Abstract

In this work, exploratory quantitative research on the opinion of the students of a course on Geometry of Welded Joints, in an introductory welding course of secondary technical education curriculum, on the didactic use of PDF-3D in the development of the course is carried out. For this purpose, a survey designed by the authors was used, which the students answered once the study of the subject had been completed. As a result, it has been found that the valuations of the virtual tool PDF-3D are very high, mainly in relation to motivation and ease of use. The importance that students attach to the ease of solving the spatial comprehension difficulties inherent to welded joints -and the imperfections linked with them- positively influences the ratings of this educational technology. On the other hand, this study reveals that students prefer a mixed methodology in which the presence of virtual resources is greater than that of the master class. Finally, the results obtained suggest that, given the lack of knowledge on the part of teachers of the potential of PDF-3D in the educational field, it would be advisable to offer specific training on the didactic use of PDF-3D to technical education professors.

1. Introduction and Literature Review

1.1. Context and Approach

The global health emergency caused by SARS-COV-2 (COVID-19) revealed problems of a diverse social nature worldwide and even more so in developing countries. In these countries, the very poor infrastructure of networks and communications affected the development of many of the usual tasks, including academic work and interaction between students and their teachers [1,2]. Specifically in Colombia, in the field of education, the effects were considerable. In fact, not only was it evident that there was little Internet coverage at the national level or the poor quality of this service but also the lack of digital devices to develop teaching-learning activities with new methodologies, using Information and Communication Technologies (ICT) [3]. This meant that educational institutions had to quickly devise ways to advance in academic programs, having to evolve and quickly incorporate multimedia tools and ICT, which allowed them to adapt to the situation, as a response, to try to bring knowledge to students [4]. These tools became visible as a solution to the little or non-existent face-to-face contact in the pedagogical processes due to the restrictions imposed by the pandemic.

Contextualizing the above, it is the duty of every institution and personnel responsible for an educational process to create and constantly update the pedagogical resources used in academic programs and teaching methodologies. This implies incorporating ICT as a facilitating means to follow a flexible methodology where the absence of direct contact between teachers and students is overcome through visual and interactive programs [5,6,7]. It is necessary, therefore, to develop digital aids that act as a mediating entity to transmit the knowledge and competencies to which a student is entitled when pursuing studies in any area.

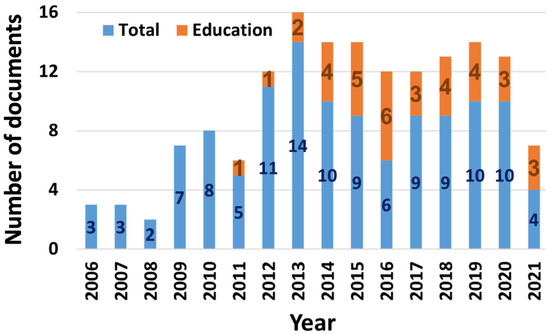

In the field of engineering and technology, the use of virtual environments for non-classroom teaching has grown in recent years [8,9]. Within technical fields, the difficulty of teaching spatial concepts [10,11], which require observing or manipulating objects of an essentially three-dimensional nature, is particularly relevant. The traditional representation of these objects in 2D necessarily results in a significant loss of information and greater difficulty for the student to learn. To solve this need, three-dimensional representation tools have emerged in recent years that have been used fruitfully in education, such as 3D virtual and augmented reality, 3D print, and PDF-3D. 3D virtual reality makes it possible to recreate three-dimensional environments with which the user can interact through computational technologies [12,13]. On the other hand, 3D print allows the effective construction of the designed three-dimensional models [14,15]. PDF-3D, on the other hand, are resources for the visualization of 3D models by means of documents in PDF format, so they can be considered an educational technology [16]. Among the described tools, 3D-print and virtual and augmented reality technologies require technical infrastructure and equipment that does not make them accessible to any school or student population [12,17]. However, PDF-3D are tools that any teacher can count on to ensure quality interactive teaching, and they are more accessible to students, easier to disseminate, and require less prior training for their use than the rest of the resources mentioned [16]. Despite this, as can be seen in Figure 1, there are hardly any scientific papers showing the use of PDF-3D (120 papers in total), especially in the educational field, where there are only 39 papers in SCOPUS. This is evidence of the lack of knowledge of the scientific community and teachers about this educational resource.

Figure 1.

Number of scientific documents published in Scopus related to the general use of PDF-3D (blue) and the use of PDF-3D with educational purposes (red). The search strings are the following: for the first case TITLE-ABS-KEY (“PDF-3D” OR “PDF 3D” OR “3D PDF” OR “3D-PDF”), and for the second one is TITLE-ABS-KEY (“PDF-3D” OR “PDF 3D” OR “3D PDF” OR “3D-PDF”) AND (education).

PDF-3D is a virtual tool, adaptable to multiple e-learning telematic environments that require fundamental techniques and equipment requirements from the user. In addition, it has proven to be a very useful resource for training the student’s spatial vision capacity, which is essential in engineering and technical education [18,19]. In this work, quantitative research is carried out on the perception of a group of technical education students with whom this tool has been used in the teaching of a subject entitled “Geometry of Welded Joints”, within a basic welding course, at the Santa Rosa de Cabal Technological Institute (ITESARC), in Colombia. Specifically, the student’s assessment of the PDF-3D tool was measured, both in general and as applied to the specific topic of work, and differences were identified in their responses according to the importance they give to the topic in question and according to the methodology preferred by the students.

It is necessary to highlight the evident void that exists in terms of background and available resources that guide with respect to methodologies or tools that support the teaching and learning of welding from virtuality. It is specifically noteworthy that there are no papers in the literature on the use of PDF-3D files for this purpose. This makes this work a pioneer in the approach of an initial proposal for a basic welding academic program at a technical level. In view of this absence of research on the didactic use of PDF-3D, this research provides evidence to support that files of this type and virtual learning environments can be an important part of the solution to address the difficulty of spatial thinking in teaching welded joint geometry, and become a public didactic tool useful to mediate the pedagogical process of welding and related topics [20].

1.2. PDF-3D

Among the many competencies and skills that welding personnel (welders, engineers, designers, supervisors, and inspectors) must possess, there is one that allows a complete and correct understanding of the work to be carried out, and that is spatial interpretation or spatial vision ability [21]. This is defined as the ability to mentally understand complex three-dimensional shapes [21]. This spatial ability, although it depends on the intrinsic capabilities of the learners, can be enhanced and stimulated by means of virtual tools and methodologies that favor its development. Through these tools, it is possible to provide the student with an understanding, not only of the positioning and dimensions of the structure or element to be manufactured but also of its construction details [22], such as the welding process to be executed and the type of weld to be deposited in the welding joints [23].

In this sense, digital aids, such as PDF-3D, emerge as a mediating entity to transmit this knowledge and acquire fundamental competencies in the engineering field. They also allow the incorporation of the educational processes, resources, and methodologies that promote the acceptance, analysis, understanding, and subsequent application of knowledge, i.e., the establishment of significant learning [24] through virtuality, using ICT resources. This is of utmost importance since transmitting or interpreting spatial concepts is quite difficult if what is to be understood is observed in a document or plan (physical or digital), which is 2D, and it should be transferred to a three-dimensional projection in the real world. This bridge between what is understood and what is shown can cause a significant loss of information and, consequently, limit the visual-spatial interpretative ability of students in a welding course [24].

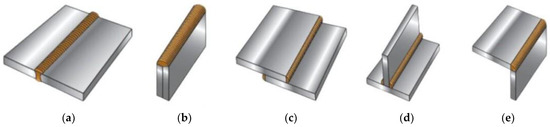

The generation of a PDF-3D requires only a three-dimensional digital model of what is to be represented, in this case, the various types of weld joints (T joint, lap joint, edge joint, butt joint, or corner joint, as shown in Figure 2), to be subsequently exported as a standard PDF file. Although for the generation of the three-dimensional model, it is necessary to use specific 3D modeling software, which may be expensive and requires intensive prior training for its use [16], there are economically viable options that use software commonly used in broad areas of education, such as AutoCAD [25] or Adobe Photoshop [16]. In this study, Autodesk Inventor, educationally licensed software available from ITESARC, has been used, where the cross-section of a butt weld joint is schematized for subsequent extrusion achieving the necessary modeling.

Figure 2.

Types of weld joints: (a) butt joint, (b) edge Joint, (c) lap joint, (d) Tee joint, and (e) corner joint.

The use of PDF-3D has become widespread in various scientific disciplines due to the multiple advantages it offers over classical 2D representations. Among them [26]: (i) PDF-3D tools have a greater capacity than 2D resources to explain and illustrate the dimensions of objects; and (ii) they hold a greater amount of information in a smaller space than any 2D illustration. Moreover, from the technical point of view, PDF-3D allows for solving certain drawbacks of other tools, such as the following [26]: (i) the problems of long-term compatibility of the created file format and hardware or software; (ii) the size of the files, which is smaller with respect to those generated with other specific programs and these are compatible with the generation of electronic documents and with any virtual platform for sharing materials and information. All these features make the tool studied an effective and highly valued resource by the students who have used it [27,28,29].

Although the literature suggests that so far there has not been a massive use of this educational technology (Figure 1), there are specific experiences that have occurred in various disciplines: representation of functional and anatomical animal morphology in biology [30]; obtaining manipulable three-dimensional biomedical models for clinical applications [31,32]; educational experiences in the health sector, such as digital models [33,34,35], applications in radiology [36] or anatomy [37,38]; representation of architectural spaces [39,40,41]; three-dimensional representations in engineering studies, such as geomodels and terrain representations [42,43,44], or representations to develop spatial abilities [45,46,47]; presentation of specialized graphic reports [24,32,48] in order to achieve improvements in the learning of graphic expression, modeling, three-dimensional comprehension (reasoning and spatial skills) and on medical procedures and morphological analysis; in the graphic design of industrial products [49]; as a tool to optimize the presentation of contents in the field of scientific research [50,51]; or for the development of diverse competences in the educational field [52,53].

However, as observed in Figure 1, there is a paucity of research highlighting the use of PDF-3D in the educational field and, specifically, a general nullity, if one specifically analyzes the field of welding education at any academic, scientific, or research level. In addition, the evidence that exists on the use of this type of technology revolves mainly around reinforcing and clarifying concepts related to visual-spatial reasoning with important results and improvements in three-dimensional understanding [24,32,41,46,52], which is of great help to facilitate understanding in a field as complex and yet useful as welding and its related subjects. Obtaining this interpretative ability is fundamental in any study of the engineering field and the teaching-learning processes can be favored through digital graphing tools, enabling the acquisition of significant learning [47,54].

1.3. Welded Joints

The subject of welded joints and their geometry is an essential part of the training of many professionals in the technical field, and requires the development, for their learning, of the aforementioned spatial and geometric visualization skills [55]. The reason is that, from the correct appreciation of the welded joints and their components, derives the proper positioning of the elements to be joined and the reading of the information contained in the symbols that accompany them in the technical drawings [56,57]. The main geometrical elements related to welded joints are the following [58]: (i) the classification of the types of joints, which is usually done following geometrical criteria of three-dimensional character; (ii) the component parts of the joints; and (iii) the dimensioning present in the joints, which includes an important metric component in the geometry of the welded joints.

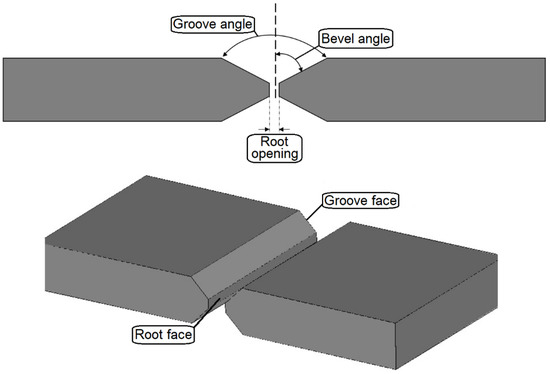

Thus, the different welded joints are classified according to the geometric shape of the joint [59]. Furthermore, as illustrated in Figure 3, knowledge of the component parts of welded joints, which encompass angular, longitudinal, and surface elements, is crucial to understand their geometry [60]: the root of joint; root face; groove face; bevel angle; groove angle; groove radius; and root opening. The combination and interrelation of all these elements can cause confusion in the trainees since it is a large amount of information contained in simple images that require sufficient spatial interpretative skills. Therefore PDF-3D emerges as the solution to this difficulty since it allows students to interact with any type of joint and to appreciate in a realistic way all those characteristics present in them and the construction details in case the subsequent materialization on site is required.

Figure 3.

PDF 3D of a double V Groove weld joint.

By PDF-3D in the topic “Geometry of Welded Joints”, the aim is to provide the student with the correct interpretation of the different joints present in a welded structure and their construction details (positioning, process to be used, appropriate dimensions, edge preparation), which go hand in hand with the symbology and the representation systems or orthogonal projections shown in the technical drawings. Indeed, for the manufacture of a welded structure, it is necessary that both the welds and their welded joints have dimensions and shapes similar (within the required tolerances) to those indicated in the designs, drawings, projects, or contracts [61,62].

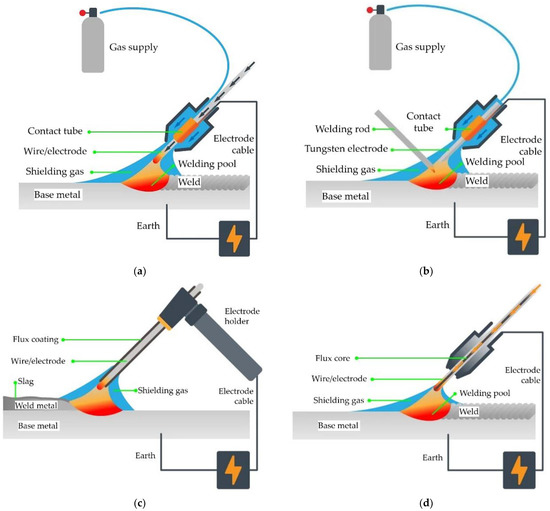

These aspects require spatial skills for their understanding, not being necessarily subject to the type of welding process to be used, since what determines the type or types of joints present in a construction are the types of profile or shapes of the base material, the configuration of the element or structure to be manufactured (which is given by the designer and the client’s needs), and the site where the welds are to be made [63]. The above are some of the conditions that determine the weld joints, but it should be noted that the implementation of PDF-3D makes it possible to transmit graphic ideas and facilitate the spatial vision of the joints generated using the different types of welds, such as the following: TIG (Tungsten Inert Gas) [64,65]; GTAW (Gas Tungsten Arc Welding) [66]; SMAW (Shield Metal Arc Welding) [67]; MIG (Metal Inert Gas) and MAG (Metal Active Gas) [68]; GMAW (Gas Metal Arc Welding) [69]; submerged arc SAW (Submerged Arc Welding) [70]; or ATW (aluminothermic welding process) [71].

Figure 4 schematically depicts the four main types of welds used in industry, which include the three most used welding methods: gas welding, arc welding, and laser welding. In MIG/MAG arc welding presented in Figure 4a, a consumable welding electrode is used as filler material for the weld. The arc is created by involving an electric current between the base metal (the parts to be joined) and electrode, shielded by an inert gas (MIG), such as Ar or He, or an active gas (MAG), such as CO2, which provides excellent quality welds by being cleaner, slag-free and with a good appearance or finish. Figure 4b shows a schematic representation of TIG welding, where a non-consumable W (tungsten) electrode and a welding shielding gas (Ar or He, or a mixture of both) are used.

Figure 4.

Types of welding: (a) Metal Inert Gas (MIG); (b) Tungsten Inert Gas (TIG); (c) Stick Welding (Shielded-Metal Arc); and (d) Flux-Cored Welding.

The great advantage of this method is that it allows the creation of high-quality, accurate, and precise welds, as thermal distortions are minimal, with good mechanical and corrosion resistance, and can be applied to steels and non-ferrous metals (Al, Mg, Cu, etc.). Figure 4c,d show Stick and Flux-Cored welds, respectively. The first one is characterized by using an electric current flow between the material to be welded and the electrode—or stick welding—widely used to weld thicker metals of stainless steel and cast iron. In contrast, the second (the Flux-Cored welding) uses a wired electrode constantly fed by the power source (a wired electrode that is fed constantly), which does not require any shielding gas since the electrode contains a flux core, as filler metal that protects the welding arc, allowing its application in conditions with the presence of strong winds.

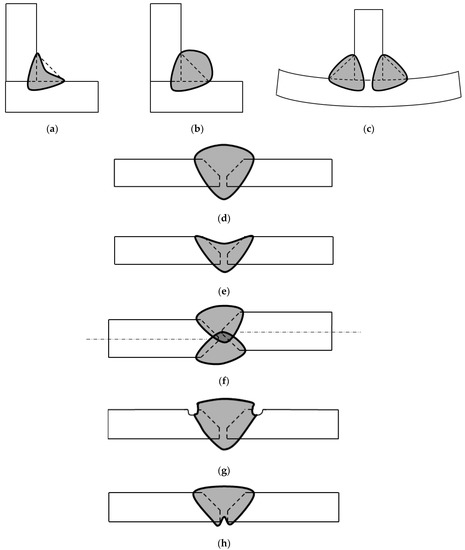

Additionally, PDF-3D opens the possibility of studying the different discontinuities that occur in different types of welded joints. Discontinuities are related to the interruption of the typical or expected structure of a welded part or joint, related to the homogeneity of the physical, mechanical, or metallurgical characteristics associated with the material or weld [72]. Among the main structural discontinuities that can be explored in PDF-3D file design are excessive concavity (Figure 5a), excessive convexity (Figure 5b), angular deformation (Figure 5c), excessive penetration (Figure 5d), insufficient deposition (Figure 5e), misalignment (Figure 5f), undercutting (Figure 5g), and lack of penetration (Figure 5h). These types of discontinuities compromise the integrity, performance, competitiveness, and quality of the projects and components, being, therefore, necessary for the use of geometric representation systems, such as PDF-3D, that allow the three-dimensional representation of these defects and discontinuities that occur in the different types of welded joints and thus facilitate their spatial understanding to minimize or correct these distortions, improving the welding processes.

Figure 5.

Types of discontinuities: (a) excessive concavity; (b) excessive convexity; (c) angular deformation; (d) excessive penetration; (e) insufficient deposition; (f) misalignment; (g) undercutting; and (h) lack of penetration.

1.4. Research Objectives

The present research has sought to achieve the following objectives: (i) to analyze the didactic methodology preferences—master class or virtual tools—that the participating students have; (ii) to assess the relevance that the students attribute to the use of the virtual tool PDF-3D in the development of the subject “Geometry of welded joints” in which it has been applied; (iii) analyze the assessments that the participating students attribute to PDF-3D as a didactic tool in general; and (iv) to identify if the importance that the students give, within the subject, to the topic that has been developed or if their preferences in terms of didactic methodology have a significant influence on the evaluations expressed about the PDF-3D virtual tool.

2. Materials and Methods

2.1. Participants

The study involved 50 students (7 women and 43 men) from 4 different groups (9 students in group A, 17 in group B, 22 in group C, 2 in group D) of an introductory welding course at the Instituto Tecnológico Santa Rosa de Cabal, in Colombia. The participating students were chosen through a non-probabilistic convenience sampling process, the only inclusion criteria being: (i) the fact of being students enrolled in the welding program; and (ii) participating in the proposed training activity with PDF-3D. The topic “Geometry of Welded Joints” was developed with the participants through the virtual tool PDF-3D, within the aforementioned program. Subsequently, the participating students answered a survey to evaluate the methodology used voluntarily, freely, and anonymously. The entire population of students to whom the survey was sent responded to it, and all the responses were validated.

2.2. Variables, Hypotheses, and Data Collection

To achieve the research objectives, the following variables were defined:

- Assessment of the importance of working on the topic “Geometry of welded joints” within the degree program. This is an ordinal quantitative variable measured on a Likert scale from 1 to 10, where 1 corresponds to no importance and 10 corresponds to maximum importance;

- Preferred methodology. It is a trichotomous nominal variable whose possible values are: (i) master class; (ii) virtual labs; and (iii) mixed methodology—in this regard, although strictly speaking the master class is compatible with the use of virtual tools, by the expression “master class” the authors refer to the master class that employs a traditional methodology, as opposed to the use of virtual tools. This was made clear to the students prior to their participation;

- Importance of the use of the virtual tool PDF-3D for the development of the topic “Geometry of welded joints”. It is a polytomous variable that can reach the following values: (i) null (the participant would use only the master class); (ii) would combine it with the master class, with a greater presence of the virtual tool; (iii) would combine it with the master class with a more significant presence of the master class; (iv) absolute (would eliminate the master class). To enrich the statistical analysis, this variable has been quantified by attributing the quantities 1 to 4, respectively, to each of the described values of the variable.

- Assessment of the PDF-3D virtual tool. This variable includes the following sub-variables, all of them ordinal quantitative, which will be measured on Likert scales from 1 to 10: (i) employability—assessment of the qualities and aptitudes of PDF-3D to be used as a didactic resource in lectures–; (ii) interactivity—PDF-3D’s ability to receive and respond to user feedback–; (iii) motivation—PDF-3D’s ability to encourage and incentivize study, making it more appealing–; (iv) facility of use—assessment of how easy it is to use PDF-3D to perform prescribed tasks–; (v) didactic usefulness –assessment of the effectiveness of PDF-3D as a resource for achieving subject-specific learning objectives–; (vi) realism—assessment of the similarity between the model illustrated by the PDF-3D and the real object–; and (vii) design—assessment of the technical capabilities of PDF-3D to adapt to the different situations required according to the objects to be illustrated–. The participating students received an explanation of the specific meaning of all the above categories prior to completing the questionnaire, in order to clarify the concepts and elicit homogeneous knowledge of them.

This work corroborates the following hypotheses: (i) the students’ assessment of the different aspects of the PDF-3D tool studied is high; (ii) the assessment of the importance of the subject treated has a positive influence on the assessment of the PDF-3D tool used; (iii) the methodology preferred by the students does not influence the assessment of the virtual tool.

A survey designed by the authors for the purposes of the present research was used. The survey consisted of 6 questions (Table 1) and was answered voluntarily, freely, and anonymously by the participating students. Data collection was conducted in April 2022.

Table 1.

Questions in the survey with their corresponding possible values and the variable they measure.

2.3. Analysis of Responses

The main descriptive statistics of the responses to the quantitative questions were computed (mean, standard deviation and coefficient of variation, skewness, and kurtosis), and the degree of dependence between them was analyzed employing the correlation test (bilateral contrast), computed with Spearman’s coefficient. This coefficient was chosen because all the quantitative variables considered are ordinal and, unlike Pearson’s coefficient, Spearman’s coefficient is sensitive to any dependence between variables, not only to linear dependence. With respect to the nominal questions, a descriptive analysis of the proportions of the responses was performed. The Lilliefors normality test showed that the answers to the quantitative questions were not normally distributed. Due to this lack of normality and the small sample size, the Kruskal–Wallis nonparametric test was chosen to study whether there are significant differences between the mean ratings of the PDF-3D virtual tool according to the methodology—master class, virtual labs, or mixed methodology—preferred by the students. As a precondition for the application of the Kruskal–Wallis test, Bartlett’s test was used to ensure that homoscedasticity in the distributions could be assumed. Likewise, to check whether the degree of importance given by the participants to the use of the virtual tool in the classroom influences their evaluations of it, Spearman’s correlation test was used. All hypothesis contrast tests were carried out at the 0.05 significance level. The last question of the questionnaire, a free-response question, was analyzed qualitatively, by a mere description of the frequencies of the different responses, made by a single rater.

3. Results

The participants give an average rating of 8.14 out of 10 to the topic “Geometry of Welded Joints”, with a coefficient of variation of 17.38% (corresponding to a standard deviation of 1.41 out of 10). Pearson’s skewness coefficient is −0.80, which proves that the distribution of the responses in this respect is slightly asymmetric, with negative skewness, and leptokurtic, because the coefficient of kurtosis is 0.70.

The rating scale of the PDF-3D virtual tool has a high level of internal consistency (Cronbach’s alpha = 0.8960). The main descriptive statistics of this scale are shown in Table 2. All the analyzed dimensions of the virtual tool obtain intermediate-high ratings, with its usability in the classroom being the most highly rated dimension and also the one with the smallest deviation from the mean (almost 7%, compared to the rest of the coefficients of variation, which range from 33% to 40%). Interactivity is the one that receives the lowest average evaluation. The distributions of all the variables are negatively asymmetric because the Pearson asymmetry coefficient is negative. The highest negative skewness is found in the distribution of employability ratings. Likewise, all the distributions are slightly platykurtic, except that of employability, which is leptokurtic. Finally, the Lilliefors test statistics do not allow us to assume that the responses are normally distributed for the aspects assessed (Table 2).

Table 2.

Descriptive statistics and Lilliefors normality test of the valuations given to the different aspects of the PDF-3D virtual tool.

The correlation tests—with bilateral contrast—carried out using Spearman’s coefficient (Table 3) show that there is a positive, slight but significant dependence between the didactic relevance attributed by the students to the subject treated in class and their evaluation of the different aspects of the virtual tool except for its usability and the realism dimension–. Likewise, all the aspects of the virtual tool that were evaluated have a positive influence with moderate-high intensity on the rest, except the employability dimension, which does not have a significant influence on any other dimension.

Table 3.

Spearman correlation coefficients between the distributions of answers to quantitative questions.

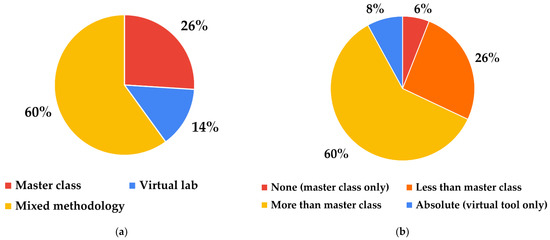

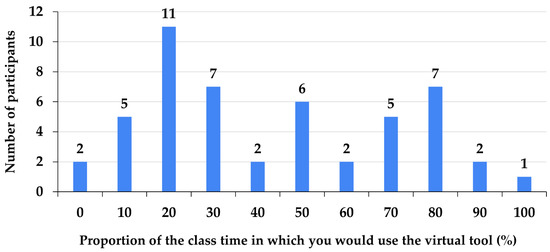

When asked about the methodology preferred by the students (Figure 6), 13 of them chose the master class (26% of the participants), only 7 chose virtual laboratories (14%), and 30 preferred a mixed methodology of master classes and virtual laboratories (60%). There are 43 participants (86% of the total) who understand that the specific topic that has been worked on in the classes should be taught by combining the master class with the use of the virtual tool (Figure 6). Of these, 30 would give more importance to the virtual tool (60% of the total), and 13 give more importance to the master class (26%). A total of 4 students (8%) would use only the virtual tool, and only 3 participants (6%) would use only the master class. Figure 7 shows that 54% of the participants would use the virtual tool less than half of the class time, but only 4% of the students would not use the tool at all.

Figure 6.

Proportions of participants according to: (a) the didactic methodology they prefer; and (b) the presence they would give to PDF-3D in the classroom.

Figure 7.

Percentage of class time that participants would use PDF-3D.

The correlation test with bilateral contrast was carried out using Spearman’s coefficient between the variable that measures the prominence that should be given to the virtual tool in the explanation of the topic “Geometry of Welded Joints” and the assessments of the different aspects of the PDF-3D tool. Previously, the variable on the prominence of the virtual tool has been quantified according to the increasing order of the intensity of its presence: (1): elimination of the use of PDF-3D in the subject studied; (2): lesser presence than the master class; (3): more significant presence than the master class; and (4): absolute presence, eliminating the master class), since the variable measures an intensity that can be expressed in terms of ordinal quantities. However, none of the tests results in significant correlations. Therefore, it cannot be assumed that the ratings of the virtual tool depend on the frequency with which students would use it in the classroom.

Bartlett’s test with 2 degrees of freedom shows that the ratings of the different aspects of the PDF-3D virtual tool are distributed with homoscedasticity when differentiated by the methodology—master class, virtual labs, or mixed methodology—preferred by the participants (Table 4). The Kruskal–Wallis test with 2 degrees of freedom does not identify significant differences in the mean ratings of the virtual tool when the participants are distinguished by the methodology chosen (Table 4).

Table 4.

Bartlett’s test statistics for comparison of variances and Kruskal–Wallis test statistics for comparison of means of the distributions of the responses to the quantitative questions when differentiated by the methodology preferred by the participants.

The last open-ended question helps to clarify the reasons why students think that the use of virtual resources in the explanation of the subject is more or less effective than the master class. The most frequent reasons of those who support that it is more effective are the following: (i) they help to understand abstract aspects, mainly geometric, that are not clear in the master class; (ii) they make the subject more fun or entertaining; (iii) they are interactive resources; (iv) they make the class more interesting; and (v) they allow easier and faster access to the information. The most frequent reasons given by those who do not believe that virtual resources are more effective than the master class are the following: (i) the master class is better understood; (ii) the use of the virtual tool consumes more of the student’s autonomous work time than the master class; and (iii) the virtual tool has distracting elements. Consequently, the students identify, above all, the effectiveness of the virtual tool in terms of graphic expression of geometric concepts and the motivation that its use arouses as the main didactics of PDF-3D. In this regard, the high ratings given by the participants to PDF-3D both in general (question 2) and on the particular topic of welded joint geometry (question 4) suggest that the effectiveness of the tool is not limited only to the topic addressed in this research. However, the demand that this tool poses at the level of autonomous work of the student is seen by many participants as a limitation because they identify as disadvantages the time consumed by its use and the distracting danger that it includes.

4. Discussion

The participating students have given very positive assessments of the different aspects of the PDF-3D tool used in the classroom, mainly its usability as a teaching resource, technical aspects, such as the design, and didactic characteristics such as the motivation it arouses or the ease of use (Table 2). All this implies that students perceive this tool as useful for facilitating understanding of the subject and increasing their learning in this regard. This observation is in line with work that has shown that 3D models are effective in achieving learning in areas of knowledge that deal with complex or abstract concepts [16,38,50] or that require spatial visualization [25,51]. The works that have been published describing experiences of the PDF-3D application are somehow linked to the teaching of some geometry subject or involve geometric aspects for whose learning it is required to develop a certain level of spatial reasoning [16,38,39,40,41,42].

In this work, the results of applying the PDF-3D virtual tool to a geometric content topic in engineering have been presented, so that the high ratings obtained by this tool in its didactic dimensions are in line with previous works [7,35,38,52]. However, it has also been shown that the importance given by the students to the topic being dealt with in the subject has a positive influence on their assessment of the virtual tool when it is applied to that topic (Table 3). This fact suggests that the high ratings expressed do not derive solely from the geometric nature of the content being worked on, but from the fact that the students perceive that topic as important, which is likely to make them engage more intensely with the didactic tool.

The positive appreciations regarding the digital tool are based on the multiple technical advantages of using PDF-3D, not only for teaching but also for welding fieldwork, e.g., changing the appearance of objects, sectioning, rotating, and enlarging them [26]. Furthermore, other advantages of PDF-3D are the accessibility and wide diffusion that it can achieve, thus making this tool one of the most versatile academic technologies currently available and widely accepted by students [27,28,29]. It is time to standardize that visualizing 3D models is more manageable than interpreting 2D information [24]. This is because those who read and interpret the drawings are not the same as those who design them and generally have a different academic level and, for this reason, it is essential to facilitate the tasks through a visual “language” that can be understood by all those involved in academic or manufacturing processes [55,56,57]. The benefits of this format invite us to extend its use to other topics of an academic program in welding such as, for example, discontinuities and defects present in welded joints, pores, lack of penetration, lack of fusion, imperfect shape and dimensions, cracks, cavities, miscellaneous imperfections, service defects, among others, which are aspects that should and can be analyzed through their three-dimensional schematization and presented for their understanding in common PDF documents [57,58,59]. Additionally, with PDF-3D it becomes possible to analyze the different types of cracks that can be generated in welded joints, such as those generated in the heat-affected zone [73] (HAZ), at the bead edges—caused by inclusions [74] and gas porosity [75] –, lamellar tearing [76]—caused mainly by sulfur inclusions [77], excess of hydrogen [78,79], and the amount of stress [80] –, solidification cracking [81,82], fatigue cracks [73,83], among others.

However, the welding course students participating in the study found limitations to using PDF-3D in their classes. Among them, they perceive it as a distracting element and understand that it requires more work than the master class. Furthermore, as far as it has been possible to explore, the limitations that the agents involved in the educational process have pointed out to this virtual tool referred to technical aspects, such as the difficulty in achieving an adequate resolution for the graphic representations [41]. The identification, therefore, of limitations of an academic nature perceived by students in this digital resource is a novel and original contribution of this study.

In addition, it has been shown that the ratings that students give to the PDF-3D tool do not depend significantly on whether they prefer a more traditional or virtual methodology or on the degree of prominence that they would give to this didactic resource in the exposition of the subject (Table 4). This fact suggests that, potentially, the virtual tool will be well received by the students, which will facilitate the achievement of the learning objectives, regardless of the methodology to which the students are more accustomed or, in principle, prefer. This positive reception, suggested by the results obtained here, has already been verified in students from other fields, such as health sciences [27,28], who, moreover, recommend the use of this tool to their peers [29].

It is proposed as a future line of research to carry out an analogous intervention with a larger sample of students, to corroborate, if necessary, the results obtained here and to obtain more easily generalizable conclusions. The application of the PDF-3D tool in other subjects of the student’s curriculum would also allow us to analyze the influence that the specific subject has on the student’s assessment of the virtual tool. It would also be useful to identify differences in the opinions expressed by students according to certain sociological characteristics, such as gender or nationality, or academic characteristics, such as the fact of being a first-year student or a senior student. All of this requires applying the virtual tool to a larger sample, distributed homogeneously between males and females and, where appropriate, made up of students coming from different centers or countries. Finally, it would be interesting to compare the academic results of the students in the experimental group with those of the students in a control group in which a traditional methodology is applied, as has been done previously in the health sciences [49]. In this way, the level of adequacy of the favorable opinions of the students with the academic effects of its application in a technical education context can be verified.

5. Conclusions

Throughout the article, the assessment made by a group of students about the didactic use of the PDF-3D tool to work on spatial thinking in a course on welded joint geometry has been analyzed. For this purpose, a questionnaire designed by the authors has been used, and whose answers have been analyzed.

Students give very high ratings to the virtual tool PDF-3D as a resource for learning the topic “Geometry of Welded Joints”. Moreover, this high rating is mainly due to the positive opinions that the students have about the motivation towards learning caused by the use of PDF-3D and the ease of its use. Likewise, the interest shown by the students in the specific topic that has been worked on in the classroom conditions the assessments they give to the use of the virtual tool. The identification of the reasons that support these high valuations is the first element of novelty of the present research. On the other hand, most of the students prefer a mixed methodology, combining the master class with the use of virtual tools, but with a greater prominence of the latter. However, the preference for one or the other methodology does not significantly condition the evaluation of PDF-3D tools. Consequently, a certain independence of the assessment of PDF-3D with respect to the methodology generally preferred by the students has been identified, which constitutes a new element of novelty of the present research.

Based on the opinions and preferences expressed by the students, it is recommended that technical education teachers introduce the PDF-3D tool into the different subjects whose contents involve geometric concepts and spatial vision. Likewise, it is suggested that schools introduce training sessions for technical education teachers on the design of teaching resources using PDF-3D because such training will probably help teachers to learn about the tool and choose to include it in their lessons.

Author Contributions

Conceptualization, L.M.A.-E. and E.A.A.-E.; methodology, L.M.A.-E. and E.A.A.-E.; validation, Á.A.-S. and D.V.; formal analysis, Á.A.-S. and D.V.; investigation, L.M.A.-E. and E.A.A.-E.; resources, L.M.A.-E. and E.A.A.-E.; data curation, Á.A.-S. and D.V.; writing—original draft preparation, Á.A.-S., E.A.A.-E. and D.V.; writing—review and editing, L.M.A.-E., Á.A.-S., E.A.A.-E. and D.V.; supervision, L.M.A.-E., Á.A.-S., E.A.A.-E. and D.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board of Instituto Tecnológico Santa Rosa de Cabal—ITESARC (protocol code 2022-03 and date of approval 20 October 2022).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fauzi, M.A. E-learning in higher education institutions during COVID-19 pandemic: Current and future trends through bibliometric analysis. Heliyon 2022, 8, e09433. [Google Scholar] [CrossRef] [PubMed]

- Alsubaie, M.A. Distance education and the social literacy of elementary school students during the COVID-19 pandemic. Heliyon 2022, 8, e09811. [Google Scholar] [CrossRef] [PubMed]

- Benty, D.D.N.; Kusumaningrum, D.E.; Santoso, F.B.; Prayoga, A.G.; Ubaidillah, E.; Rochmawati; Wardani, A.D. Use of Information and Communication Technology in learning in the COVID-19 pandemic period to improve student learning outcomes. In Proceedings of the 6th International Conference on Education and Technology (ICET 2020); Malang, Indonesia, 17 October 2020, Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020; pp. 165–169. [Google Scholar] [CrossRef]

- He, W.; Zhang, Z.; Li, W. Information technology solutions, challenges, and suggestions for tackling the COVID-19 pandemic. Int. J. Inf. Manag. 2021, 57, 102287. [Google Scholar] [CrossRef] [PubMed]

- Extremera, J.; Vergara, D.; Dávila, L.P.; Rubio, M.P. Virtual and augmented reality environments to learn the fundamentals of crystallography. Crystals 2020, 10, 456. [Google Scholar] [CrossRef]

- Torres, F.; Tovar, L.A.N.; Del-Rio, M.S. A learning evaluation for an immersive virtual laboratory for technical training applied into a welding workshop. Eurasia J. Math. Sci. Technol. Educ. 2017, 13, 521–532. [Google Scholar] [CrossRef]

- Angela, S.; Sergiu, D.; Petru, V. Three-dimensional models’ usage in courses placed on moodle platform. In Proceedings of the 2017 International Conference on Electromechanical and Power Systems (SIELMEN), Iasi, Romania, 11–13 October 2017; pp. 347–352. [Google Scholar] [CrossRef]

- Vergara, D. Introduction of virtual laboratories in the education of the XXI century. Rev. Eduweb 2019, 13, 119–128. [Google Scholar]

- Vergara, D.; Rubio, M.P.; Lorenzo, M. Interactive virtual platform for simulating a concrete compression test. Key Eng. Mater. 2013, 572, 582–585. [Google Scholar] [CrossRef]

- Vergara, D.; Rubio, M.P.; Lorenzo, M. A virtual resource for enhancing the spatial comprehension of crystal lattices. Educ. Sci. 2018, 8, 153. [Google Scholar] [CrossRef]

- Vergara, D.; Rubio, M.P.; Extremera, J.; Lorenzo, M. Interdisciplinary learning methodology for supporting the teaching of industrial radiology through technical drawing. Appl. Sci. 2021, 11, 5634. [Google Scholar] [CrossRef]

- Vergara, D.; Antón-Sancho, A.; Dávila, L.P.; Fernández-Arias, P. Virtual reality as a didactic resource from the perspective of engineering teachers. Comput. Appl. Eng. Educ. 2022, 30, 1086–1101. [Google Scholar] [CrossRef]

- Antón-Sancho, Á.; Vergara, D.; Fernández-Arias, P.; Ariza-Echeverri, E.A. Didactic use of virtual reality in Colombian universities: Professors’ perspective. Multimodal Technol. Interact. 2022, 6, 38. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D print of polymer bonded rare-earth magnets, and 3D magnetic field scanning with an end-user 3D printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Alhamad, I.M.; Ahmed, W.K.; Ali, H.Z.; AlJassmi, H. 3D printing applications in mechanical engineering education. In Integrating 3D Printing into Teaching and Learning: Practitioners’ Perspectives; Ali, N., Khine, M.S., Eds.; Contemporary Approaches to Research in Learning Innovations; Koninklijke Brill NV: Leiden, The Netherlands, 2020; Volume 13, pp. 90–131. [Google Scholar] [CrossRef]

- Rubio, M.P.; Vergara-Rodríguez, D. PDF-3D as educational technology. Rev. Eduweb 2018, 12, 205–213. Available online: https://revistaeduweb.org/index.php/eduweb/article/view/59 (accessed on 25 July 2022).

- Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Uttal, D.H.; Miller, D.I.; Newcombe, N.S. Exploring and enhancing spatial thinking: Links to achievement in science, technology, engineering, and mathematics. Curr. Dir. Psychol. Sci. 2013, 22, 367–373. [Google Scholar] [CrossRef]

- Keyvanfar, A.; Shafaghat, A. Emerging dimensions of unmanned aerial vehicle (UAV) technology’s 3D reconstruction modeling and photogrammetry in architecture and construction management. ACE 2022, 16, 10492. [Google Scholar] [CrossRef]

- Vergara, D.; Rubio, M.P. The application of didactic virtual tools in the instruction of industrial radiography. J. Mater. Educ. 2015, 37, 17–26. [Google Scholar]

- Hsi, S.; Linn, M.C.; Bell, J.E. The role of spatial reasoning in engineering and the design of spatial instruction. J. Eng. Educ. 1997, 86, 151–158. [Google Scholar] [CrossRef]

- Crown, S.W. Improving visualization skills of engineering graphics students using simple JavaScript web based games. J. Eng. Educ. 2001, 90, 347–355. [Google Scholar] [CrossRef]

- Liu, T.; Bao, J.; Zheng, H.; Wang, J.L.; Yang, C.Q.; Gu, J. Learning semantic-specific visual representation for laser welding penetration status recognition. Sci. China Technol. Sci. 2022, 65, 347–360. [Google Scholar] [CrossRef]

- Vergara, D.; Rubio, M.P.; Lorenzo, M. On the use of PDF-3D to overcome spatial visualization difficulties linked with ternary phase diagrams. Educ. Sci. 2019, 9, 67. [Google Scholar] [CrossRef]

- Kotarska-Lewandowska, B. Visualization of spatial issues in Adobe Acrobat PDF 3D. J. Pol. Soc. Geom. Eng. Graph. 2014, 26, 27–32. Available online: http://ogigi.polsl.pl/biuletyny/zeszyt_26/Biuletyn-26-27-32.pdf (accessed on 25 July 2022).

- Ruthensteiner, B.; Heß, M. Embedding 3D models of biological specimens in PDF publications. Microsc. Res. Technol. 2008, 71, 778–786. [Google Scholar] [CrossRef] [PubMed]

- Newe, A.; Becker, L.; Schenk, A. Application and evaluation of interactive 3D PDF for presenting and sharing planning results for liver surgery in clinical routine. PLoS ONE 2014, 9, e115697. [Google Scholar] [CrossRef]

- Karsenty, C.; Guitarte, A.; Dulac, Y.; Briot, J.; Hascoet, S.; Vincent, R.; Delepaul, D.; Vignaud, P.; Djeddai, C.; Hadeed, K.; et al. The usefulness of 3D printed heart models for medical student education in congenital heart disease. BMC Med. Educ. 2021, 21, 480. [Google Scholar] [CrossRef]

- Drapkin, Z.A.; Lindgren, K.A.; Lopez, M.J.; Stabio, M.E. Development and assessment of a new 3D neuroanatomy teaching tool for MRI training. Anat. Sci. Educ. 2015, 8, 502–509. [Google Scholar] [CrossRef]

- Van-de-Kamp, T.; Dos-Santos-Rolo, T.; Vagovič, P.; Baumbach, T.; Riedel, A. Three-dimensional reconstructions come to life—Interactive 3D PDF animations in functional morphology. PLoS ONE 2014, 9, e102355. [Google Scholar] [CrossRef]

- Tabernero-Rico, R.D.; Juanes-Méndez, J.A.; Prats-Galino, A.; Pozo-González, S.F. Taking advantage of 3D technology in health sciences: 3D PDF. In Proceedings of the Seventh International Conference on Technological Ecosystems for Enhancing Multiculturality (TEEM’19), León, Spain, 16–18 October 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 321–325. [Google Scholar] [CrossRef]

- Mavar-Haramija, M.; Prats-Galino, A.; Méndez, J.A.J.; Puigdelívoll-Sánchez, A.; Notaris, M.D. Interactive 3D-PDF presentations for the simulation and quantification of extended endoscopic endonasal surgical approaches. J. Med. Syst. 2015, 39, 127. [Google Scholar] [CrossRef]

- Erolin, C. Interactive 3D digital models for anatomy and medical education. Adv. Exp. Med. Biol. 2019, 1138, 1–16. [Google Scholar] [CrossRef]

- Chekrouni, N.; Kleipool, R.P.; de Bakker, B.S. The impact of using three-dimensional digital models of human embryos in the biomedical curriculum. Ann. Anat. 2020, 227, 151430. [Google Scholar] [CrossRef]

- Rosen, D.; Nesic, O. A novel approach to design 3D models in medical education. Med. Sci. Educ. 2021, 31, 317–318. [Google Scholar] [CrossRef] [PubMed]

- Tabernero-Rico, R.D.; Pozo-González, S.; Prats-Galino, A. Mangement of a 3D visualization program from radiological images in neuroradiology. In Technological Adoption and Trends in Health Sciences Teaching, Learning, and Practice; Marcos-Pablos, S., Juanes-Méndez, J., Eds.; IGI Global: Hershey, PA, USA; pp. 215–244. [CrossRef]

- Thiriet, P.; Batier, C.; Rastello, O.; Sylvestre, E.; Van-Reeth, N.; Guillot, A.; Collet, C.; El-Hoyek, N. 3D human anatomy learning—Demonstration of 3D tools used in teaching: 3D videos, podcasts, PDF. In Proceedings of the 3rd International Conference on Computer Supported Education, Noordwijkerhout, The Netherlands, 6–8 May 2011; Volume 1, pp. 408–411. [Google Scholar] [CrossRef][Green Version]

- Newe, A.; Ganslandt, T. Simplified generation of biomedical 3D surface model data for embedding into 3D portable document format (PDF). Files for publication and education. PLoS ONE 2013, 8, e79004. [Google Scholar] [CrossRef] [PubMed]

- Grussenmeyer, P.; Landes, T.; Alby, E.; Carozza, L. High resolution 3D recordng and modelling on the Bronze Age cave “les Fraux” in Perigord (France). In Proceedings of the Conference ISPRS Commission V Symposium, Nexcastle, UK, 14–20 June 2020; pp. 262–267. Available online: https://hal.archives-ouvertes.fr/hal-03099460 (accessed on 25 July 2022).

- Konsolaki, A.; Vassilakis, E.; Gouliotis, L.; Kontostavlos, G.; Giannopoulos, V. High resolution digital 3D modelling of subsurface morphological structures of Koutouki Cave, Greece. Acta Carsol. 2020, 49, 166–177. [Google Scholar] [CrossRef]

- Álvarez, A.; Javier, F.; Parra, B.; Beatriz, E.; Tubio, M.; Paula, F.D. From 2D to 3D: Teaching terrain representation in engineering studies through Augmented reality: Comparative versus 3D pdf. In Proceedings of the 2014 IEEE Frontiers in Education Conference (FIE), Madrid, Spain, 22–25 October 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Calcagno, P.; Trumpy, E.; Gutiérrez-Negrín, L.C.; Liotta, D. A collection of 3D geomodels of the Los Humeros and Acoculco geothermal systems (Mexico). Sci. Data 2022, 9, 280. [Google Scholar] [CrossRef]

- Petrov, S.; Merenkov, D.; Shirinskii, S.; Kryzhov, D.; Letyagina, M. Empowerment of LMS “Prometheus” for MPEI educational process. In Proceedings of the 2022 VI International Conference on Information Technologies in Engineering Education (Inforino), Moscow, Russia, 12–15 April 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Mas, P.; Calcagno, P.; Caritg-Monnot, S.; Beccaletto, L.; Capar, L.; Hamm, V. A 3D geomodel of the deep aquifers in the Orléans area of the southern Paris Basin (France). Sci. Data 2022, 9, 781. [Google Scholar] [CrossRef]

- Emmer, C.; Fröhlich, A.; Stjepandic, J. Advanced engineering visualization with standardized 3D formats. In Digital Product and Process Development Systems, Proceedings of the IFIP TC 5 International Conference, Dresden, Germany, 10–22 October 2013; Springer: Berlin/Heidelberg, Germany, 2013; pp. 286–295. [Google Scholar] [CrossRef]

- Diago-Ferrer, L.; Zubiaurre-Eizaguirre, V.; Tardio-Monreal, E. Active learning, improvement of spatial abilities and understanding of technical drawing in the graphic expression course. In Advances in Design Engineering, Proceedings of the XXIX International Congress INGEGRAF, Logroño, Spain, 20–21 June 2019; Springer: Berlin/Heidelberg, Germany, 2013; pp. 374–385. [Google Scholar] [CrossRef]

- Gómez-Tone, H.C. Impact of descriptive geometry’s teaching using 3d-pdf files as spatial skill training in civil engineering students in Peru. Form. Univ. 2019, 12, 73–82. [Google Scholar] [CrossRef][Green Version]

- Kuna, P.; Kozík, T.; Kunová, S.; Šebo, M. Software tools for creating and presenting virtual 3D models. In Teaching and Learning in a Digital World, Proceedings of the 20th International Conference on Interactive Collaborative Learning, Budapest, Hungary, 27–29 September 2018; Springer: Berlin/Heidelberg, Germany, 2018; Volume 2, pp. 17–26. [Google Scholar] [CrossRef]

- Miralbes-Buil, R.; Peña-Baquedano, J.A.; Paricio-Sánchez, J.M.; Ranz-Angulo, D. The model based definition features—MBD applied to the technical computer aid design and drawing. In Advances in Design Engineering; Cavas-Martínez, F., Sanz-Adan, F., Morer-Camo, P., Lostado Lorza, R., Santamaría-Peña, J., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2020; pp. 105–114. [Google Scholar] [CrossRef]

- Newe, A. Enriching scientific publications with interactive 3D PDF: An integrated toolbox for creating ready-to-publish figures. PeerJ. Comput. Sci. 2016, 2, e64. [Google Scholar] [CrossRef]

- Ruthensteiner, B.; Baeumlera, N.; Barnes, D.G. Interactive 3D volume rendering in biomedical publications. Micron 2010, 41, 886.e1–886.e17. [Google Scholar] [CrossRef]

- Menn, J.P.; Seliger, G. Increasing knowledge and skills for assembly processes through interactive 3D-PDFs. In Proceedings of the 23rd CIRP Conference on Life Cycle Engineering, Berlin, Germany, 22–24 May 2016; Elsevier: Amsterdam, The Netherlands, 2016; Volume 48, pp. 454–459. [Google Scholar] [CrossRef]

- Mavar-Haramija, M.; Prats-Galino, A.; Escuder, C.B.; Méndez, J.A.J.; Puigdelívoll-Sánchez, A. 3D PDF technology combined with Javascript functions enables the creation and visualization of interactive 3D presentations. In Proceedings of the First International Conference on Technological Ecosystems for Enhancing Multiculturality (TEEM ’13), Salamanca, Spain, 14–15 November 2013; pp. 67–72. [Google Scholar] [CrossRef]

- Loch, F.; Böck, S.; Vogel-Heuser, B. Teaching styles of virtual training systems for industrial applications—A review of the literature. Interact. Des. Archit. J. 2018, 38, 46–63. [Google Scholar] [CrossRef]

- Krampit, A.G.; Yu, N. A method for the determination of the geometrical dimensions and area of the welded joint. Weld. Int. 2013, 27, 834–836. [Google Scholar] [CrossRef]

- Martínez-Conesa, E.J.; Egea, J.A.; Miguel, V.; Toledo, C.; Meseguer-Valdenebro, J.L. Optimization of geometric parameters in a welded joint through response surface methodology. Constr. Build. Mater. 2017, 154, 105–114. [Google Scholar] [CrossRef]

- Hobbacher, A.F. The new IIW recommendations for fatigue assessment of welded joints and components—A comprehensive code recently updated. Int. J. Fatigue 2009, 31, 50–58. [Google Scholar] [CrossRef]

- Dong, P. A structural stress definition and numerical implementation for fatigue analysis of welded joints. Int. J. Fatigue 2001, 23, 865–876. [Google Scholar] [CrossRef]

- Taylor, D.; Barrett, N.; Lucano, G. Some new methods for predicting fatigue in welded joints. Int. J. Fatigue 2002, 24, 509–518. [Google Scholar] [CrossRef]

- Martikainen, J. Conditions for achieving high-quality welds in the plasma-arc keyhole welding of structural steels. J. Mater. Processing Technol. 1995, 52, 68–75. [Google Scholar] [CrossRef]

- Purzer, S.; Quintana-Cifuentes, J.; Menekse, M. The honeycomb of engineering framework: Philosophy of engineering guiding precollege engineering education. J. Eng. Educ. 2022, 111, 19–39. [Google Scholar] [CrossRef]

- Lie, J.; Jin, S.; Wang, C.; Xue, J.; Wang, X. Weld line recognition and path planning with spherical tank inspection robots. J. Fields Robot. 2022, 39, 131–152. [Google Scholar] [CrossRef]

- Prasad, L.; Kumar, A.; Jaiswal, R.; Kumar, A.; Kumar, V.; Yadav, A. Mechanical properties of AA6061T6 and AA6351T6 plates joined by friction stir welding. Mater. Sci. Eng. Technol. 2022, 53, 888–896. [Google Scholar] [CrossRef]

- Fande, A.W.; Taiwade, R.V.; Raut, L. Development of activated tungsten inert gas welding and its current status: A review. Mater. Manuf. Processes 2022, 37, 841–876. [Google Scholar] [CrossRef]

- Juang, S.C.; Tarng, Y.S. Process parameter selection for optimizing the weld pool geometry in the tungsten inert gas welding of stainless steel. J. Mater. Processing Technol. 2002, 122, 33–37. [Google Scholar] [CrossRef]

- Darji, R.; Badheka, V.; Mehta, K.; Joshi, J.; Yadav, A.; Chakraborty, A.K. Investigation on stability of weld morphology, microstructure of processed zones, and weld quality assessment for hot wire gas tungsten arc welding of electrolytic tough pitch copper. Mater. Manuf. Processes 2022, 37, 908–920. [Google Scholar] [CrossRef]

- Pathak, D.; Singh, R.P.; Gaur, S.; Balu, V. To study the influence of process parameters on weld bead geometry in shielded metal arc welding. Mater. Today Proc. 2021, 41, 39–44. [Google Scholar] [CrossRef]

- Tayier, W.; Janasekaran, S.; Vijayasree, V.P. Evaluation of heat input and bead geometry of zincalume steel (G550) welded joint between metal inert gas (MIG) and laser beam welding (LBW). Mater. Today Proc. 2022, 48, 895–904. [Google Scholar] [CrossRef]

- Shakya, P.; Singh, K.; Arya, H.K. Influence of magnets on arc shape and bead geometry in gas tungsten arc welding. Mater. Manuf. Processes 2022, 1–8. [Google Scholar] [CrossRef]

- Ren, T.; Mohammadijoo, M.; Wiskel, J.; Lazor, R.; Willett, E.; Ivey, D.G.; Henein, H. Effect of cold wire addition in tandem submerged arc welding on weld geometry and micro-hardness of heavy gauge X70 steel. Int. J. Adv. Manuf. Technol. 2022, 121, 7607–7625. [Google Scholar] [CrossRef]

- Lima, E.A.; Bertelli, F.; Días, A.P.C.; Santos, A.A. Aluminothermic welding modeling of heavy haul rails using the element birth and death technique. J. Therm. Stresses 2022, 45, 793–816. [Google Scholar] [CrossRef]

- Dwivedi, D.K. Design of welded joints: Weld failure modes, welding symbols: Type of welds, joints, welding position. In Fundamentals of Metal Joining; Dwivedi, D.K., Ed.; Springer: Singapore, 2022; pp. 327–342. [Google Scholar] [CrossRef]

- Liu, S.D.; Zhu, M.L.; Zhou, H.B.; Wan, D.; Xuan, F.Z. Strain visualization of growing short fatigue cracks in the heat-affected zone of a Ni–Cr–Mo–V steel welded joint: Intergranular cracking and crack closure. Int. J. Press. Vessel. Pip. 2019, 178, 103992. [Google Scholar] [CrossRef]

- Zhang, L.; Mostavi, A.; Basantes-Defaz, A.D.C.; Ozevin, D.; Indacochea, J.E. The measurement of weld morphology and inclusions using ultrasonics. Measurement 2019, 144, 33–43. [Google Scholar] [CrossRef]

- Ramírez-Luna, L.E.; Bracarense, A.Q.; Pessoa, E.C.P.; Costa, P.S.; Altamirano-Guerrero, G.; Salas-Reyes, A.E. Effect of the welding angle on the porosity of underwater wet welds performed in overhead position at different simulated depths. J. Mater. Processing Technol. 2021, 294, 117114. [Google Scholar] [CrossRef]

- Cai, G.; Culla, C.; Manfredi, E.; Tesi, B. The interaction between low cycle fatigue and lamellar tearing in AISI 316L welded joints. Int. J. Fatigue 1988, 10, 81–90. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, L.; Zhang, H. Crack propagation rate of hydrogen-induced cracking in high sulfur-containing pipelines. Eng. Fail. Anal. 2021, 123, 105271. [Google Scholar] [CrossRef]

- Park, H.; Park, C.; Lee, J.; Nam, H.; Moon, B.; Moon, Y.; Kang, N. Microstructural aspects of hydrogen stress cracking in seawater for low carbon steel welds produced by flux-cored arc welding. Mater. Sci. Eng. A 2021, 820, 141568. [Google Scholar] [CrossRef]

- Padhy, G.K.; Terasaki, H.; Komizo, Y.I. Hydrogen distribution and hydrogen cracking susceptibility of a martensitic-austenitic steel welding wire. Mater. Lett. 2014, 136, 22–25. [Google Scholar] [CrossRef]

- Pereira-Boschetti, H.; Ariza-Echeverri, E.; Diaz-Alves, L.; Goldenstein, H. Evaluation of the effect of heat input and cooling rate of rail flash-butt welding using finite element method simulation. Soldag. Insp. 2022, 27, 1–18. [Google Scholar] [CrossRef]

- Ramon, J.; Basu, R.; Voort, G.V.; Bolar, G. A comprehensive study on solidification (hot) cracking in austenitic stainless steel welds from a microstructural approach. Int. J. Press. Vessel. Pip. 2021, 194, 104560. [Google Scholar] [CrossRef]

- Pan, P.; Chen, S.; Zheng, J.; Xu, C.; Liu, F.; Li, Z. Welding solidification cracking susceptibility and behavior of nickel based ERNiMo-2 wire. Mater. Lett. 2022, 314, 131774. [Google Scholar] [CrossRef]

- Ronevich, J.A.; Song, E.J.; Feng, Z.; Wang, Y.; D’Elia, C.; Hill, M.R. Fatigue crack growth rates in high pressure hydrogen gas for multiple X100 pipeline welds accounting for crack location and residual stress. Eng. Fract. Mech. 2020, 228, 106846. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).