Wire Tool Electrode Behavior and Wear under Discharge Pulses

Abstract

1. Introduction

- 12kH18N10T (AISI321) chrome-nickel anti-corrosion structural steel that is often used in injection mold manufacturing;

- D16 (AA 2024) duralumin used for aviation purposes.

- Applying the vibroacoustic means for research on dependencies between the tool behavior and surface quality;

- Research of the tool and machined surface morphology and chemical composition;

- Classification of the observed defects and traces of tool destruction at roughing and finishing of two material types;

- Analyses of the chemical interactions between components that occurred in the discharge gap and conclusions on type material destruction and changes occurred at surface and subsurface layers.

2. Materials and Methods

2.1. Equipment

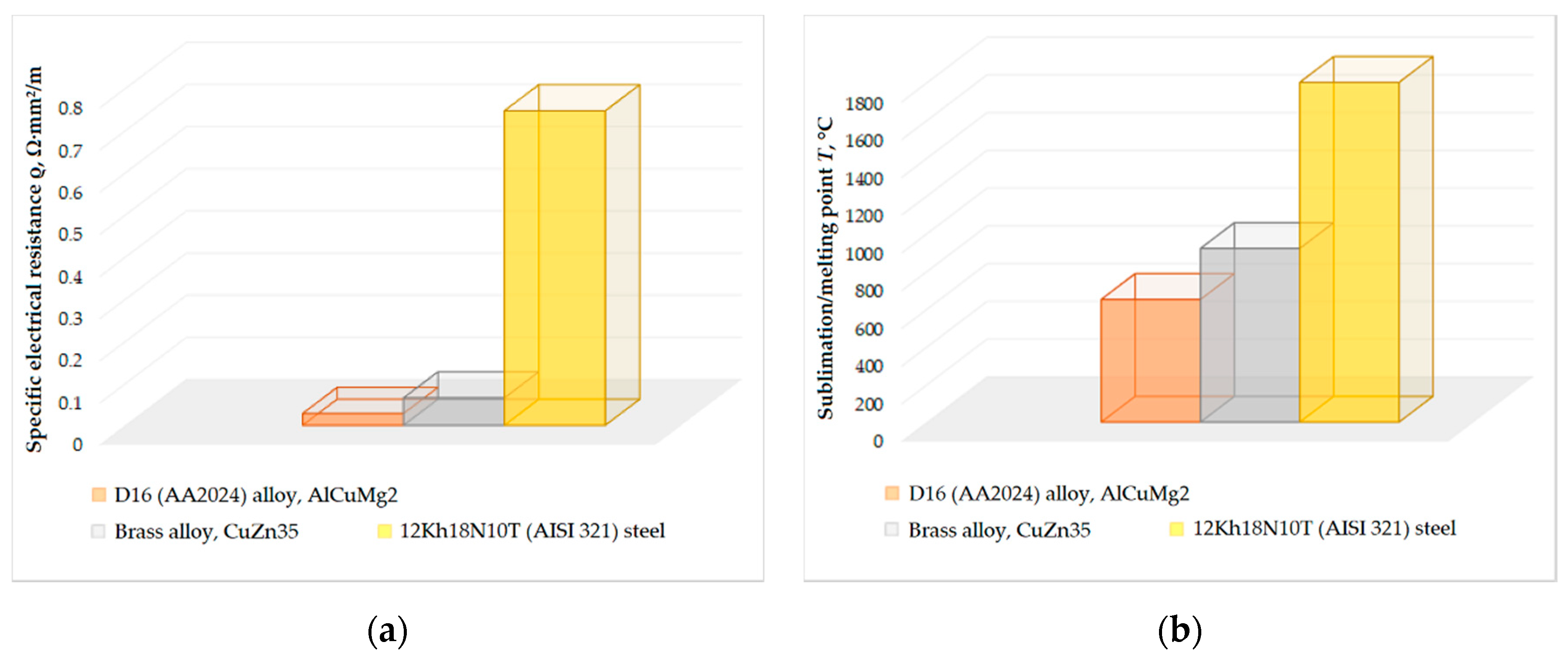

2.2. Materials

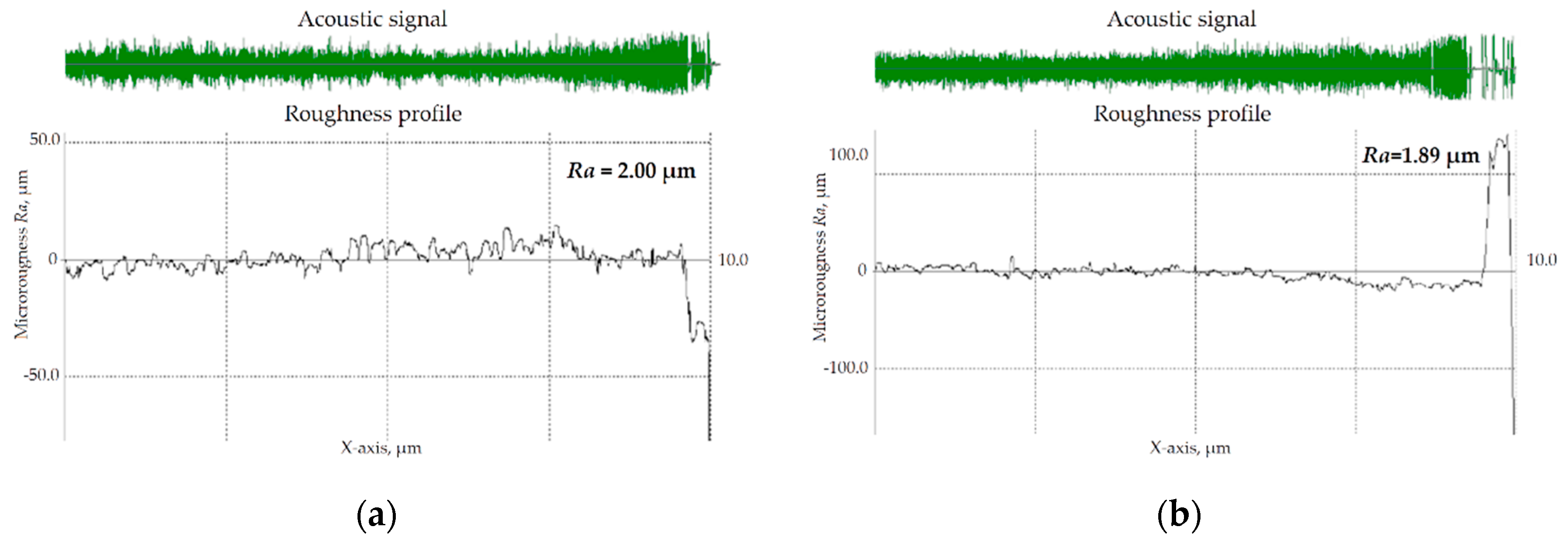

2.3. Monitoring

2.4. Physical Relationship of EDM Factors and Vibration Amplitude

2.5. Characterization of the Samples, Wear Rate, and Discharge Gap

3. Results

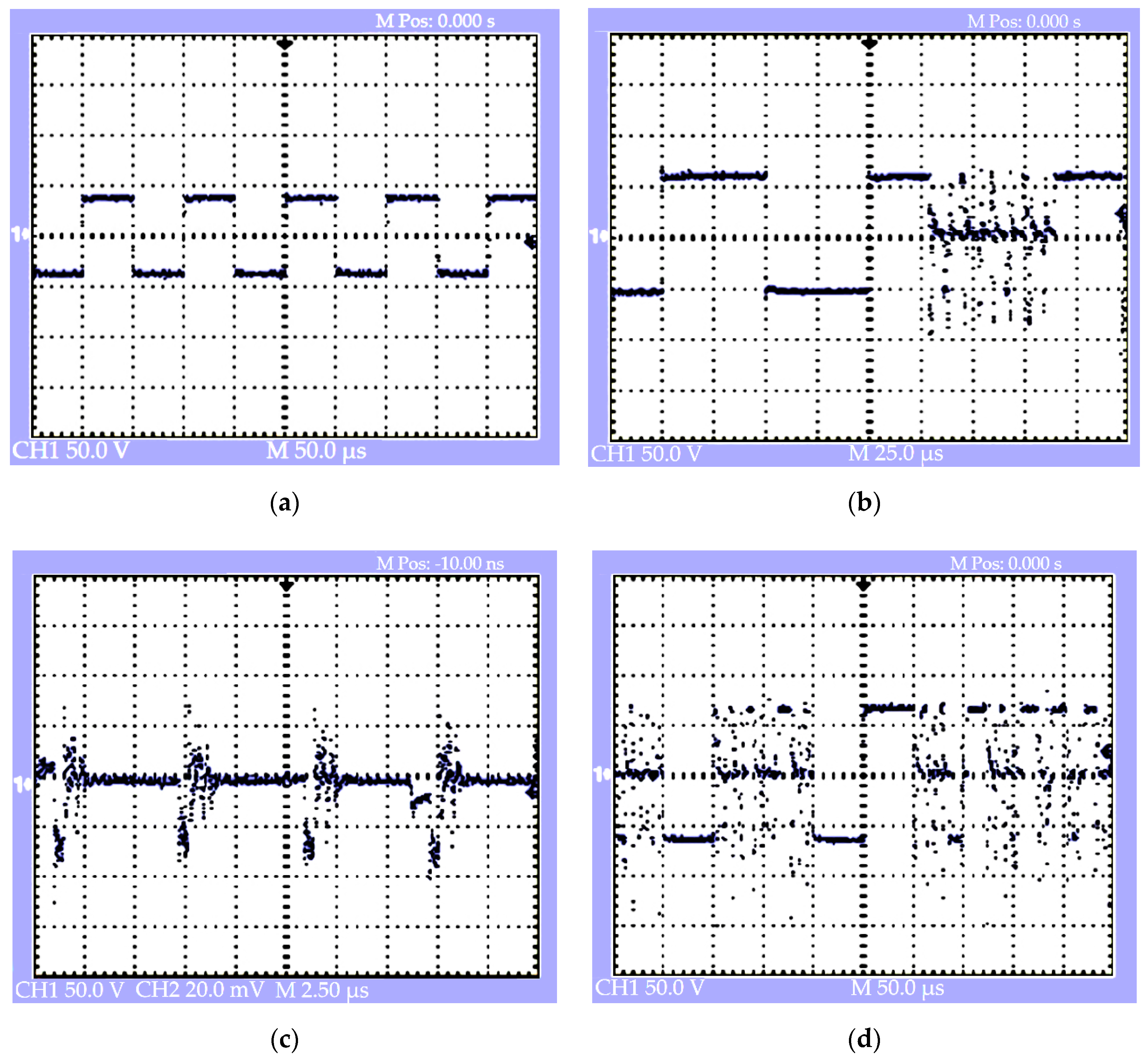

3.1. Electrical Discharge Pulses

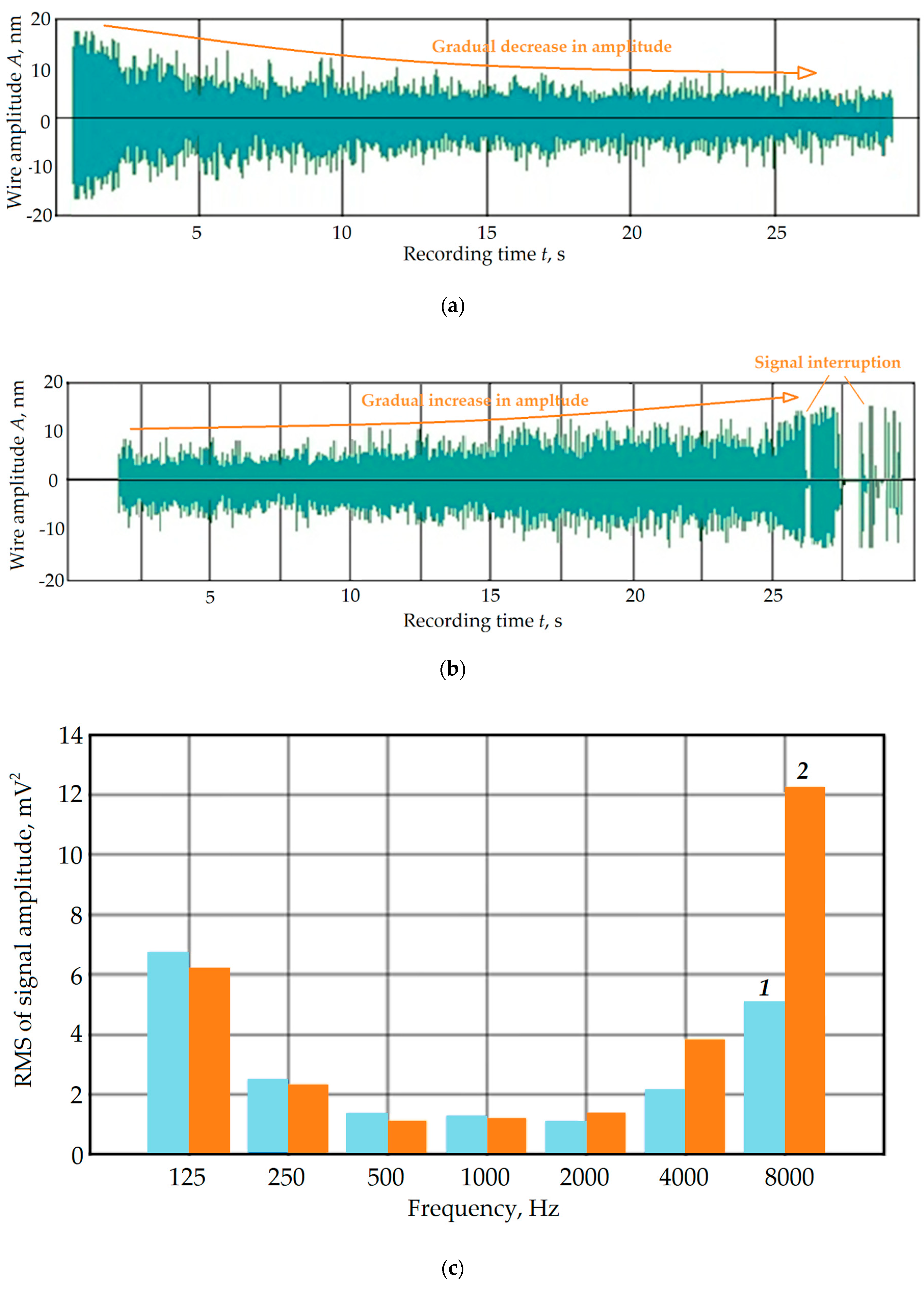

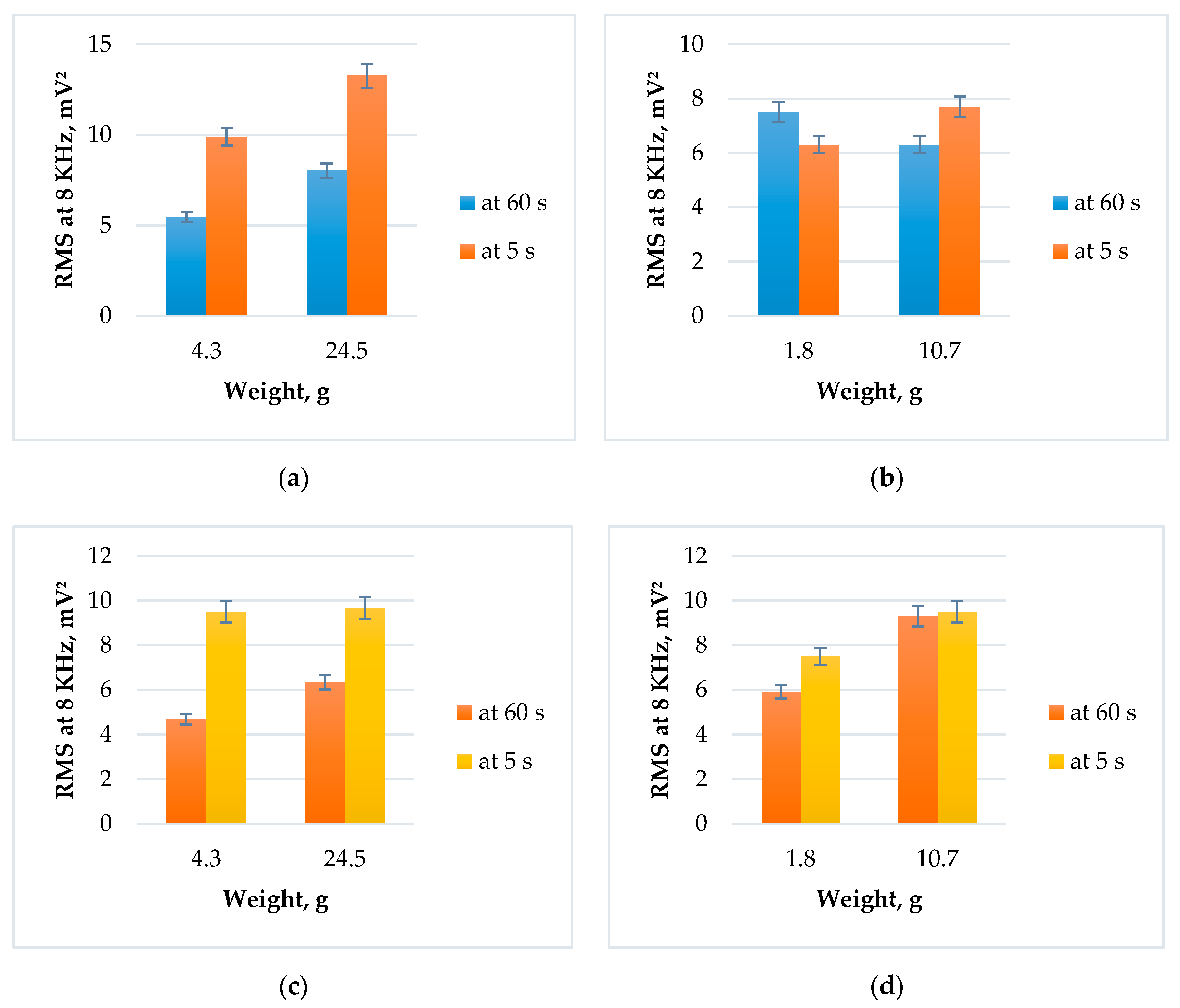

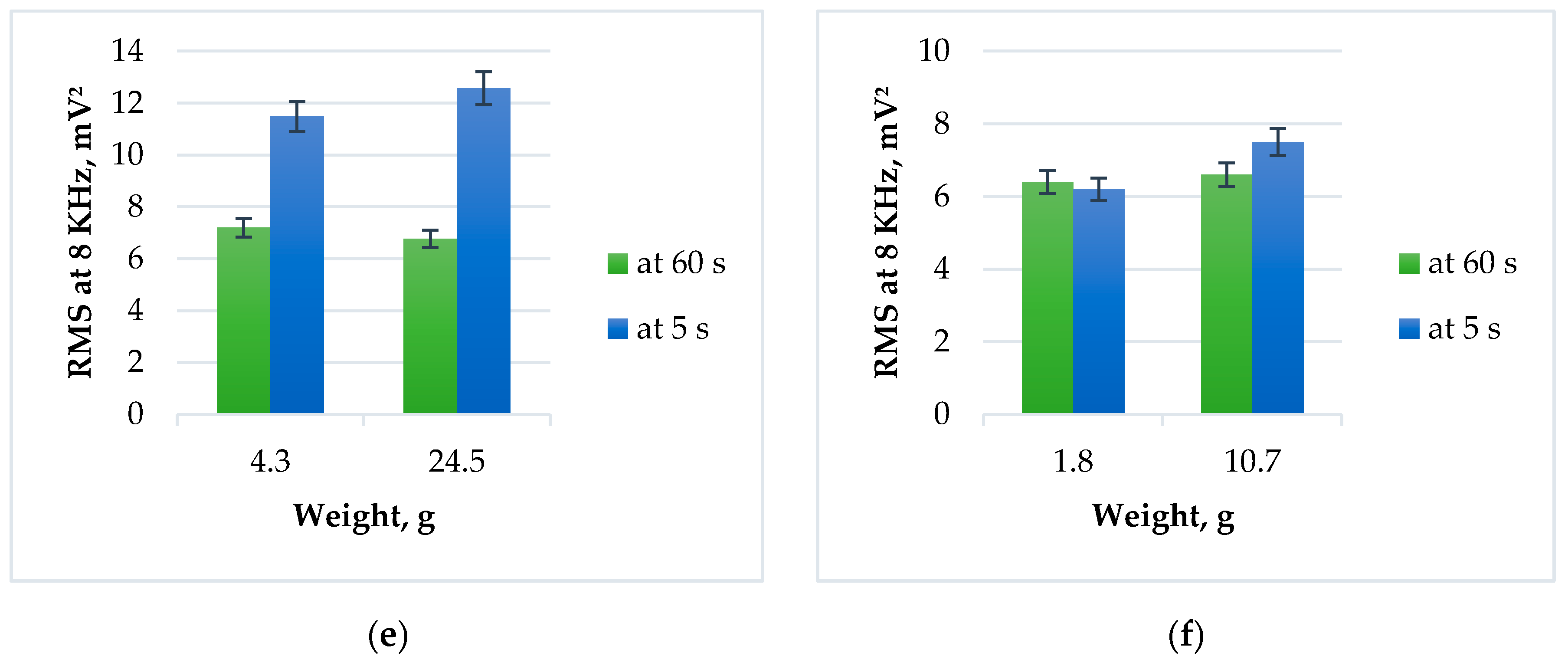

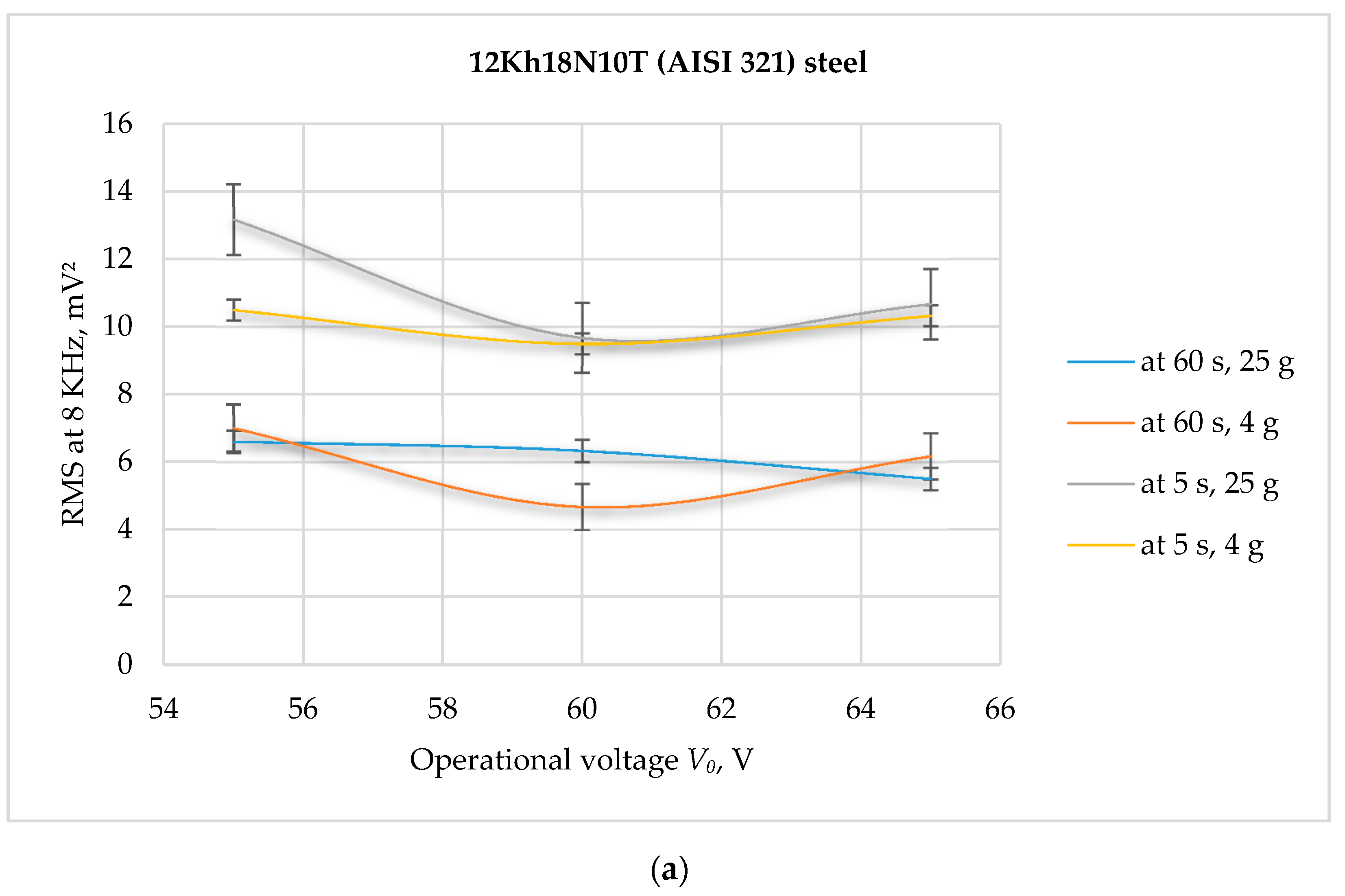

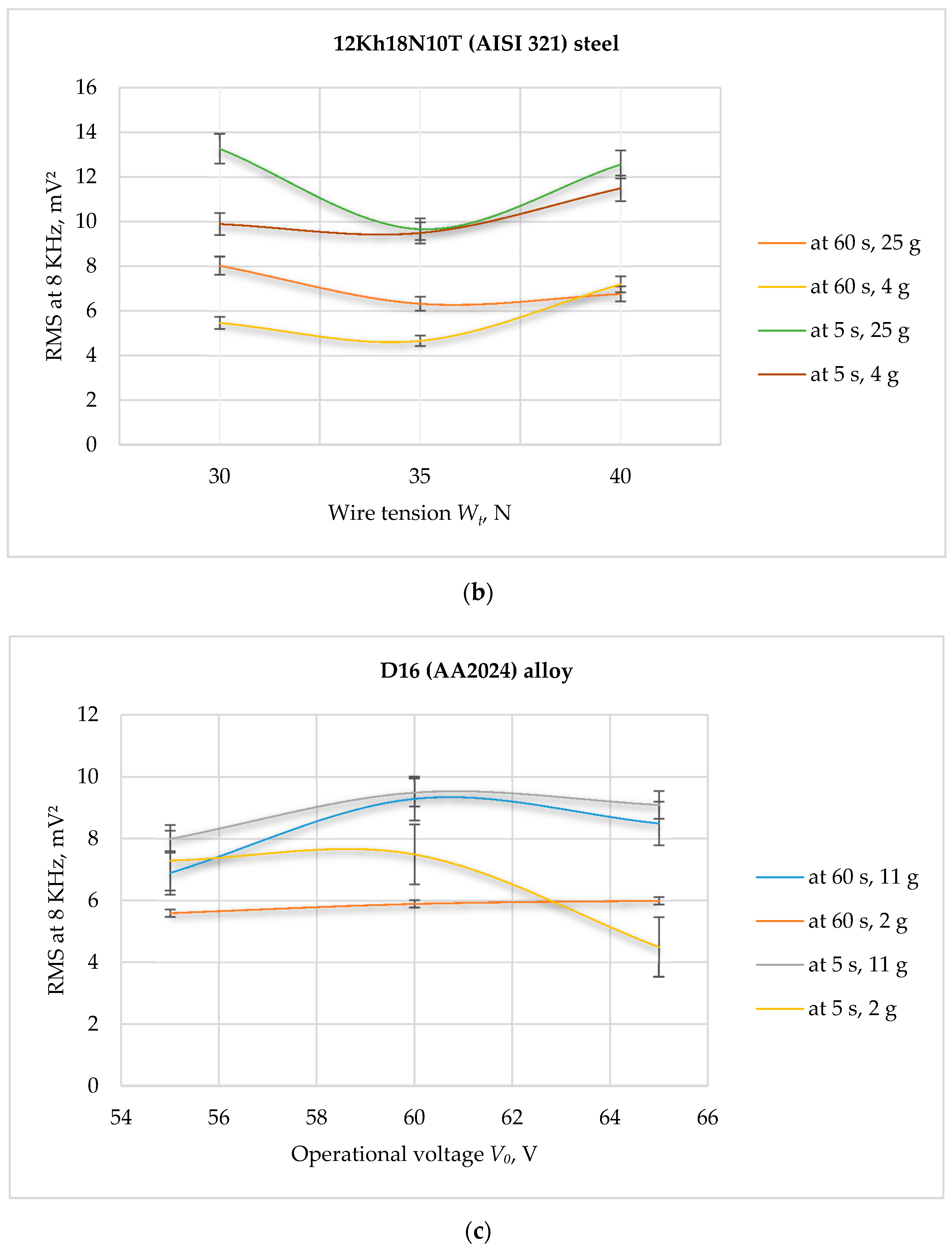

3.2. Wire Electrode Oscilations

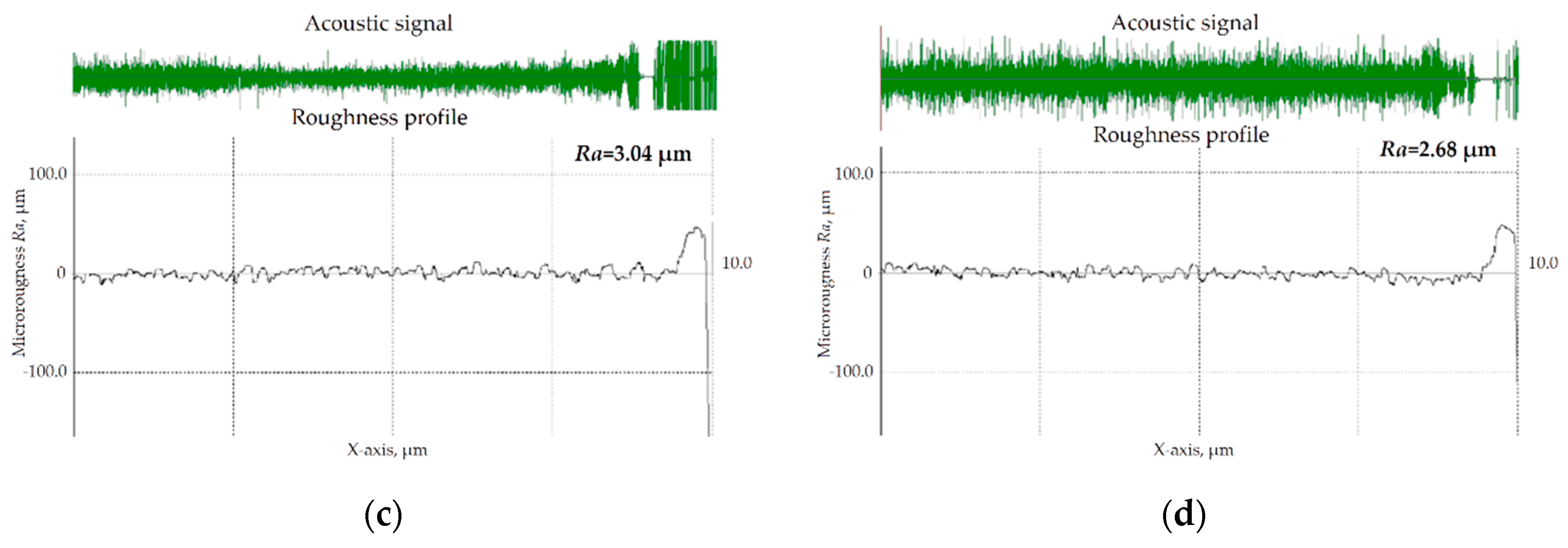

3.3. Morphology of the Samples

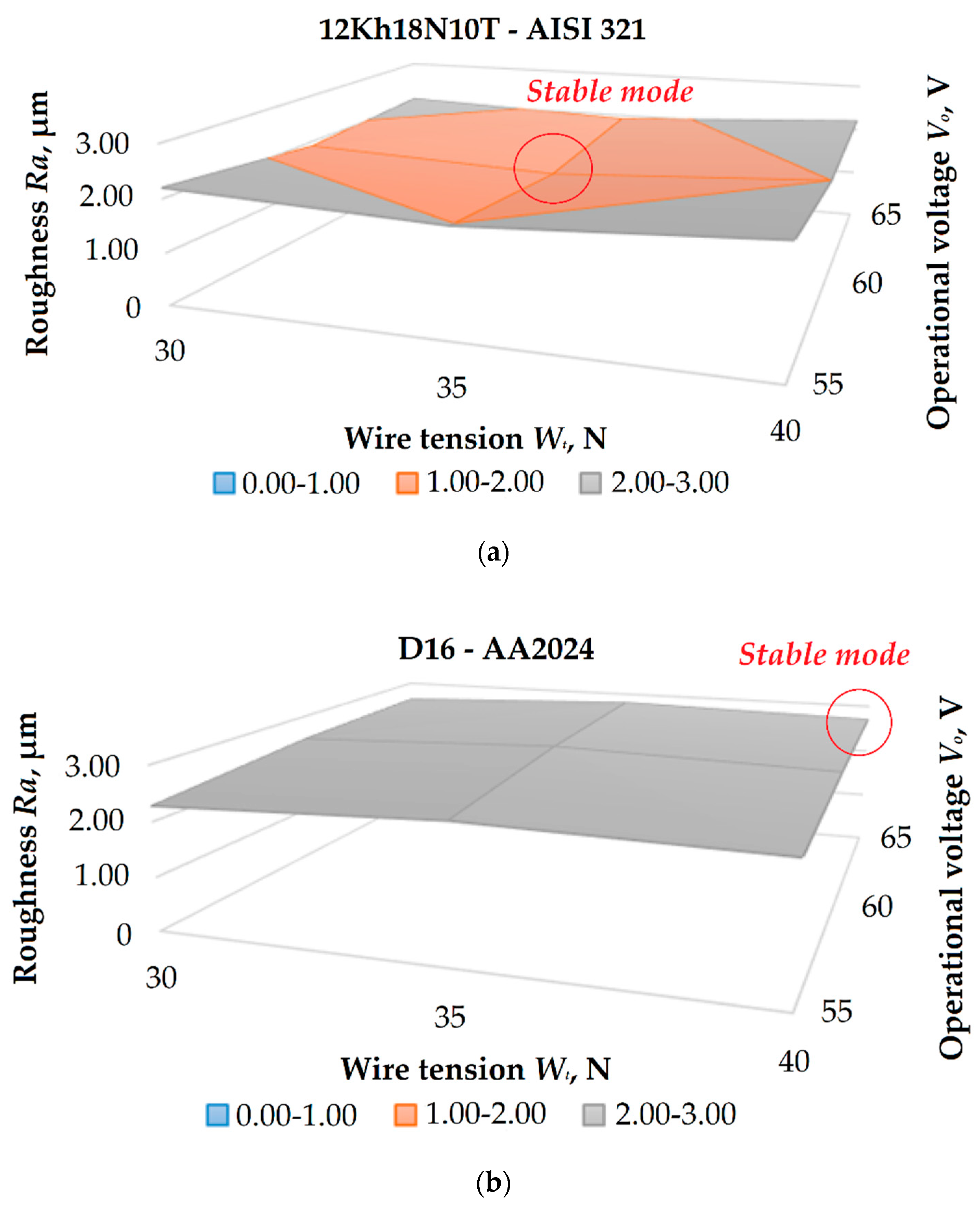

3.4. Discharge Gap

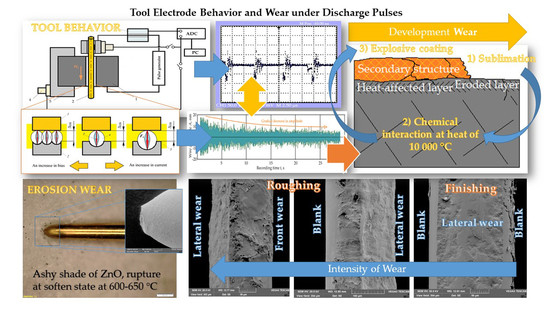

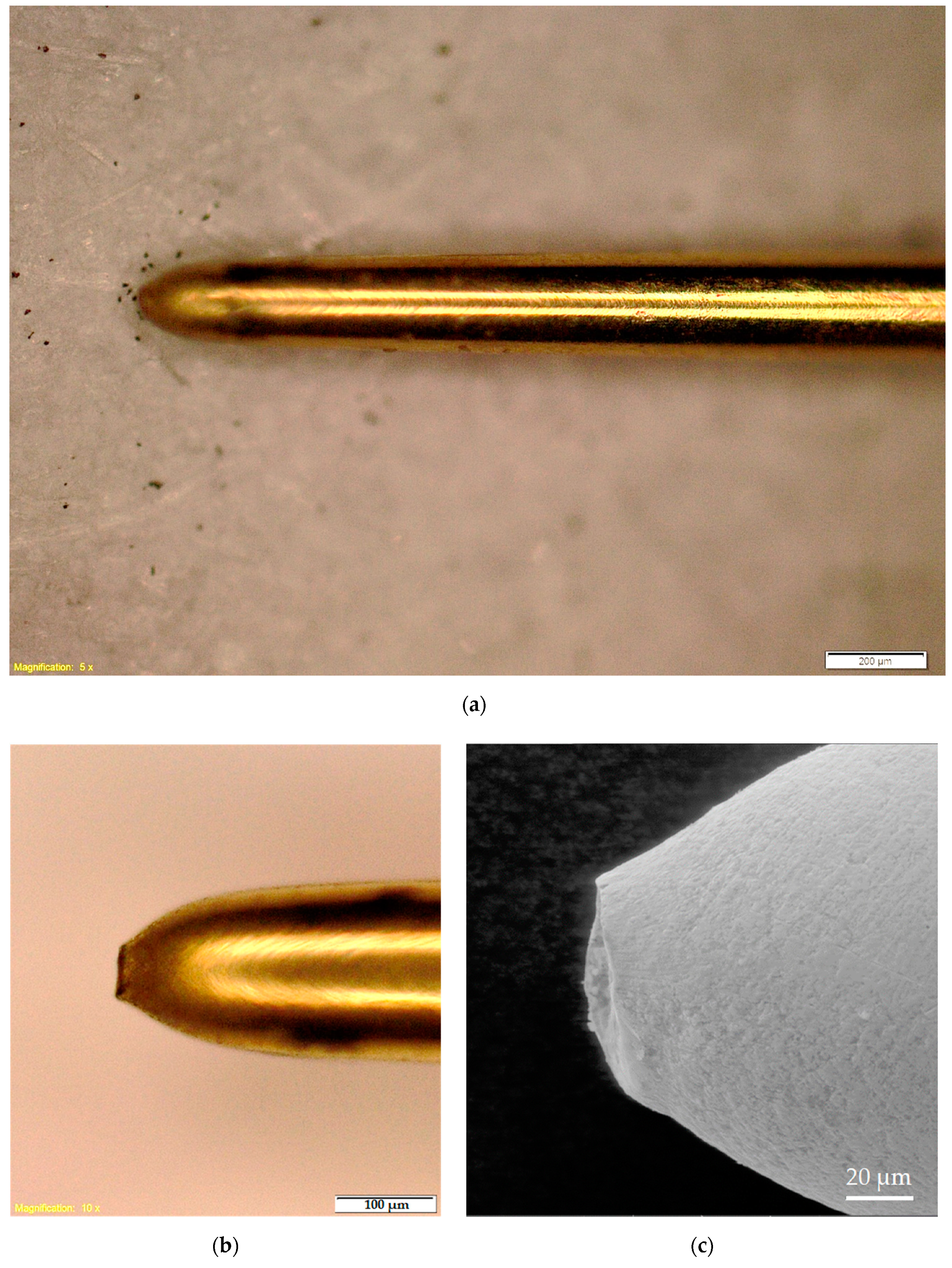

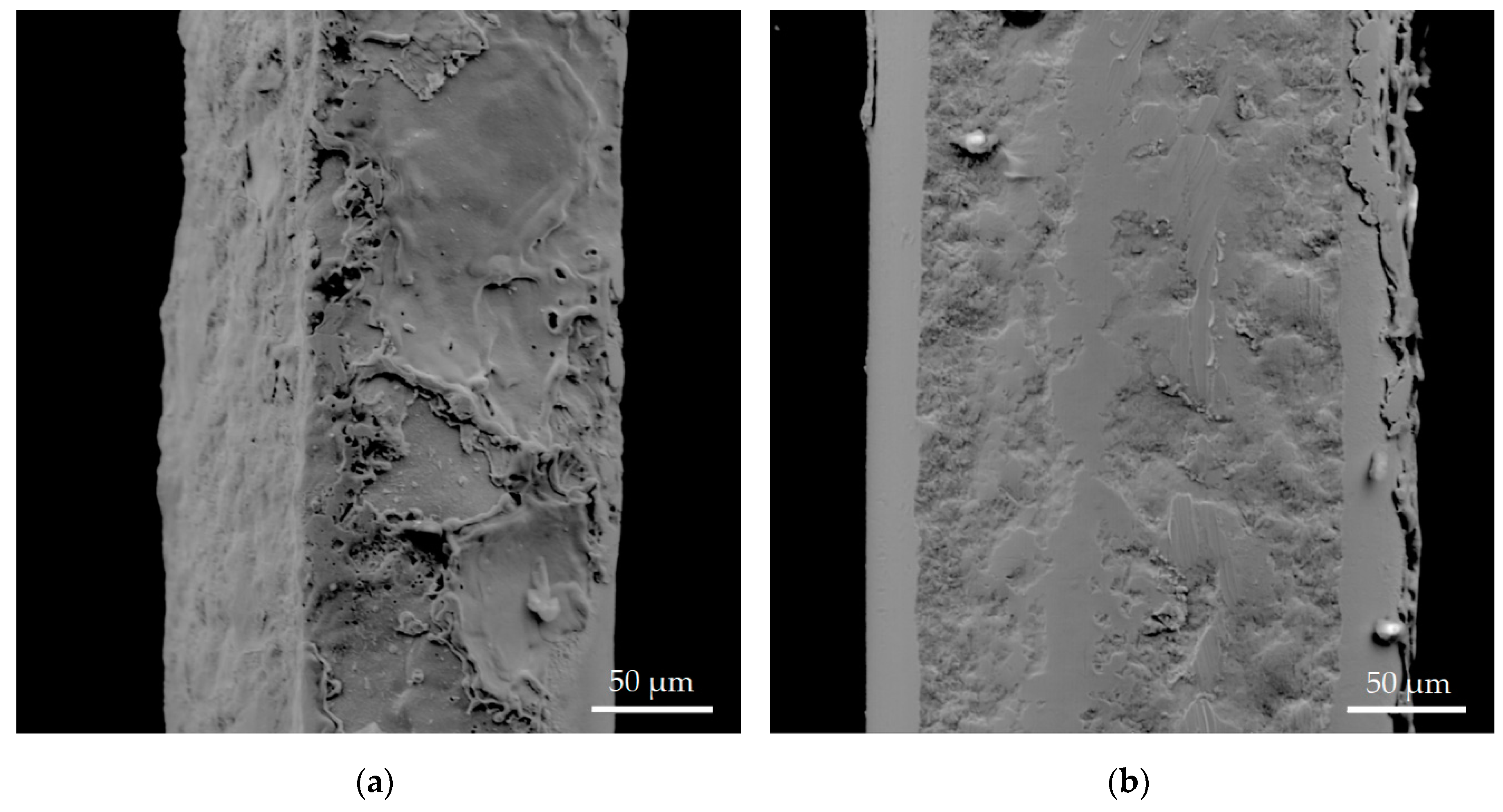

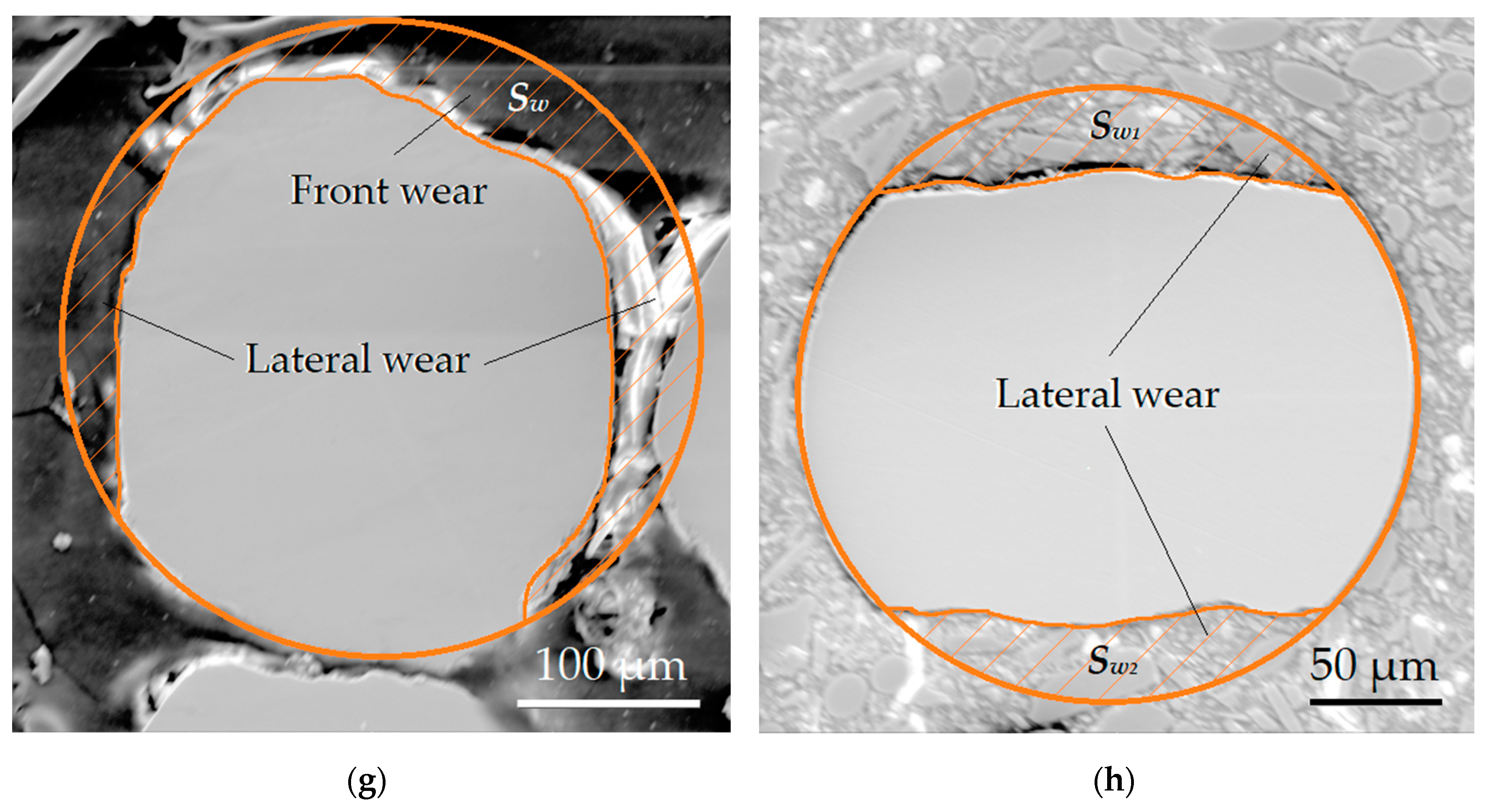

3.5. Tool Wear

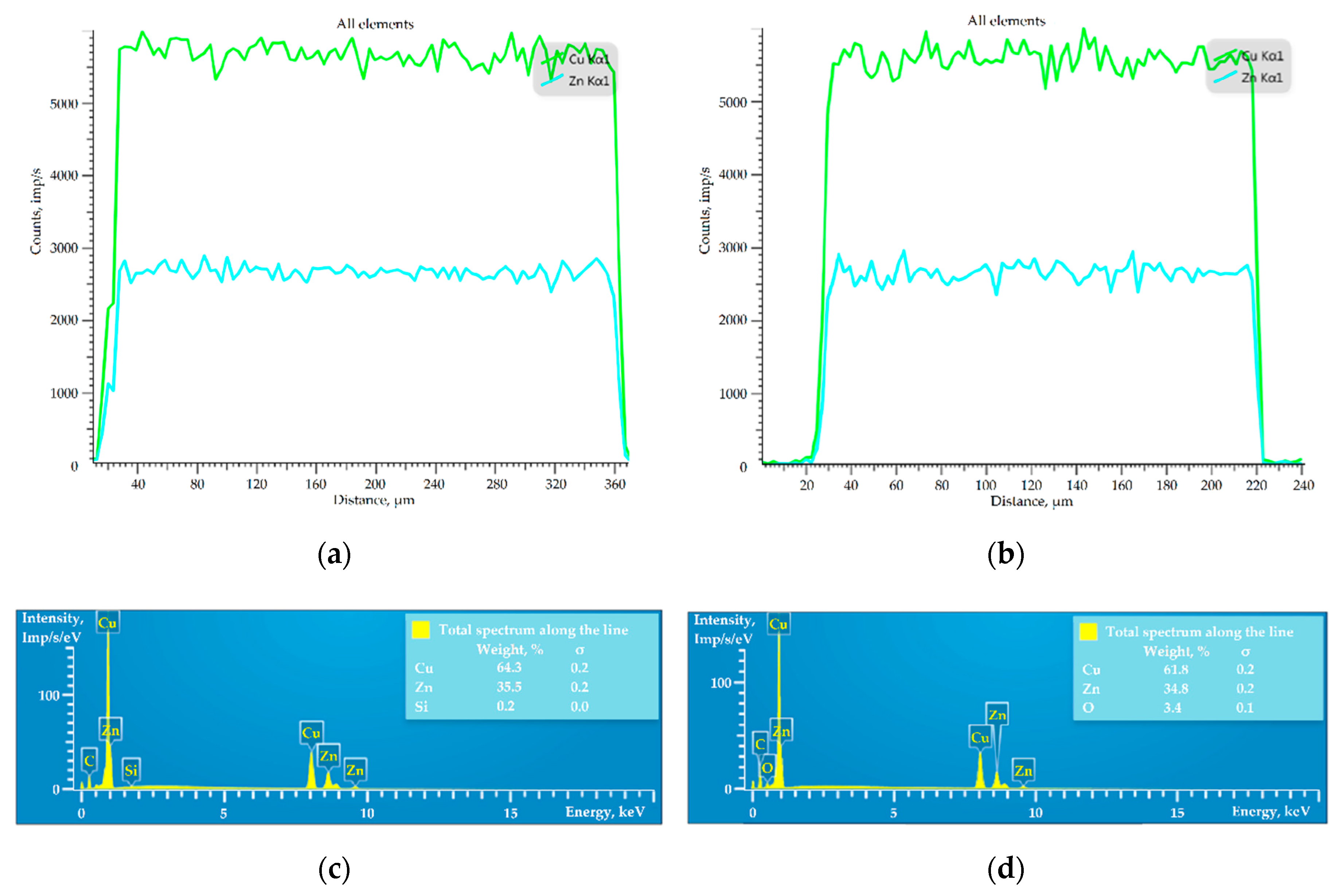

3.6. Chemical Content

4. Discussion

4.1. Discharge Pulses and Oscillations Control

4.2. Wire Breakage and Tool Wear

5. Conclusions

5.1. Monitoring System and Tool Behavior

5.2. Wire Tool Topology and Wear Rate

5.3. Further Procpects amd Paractical Significance of the Work

- -

- Sublimation of the electrode surfaces under discharge;

- -

- Chemical interaction of the sublimated electrode components in the presence of high heat;

- -

- Explosive deposition of the formed secondary structure of first and second order material;

- -

- Re-sublimation of the secondary structure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description | Unit |

| Vo | Operational voltage | V |

| Wt | Wire tension | N |

| I | Strength of the working current | A |

| f | Frequency of discharge pulses | s−1 |

| Δ | Distance between electrodes | µm |

| ΔDB | Effective discharge gap | µm |

| Δ*DB | Offset of the path | µm |

| dw | Wire diameter | mm |

| rw | Wire radius | mm |

| SRA | Reduction area | mm2 |

| S0 | Original transverse area | mm2 |

| Smin | Minimal area of the final neck | mm2 |

| Sw | Circle segment area | mm2 |

| α | Segment angle | degree |

| An | Wire amplitude of nth vibration, n is a positive integer (1, 2, 3, ...) | mm |

| An’ | Registered signal amplitude | mV |

| RMS | Root-mean-square mean of signal amplitude | mV2 |

| ΣFimp | Summarized force of working impulses | N |

| ΣEimp | Summarized energy of working impulses | J |

| kn | Stiffness (coefficient of elasticity) | N·mm−1 |

| mn | Mass of system | g |

| ln | Wire length | mm |

| Δl | Change in the wire length | mm |

| T | Period of self-oscillations | s |

| Fe | Restoring force (opposite and equal to Wt) | N |

| E | Young’s modulus | Pa |

| Rv | Volumetric wear rates | mm3·s−1 |

| Rm | Mass wear rates | g·s−1 |

| ΔV | Volumetric wear | mm3 |

| Δm | Worn mass | g |

| t | Wire length wear time | s |

| ls | Slot width | mm |

References

- Faisal, N.; Kumar, K. Optimization of Machine Process Parameters in EDM for EN 31 Using Evolutionary Optimization Techniques. Technologies 2018, 6, 54. [Google Scholar] [CrossRef]

- Wu, Y.-Y.; Huang, T.-W.; Sheu, D.-Y. Desktop Micro-EDM System for High-Aspect Ratio Micro-Hole Drilling in Tungsten Cemented Carbide by Cut-Side Micro-Tool. Micromachines 2020, 11, 675. [Google Scholar] [CrossRef] [PubMed]

- Borchers, F.; Clausen, B.; Eckert, S.; Ehle, L.; Epp, J.; Harst, S.; Hettig, M.; Klink, A.; Kohls, E.; Meyer, H.; et al. Comparison of Different Manufacturing Processes of AISI 4140 Steel with Regard to Surface Modification and Its Influencing Depth. Metals 2020, 10, 895. [Google Scholar] [CrossRef]

- Tran, T.-H.; Nguyen, M.-C.; Luu, A.-T.; Do, T.-V.; Le, T.-Q.; Vu, T.-T.; Tran, N.-G.; Do, T.-T.; Vu, N.-P. Electrical Discharge Machining with SiC Powder-Mixed Dielectric: An Effective Application in the Machining Process of Hardened 90CrSi Steel. Machines 2020, 8, 36. [Google Scholar] [CrossRef]

- Chai, H.; Phung, B.; Mitchell, S. Application of UHF Sensors in Power System Equipment for Partial Discharge Detection: A Review. Sensors 2019, 19, 1029. [Google Scholar] [CrossRef] [PubMed]

- Porvatov, A.N.; Kozochkin, M.P.; Fedorov, S.V.; Okunkova, A.A. About possibility of vibroacoustic diagnostics of electrical discharge machining and characterization of defects. Mech. Ind. 2015, 16, 707. [Google Scholar] [CrossRef][Green Version]

- Gu, L.; Zhu, Y.; Zhang, F.; Farhadi, A.; Zhao, W.S. Mechanism analysation and parameter optimisation of electro discharge machining of titanium-zirconium-molybdenum alloy. J. Manuf. Process. 2018, 32, 773–781. [Google Scholar] [CrossRef]

- Scherjau, D.; Meyer, G.; Rosc, J.; Mai, T.; Gschirr, A.; Wimmer, A. Erosion processes of electrodes—Experiments and modeling. Wear 2019, 428, 85–92. [Google Scholar] [CrossRef]

- Singh, M.A.; Sarma, D.K.; Hanzel, O.; Sedlacek, J.; Sajgalik, P. Surface characteristics and erosion phenomena in WEDM of alumina composites. Mater. Manuf. Process. 2018, 33, 1815–1821. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, S.; Zhang, Z.; Hao, H.; Wenyuan, L.; Guojun, Z.; Yu, H. Simulation and experimental investigations of complex thermal deformation behavior of wire electrical discharge machining of the thin-walled component of Inconel 718. J. Mater. Process. Technol. 2019, 270, 306–322. [Google Scholar] [CrossRef]

- Roy, T.; Balasubramaniam, R. Influence of ion-rich plasma discharge channel on unusually high discharging points in reverse micro electrical discharge machining. Int. J. Adv. Manuf. Technol. 2020, 106, 4467–4475. [Google Scholar] [CrossRef]

- Yu, Z.; Li, D.; Yang, J.; Zeng, Z.J.; Yang, X.L.; Li, J.Z. Fabrication of micro punching mold for micro complex shape part by micro EDM. Int. J. Adv. Manuf. Technol. 2019, 100, 743–749. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Xu, J.; Wang, Y.K.; Li, J.W.; Liu, H.Z. Sustainable production of micro gears combining micro reciprocated wire electrical discharge machining and precision forging. J. Clean. Prod. 2018, 188, 1–11. [Google Scholar] [CrossRef]

- Korznikova, G.F.; Nazarov, K.S.; Khisamov, R.K.H.; Sergeev, S.N.; Shayachmetov, R.U.; Khalikova, G.R.; Baimova, J.A.; Glezer, A.M.; Mulyukov, R.R. Intermetallic growth kinetics and microstructure evolution in Al-Cu-Al metal-matrix composite processed by high pressure torsion. Mater. Lett. 2019, 253, 412–415. [Google Scholar] [CrossRef]

- Liu, M.; Jin, Y.; Pan, J.; Leygraf, C. Co-Adsorption of H2O, OH, and Cl on Aluminum and Intermetallic Surfaces and Its Effects on the Work Function Studied by DFT Calculations. Molecules 2019, 24, 4284. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Srivastava, C. Microstructural Evolution and Corrosion Behavior of ZnNi-Graphene Oxide Composite Coatings. Metall. Mater. Trans. A 2019, 50, 5896–5913. [Google Scholar] [CrossRef]

- Endo, N.; Ito, S.; Tomishige, K.; Kameoka, S.; Tsai, A.P.; Hirata, T.; Nishimura, C. CO hydrogenation over a hydrogen-induced amorphization of intermetallic compound CeNi2. Catal. Today 2011, 164, 293–296. [Google Scholar] [CrossRef]

- Kochetov, N.A.; Seplyarskii, B.S. Effect of Initial Temperature and Mechanical Activation on Synthesis in a Ti plus Al System. Combust. Explo Shock 2020, 56, 308–316. [Google Scholar] [CrossRef]

- Miloserdov, P.A.; Gorshkov, V.A.; Sachkova, N.V.; Khomenko, N.Y.; Miloserdova, O.M. Synthesis of Composite Materials in the System Cr-Ti-B by the Self-Propagating High-Temperature Synthesis from Mixtures CaCrO4/TiO2/Al/B. Russ. J. Appl. Chem. 2020, 93, 362–368. [Google Scholar] [CrossRef]

- Vasilyev, N.; Borisov, E.N.; Novikov, B.V.; Akopyan, I.K.; Labzovskaya, M.E. Random lasing in ZnO self-organized nanoparticles produced by laser induced breakdown. J. Lumin. 2019, 215, 116668. [Google Scholar] [CrossRef]

- Yue, X.; Yang, X.; Tian, J.; He, Z.F.; Fan, Y.Q. Thermal, mechanical and chemical material removal mechanism of carbon fiber reinforced polymers in electrical discharge machining. Int. J. Mach. Tool Manu. 2018, 133, 4–17. [Google Scholar] [CrossRef]

- Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Mikhailova, M.A. Electrical Discharge Machining Non-Conductive Ceramics: Combination of Materials. Technologies 2020, 8, 32. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Porvatov, A.N.; Volosova, M.A.; Okunkova, A.A. Electrical discharge machining of ceramic nanocomposites: Sublimation phenomena and adaptive control. Heliyon 2019, 5, e02629. [Google Scholar] [CrossRef]

- Shlykov, E.; Ablyaz, T. Complex Analysis of the Process of Electrical Discharge Machining of Bimetallic Steel-Copper Material. Obrab. Metallov-Metal Work. Mater. Sci. 2020, 22, 16–26. [Google Scholar]

- Grigoriev, S.N.; Kozochkin, M.P.; Kropotkina, E.Y.; Okunkova, A.A. Study of wire tool-electrode behavior during electrical discharge machining by vibroacoustic monitoring. Mech. Ind. 2016, 17, 717. [Google Scholar] [CrossRef]

- Dwaraka, R.; Arunachalam, N. Investigation on the effect of EDM process variables and environments on acoustic emission signals. Mach. Sci. Technol. 2020, 24, 638–662. [Google Scholar] [CrossRef]

- Melnik, Y.A.; Kozochkin, M.P.; Porvatov, A.N.; Okunkova, A.A. On adaptive control for electrical discharge machining using vibroacoustic emission. Technologies 2018, 6, 96. [Google Scholar] [CrossRef]

- Lazarenko, B.R.; Mikhailov, V.V.; Gitlevich, A.E.; Verkhoturov, A.D.; Anfimov, I.S. Distribution of elements in surface layers during electric spark alloying. (Raspredelenie Elementov V Poverkhnostnykh Sloyakh Pri Elektroiskrovom Legirovanii). Surf. Eng. Appl. Electrochem. (Elektron. Obrab. Mater.) 1977, 3, 28–33. [Google Scholar]

- Lazarenko, B.R.; Duradzhi, V.N.; Bryantsev, I.V. Effect of Incorporating an additional inductance on the characteristics of anode and cathode processes. (O Vliyanii Vklyucheniya Dopolnitel’noi Induktivnosti Na Kharakteristiki Anodnogo I Katodnogo Protsessov). Surf. Eng. Appl. Electrochem. (Elektron. Obrab. Mater.) 1979, 5, 8–13. [Google Scholar]

- Lazarenko, B.R.; Lazarenko, N.I. Electric spark machining of metals in water and electrolytes. (Elektroiskrovaya Obrabotka Metallov V Vode I Elektrolitakh). Surf. Eng. Appl. Electrochem. (Elektron. Obrab. Mater.) 1980, 1, 5–8. [Google Scholar]

- Volosova, M.A.; Okunkova, A.A.; Povolotskiy, D.E.; Podrabinnik, P.A. Study of electrical discharge machining for the parts of nuclear industry usage. Mech. Ind. 2015, 16, 706. [Google Scholar] [CrossRef]

- Gavrin, V.N.; Kozlova, Y.P.; Veretenkin, E.P.; Logachev, A.V.; Logacheva, A.I.; Lednev, I.S.; Okunkova, A.A. Reactor target from metal chromium for “pure” high-intensive artificial neutrino source. Phys. Part. Nucl. Lett. 2016, 13, 267–273. [Google Scholar] [CrossRef]

- Steuer, P.; Weber, O.; Baehre, D. Structuring of wear-affected copper electrodes for electrical discharge machining using Pulse Electrochemical Machining. Int. J. Refract. Met. H 2015, 52, 85–89. [Google Scholar] [CrossRef]

- Ay, M.; Etyemez, A. Optimization of the effects of wire EDM parameters on tolerances. Emerg. Mater. Res. 2020, 9, 527–531. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. [Google Scholar] [CrossRef]

- Yun, J.D.; Go, C.; Wang, D.H.; Ahn, Y.C. Electrical discharge machining of aluminum oxide matrix composites containing titanium carbide as a conductive second phase. In Processing and Fabrication of Advanced Materials VI, Vols 1 & 2, Proceedings of International Symposium on Processing and Fabrication of Advanced Materials, Singapore, 24–26 November 1997; Khor, K.A., Srivatsan, T.S., Moore, J.J., Eds.; IOM Communications Ltd.: London, UK, 1998; pp. 1773–1781. [Google Scholar]

- Yarovchuk, A.V.; Maksimkin, O.P.; Tsay, K.V. Effect of Low-Cycle Thermocycling Treatment on Corrosion and Mechanical Properties of Corrosion-Resistant Steel 12Kh18N10T Irradiated with Neutrons. Met. Sci. Heat Treat. 2017, 59, 446–453. [Google Scholar] [CrossRef]

- Zhelezkov, O.S.; Galiakhmetov, T.S.; Malakanov, S.A. Shaping the Hexahedral Head of a 12Kh18N10T Stainless Steel Bolt. Steel Transl. 2017, 47, 824–826. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Sinebryukhov, S.L.; Egorkin, V.S.; Vyaliy, I.E.; Imshinetskiy, I.M.; Kostina, M.V.; Muradyan, S.O.; Sergienko, V.I. Corrosion stability of austenitic steels 05Kh22AG15N8M2F and 12Kh18N10T in chloride-containing media. Prot. Met. Phys. Chem. Surf. 2017, 53, 910–915. [Google Scholar] [CrossRef]

- Denisov, E.A.; Kompaniets, T.N.; Yukhimchuk, A.A.; Boitsov, I.E.; Malkov, I.L. Hydrogen and helium in nickel and 12Kh18N10T steel. Tech. Phys. 2013, 58, 779–786. [Google Scholar] [CrossRef]

- Krymskiy, S.V.; Ilyasov, R.R.; Avtokratova, E.V.; Sitdikov, O.S.; Markushev, M.V. Intergranular Corrosion of Cryorolled and Aged D16 Aluminum Alloy. Prot Met. 2017, 53, 1091–1099. [Google Scholar] [CrossRef]

- Markushev, M.; Krymskiy, S.; Ilyasov, R.; Avtokratova, E.; Khazgalieva, A.; Sitdikov, O. Influence of Zr on intergranular corrosion of cast and cryorolled D16 aluminum alloy. Lett. Mater. 2017, 7, 447–451. [Google Scholar] [CrossRef]

- Ponomarev, A.N. An investigation of diffusion in droplets and of evaporation of volatile components into vacuum. High. Temp. 2005, 43, 930–936. [Google Scholar] [CrossRef]

- Nikitina, E.V.; Kazakovtseva, N.A. High Temperature Corrosion of 12Kh18N10T Steel in Molten Lithium and Potassium Chlorides with a Cerium Trichloride Addition. Russ. Metall. 2018, 8, 747–749. [Google Scholar] [CrossRef]

- Elshina, L.A.; Elshina, V.A. Synthesis of a Nanocrystalline alpha-Al2O3 Powder in Molten Halides in the Temperature Range 700–800 degrees C. Russ. Metall. 2020, 2, 138–141. [Google Scholar] [CrossRef]

- Pang, W.K.; Low, I.M. Understanding and improving the thermal stability of layered ternary carbides in ceramic matrix composites. In Advances in Ceramic Matrix Composites; Low, I.M., Ed.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publ Ltd.: Cambridge, UK, 2014; Volume 45, pp. 340–368. [Google Scholar] [CrossRef]

- Lekhov, O.S.; Chukov, I.Y.; Karpova, N.M.; Peskov, A.V. Investigation of Cyclic Deformation of Continuously Cast Stainless-Steel Slabs. Steel USSR 1990, 20, 279–280. [Google Scholar]

- Armstrong, R.W. Dislocation Mechanics Pile-Up and Thermal Activation Roles in Metal Plasticity and Fracturing. Metals 2019, 9, 154. [Google Scholar] [CrossRef]

- Maksimov, E.A. Test of Stress-Strain State and Flatness Parameter under Bending of the Corrugated Part of a Flat Bar in the Course of Sheet Rolling of Flat Bars and Bands of Brass Alloys. Russ. J. Non-Ferrous Met. 2010, 51, 74–78. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Young, B. Tests and Design of Aluminum Flexural Members. In Proceeding of the 10th International Symposium on Structural Engineering for Young Experts, Changsha, China, 19–21 Octber 2008, Vols I and II; Xu, B., Xiao, Y., Ru, J.P., Ren, W.X., Eds.; Science Press Beijing: Beijing, China, 2008; pp. 1769–1774. [Google Scholar]

- Grigor’ev, S.N.; Kozochkin, M.P.; Fedorov, S.V.; Porvatov, A.N.; Okun’kova, A.A. Study of electroerosion processing by vibroacoustic diagnostic methods. Meas. Tech. 2015, 58, 878–884. [Google Scholar] [CrossRef]

- Goswami, K.; Samuel, G.L. Monitoring of material-removal mechanism in micro-electrical discharge machining by pulse classification and acoustic emission signals. Proc. Inst. Mech. Eng. B-J. Eng. 2020. [Google Scholar] [CrossRef]

- Shilov, M.A.; Smirnova, A.I.; Gvozdev, A.A.; Rozhkova, N.N.; Dyachkova, T.P.; Burkov, A.A.; Stolbov, D.N.; Savilov, S.V.; Usol’tseva, N.V. Rheology of Plastic Lubricants with Additives of Carbon Nanostructures of Various Type. J. Frict. Wear 2019, 40, 546–554. [Google Scholar] [CrossRef]

- Patzer, G.; Woydt, M.; Shah, R.; Miller, C.; Iaccarino, P. Test Modes for Establishing the Tribological Profile under Slip-Rolling. Lubricants 2020, 8, 59. [Google Scholar] [CrossRef]

- Haroon, M.; Adams, D.E. Development of component-level damage evolution models for mechanical prognosis. J. Appl. Mech.-T ASME 2008, 75, 021017. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A. Synergic Role of Self-Interstitials and Vacancies in Indium Melting. Metals 2015, 5, 1061–1072. [Google Scholar] [CrossRef]

- Sun, H.; Singh, C.V. Temperature dependence of grain boundary excess free volume. Scr. Mater. 2020, 178, 71–76. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Source of metal atoms and fast gas molecules for coating deposition on complex shaped dielectric products. Surf. Coat. Technol. 2013, 225, 34–39. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Broad beam sources of fast molecules with segmented cold cathodes and emissive grids. Instrum. Exp. Tech. 2012, 55, 122–130. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Fedorov, M.Y. Role of the thermal factor in the wear mechanism of ceramic tools. Part 2: Microlevel. J. Frict. Wear 2015, 36, 40–44. [Google Scholar] [CrossRef]

- Sevastianov, S.V. An introduction to multi-parameter complexity analysis of discrete problems. Eur. J. Oper. Res. 2005, 165, 387–397. [Google Scholar] [CrossRef]

- Perez, C. Technological revolutions and techno-economic paradigms. Camb. J. Econ. 2010, 34, 185–202. [Google Scholar] [CrossRef]

- Bobovich, B.B. Glass-fiber reinforced plastics—Construction materials of the sixth technological paradigm? Glas. Ceram. 2019, 76, 38–41. [Google Scholar] [CrossRef]

- Wonglimpiyarat, J. Towards the sixth Kondratieff cycle of nano revolution. Int. J. Nanotechnol. Mol. Comput. 2011, 3, 87–100. [Google Scholar] [CrossRef]

- Grigoriev, S.; Melnik, Y.; Metel, A. Broad fast neutral molecule beam sources for industrial-scale beam-assisted deposition. Surf. Coat. Technol. 2002, 156, 44–49. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N. Estimation of Uncertainty in Solving Multi-Parameter Diagnostic Problems. Meas. Tech. 2015, 58, 173–178. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Masterenko, D.A.; Teleshevskii, V.I.; Emelyanov, P.N. Contemporary state and outlook for development of metrological assurance in the machine-building industry. Meas. Tech. 2013, 55, 1311. [Google Scholar] [CrossRef]

- Alsagabi, S.; Shrestha, T.; Charit, I. High temperature tensile deformation behavior of Grade 92 steel. J. Nucl. Mater. 2014, 453, 151–157. [Google Scholar] [CrossRef]

- Maziasz, P.J.; Mckamey, C.G. Microstructural Characterization of Precipitates Formed During High-Temperature Testing and Processing Of Iron Aluminide Alloys. Mater. Sci. Eng. A 1992, 152, 322–334. [Google Scholar] [CrossRef]

- Ryczek, K.; Koziel, M.; Wiercigroch, E.; Malek, K.; Jarosz, M.; Sulka, G.D.; Zaraska, L. Fast fabrication of nanostructured semiconducting oxides by anodic oxidation of brass. Mater. Sci. Semicond. Process. 2020, 113, 105035. [Google Scholar] [CrossRef]

- Panova, T.V.; Kovivchak, V.S. Formation of Oxide Layers on the Surface of Copper and its Alloys Modified by a High-Power Ion Beam. J. Surf. Investig. 2019, 13, 1098–1102. [Google Scholar] [CrossRef]

- Murzin, S.P.; Kryuchkov, A.N. Formation of ZnO/CuO heterostructure caused by laser-induced vibration action. Procedia Eng. 2017, 176, 546–551. [Google Scholar] [CrossRef]

- Chorley, R.W.; Lednor, P.W. Synthetic Routes to High Surface-Area Nonoxide Materials. Adv. Mater. 1991, 3, 474–485. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sobol, O.V.; Beresnev, V.M.; Serdyuk, I.V.; Pogrebnyak, A.D.; Kolesnikov, D.A.; Nemchenko, U.S. Tribological characteristics of (TiZrHfVNbTa)N coatings applied using the vacuum arc deposition method. J. Frict. Wear 2014, 35, 359–364. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of titanium nitride coating on stress structural inhomogeneity in oxide-carbide ceramic. Part 4. Action of heat flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigor’ev, S.N.; Volosova, M.A. Effect of a TiC Coating on the Stress-Strain State of a Plate of a High-Density Nitride Ceramic Under Nonsteady Thermoelastic Conditions. Refract. Ind. Ceram. 2014, 54, 376–380. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigoriev, S.N.; Ostrikov, E.A. Use of laser ablation for formation of discontinuous (discrete) wear-resistant coatings formed on solid carbide cutting tool by electron beam alloying and vacuum-arc deposition. Mech. Ind. 2016, 17, 720. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Vereschaka, A.S.; Popov, A.Y.; Batako, A.D. Nano-scale multilayered composite coatings for cutting tools operating under heavy cutting conditions. Proc. CIRP 2014, 14, 239–244. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Volosova, M.A.; Grigoriev, S.N.; Vereschaka, A.S. Development of wear-resistant complex for high-speed steel tool when using process of combined cathodic vacuum arc deposition. Proc. CIRP 2013, 9, 8–12. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Technol. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Abdulhadi, H.A.; Ahmad, S.N.A.S.; Ismail, I.; Ishak, M.; Mohammed, G.R. Thermally-Induced Crack Evaluation in H13 Tool Steel. Metals 2017, 7, 475. [Google Scholar] [CrossRef]

- Liu, Z.G.; Guo, J.T.; Hu, Z.Q. Mechanical Alloying Of The Ni-Al(M) (M Ti, Fe) System. Mat. Sci. Eng. A-Struct. 1995, 192, 577–582. [Google Scholar] [CrossRef]

- Talawar, M.B.; Agrawal, A.P.; Asthana, S.N. Energetic co-ordination compounds: Synthesis, characterization and thermolysis studies on bis-(5-nitro-2H-tetrazolato-N-2)tetraammine cobalt(III) perchlorate (BNCP) and its new transition metal (Ni/Cu/Zn) perchlorate analogues. J. Hazard. Mater. 2005, 120, 25–35. [Google Scholar] [CrossRef]

- Friedrich, M.; Teschner, D.; Knop-Gericke, A.; Armbruster, M. Surface and Subsurface Dynamics of the Intermetallic Compound ZnNi in Methanol Steam Reforming. J. Phys. Chem. C 2012, 116, 14930–14935. [Google Scholar] [CrossRef]

- Grigoriev, S.; Metel, A. Plasma- and Beam-Assisted Deposition Methods. In Nato Science Series, Series Ii: Mathematics, Physics and Chemistry; Nanostructured Thin Films and Nanodispersion Strengthened Coatings. NATO Science Series II: Mathematics, Physics and Chemistry; Voevodin, A.A., Shtansky, D.V., Levashov, E.A., Moore, J.J., Eds.; Springer: Dordrecht, The Netherlands, 2004; Volume 155, pp. 147–154. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Mouralova, K.; Benes, L.; Bednar, J.; Zahradnicek, R.; Prokes, T.; Fries, J. Analysis of Machinability and Crack Occurrence of Steels 1.2363 and 1.2343ESR Machined by Die-Sinking EDM. Coatings 2020, 10, 406. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Prudnikov, V.V. Glow discharge with electrostatic confinement of electrons in a chamber bombarded by fast electrons. Plasma Phys. Rep. 2011, 37, 628–637. [Google Scholar] [CrossRef]

- Sobol’, O.V.; Andreev, A.A.; Grigoriev, S.N.; Gorban’, V.F.; Volosova, M.A.; Aleshin, S.V.; Stolbovoy, V.A. Physical characteristics, structure and stress state of vacuum-arc tin coating, deposition on the substrate when applying high-voltage pulse during the deposition. Probl. Atom. Sci. Technol. 2011, 4, 174–177. [Google Scholar]

- Yuan, H.; Song, J. An Improved Calculation Model for the Prediction of the Wear of Coated Electrical Contacts. Technologies 2019, 7, 77. [Google Scholar] [CrossRef]

- Phipon, R.; Shivakoti, I.; Sharma, A. Sustainable processing of Inconel 718 super alloy in electrical discharge machining process. World J. Eng. 2020. [Google Scholar] [CrossRef]

- Brzezińska, M.; García-Muñoz, P.; Ruppert, A.M.; Keller, N. Photoactive ZnO Materials for Solar Light-Induced CuxO-ZnO Catalyst Preparation. Materials 2018, 11, 2260. [Google Scholar] [CrossRef]

- Lee, H.; Zhang, X.; Hwang, J.; Park, J. Morphological Influence of Solution-Processed Zinc Oxide Films on Electrical Characteristics of Thin-Film Transistors. Materials 2016, 9, 851. [Google Scholar] [CrossRef]

- Silva, N.; Ramírez, S.; Díaz, I.; Garcia, A.; Hassan, N. Easy, Quick, and Reproducible Sonochemical Synthesis of CuO Nanoparticles. Materials 2019, 12, 804. [Google Scholar] [CrossRef]

- Zheng, W.; Chen, Y.; Peng, X.; Zhong, K.; Lin, Y.; Huang, Z. The Phase Evolution and Physical Properties of Binary Copper Oxide Thin Films Prepared by Reactive Magnetron Sputtering. Materials 2018, 11, 1253. [Google Scholar] [CrossRef] [PubMed]

| Characteristic | Value and Description |

|---|---|

| Max axis motions along the axes X×Y×Z, mm | 500 × 350 × 310 |

| Max angle of conical machining, degree | ±10° |

| Max weight of workpiece, kg | 800 |

| Accuracy of positioning along the axes, µm | ± 1 ÷ 2 |

| Achievable roughness Ra, µm | 0.4 |

| Dielectric medium | Deionized water |

| Machine body | The frame is made of gray cast iron having good thermal and vibration compensating characteristics |

| Factor | Value |

|---|---|

| Seibu M500S 1 | |

| Operational voltage in the interelectrode gap before the approach of the tool electrode to the workpiece, Vo | 55, 60, 65 |

| Auxiliary voltage that occurs at the moment of discharge between the tool electrode and workpiece, Vg | 32 |

| Strength of the working current in the interelectrode gap, I | 8 |

| Auxiliary current to increase the cutting efficiency when the circuit is turned back on, Ns | 43 |

| Time of disconnection of the current source, the percentage ratio of the time of the discharge pulse to the time of its absence, Toff | 6 |

| Time intermittent pause to ensure the stability of the processing process, Ad | 305 |

| Speed of the tool rewinding, Ws | 35 |

| Feed speed, Sg | 5 |

| Wire tension, Wt | 30, 35, 40 |

| Dielectric pressure in nozzles for flushing, Fl | 245 |

| Element | Fe | Cr | Ni | Ti | Si | S | Mn | Cu | P | C |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | Balance | 17–19 | 9–11 | About 0.8 | Up to 0.8 | Up to 0.02 | Up to 2.0 | Up to 0.03 | Up to 0.035 | About 0.12 |

| Element | Al | Cu | Mg | Mn | Fe | Si | Zn | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| wt% | 90.8–94.7 | 3.8–4.9 | 1.2–1.8 | 0.3–0.9 | Up to 0.5 | Up to 0.5 | Up to 0.3 | Up to 0.1 | Up to 0.1 |

| Material | Specific Electrical Resistance |

|---|---|

| 12Kh18N10T (AISI 321) steel | 0.746 |

| D16 (AA2024) alloy | 0.028 |

| Brass alloy, CuZn35 | 0.065 |

| Type of Machining | Worn Surfaces | Measuring Error | Worn Area Sw | Summarized Worn Area Ss | Volumetric Wear ΔV | Volumetric Wear Rate 2 Rv | Error | |

|---|---|---|---|---|---|---|---|---|

| [µm] | [mm2] | [mm2] | [%] 1 | [mm3] | [mm3·s−1] | [µm3·µs−1] | ||

| Roughing | Front | ± 1 ÷ 2 | 0.0014 ± 0.00015 | 0.021 ± 0.0022 | 51 ± 10.5 | 0.42 ± 0.0002 | 1.22 ± 0.04 | ± 20 ÷ 40 |

| Lateral | 0.0048 ± 0.0010 | |||||||

| Finishing | Lateral | 0.0045 ± 0.00005 | 0.009 ± 0.0001 | 18 ± 5.56 | 0.18 ± 0.00001 | 0.52 ± 0.002 | ||

| Type of Machining | Measuring Error | Worn Mass 1 Δm | Mass Wear Rate 2 Rm | Error |

|---|---|---|---|---|

| [g] | [g] | [g·s−1] | [g·µs−1] | |

| Roughing | ±0.0001 | 3.3 × 10−3 ± 0.00005 | 9.6 × 10−3 ± 0.01 | ± 0.01 ÷ 0.02 |

| Finishing | 1.4 × 10−3 ± 0.00004 | 4.0 × 10−3 ± 0.008 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A.; Pivkin, P.M.; Kozochkin, M.P.; Porvatov, A.N. Wire Tool Electrode Behavior and Wear under Discharge Pulses. Technologies 2020, 8, 49. https://doi.org/10.3390/technologies8030049

Grigoriev SN, Volosova MA, Okunkova AA, Fedorov SV, Hamdy K, Podrabinnik PA, Pivkin PM, Kozochkin MP, Porvatov AN. Wire Tool Electrode Behavior and Wear under Discharge Pulses. Technologies. 2020; 8(3):49. https://doi.org/10.3390/technologies8030049

Chicago/Turabian StyleGrigoriev, Sergey N., Marina A. Volosova, Anna A. Okunkova, Sergey V. Fedorov, Khaled Hamdy, Pavel A. Podrabinnik, Petr M. Pivkin, Mikhail P. Kozochkin, and Artur N. Porvatov. 2020. "Wire Tool Electrode Behavior and Wear under Discharge Pulses" Technologies 8, no. 3: 49. https://doi.org/10.3390/technologies8030049

APA StyleGrigoriev, S. N., Volosova, M. A., Okunkova, A. A., Fedorov, S. V., Hamdy, K., Podrabinnik, P. A., Pivkin, P. M., Kozochkin, M. P., & Porvatov, A. N. (2020). Wire Tool Electrode Behavior and Wear under Discharge Pulses. Technologies, 8(3), 49. https://doi.org/10.3390/technologies8030049