Fracture System Characteristics and Their Control on Permeability Anisotropy in Bright and Dull Coal

Abstract

1. Introduction

2. Experimental Method

2.1. Sample Information

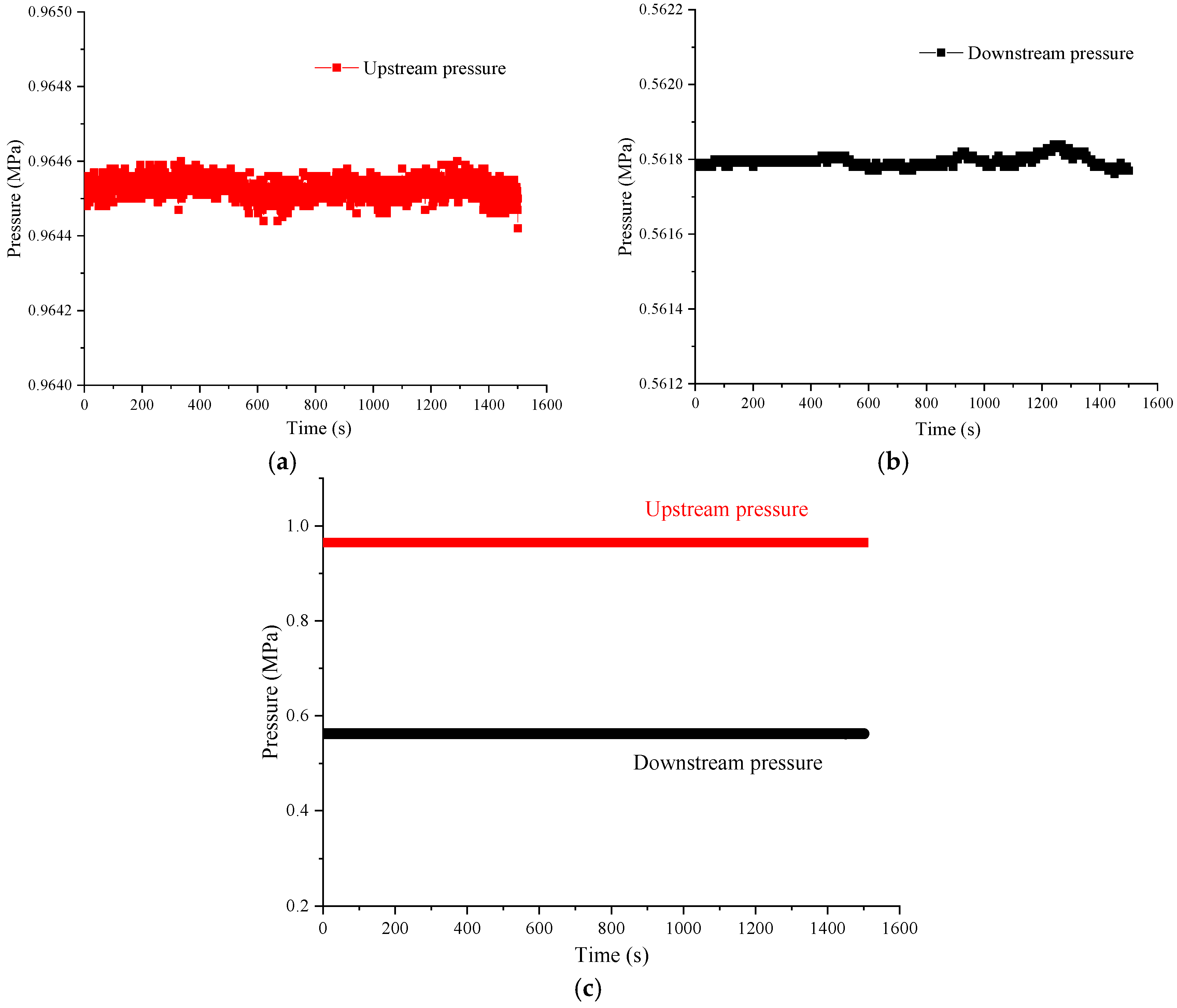

2.2. Experimental Conditions

2.3. Experimental Setup

2.4. Permeability Calculation Method

3. Experimental Results

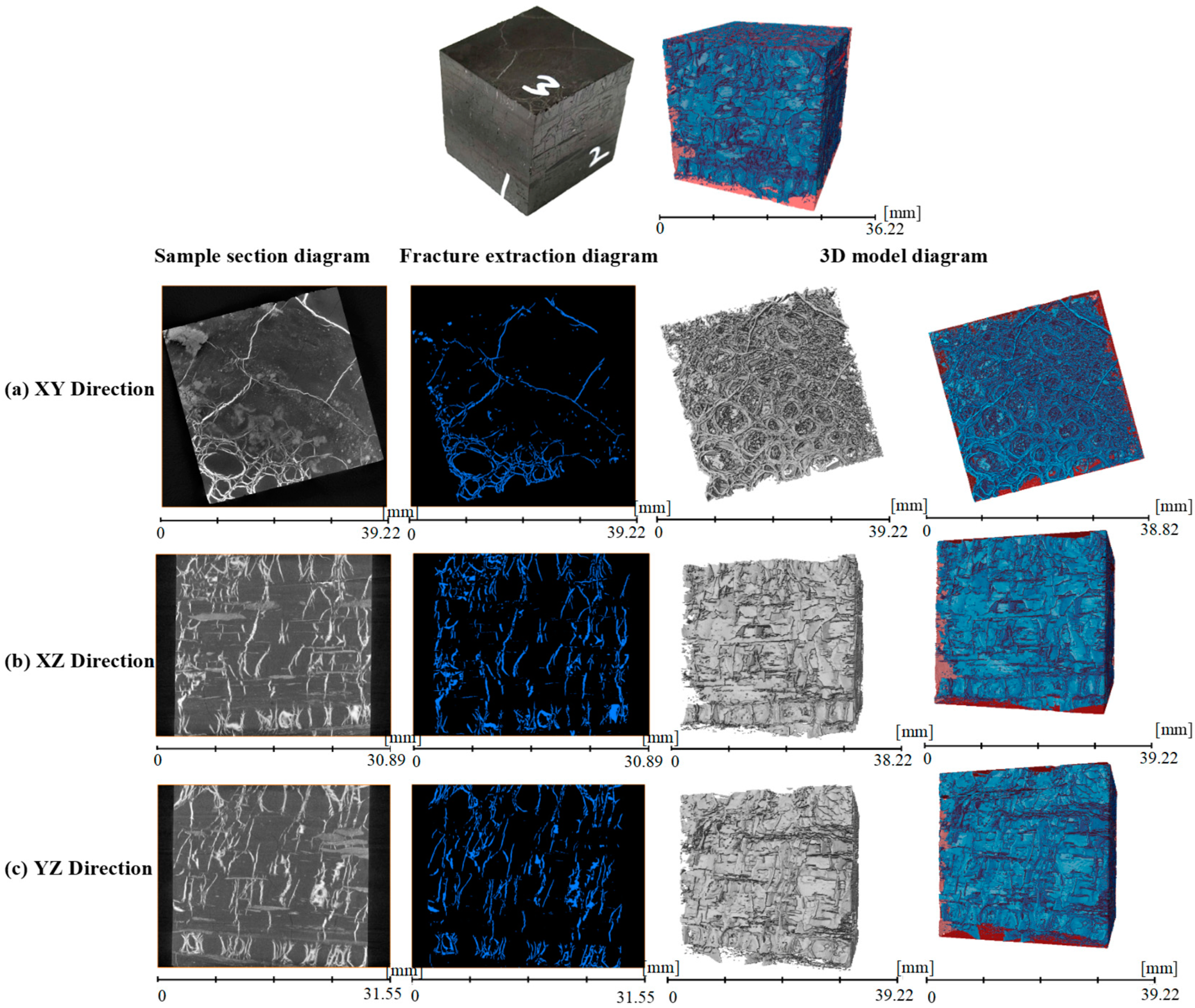

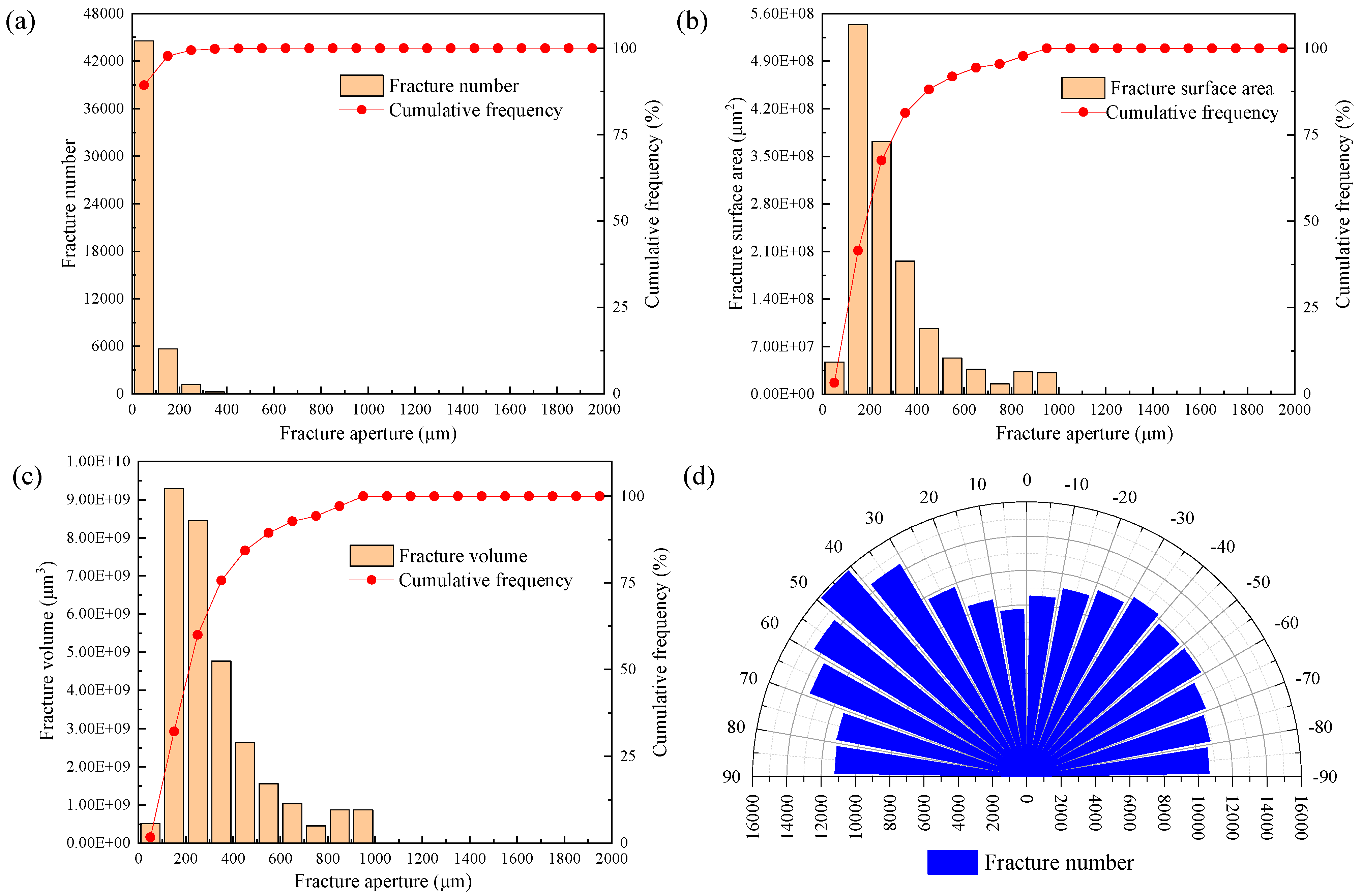

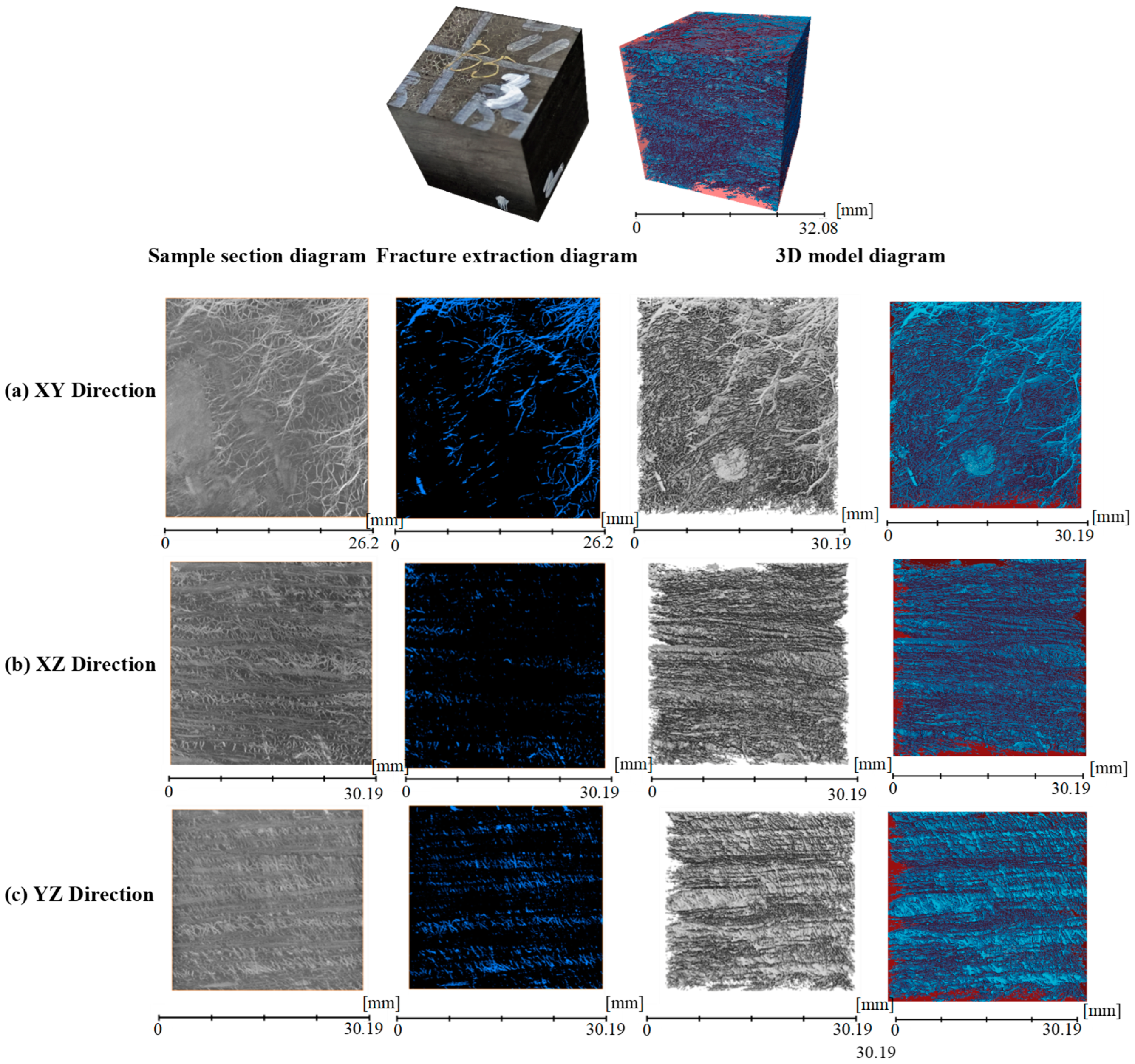

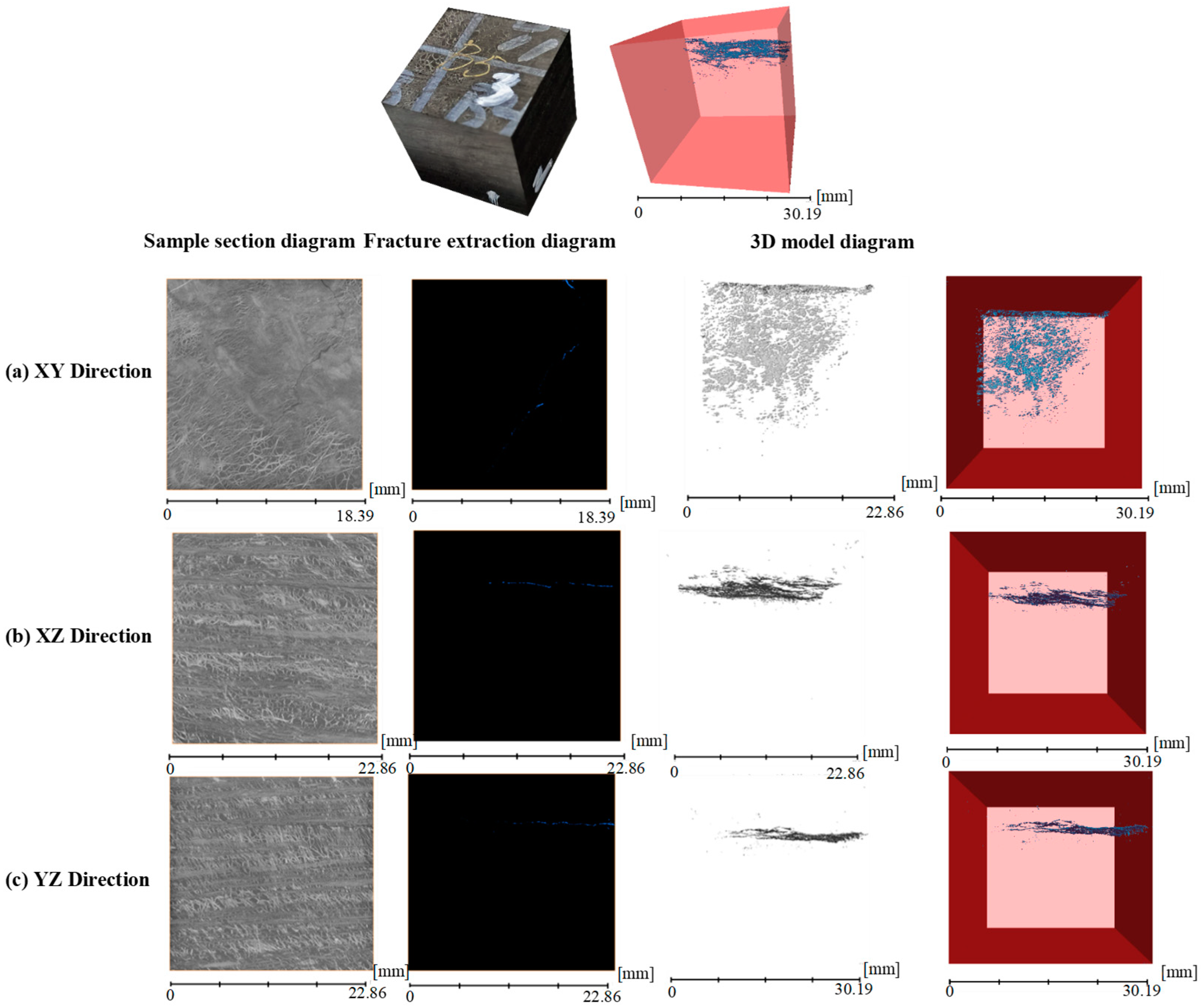

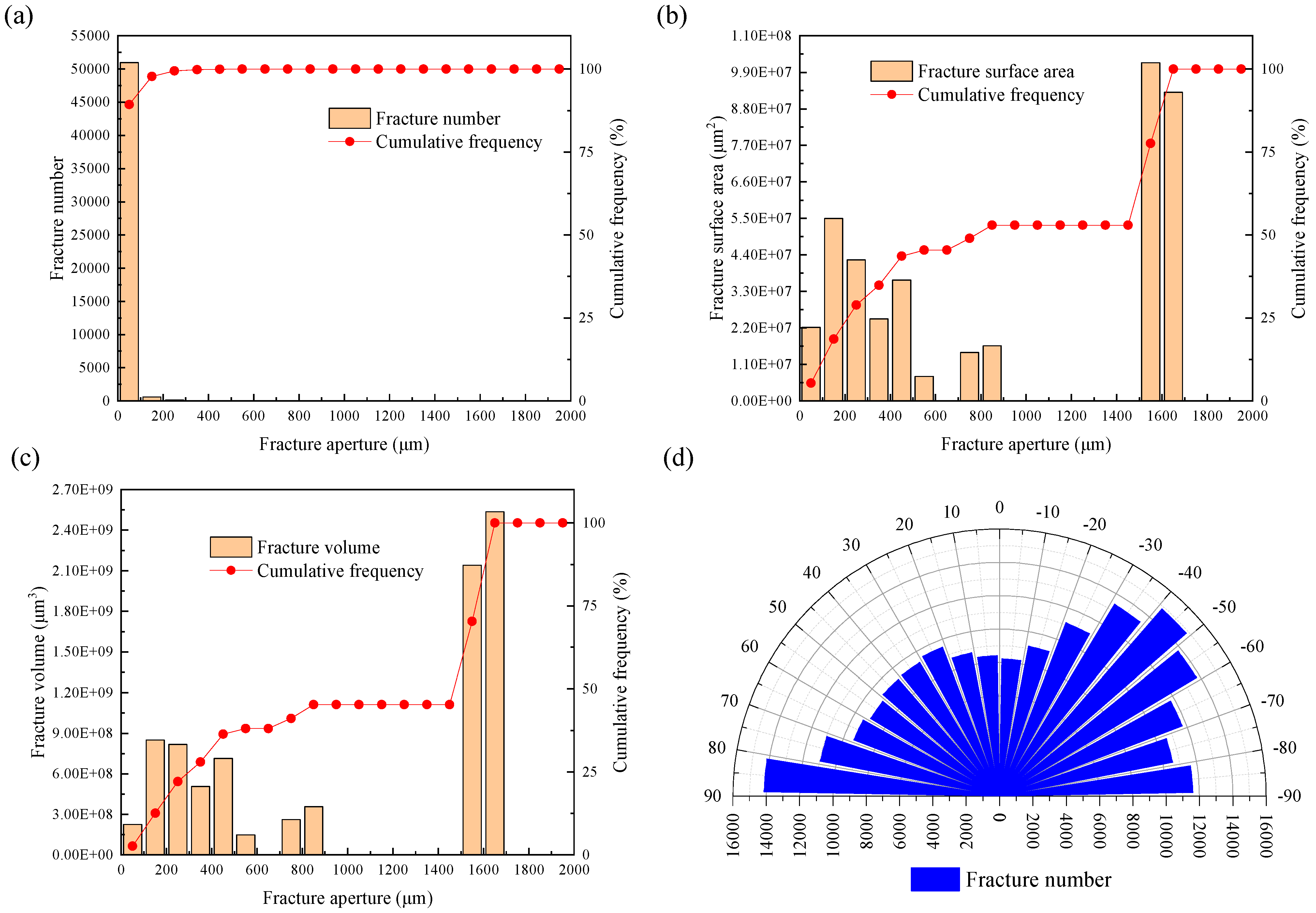

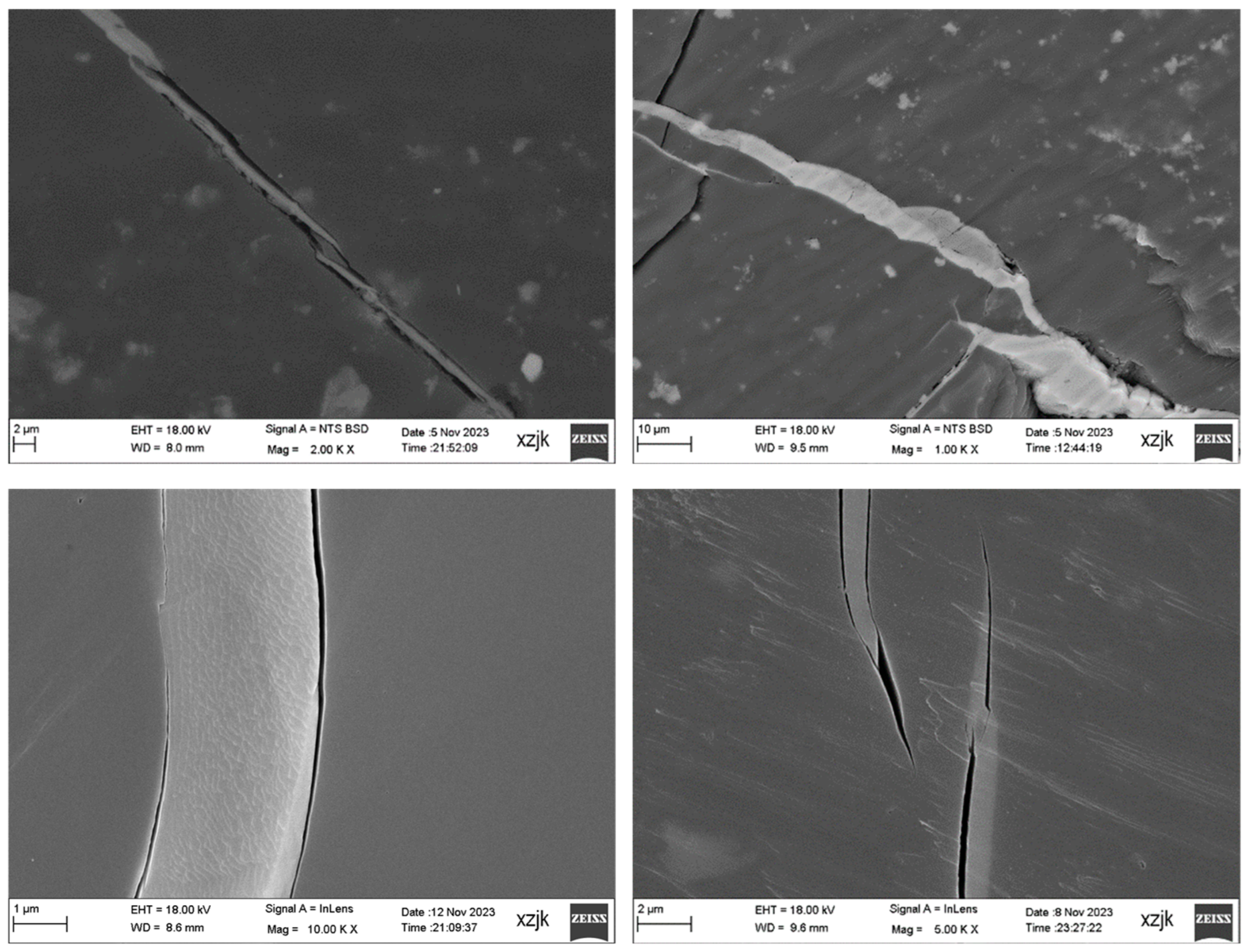

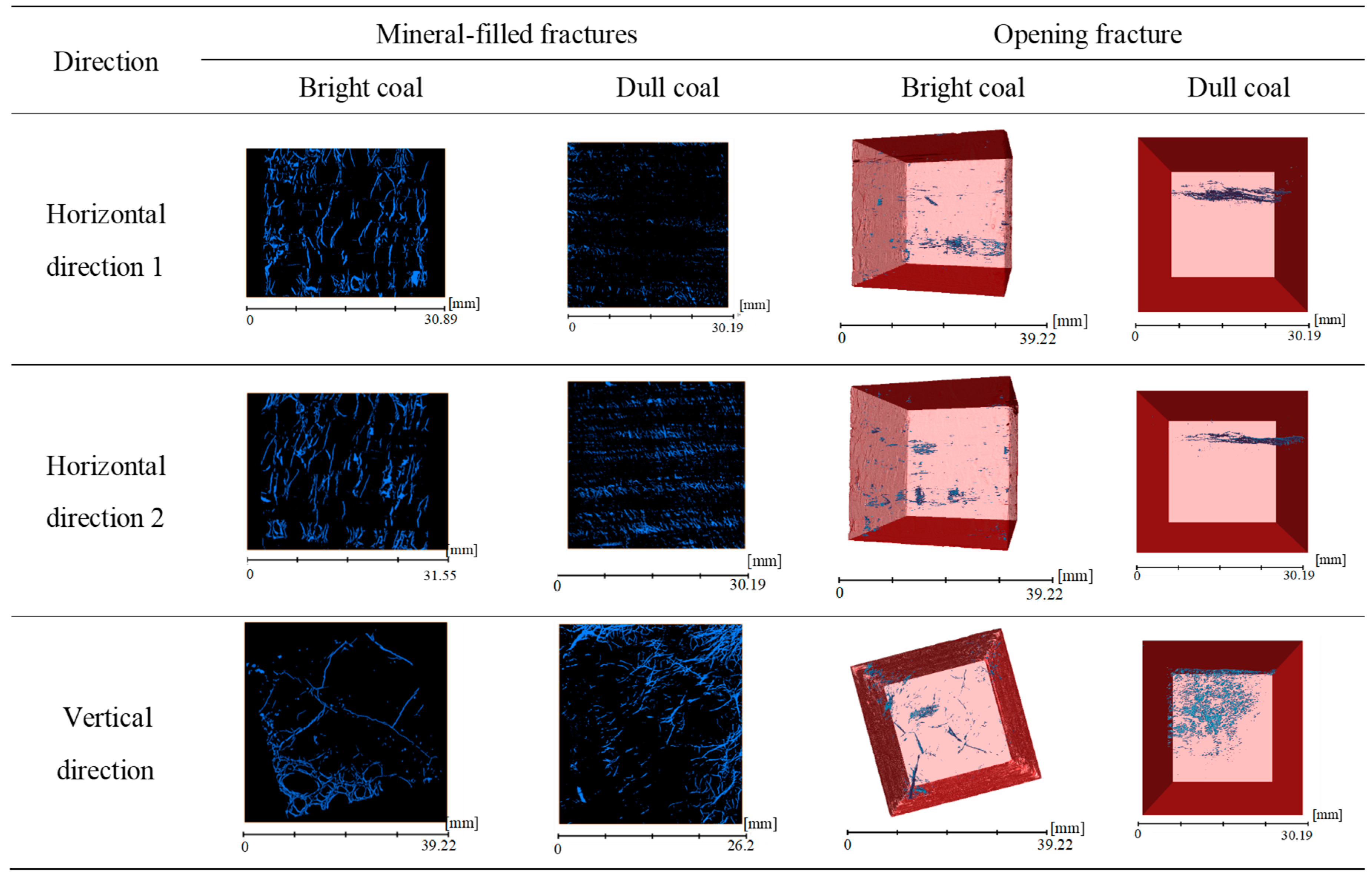

3.1. CT Scan Results of the Fracture System of the Sample

3.1.1. CT Scan Results of Bright Coal

3.1.2. CT Scan Results of Dull Coal

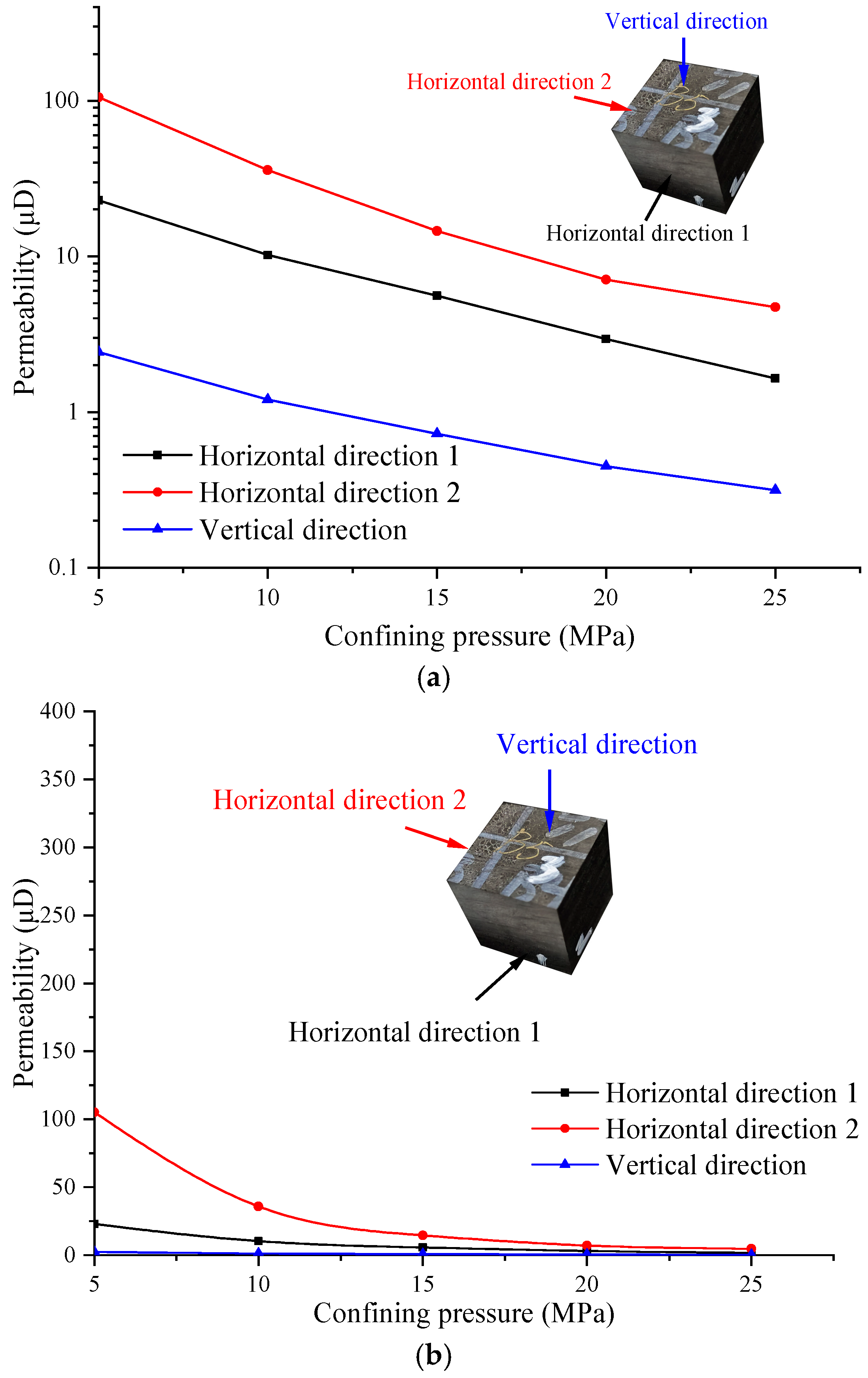

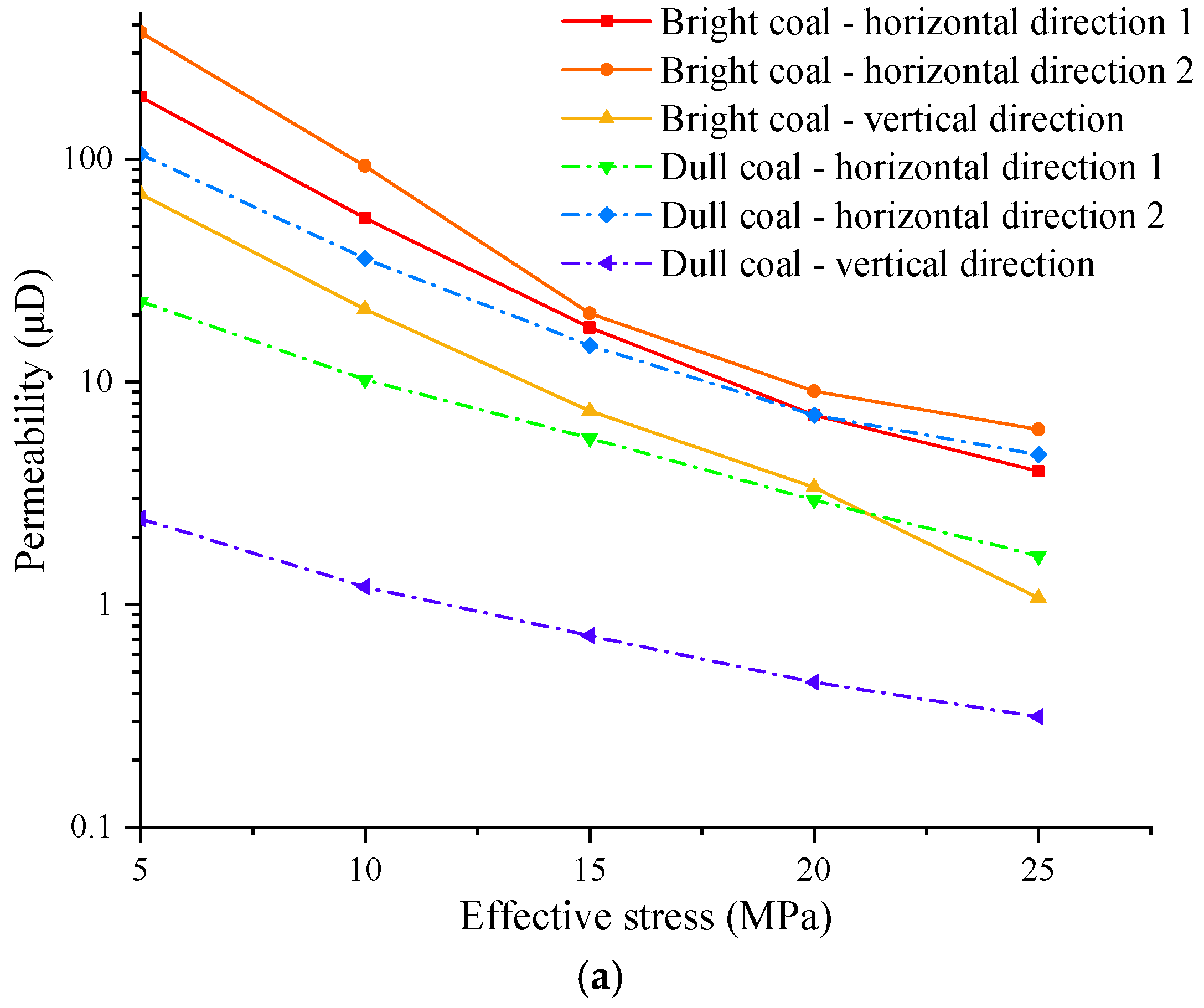

3.2. Anisotropic Permeability Test Results

3.2.1. Permeability Results of Bright Coal

3.2.2. Permeability Results of Dull Coal

4. Discussion

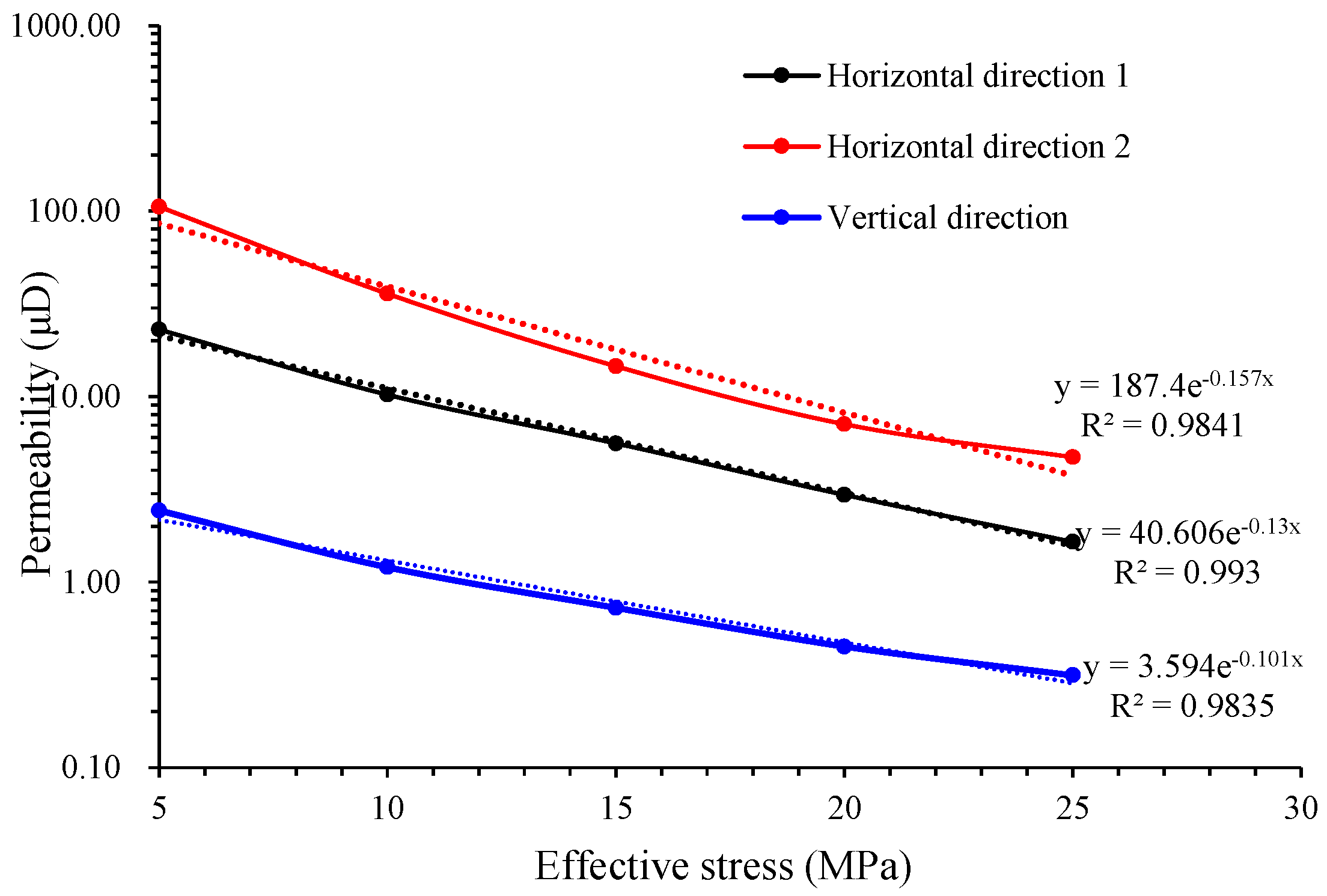

4.1. Fitting Analysis of Permeability Evolution Data

4.2. Influence of Fracture Development Characteristics on Permeability Evolution

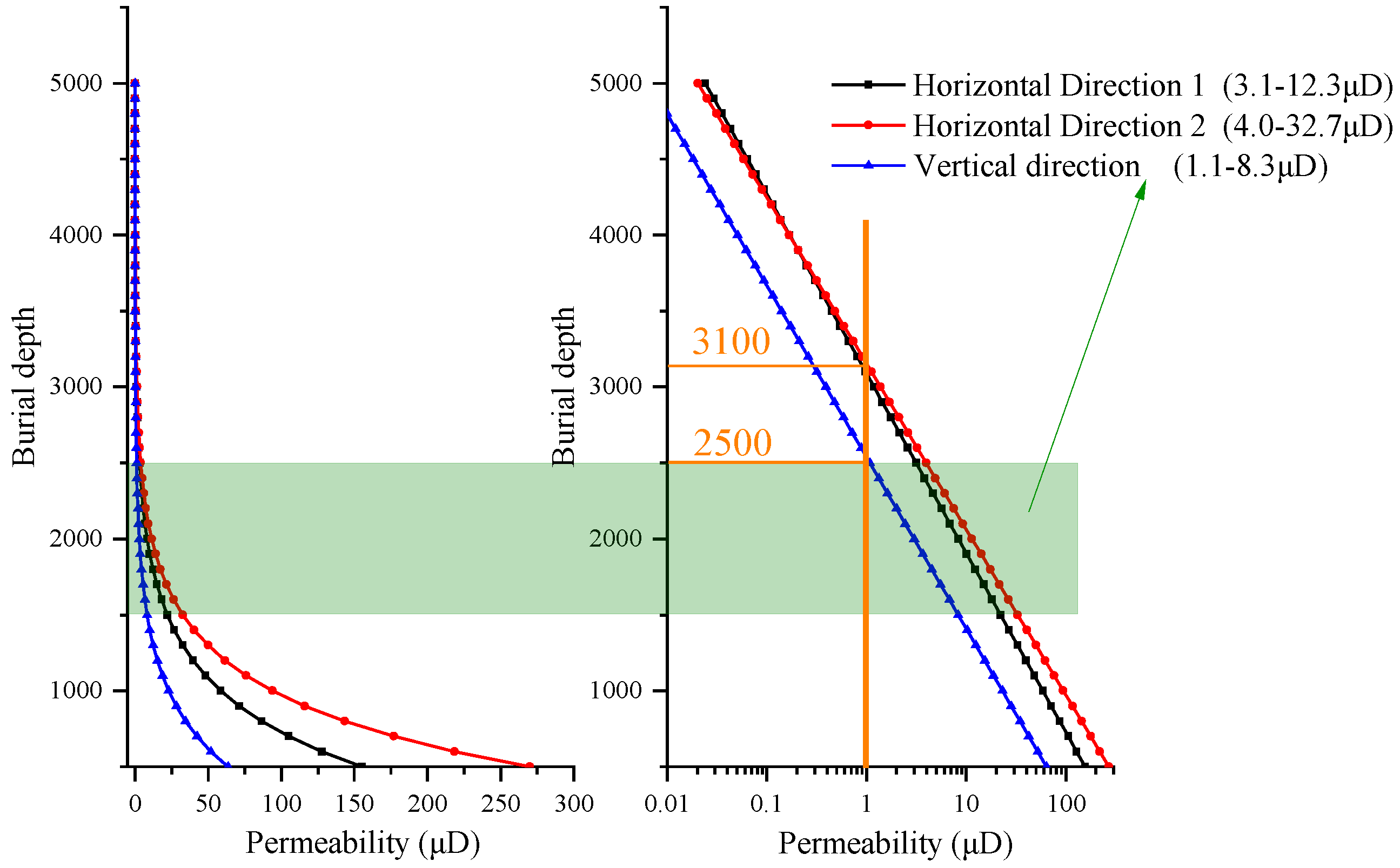

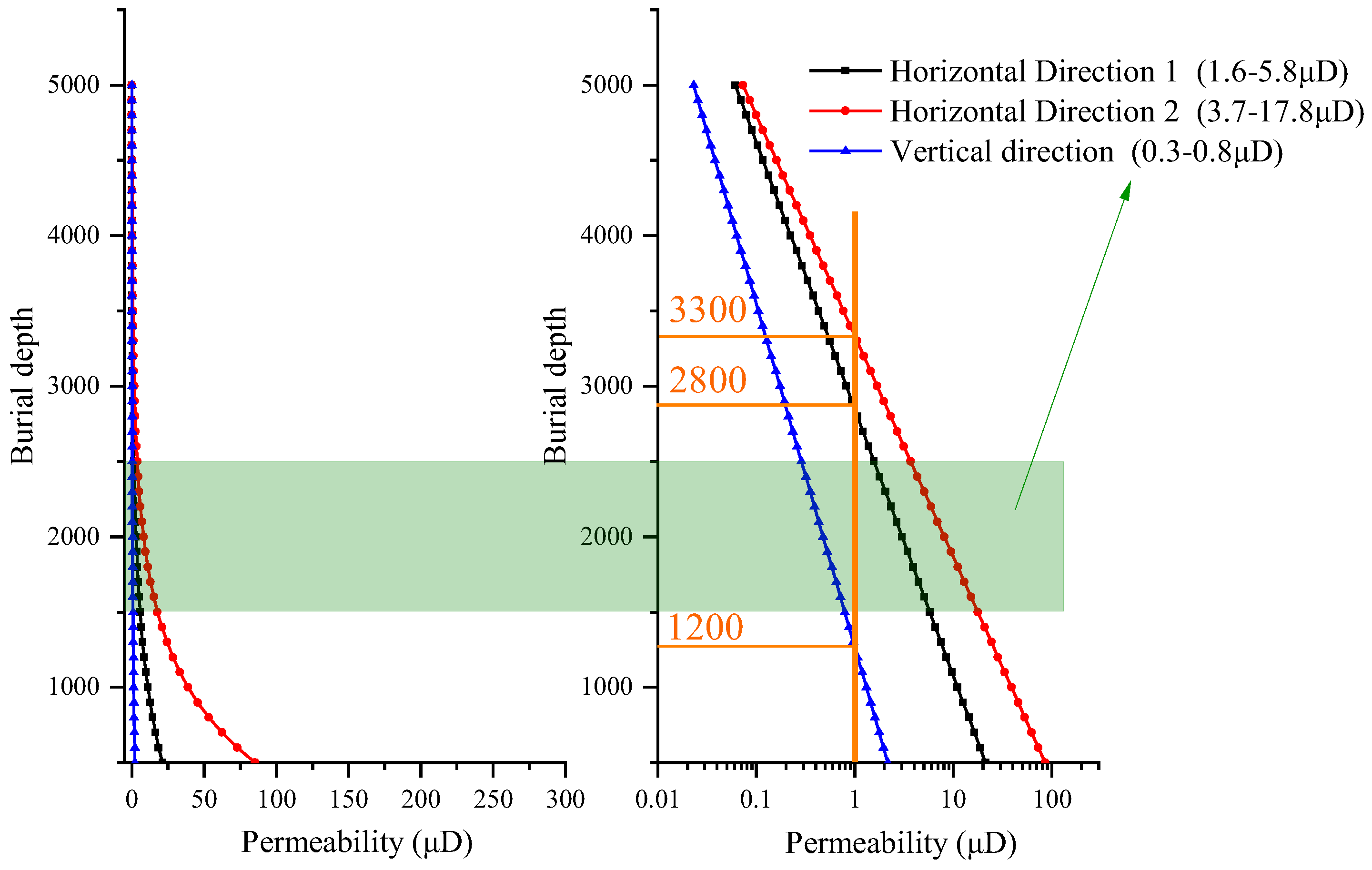

4.3. Permeability Prediction of Deep Coal Reservoir

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, Y.; Shen, J.; Shi, R. Strategic value and choice on construction of large CMG industry in China. J. China Coal Soc. 2022, 47, 371–387. [Google Scholar]

- Xu, F.; Wang, C.; Xiong, X.; Xu, B.; Wang, H.; Zhao, X.; Jiang, S.; Song, W.; Wang, Y.; Chen, G.; et al. Evolution law of deep coalbed methane reservoir formation and exploration anddevelopment practice in the eastern margin of Ordos Basin. Acta Pet. Sin. 2023, 44, 1764–1780. [Google Scholar]

- Shi, R.; Liu, J.; Wei, M.; Elsworth, D.; Wang, X. Mechanistic analysis of coal permeability evolution data under stress-controlled conditions. Int. J. Rock Mech. Min. Sci. 2018, 110, 36–47. [Google Scholar] [CrossRef]

- Li, Y.; Guo, X.; Song, D.; Liu, S.; Pan, J.; Wang, H. Expulsion of small molecule hydrocarbons and expansion of nanopores effect in tectonically deformed coal evolution. Fuel 2024, 357, 129961. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Zang, Y.; Zhong, R.; Wang, J.; Wu, Y.; Jiang, Y.; Chen, Z. Time-dependent coal permeability: Impact of gas transport from coal cleats to matrices. J. Nat. Gas Sci. Eng. 2021, 88, 103806. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, Y.; Yao, Y.; Wu, K. Imaged based fractal characterization of micro-fracture structure in coal. Fuel 2019, 239, 53–62. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Song, D.; Pan, J.; Wang, Z.; Guo, X. The evolution process of fractures and their modification effects on the liquid–solid interface during liquid nitrogen cyclic freeze–thaw of coal and shale. Fuel 2024, 362, 130877. [Google Scholar] [CrossRef]

- Sang, G.; Liu, S. Carbonate caprock–brine–carbon dioxide interaction: Alteration of hydromechanical properties and implications on carbon dioxide leakage. SPE J. 2021, 26, 2780–2792. [Google Scholar] [CrossRef]

- Shi, R.; Elsworth, D.; Wang, X.; Shen, J.; Liu, J.; Wang, Z. Multimodal Evolution of Coal Permeability due to Interior Deformations within a Triple Porosity System. SPE J. 2023, 28, 1945–1955. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Elsworth, D. How sorption-induced matrix deformation affects gas flow in coal seams: A new FE model. Int. J. Rock Mech. Min. Sci. 2008, 45, 1226–1236. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Wang, Z.; Ren, C.; Yang, K.; Gao, Z. A permeability model for anisotropic coal masses under different stress conditions. J. Pet. Sci. Eng. 2021, 198, 108197. [Google Scholar] [CrossRef]

- Yu, Y.; Meng, Z.; Gao, C.; Lu, Y.; Li, J. Experimental investigation of pore pressure effect on coal sample permeability under different temperatures. Nat. Resour. Res. 2022, 31, 1585–1599. [Google Scholar] [CrossRef]

- Laubach, S.; Marrett, R.; Olson, J.; Scott, A. Characteristics and origins of coal cleat: A review. Int. J. Coal Geol. 1998, 35, 175–207. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Elsworth, D.; Qu, H.; Chen, D. Interactions of multiple processes during CBM extraction: A critical review. Int. J. Coal Geol. 2011, 87, 175–189. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Cheng, Q.; Gao, Z. Evolution of anisotropic coal permeability under the effect of heterogeneous deformation of fractures. Nat. Resour. Res. 2021, 30, 3623–3642. [Google Scholar] [CrossRef]

- Zhang, G.; Ranjith, P.; Liang, W.; Haque, A.; Perera, M.; Li, D. Stress-dependent fracture porosity and permeability of fractured coal: An in-situ X-ray tomography study. Int. J. Coal Geol. 2019, 213, 103279. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Mallik, J. An optimum solution for coal permeability estimation from mesoscopic scale calibrated stochastic and deterministic discrete fracture network models. Fuel 2023, 331, 125626. [Google Scholar] [CrossRef]

- Jing, Y.; Armstrong, R.T.; Ramandi, H.L.; Mostaghimi, P. Coal cleat reconstruction using micro-computed tomography imaging. Fuel 2016, 181, 286–299. [Google Scholar] [CrossRef]

- Sakhaee-Pour, A.; Wheeler, M.F. Effective flow properties for cells containing fractures of arbitrary geometry. SPE J. 2016, 21, 0965–0980. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Pan, Z.; Wang, Z.; Yang, K.; Ren, C.; Xu, J. Coal permeability evolution under different water-bearing conditions. Nat. Resour. Res. 2020, 29, 2451–2465. [Google Scholar] [CrossRef]

- Somr, M.; Nežerka, V.; Kabele, P.; Švagera, O. Review of Discrete Fracture Network Modeling; SÚRAO: Prague, Czech Republic, 2016. [Google Scholar]

- Wei, M.; Liu, J.; Shi, R.; Elsworth, D.; Liu, Z. Long-Term Evolution of Coal Permeability Under Effective Stresses Gap Between Matrix and Fracture During CO2 Injection. Transp. Porous Media 2019, 130, 969–983. [Google Scholar] [CrossRef]

- Sander, R.; Pan, Z.; Connell, L.D. Laboratory measurement of low permeability unconventional gas reservoir rocks: A review of experimental methods. J. Nat. Gas Sci. Eng. 2017, 37, 248–279. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Elsworth, D.; Cui, G.; Li, B.; Zhou, M.; Li, W.; Zhang, J. Revaluating coal permeability-gas pressure relation under various gas pressure differential conditions. Int. J. Coal Sci. Technol. 2023, 10, 55. [Google Scholar] [CrossRef]

- Purl, R.; Evanoff, J.; Brugler, M. Measurement of coal cleat porosity and relative permeability characteristics. In Proceedings of the SPE Gas Technology Symposium, Houston, TX, USA, 22–24 January 1991. [Google Scholar]

- Palmer, I. Permeability changes in coal: Analytical modeling. Int. J. Coal Geol. 2009, 77, 119–126. [Google Scholar] [CrossRef]

- Sparks, D.; McLendon, T.; Saulsberry, J.; Lambert, S. The effects of stress on coalbed reservoir performance, Black Warrior Basin, USA. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995; pp. 339–351. [Google Scholar]

- Cui, X.; Bustin, R.M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 2005, 89, 1181–1202. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Zhu, Z.; Zhao, B.; Tian, C.; Sheng, Q.; Li, Z.; Zhang, N.; Wang, J.; Yang, X. Polyaspartic acid, an eco-friendly regulator for the improvement of coking coal flotation: Applications and mechanism. Int. J. Coal Prep. Util. 2024, 44, 2180–2199. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int. J. Coal Geol. 2011, 87, 13–25. [Google Scholar] [CrossRef]

| Main Parameter | Bright Coal | Dull Coal |

|---|---|---|

| Mad | 0.63 | 0.49 |

| Aad | 5.53 | 20.59 |

| Vdaf | 6.43 | 14.75 |

| FCad | 87.82 | 67.29 |

| Main Parameter | The Distribution Range of Main Parameters |

|---|---|

| Maximum axial and confining pressure | Axial 70 MPa, circumferential 50 MPa |

| Gas flow meter range | Flow rate: ≤500 mL/min; Accuracy 0.001 mL/min |

| Maximum gas injection pressure | 20 MPa |

| Gas pressure sensor accuracy | Full scale ± 0.25% |

| Confining Pressure | Horizontal Direction 1 | Horizontal Direction 2 | Vertical Direction | |||

|---|---|---|---|---|---|---|

| MPa | Permeability (μD) | Rate of Decline (%) | Permeability (μD) | Rate of Decline (%) | Permeability (μD) | Rate of Decline (%) |

| 5 | 189.71 | 0.0% | 369.52 | 0.0% | 69.71 | 0.0% |

| 10 | 54.40 | 71.3% | 92.95 | 74.8% | 21.18 | 69.6% |

| 15 | 17.52 | 90.8% | 20.27 | 94.5% | 7.39 | 89.4% |

| 20 | 7.09 | 96.3% | 9.07 | 97.5% | 3.36 | 95.2% |

| 25 | 3.97 | 97.9% | 6.11 | 98.3% | 1.07 | 98.5% |

| Confining Pressure | Horizontal Direction 1 | Horizontal Direction 2 | Vertical Direction | |||

|---|---|---|---|---|---|---|

| MPa | Permeability (μD) | Rate of Decline (%) | Permeability (μD) | Rate of Decline (%) | Permeability (μD) | Rate of Decline (%) |

| 5 | 22.93 | 0.0% | 105.14 | 0.0% | 2.43 | 0.0% |

| 10 | 10.21 | 55.5% | 35.81 | 65.9% | 1.20 | 50.5% |

| 15 | 5.59 | 75.6% | 14.55 | 86.2% | 0.73 | 70.1% |

| 20 | 2.95 | 87.1% | 7.09 | 93.3% | 0.45 | 81.5% |

| 25 | 1.65 | 92.8% | 4.71 | 95.5% | 0.31 | 87.1% |

| Direction of Seepage Flow | k0 | Permeability Fitting Function | Compressibility Coefficient of the Fractures (Cpσ) |

|---|---|---|---|

| Horizontal direction 1 | = 411.58 | 0.065 | |

| Horizontal direction 2 | = 775.22 | 0.070 | |

| Vertical direction | = 176.59 | 0.068 |

| Direction of Seepage Flow | k0 | Permeability Fitting Function | Compressibility Coefficient of the Fractures (Cpσ) |

|---|---|---|---|

| Horizontal direction 1 | = 40.61 | 0.043 | |

| Horizontal direction 2 | = 187.40 | 0.052 | |

| Vertical direction | = 3.59 | 0.034 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, L.; He, Y.; Shi, R.; Ji, L.; Zhang, W.; Ma, Z.; Wu, P.; Shen, J. Fracture System Characteristics and Their Control on Permeability Anisotropy in Bright and Dull Coal. Processes 2025, 13, 1509. https://doi.org/10.3390/pr13051509

Bian L, He Y, Shi R, Ji L, Zhang W, Ma Z, Wu P, Shen J. Fracture System Characteristics and Their Control on Permeability Anisotropy in Bright and Dull Coal. Processes. 2025; 13(5):1509. https://doi.org/10.3390/pr13051509

Chicago/Turabian StyleBian, Liheng, Yanxiang He, Rui Shi, Liang Ji, Wei Zhang, Zhuang Ma, Peng Wu, and Jian Shen. 2025. "Fracture System Characteristics and Their Control on Permeability Anisotropy in Bright and Dull Coal" Processes 13, no. 5: 1509. https://doi.org/10.3390/pr13051509

APA StyleBian, L., He, Y., Shi, R., Ji, L., Zhang, W., Ma, Z., Wu, P., & Shen, J. (2025). Fracture System Characteristics and Their Control on Permeability Anisotropy in Bright and Dull Coal. Processes, 13(5), 1509. https://doi.org/10.3390/pr13051509