A Scalable Learning Factory Concept for Interdisciplinary Engineering Education: Insights from a Case Implementation

Abstract

1. Introduction

2. Learning Factory Practices in the European Context

2.1. Mid- to Large-Scale Learning Factories in Academic Institutions

2.2. Compact and Scalable Learning Factories in Academic Institutions

2.3. Review of Existing Learning Factory Design Methodologies

3. Methodological Framework for Designing an Academic Learning Factory Concept

3.1. Methodological Foundations

3.2. General Phases in Developing a Learning Factory Concept

- Exploratory analysis and design objectives: Identify best practices, configurations, and educational approaches from existing learning factories and define educational, technological, and operational objectives based on stakeholder needs and internal constraints.

- Assess stakeholder needs: Obtain input from students, academic staff, and SMEs, specifically to identify skills gaps and digital transformation needs.

- Infrastructure and capability audit: Map available institutional resources, including physical space, equipment, software, staff expertise, and the potential for flexible use and integration of technologies appropriate to the intended learning and objectives.

- Concept development and validation: Develop a concept for a learning factory and validate its structure and feasibility through stakeholder workshops, pilot sessions, or expert assessments.

3.3. Key Dimensions to Consider

- Educational integration: Aligning the design of the learning factory with the desired learning outcomes and teaching methods, active learning approaches and realistic environments that simulate the manufacturing and service context.

- Technological readiness: Selection of technologies that reflect current industrial practice while being suitable for a flexible, educational environment.

- Industrial relevance and SME orientation: Ensuring that the learning factory responds to the industrial needs.

- Flexibility and scalability: Considering the degree to which the LF should be modular, reconfigurable, and expandable over time. This dimension emphasizes planning for both adaptability and sustainability.

4. Concept Development: Translating Framework into a Learning Factory Concept

4.1. Institutional and Regional Context

4.2. Applying the Design Phases

4.2.1. Exploratory Analysis and Design Objectives

- Educational integration—aimed at aligning the LF with the RITEH interdisciplinary engineering curricula and to support different teaching methods, such as project-based and collaborative learning. The priority at this dimension was to define the LF as an educational resource embedded in multiple engineering disciplines, while being adaptable to future pedagogical developments.

- Technological readiness—intended to guide selection of technologies that reflect current industrial practice while remaining appropriate for flexible educational use. This dimension also recognizes that regional SMEs operate at different stages of digital maturity (Krulčić et al., 2025), requiring the LF to accommodate both foundational and advanced technological practices.

- Industrial relevance and SME orientation—aimed at ensuring that the LF supports regional SMEs by equipping students with applicable engineering and management skills, while serving as a collaborative platform for industry training and applied research. The dimension emphasizes hands-on learning that reflects the realities of regional SMEs operations.

- Flexibility and scalability—intended to ensure adaptability and the potential for incremental development. The LF should be designed as a system that can evolve over time—both technologically and pedagogically—to remain relevant as institutional capacity and industry needs change.

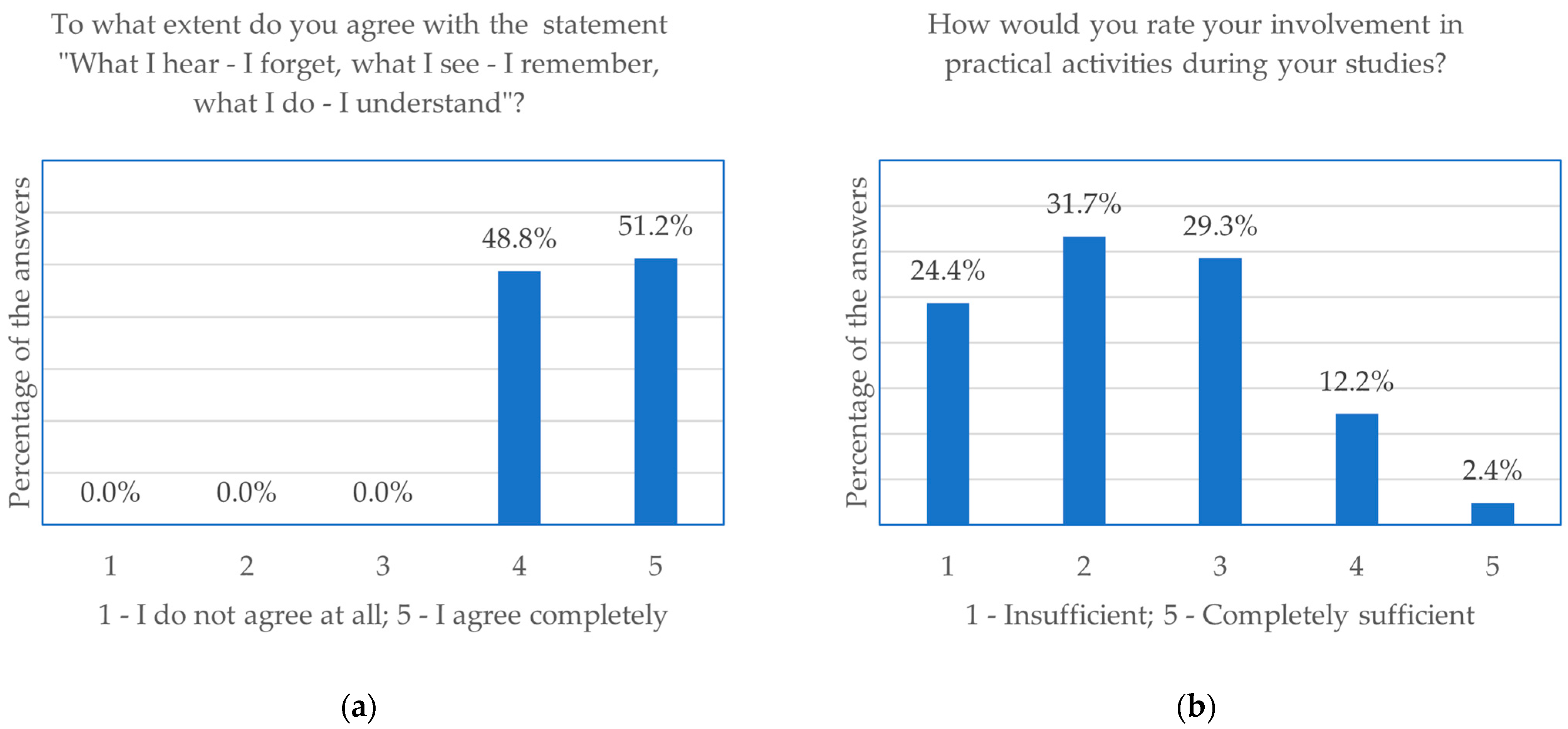

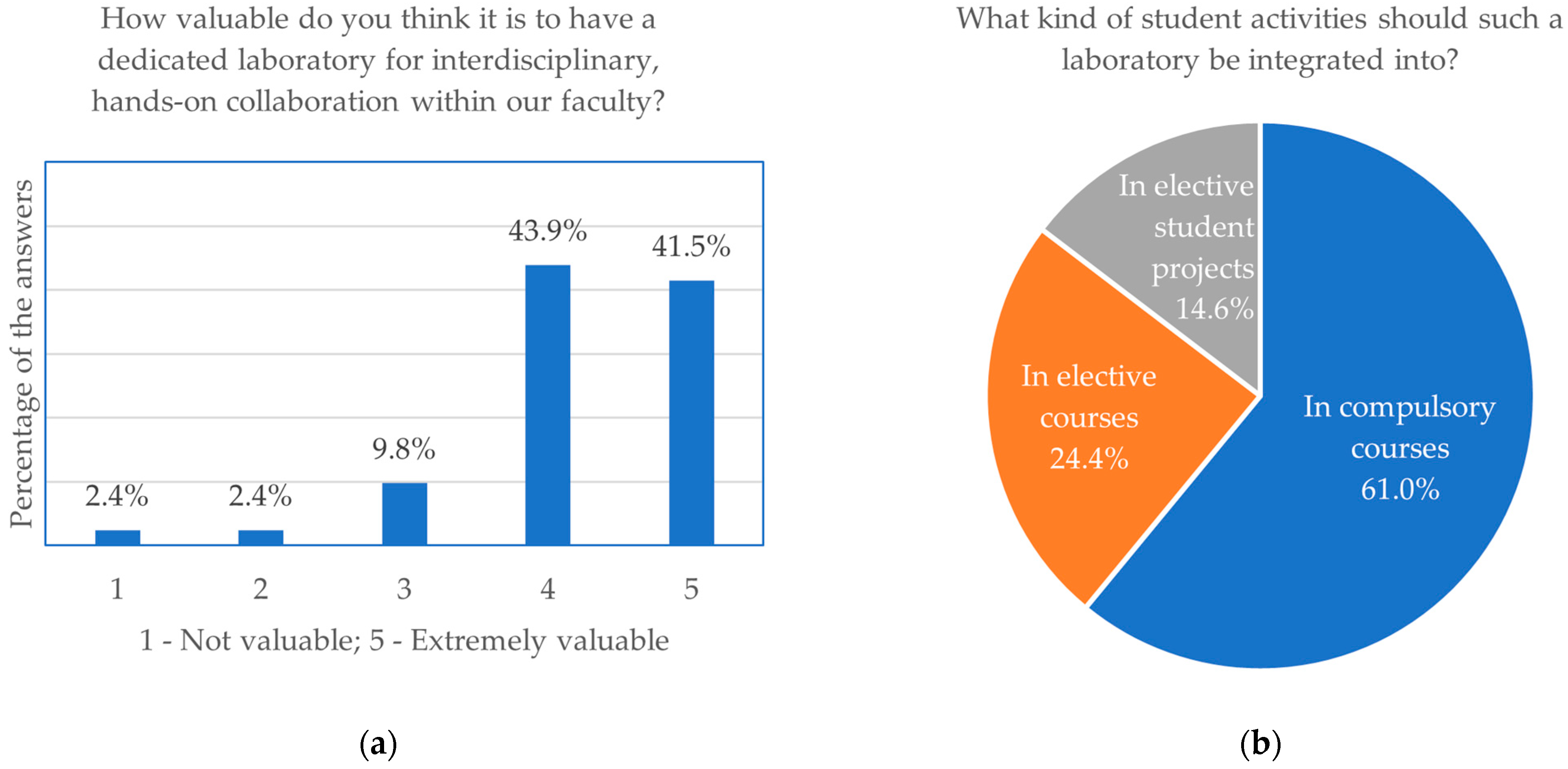

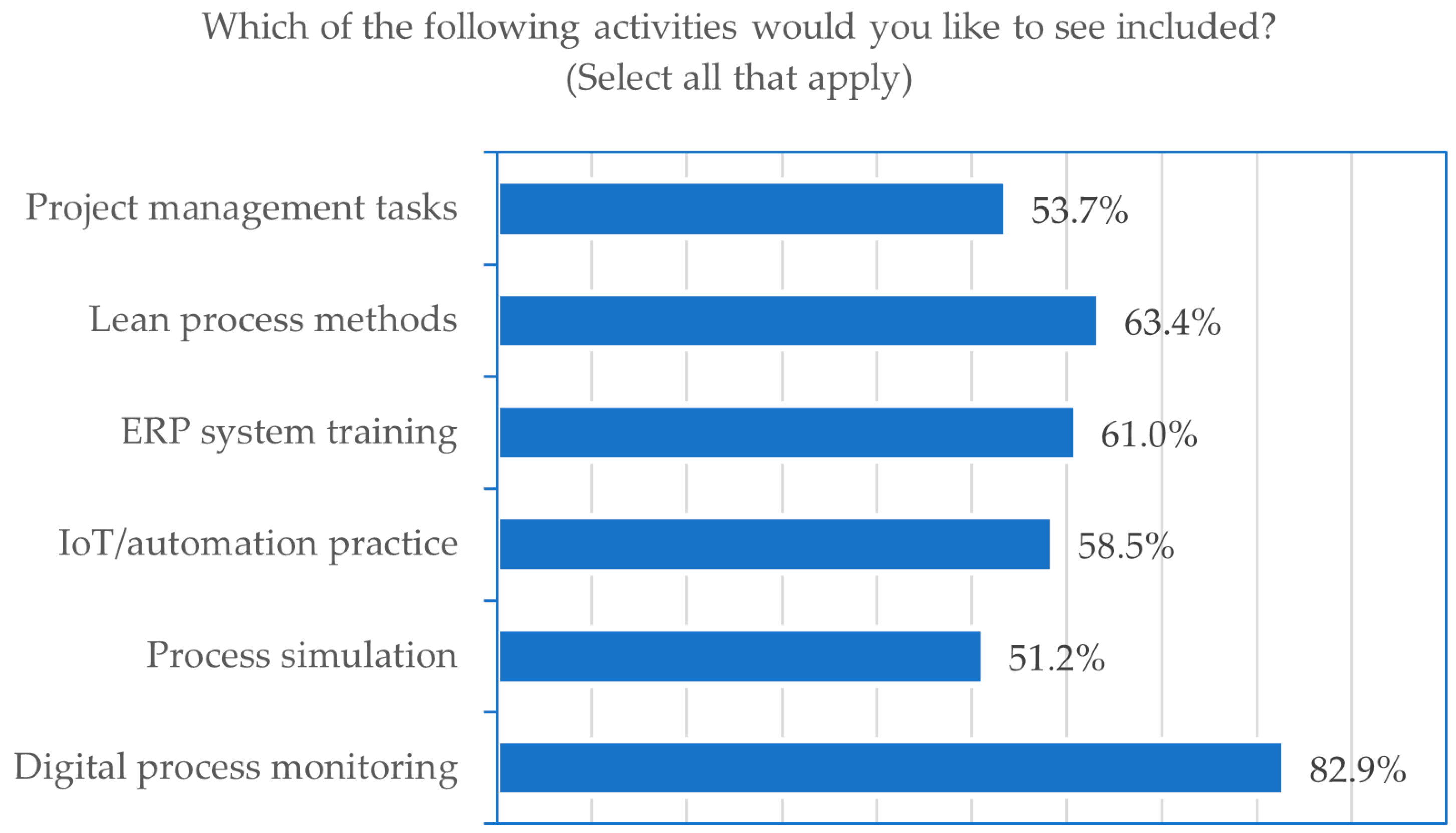

4.2.2. Stakeholder Needs Assessment

4.2.3. Infrastructure and Capability Audit

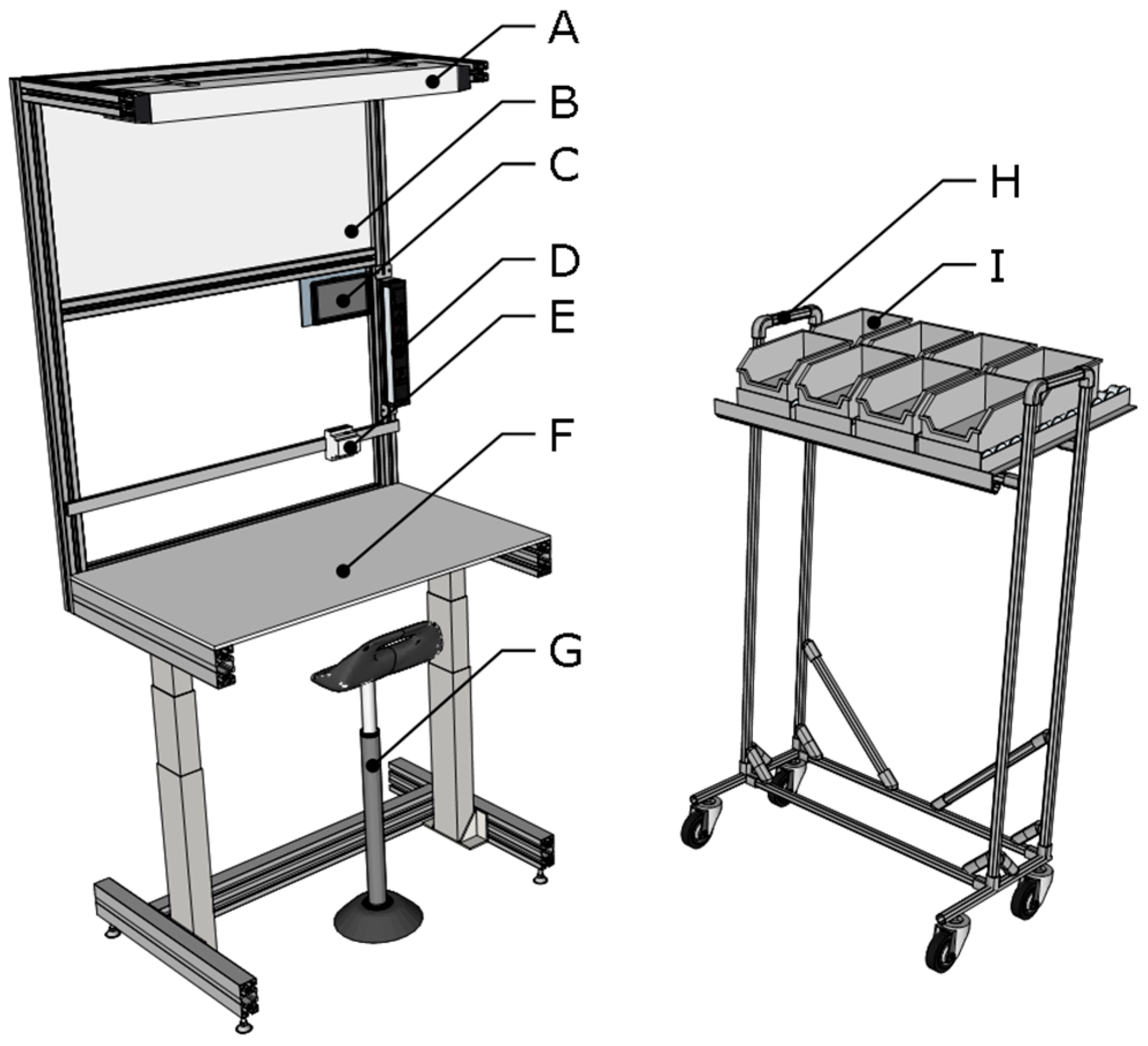

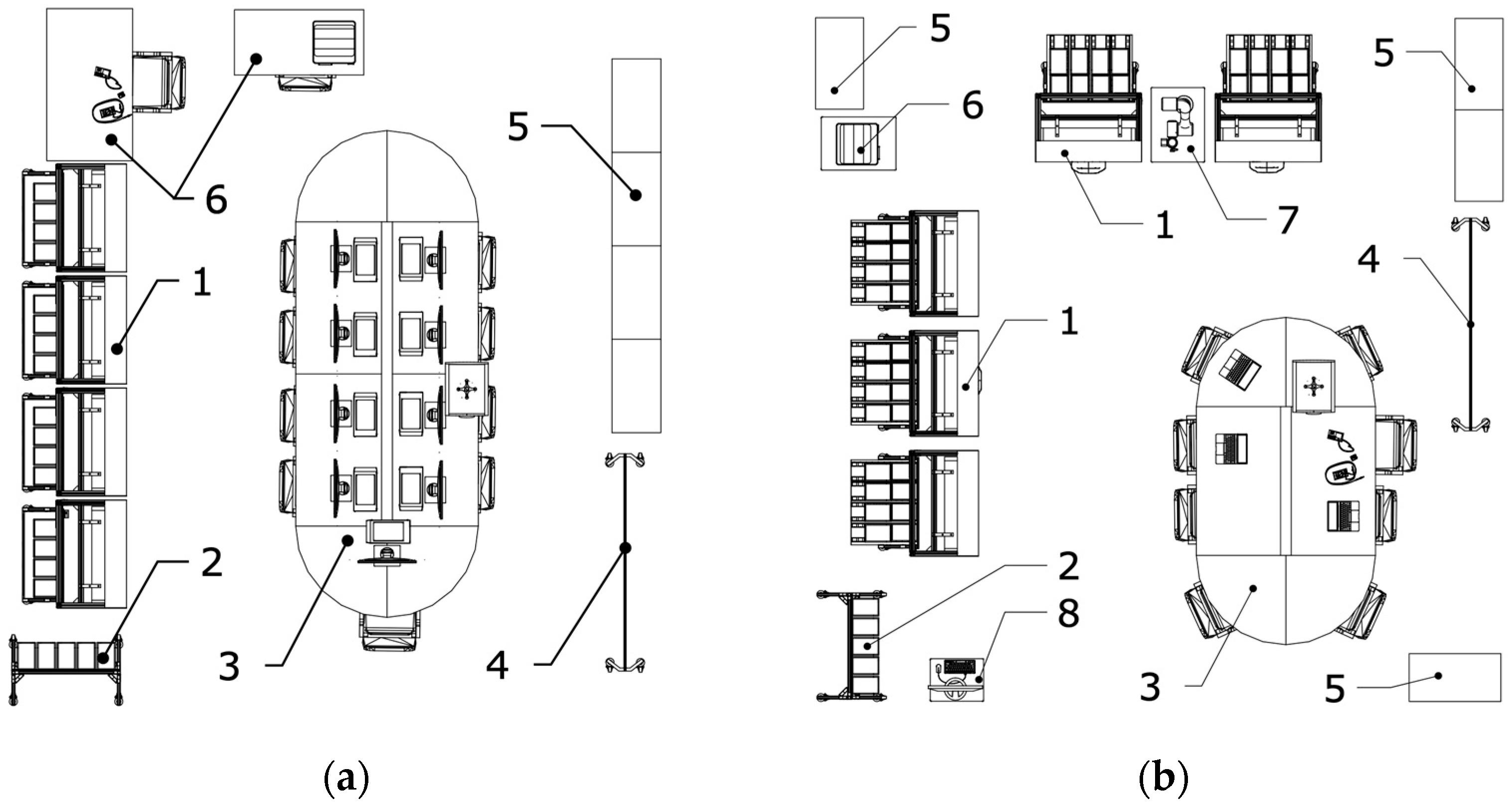

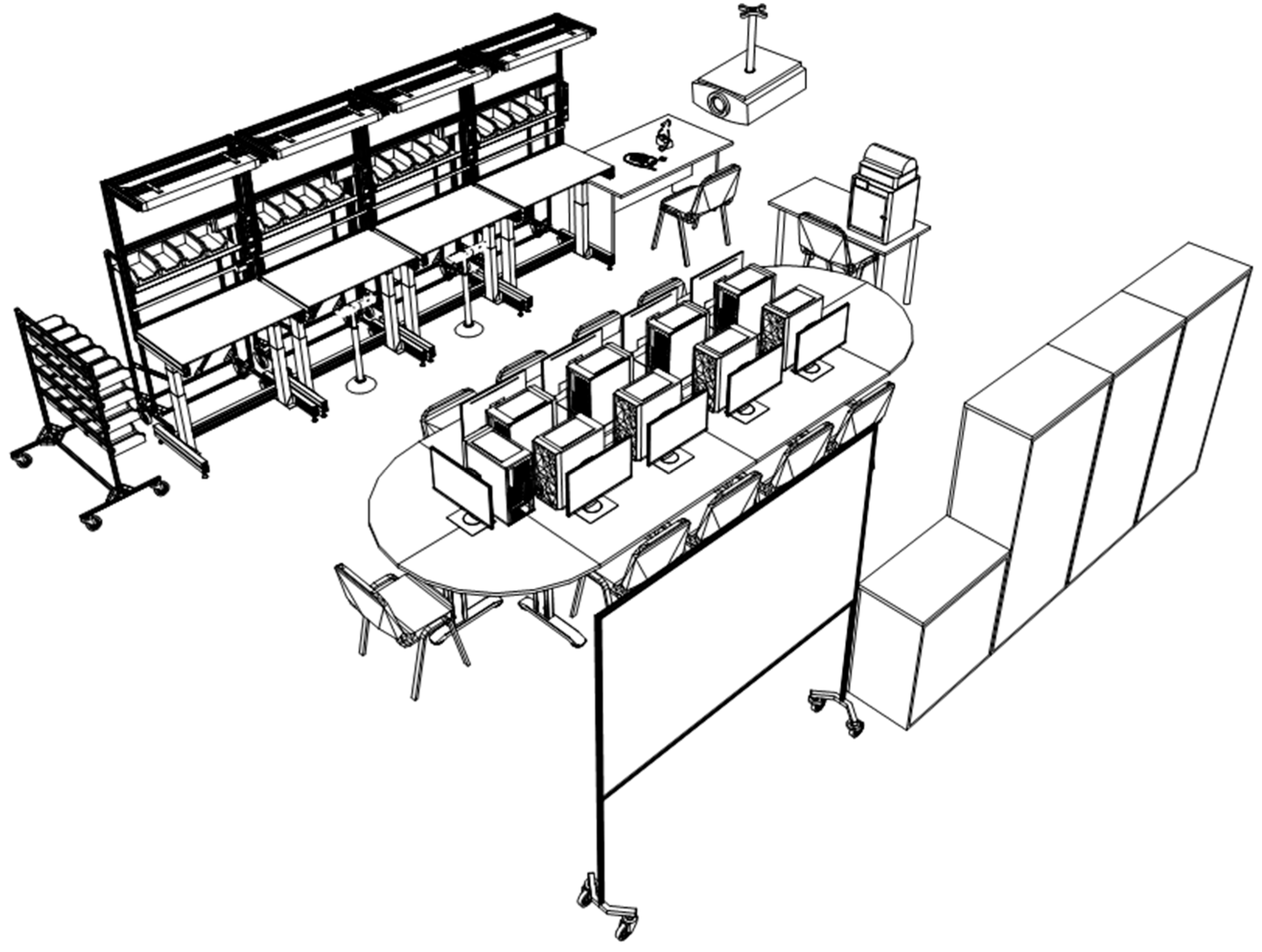

- Four manual assembly workstations (1) with assigned mobile flow rack to facilitate Lean manufacturing principles, reconfiguration between serial and hybrid (serial-parallel) layouts, ergonomic material handling and simulation of process flows and inventory logistics

- A mobile flow rack (2) that serves as a simulation area for an input–output warehouse

- A centralized teamwork and digital interface area (3) with a conference table equipped with desktop workstations. This area supports planning, interaction with ERP systems and simulations

- Additional area for Kanban or Lean visual management (4)

- Additional area for static shelving for general storage (5)

- Dedicated areas for prototyping and 3D printing (6) to support physical validation of student design tasks and small part manufacturing.

- A collaborative robot station (7) for advanced learning in safe automation environments

- A digital warehouse interface with touch-sensitive terminals (8) to simulate real-time inventory management or picking lists.

4.2.4. Concept Development and Validation

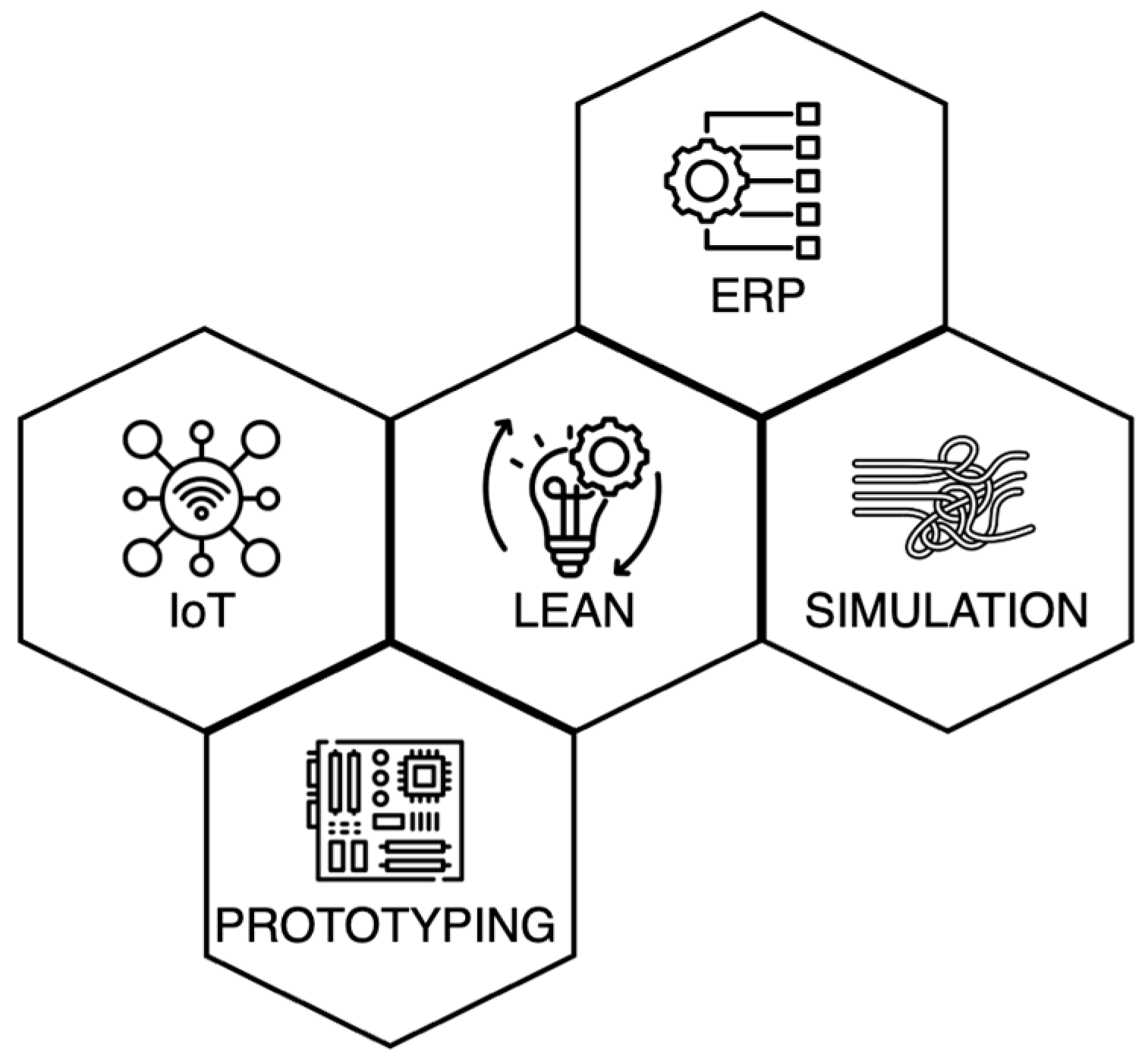

- Lean processes—the educational anchor for hands-on improvement and flow-based learning

- ERP systems—enabling enterprise-level coordination and integration of processes with management

- Simulation environments—to support scenario exploration, decision-making, and process optimization

- IoT technologies—provide real-time monitoring, data-driven feedback, and cyber-physical connectivity

- Physical prototyping—linking product development and process design and reinforcing iterative learning.

4.2.5. Morphological Characterization of the Learning Factory

4.3. Resulting Learning Factory Concept

- Validated thematic structure—The LF is organized around five thematic components. The validation workshops have confirmed that this structure is perceived as relevant by SMEs and engaging by students.

- Educational focus—The LF is based on experiential and hands-on learning methods. The focus of activities is on teamwork, process simulation, and iterative improvement, supported by digital integration. This positions the LF as a platform not only for the development of technical skills, but also for interdisciplinary collaboration, in line with the principles of Education 4.0.

- Physical layout and scalability—The resulting LF design is compact, occupying an area of 43 m2 configured around manual assembly stations. Despite the limited footprint, the space supports a step-by-step evolution: starting with manual workflows, through ERP integration and IoT-based monitoring, robotics and digital warehousing.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abele, E., Chryssolouris, G., Sihn, W., Metternich, J., ElMaraghy, H., Seliger, G., Sivard, G., ElMaraghy, W., Hummel, V., Tisch, M., & Seifermann, S. (2017). Learning factories for future oriented research and education in manufacturing. CIRP Annals—Manufacturing Technology, 66(2), 803–826. [Google Scholar] [CrossRef]

- Abele, E., Metternich, J., Tisch, M., & Kreß, A. (2024a). Best practice examples. In Learning factories (pp. 391–637). Springer. [Google Scholar] [CrossRef]

- Abele, E., Metternich, J., Tisch, M., & Kreß, A. (2024b). The life cycle of learning factories for competence development. In Learning factories (pp. 129–212). Springer International Publishing. [Google Scholar] [CrossRef]

- Abele, E., Metternich, J., Tisch, M., & Kreß, A. (2024c). The variety of learning factory concepts. In Learning factories (pp. 97–127). Springer International Publishing. [Google Scholar] [CrossRef]

- Arts et Métiers. (2025). Evolutive learning factory. Available online: https://artsetmetiers.fr/en/evolutive-learning-factory (accessed on 1 April 2025).

- Bauer, H., Brandl, F., Lock, C., & Reinhart, G. (2018). Integration of industry 4.0 in lean manufacturing learning factories. Procedia Manufacturing, 23(1), 147–152. [Google Scholar] [CrossRef]

- Celar, S., Veza, I., Turic, M., & Dragicevic, S. (2016, February 28–March 2). Digital learning factory at FESB—University of split. XXII Scientific and Business Conference YUINFO 2016 (pp. 1–6), Kopaonik, Srbija. Available online: https://www.researchgate.net/publication/299338211 (accessed on 21 May 2025).

- European Commission (EC). (2020). An SME strategy for a sustainable and digital Europe. European Commission. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52020DC0103 (accessed on 3 April 2025).

- European Commission (EC). (2024, July 3). SME performance review 2024—Croatia country sheet. Available online: https://ec.europa.eu/docsroom/documents/60557 (accessed on 28 August 2025).

- Hevner, A., & Chatterjee, S. (2010). Design science research in information systems. In Design research in information systems (pp. 9–22). Springer. [Google Scholar] [CrossRef]

- Institute of Innovation and Industrial Management. (n.d.). Lead factory. Available online: https://www.tugraz.at/en/institutes/iim/facilities/lead-factory (accessed on 4 April 2025).

- Kagermann, H., Wahlster, W., & Heblig, J. (2013). Securing the future of German manufacturing industry: Recommendations for implementing the strategic initiative Industrie 4.0. Final Report of the Industrie 4.0 Working Group. National Academy of Science and Engineering. [Google Scholar]

- Karlsruhe Institute of Technology. (2016, February 22). Unique learning factory for global production at KIT. Available online: https://www.kit.edu/kit/english/pi_2016_027_unique-learning-factory-for-global-production-at-kit.php (accessed on 4 April 2025).

- Kemény, Z., Nacsa, J., Erdos, G., Glawar, R., Sihn, W., Monostori, L., & Ilie-Zudor, E. (2016). Complementary research and education opportunities—A comparison of learning factory facilities and methodologies at TU Wien and MTA SZTAKI. Procedia CIRP, 54, 47–52. [Google Scholar] [CrossRef]

- Kolberg, D., & Zühlke, D. (2015). Lean automation enabled by industry 4.0 technologies. IFAC-PapersOnLine, 48(3), 1870–1875. [Google Scholar] [CrossRef]

- Kreß, A., & Metternich, J. (2020). System development for the configuration of learning factories. Procedia Manufacturing, 45, 146–151. [Google Scholar] [CrossRef]

- Krulčić, E., Doboviček, S., Pavletić, D., & Čabrijan, I. (2025). A dynamic assessment of digital maturity in industrial SMEs: An adaptive AHP-based digital maturity model (DMM) with customizable weighting and multidimensional classification (DAMA-AHP). Technologies, 13(7), 282. [Google Scholar] [CrossRef]

- Küsters, D., Praß, N., & Gloy, Y. S. (2017). Textile learning factory 4.0—Preparing Germany’s textile industry for the digital future. Procedia Manufacturing, 9, 214–221. [Google Scholar] [CrossRef]

- Lugaresi, G., Frigerio, N., & Matta, A. (2020). A new learning factory experience exploiting LEGO for teaching manufacturing systems integration. Procedia Manufacturing, 45, 271–276. [Google Scholar] [CrossRef]

- Mladineo, M., Celent, L., Milković, V., & Veža, I. (2024). Current state analysis of Croatian manufacturing industry with regard to industry 4.0/5.0. Machines, 12(2), 87. [Google Scholar] [CrossRef]

- Pilot Factory at TU Wien. (2025). Context industry 4.0. Available online: https://www.pilotfabrik.at/language/en/uber-uns-en/ (accessed on 23 May 2025).

- RICAIP Testbed. (n.d.). RICAIP testbed for industry 4.0. Available online: https://testbed.ciirc.cvut.cz/about/ (accessed on 4 April 2025).

- Royal Institute of Technology. (2025, April 12). Om KTH leancentrum. Available online: https://www.kth.se/2.95415/om-kth-leancentrum (accessed on 23 May 2025).

- Schuhmacher, J., & Hummel, V. (2022, April 11–13). Training module on probabilistic forecasting of production and intralogistics turbulences within learning factories. 12th Conference on Learning Factories (CLF 2022) (pp. 161–166), Singapore. [Google Scholar] [CrossRef]

- Schumacher, A., Erol, S., & Sihn, W. (2016). A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP, 52, 161–166. [Google Scholar] [CrossRef]

- Simons, S., Abé, P., & Neser, S. (2017). Learning in the AutFab—The fully automated industrie 4.0 learning factory of the university of applied sciences Darmstadt. Procedia Manufacturing, 9, 81–88. [Google Scholar] [CrossRef]

- Smart Mini Factory. (n.d.). Smart mini factory—Laboratory for industry 4.0 unibz. Available online: https://smartminifactory.it/ (accessed on 21 May 2025).

- Smart Production Lab. (2025). Lernfabrik. Available online: https://iwb-spl.de/lernfabrik/ (accessed on 16 May 2025).

- Sorensen, D. G. H., Lassen, A. H., Larsen, M. S. S., & Hansen, A. K. (2022). Learning factories for learning and experimentation on industry 4.0 in SMEs. In O. Madsen, U. Berger, C. Møller, A. Heidemann Lassen, B. Vejrum Waehrens, & C. Schou (Eds.), The future of smart production for SMEs (pp. 431–440). Springer. [Google Scholar] [CrossRef]

- Tortorella, G. L., & Fettermann, D. (2017). Implementation of industry 4.0 and lean production in Brazilian manufacturing companies. International Journal of Production Research, 56(8), 2975–2987. [Google Scholar] [CrossRef]

- Veza, I., Gjeldum, N., & Mladineo, M. (2015). Lean learning factory at FESB—University of Split. Procedia Cirp, 32, 132–137. [Google Scholar] [CrossRef]

- Vogt, L., Pelzer, F., Klose, A., Khaydarov, V., Lange, H., Viedt, I., Mädler, J., & Urbas, L. (2023, May 9–11). P2O-Lab: A learning factory for digitalization and modularization. 13th Conference on Learning Factories (CLF 2023), Reutlingen, Germany. [Google Scholar] [CrossRef]

| Dimension | Characteristic(s) |

|---|---|

| Main purpose | Education and training |

| Secondary purpose | Test environment/pilot projects |

| Product life cycle | Prototyping |

| Factory life cycle | Factory concept, process planning, assembly, logistics |

| Order life cycle | Configuration & order, order sequencing, planning, scheduling |

| Indirect functions | Procurement (simulation via teamwork/digital area) |

| Learning environment | Physical LF supported by digital tools (ERP, IoT, VR) |

| Environment scale | Life-size (miniature factory with full-process simulation) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doboviček, S.; Krulčić, E.; Pavletić, D.; Godina, R. A Scalable Learning Factory Concept for Interdisciplinary Engineering Education: Insights from a Case Implementation. Educ. Sci. 2025, 15, 1574. https://doi.org/10.3390/educsci15121574

Doboviček S, Krulčić E, Pavletić D, Godina R. A Scalable Learning Factory Concept for Interdisciplinary Engineering Education: Insights from a Case Implementation. Education Sciences. 2025; 15(12):1574. https://doi.org/10.3390/educsci15121574

Chicago/Turabian StyleDoboviček, Sandro, Elvis Krulčić, Duško Pavletić, and Radu Godina. 2025. "A Scalable Learning Factory Concept for Interdisciplinary Engineering Education: Insights from a Case Implementation" Education Sciences 15, no. 12: 1574. https://doi.org/10.3390/educsci15121574

APA StyleDoboviček, S., Krulčić, E., Pavletić, D., & Godina, R. (2025). A Scalable Learning Factory Concept for Interdisciplinary Engineering Education: Insights from a Case Implementation. Education Sciences, 15(12), 1574. https://doi.org/10.3390/educsci15121574