Sizing, Modeling, and Performance Comparison of Squirrel-Cage Induction and Wound-Field Flux Switching Motors

Abstract

:1. Introduction

2. Sizing-Design Algorithms and Analytical Performance Calculations for SCIM and WF-FSM

2.1. Design Process of SCIM

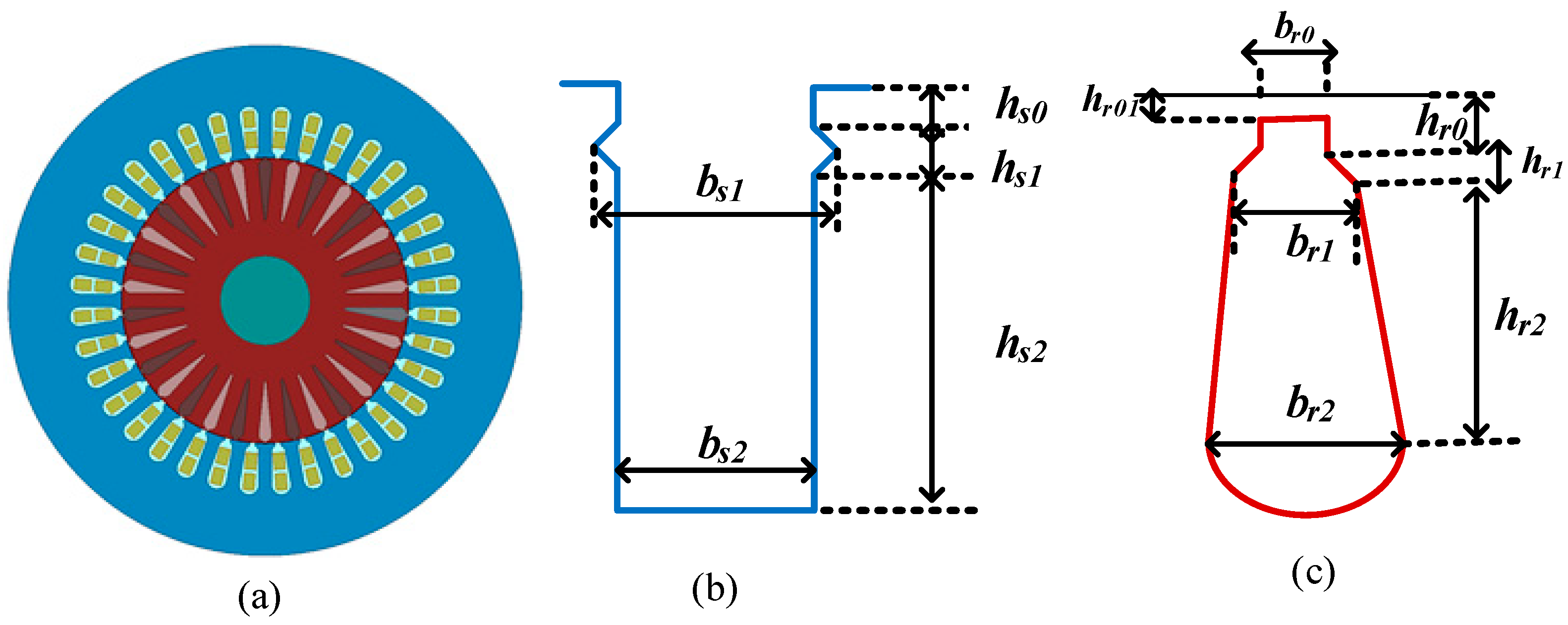

2.1.1. Design Sizing for SCIM

2.1.2. Performance Calculations for SCIM

2.2. Design Process of WFFSM

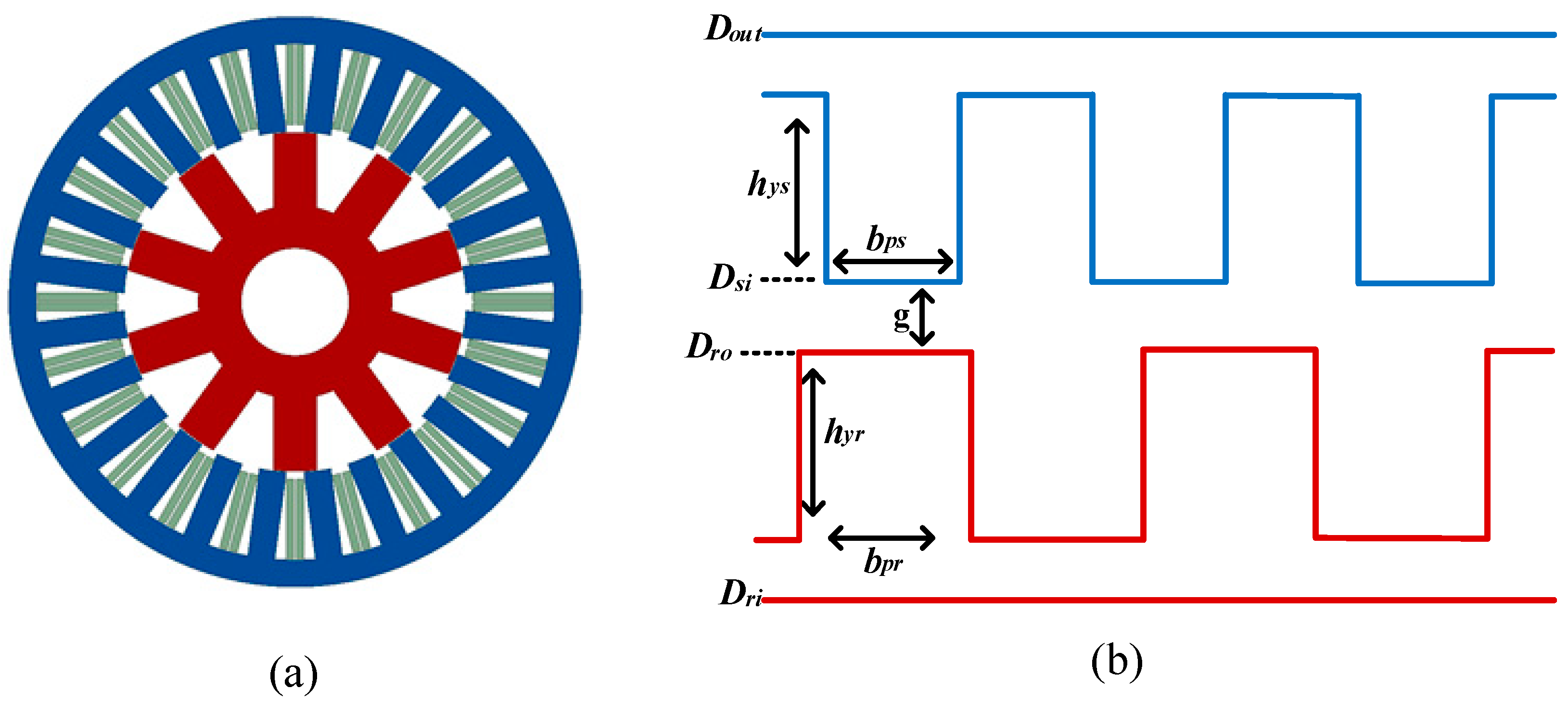

2.2.1. Design Sizing for WFFSM

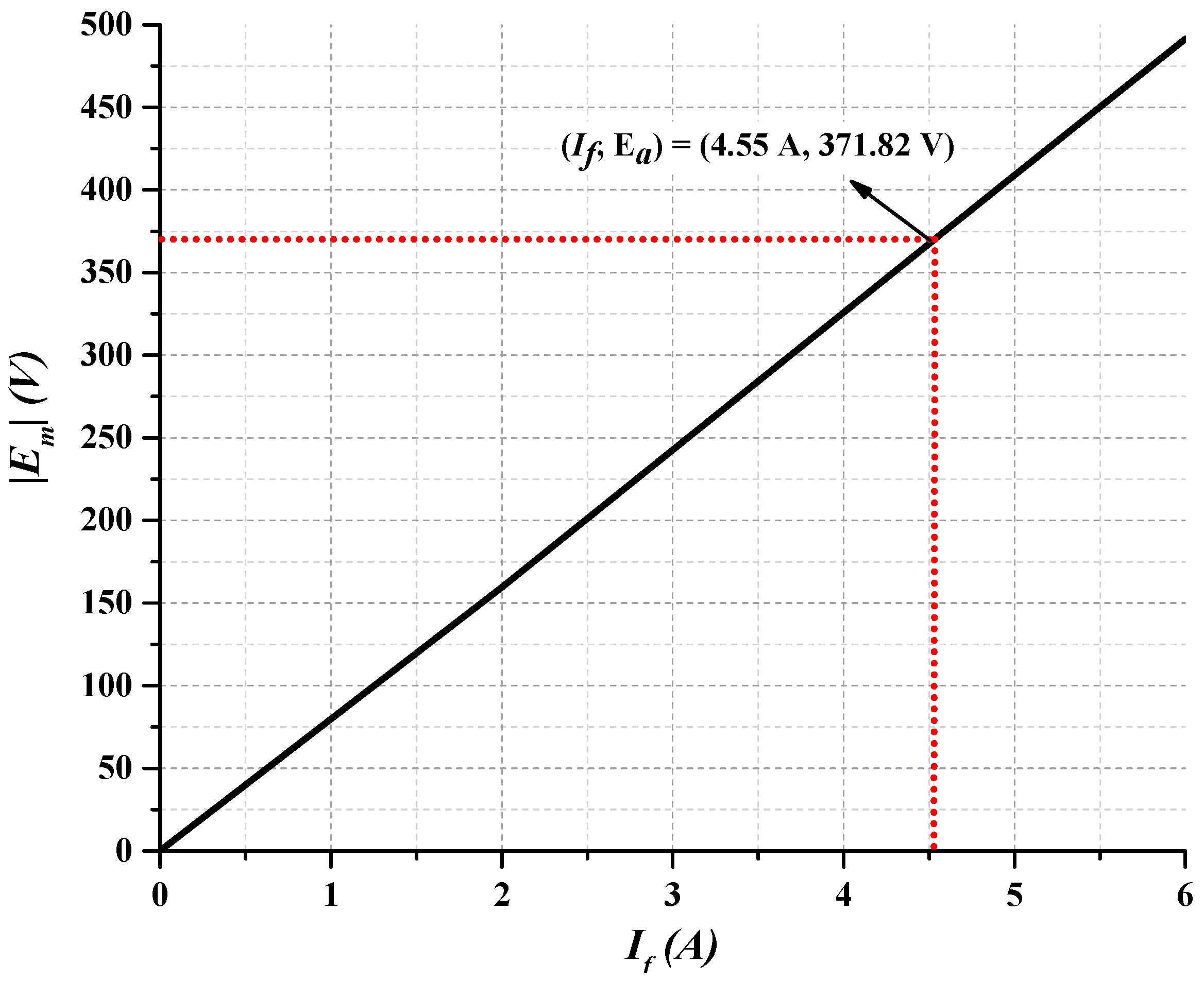

2.2.2. Performance Calculations for WFFSM

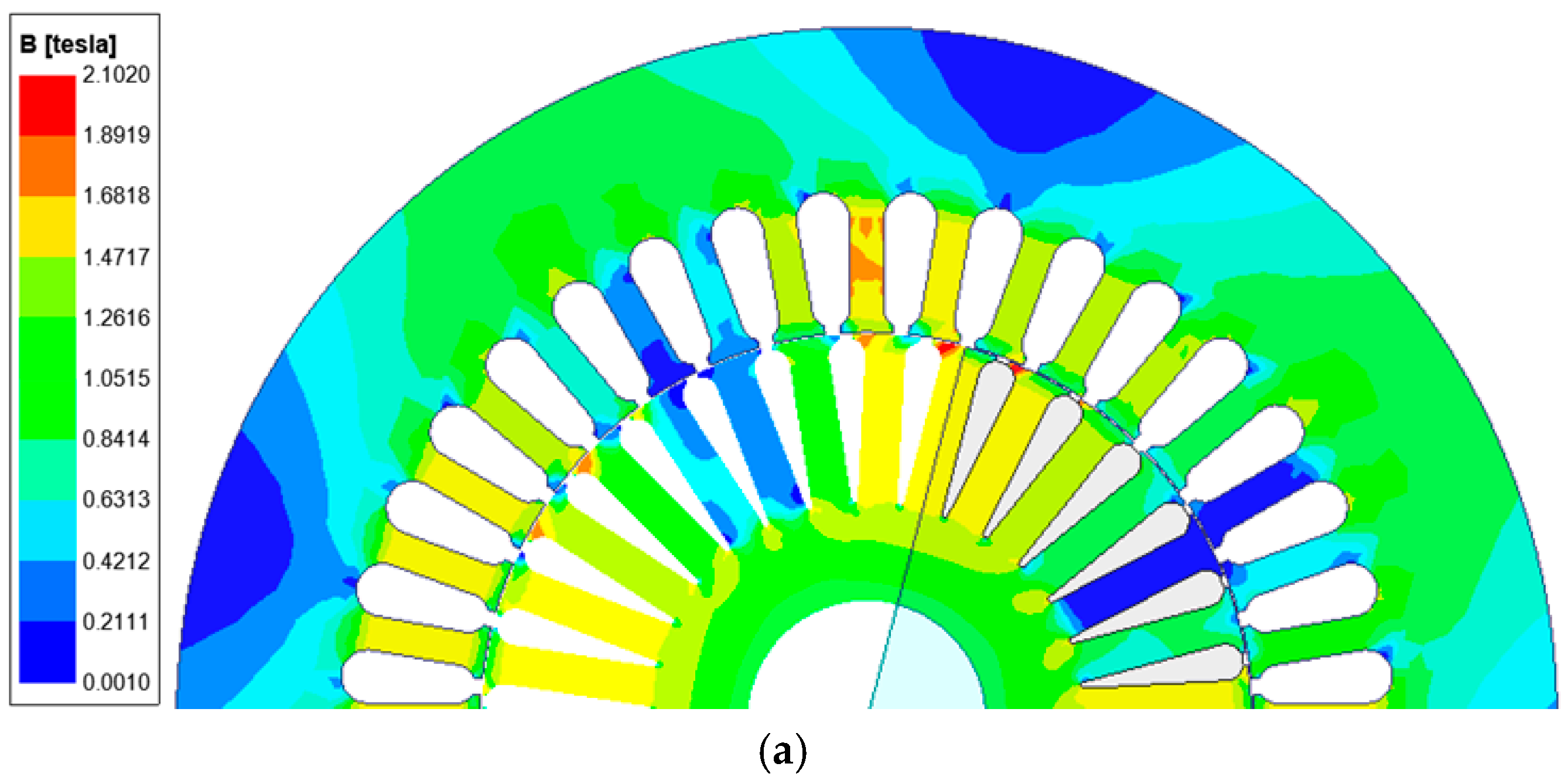

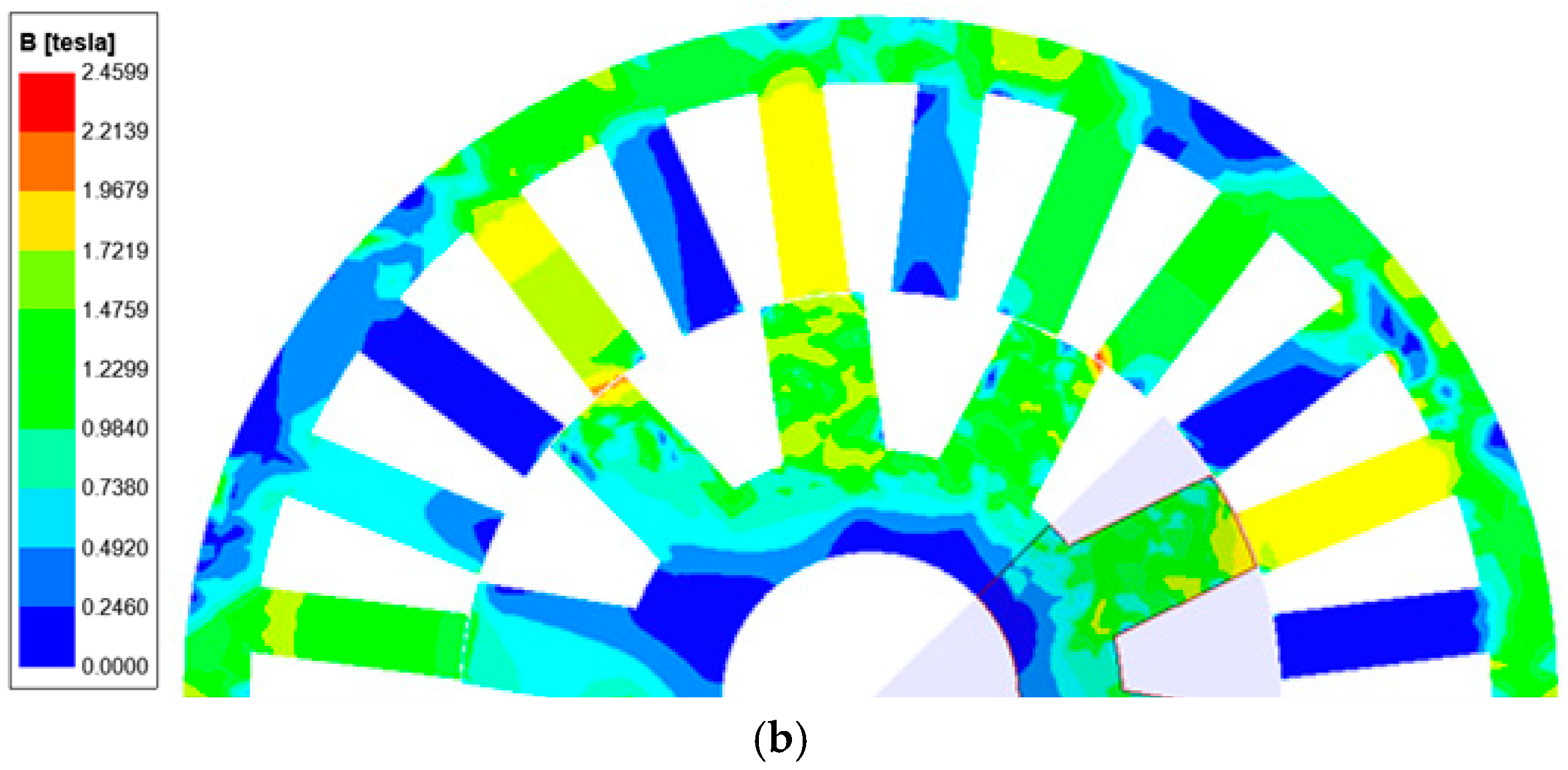

3. FEA Design and Modeling

4. Results and Discussion

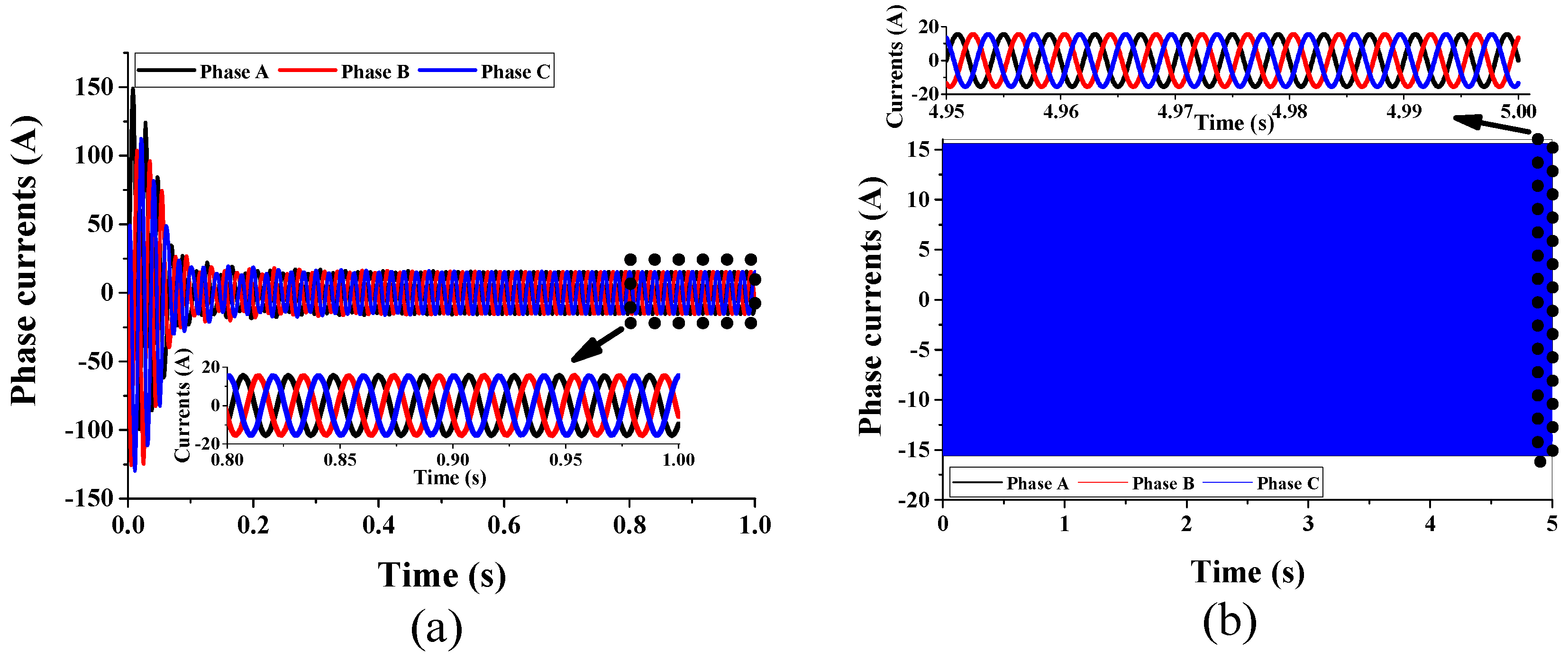

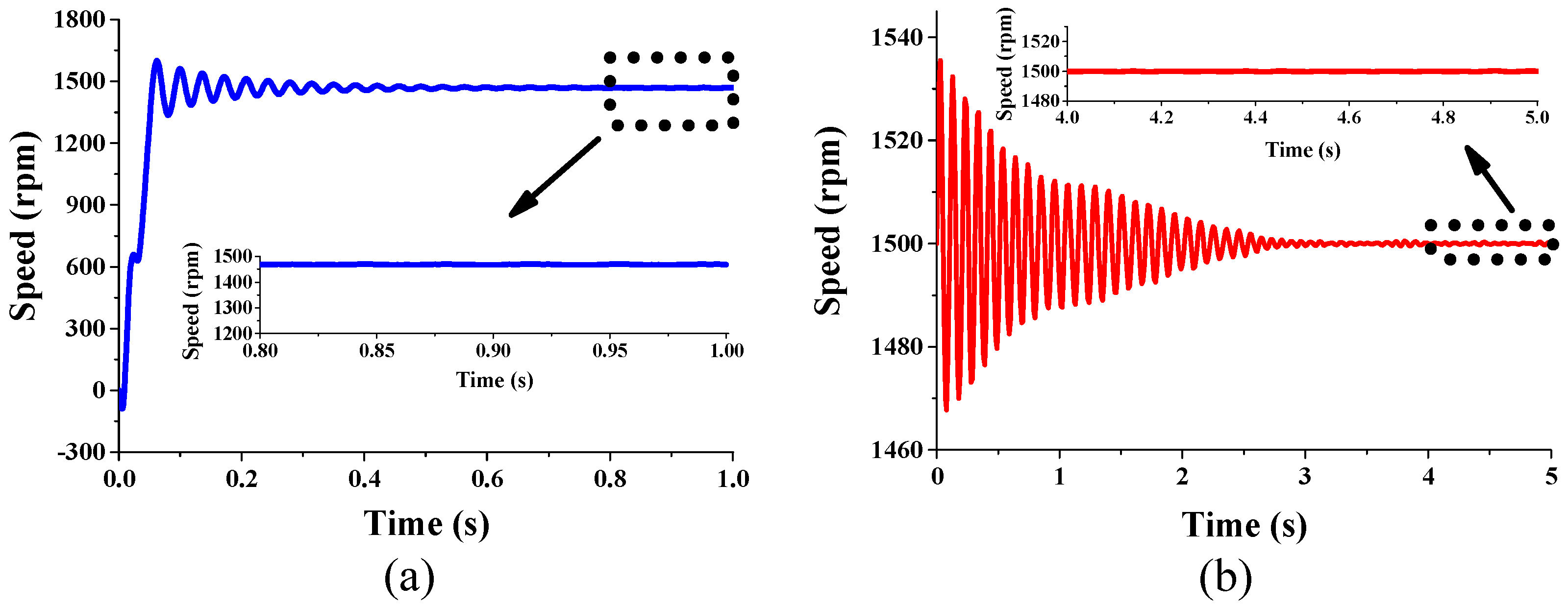

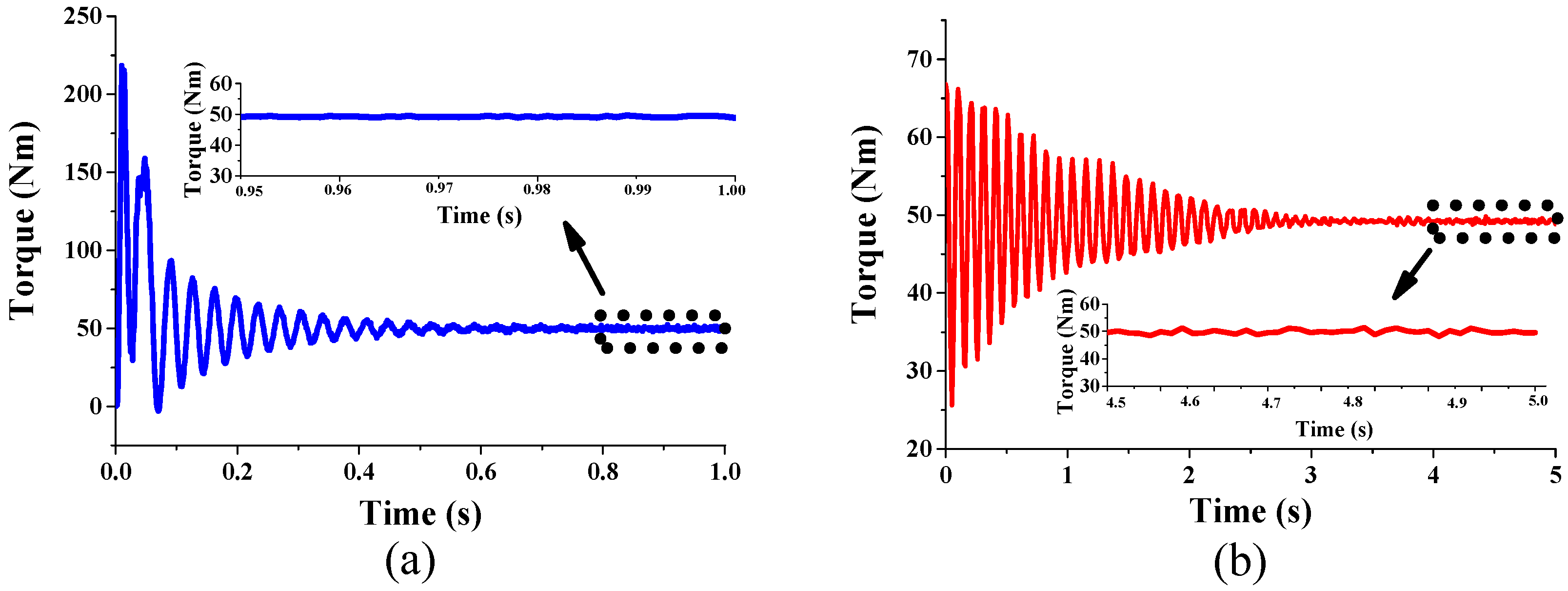

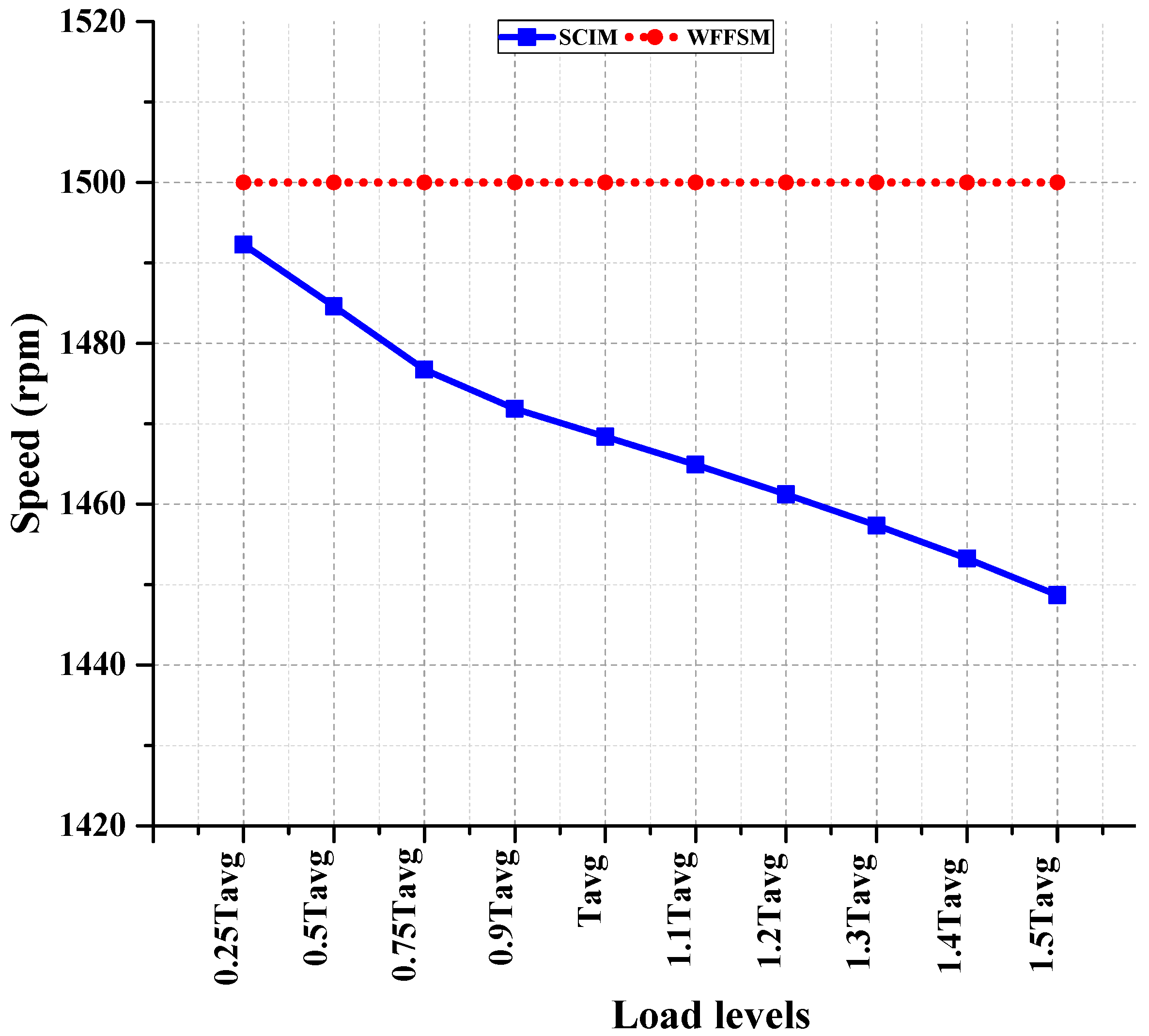

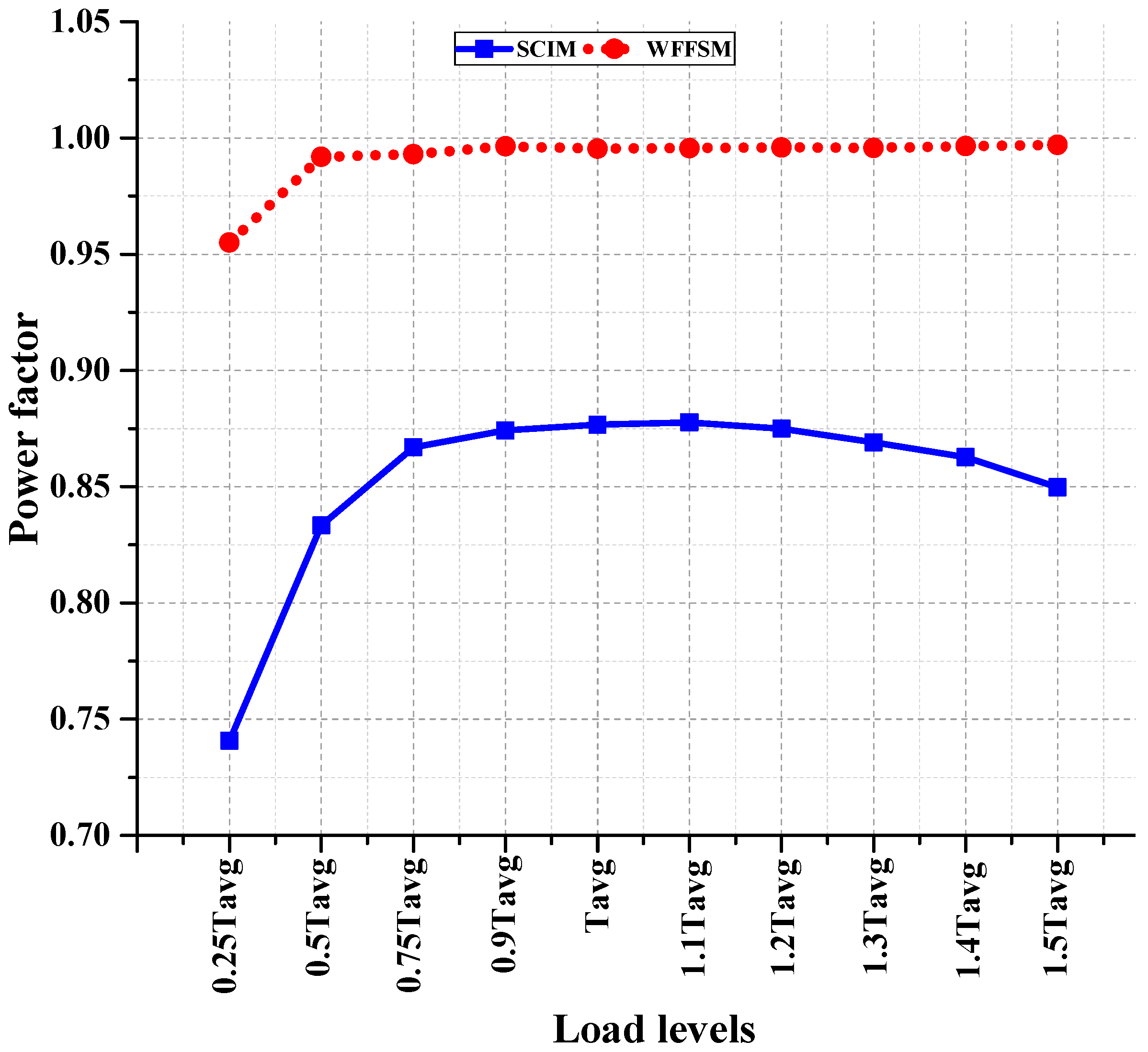

4.1. Steady-State Transient Motor Characteristics

4.2. Dynamic On-Load Transient Motor Characteristics

4.3. Validation and Cost Analysis Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trianni, A.; Cagno, E.; Accordini, D. Energy efficiency measures in electric motors systems: A novel classification highlighting specific implications in their adoption. Appl. Energy 2019, 252, 113481. [Google Scholar] [CrossRef]

- Almeida, A.T.; Ferreira, F.J.; Baoming, G. Beyond Induction Motors—Technology Trends to Move Up Efficiency. IEEE Trans. Ind. Appl. 2014, 50, 2103–2114. [Google Scholar] [CrossRef]

- De Souza, D.F.; Salotti, F.A.M.; Sauer, I.L.; Tatizawa, H.; de Almeida, A.T.; Kanashiro, A.G. A Performance Evaluation of Three-Phase Induction Electric Motors between 1945 and 2020. Energies 2022, 15, 2002. [Google Scholar] [CrossRef]

- Khan, F.; Sulaiman, E.; Ahmad Md, Z. Review of switched flux wound-field machines technology. IETE Tech. Rev. 2017, 34, 343–352. [Google Scholar] [CrossRef]

- Melfi, M.J.; Umans, S.D. Squirrel-Cage Induction Motors: Understanding Starting Transients. IEEE Ind. Appl. Mag. 2012, 18, 28–36. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, Z.Q.; Hua, W.; Akehurst, S.; Zhu, X.; Zhang, W.; Hu, J.; Li, H.; Zhu, J. Analysis and suppression of induced voltage pulsation in DC winding of five-phase wound-field switched flux machines. IEEE Trans. Energy Convers. 2019, 34, 1890–1905. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Potentials of Locally Manufactured Wound-Field Flux Switching Wind Generator in South Africa. J. Energy S. Afr. 2019, 30, 110–117. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Performance Comparison of Optimum Wound-field and Ferrite PM Flux Switching Machines for Wind Energy Applications. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 2478–2485. [Google Scholar] [CrossRef]

- Zhao, G.; Hua, W.; Qi, J. Comparative Study of Wound-Field Flux-Switching Machines and Switched Reluctance Machines. IEEE Trans. Ind. Appl. 2019, 55, 2581–2591. [Google Scholar] [CrossRef]

- Sethupathi, P.; Senthilnathan, N. Comparative analysis of line-start permanent magnet synchronous motor and squirrel cage induction motor under customary power quality indices. Electr. Eng. 2020, 102, 1339–1349. [Google Scholar] [CrossRef]

- Muteba, M. Comparison of Dynamic Behaviors between a Synchronous Reluctance Motor with Brass Rotor Bars and a Squirrel Cage Induction Motor. In Proceedings of the 2019 IEEE PES/IAS PowerAfrica, Abuja, Nigeria, 20–23 August 2019; pp. 374–378. [Google Scholar] [CrossRef]

- Ozcelik, N.G.; Dogru, U.E.; Imeryuz, M.; Ergene, L.T. Synchronous Reluctance Motor vs. Induction Motor at Low-Power Industrial Applications: Design and Comparison. Energies 2019, 12, 2190. [Google Scholar] [CrossRef]

- Boldea, I. Induction Machines Handbook; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Cao, R.; Yuan, X.; Jin, Y.; Zhang, Z. MW-Class Stator Wound Field Flux-Switching Motor for Semidirect Drive Wind Power Generation System. IEEE Trans. Ind. Electron. 2019, 66, 795–805. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Formulation and multiobjective design optimization of wound-field flux switching machines for wind energy drives. IEEE Trans. Ind. Electron. 2018, 65, 1828–1836. [Google Scholar] [CrossRef]

- Zulu, A.; Mecrow, B.C.; Armstrong, M. A wound-field three-phase flux-switching synchronous motor with all excitation sources on the stator. IEEE Trans. Ind. Appl. 2010, 46, 2363–2371. [Google Scholar] [CrossRef]

- Sulaiman, E.B.; Kosaka, T.; Matsui, N. Design study and experimental analysis of wound field flux switching motor for HEV applications. In Proceedings of the XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1269–1275. [Google Scholar]

- Campbell, B.; Galleno, J. Motor life: The effects of loading, service factor and temperature rise on insulation life. In Proceedings of the IEEE Industry Applications Society 45th Annual Petroleum and Chemical Industry Conference, Indianapolis, Indiana, 28–30 September 1998; pp. 303–310. [Google Scholar]

- Udosen, D.; Kalengo, K.; Akuru, U.B.; Popoola, O.; Munda, J.L. Non-Conventional, Non-Permanent Magnet Wind Generator Candidates. Wind 2022, 2, 429–450. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Intriguing Behavioral Characteristics of Rare-Earth-Free Flux Switching Wind Generators at Small- and Large-Scale Power Levels. IEEE Trans. Ind. Appl. 2018, 54, 5772–5782. [Google Scholar] [CrossRef]

- Yu, W.; Hua, W.; Zhang, Z. High-Frequency Core Loss Analysis of High-Speed Flux-Switching Permanent Magnet Machines. Electronics 2021, 10, 1076. [Google Scholar] [CrossRef]

- Fukami, T.; Aoki, B.; Shima, K.; Momiyama, M.; Kawamura, M. Assessment of Core Losses in a Flux-Modulating Synchronous Machine. IEEE Trans. Ind. Appl. 2012, 48, 603–611. [Google Scholar] [CrossRef]

| Description | Parameter | Value |

|---|---|---|

| Rated speed (rpm) | ωs | 1450 |

| Number of poles | P1 | 4 |

| Number of stator slots | Ns | 36 |

| Split ratio | KD | 0.62 |

| Stack length (mm) | Lst(SCIM) | 154 |

| Stator outer diameter (mm) | Dos(SCIM) | 210.8 |

| Stator inner diameter (mm) | Dis(SCIM) | 130.7 |

| Stator slot height (mm) | hs0 | 0.8 |

| Number of turns per phase | W1 | 48 |

| Number of rotor slots | Nr | 30 |

| Airgap length (mm) | g(SCIM) | 0.33 |

| Rotor outer diameter (mm) | Dor(SCIM) | 130.37 |

| Rotor slot height (mm) | hr0 | 0.5 |

| Description | Parameter | Values |

|---|---|---|

| Rated speed (rpm) | ωr | 1500 |

| Stack length (mm) | Lst | 107 |

| Aspect ratio | KL | 0.7 |

| Split ratio | Ʌ0 | 0.6 |

| Number of stator slots | Ps | 24 |

| Stator outer diameter (mm) | Dout | 254 |

| Stator inner diameter (mm) | Din | 152 |

| Stator tooth arc factor | Cs | 0.25 |

| Number of rotor slots | Pr | 10 |

| Airgap length (mm) | g | 0.5 |

| Rotor outer diameter (mm) | Dor | 151.5 |

| Slot filling factor | af | 0.45 |

| Area of field coils (mm2) | Sf | 124 |

| Performance Quantity | SCIM | WFFSM | ||

|---|---|---|---|---|

| Analytical Results | FEA Results | Analytical Results | FEA Results | |

| Tavg (Nm) | 49.39 | 48.47 | 47.75 | 49.22 |

| TR (%) | - | 2.58 | - | 3.60 |

| Pout (kW) | 7.50 | 7.45 | 7.50 | 7.73 |

| Slip (%) | 3.10 | 2.93 | - | - |

| Pcu (W) | 181.23 | 176.38 | 135.45 | 107.39 |

| Pcore (W) | 119.41 | 104.23 | - | 191.18 |

| Ƞ (%) | 89.50 | 93.48 | 89.50 | 96.28 |

| PF | 0.8300 | 0.8767 | 0.8300 | 0.9954 |

| Tm (Nm/Kg) | 1.34 | - | 1.57 | - |

| Td (kNm/m3) | 9.17 | 9.15 | 8.81 | 9.08 |

| Cost (€) | 53.50 | - | 65.45 | - |

| Motor Parts | SCIM | WFFSM | ||

|---|---|---|---|---|

| Mass (Kg) | Cost (€/Kg) | Mass (Kg) | Cost (€/Kg) | |

| Stator | 17.60 | 1 | 17.30 | 1 |

| Rotor | 15.20 | 1 | 8.36 | 1 |

| Copper coils | 2.45 | 7 | 5.68 | 7 |

| Aluminum bars | 1.01 | 3.5 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abunike, C.E.; Akuru, U.B.; Okoro, O.I.; Awah, C.C. Sizing, Modeling, and Performance Comparison of Squirrel-Cage Induction and Wound-Field Flux Switching Motors. Mathematics 2023, 11, 3596. https://doi.org/10.3390/math11163596

Abunike CE, Akuru UB, Okoro OI, Awah CC. Sizing, Modeling, and Performance Comparison of Squirrel-Cage Induction and Wound-Field Flux Switching Motors. Mathematics. 2023; 11(16):3596. https://doi.org/10.3390/math11163596

Chicago/Turabian StyleAbunike, Chiweta E., Udochukwu B. Akuru, Ogbonnaya I. Okoro, and Chukwuemeka C. Awah. 2023. "Sizing, Modeling, and Performance Comparison of Squirrel-Cage Induction and Wound-Field Flux Switching Motors" Mathematics 11, no. 16: 3596. https://doi.org/10.3390/math11163596

APA StyleAbunike, C. E., Akuru, U. B., Okoro, O. I., & Awah, C. C. (2023). Sizing, Modeling, and Performance Comparison of Squirrel-Cage Induction and Wound-Field Flux Switching Motors. Mathematics, 11(16), 3596. https://doi.org/10.3390/math11163596