Experimental Study on the Influence of Expanding/Reducing Ratio on the Impact Performance of Offshore Oil and Gas Transmission Pipelines

Abstract

1. Introduction

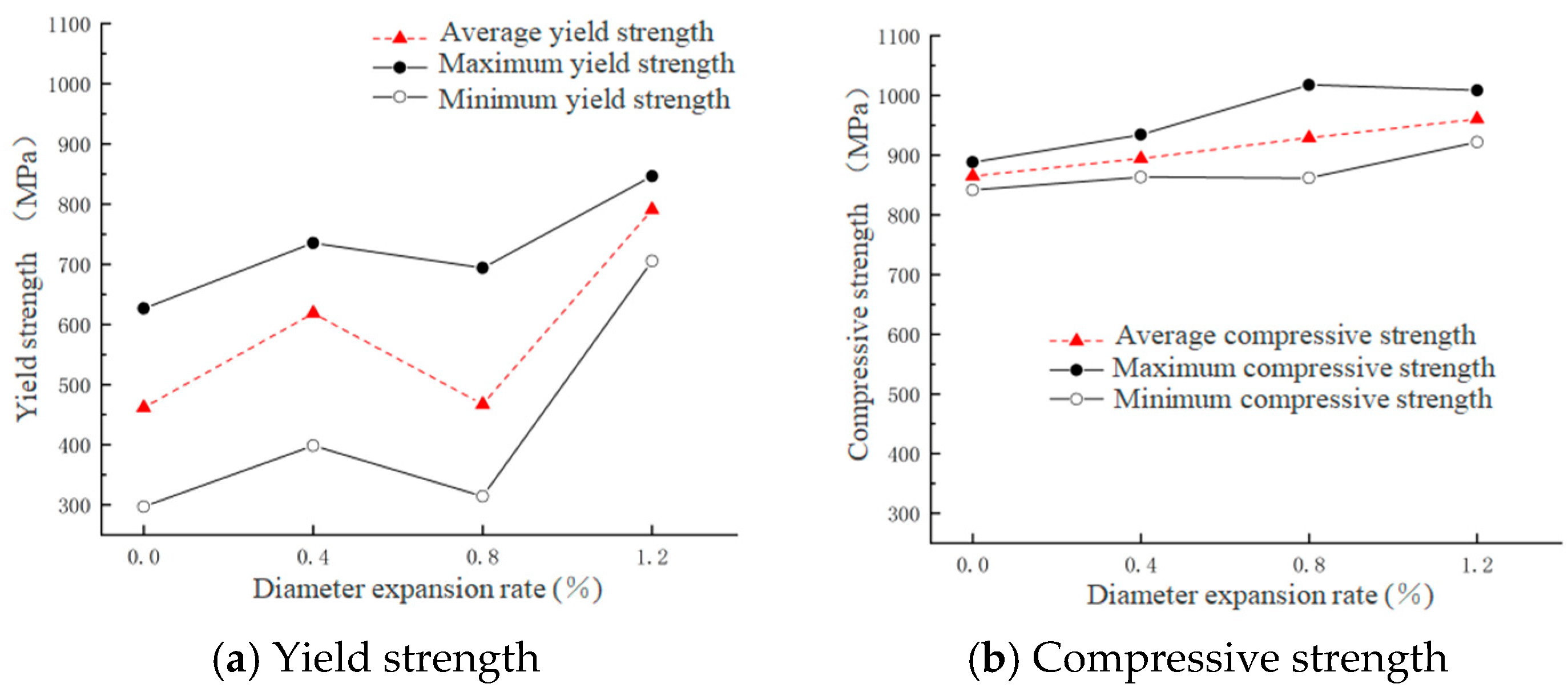

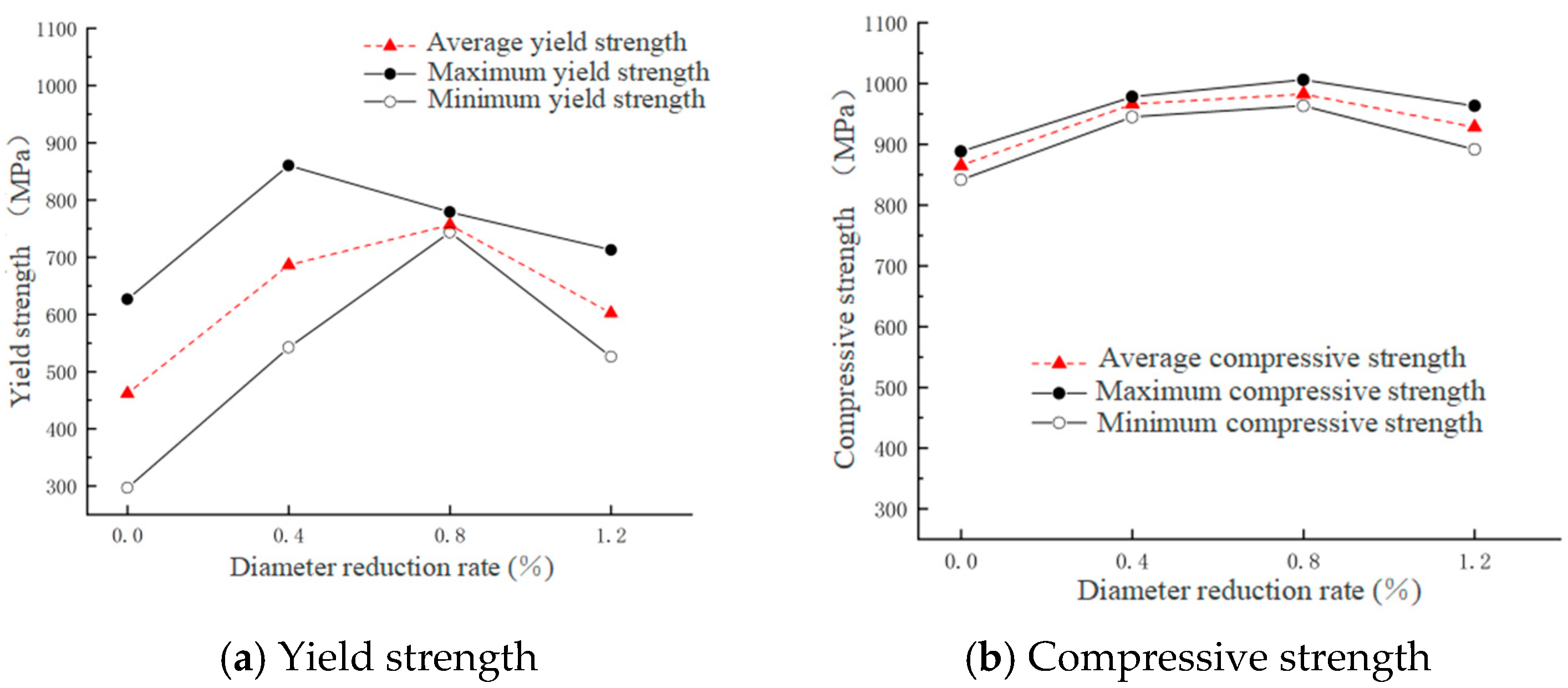

2. Sample Preparation and Experimental Methods

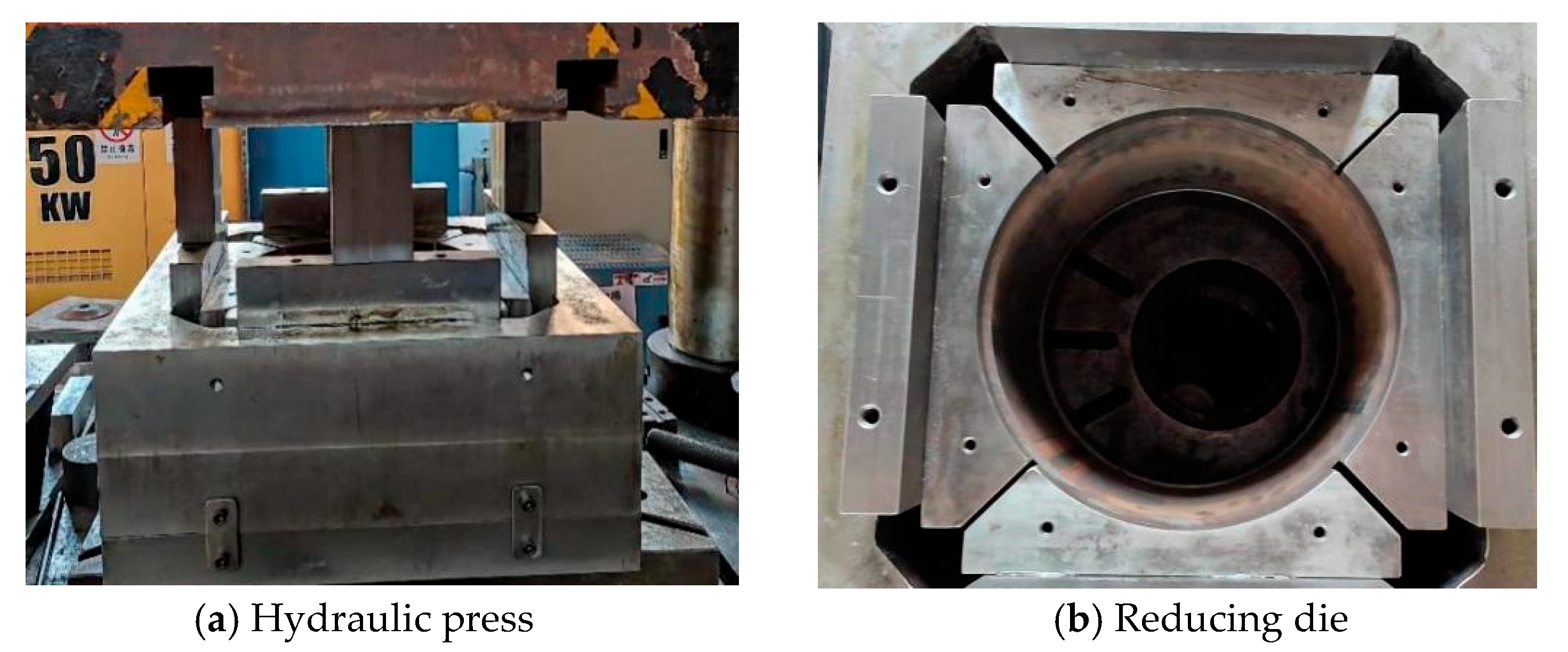

2.1. Sample Preparation

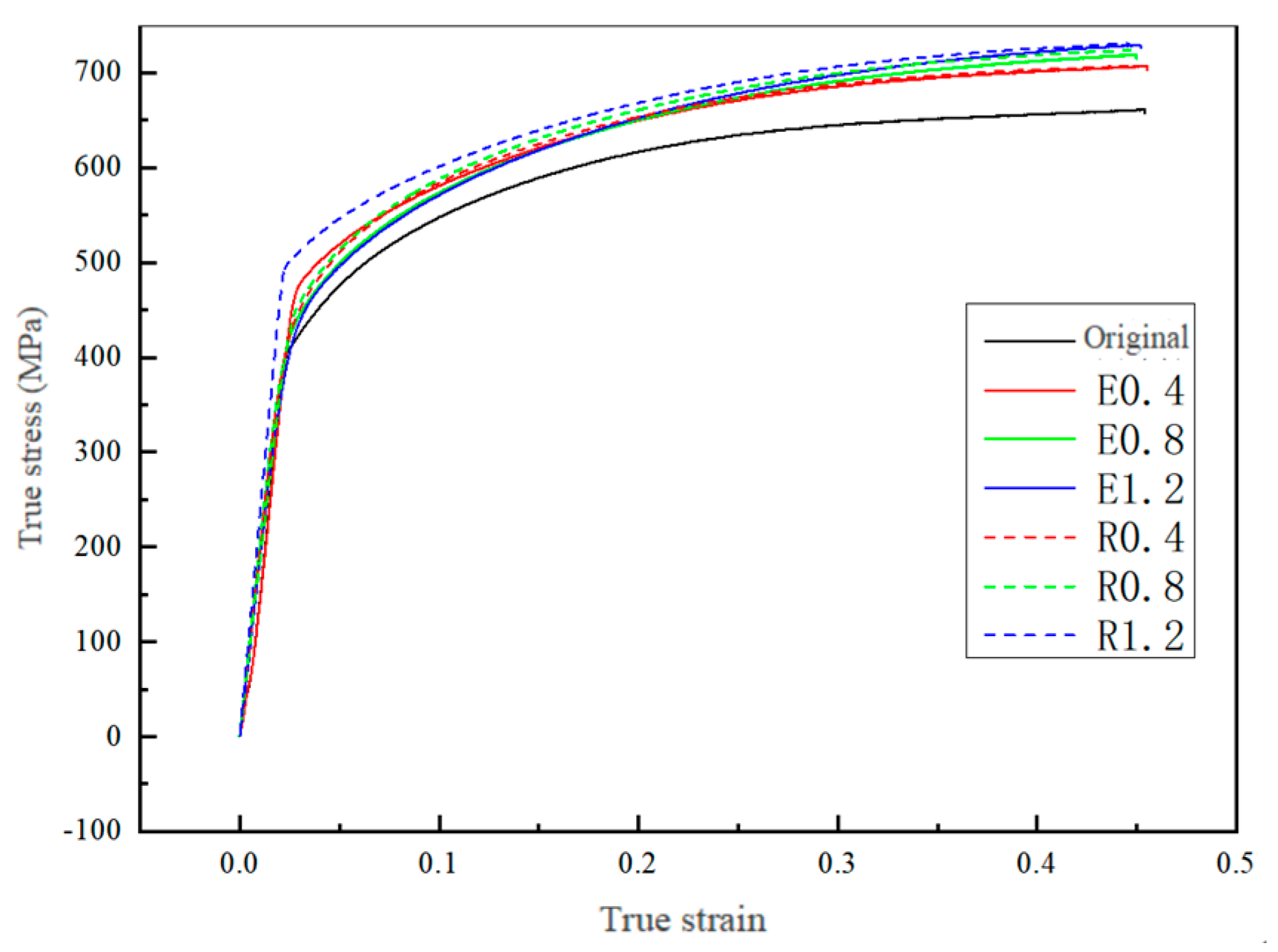

2.2. Static Mechanical Properties of Expansion/Reduction Specimens

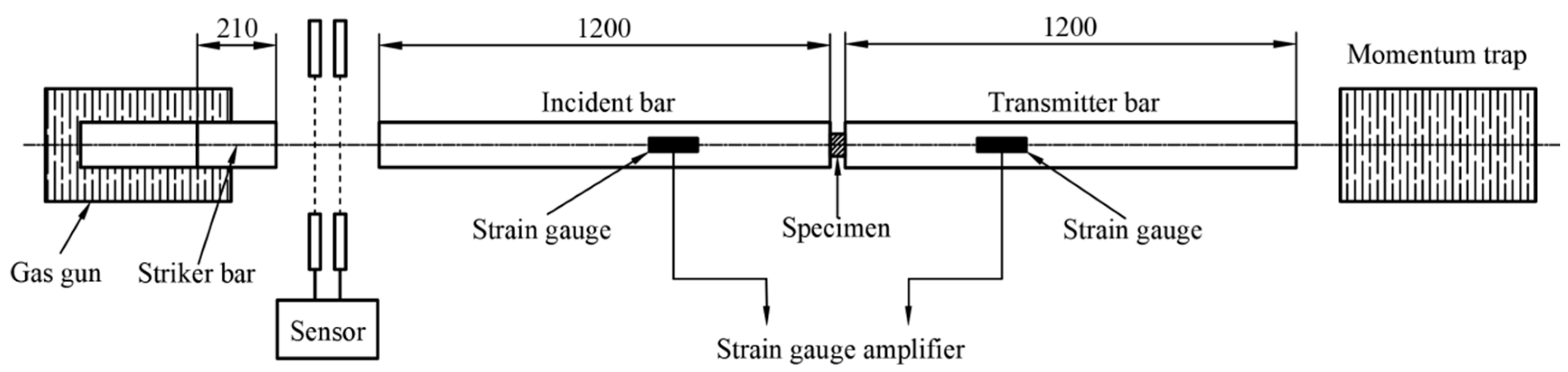

2.3. Split Hopkinson Pressure Bar (SHPB) Experimental Method

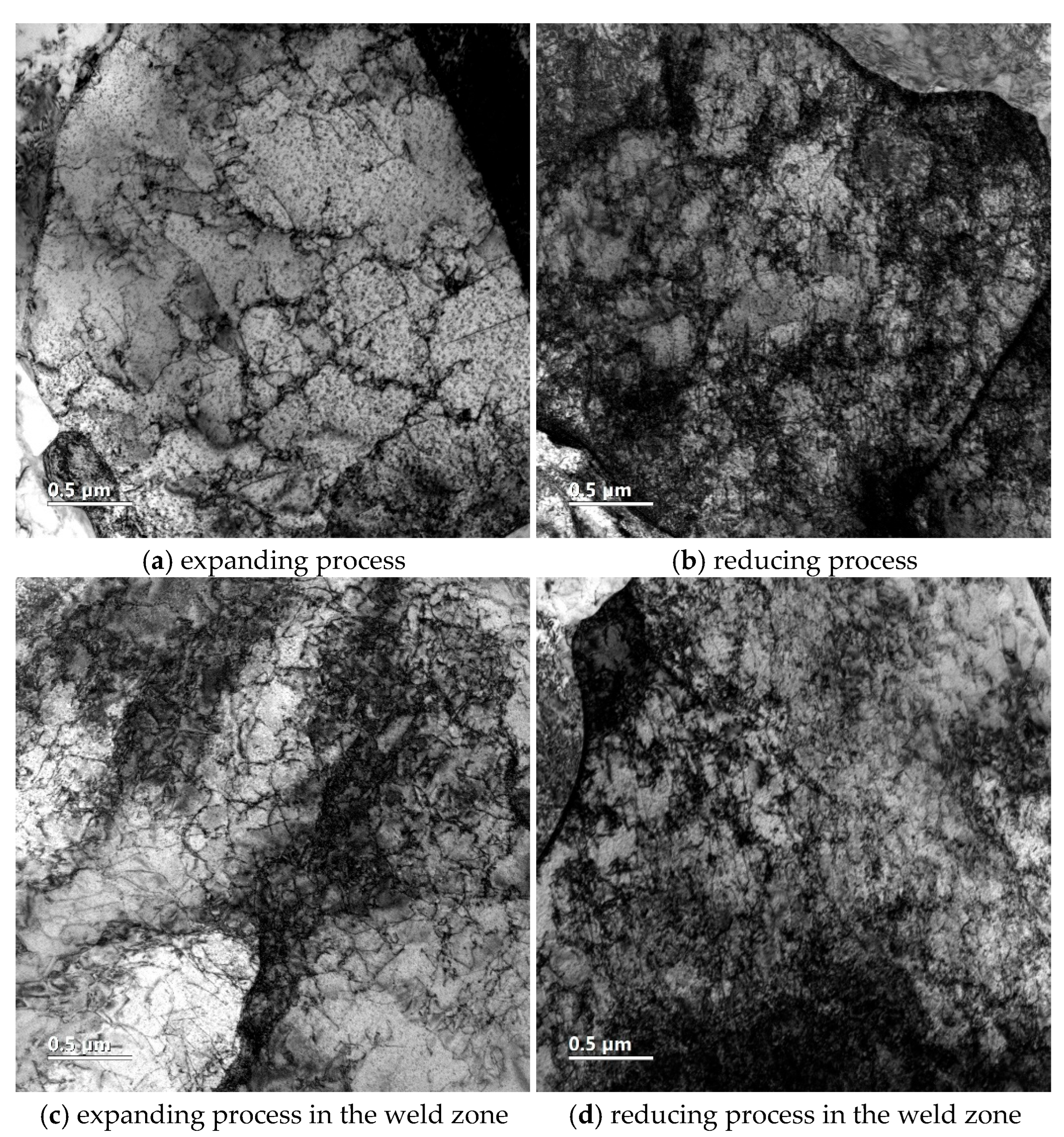

2.4. Transmission Electron Microscopy (TEM) Observation

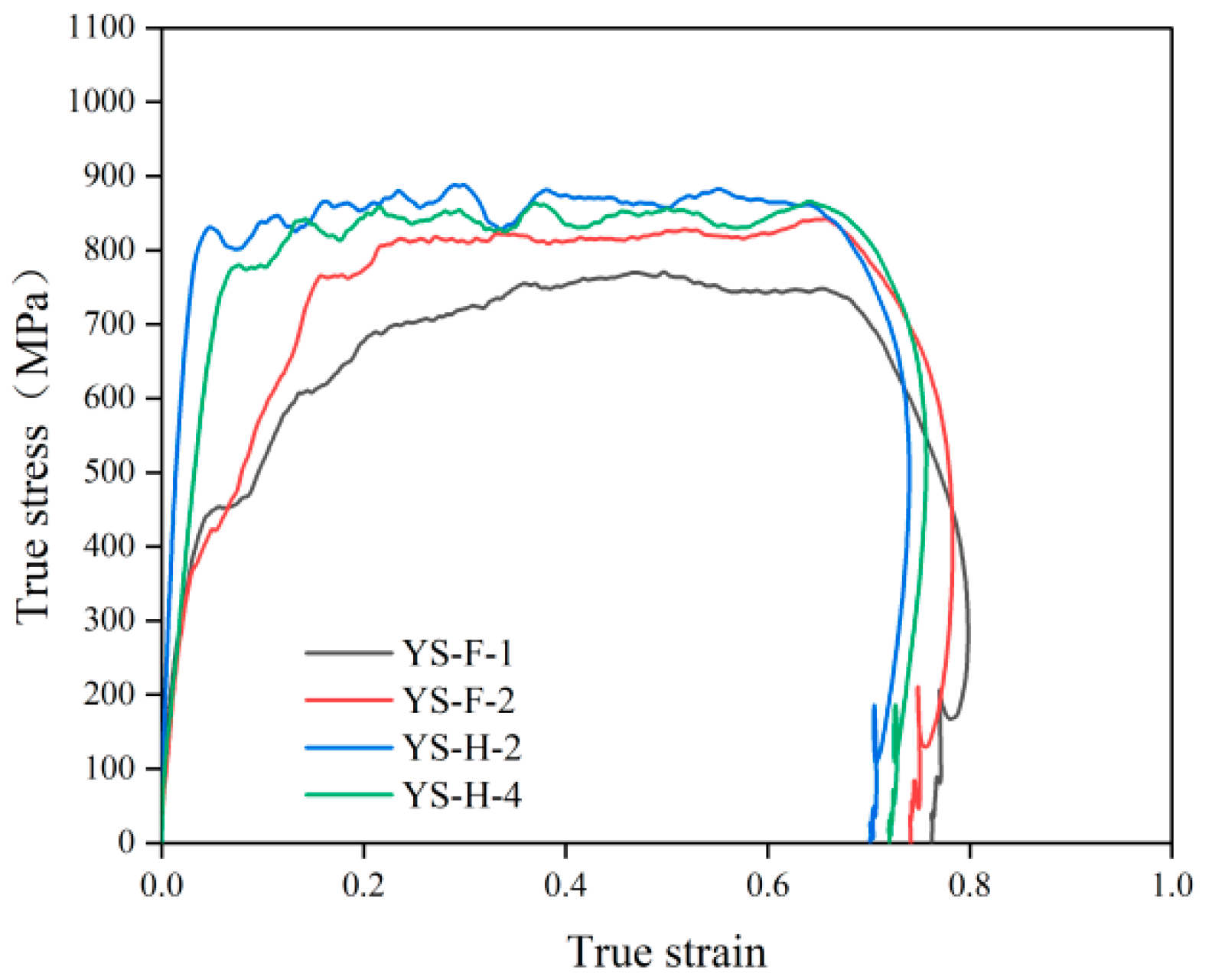

3. Impact Test Results and Analysis of JCO Pipe Fittings

3.1. Impact Test Results

3.2. Influence of Sample Orientation on Test Results

3.3. Influence of Expansion and Reduction Deformation Ratios on Impact Performance

3.4. Influence of Expanding and Reducing Process on Microstructure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, F.; Dong, S. A review on the damage mechanism analysis and risk assessment for offshore pipelines subjected to impact loads from third-party activities. Ocean Eng. 2023, 41, 187–199. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Y.; Long, T.; Xing, J.; Huang, L. Risk analysis of Chinese overseas oil supply. Geol. Explor. 2018, 54, 1091–1098. [Google Scholar] [CrossRef]

- Wang, L.; Lu, S.; Wei, S.; Jiang, J. Development and Application of Straight Welded Line pipes for Deep Ocean Gas Pipeline Project. Welded Pipe Tube 2014, 43, 22–30. [Google Scholar] [CrossRef]

- Cai, X. Influence of Forming Process of Large Diameter Straight Seam Submerged Arc Welding Pipe on Mechanical Properties of Blank Sheet. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2014. [Google Scholar]

- Mandal, A.; Syed, B.; Bhandari, K.K.; Bhattacharya, B.; Deb, A.; Singh, S.B.; Chakrabarti, D. Cold-bending of line pipe steel plate to pipe, detrimental or beneficial? Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 746, 58–72. [Google Scholar] [CrossRef]

- Al-Abri, O.S.; Pervez, T.; Al-Maharbi, M.H.; Khan, R. Microstructure evolution of ultra-fine grain low-carbon steel tubular undergoing radial expansion process. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 654, 94–106. [Google Scholar] [CrossRef]

- Shinohara, Y.; Hara, T.; Tsuru, E.; Asahi, H. Development of A High Strength Steel Line Pipe for Strain-based Design Applications. In Proceedings of the 17th International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007. [Google Scholar]

- Peng, D.; Yang, J.; Wang, G.; Jing, Y.; Chen, J.; Liu, H. Impact of roundness deformation ratio on electrochemical corrosion behavior of JCO welded pipe. Welded Pipe 2025, 48, 18–23. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, X.; Zhang, Y.; Yang, S.; Yu, X.; Fang, Z. Research on Bauschinger effect of X65MO submarine pipeline steel. Teel Roll. 2020, 37, 33–36. [Google Scholar] [CrossRef]

- Zou, T.X.; Li, D.Y.; Wu, G.H.; Peng, Y.H. Yield strength development from high strength steel plate to UOE pipe. Mater. Des. 2016, 89, 1107–1122. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y.; Ji, L. Effect of Expansion Rate on Tensile Performance of Longitudinal Submerged Are Welded Pipe. Weld Pipe 2016, 39, 42–45. [Google Scholar] [CrossRef]

- Wang, B.; Boli, R.; Hou, G.Y.; Chen, Q.; Zheng, H.; Gu, H.; Wang, Y. Experiment and Research on Expansion of HSAW Pipe Body. Steel Pipe 2022, 51, 22–28. [Google Scholar] [CrossRef]

- Wang, W.; Suo, T.; Guo, Y.; Li, Y.; Nie, H.; Liu, H.; Jin, K.; Du, B.; Jiang, B. Experimental technique and research progress of electromagnetic Hopkinson bar. Adv. Mech. 2021, 51, 729–754. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhu, X.; Dong, X.; Ma, Z. Theoretical and experimental studies on the axial impact behavior of Q235B longitudinally welded tubes. J. Vib. Shock. 2016, 35, 98–103. [Google Scholar] [CrossRef]

- Meng, H.; Li, Q. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments. Int. J. Impact Eng. 2003, 28, 537–555. [Google Scholar] [CrossRef]

- Li, Y.Z.; Zhao, S.L.; He, S.H.; Huang, C.P.; Huang, M.X. Enhancing yield stress and uniform elongation in an ultrathin packaging steel via controlling dislocation density. Int. J. Plast. 2022, 155, 103334. [Google Scholar] [CrossRef]

- Hoffmann, B.; Vöhringer, O.; Macherauch, E. Effect of compressive plastic deformation on mean lattice strains, dislocation densities and flow stresses of martensitically hardened steels. Mater. Sci. Eng. A 2001, 319–322, 299–303. [Google Scholar] [CrossRef]

- Liu, J.; Jin, Y.; Fang, X.; Chen, C.; Feng, Q.; Liu, X.; Chen, Y.; Suo, T.; Zhao, F.; Huang, T.; et al. Dislocation Strengthening without Ductility Trade-off in Metastable Austenitic Steels. Sci. Rep. 2016, 6, 35345. [Google Scholar] [CrossRef] [PubMed]

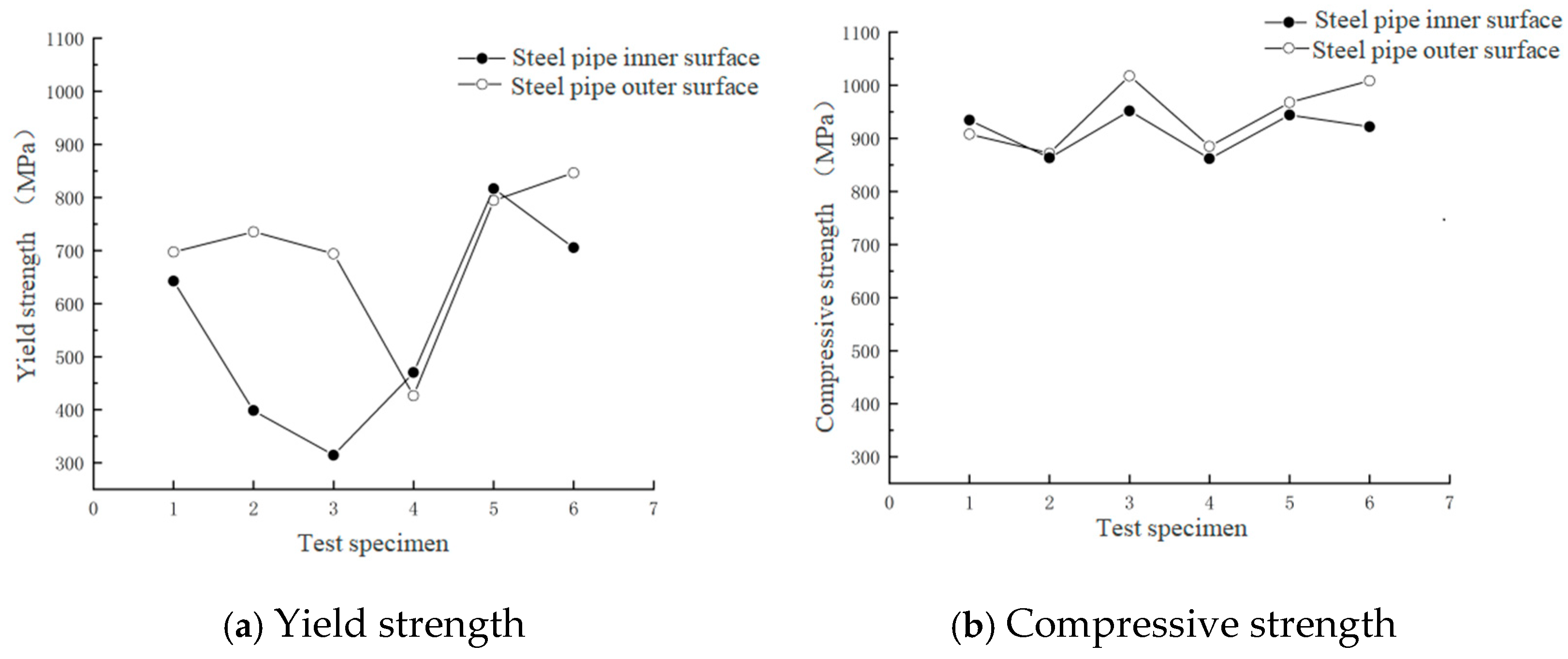

| Sample | Deformation Ratio | Region | Orientation | Yield Strength/MPa | Compressive Strength/MPa |

|---|---|---|---|---|---|

| Original sample (YS) | 0 | F | 297 | 842 | |

| H | 627 | 888 | |||

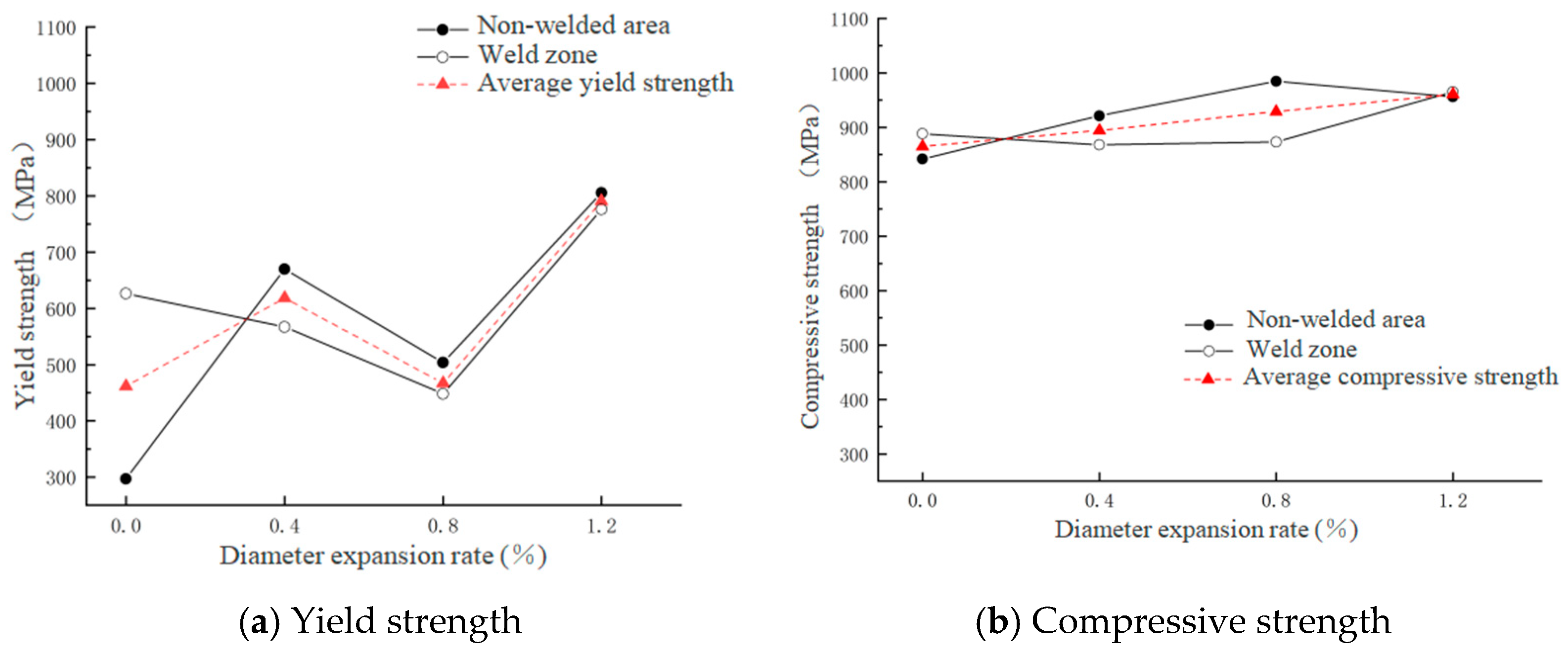

| Expanded diameter specimen (KJ) | 0.4 | F | N | 643 | 934 |

| W | 697 | 908 | |||

| H | N | 399 | 863 | ||

| W | 735 | 872 | |||

| 0.8 | F | N | 314 | 952 | |

| W | 694 | 1018 | |||

| H | N | 470 | 862 | ||

| W | 427 | 885 | |||

| 1.2 | F | N | 817 | 944 | |

| W | 794 | 968 | |||

| H | N | 705 | 922 | ||

| W | 847 | 1009 | |||

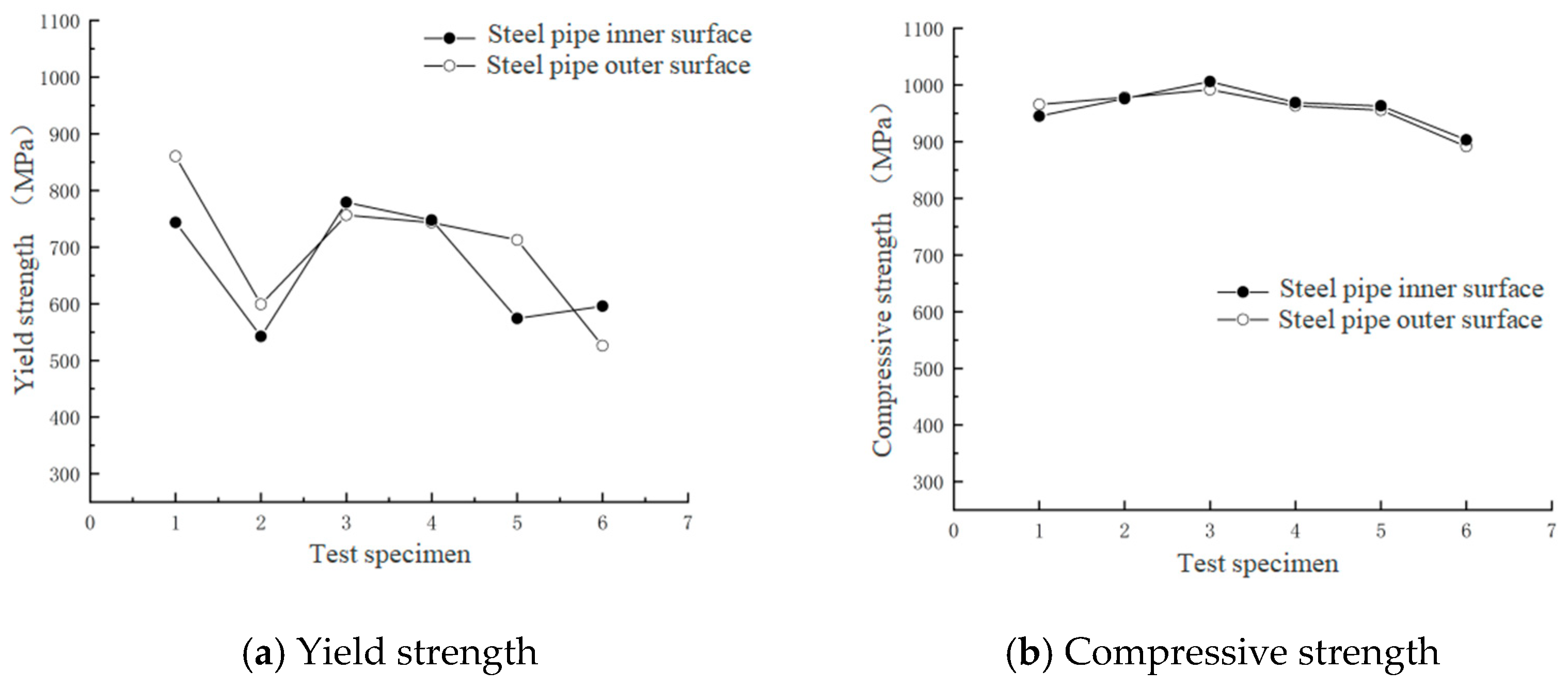

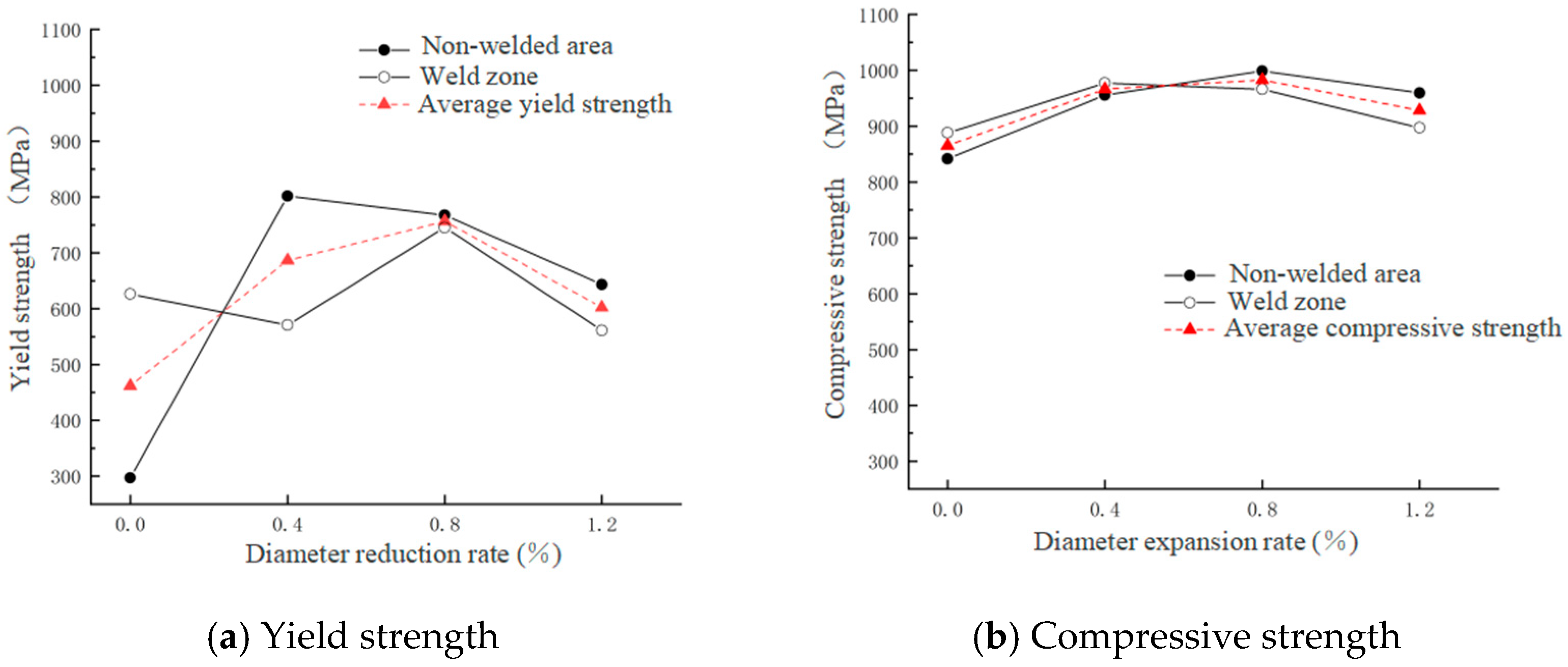

| Reduced diameter specimen (SJ) | 0.4 | F | N | 743 | 945 |

| W | 860 | 966 | |||

| H | N | 542 | 976 | ||

| W | 599 | 978 | |||

| 0.8 | F | N | 779 | 1006 | |

| W | 756 | 992 | |||

| H | N | 748 | 969 | ||

| W | 743 | 963 | |||

| 1.2 | F | N | 574 | 963 | |

| W | 713 | 956 | |||

| H | N | 596 | 903 | ||

| W | 526 | 892 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, D.; Wang, G.; Yang, J.; Jin, Y.; Wan, B.; Liu, X. Experimental Study on the Influence of Expanding/Reducing Ratio on the Impact Performance of Offshore Oil and Gas Transmission Pipelines. Processes 2025, 13, 3333. https://doi.org/10.3390/pr13103333

Peng D, Wang G, Yang J, Jin Y, Wan B, Liu X. Experimental Study on the Influence of Expanding/Reducing Ratio on the Impact Performance of Offshore Oil and Gas Transmission Pipelines. Processes. 2025; 13(10):3333. https://doi.org/10.3390/pr13103333

Chicago/Turabian StylePeng, Deping, Gan Wang, Jixin Yang, Yongping Jin, Buyan Wan, and Xiao Liu. 2025. "Experimental Study on the Influence of Expanding/Reducing Ratio on the Impact Performance of Offshore Oil and Gas Transmission Pipelines" Processes 13, no. 10: 3333. https://doi.org/10.3390/pr13103333

APA StylePeng, D., Wang, G., Yang, J., Jin, Y., Wan, B., & Liu, X. (2025). Experimental Study on the Influence of Expanding/Reducing Ratio on the Impact Performance of Offshore Oil and Gas Transmission Pipelines. Processes, 13(10), 3333. https://doi.org/10.3390/pr13103333