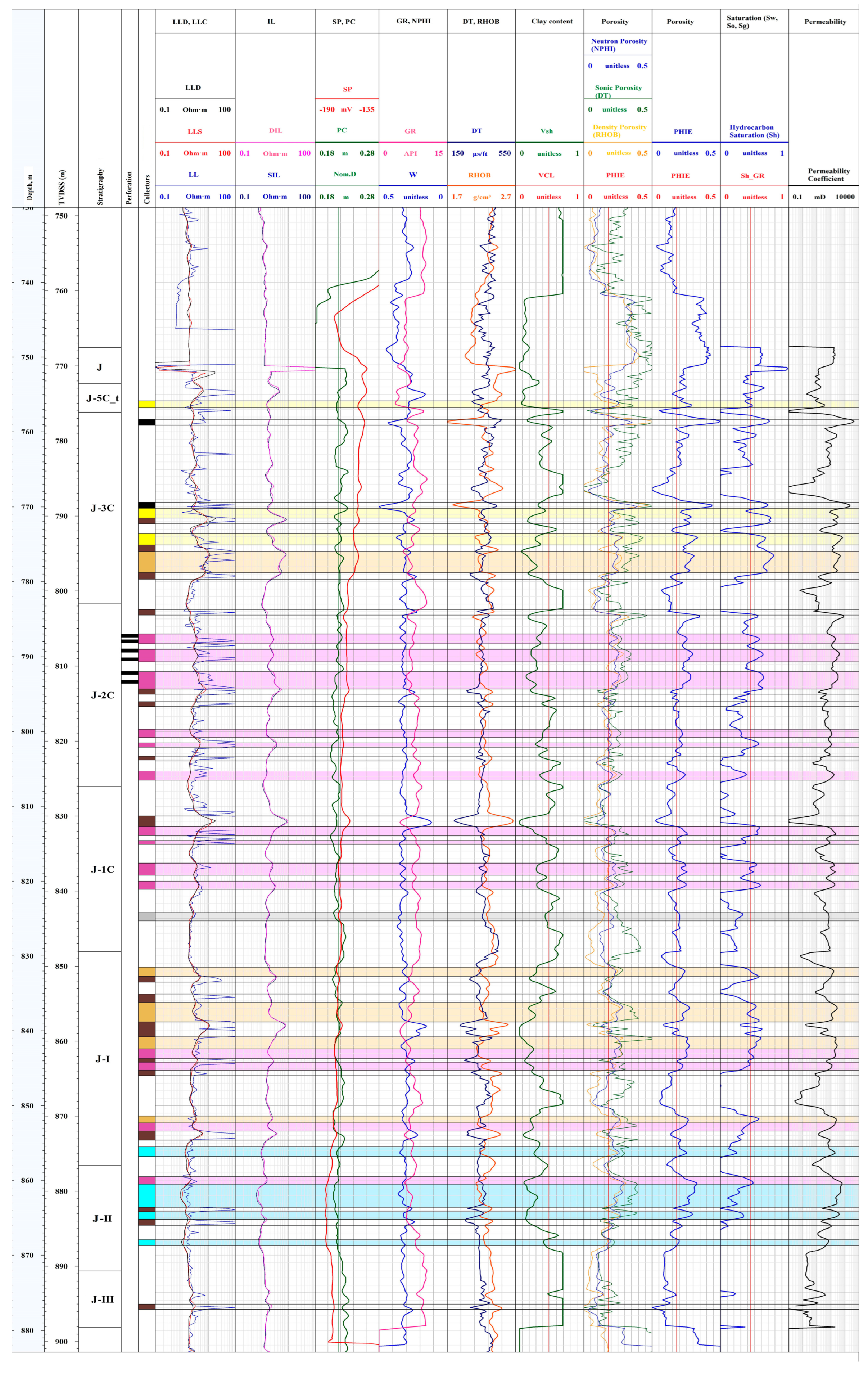

It is noteworthy that the quality of the MLL (micro-laterolog) curve in the wells of CNLC LLP is of a high standard. The micro-laterolog provides no meaningful information. The MLL and LL curves demonstrate no divergence against the Neocomian clay (the reference bed). Furthermore, a divergence across the entire section of the MLL curve above the LL is observed, and the cause of this divergence is unexplained (Figure 2). The diagram presents the results of a comprehensive geophysical survey (well logging) for well No. 9137, which is located at the Kalamkas field. The primary logging curves that are displayed include gamma ray (GR), neutron log (NL), density log (DL), electric log (SP), apparent resistivity (AR), along with flow rate and reservoir pressure curves. At the base of the figure is a lithological column, with facies and fluid saturation decoding.

Figure 2.

Chart fragment for well 9137.

As demonstrated by the logging data, the presence of oil-saturated intervals has been identified in the Yu-1, Yu-2, and Yu-3 reservoirs, a finding that has been corroborated by characteristic GR, NL, and SP values. The presence of gas, water, and weakly oil-saturated zones is also recorded and marked on the diagram with standard symbols. The well was selected as a typical example of a productive profile for Jurassic series reservoirs in this area of the field. The analysis was conducted utilising the “AINC-42” equipment and the “LOG_PWIN” and “LOG TOOLS” Techlog software.

In September 2020, well 9137 was initiated with a design depth of 900 metres. The objective horizon is designated Yu-1. The results of open-hole logging have identified the presence of oil-saturated reservoirs in the Yu-1 horizon, while the Yu-1S and Yu-2S horizons have been determined to be water-saturated, indicating alterations resulting from development. The Yu-3S horizon is distinguished by the presence of gas-saturated and oil-saturated reservoirs. In the intervals 831.5–833.0 m and 836.0–838.5 m (Yu-1 horizon), perforation and blasting operations (PBO) were conducted. Following the implementation of PBO, and given the elevated water cut, this particular filter interval was isolated. The well was subsequently transitioned to the overlying Yu-2S horizon, with perforation intervals of 787–788 m, 789–790.5 m, and 792–793.5 m. Subsequent to the transition, the well functions with a total fluid flow rate of 54 m3, an oil flow rate of 7.2 t, and a water cut of 85%.

In order to clarify the producing intervals, geophysical studies were conducted after the switch. The results of the working interval identification logging (GIS-ORI) conducted on 23 December 2020 indicate that the intervals 789.3–790.5 m, 792.4–793 m, and 793–793.5 m are primarily producing water, with minor traces of oil.

A thorough analysis of all geological and geophysical data pertaining to well 9137 reveals a correlation between the high water cut in the reservoirs and field development. It can be deduced that the reservoirs have been altered by production (Figure 2). The selection of well 9137 is predicated on its representation of a paradigmatic example of operation under conditions of elevated water cut, a phenomenon that is characteristic of mature sections of the productive Yu-1S and Yu-IV horizons. This well has been utilised for the purpose of annual monitoring, and a substantial amount of reliable data has been accumulated for the period under analysis. As demonstrated in Figure 1, the logging curves permit the monitoring of reservoir saturation, the delineation of oil-saturated intervals, the alteration of the filtration capacity properties of the rocks, and the identification of zones affected by water influx.

The findings from these open-hole studies have been utilised in the context of stratigraphic breakdown, reservoir identification, and the classification of reservoir saturation types. The obtained results are also considered during the selection of new well locations for drilling.

3.1. Well Logging Surveys—Monitoring in Production and Injection Wells

Geophysical monitoring surveys (well logging control, GIS-C) have been shown to be a valuable tool in determining the inflow profile and the composition of fluids entering the well. In addition, they facilitate the estimation of the intervals of outflow and absorption of injected fluids, as well as the technical condition of the casing. The determination of inflow and injectivity profiles by formation facilitates the identification of the distribution of produced and injected fluids across the intervals of the studied horizon.

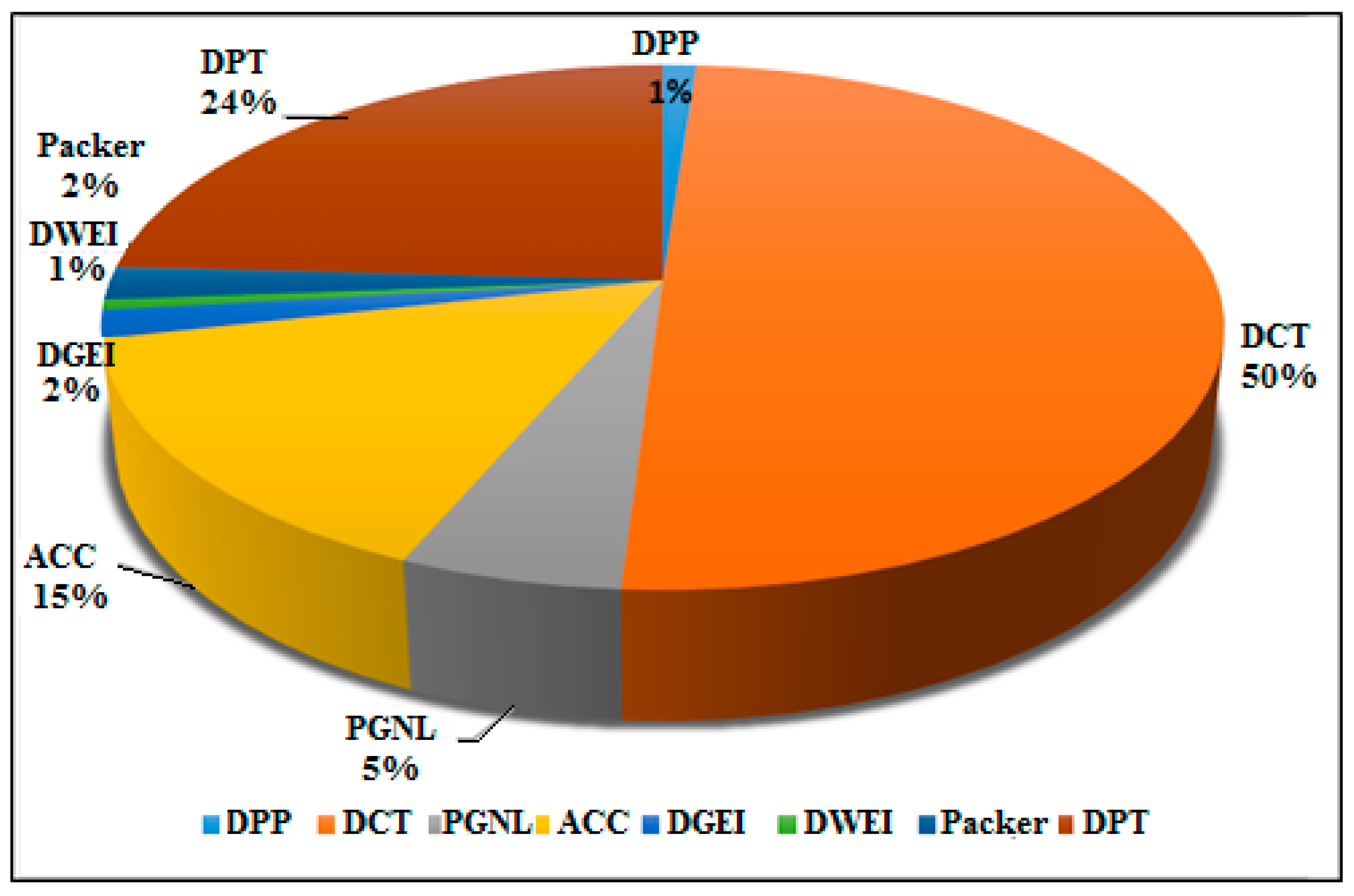

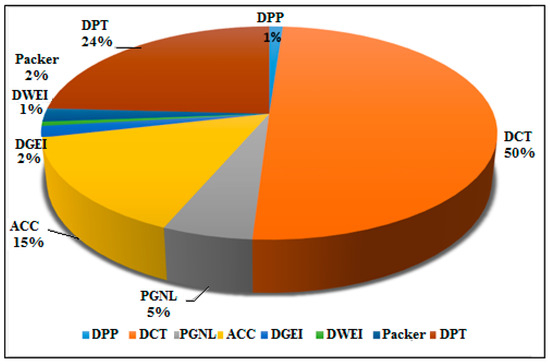

During the period under analysis at the Kalamkas field, surveys were conducted in 338 production wells and 313 injection wells. As illustrated in Figure 3, the scope of well logging control (GIS-C) surveys conducted during the specified period is delineated by type. The diagram illustrates the distribution of survey types in wells for 2020. The largest share is accounted for by general geophysical control surveys (OGK), which represent 50% of the total volume. A substantial proportion of the latter consists of annulus integrity surveys (OGP)—24%—and acoustic cementation surveys (AC)—15%. The surveys that were conducted with the least frequency were those pertaining to the determination of reservoir parameters (OPP), the assessment of intercasing flow (OMPG), and the evaluation of interaction between reservoirs (OMPV). These surveys accounted for a percentage of the total that was between 1 and 2. This distribution is indicative of the priority assigned to comprehensive technical condition monitoring of wells.

Figure 3.

Ratio of completed trials by type for the reporting period.

3.2. Production Wells

During the analysed period, geophysical surveys in producing wells were carried out to determine column tightness and pickup profile (DCT PP), working intervals, water inflow intervals, string failures during compression (DCT WF), gas inflow location, packer tightness, tracing of liquid level, and water–oil interface. The abovementioned studies were performed in 1217 wells; in 538 wells, 607 studies were performed to determine the tightness of the string; in 20 wells, the determination of gas entry intervals (DGEI) was performed; determination of water entry intervals (DWEI) was performed in 8 wells; and packer stripping was performed in 24 wells.

During the period under review, GPS control works carried out at the field allowed the identification of well failures caused by leaky production strings. According to the results of geophysical surveys, string failures were detected in 135 production wells.

Geophysical surveys in production wells were not carried out due to non-passage of instruments in 26 wells, which indicates poor quality preparation of the well for work.

3.3. Injection Wells

During the analysed period, geophysical surveys were conducted in injection wells to determine:

- -

- column tightness and injectivity profile (DCT and DPP);

- -

- string tightness and bottomhole overflows (DCT and BF);

- -

- packer tightness and injectivity profile (DPT and DPP).

Studies to determine the injectivity profile were carried out in 13 wells; in 318 wells, column tightness (DCT) was determined; and packer tightness (DPT) studies were carried out in 291 wells. As a result of investigations in 144 wells, string failures were detected.

As illustrated in Table 3, the following categories of faults were identified during geophysical monitoring surveys in production and injection wells during the period under analysis. From 2018 to 2020, the number of recorded technical faults in the production well stock increased from 41 to 69, which may indicate the need for timely geological and technical interventions (GTM). A similar trend is observed in the injection well stock, where the number of faults ranged from 58 to 47, with a consistently high proportion of casing defects and problems with isolation integrity.

Table 3.

The distribution of surveys is illustrated by type of identified technical fault.

Geophysical surveys in injection wells were not carried out due to the lack of instrumentation in 46 wells, which indicates the poor quality of well preparation for GPS.

3.4. Quality Assessment of Production String Grouting

ACC and FCD studies were performed after the cementing of production casing in all newly drilled wells. High-quality cementing of casing strings is necessary for unambiguous fluid determination, correct estimation of reservoir parameters, and effective control over reservoir production.

In the old stock wells, the condition of cement behind the string was evaluated: when preparing wells for hydraulic fracturing (HF), for returning to another horizon, and after isolation works. At the same time, not the whole string was tested, but only the interval of interest exposed to influence.

3.5. Determining the Current Nature of Saturation

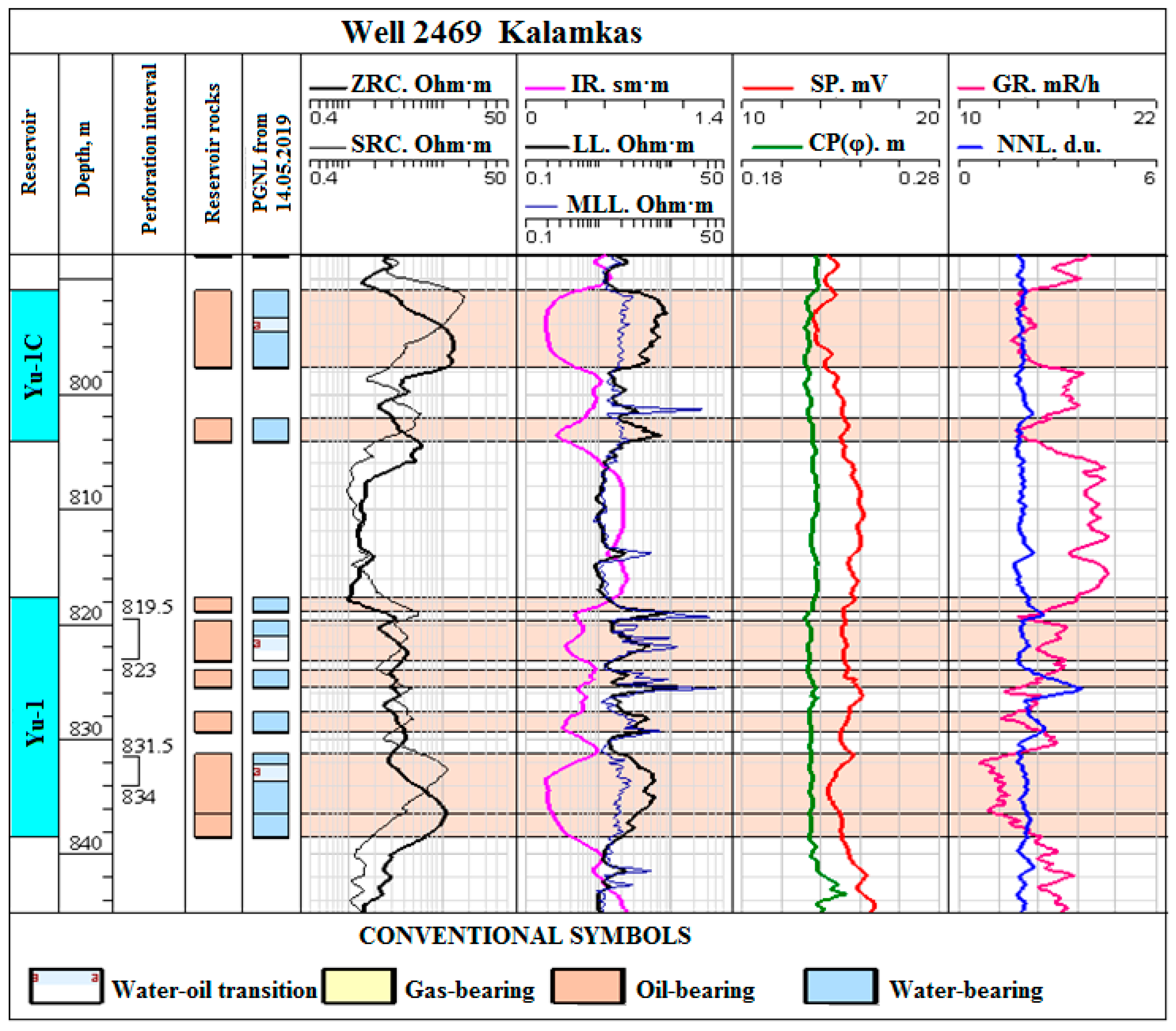

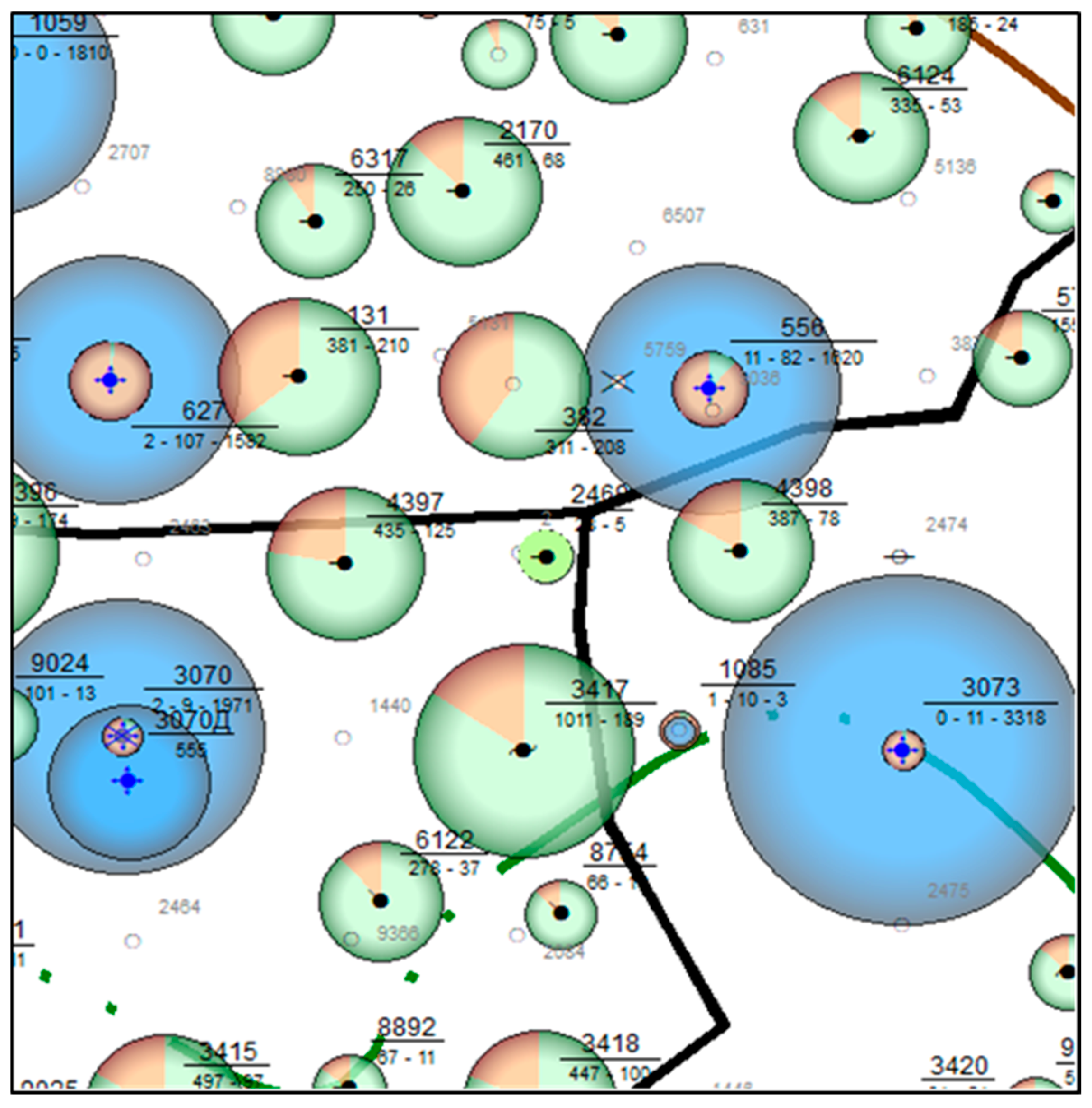

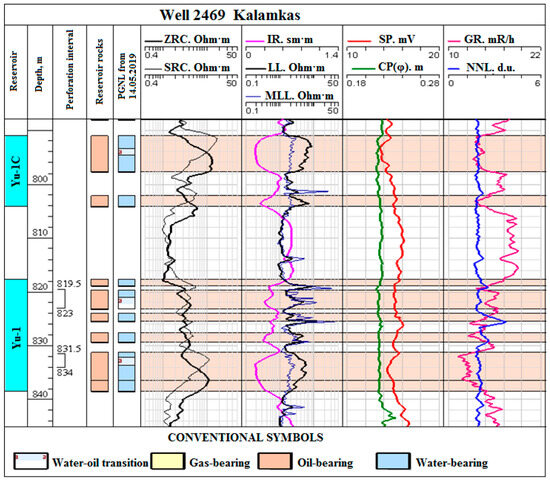

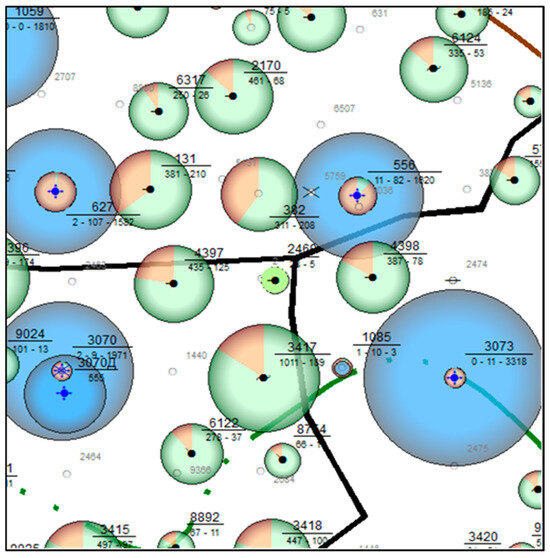

Pulsed neutron logging methods (PNNL, PNGL) are widely used in the field to determine the current saturation character of non-perforated reservoirs. In total, during the reporting period, pulsed neutron method studies were carried out in 55 production wells and 26 injection wells, mainly before returning to another horizon or completing productive intervals. Recording of research and interpretation for the determination of current oil saturation of formations for the analysed period was carried out by AINK-42 equipment; interpretation was performed using the LOG_PWIN and LOG TOOLS programs. Pulsed neutron-neutron logging (PNNL) was used in the study of active, cased wells to trace oil–water and gas–liquid contacts to quantify the initial, current, and residual oil and gas saturation of non-perforated reservoirs. Based on the results of the PNNL, it can be concluded that the previously identified oil-saturated reservoirs are being watered over the development period and according to the results of PGNL (pulsed gamma-neutron logging) dated 14 May 2019, the reservoir layers of the Yu-1 horizon are characterized as water-saturated. Figure 4 and Figure 5 show well 2469 as an example, where open hole logging data shows reservoir layers in the Yu-1C and Yu-I horizons.

Figure 4.

Geophysical characterisation of reservoir formations in the Yu-1C, Yu-I horizon in well 2469.

Figure 5.

Map of the U-1 horizon for well 2469 with neighbouring wells.

The methodology of this study is based on the comprehensive interpretation of hydrodynamic well test results (HDS), including the analysis of the pressure build-up curve (PBU) and the steady-state testing method (SST). The data processing was undertaken utilising analytical and numerical methods, with the non-stationary Darcy flow equation being solved under constant porosity conditions. The primary objective of this study was to interpret the asymptotic part of the pressure build-up curve, utilising approximation methods and identifying heterogeneities in the near-wellbore zone.

Furthermore, the study utilised contemporary software tools, namely Interactive Petrophysics and Prime, for the purpose of petrophysical analysis and interpretation of well logging data. These tools enabled the consideration of the geological and physical characteristics of the reservoirs, and the adaptation of standard techniques to the specific conditions of the field. All calculations and analyses were carried out using contemporary data from the Kalamkas field wells, including reservoir pressure measurements, temperature, fluid properties, and well intervention results. The technological effectiveness of interventions was assessed by comparing parameters before and after reservoir treatments (such as selective conformance control, hydraulic fracturing, etc.).

4. Results and Discussion

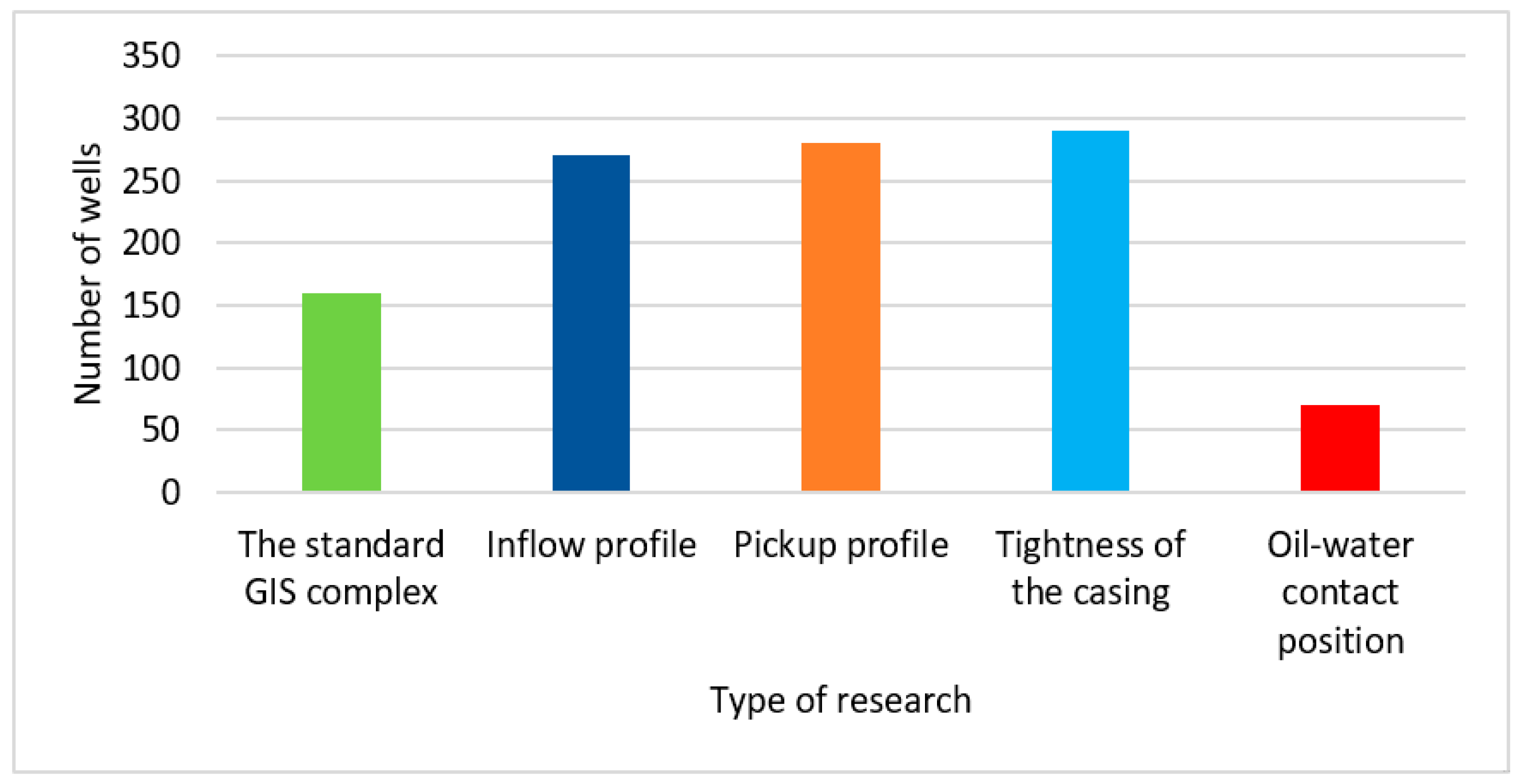

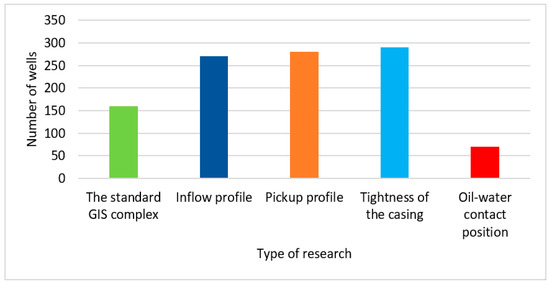

As illustrated in Table 4, a compendium of recommended geophysical surveys (well logging) has been provided for a variety of well types, indicating the frequency of surveys and the subsequent implementation. The following brief interpretation of the data in the table is proposed:

Table 4.

Recommended GPS, frequency of surveys, and actual implementation.

- 1.

- Standard open-hole well logging suite:

These are one-time surveys conducted in all newly drilled wells with the objective of identifying reservoirs and determining fluid capacity. A total of 161 surveys have been carried out.

- 2.

- Determination of inflow profile:

This survey is conducted in production wells following stabilisation during commissioning, as well as when operational changes occur. The frequency of the study is biennial, with 270 surveys having been completed to date.

- 3.

- The determination of the injectivity profile and the absorption interval is conducted in the designated injection wells. This procedure is conducted on an annual basis, with the understanding that it may be undertaken in the aftermath of hydraulic fracturing or the implementation of operational modifications. To date, 278 surveys have been completed.

- 4.

- Determination of casing integrity:

These are one-time surveys conducted with the objective of assessing casing integrity in production and injection wells during the processes of fluid injection or compression. To date, 289 surveys have been completed.

- 5.

- The assessment of casing and cement stone condition is a procedure that is carried out on all newly drilled and operational wells, as well as during well interventions, in order to ensure the optimal functioning of the wells. A total of 161 surveys have been completed.

- 6.

- The monitoring of oil-water contact (OWC) position and the assessment of current oil saturation are conducted in operational wells or during well interventions. A total of 66 surveys have been completed.

The table illustrates the regularity and scope of various geophysical surveys performed to monitor well conditions, which helps ensure effective management of production and injection processes.

The attainment of enhanced hydrocarbon production can be accomplished through the concerted utilisation of engineering, geological, and geophysical expertise. In the context of synergistic studies, geologists must possess the expertise to ascertain the properties of rocks that are instrumental for the extraction of oil and gas. The present article offers a comprehensive overview of the field of geological technology, encompassing the underlying concepts and principles that govern its application [14].

Geophysical surveys are utilised in the context of development monitoring to address issues pertaining to water encroachment and reservoir depletion, in addition to the technical condition of wells. The results of well logging control (GIS-C) facilitate a rapid response to any alterations in well operation. These alterations can then be taken into consideration when planning geological and technical measures (GTM). Furthermore, the effectiveness of interventions can be evaluated, and any necessary adjustments can be made to future operations.

It is important to note that at the Kalamkas field, surveys in cased wells are primarily conducted when technical issues are suspected, with the aim of identifying locations of casing leaks. These surveys are also conducted in wells with high water cut or declining flow rates.

Figure 6 shows the number of wells actually surveyed compared to the recommended number of surveys for each type of well.

Figure 6.

Comparison of recommended and actually performed surveys.

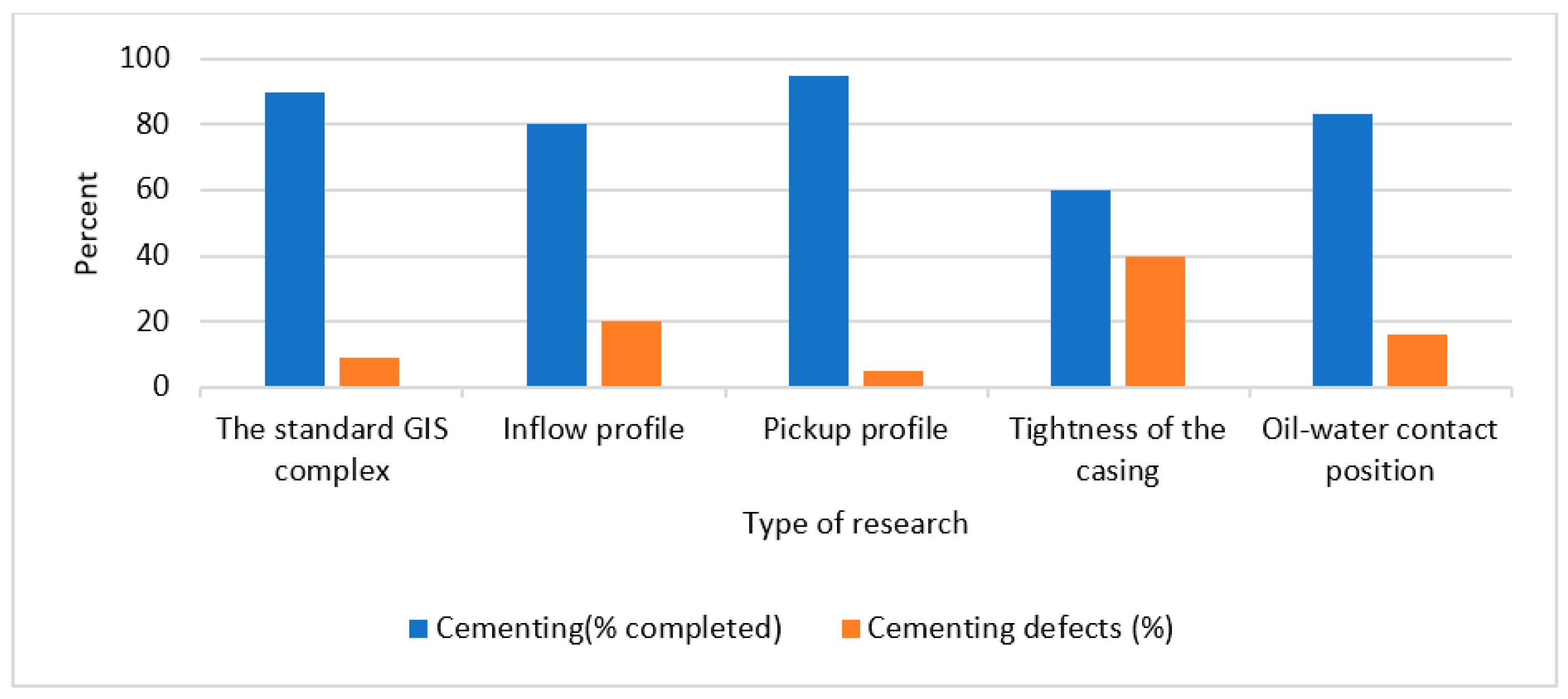

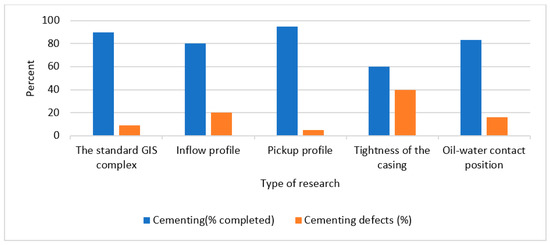

As illustrated in Figure 7, the percentage of cementing surveys performed is plotted alongside the percentage of wells with cementing defects. This enables an assessment of casing integrity.

Figure 7.

Indicators of integrity and cementing condition.

Key conclusions from well logging surveys (GIS) at the Kalamkas field:

- -

- Casing integrity: Integrity surveys are conducted primarily in instances where technical complications are suspected in wells. In such cases, the investigation focuses on sections where fluid or gas leakage may occur.

- -

- Casing cementing: Cementometry data indicate that the condition of casing cementing at the Kalamkas field is satisfactory. It is imperative to note that in the case of older wells, surveys are conducted only at specific intervals along the casing, a method that may not be adequately effective.

- -

- Water cut and flow rate decline: Conducting surveys in wells with elevated water cut or declining flow rates facilitates the expeditious identification of problem areas and the effective management of injection and production processes.

- -

- Drilling technology: In order to achieve high-quality well logging, it is imperative to adhere to the proper drilling technology and well preparation. This is due to the fact that such adherence has a significant impact on the quality and outcomes of the surveys.

Suggested enhancements to the process:

- The standardisation of well logging procedures in older wells is recommended in order to facilitate a more effective evaluation of casing and cementing conditions along the entire casing length.

- It is imperative to implement a systematic and consistent monitoring programme for water cut, alongside a comprehensive analysis of alterations in well performance. This approach is instrumental in averting declines in flow rate.

- The execution of well logging surveys for all wells is imperative, with particular consideration given to injection dynamics and declining performance, especially for wells that have been in operation for an extended period.

These approaches have the potential to enhance the accuracy and timeliness of diagnostics in field settings.

In the course of the study, hydrodynamic testing results were obtained from wells at the Kalamkas field, incorporating pressure and temperature measurements at various horizons and in different wells. The results of the pressure build-up (PBU) and steady-state filtration (SST) tests yielded the following key findings:

- In the reference well network, pressure stabilised after X hours following well shut-in. This confirmed the effectiveness of the technologies used (hydraulic fracturing, selective conformance control). The measured pressure values exhibited substantial deviations from the anticipated values, suggesting the presence of heterogeneities within the near-wellbore zone. These findings are corroborated by numerical modelling results, wherein the nature of pressure recovery following intervention closely corresponds to the asymptotic curve as time progresses.

- In wells where temperature monitoring was performed, a noticeable correlation between changes in pressure and temperature was observed. This finding indicates significant thermobaric changes during operation. These alterations were documented in 30% of wells, which may suggest an enhancement in pore connectivity within the reservoir following hydraulic fracturing.

- Studies conducted using the PBU method demonstrated improved filtration properties in certain sections of wells that previously exhibited low permeability. Specifically, following hydraulic fracturing, there was an increase in reservoir permeability of 10–15% compared to initial values. The veracity of these findings was further substantiated by a thorough examination of well logging data.

- The following assessment of technological effect is presented: a comparison of indicators before and after interventions in the near-wellbore zone (selective conformance control, hydraulic fracturing) showed that the oil recovery factor increased by an average of 5% compared to previous periods of operation. This enhancement is substantiated by the observation of improved filtration characteristics and additional increases in well flow rates.

A comprehensive analysis of geophysical surveys conducted in the stock of production and injection wells from 2018 to 2020 was undertaken. This analysis yielded several key trends and issues affecting well performance, the details of which are outlined below:

The number of technical faults recorded in the production well stock increased from 41 in 2018 to 69 in 2020. This phenomenon is indicative of equipment ageing and increased wear, which can result in a decline in productivity. The primary issues are associated with casing defects and breaches of isolation integrity, which have the potential to adversely impact the oil recovery factor.

In the injection well stock, the number of faults decreased to 47 in 2020 compared to 58 in 2019; however, issues with casing and tubing integrity remain relevant, indicating the need for regular geological and technical interventions to prevent leaks and maintain productivity.

The observed trend of increasing faults in the production stock and the need for improved equipment condition in the injection stock highlight the importance of regular monitoring and geological and technical interventions (GTM) to maintain optimal well performance and enhance production efficiency.

5. Conclusions

Thus, geophysical surveys are an important tool for optimizing oil recovery at various stages of development, including complex reservoirs such as fractured and layered formations.

Analysing the geological and geophysical data for well 9137, we can conclude that high watering of the formations is related to the consequences of field exploitation. This may indicate that the formations were altered during development, which led to such changes.

Geophysical development control surveys in the Kalamkas field were conducted in 338 production wells and 313 injection wells. These surveys allow the assessment of the fluid flow profile, absorption intervals, and the technical condition of the strings, which is important for the optimization of the field development.

Based on pulsed neutron logging data, it can be concluded that the reservoir of the Yu-1 horizon, previously characterized as oil-saturated, is being watered during field development. This indicates that the reservoir is gradually losing its oil saturation and becoming water-saturated, which is associated with changes in reservoir characteristics and possible reservoir disruption or deterioration of operating conditions. Such changes require adjustments to the development and monitoring strategy to prevent further deterioration in production performance. The findings substantiate the efficacy of the proposed methodologies and technologies for enhancing the recovery factor in mature fields such as Kalamkas. The enhancement of reservoir permeability and the optimisation of filtration parameters, consequent to hydraulic fracturing and associated interventions, signifies the viability of further implementation of these technologies to augment oil recovery.

Concurrently, it is imperative to acknowledge that, despite the favourable outcomes, certain wells manifest reservoir heterogeneities, which are concomitant with variations in geological conditions. In order to achieve more accurate forecasting and optimisation of field development, further studies are required that take these factors into account.

Author Contributions

Conceptualization, R.B. and A.T.; methodology, R.B., A.T. and D.S.; validation, R.B., A.T. and A.Z.; formal analysis, M.T. and A.G.; investigation, R.B. and A.T.; resources, D.S. and M.S.; writing—original draft preparation, R.B., A.T. and D.S.; writing—review and editing, R.B., A.T., B.N., S.N. and A.Z.; visualization, A.T.; supervision, R.B. and A.T.; project administration, R.B., A.T. and A.Z.; funding acquisition, A.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP19679430).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Shyngys Nugumarov was employed by the company Aktau Petroleum Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lysenko, V.D. Innovative Development of Oil Fields; Nedra-Business Center LLC: Moscow, Russia, 2000; p. 516. [Google Scholar]

- Oberkircher, J.; Cavender, T.; Nielsen, V.J.; Beleau, M. Intelligent Multilaterals: The Next Step in the Evolution of Well Construction. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; p. 12. [Google Scholar] [CrossRef]

- Fakhrullin, R.G. Complex of Field Studies on the Control of Oil Reserves Development; Tatpoligraf Publishing House: Kazan, Russia, 2002; p. 304. [Google Scholar]

- Refined Project of Kalamkas Field Development; JSC KazNIPImunaigas: Aktau, Kazakhstan, 2018; Volume 8.

- Bayamirova, R.; Sudakov, A.; Togasheva, A.; Sarbopeyeva, M. Application of flow-diversion technologies to increase oil recovery at the Uzen field. E3S Web Conf. EDP Sci. 2024, 567, 01003. [Google Scholar] [CrossRef]

- Tajibayev, M.; Bayamirova, R.; Togasheva, A. Development of an integrated approach to assess the localization of residual recoverable oil reserves to improve the efficiency of geological and technical measures at the Uzen field. Kazakhstan J. Oil Gas Ind. 2025, 7, 42–53. [Google Scholar] [CrossRef]

- Eltahan, E.; Rego, F.B.; Yu, W.; Sepehrnoori, K. Impact of well shut-in after hydraulic-fracture treatments on productivity and recovery of tight oil reservoirs. J. Pet. Sci. Eng. 2021, 203, 108592. [Google Scholar] [CrossRef]

- Eltahan, E.; Bordeaux Rego, F.; Yu, W.; Sepehrnoori, K. Impact of well shut-in after hydraulic-fracture treatments on productivity and recovery in shale oil reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020; p. D011S003R003. [Google Scholar]

- Zhang, C.; Prasanna, V.; Orangi, A.; Da Sie, W.; Kwatra, A. Modeling methodology for application development in petroleum industry. In Proceedings of the IRI-2005 IEEE International Conference on Information Reuse and Integration, Conf, 2005, Las Vegas, NV, USA, 15–17 August 2005; pp. 445–451. [Google Scholar] [CrossRef]

- Iske, A.; Randen, T. Methods and Modelling in Hydrocarbon Exploration and Production; Springer: Berlin/Heidelberg, Germany, 2005; Volume 10, p. b137702. [Google Scholar]

- Abasova, I. Hydrodynamic Methods for the Investigation of Wells and Reservoir. Sci. Rev. 2019, 3, 3–8. [Google Scholar] [CrossRef]

- Babadagli, T. Development of mature oil fields—A review. J. Pet. Sci. Eng. 2007, 57, 221–246. [Google Scholar] [CrossRef]

- O’Brien, J.; Sayavedra, L.; Mogollon, J.L.; Lokhandwala, T.; Lakani, R. Maximizing mature field production-A novel approach to screening mature fields revitalization options. In Proceedings of the SPE Europec featured at 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016; p. SPE-180090-MS. [Google Scholar] [CrossRef]

- Yu, Q.; Mu, Z.; Liu, P.; Hu, X.; Li, Y. A new evaluation method for determining reservoir parameters for the development of edge-water-driven oil reservoirs. J. Pet. Sci. Eng. 2019, 175, 255–265. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).